Wood board surface powder spraying treatment technology

A treatment process and surface coating technology, which is used in devices for coating liquids on surfaces, pretreatment surfaces, coatings, etc., and can solve problems such as low surface resistance, wood damage, and liquid penetration.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

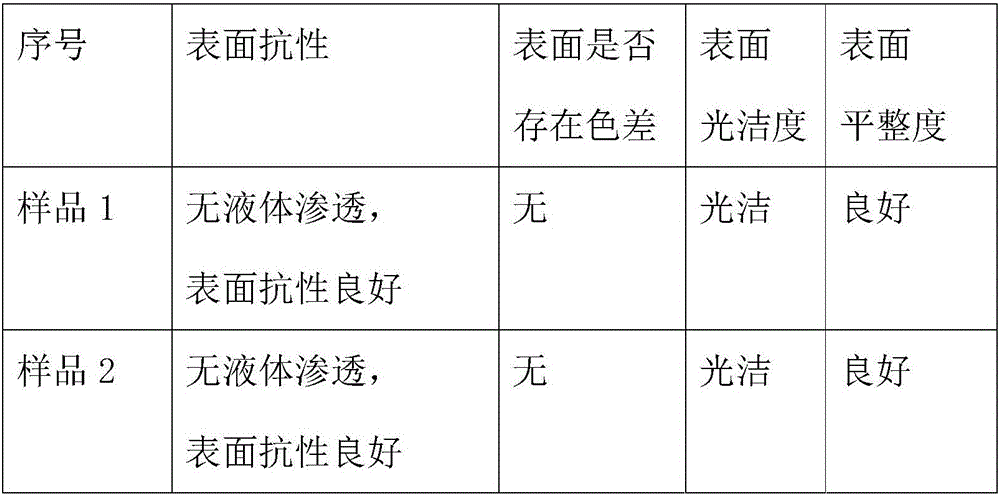

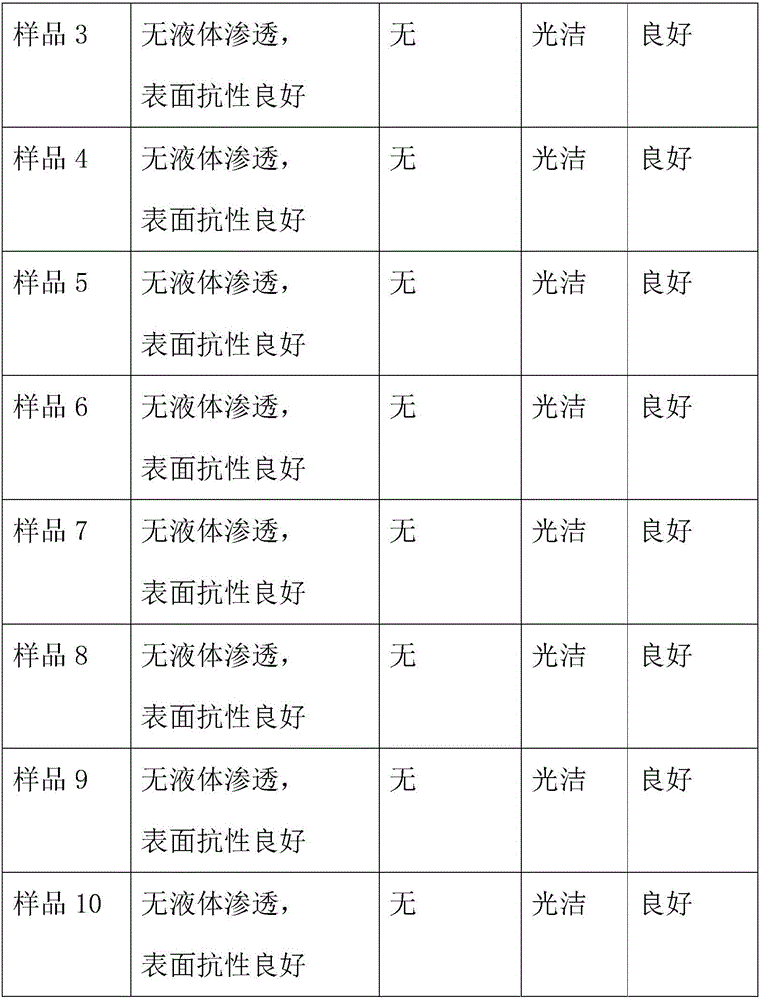

Examples

Embodiment 1

[0072] A powder spraying treatment process on the surface of a wood panel is carried out through the following steps:

[0073] A, Carry out primary sanding treatment on the surface of the wood panel;

[0074] B, using UV putty paint for coating;

[0075] C, carry out drying for the first time and make the UV putty paint that step B is coated solidify;

[0076] D, carry out the second sanding treatment;

[0077] E, using UV primer for coating;

[0078] F, carry out drying for the second time to cure the UV primer coated in step E;

[0079] G, carry out one or more powder spraying.

[0080] In the surface powder spraying treatment process of the wood panel, the surface of the wood panel is first coated with UV putty paint and UV primer, and then powder sprayed. The UV layer is formed by coating the UV putty paint and the UV primer, the surface of the prepared plate has no defects such as pinholes and cracks, and the surface resistance test performance is good.

[0081] The...

Embodiment 2

[0083] A powder spraying treatment process on the surface of a wood panel is carried out through the following steps:

[0084] A. Use 240#~320# abrasive belts to perform primary sanding treatment on the surface of the wood panel.

[0085] B. Heat the UV putty paint to 15-20°C and then apply it. The specific process is as follows:

[0086] Use UV putty paint according to the first coating direction, coating 10 ~ 15g / m 2 The first putty paint layer, the thickness of the first putty paint layer is 5-7 μm; stop for 2-5 minutes after the first putty paint layer is coated;

[0087] Then use UV putty paint to apply 13-25g / m on the surface of the first putty paint layer according to the second coating direction 2 The second putty paint layer, the thickness of the second putty paint layer is 5-10 μm; stop for 2-5 minutes after the second putty paint layer is coated;

[0088] Then use UV putty paint to apply 20-35g / m on the surface of the second putty paint layer according to the thi...

Embodiment 3

[0106]A kind of surface powder spraying treatment process of wood panels, other features are the same as embodiment 2, the difference is: in the process of carrying out UV putty paint coating in the step B, keep the ambient temperature as 15~20 ℃, at this ambient temperature Under the circumstances, during the UV putty coating process, the pits on the surface of the board are in the best state, and the bonding method of the UV putty on the surface of the board is the best. The coated UV putty can seal the vacuum on the surface and avoid all Defects such as vacuum appear on the surface of the prepared coating. At the same time, in this environment, the performance of UV putty is also at its best.

[0107] During the process of coating the UV primer in step E, keep the ambient temperature at 15-20°C. Under this ambient temperature, the UV primer and the UV putty layer can be effectively bonded, and the surface of the formed UV primer layer is smooth without through holes, crack...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com