Steel cofferdam initiative sinking deviation correcting construction device and method

A construction method and technology of construction devices are applied in the field of construction devices for active subsidence and deviation correction of steel cofferdams, which can solve the problems of insufficient weight, long time consumption, and difficulty in conveying, so as to save project cost, improve construction speed, and accelerate subsidence. effect of speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

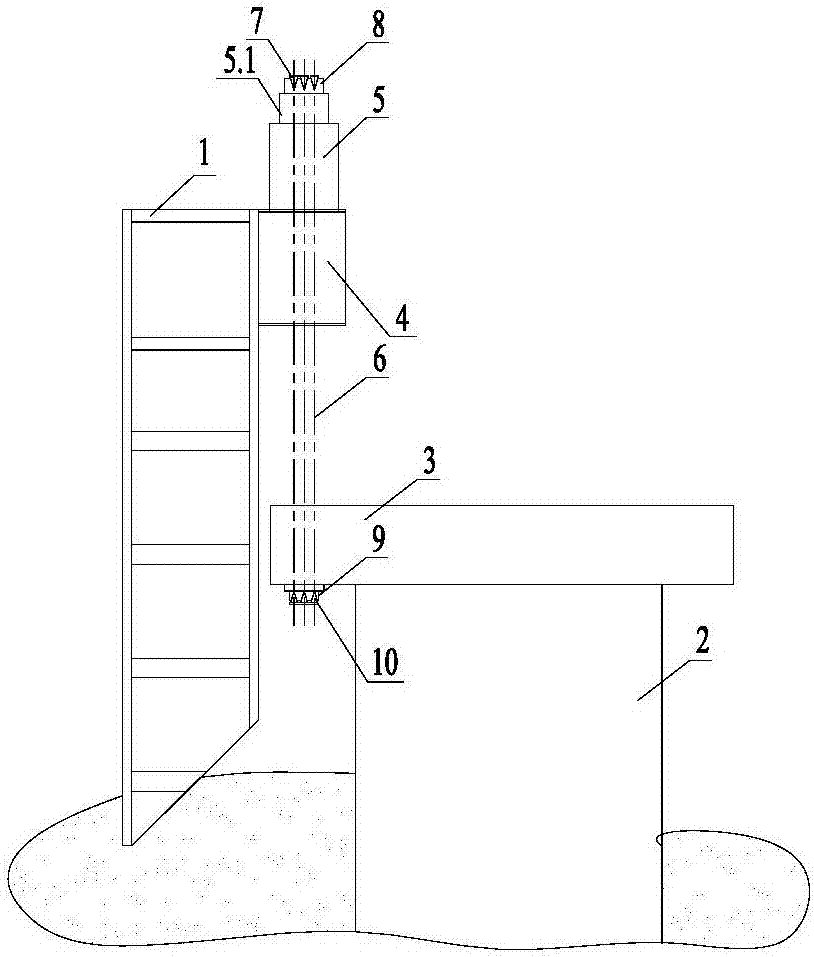

[0037] Such as figure 2 As shown, when the steel strand is used as the tie rod, the specific construction method is as follows:

