Patents

Literature

107results about How to "Improve surface resistance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

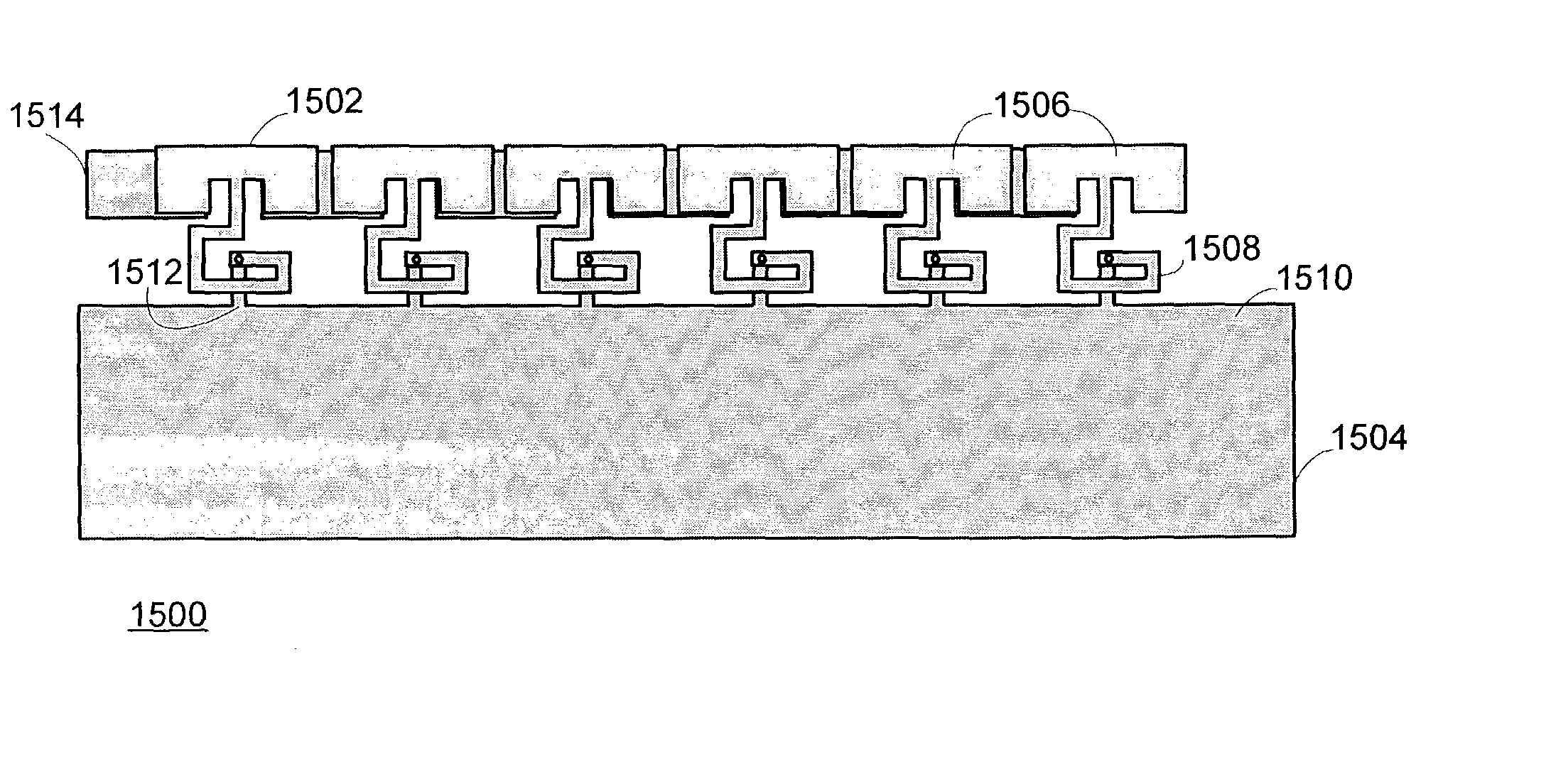

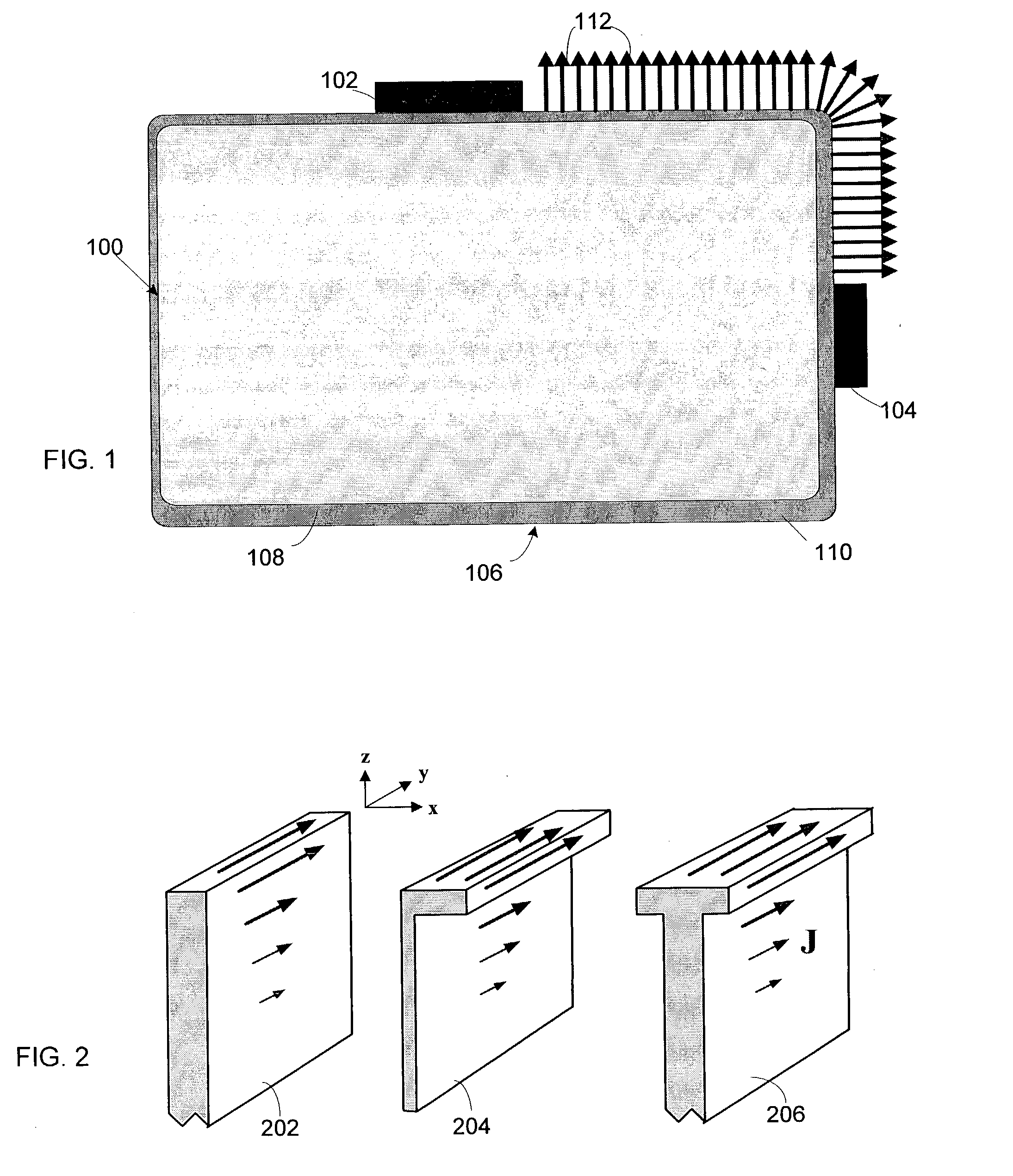

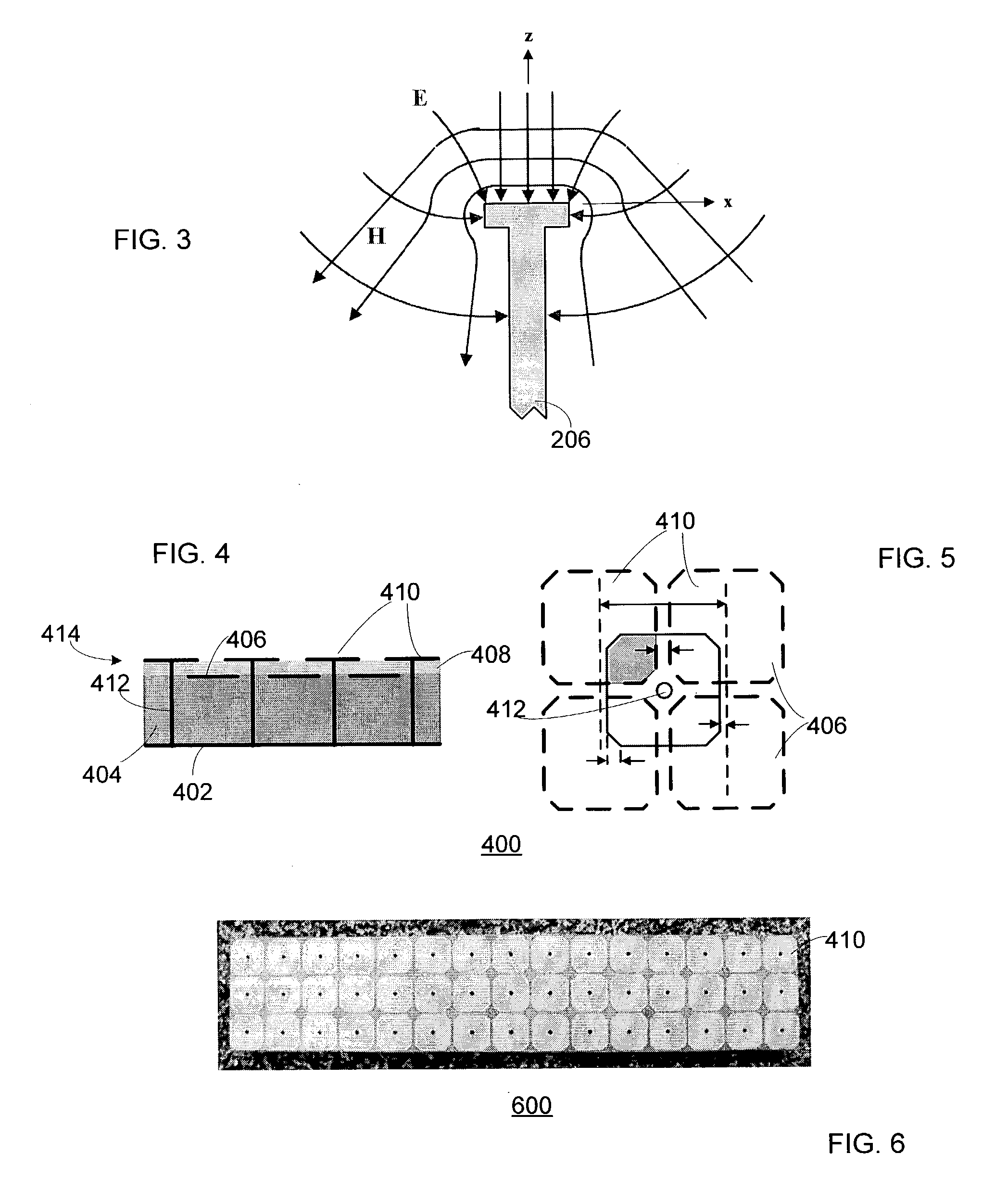

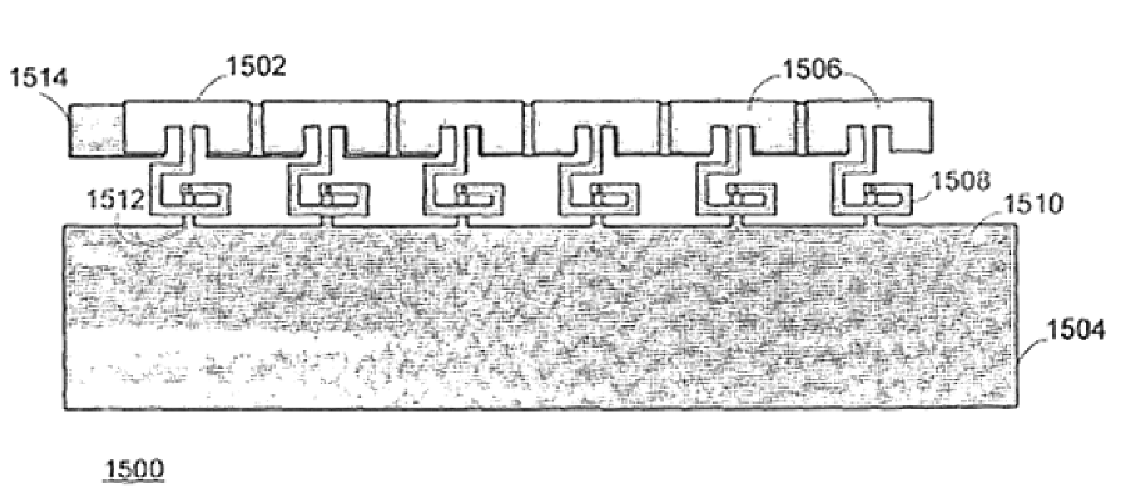

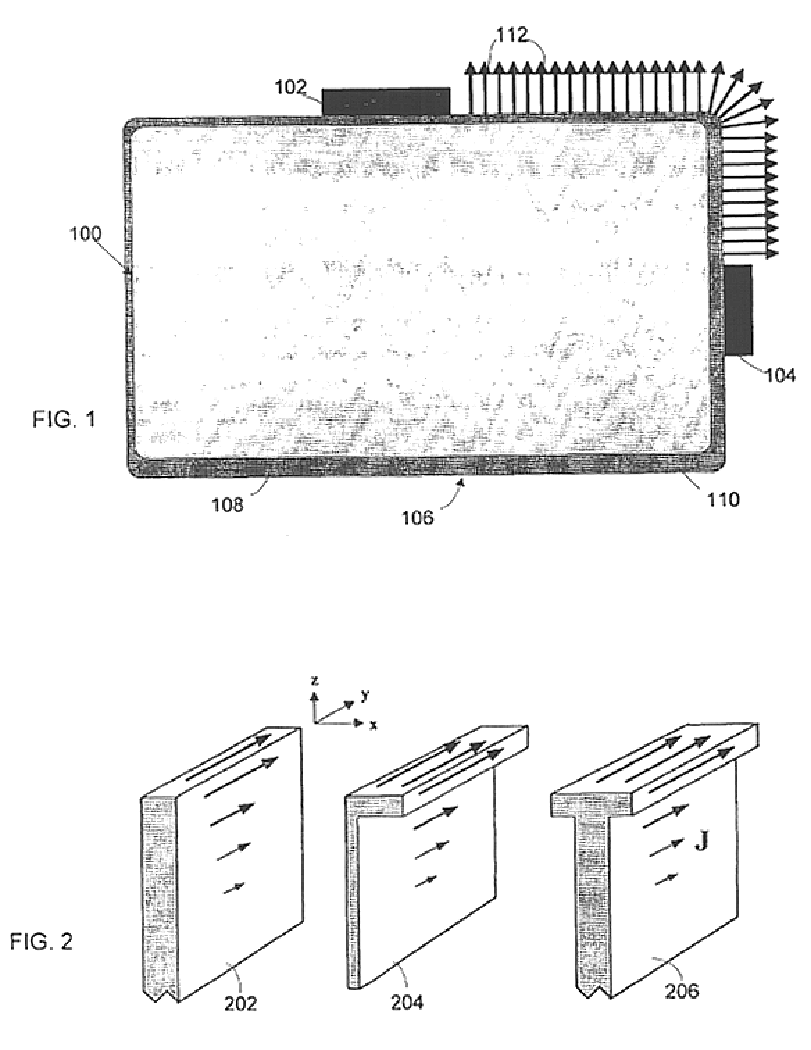

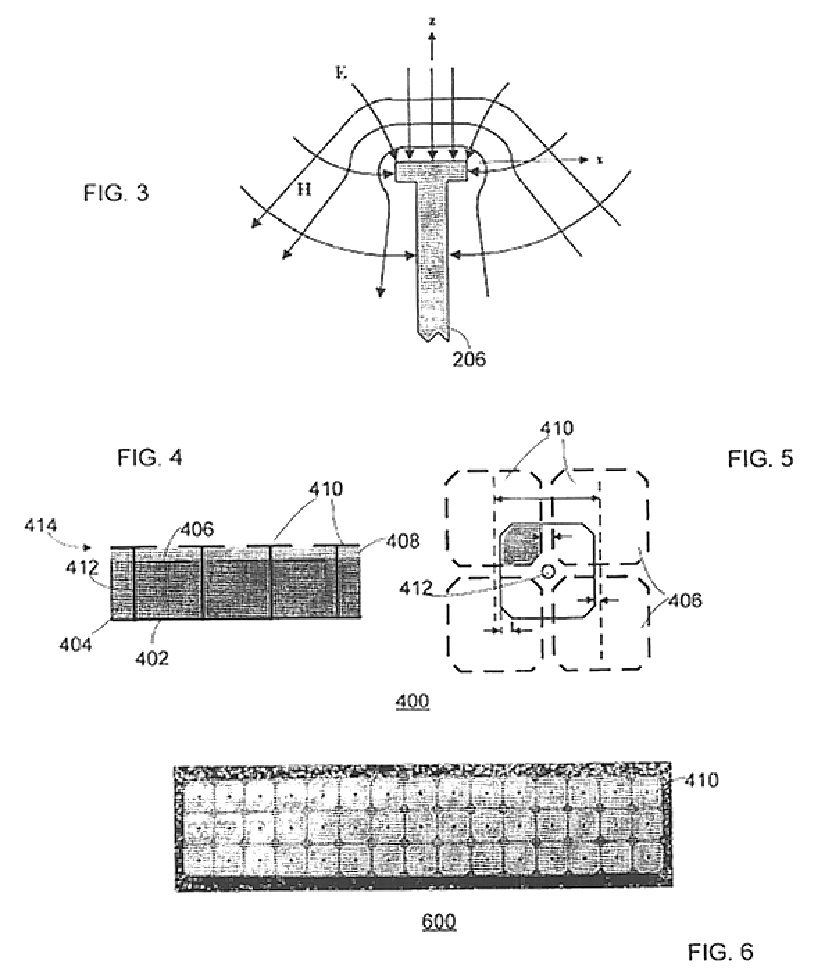

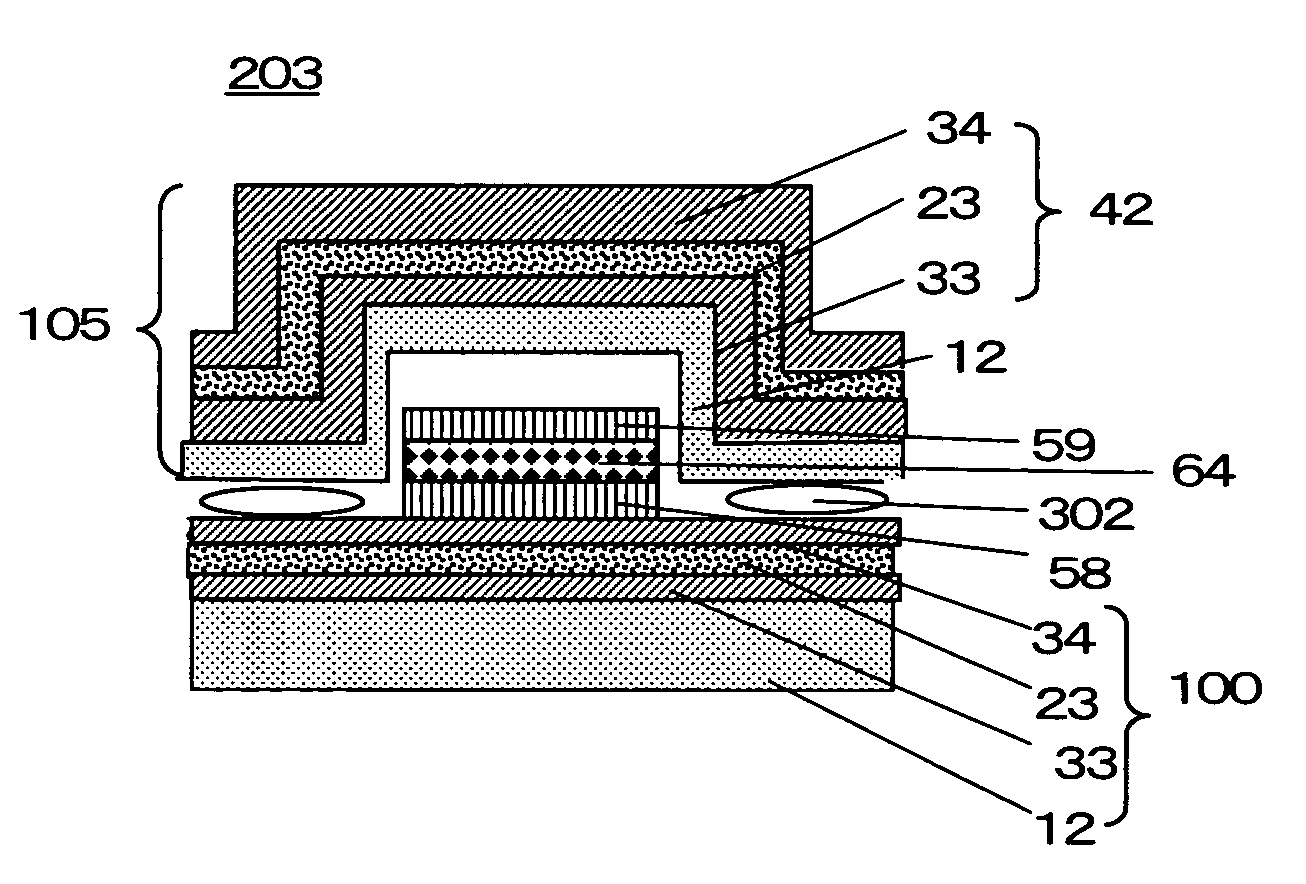

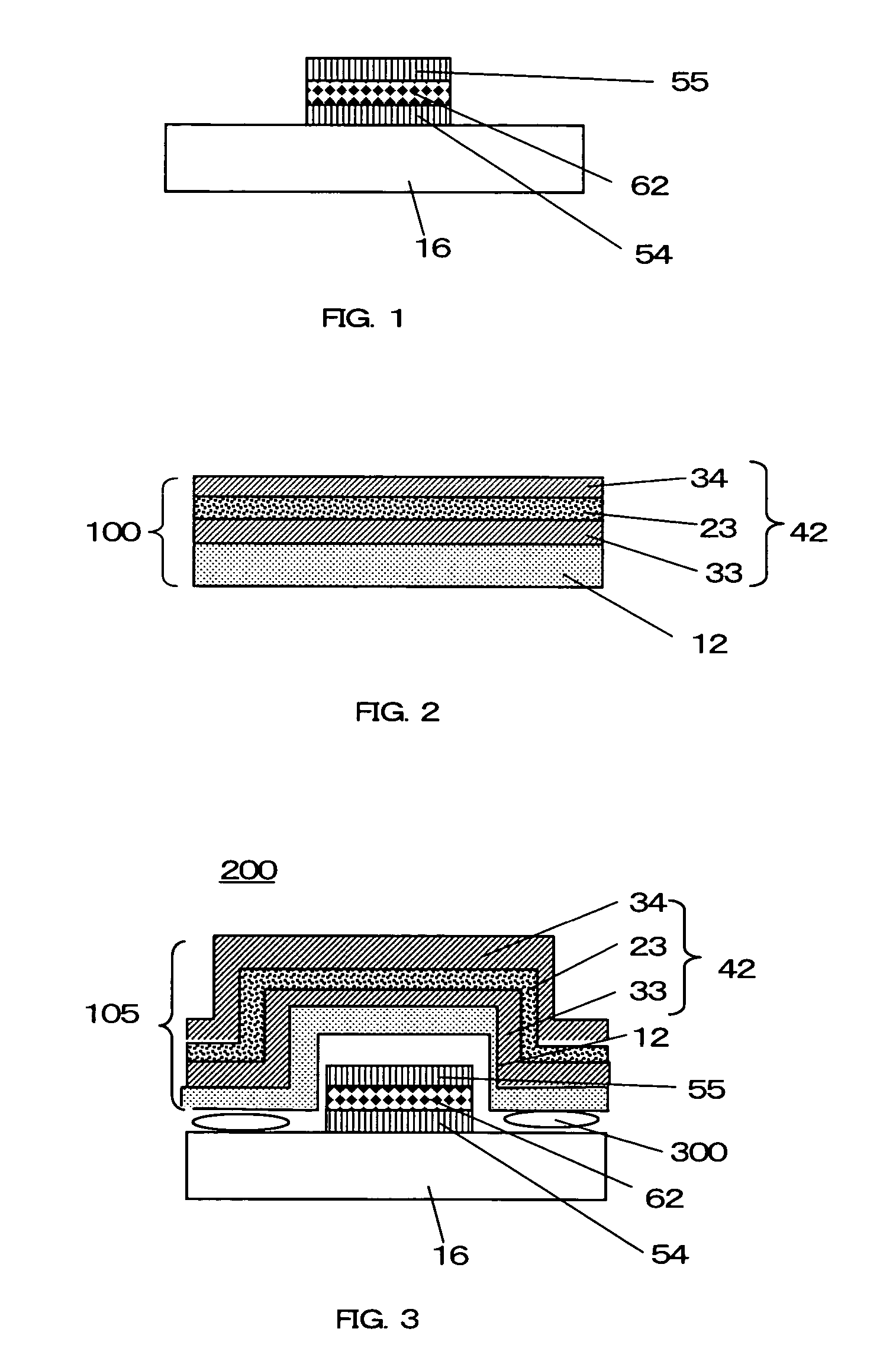

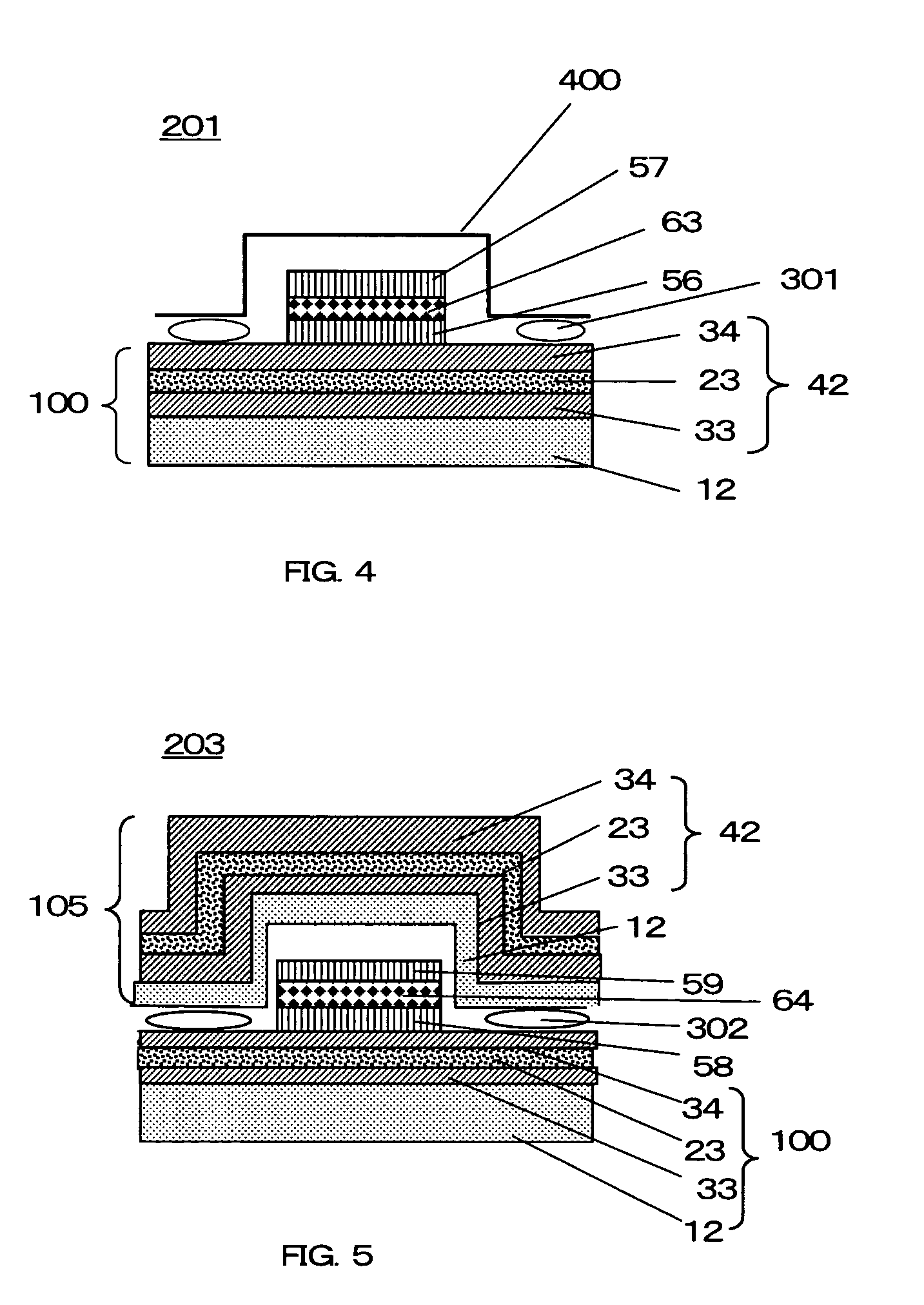

Narrow reactive edge treatments and method for fabrication

InactiveUS20040160367A1High isolationImprove isolationSimultaneous aerial operationsAntenna supports/mountingsSurface waveUltrasound attenuation

An electromagnetic bandgap material is electrically attached to an edge, and enables high isolation between antennas due to the attenuation of surface waves. The disclosed embodiments further provide narrow reactive edge treatments in the form of artificial magnetic conductors (AMCS) whose physical width is less than {fraction (1 / 10 of a free space wavelength for the frequency of surface currents intended to be suppressed. These embodiments still further provide several AMCs suitable for this purpose, along with several exemplary manufacturing techniques for the AMCs.

