Patents

Literature

143 results about "Molding (decorative)" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Moulding (also spelled molding in the United States though usually not within the industry), also known as coving , is a strip of material with various profiles used to cover transitions between surfaces or for decoration. It is traditionally made from solid milled wood or plaster, but may be of plastic or reformed wood. In classical architecture and sculpture, the molding is often carved in marble or other stones.

Three-dimensional high simulation ceramic tile with matte glaze surface and preparation method thereof

ActiveCN108727037AExtended service lifeGood three-dimensionalCeramic shaping apparatusAdobeComputer printing

The invention discloses a three-dimensional high simulation ceramic tile with matte glaze surface and a preparation method thereof, the method comprising the following steps: 1) adopting a laser four-dimensional fine carving system to finely carve a digital mold; 2) Positively pressing green body molding; 3) Controlling the water absorption rate of the ceramic tile before glazing at 15%-20% by controlling the drying temperature of the ceramic tile adobe or the biscuiting temperature of the ceramic tile adobe; 4) spraying a small amount of high-titanium impervious ground coat under high pressure; 5) spraying a small amount of matte glaze under high pressure; 6) using a digital ink jet printer to print decorative ink and functional ink; 7) decorating the dry particle frit, and adopting a controllable negative pressure absorbing dry particle frit equipment to absorb excess dry particle frit; 8) sintering to obtain the three-dimensional high imitation ceramic tile with matt glaze surface,the preparation method provided by the invention obtains the three-dimensional high simulation ceramic tile with matte glaze surface with three-dimensional simulation, 2-6 glossy units of glaze surface gloss and lifelike surface decoration effect through the collaborative and innovative preparation including mold sculpture, glaze formula control, high-pressure glaze spraying and effect decoration.

Owner:广东协进陶瓷有限公司

Artificial stone with irregular pore and preparation method thereof

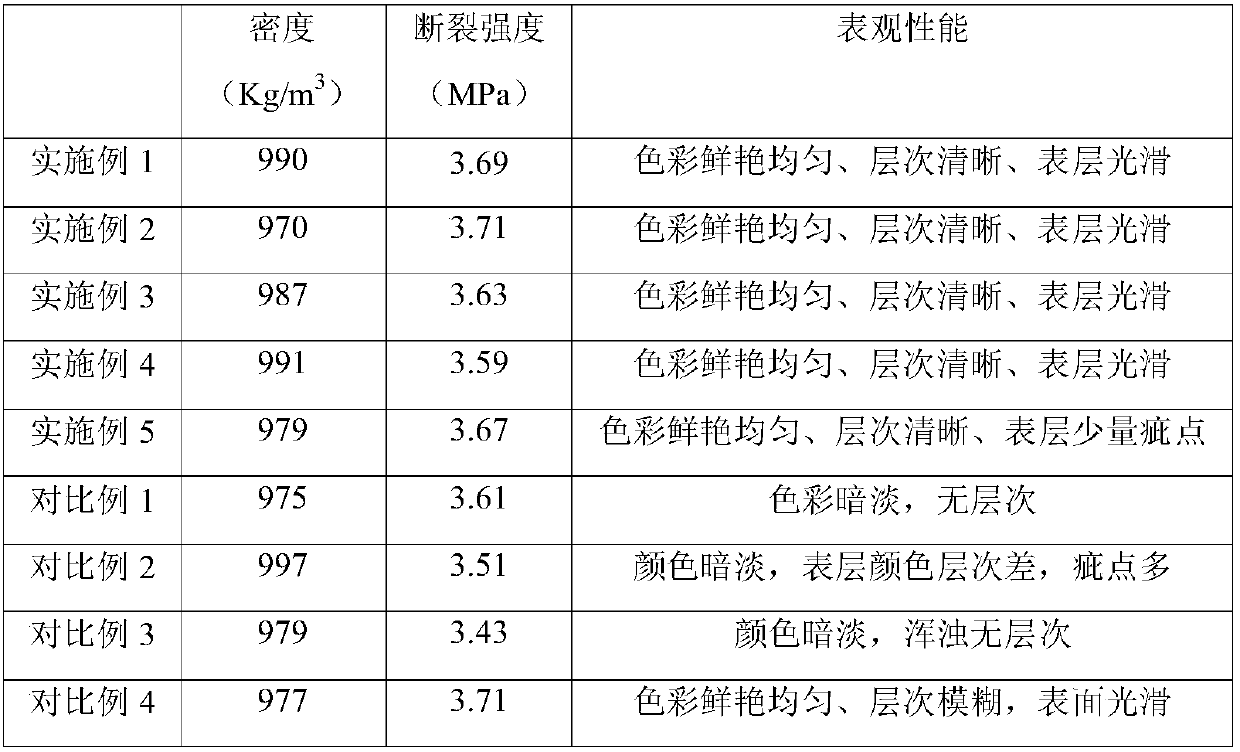

The invention provides an artificial stone with irregular pores and a preparation method thereof. The artificial stone composed of a cementitious material, a pore forming agent and a thickener is prepared by the following method: preparing a slurry; casting the prepared slurry in a mould; and vibrating for molding in a vibration table. Compared with the natural stone, the artificial stone with irregular pores provided by the invention has the advantages of low cost, multiple effect changes, environment-friendliness, no radiation, low density, excellent thermal insulation, sound insulation and refractory properties, and good mechanical property; and the artificial stone with irregular pores has strong durability and color stability in all kinds of weather conditions, and is an ideal decorative material.

