Preparation method of ultrasonic-assisted starch/rosin clathrate-based modified filler

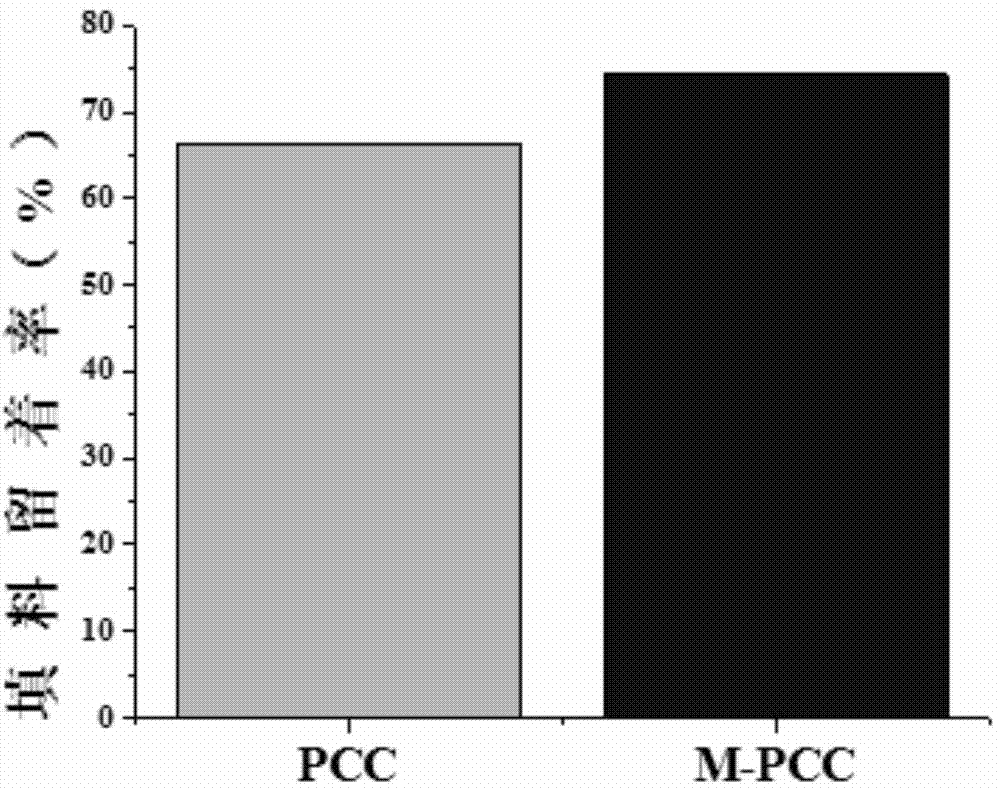

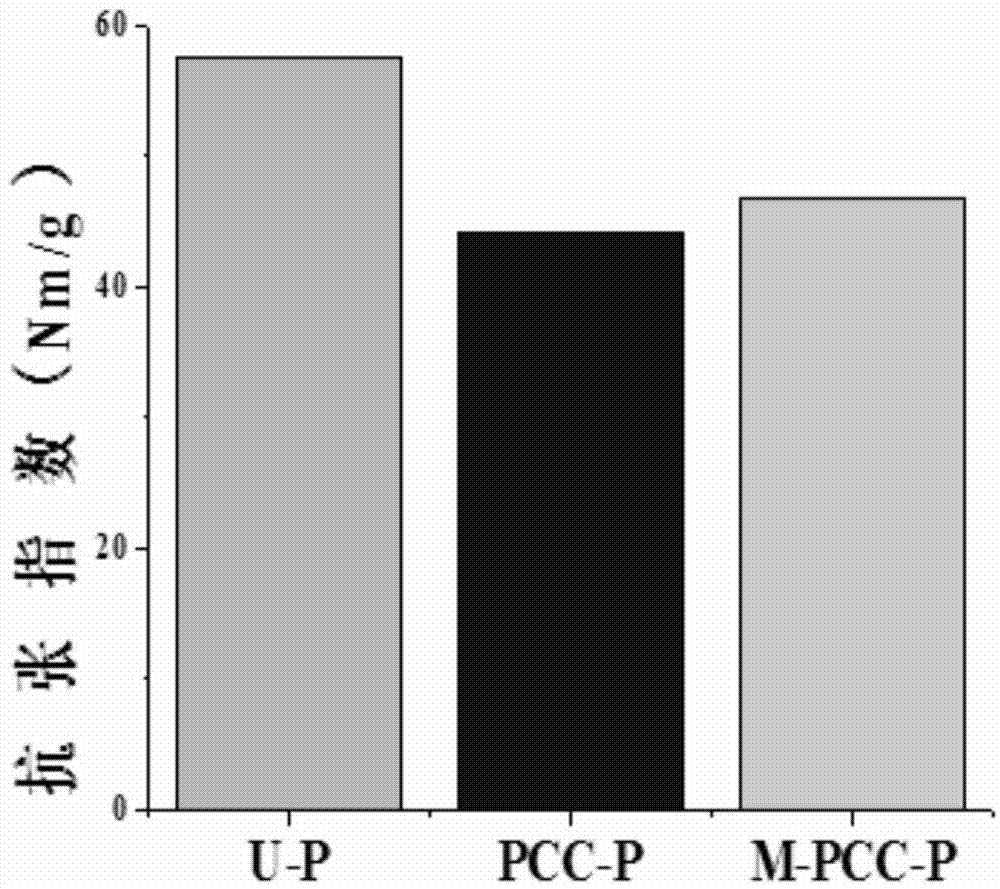

A technology of ultrasonic waves and clathrates, applied in the direction of fibrous fillers, inorganic compound additions, chemical instruments and methods, etc., can solve the problems of negative impact of sizing agent application efficiency on paper strength performance, improve hydrophobic performance and improve bonding force, the effect of mitigating negative effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

[0020] Embodiment 1: A method for preparing starch / rosin inclusion compound-based modified filler assisted by ultrasonic waves in this embodiment is carried out according to the following steps:

[0021] 1. Preparation of gelatinized starch: mix starch and water evenly, then gelatinize, the gelatinization temperature is 60-100°C, and the gelatinization time is 0.5h-2h to obtain gelatinized starch; the starch and water The mass ratio is 1: (10-100);

[0022] Two, the preparation of rosin saponification liquid: adopt saponification agent to carry out saponification treatment to rosin, saponification temperature is 60~100 ℃, saponification treatment time is 0.5h~4h, obtains rosin saponification liquid; The mass ratio of described saponification agent and rosin is 1: (2~30);

[0023] 3. Preparation of starch / rosin inclusion complex aqueous system: mix the gelatinized starch obtained in step 1 with the rosin saponification liquid obtained in step 2, and then perform ultrasonic tre...

specific Embodiment approach 2

[0026] Embodiment 2: This embodiment differs from Embodiment 1 in that: the gelatinization temperature described in step 1 is 95° C., and the gelatinization time is 1 hour. Other steps and parameters are the same as those in the first embodiment.

specific Embodiment approach 3

[0027] Embodiment 3: The difference between this embodiment and Embodiment 1 or 2 is that the mass ratio of starch to water in Step 1 is 1:32. Other steps and parameters are the same as those in Embodiment 1 or 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Turbidity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com