Antistatic photosensitive resin for photocuring rapid prototyping and preparation method and application thereof

A photosensitive resin, antistatic technology, used in the field of 3D printing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0062] Among them, in the preparation process of modified multi-walled carbon nanotube 1#, hyperbranched epoxy resin HyPerE102 was selected; in the preparation process of modified multi-walled carbon nanotube 2#, hyperbranched epoxy resin HyPerDE1050 was selected.

[0063] The antistatic photosensitive resins of the various embodiments of the present invention and comparative examples are prepared through the following processes: cationic photocurable components, free radical photocurable components, cationic photoinitiators, free radical photoinitiators, modified multi-walled carbon nanotubes Stir and mix with antioxidant at 25°C for 60 minutes to obtain.

[0064] Wherein, the test method of each performance index of each embodiment and comparative example is as follows:

[0065] 1) Critical exposure energy E c and curing depth D p The test: using the SLA 3D printer, in the known laser power P L , laser scanning interval h s case, using different laser scan rates V s , f...

Embodiment 1~7 and comparative example 1~5

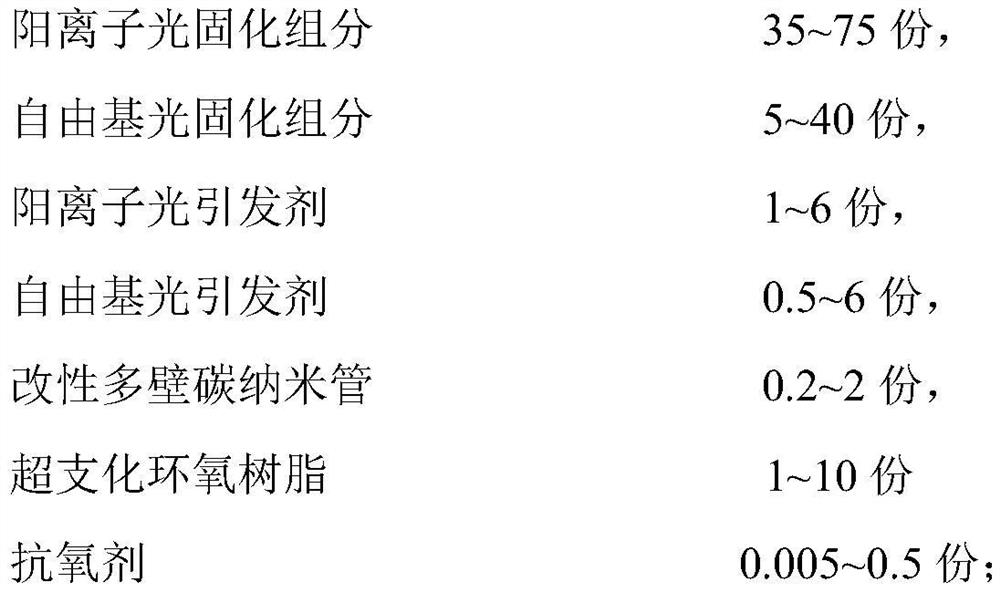

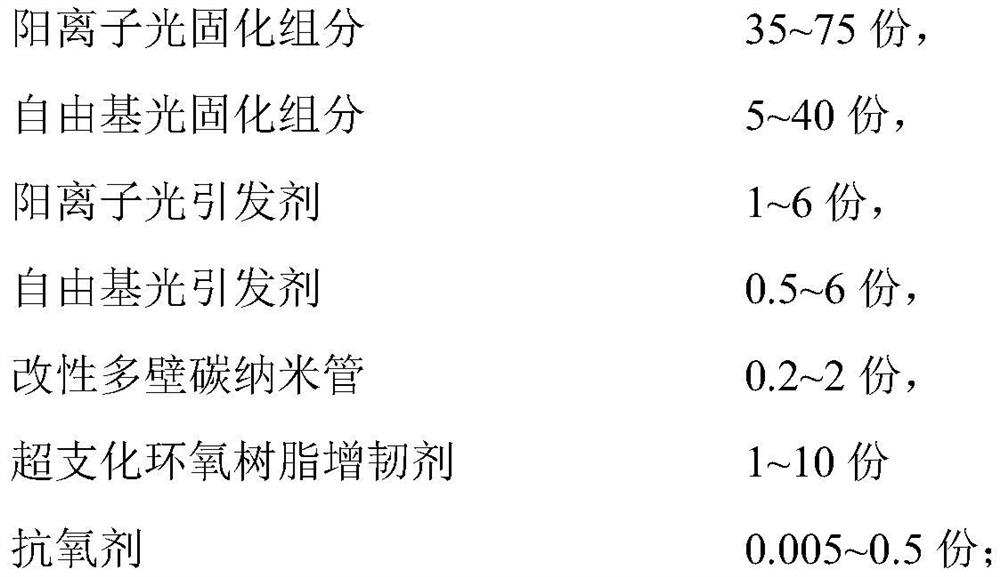

[0075] The present embodiment and comparative example provide a series of antistatic photosensitive resins, the formulations of which are listed in Table 1 below.

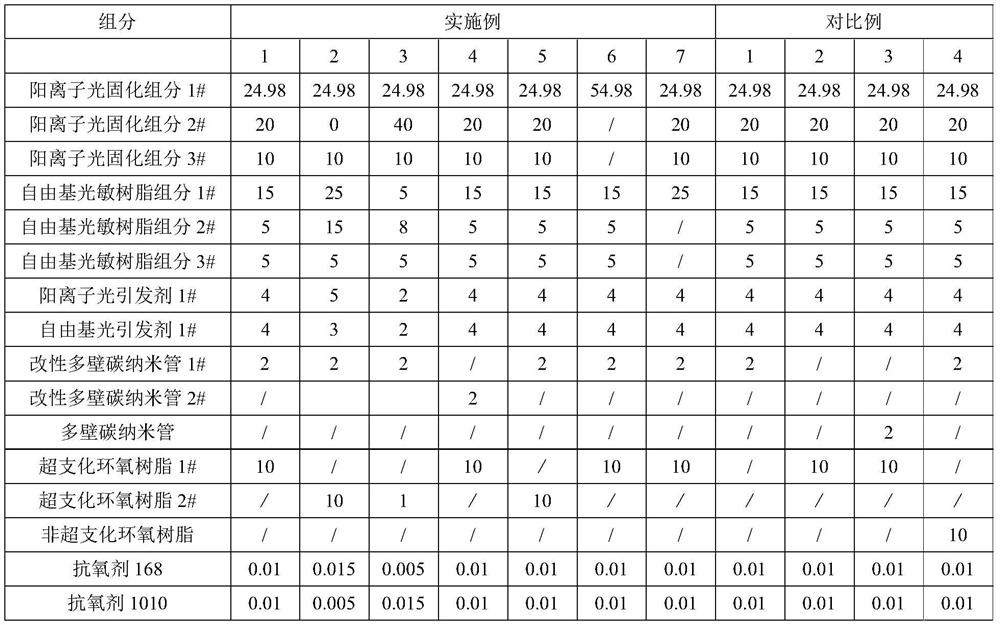

[0076] The formula (part) of table 2 embodiment 1~7 and comparative example 1~4

[0077]

[0078] In addition, a commercially available white material was used as Comparative Example 5.

[0079] According to the method mentioned above, the properties of the antistatic photosensitive resins of the various examples and comparative examples were measured, and the results are shown in Table 2.

[0080] The performance test result of each embodiment and comparative example of table 2

[0081]

[0082] It can be seen from Table 2 that the antistatic photosensitive resin provided by each embodiment of the present invention has a good antistatic effect under the addition of a very low conductive agent, and the surface resistance value of the cured product is far lower than 10 9 Ω, low viscosity, excellent mechanica...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Surface resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com