Owner:SHANGHAI APE STONE

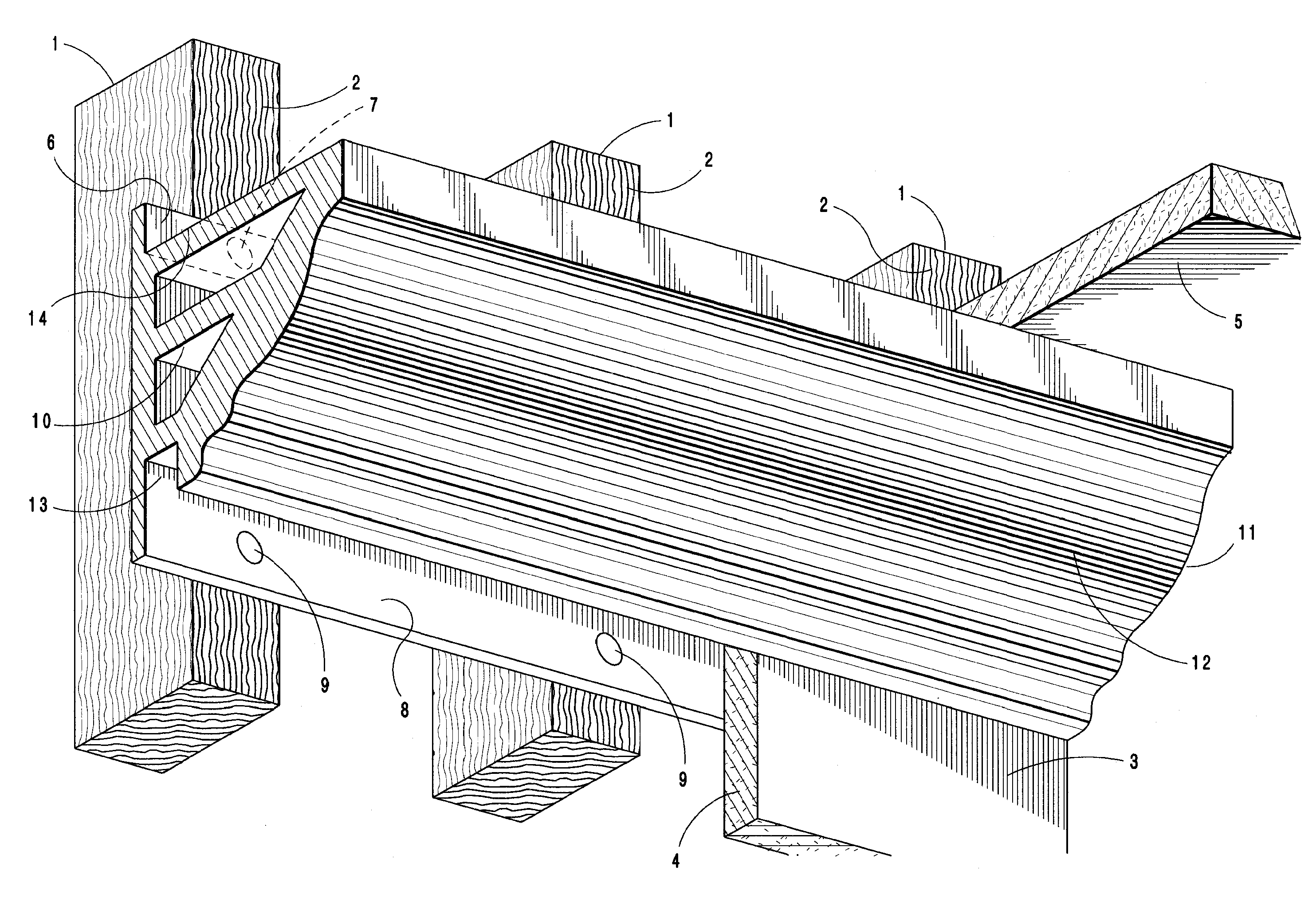

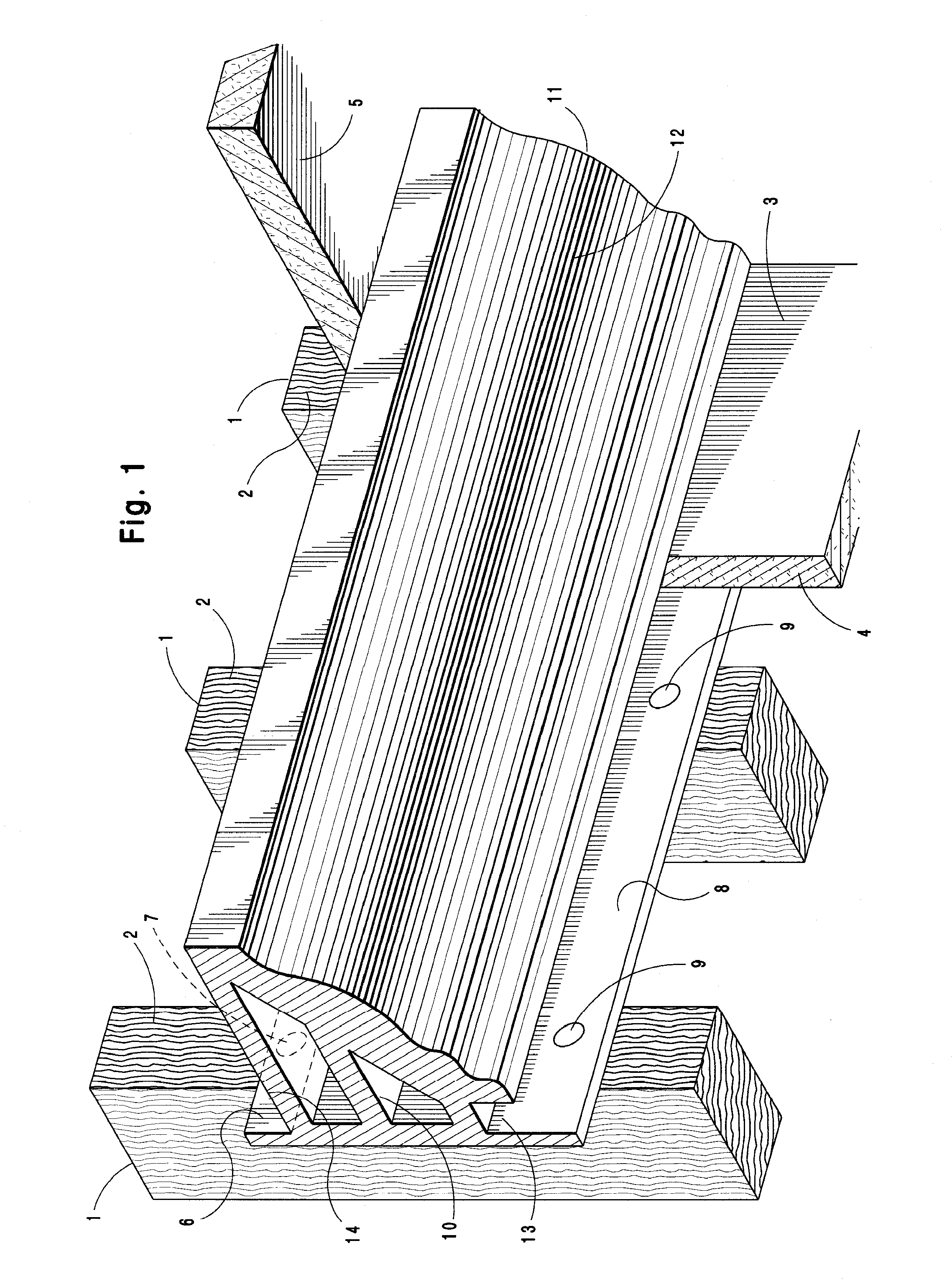

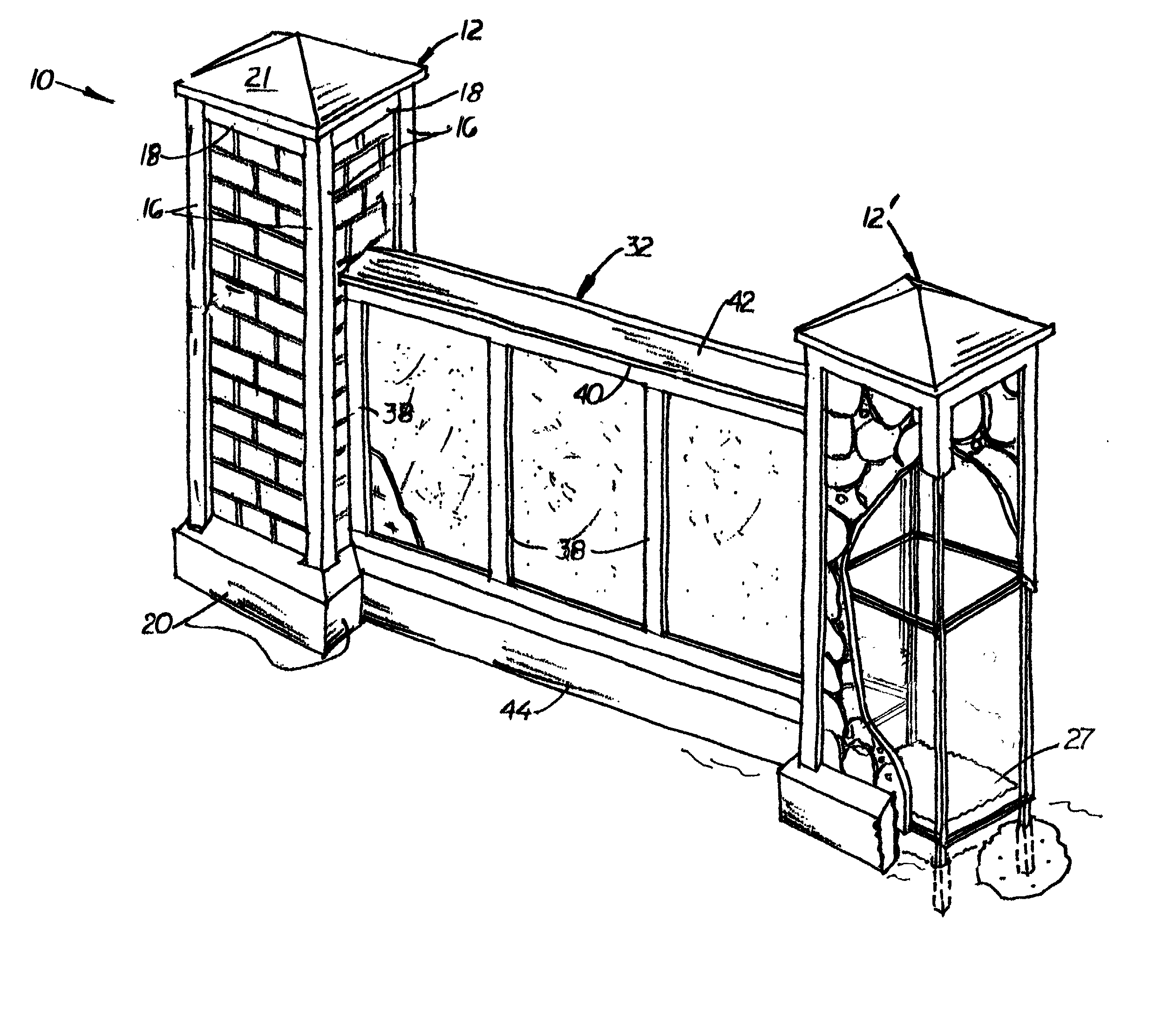

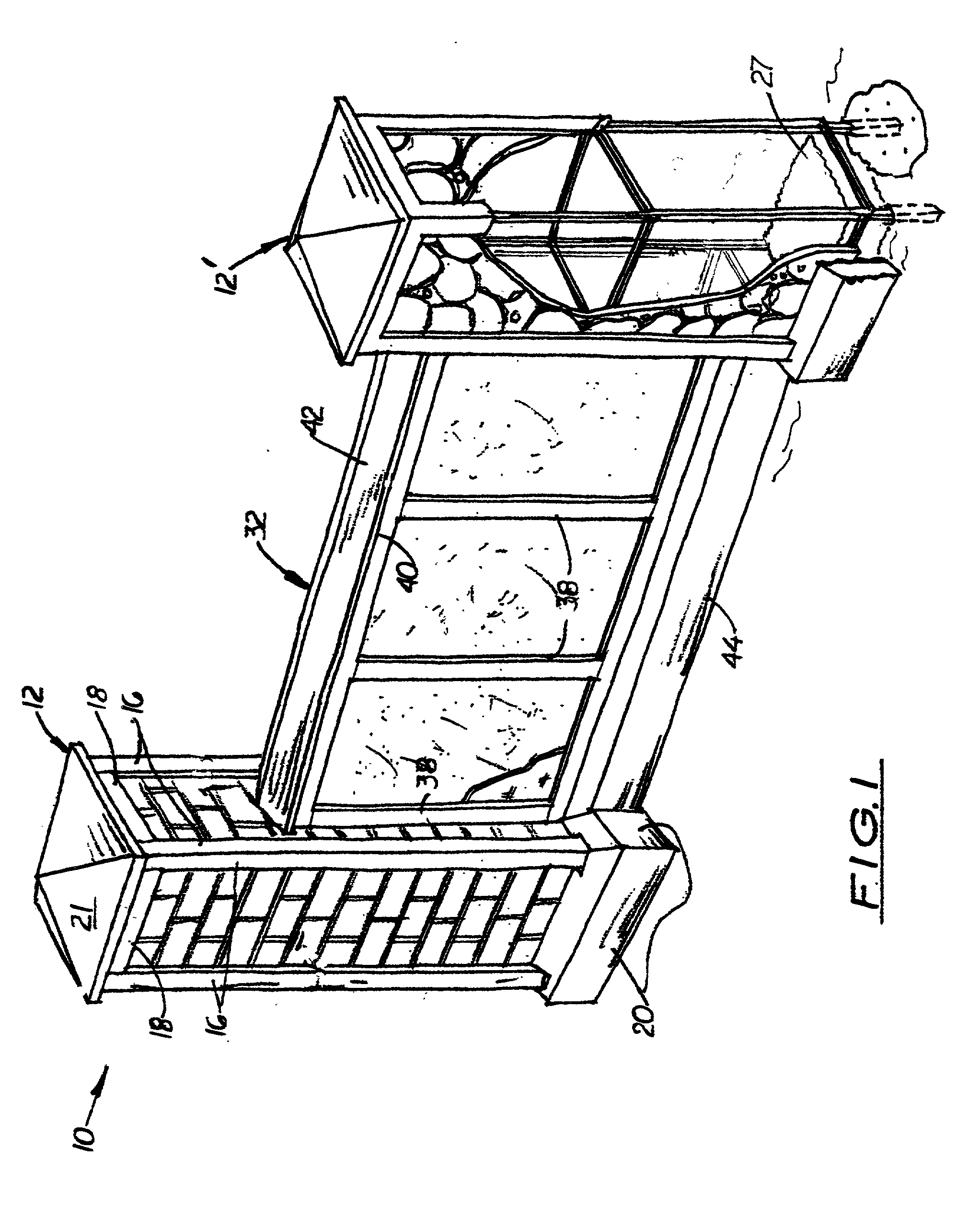

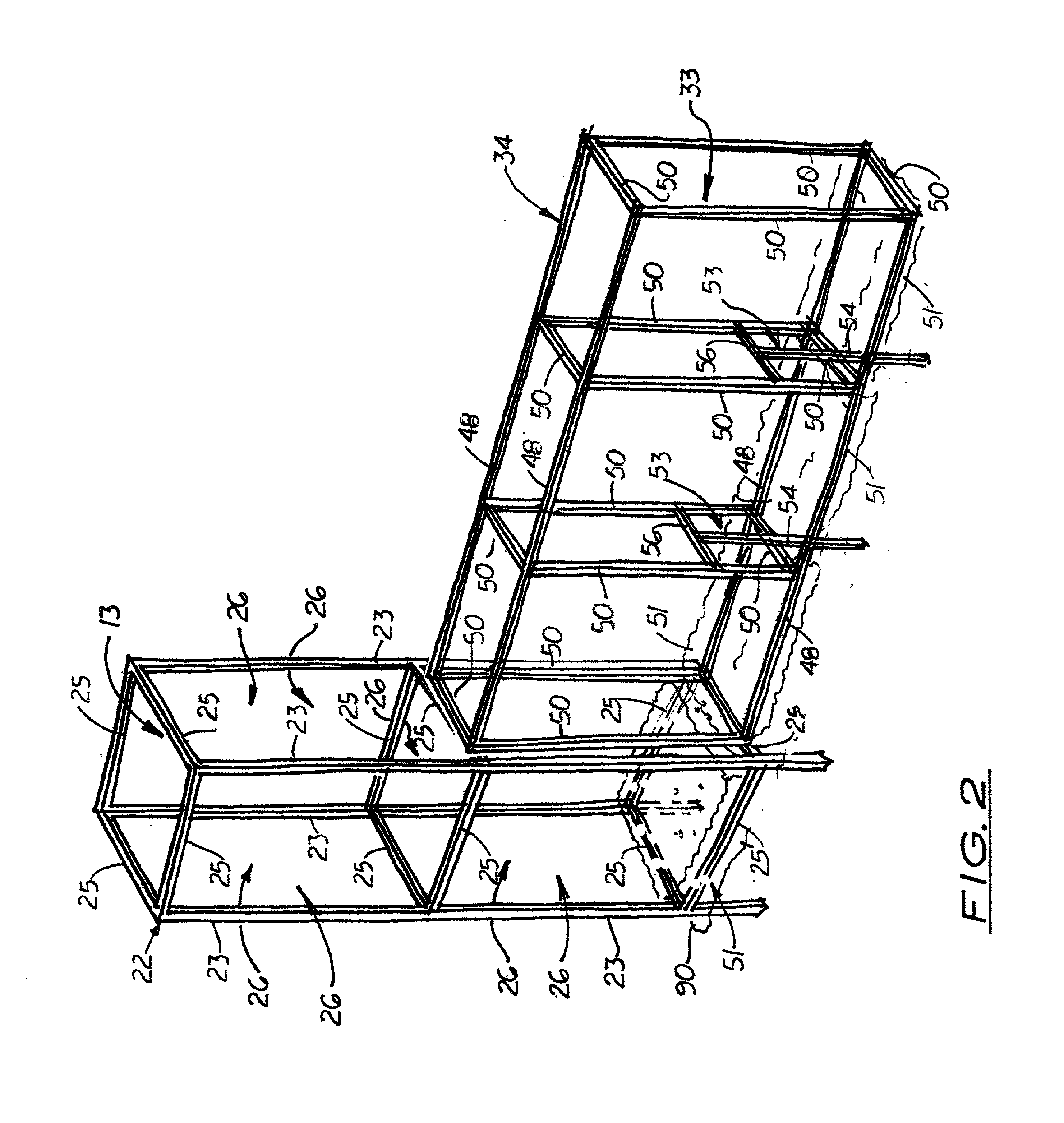