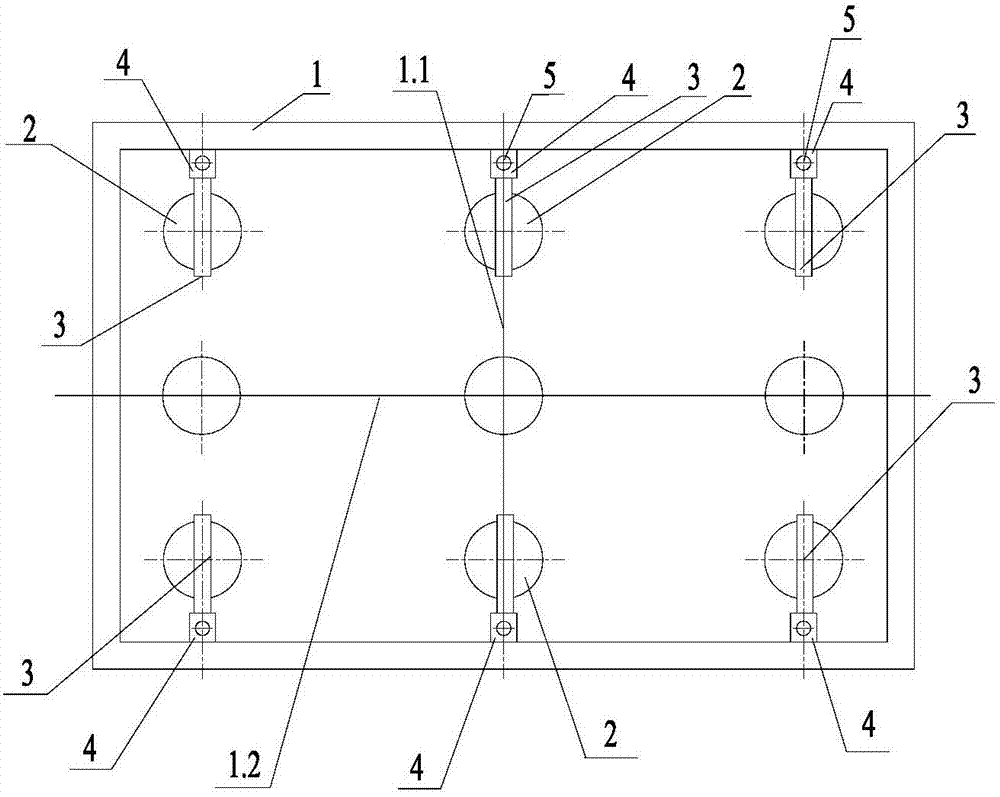

[0038] 1) A steel casing reaction corbel 3 is installed on the upper end surface of the steel casing 2 adjacent to the inner wall of the steel cofferdam 1, and all steel casing reaction corbels 3 are arranged in a rectangle; the steel casing reaction corbels in a rectangular arrangement The steel casing reaction corbels 3 vertically arranged in the force corbel 3 are symmetrically arranged along the horizontal centerline 1.2 of the steel cofferdam, and the steel casing reaction corbels 3 vertically arranged on the left and right sides are arranged along the steel cofferdam The vertical center line 1.1 is symmetrically arranged; among the rectangularly arranged steel casing reaction corbels 3, the horizontally arranged steel casing reaction corbels 3 are symmetrically arranged along the vertical center line 1.1 of the steel cofferdam, and the front ...

Embodiment 2

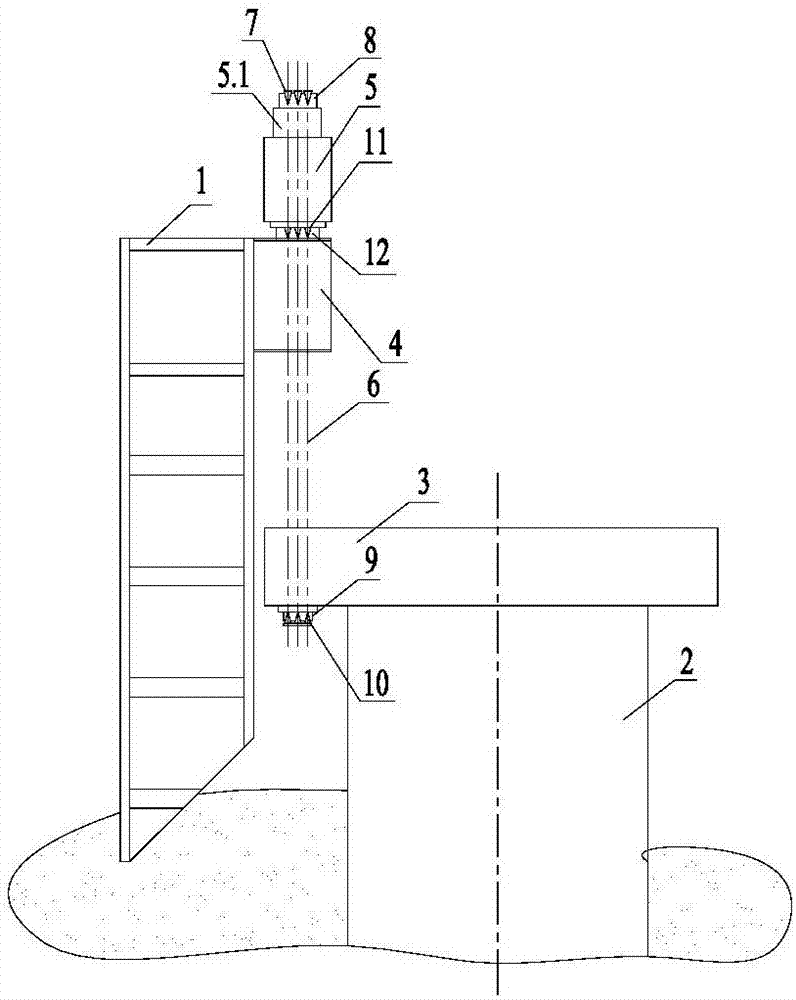

[0047] The difference between embodiment 2 and embodiment 1 is: combining image 3 As shown, an intermediate locking piece is provided between the steel cofferdam reaction corbel 4 and the jack, and the intermediate locking piece includes an intermediate anchor plate and an intermediate wedge-shaped clip 11 installed in the intermediate anchor plate 12, and the intermediate wedge-shaped clip The sheet 11 and the lower wedge clip 10 are arranged on top. If the steel cofferdam 1 is very high and the steel strand is too long, when the piston 5.1 of the jack 5 returns, the wedge-shaped clip 7 above the jack 5 is released, and the steel strand elastically retracts, while the middle wedge-shaped clip 11 below the jack 5 It will be brought into the middle anchor plate 12 to clamp the steel strand by the retraction of the steel strand, so that the steel strand can also maintain a tensioned state during the return journey of the jack 5, so that the steel cofferdam 1 also maintains a co...

Embodiment 3

[0049] Such as image 3 As shown, when threaded steel is used as tie rod, the specific construction method is as follows:

[0050] 1) A steel casing reaction corbel 3 is installed on the upper end surface of the steel casing 2 adjacent to the inner wall of the steel cofferdam 1, and all steel casing reaction corbels 3 are arranged in a rectangle; the steel casing reaction corbels in a rectangular arrangement The steel casing reaction corbels 3 vertically arranged in the force corbel 3 are symmetrically arranged along the horizontal centerline 1.2 of the steel cofferdam 1, and the steel casing reaction corbels 3 vertically arranged on the left and right sides are arranged along the steel cofferdam 1 The vertical centerline 1.1 of the weir 1 is symmetrically arranged; among the rectangularly arranged steel casing reaction corbels 3, the steel casing reaction corbels 3 arranged in the horizontal direction are symmetrically arranged along the vertical centerline 1.1 of the steel c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com