Manufacturing method of open caisson

A manufacturing method and caisson technology, which is applied to caissons, buildings, and infrastructure engineering, can solve the problems of small anti-heaving coefficient of caissons, difficulties in deflection correction and structural positioning, and rapid subsidence of large-scale structures.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

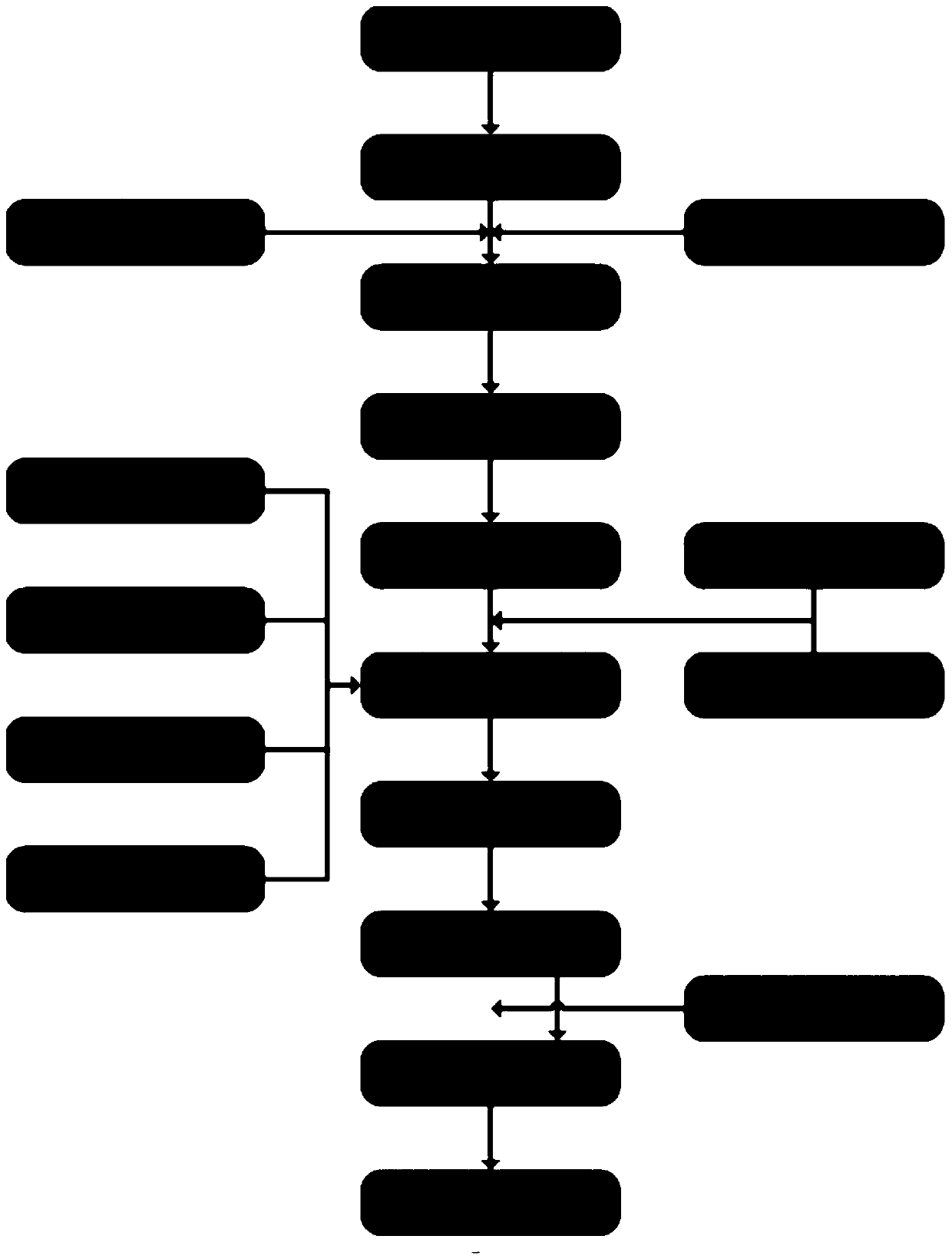

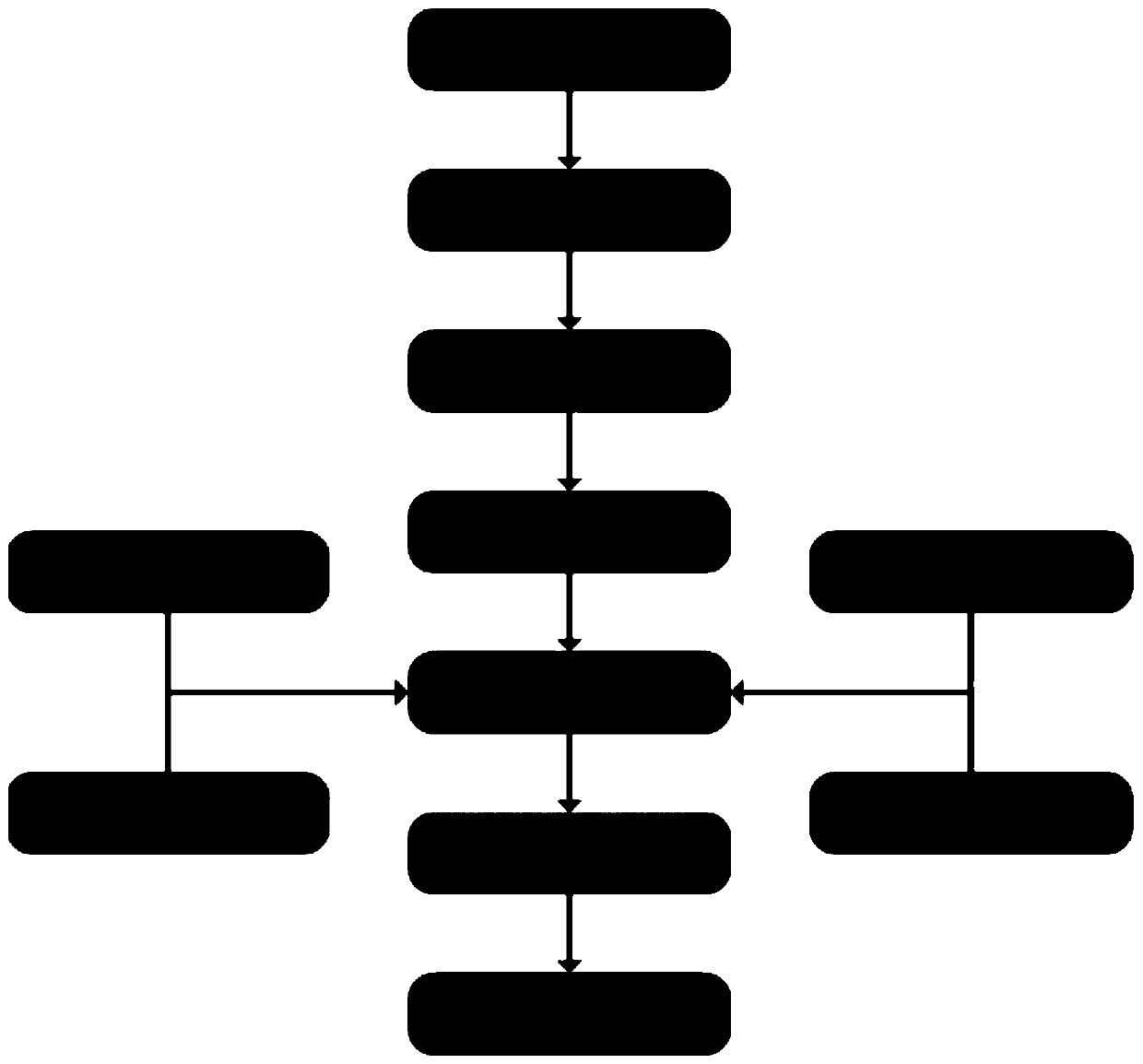

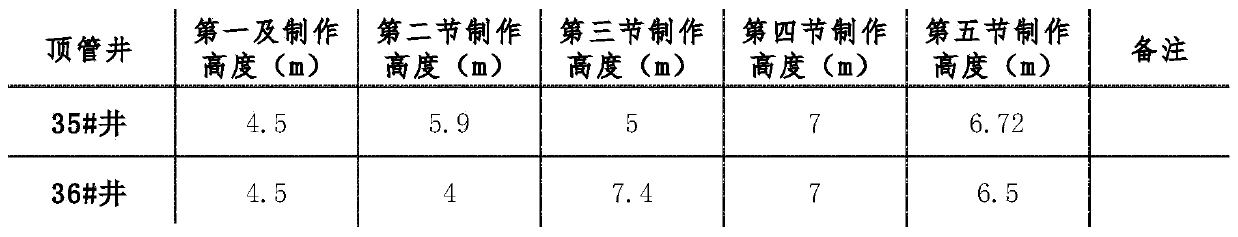

[0078] Example 1, such as figure 1 , image 3 As shown, a method for making caisson includes the following steps:

[0079] (1) Construction preparations, according to the general layout plan, arrange temporary erection, mechanical equipment and construction water and electricity lines on site; set up gantry piles around the caisson, and use lime powder to draw the center axis of the well and the outline of the foundation pit. As the basis for caisson production and sinking positioning; it needs to be explained that in order to meet the requirements of construction machinery and equipment and civilized construction, the construction road is installed in the construction fence. The structure of the construction road is: ordinary area first lay 25cm thick pulverized coal Pave the ash three slag, and then pave 20cm concrete; the heavy-duty vehicle and crane driving area first lay 25cm thick fly ash three slag, and then pave 25cm concrete; the inner surface of the concrete is Φ8@250 t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Ultimate bearing capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com