Owner:E TENNA CORP

Narrow reactive edge treatments and method for fabrication

InactiveUS6933895B2Improve isolationNone is suitable for purposeSimultaneous aerial operationsAntenna supports/mountingsUltrasound attenuationManufacturing technology

An electromagnetic bandgap material is electrically attached to an edge, and enables high isolation between antennas due to the attenuation of surface waves. The disclosed embodiments further provide narrow reactive edge treatments in the form of artificial magnetic conductors (AMCs) whose physical width is less than 1 / 10 of a free space wavelength for the frequency of surface currents intended to be suppressed. These embodiments still further provide several AMCs suitable for this purpose, along with several exemplary manufacturing techniques for the AMCs.

Owner:E TENNA CORP

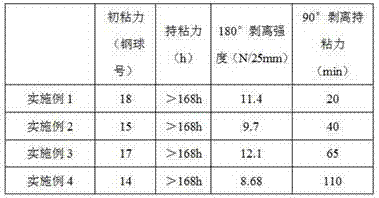

Preparation method of acrylate pressure-sensitive adhesive emulsion with block structure

The invention discloses a preparation method of an acrylate pressure-sensitive adhesive emulsion with a block structure. The preparation method comprises the steps of uniformly mixing an acrylate monomer with deionized water and an emulsifying agent, uniformly mixing a styrene monomer with deionized water and an emulsifying agent, and stirring and emulsifying to obtain an acrylate monomer pre-emulsion and a styrene monomer pre-emulsion; uniformly stirring and mixing deionized water and a bottoming emulsifying agent, rising temperature, and carrying out condensation reflux; adding the acrylatemonomer pre-emulsion, and then adding a first initiating agent; dropwise adding part of styrene acrylate monomer pre-emulsion and a second initiating agent into the emulsion of the step (2), then dropwise adding all styrene monomer pre-emulsion, finally dropwise adding the rest acrylate monomer pre-emulsion, and discharging to obtain the emulsion. The emulsion is low in vitrifaction temperature and good in wettability, provides an adhesion property, is low in cost of a pressure-sensitive adhesive, has favorable initial adhesion, permanent adhesion and peeling strength, outstanding comprehension property, and good curve surface resistance, and can be widely applied in the field of curve-surface tags.

Owner:JIANGSU JINGHONG NEW MATERIAL TECH

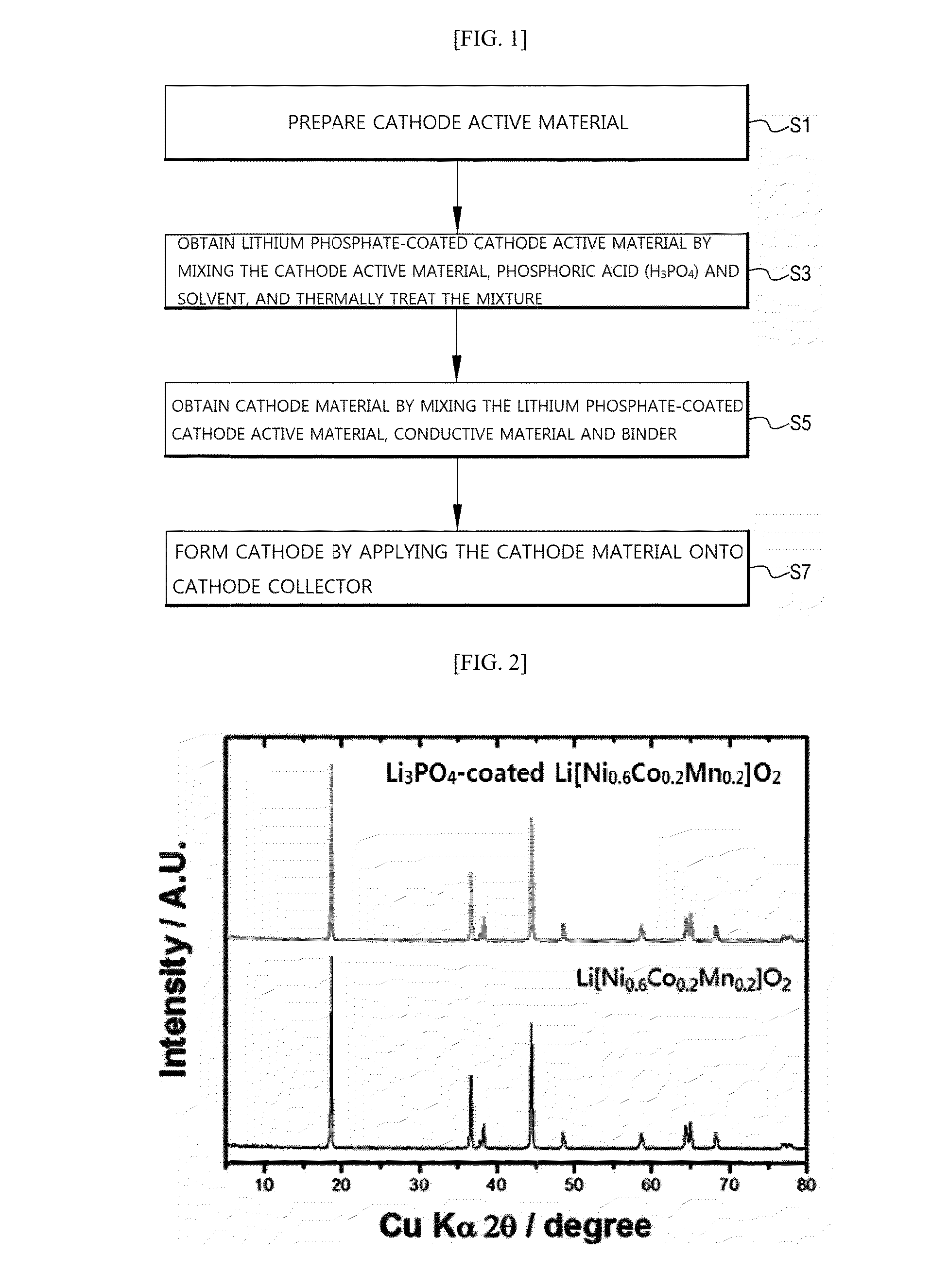

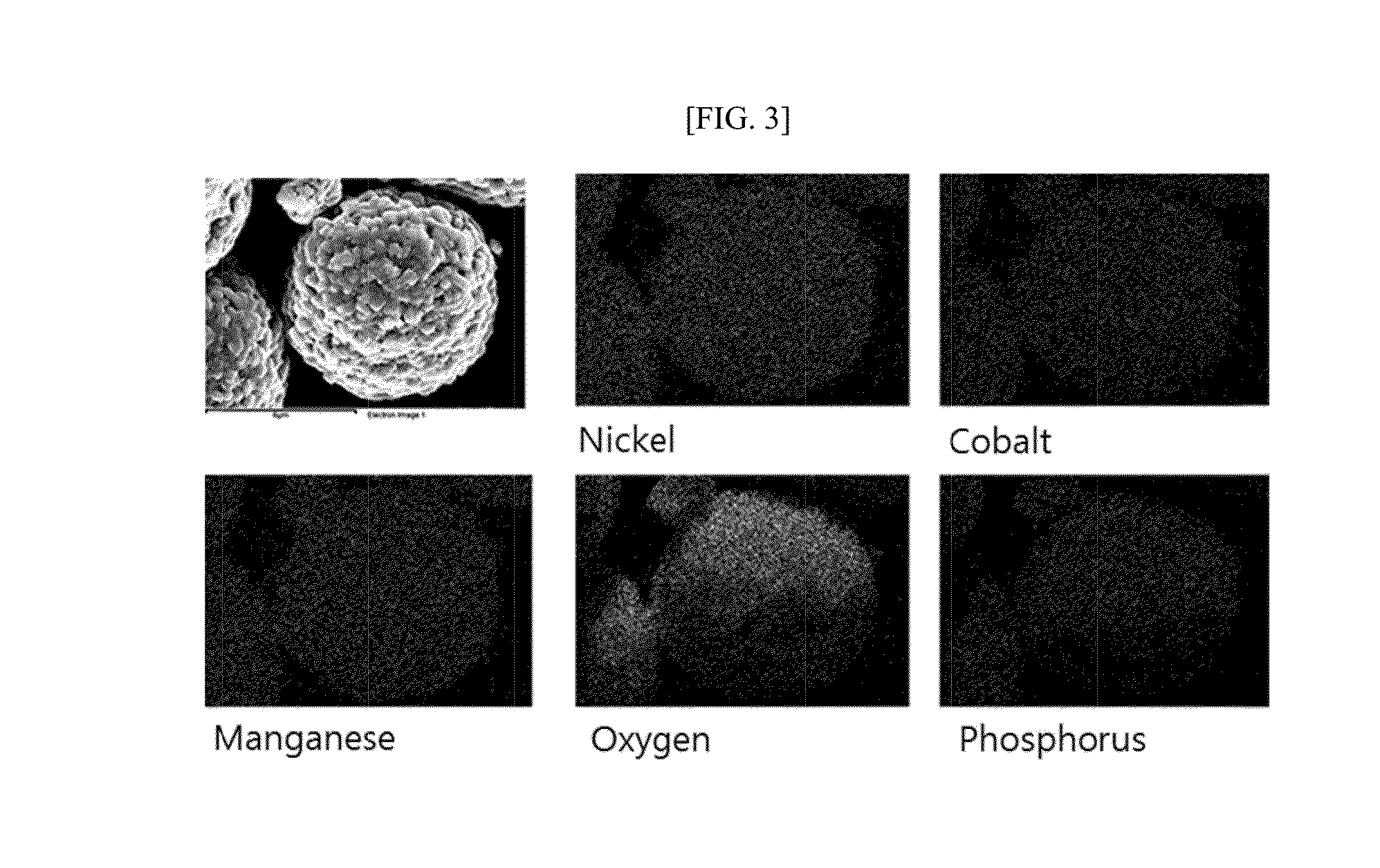

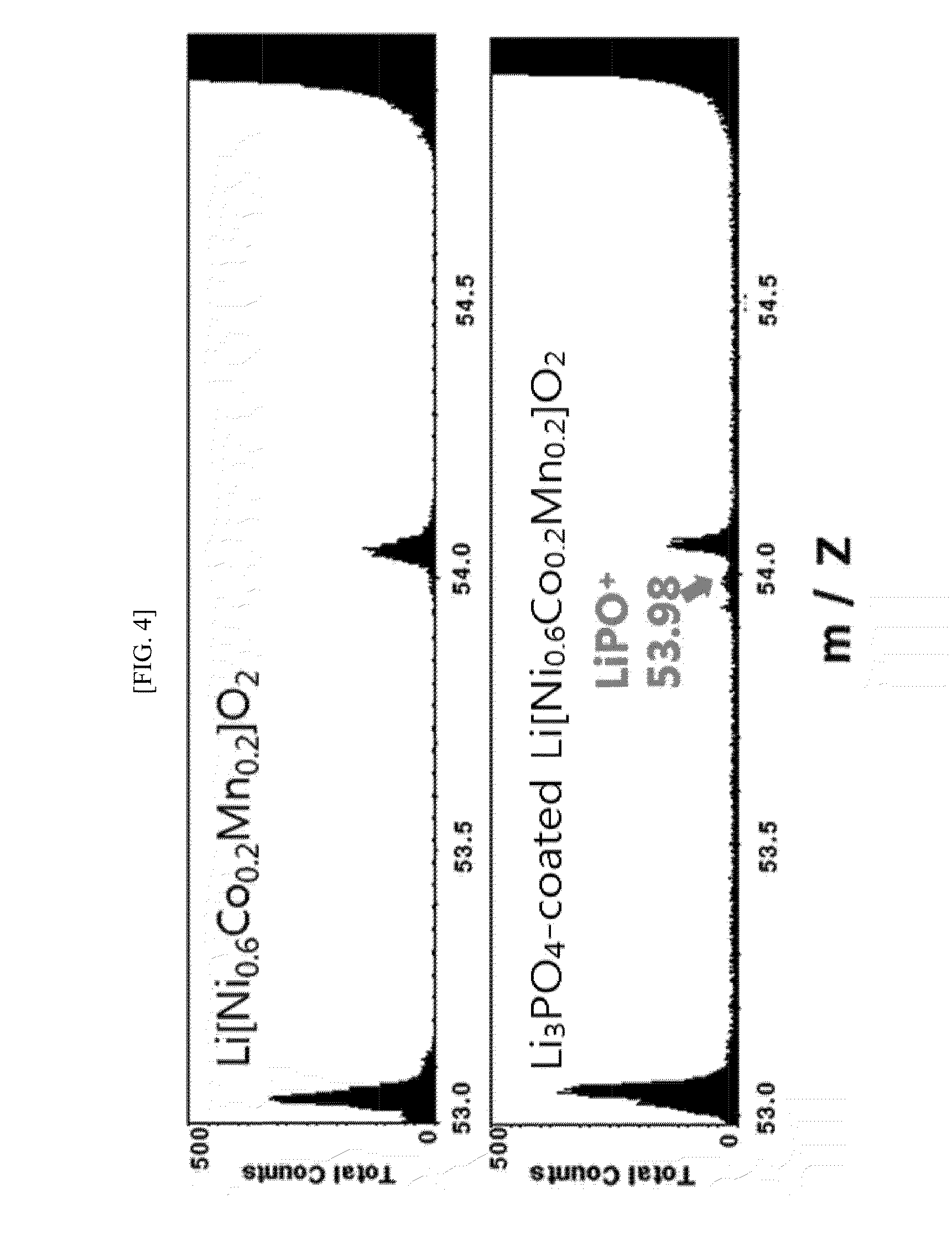

Cathode material for lithium secondary battery, and lithium secondary battery containing same

ActiveUS20160197346A1Prevent degradationReduce materialFinal product manufacturePositive electrodesMetalCathode material

Provided are a cathode material for a lithium secondary battery, and a lithium secondary battery containing the same. The cathode material for a lithium secondary battery comprises: a cathode active material, which is a lithium-transition metal oxide, and a lithium phosphate layer coated on a surface of the cathode active material.

