Petroleum platform pile shoe lifting auxiliary system

A technology for oil platforms and pile boots, which is applied in sheet pile walls, water conservancy projects, artificial islands, etc., can solve the problems of affecting the safe construction of oil platforms, high cost, and difficult construction, so as to improve the efficiency of relocation and construction, and improve the construction efficiency of piles. The effect of fast and shortened construction period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The system of the present invention will be described in detail below with reference to the accompanying drawings.

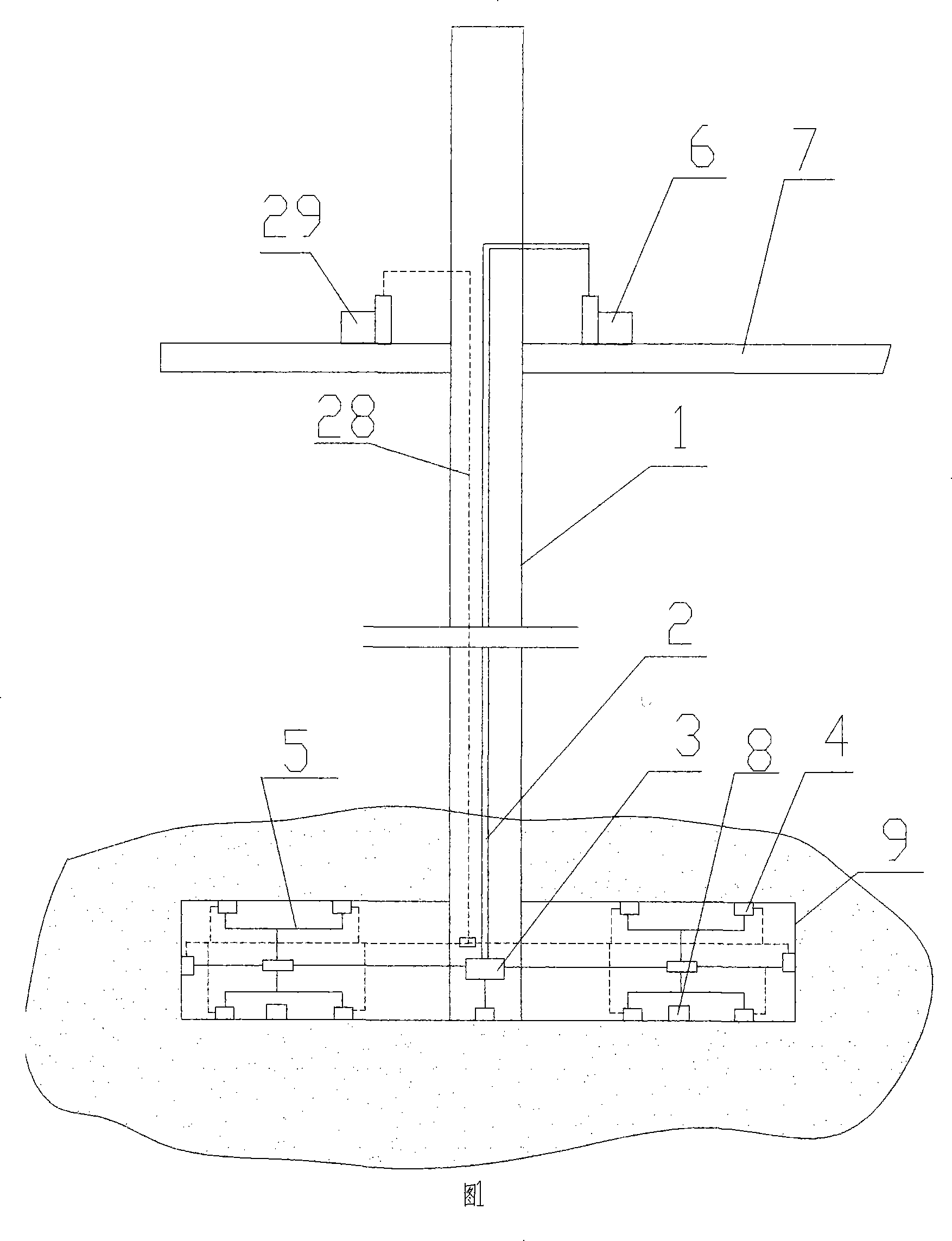

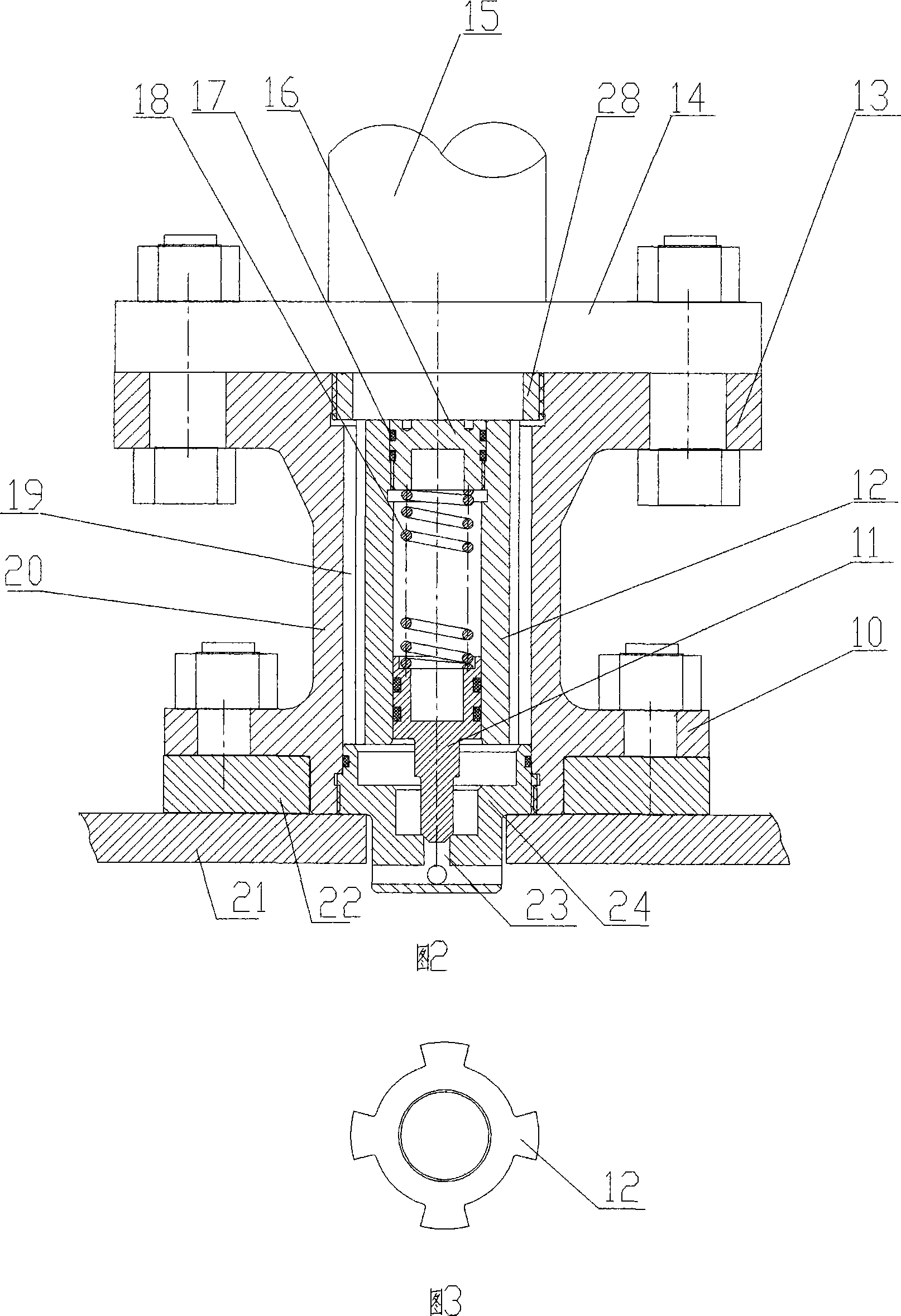

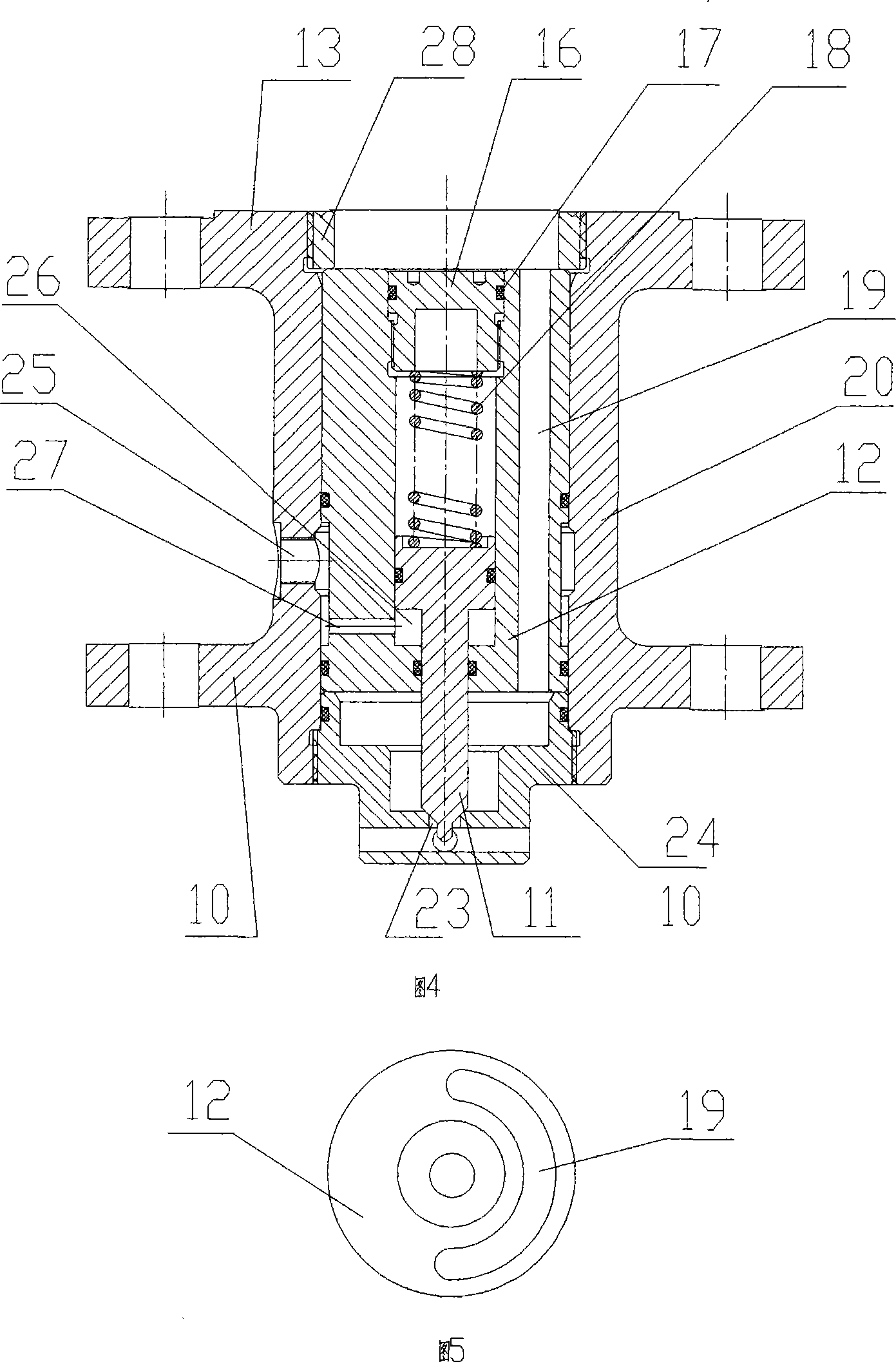

[0014] The oil platform spud shoe lifting system of the present invention has a structure that a high-pressure pump 6 is set on the oil platform 7, and the water supply pipe 2 of the high-pressure pump 6 passes through the middle lumen of the pile 1 and the anti-corrosion pump in the pile shoe 9 at the lower end of the pile 1. The blocking jet flusher 4 is connected, and the anti-blocking jet flusher 4 is arranged on the upper, lower, and peripheral sides of the inner wall of the spud shoe 9. The anti-blocking jet flusher 9 sprays high-pressure water flow to shear the silt bonded to the outer surface of the spud shoe 9, and the spud boot Also be provided with vibrator 8 in 9, the vibration of vibrator 8 loosens the silt that cements spud shoe 9 outer surfaces and makes it porridge flow, to improve the lifting speed of spud shoe 9.

[0015] The anti-blocki...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com