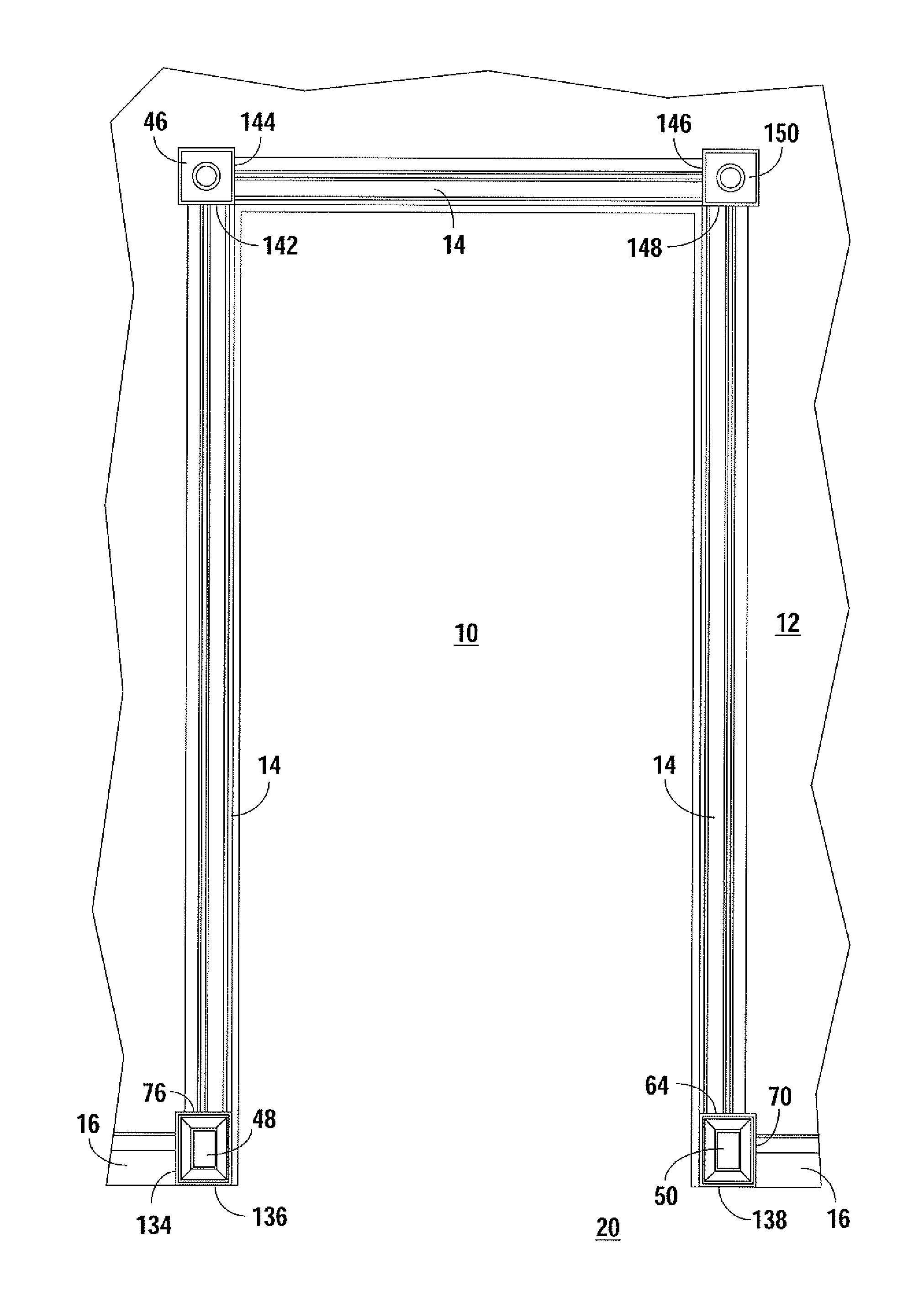

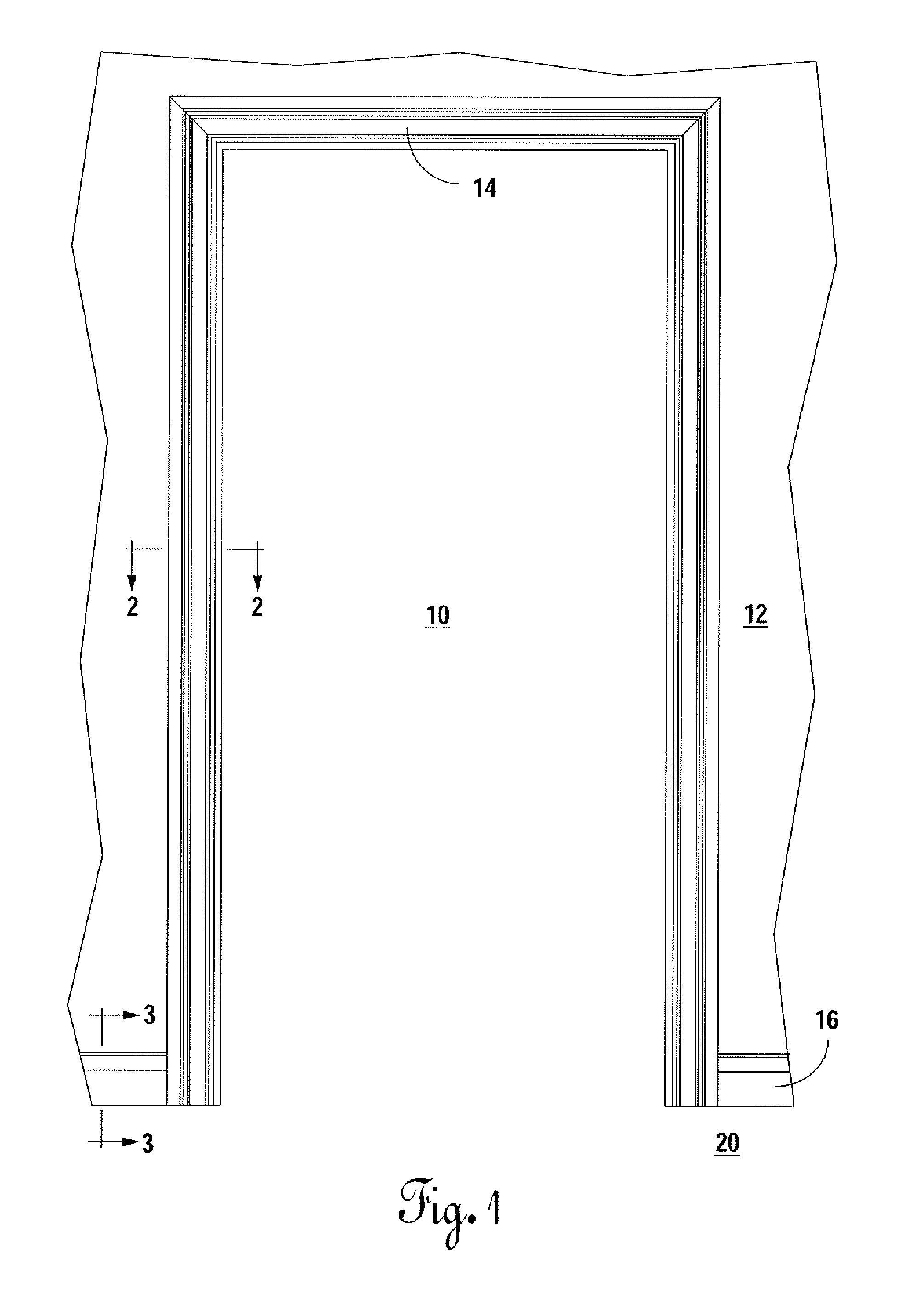

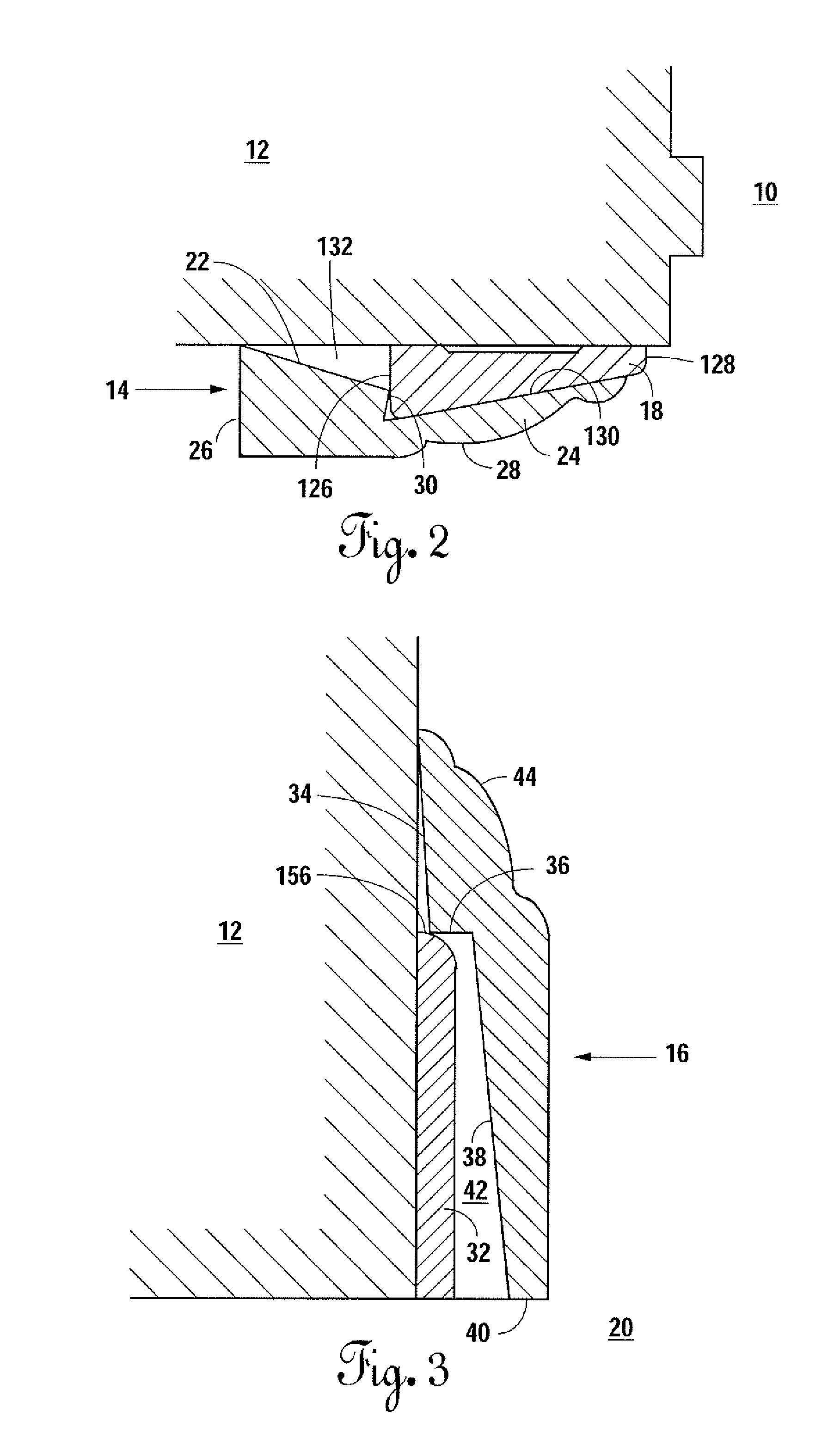

System and method for installation of decorative molding

ActiveUS7997043B1Improve rigidityAvoid assemblyCovering/liningsBuilding componentsInterior spaceEngineering

A molding system for use in interior spaces for use either with new construction or finished spaces, and in addition can be used with either a suspended ceiling or conventional ceiling, whereby the molding is incorporated with the wall and ceiling surfaces in such a manner that the joints with the ceiling and wall are plumb and being mounted such that the decorative molding surface of the molding can be installed in a finished form that does not require further finishing after installation.