Owner:IND ACAD COOP GRP OF SEJONG UNIV

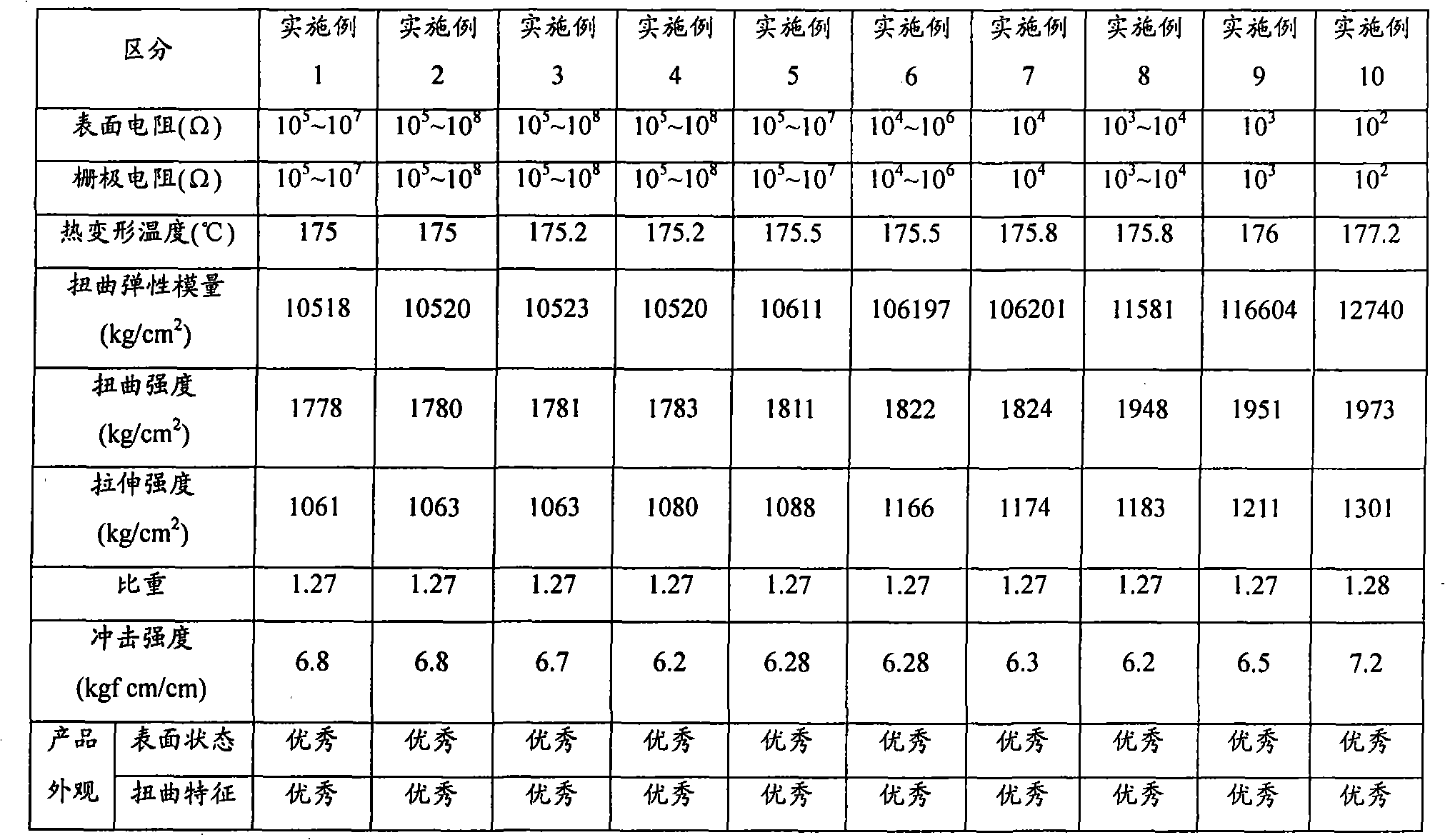

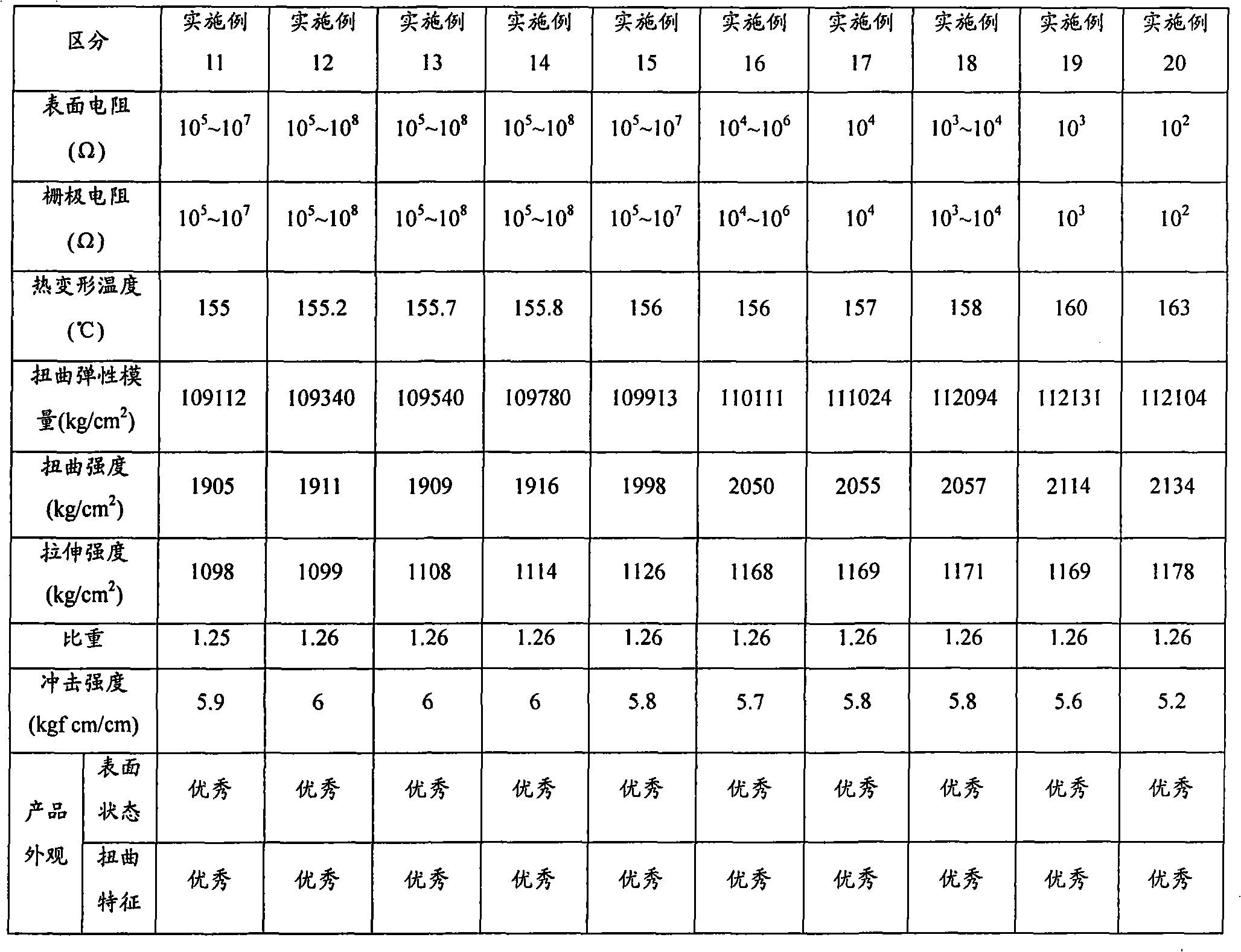

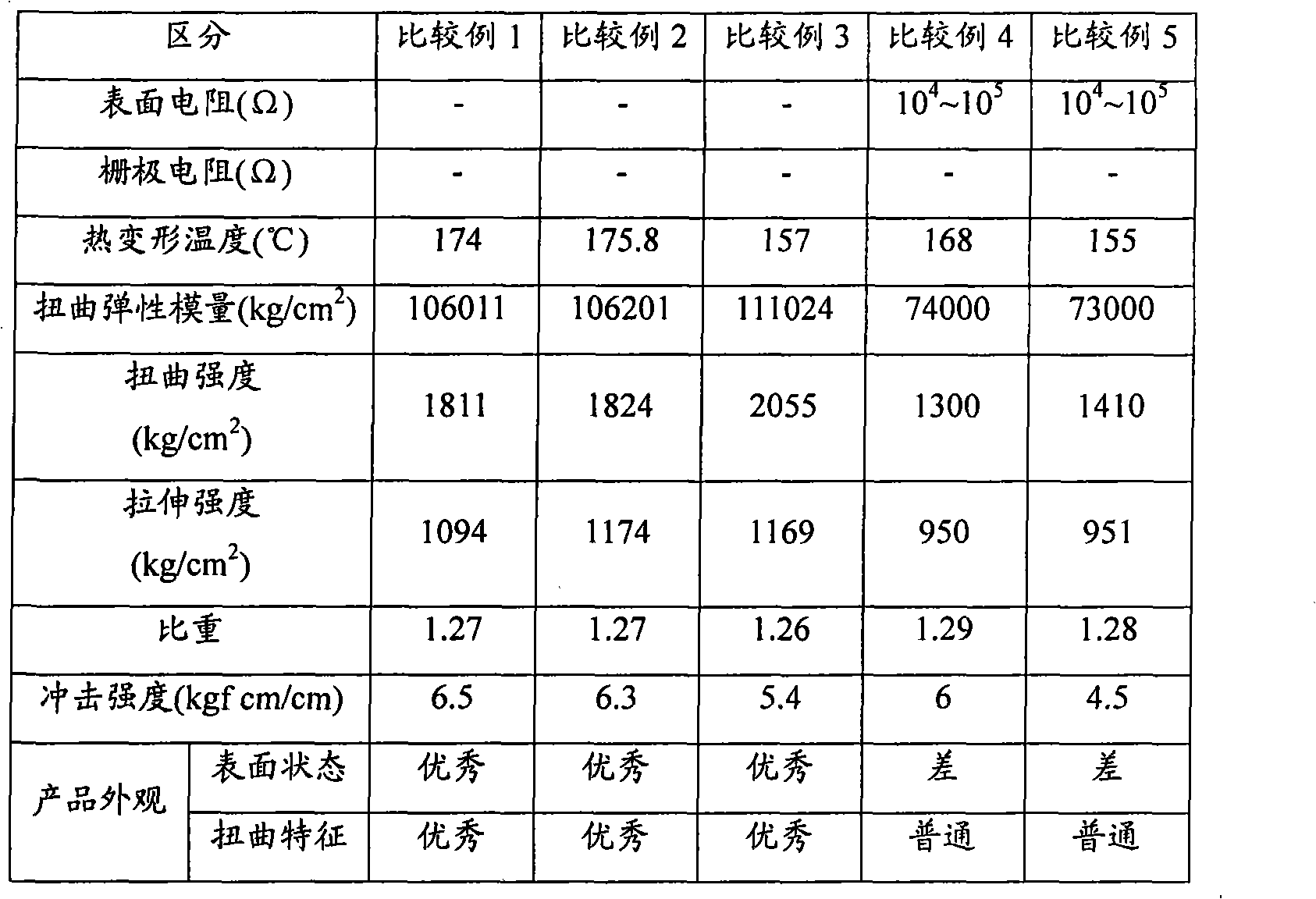

Modified polyphenylene oxide resin composition comprising carbon nano tube

The present invention relates to conductivity modified polyphenylene oxide (MPPO) resin composition comprising carbon nano tube (CNT), in more detail, relating to a MPPO resin composition with excellent heat-resisting quantity, dimension stability and electroconductivity, the MPPO resin composition containing (a) 20-60 wt% polyphenylene oxide, (b) 10-30wt% fiberglas, (c) 10-20 wt% mineral filler, (d) 0.5-5 wt% carbon nano tube and (e) 10-30 wt% high impact polystyrol.The MPPO resin composition of the present invention displays 102-109Omega by using the carbon nano tube, especially optimum surface resistance at certain area belt 104-109 Omega, improving heat-resisting quantity, dimension stability and rigidity. Comparing with the present carbon fibre, various things represented with surface conditions, tortility property and so on are more excellent, and can saving cost of manufacture to produce trays products, can using in electric and electronic field effectively, especially semi-conductor packaging field.

