Treatment system and treatment method of solid-liquid mixture

A technology of solid-liquid mixture and treatment method, which is applied in water/sewage treatment, water treatment parameter control, chemical instruments and methods, etc. Reduced impact, reduced demand effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

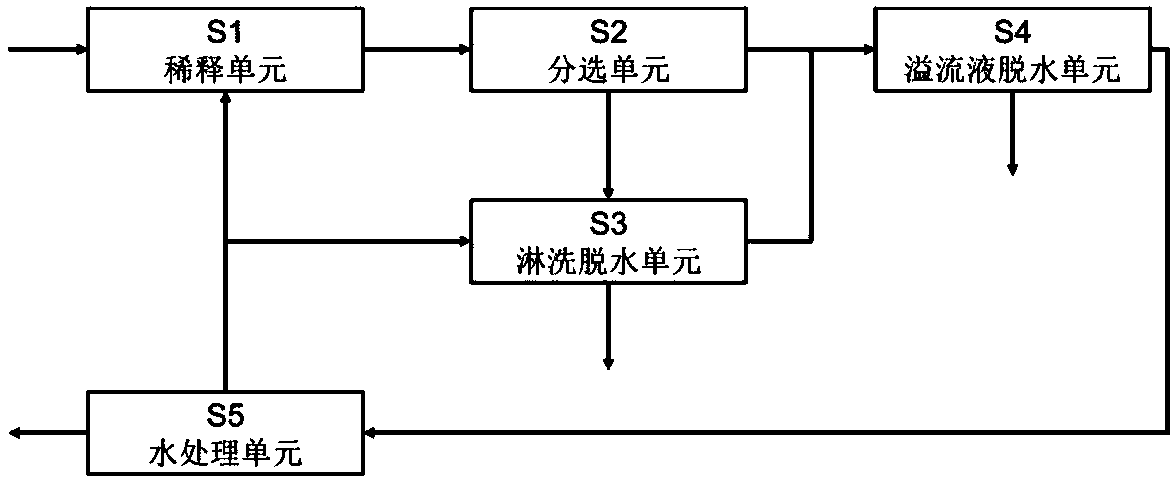

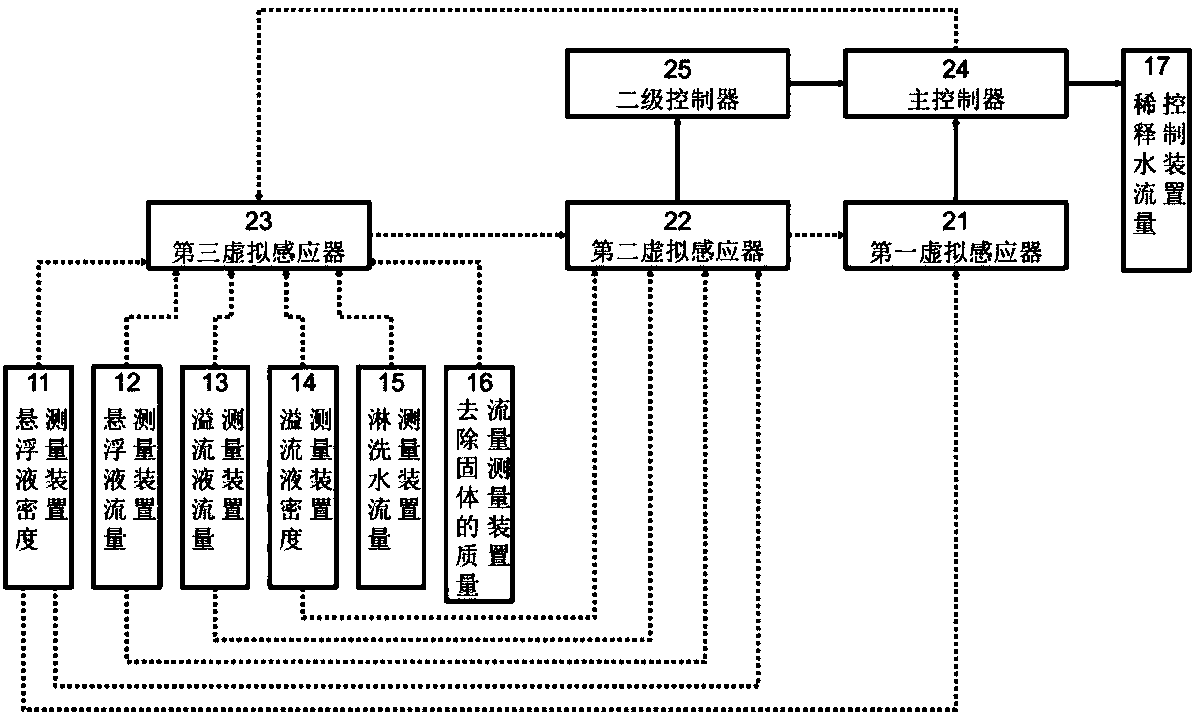

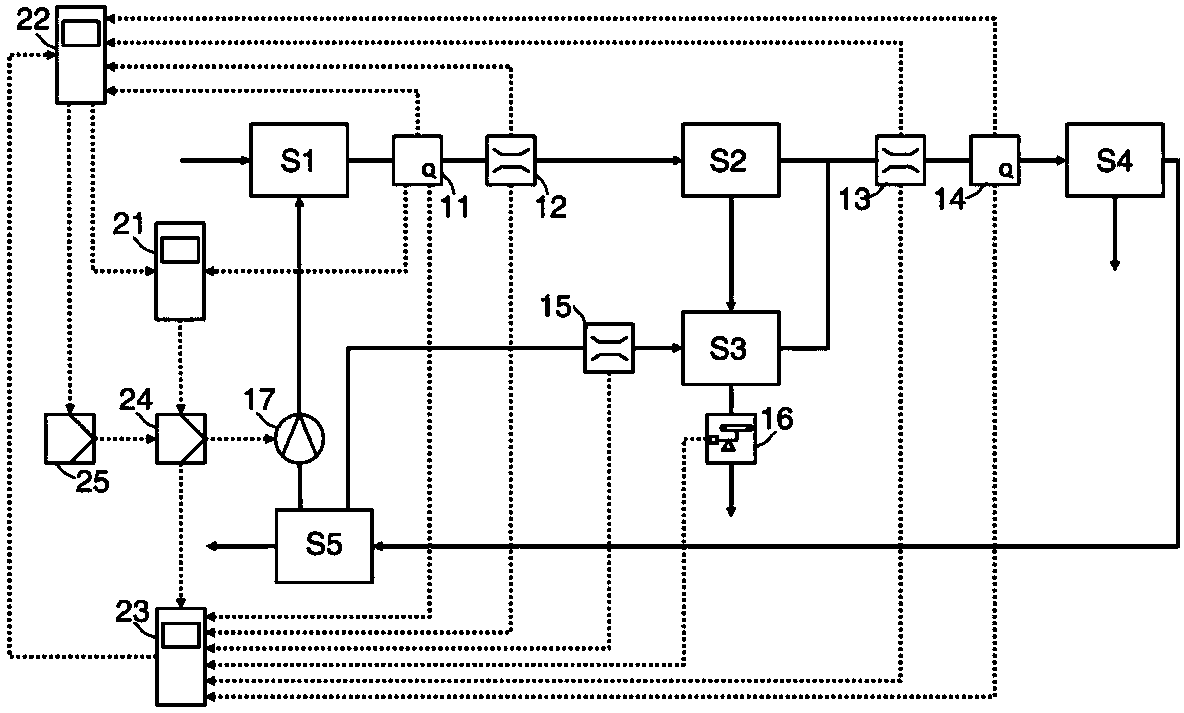

[0073] Such as Figure 1 ~ Figure 3 As shown, a solid-liquid mixture treatment system, the solid-liquid mixture contains inorganic solids, organic matter and water; the solid-liquid mixture treatment system includes a dilution unit S1, a sorting unit S2, a rinsing and dehydration unit S3, The overflow liquid dehydration unit S4, the water treatment unit S5 and the control device. The solid-liquid mixture enters the sorting unit S2 after being diluted with water in the dilution unit S1. The solid outlet of the sorting unit S2 is connected to the elution dehydration unit S3; the liquid outlets of the sorting unit S2 and the leaching dehydration unit S3 are connected to the overflow liquid dehydration unit S4. The solid outlet of the rinsing and dehydration unit S3 is discharged for recycling. The liquid outlet of the overflow dehydration unit S4 is connected to the water treatment unit S5; the dilution unit S1 is connected to the dilution water flow control device 17; the outl...

Embodiment 2

[0085] The above-mentioned system is used to process the solid-liquid mixture, including the following steps:

[0086] Step S1, adding water to the solid-liquid mixture for dilution to obtain a suspension;

[0087] Step S2, sorting stage: sorting the suspension to obtain sorted overflow liquid and sorted particles.

[0088] In step S3, adding rinsing water to the sorted particles for rinsing and dehydration to obtain rinsing overflow liquid and removing solids. Removal of solids can be recycled after rinsing and dehydration.

[0089] Step S4, dehydrating the sorting overflow liquid and the washing overflow liquid to obtain a filtrate and a dehydration residue.

[0090] Step S5, the filtrate needs to be processed for reuse.

[0091] Wherein, the flow rate of the dilution water of the solid-liquid mixture in step S1 is determined by the following steps:

[0092] Step S101, using the first virtual sensor to measure the total solid mass fraction of the diluted suspension;

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com