Owner:MACMILLAN ROBERT +1

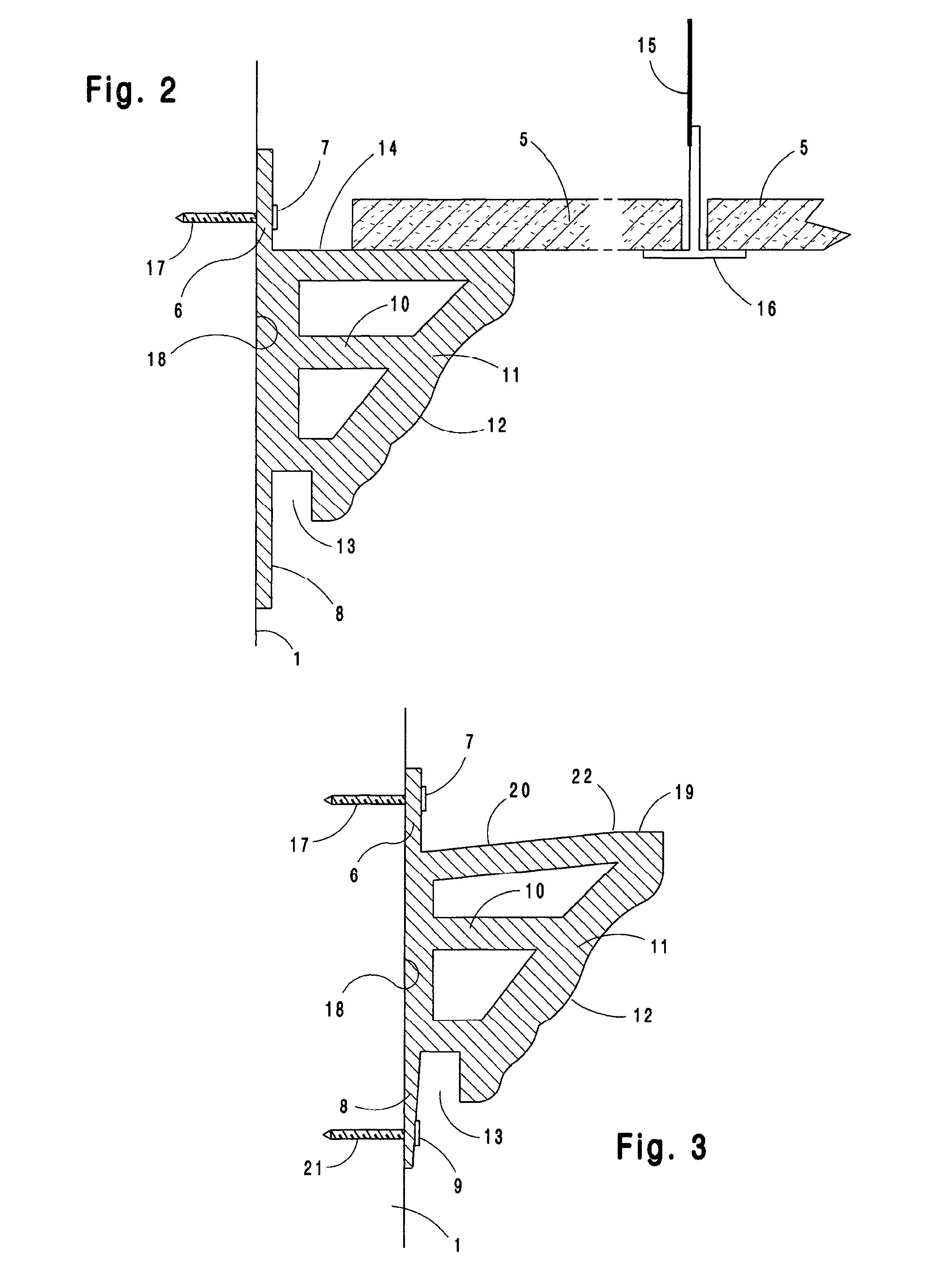

Full digitalization decorative porcelain polished tile and production method thereof

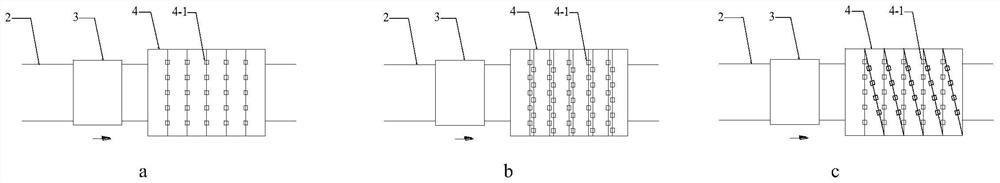

ActiveCN111168825ACaliber size controllableMake up for the missing partCeramic shaping apparatusCompression moldingMarking out

The invention discloses a full digitalization decorative porcelain polished tile and a production method thereof. The production method of the full digitalization decorative porcelain polished tile comprises the following steps of (a) preparing a porcelain polished tile green body base material and a porcelain polished tile green body surface material through a conventional method; (b) conductingmaterial distribution through a high-precision digitalization colorful material distribution system and a material distribution process; (c) conducting compression molding of a porcelain polished tilegreen body; (d) conducting sign marking on the texture of the porcelain polished tile green body compressed and molded in the step (c) through a sign marking device; (e) drying the porcelain polishedtile green body; (f) conducting sign marking recognition on the porcelain polished tile green body dried in the step (e) through a sign marking recognition device and then recognizing the texture ofthe green body; (g) spraying permeable ink; (h) drying the porcelain polished tile green body again; (i) firing the porcelain polished tile green body; and (j) conducting edge grinding to obtain the full digitalization decorative porcelain polished tile. Through the production method of the full digitalization decorative porcelain polished tile, the continuous overall texture is realized through accurate fixed-position and fixed-point quantitative application and distribution of colorful powder comprising multiple compositions; through combination of the sign marking and sign marking recognition process, a permeable ink jet pattern is accurately aligned, sprayed and printed on the surface of the green body, and perfect connection of the surface texture of the green body and the texture ofthe overall distributed material is realized; and the problems that in the decoration process, groove broaching, edge cutting or chamfering needs to be carried out on the surface of the porcelain polished tile, and the decoration effect is reduced and the aesthetic sense is affected due to inconformity of the surface texture of the porcelain polished tile and the color or texture of the green bodyare solved.