Owner:SHINIL CHEM IND CO LTD

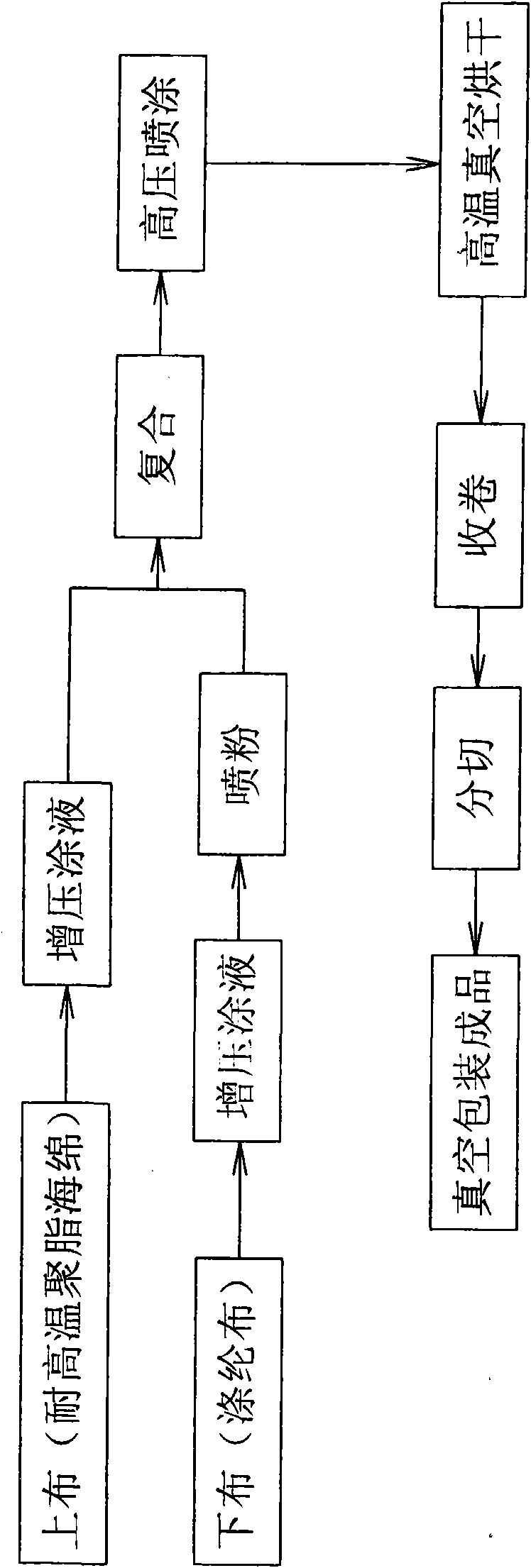

Production method of semi-conductive buffer water-blocking band

ActiveCN101567236AGood surface conductivityReduce surface resistanceFibre treatmentClimate change adaptationPolyesterVacuum pack

The invention relates to a production method of a water-blocking band, in particular to a production method of a semi-conductive buffer water-blocking band. The production method comprises the following steps: firstly, supercharging and soaking a high-temperature resistant polyester sponge and terylene cloth in conductive liquid, spraying high water-absorbent resin on the terylene cloth and compounding the high-temperature resistant polyester sponge and the terylene cloth; then, spraying the conductive liquid with a high-pressure spray gun and drying the high-temperature resistant polyester sponge and the terylene cloth which are compounded in vacuum at a high temperature; and finally, coiling, cutting and packaging the high-temperature resistant polyester sponge and the terylene cloth which are compounded in vacuum to be a finished semi-conductive buffer water-blocking band . Proved by detection, the semi-conductive buffer water-blocking band has the advantages of high intensity, thinness, rapid swelling in water, high water absorption, good water-blocking effect, high-temperature environment influence resistance, small surface resistance, low volume electric resistivity, European Union environmental protection accordance, and the like, can satisfy the water blocking and the electric field shielding among parts of power cables, and the like, maintains the safe use of the cables, can generate the semi-conductive shielding action so as to buffer an electric field, can be lined at the inner side of a metal protective sleeve to buffer the friction between the inner protective sleeve and the metal protective sleeve and can satisfy the normal working temperature of the cables.

Owner:YANG ZHOU TENGFEI ELECTRIC CABLE & APPLIANCE MATERIALS CO LTD

High-temperature-resistant low-resistance high-organic-compatibility coated-carbon aluminum foil and preparation method thereof

ActiveCN104659371AImprove surface resistanceGood compatibilityElectrolytic capacitorsElectrode carriers/collectorsCarbon layerGraphite

The invention relates to a high-temperature-resistant low-resistance high-organic-compatibility coated-carbon aluminum foil and a preparation method thereof. A carbon layer of the carbon-coated aluminum foil contains a co-existing mixture of graphite and linear carbon and is excellent in high temperature resistance, low resistance, and high organic system compatibility. According to the preparation method of the high-temperature-resistant low-resistance high-organic-compatibility coated-carbon aluminum foil, the limitation of a traditional chemical vapor precipitation carbon process that only hydrocarbon is adopted as a carbon source is broken through, a compound containing carbon element, hydrogen element and oxygen element or composite gas obtained by heating a mixture of the compound containing the carbon element, the hydrogen element and the oxygen element and a carbon material is used as a carbon source, so that the raw material is simple and is easily available, the process safety is controllable, and the prepared carbon-coated aluminum foil has advantages of high temperature resistance, low resistance, high carbon layer bonding rate, large specific surface area and high organic compatibility.

Owner:南通宇华新材料科技有限公司

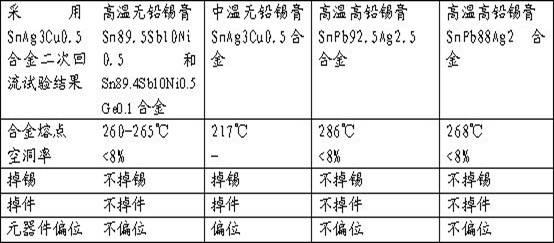

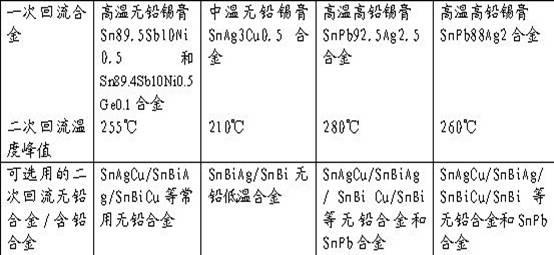

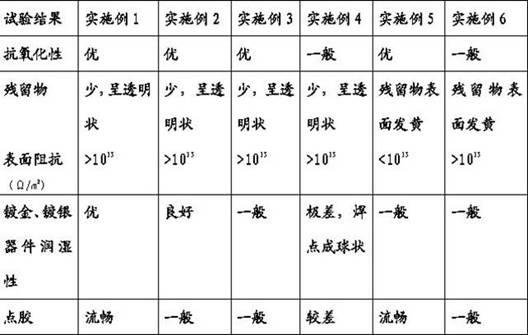

High-temperature lead-free halogen-free solder paste and preparation method thereof

InactiveCN102513739AChemically stableImprove antioxidant capacityWelding/cutting media/materialsSoldering mediaDevice materialAlloy

The invention provides a high-temperature lead-free halogen-free solder paste and a preparation method thereof. The high-temperature lead-free halogen-free solder paste is prepared from the components in percentage by weight: 80-91 percent of solder powder and 20-90 percent of flux paste, wherein the solder powder is tin-nickel-antimony or tin-nickel-antimony alloy powder. The high-temperature lead-free halogen-free solder paste has the beneficial effects that 1, the solder paste provided by the invention does not contain lead and is environmentally friendly, and the solder paste replaces a high-lead solder paste to be used for packaging semiconductor devices, particularly power devices and LED (Light Emitting Diode) in high temperature operation, packaging high-density integrated circuits and welding circuit boards needing secondary backflow; 2, the solder paste provided by the invention has stable chemical property and strong antioxidant capacity and is easily stored; 3, after the high-temperature lead-free halogen-free solder paste provided by the invention is adopted for welding, no solder ball exists, residues are less, the welding position is transparent, the surface impedance is high, and the safety performance of a product working in a high temperature and humid environment is effectively increased; the wetting property of gold-plated, silver-plated and nickel-plated devices is good, and the welding strength is large; 4, a precision device adopts the high-temperature lead-free halogen-free solder paste provided by the invention, a needle tube glue-dispensing process has uniform and smooth flow, and the void content after welding is lower than 8%.

Owner:深圳市晨日科技股份有限公司

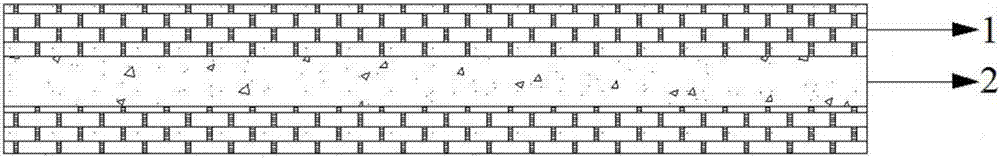

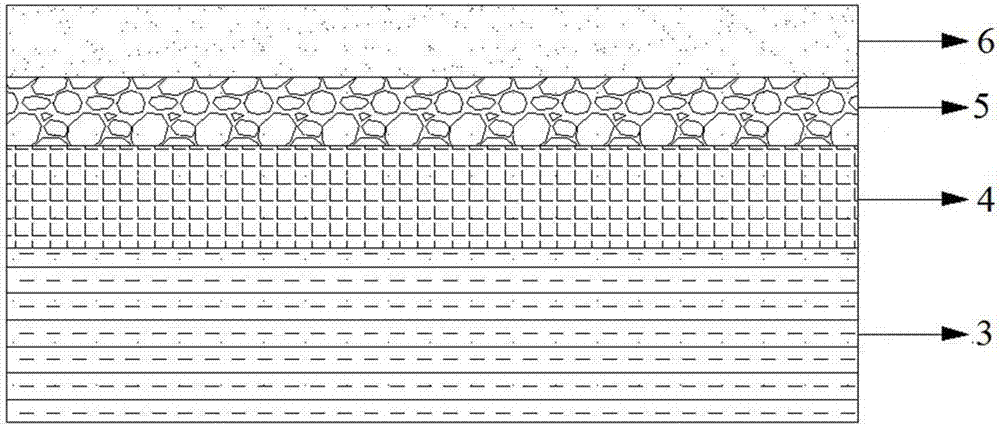

Tensile abrasion-resistant conveying belt

InactiveCN105621011AGood surface resistanceGood weather resistanceConveyorsThermoplastic elastomerEngineering

The invention discloses a tensile abrasion-resistant conveying belt. The framework of the tensile abrasion-resistant conveying belt is nylon cloth. Covering rubber layers which are made of thermoplastic elastomer materials are arranged on the two sides of the nylon cloth. Two reinforcing ribs which are made of thin tawny daylily and hemp ropes are arranged in the covering rubber layer on one side of the nylon cloth side by side. The surface of the tensile abrasion-resistant conveying belt is resistant to compression and abrasion and good in weatherability, and the tensile property of the conveying belt in the length direction is good; the tensile abrasion-resistant conveying belt is particularly suitable for conveying sand and stones.

Owner:戴小军

High-nickel cathode material rich in rock salt phase on the surface, and a preparation method and application thereof

ActiveCN109273688AImprove structural stabilitySlow down the speed of phase transitionSecondary cellsPositive electrodesLithium compoundChemistry

The invention discloses a high-nickel cathode material rich in rock salt phase on the surface and a preparation method and application thereof. The high-nickel cathode material comprises LiNi1 doped with high-valence transition metal M; X-YCoxNyO2 matrix and NiO-type rock salt layer coated on the surface of matrix, high valence transition metal M is +4 +6 valence transition metal, the thickness ofNiO-type rock salt layer is 4-50nm; The preparation method comprises: mixing a Ni1-x-yCoxNy(OH)2 precursor, a nano-scale high-valence transition metal M compound and a lithium compound, and calciningat a high temperature in an oxidizing atmosphere. In the high-nickel cathode material provided by the invention, the bulk phase doping forms a strong M. O bond, which helps to improve the structuralstability; The rock salt phase on the surface of the material can inhibit the corrosion of the electrolyte, slow down the phase transformation rate in the cycle process, and inhibit the increase of the surface impedance of the material. The synergistic effect of the two phases can significantly improve the cycle performance in the application of the positive electrode of the battery.

Owner:CHINA AUTOMOTIVE BATTERY RES INST CO LTD

Heat-conducting silicone rubber

The invention discloses heat-conducting silicone rubber. The heat-conducting silicone rubber comprises the following raw materials in parts by weight: 3-5 parts of aluminum powder, 12-17 parts of graphene, 2-3 parts of ceramic powder, 1-2 parts of lithium carbonate, 0.4-1 part of ammonium metavanadate, 0.3-1 part of ascorbic acid, 10-13 parts of polybutylene terephthalate, 2-3 parts of calcium fluoride, 1-2 parts of 1, 2-dimethyl imidazole, 2-4 parts of chlorinated paraffin, 0.5-1 part of potassium citrate, 0.5-1 part of dipropylene glycol, 1-2 parts of an accelerant CA, 3-4 parts of a rare earth additive, 100-108 parts of methyl vinyl phenyl silicone rubber and 1-2 parts of 1, 1-di-tetrabutylperoxycyclohexane. The aluminum powder, the graphene, the ceramic powder and the like are added into the heat-conducting silicone rubber provided by the invention, so that the heat-conducting performance of the heat-conducting silicone rubber can be obviously improved, aging of the rubber caused by high temperature and slow heat conduction can be slowed down, the service life of a rubber product is prolonged, and the application range of the silicon rubber is widened.

Owner:滁州君越高分子新材料有限公司

Transparent conductive sheet for touch panel, method for manufacturing same and touch panel

InactiveCN101273417AImprove surface resistanceImprove waterproof performanceConductive layers on insulating-supportsCable/conductor manufactureDopantConductive polymer

Disclosed is a transparent conductive sheet for touch panels which has a surface resistivity of not more than 1000omega, a total light transmittance of not less than 80% and a haze of not more than 5%, while being excellent in water resistance and adhesion between a transparent base and a transparent conductive layer. Specifically disclosed is transparent conductive sheet for touch panels which comprises a transparent base and a transparent conductive layer formed on the transparent base. The transparent conductive layer contains a pi-conjugated conductive polymer, a polyanion and an ester compound or a specific polymerizable compound. The transparent conductive layer may contain, if necessary, a conductivity improver, a dopant, another resin component and an additive. In particular, a conductivity improver may preferably be contained for increasing the conductivity.

Owner:SHIN-ETSU POLYMER CO LTD

High-strength conveying belt

InactiveCN105621013AGood surface resistanceGood weather resistanceConveyorsWeather resistanceThermoplastic elastomer

The invention provides a high-strength conveying belt. A frame layer of the high-strength conveying belt is made of nylon cloth. Covering rubber layers composed of thermoplastic elastomer materials are arranged on the two sides of the nylon cloth. The covering rubber layers on the two sides of the nylon cloth are each internally provided with a layer of stainless steel mesh. The surface of the high-strength conveying belt is good in compression resistance, abrasion resistance and weather resistance, the tensile property in the length direction of the conveying belt is good, and the high-strength conveying belt is especially suitable for conveying gravels.

Owner:戴小军

Aqueous environmentally-friendly coating

InactiveCN105153838AReduce volatilityImprove surface resistanceFireproof paintsEpoxy2-mercaptobenzimidazole

The invention discloses an aqueous environmentally-friendly coating. The coating comprises, by weight, 91-100 parts of an aqueous acrylic emulsion, 1-2 parts of polydicyclopentadiene, 0.5-1 part of ammonium molybdate, 0.1-0.2 parts of iron trifluoroacetylacetonate, 1-2 parts of polypropylene glycol, 1-2 parts of potassium silicate, 2-4 parts of octyl epoxy stearate, 0.5-1 part of 2-mercaptobenzimidazole, 10-12 parts of ultrafine barium sulfate, 2-3 parts of polymethyl acrylate, 0.3-1 part of lauryl dimethyl amine oxide, 2-4 parts of a flame retardation assistant, 2-3 parts of ethylene glycol butyl ether and 20-30 parts of deionized water. Compared with solvent-based coatings, the coating disclosed in the invention has the advantages of environmental protection, low volatility, good resistance of the surface of a coating layer, good stability, certain flame retardation effect and security improvement.

