Transverse shearing interferometer agglutination checking method

A technology of transverse shearing and detection method, which is applied in the field of gluing detection of transverse shearing interferometer, can solve the problem that the lateral shearing amount of transverse shearing interferometer is difficult to control accurately, achieve convenient optical path adjustment and calibration, and reduce interpretation Error, the effect of improving control accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

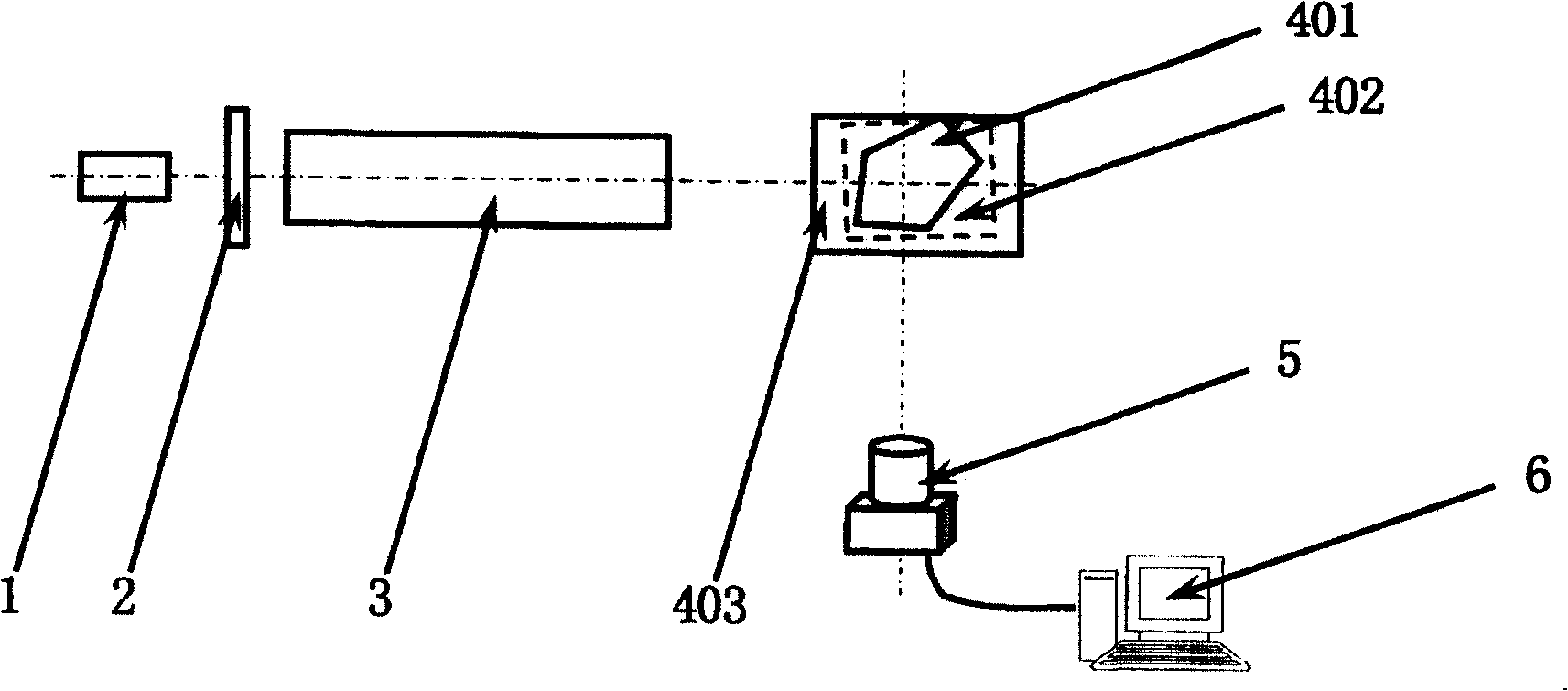

[0040] The principle of the invention: the gas laser has the characteristics of high collimation and high monochromaticity. The laser output from the gas laser enters the transverse shearing interferometer after beam expansion, and quasi-monochromatic interference fringes with high contrast can be obtained. For the convenience of fringe reading, each interference fringe is collected with no less than 5 CCD pixels.

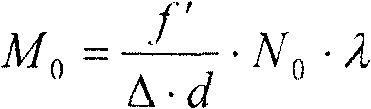

[0041] Suppose: the laser wavelength is λ, the focal length of the digital camera is f′, the CCD pixel size is d, and the number of interference fringes is N 0 , N 0 The number of CCD pixels occupied by each interference fringe is M 0 ;

[0042] Then the shear amount is calculated by the formula: Δ = f ′ M 0 · d · N 0 · λ , ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com