Owner:HANGZHOU NABEL CERAMIC +2

Solid-appearing fence system

A fencing system that has the appearance of having solid columns and panels made of concrete, brick, rock, or stucco, yet is substantially less expensive to construct. The system includes a plurality of hollow columns and hollow wall members, both with interior cages covered with thin, relatively inexpensive panels. The panels may be easily attached to the exposed surfaces of the interior cages. In one embodiment, the panels are made of concrete, which may be exposed or are sufficiently durable to be covered with soil-based materials, such as brick, rock, or stucco thereby creating the appearance that the entire fence is made of these materials. In another embodiment, the panels are made of lightweight foam with an aluminum sheet packing. The interior cage of the column includes a plurality of vertical legs, which during construction, are embedded into a concrete footing. The interior cage of the wall member is disposed and connected in an end-to-end manner to the interior cages of the two adjacent columns. A decorative cap or lighting fixture may be attached to the top of each column, and moldings may be attached to the sides and bottom edges to provide a more finished, attractive appearance. Also, decorative molding or bars may be added to the panels.

Owner:HAZAN AVSHALOM

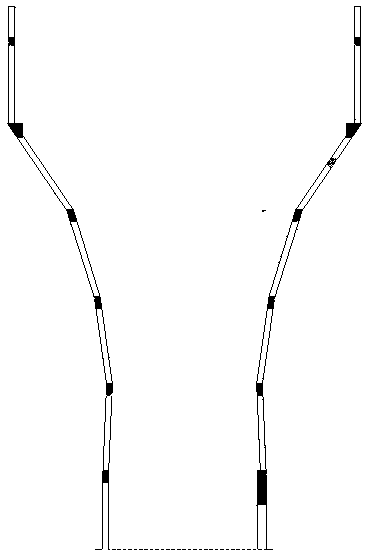

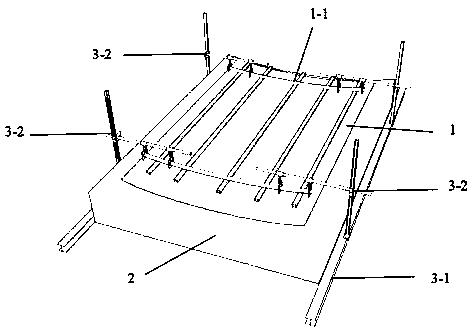

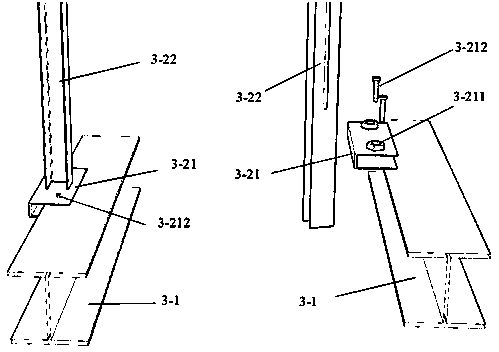

Precise molding method of spatial curved surface GRC curtain wall

ActiveCN111173175AAdvantages of precise forming methodsQuick buildWallsBuilding material handlingFiberSupporting system

The invention provides a precise molding method of a spatial curved surface GRC curtain wall. The method improves the molding precision, quality and safety guarantee of GRC curtain wall unit plates and reduces construction rework of a curtain wall, anchoring plate falling and other problems. The method is characterized by including the steps that 1, parameters of the GRC curtain wall unit plates are refined; 2, a mold and a back-attached steel frame are manufactured; 3, a support system is installed; 4, a positioning beam is mounted; 5, a mold release agent is sprayed; 6, a decorative layer issprayed; 7, the back-attached steel frame is mounted; 8, embedded parts are installed; 9, a fiber net is laid; 10, fiber mortar is sprayed; 11, maintaining is carried out; 12, demolding is performed.According to the method, the molding precision, quality and safety guarantee of the GRC curtain wall unit plates can be improved, and construction rework of the curtain wall, anchoring plate fallingand other problems can also be avoided.

Owner:SHANGHAI ERSHIYE CONSTR CO LTD +1

Base paint of litchi surface stone-like paint and preparation method of base paint

The invention relates to a base paint of a litchi surface stone-like paint and a preparation method of the base paint, and provides a litchi surface stone-like paint which has the advantages of natural stone-like effect, high hardness of a coating, strong water resistance, strong adhesion and weather resistance and a manufacturing method of the litchi surface stone-like paint. By improving the formula of the base paint and the manufacturing method of the base paint, the water resistance of the coating is greatly improved. The base paint provided by the invention has the beneficial effects of reasonable and unique formula, natural stone-like effect, high hardness of the coating, strong water resistance, strong adhesive force, good weather resistance, good anti-aging effect and the like. The preparation method provided by the invention has simple construction process flow and one-time spray molding and is easy to realize, the manpower is saved, the construction period can be greatly shortened, and the production efficiency is improved; and furthermore, the prepared stone-like paint has good quality and relatively good decorative effect.