Owner:ANHUI OS BUILDING MATERIAL

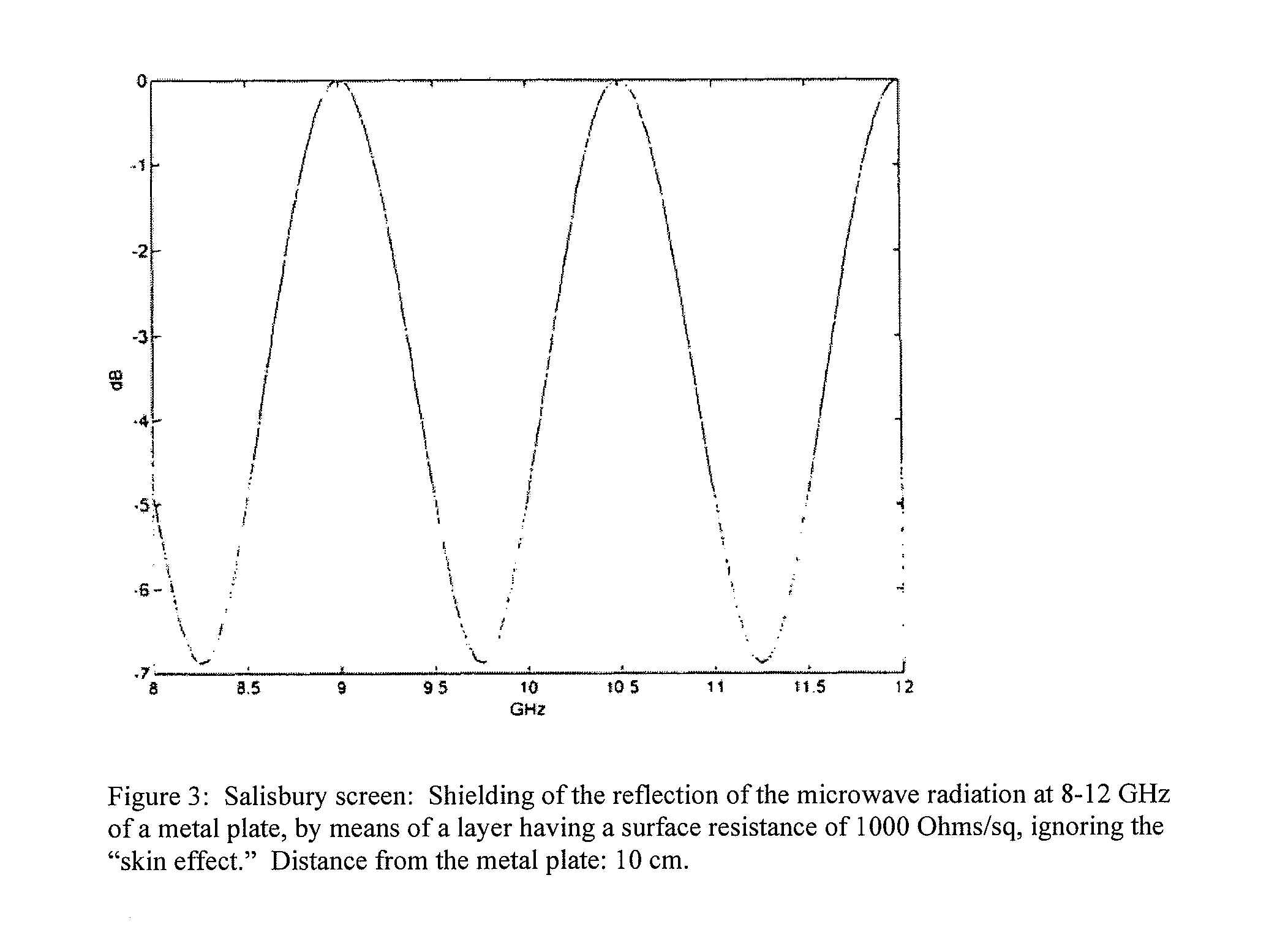

Device for camouflaging objects and/or persons

InactiveUS20100093238A1Improve shielding effectHigh surface resistanceSynthetic resin layered productsPretreated surfacesPolymer sciencePolythiophene

A knitted or woven material is proposed for camouflaging objects or persons, having a coating that comprises or has at least one conductive polymer (ICP). Suitable substances for the coating are conductive polymers, for example based on polythiophene (PEDOT).

Owner:SSZ CAMOUFLAGE TECH AG

Surface treating agent for trace rare earth aluminum alloy

InactiveCN104099593AGood water solubilityGood compatibilityMetallic material coating processesPhosphorous acidCerium

The invention discloses a surface treating agent for trace rare earth aluminum alloy. The surface treating agent comprises the following raw materials in parts by weight: 1-2 parts of phosphorous acid, 0.01-0.04 part of lanthanum citrate, 0.02-0.03 part of cerium citrate, 1-2 parts of hydrolytic polymaleic anhydride, 2-3.1 parts of pentaerythritol, 2-3 parts of amino trimethylene phosphonic acid, 0.1-0.4 part of melamine, 0.2-0.3 part of aluminum nitride powder, 0.6-1 part of ethylene bis-stearamide, 2-3.5 parts of ethylene glycol, 0.2-0.3 part of tributyl tin chloride, 2-3 parts of a coalescing agent, 10-13 parts of 3-amino propyl trimethoxy silane, 5-8 parts of bis(gamma-triethoxysilyl propyl) tetrasulfide, and 110-140 parts of de-ionized water. The lanthanum citrate and the cerium citrate added in the surface treating agent have good water solubility, so that the compatibility among all the materials is improved, the surface resistance and the weather resistance of a coating film are improved, and the coating film is uniform, smooth and stable.

Owner:RUIZHAN TONGLING TECH

Silicone rubber for sealing two ends of heater

InactiveCN104371331AImprove water resistanceWater resistance, good sealing effectPolymer scienceDiboride

The invention discloses silicone rubber for sealing two ends of a heater. The silicone rubber comprises the following raw materials in parts by weight: 1-2 parts of 1,4-cyclohexanedimethanol, 0.4-1 parts of vanadium diboride, 3-4 parts of polypropylene powder, 1-2 parts of accelerant TT, 0.4-1 part of trithiocyanuric acid, 0.7-1 part of 2-mercaptobenzimidazole, 1-2 parts of 1-hydroxycyclohexyl phenyl ketone, 10-17 parts of superfine barium sulfate, 10-13 parts of bis(2-ethylhexyl)sebacate, 2-3 parts of calcium fluoride, 0.5-1 part of butyltin mercaptide, 3-4 parts of rare earth auxiliaries, 100-110 parts of methyl vinyl phenyl siloxane rubber, 1-2 parts of sulfur, and 0.2-0.5 part of tetrahydrofuran, wherein the rare earth auxiliaries are prepared by the following steps: fully melting magnesium-aluminum silicate and colloid formed by polyvinyl acetal under the condition of taking deionized water as a solvent, so as to form stable and high-viscosity colloidal state, adding the treated acidified rare earth into the high-viscosity colloidal state system to form stable rare earth colloidal liquid, and then mixing and modifying with the esterified zeolite. By adopting the rare earth auxiliaries, not only can the mechanical performance and surface resistance of the finished products be effectively improved, but also the compatibility of materials can be enhanced, the stability of the finished products can be improved, the volume wear can be reduced by rare earth, and the wear resistance of the rubber can be improved.

Owner:滁州君越高分子新材料有限公司

Layered product, luminescence device and use thereof

ActiveUS8547011B2Improve scratch resistanceLittle reflection lossDischarge tube luminescnet screensElectroluminescent light sourcesOrganic filmLight emitting device

A layered product comprising: sealing film comprising a laminate of at least one organic film and at least one inorganic film, and transparent resin substrate; in which the organic film is made from fluorine compound or alicyclic structure containing polymer and metallic simple substance or metallic compound as raw material, and in which the inorganic film is made from metallic simple substance or metallic compound as raw material. A luminescence device comprising: substrate, and lower electrode layer, luminescent-material layer, upper electrode layer and sealing film which are laminated in turn on the substrate; in which the substrate and the sealing layer comprises the layered product.

Owner:ZEON CORP

Hard coating film and flexible display window including touch sensor using the same

InactiveUS20180024592A1Avoid dust adhesionExcellent surface hardnessDigital data processing detailsSynthetic resin layered productsEngineeringFlexible display

The present invention relates to a hard coating film used as a film for a flexible display window including a touch sensor and a flexible display window including a touch sensor using the same, and particularly, to a hard coating film having a surface resistance of 5*1011 Ω / sq to 5*1013 Ω / sq.

Owner:DONGWOO FINE CHEM CO LTD

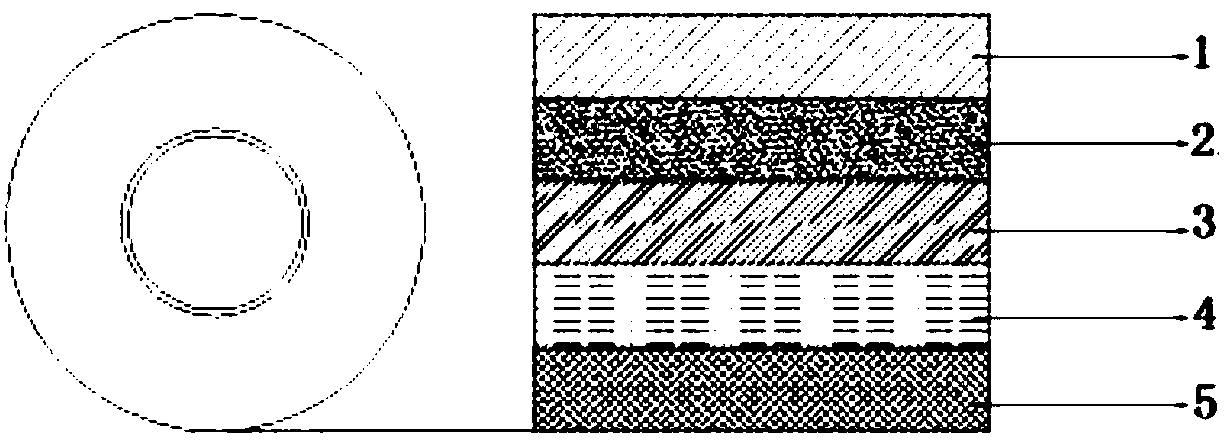

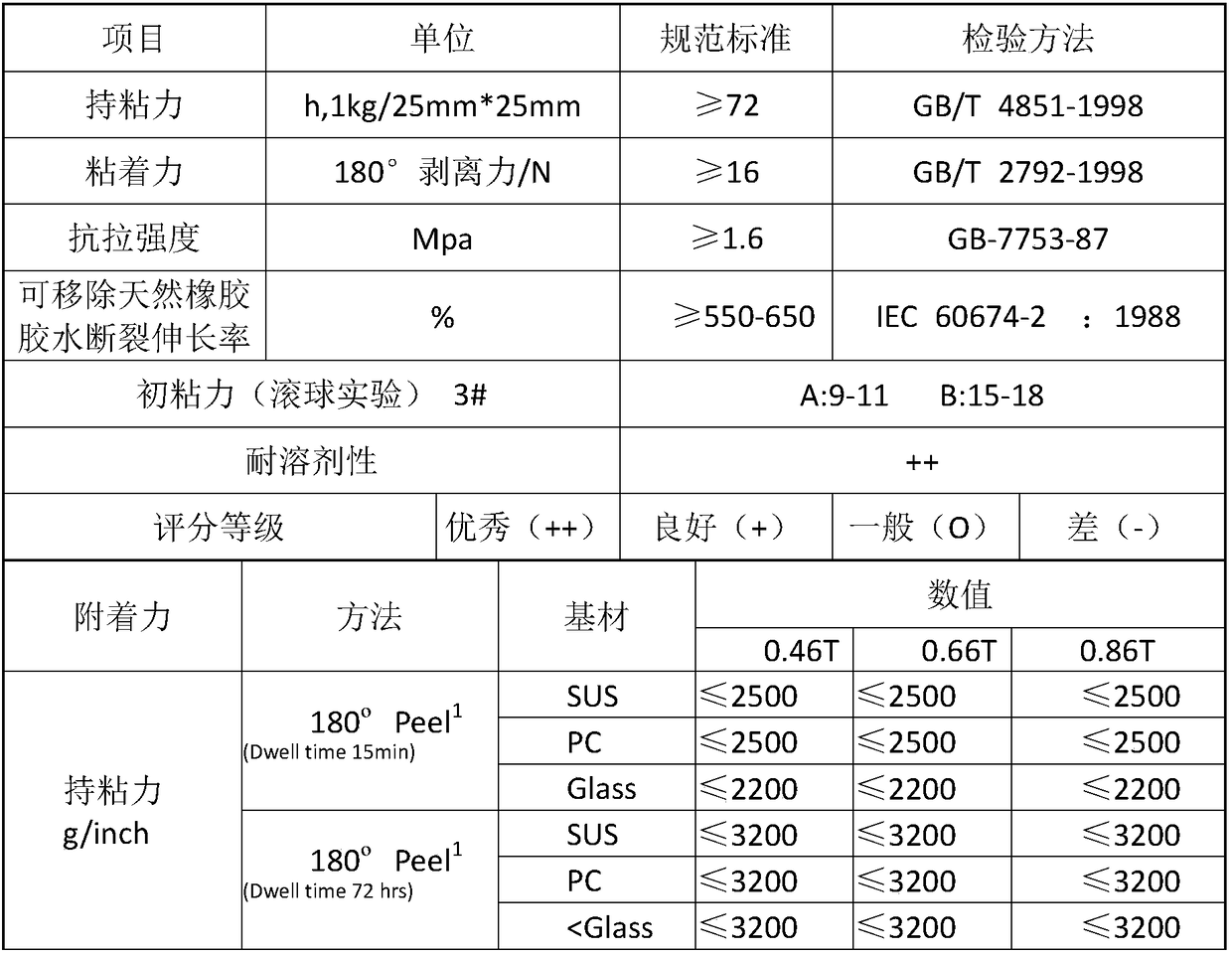

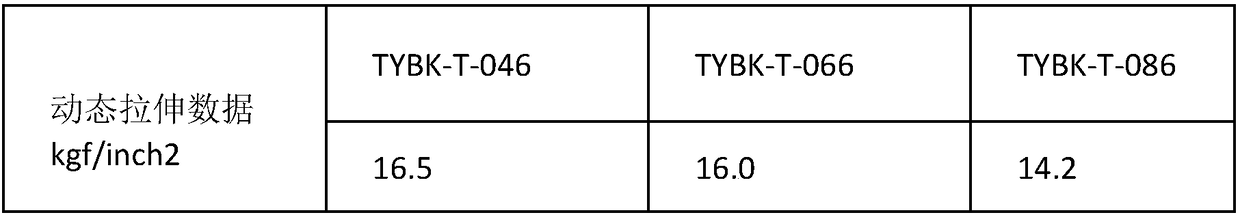

PU black foam double-sided tape material

The invention discloses a PU black foam double-sided tape material. The material is formed by sticking an easy-to-pull adhesive material layer, a foam layer, an ultrathin black PET base material layer, a shading adhesive material layer and a double silicon PET release film base material layer in sequence from top to bottom; the thickness of the PU black foam double-sided tap material is 0.46-0.86mm. By combining multiple test detection, the material has the following advantages that the material is light, excellent adhesion is achieved, the adhesion to a thin edge is excellent, the stress relieving effect, reflex action resistant property, surface resistance and anti-rejection property are good, the material can be removed safely on a glass panel and the surfaces of a PC, stainless steeland plastics, the die-cut machining property is excellent, and the material is applicable to large-size intelligent TV module assembly and the like.

