PU black foam double-sided tape material

A double-sided tape, black technology, applied in the direction of adhesives, film/flake adhesives, etc., can solve the problems of affecting the visual effect of the client, light leakage, etc., to achieve superior light leakage improvement, excellent adhesion, die-cutting Excellent processing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

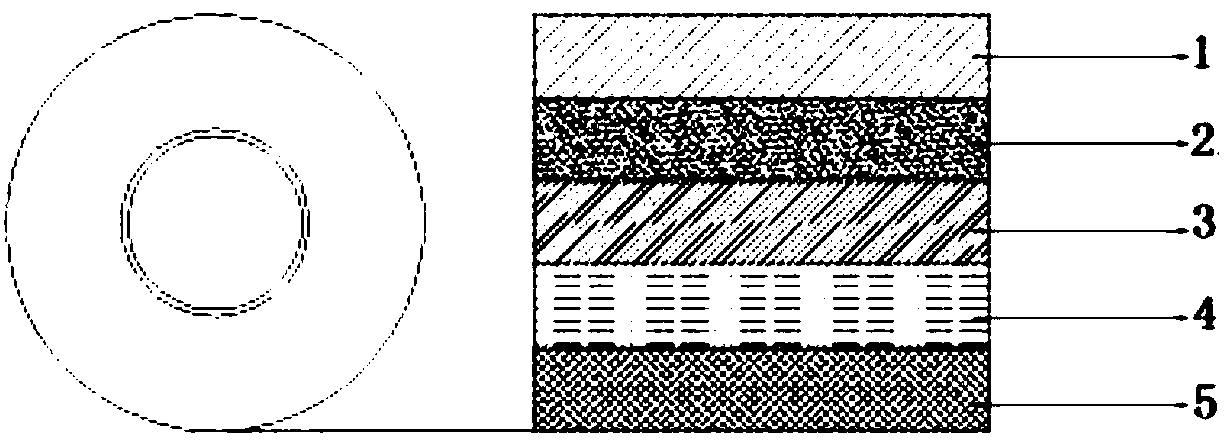

[0026] like figure 1 As shown, a PU black foam double-sided tape material consists of an easy-to-pull adhesive material layer, a foam layer, an ultra-thin black PET substrate layer, a light-shielding adhesive material layer, and a double-silicon PET release film substrate layer. Layered and arranged in sequence from top to bottom and bonded to each other to form. The easy-to-pull viscose material layer is a base layer of pure natural rubber glue. The light-shielding adhesive material layer is an acrylic glue base layer. The foam layer is a PU black foam foam substrate layer. A PU foam foam base material layer 2 is arranged between the natural rubber glue base material layer 1 and the ultra-thin black PET base material layer 3, and the ultra-thin black PET base material layer 3 and the double silicon There is an acrylic glue substrate layer 4 between the PET release film substrate layers 5; the material name and material number are TYBK-T-046; the total material thickness is...

Embodiment 2

[0029] A PU black foam double-sided tape material consists of an easy-to-pull adhesive material layer, a foam layer, an ultra-thin black PET substrate layer, a light-shielding adhesive material layer, and a double-silicon PET release film substrate layer from top to bottom. The layers are stacked and arranged to be bonded to each other. The easy-to-pull viscose material layer is a base layer of pure natural rubber glue. The light-shielding adhesive material layer is an acrylic glue base layer. The foam layer is a PU black foam foam substrate layer. The material name is TYBK-T-066; the total thickness of the material is 0.66mm, and the tolerance range is 10%.

[0030] 0024 Wherein, the thickness of the natural rubber glue base material layer 1 is 0.20mm; the thickness of the PU black foam foam base material layer 2 is 0.40mm; the thickness of the ultra-thin black PET base material layer 3 is 0.03mm; The thickness of the acrylic glue substrate layer 4 is 0.03mm; the thickness...

Embodiment 3

[0032] A PU black foam double-sided tape material consists of an easy-to-pull adhesive material layer, a foam layer, an ultra-thin black PET substrate layer, a light-shielding adhesive material layer, and a double-silicon PET release film substrate layer from top to bottom. The layers are stacked and arranged to be bonded to each other. The easy-to-pull viscose material layer is a base layer of pure natural rubber glue. The light-shielding adhesive material layer is an acrylic glue base layer. The foam layer is a PU black foam foam substrate layer. The material name is TYBK-T-086; the total thickness of the material is 0.86mm, and the tolerance range is 10%.

[0033] 0026 wherein, the thickness of the natural rubber glue base material layer 1 is 0.25mm; the thickness of the PU black foam foam base material layer 2 is 0.55mm; the thickness of the ultra-thin black PET base material layer 3 is 0.03mm; The thickness of the acrylic glue substrate layer 4 is 0.03mm; the thickness...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com