Anti-static down feather weighing box

A weighing box and anti-static technology, which is applied in the direction of weighing, weighing equipment and measuring devices for materials with special properties/forms, can solve the problems of deformation of the weighing box, affecting the workplace, and affecting the amount of cashmere filling , to reduce negative pressure, ensure weighing accuracy and avoid deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

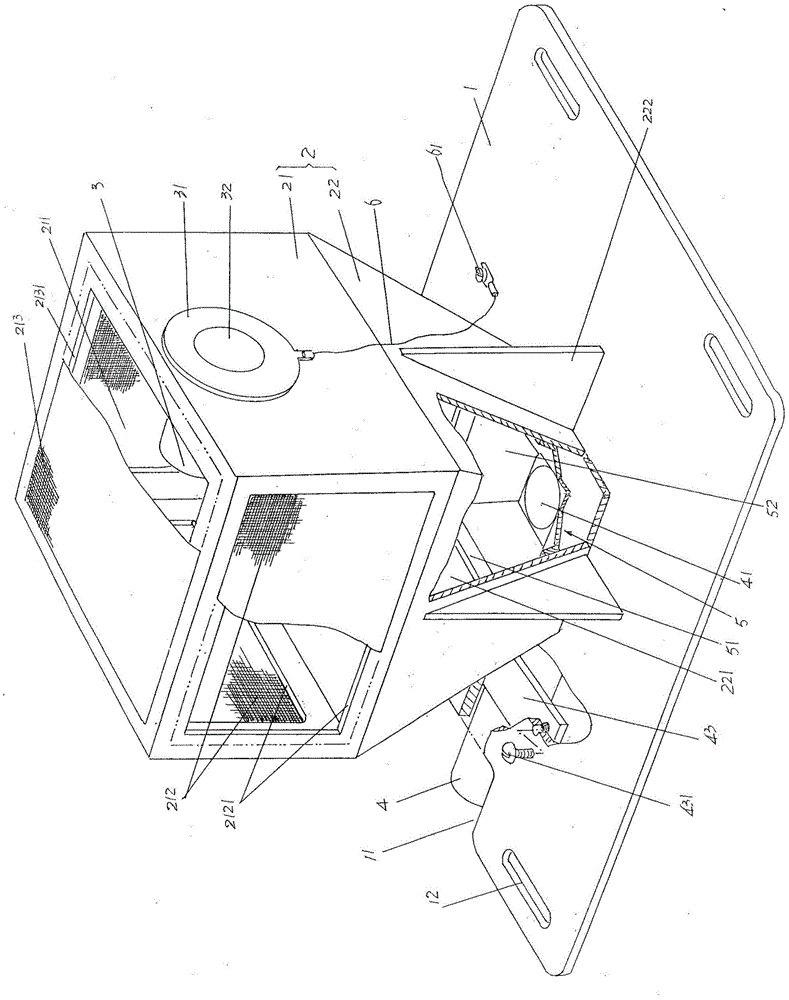

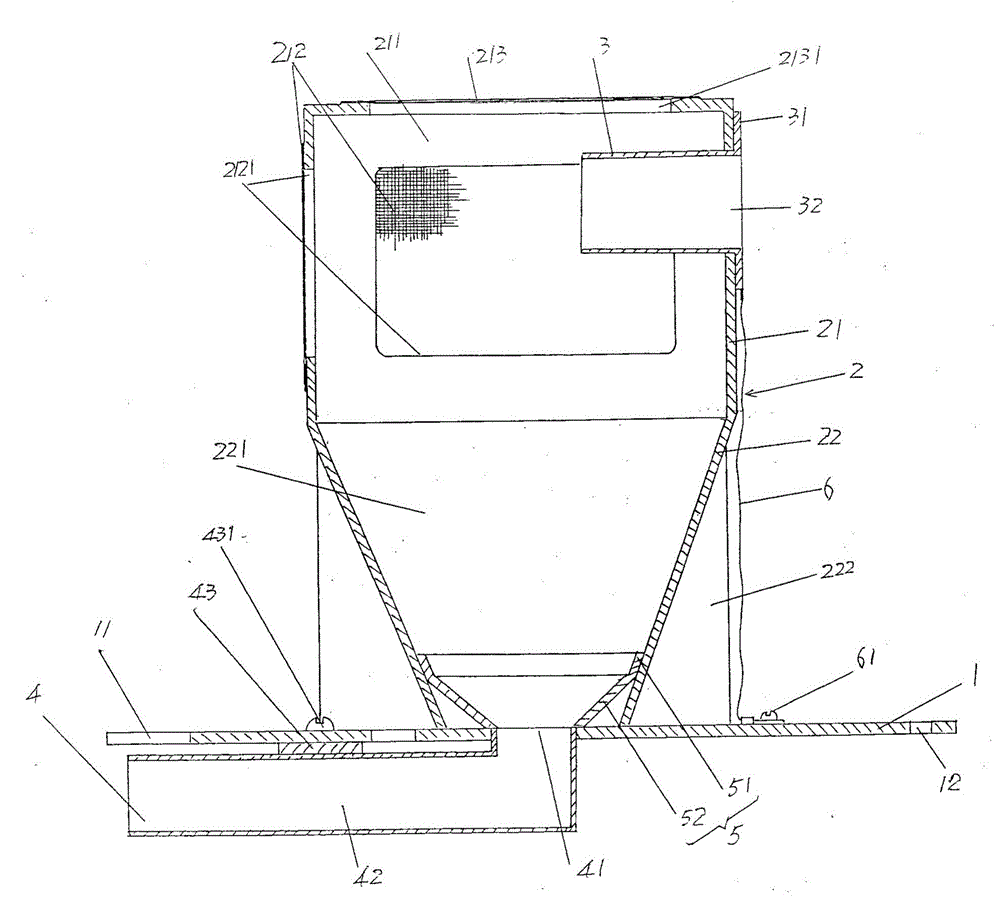

[0024] See figure 1 and figure 2 , Give a bottom 1, the bottom plate 1 is fixed in a horizontal state and the weight sensor of the weighing mechanism when used.The bottom plate; a weighing box box 2 is given.Then it should be regarded as an equivalent replacement and still belongs to the technical content category of the publicity of the present invention.The bottom of the box 21 is connected and composed of the box 21, and the bottom of the lower box 22 is fixed with the aforementioned bottom board 1;The down introduced tube 3 in the 2, the down introduction of the down pipe 3 is set on the side wall of the outlet 21 (the example of this embodiment is the right wall) and is connected with the outlet of the box 21;Yu will complete the down dwarn tube 4 caused by the weight -bearing down.There is an air filter 212 on the side wall.

[0025] Please continue to see figure 1 and figure 2 As the technical point of the technical solution provided by the present invention: the aforementi...

Embodiment 2

[0038] The diagram, one end of the removing electrostatic wire 6 with the aforementioned down tube 4 is fixed, and the other end is composed of the ground end. The ground terminal is connected by any situation in the two connections of fixed screws 61: one is, one is, one is, one is, one is, one is, one is, one is, one is, one is, one is, one is, one is, one is, one is, one is, one is the one is the one is the one is the one is the one is the one is the one is the one is the one is the one is the one is theThe conductive body of the velvet mechanism is the fixed connection of the metal parts; the second is to expose the unpreparedness of the lumen wall with the down of the pipe 42 with the down of the pipe 4 with the down of the fluff.The full velvet and down in the 4 lead the tube fixed connection.Because one end of the removing electrostatic wire 6 in this embodiment is introduced with the down tube 4, the downward tube 4 must be cited with a metallic down tube.Plel introduced t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com