Owner:苏州天煜新材料科技有限公司

High-pressure decorative door sheet comprising wood base materials and preparation method of door sheet

PendingCN107379683AReduce pollutionIncrease productivityFireproof doorsSynthetic resin layered productsPolypropyleneMolding (decorative)

The invention discloses a high-pressure decorative door sheet comprising wood base materials and a preparation method of the door sheet. The door sheet comprises base plate layers, buffer layers, decorative layers and wear-resistant protective layers which are sequentially arranged from bottom to top, wherein the base plate layer comprises at least two wood base material layers and impregnated surface paper layers for bonding are arranged between the wood base material layers. The plate layers are sequentially stacked in an intermittent hot press in the order of one wear-resistant protection layer, one decorative layer, one buffer layer, one impregnated surface paper layer for bonding, one base plate layer, a polypropylene isolating membrane, the other base plate layer, the other impregnated surface paper layer for bonding, the other buffer layer, the other decorative layer and the other wear-resistant protection layer and then subjected to high-temperature and high-pressure one-time hot press molding. The high-pressure decorative door sheet comprising the wood base materials is flame-retardant, fireproof, wear-resistant, scratch-resistant, waterproof, damp-proof, impact-resistant, fouling-resistant and scrape-resistant, the decorative layers and the base materials are subjected to one-time hot press molding and can be used without pasting, decorative surface layers cannot peel off and mildew, the surface is easy to clean, the formaldehyde release amount and TVOC release amount are low, and no heavy metals are contained.

Owner:HENAN YONGWEI SECURITY

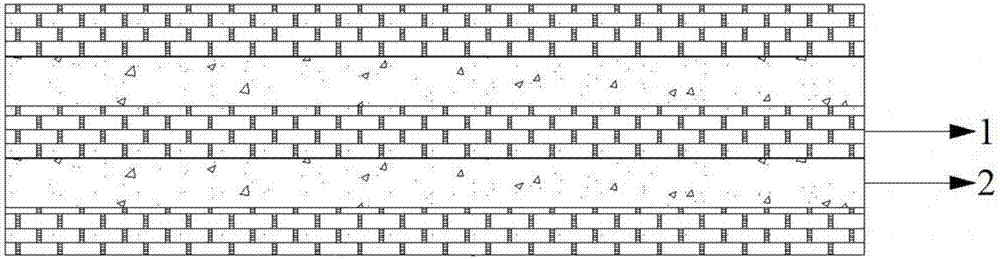

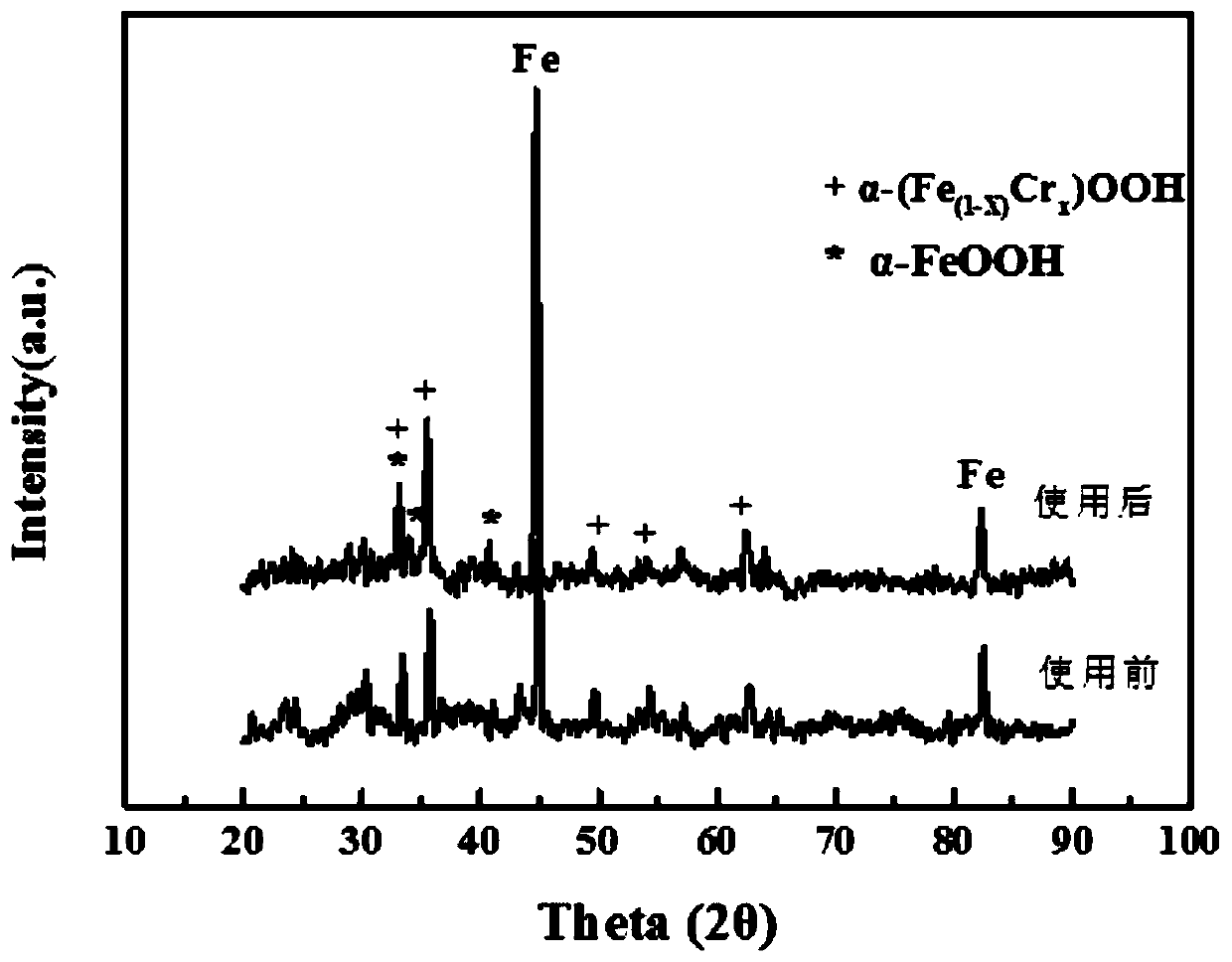

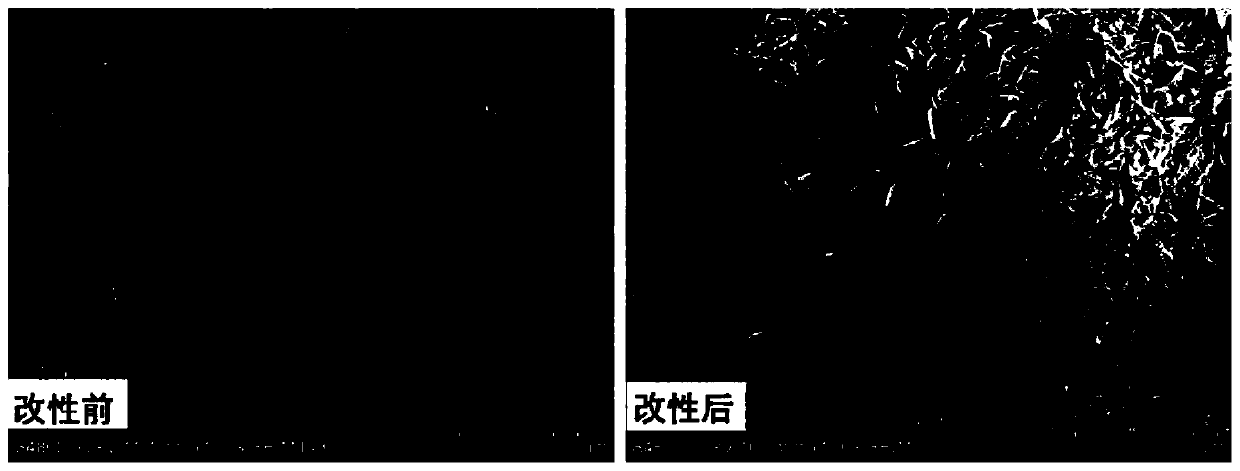

Iron filings surface modifier and method for preparing alpha-Fe<(1-x)>Cr<x>OOH active layer

ActiveCN110813305AEasy to preparePromote formationCatalyst protectionWater contaminantsPtru catalystSodium phosphates

The invention relates to an iron filings surface modifier and a method for preparing an alpha-Fe<(1-x)>Cr<x>OOH active layer. The surface modifier comprises the following components in percentage by mass: 30-50% of polyethylene butyral resin, 3-10% of chromium sulfate, 3-10% of ferric oxide, 0.2-2% of sodium phosphate, 0.5-5% of sodium dodecylsulfonate, and the balance water. The modification is performed by the following steps: (1) performing degreasing cleaning on waste iron filings; (2) performing surface modification in the iron filings surface modifier; and (3) cleanly rinsing the surfacewith water after the surface modification is completed, and then performing natural air-drying. Compared with the prior art, the method uses iron filings as a raw material, and the surface of the iron filings is modified by an appropriate chemical method, so that surface components of the iron filings have catalytic ozone activity, and a dense structure to protect the iron filings matrix, the total iron content in outlet water is reduced, the catalyst's dissolution loss is inhibited, and thereby the method is a feasible way to reduce the catalyst cost of an advanced oxidation method and improve the outlet water quality, and has important practical value.

Owner:TONGJI UNIV

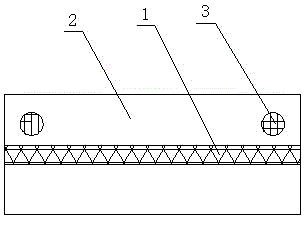

Metallising using thin seed layer deposited using plasma-assisted process

InactiveCN101067195AEfficient manufacturingFast preparationFixed capacitor electrodesThin/thick film capacitorGas phaseDeposition process

The invention relates to a making method for metalization meshwork (3) and equipment thereof, specifically relates to metalization plastic meshwork of foil capacitor. In said method, metallic layer (17) is deposited in vapor phase or gas-phase, wherein before the metallic layer is deposited, vapor phase or gas-phase deposition processes of metallic inoculating seed layer assisted by plasma, and the thickness of the metallic inoculating seed layer is in a scope of at most several atomic layers. Further, the invention also relates to plastic foil made by the said method, wherein the thickness of the inoculating seed layer between the metallic layer and plastic foil is that of at most several atomic layers.

Owner:APPLIED MATERIALS INC

Water-based rubber treating agent

InactiveCN110183708AModified dispersion propertiesImprove the effect of surface treatmentAdhesive processes with surface pretreatmentBenzimidazoleMethyl methacrylate

The invention discloses a water-based rubber treating agent. The water-based rubber treating agent is prepared from raw materials in parts by weight as follows: 3-5 parts of nano-silica, 80-100 partsof methyl methacrylate, 10-15 parts of rosin, 3-5 parts of polyethylenimine, 4-7 parts of oleic acid, 0.3-1 part of 2-mercapto-benzimidazole, 20-30 parts of a rubber matrix, 2-4 parts of ammonium persulfate and 0.7-1 part of a dispersant. The treating agent improves a traditional organic solvent treatment method and is high in safety and environmental protection property and good in effect.

Owner:南宝树脂(佛山)有限公司

Conductive silicone rubber for cable accessories

InactiveCN104403327AImprove surface strengthGood aging resistanceInorganic pigment treatmentSurface strengthErythritol

The invention discloses conductive silicone rubber for cable accessories. The conductive silicone rubber comprises the following raw materials in parts by weight: 0.1 to 0.5 part of erythritol, 1 to 2 parts of polyacrylamide, 1 to 2 parts of an accelerant DBTU, 1 to 2 parts of hydroxyethyl cellulose, 2 to 3 parts of stearoyl-rac-glycerol, 1 to 2 parts of zinc dihydrogen phosphate, 15 to 25 parts of acetylene black, 1 to 2 parts of ammonium polyphosphate, 7 to 10 parts of chlorinated paraffin, 2 to 3 parts of calcium stearate, 1 to 2 parts of benzotriazole, 1 to 2 parts of dimethylacrylicacid 1,4-butylene terephthalate, 1 to 2 parts of butylene terephthalate potassium zirconium carbonate, 3 to 4 parts of a rare earth promoter, 100 to 116 parts of methyl vinyl phenyl polysiloxane rubber, 1 to 2 parts of a vulcanizing agent DCP, and 1 to 2 parts of Hexamethylcyclotrisiloxane. The rubber provided by the invention is black rubber, is high in surface strength, good in ageing resistance, high in acid and alkali corrosion resistance, good in water resistance and high and low temperature resistance, high in tensile strength, good in mechanical property, and particularly suitable for serving as conductive bushing and conductive rubber shock absorption products.

Owner:滁州君越高分子新材料有限公司

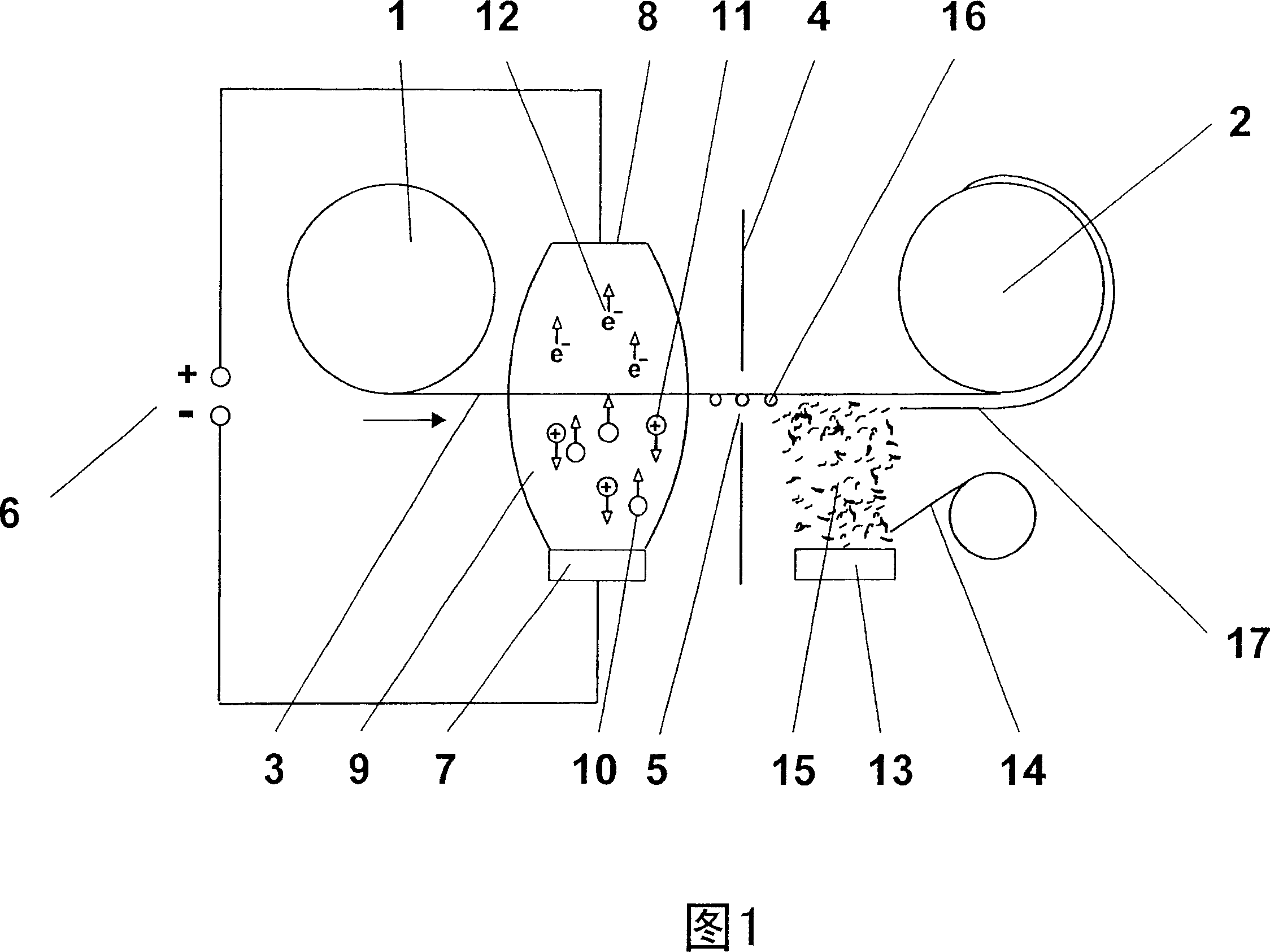

Wood board surface powder spraying treatment technology

InactiveCN106216208AImprove surface resistanceHigh surface quality of the coatingPretreated surfacesCoatingsCoated surfacePowder Spray

The invention provides a wood board surface powder spraying treatment technology. The wood board surface powder spraying treatment technology comprises the following steps of (1) carrying out primary sanding treatment on the surface of a wood board, (2) carrying out spraying with UV putty paint, (3) carrying out the first time of drying to solidify the UV putty paint sprayed in the step (2), (4) carrying out the second time of sanding treatment, (5) carrying out spraying with UV primer, (6) carrying out the second time of drying to solidify the UV primer sprayed in the step (5), and (7) carrying out one time or more than one time of powder spraying. A coating prepared with the wood board surface powder spraying treatment technology is good in surface resistance and high in surface quality; and the wood board surface powder spraying treatment technology has the advantages of being high in spraying speed, low in cost, high in the pass percent of prepared products and the like.

Owner:LITAI FURNITURE QINGYUAN

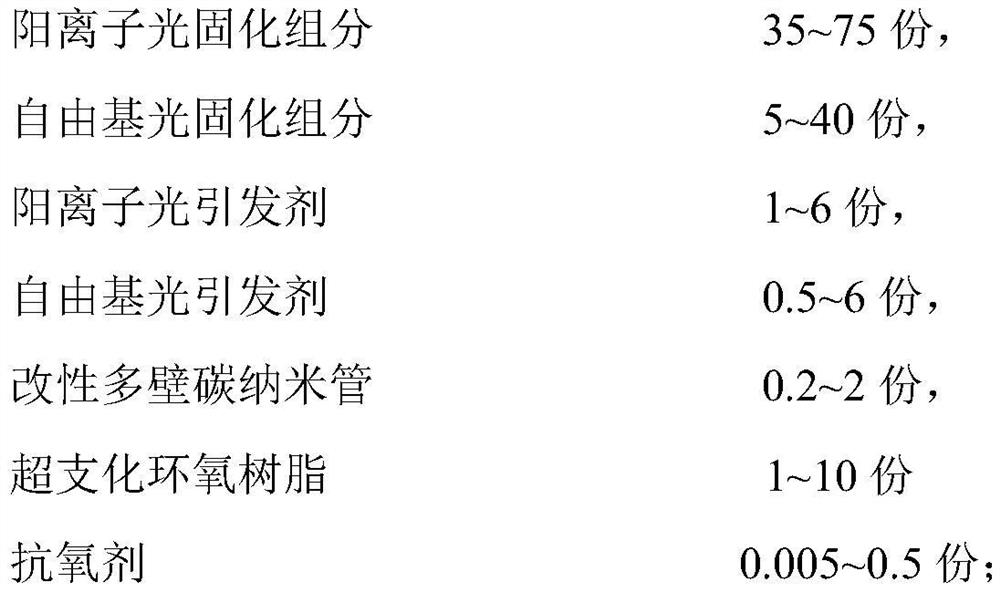

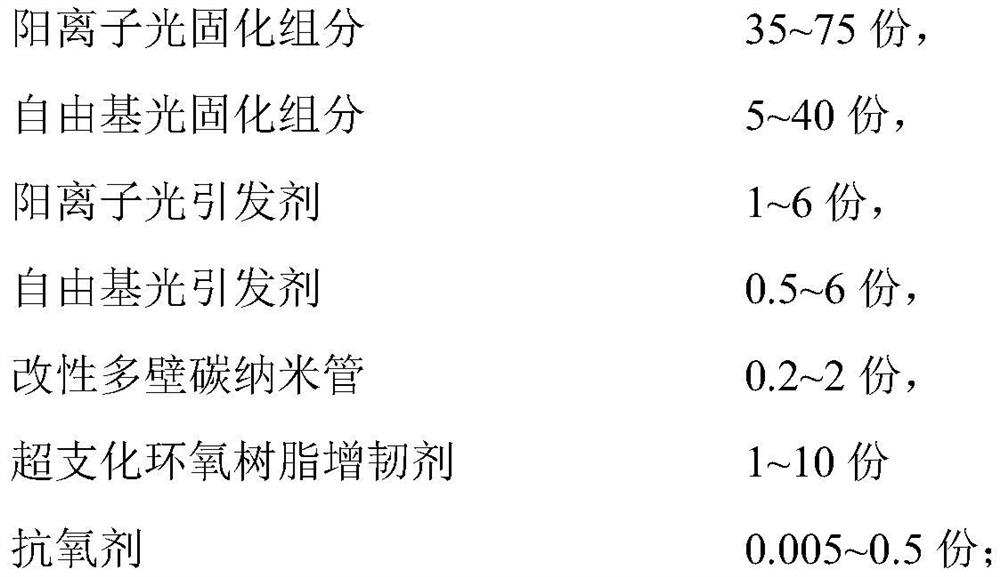

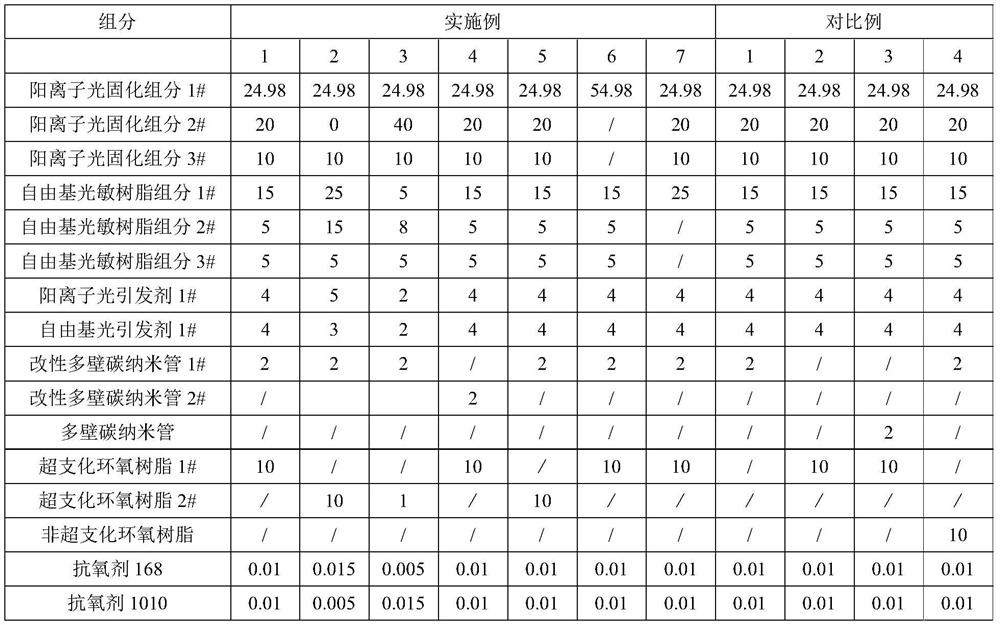

Antistatic photosensitive resin for photocuring rapid prototyping and preparation method and application thereof

ActiveCN112679677AImprove antistatic performanceLow viscosityAdditive manufacturing apparatusPhotoinitiatorElectrically conductive

The invention relates to antistatic photosensitive resin for photocuring rapid forming and a preparation method and application thereof. The antistatic photosensitive resin comprises a cationic photocuring component, a free radical photocuring component, a cationic photoinitiator, a free radical photoinitiator, a modified multi-walled carbon nanotube, hyperbranched epoxy resin and an antioxidant. The antistatic photosensitive resin provided by the invention has the advantages of better antistatic effect, low viscosity, extremely low conductive agent addition amount, better photocuring activity of a resin system, excellent mechanical properties of a resin curing material, good toughness, uniform resistance value, and good surface precision and dimensional stability of a printed piece, and the surface resistance value of a cured product is lower than 10<9> ohms.

Owner:SUN YAT SEN UNIV

Compound radiating coating

InactiveCN103773122AImprove the level ofImprove surface resistancePowdery paintsEpoxy resin coatingsEpoxyIsooctyl acrylate

The invention discloses a compound radiating coating which is prepared from the following raw materials in parts by weight: 100-105 parts of high density polyethylene, 10-13 parts of E-44 epoxy resin, 1-2 parts of trimethyl hexamethylene diamine, 1-2 parts of powdered aluminum, 0.3-0.5 part of 8-copper hydroxyquinoline, 1-2 parts of phthalic anhydride, 1-2 parts of dodecyl trimethyl ammonium chloride, 3-5 parts of stalactite powder, 5-8 parts of marble powder, 3-5 parts of isooctyl acrylate, 0.3-0.4 parts of potassium zirconium carbonate, 3-4 parts of calcium stearate, 1-2 parts of pine tar and 7-11 parts of modified filler. The radiating coating disclosed by the invention uses polyethylene and epoxy resin mixed as a main material, so that the leveling property and surface resistance of the coating are improved. The coating further has a certain effect on improving the impact resistance, and is excellent in comprehensive performance and strong radiation.

Owner:WUHU BAOYI AMUSEMENT EQUIP

Titanium sol modified geogrid and production method thereof

InactiveCN106117714APromote oxidation chain reactionReduce free radical contentMicrocrystalline waxAntioxidant

The invention discloses a titanium sol modified geogrid, which is composed of the following raw materials in parts by weight: aluminum nitride powder 2-3, polypropylene imine 10-17, tert-butyl acrylate 6-8, Lithium aluminum hydride 0.1‑0.3, 4‑dimethylaminopyridine 0.3‑1, antioxidant 10100.4‑1, multi-walled carbon nanotubes 10‑15, antioxidant 1680.6‑1, high density polyethylene 140‑160, lignin Sodium sulfonate 1‑2, butyl benzyl phthalate 4‑7, dibasic lead phosphite 0.04‑0.1, triethanolamine 1‑2, microcrystalline paraffin 3‑4, silane coupling agent kh5600.6‑1 , Tetrabutyl titanate 3‑4. The combination of antioxidant 1010 and antioxidant 168 added in the present invention can eliminate alkyl free radicals, peroxyl free radicals, alkoxyl free radicals and hydroperoxides, and greatly reduce the freedom to participate in polymer autooxidation chain reactions. The base content can delay the oxidative degradation process of the polymer and improve the oxidation resistance of the finished material.

Owner:ANHUI JIEAOMAKE SYNTHETIC MATERIAL TECH

Rare earth containing aqueous polyester coating and preparation method thereof

InactiveCN106010214ASmall free volumeIncreased weight loss temperatureFireproof paintsAntifouling/underwater paintsPolyesterRare earth

The invention discloses a rare earth containing aqueous polyester coating which comprises the following raw materials in parts by weight: 0.5-1 part of alkenyl succinate, 0.07-0.1 part of lanthanum nitrate, 0.01-0.02 part of cerous nitrate, 1-2 parts of polyvinylidene fluoride, 35-40 parts of rosin, 8-10 parts of fumaric acid, 6-7 parts of a 20-30% sodium hydroxide solution, 20-34 parts of ethylene glycol, 0.1-0.2 part of antimonous oxide, 2-3 parts of antimonous oxide, 13-20 parts of zinc chloride, 80-90 parts of polyether glycol, 100-130 parts of toluene diisocynate, 2-3 parts of 2,2-dimethylolpropionic acid, 4-5 parts of diethylene glycol, 1-2 parts of triethylamine, 0.2-0.4 part of 2-mercapto benzimidazole, 0.6-1 part of polydimethylsilane, 6-7 parts of N-methyl pyrrolidone, 2-3 parts of calcium palmitate and 0.5-1 part of ethylene bis stearamide. Due to adoption of lanthanum nitrate, cerous nitrate and the like in the rare earth containing aqueous polyester coating, the surface resistance of a finished product can be effectively improved.

Owner:BENGBU ZHENGYUAN ELECTRONICS TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com