Owner:SHANDONG HORIZON BUILDING ENERGY EFFICIENCY TECH CO LTD

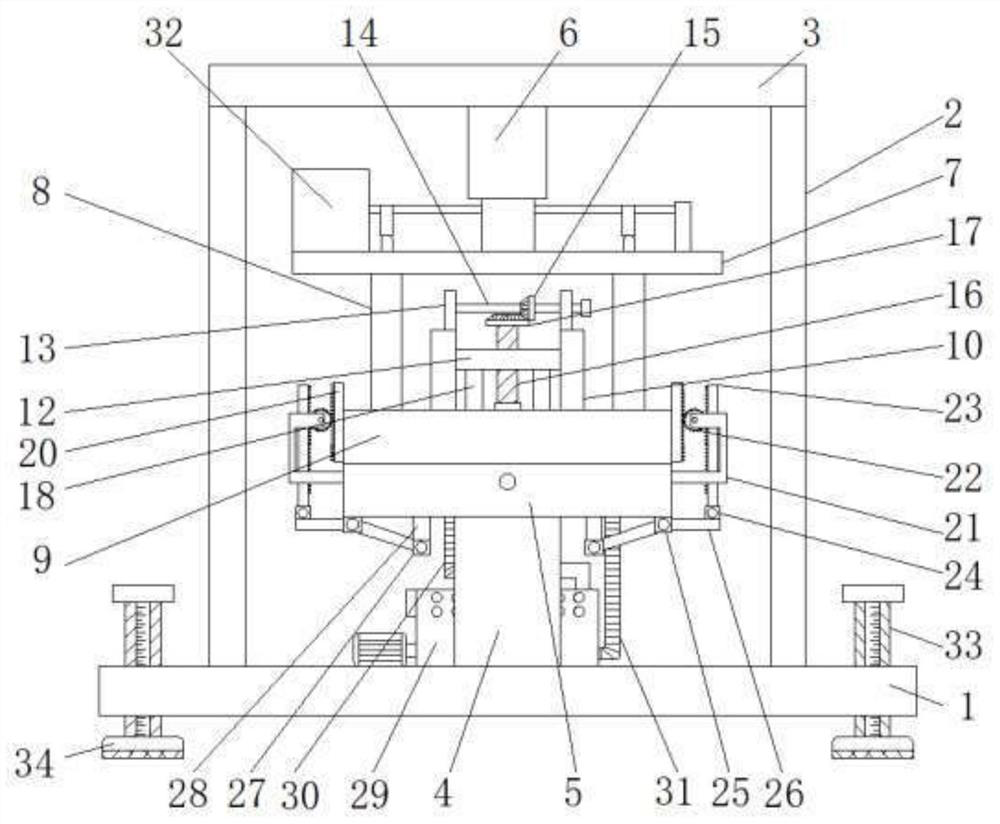

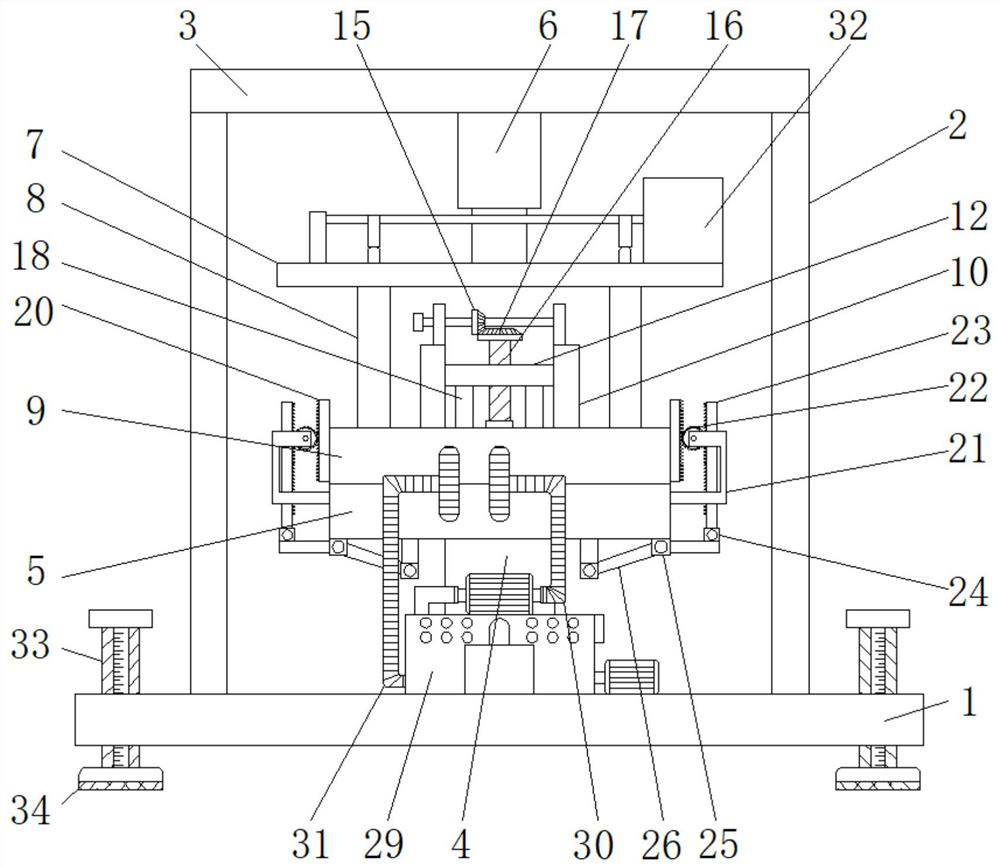

Adjustable mold for decorative materials

Owner:厦门魏姗颜市政工程有限公司

UHPC stone-like outer wall hanging plate and manufacturing process thereof

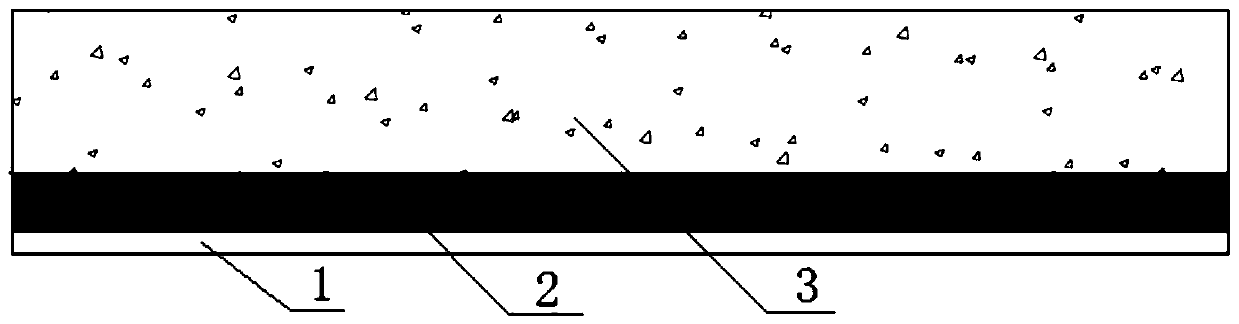

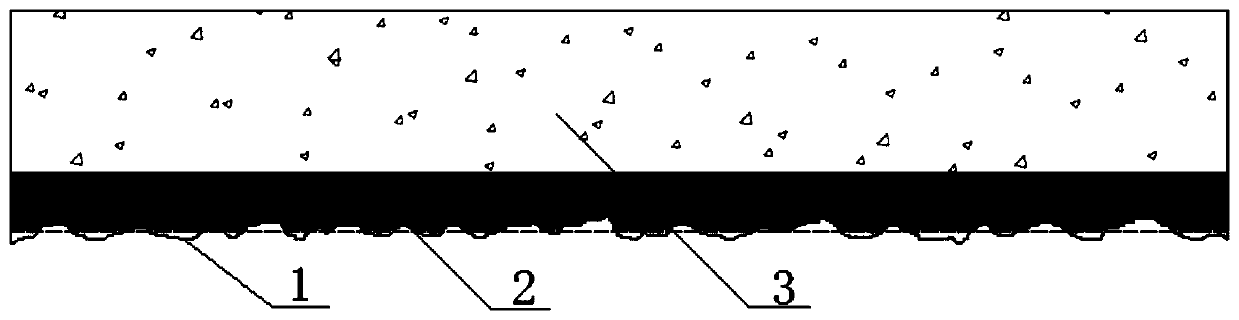

InactiveCN109989548AReduce energy consumptionReduce usageCovering/liningsCeramic shaping apparatusSlurryEngineering

The invention provides a UHPC stone-like outer wall hanging plate. The UHPC stone-like outer wall hanging plate comprises a first decorating layer, a second decorating layer and a structural layer which are sequentially arranged in a laminated mode, and are all made of UHPC mortar; the first decorating layer and the second decorating layer are different in color RGB value; and the surface of the second decorating layer is partially exposed out of the surface of the first decorating layer. The invention further provides a manufacturing process of the UHPC stone-like outer wall hanging plate. The manufacturing process comprises the following steps: S1, material blending is conducted; S2, first decorative layer slurry is poured; S3, second decorative layer slurry is poured; S4, structural layer slurry is poured and vibrated; S5, curing and forming is carried out; and S6, demolding is carried out, and treatment of one or a combination of two or more of shot blasting, chiseling, hammering,mincing and burning stripping is carried out. According to the technical scheme, the UHPA outer wall hanging plate adopts a double-decorative-layer structure form, inorganic pigments with different colors or different proportions are added, so that the tones of the two decorative layers are inconsistent, and various decorative effects can be provided for buildings.

Owner:筑友智造新材有限公司

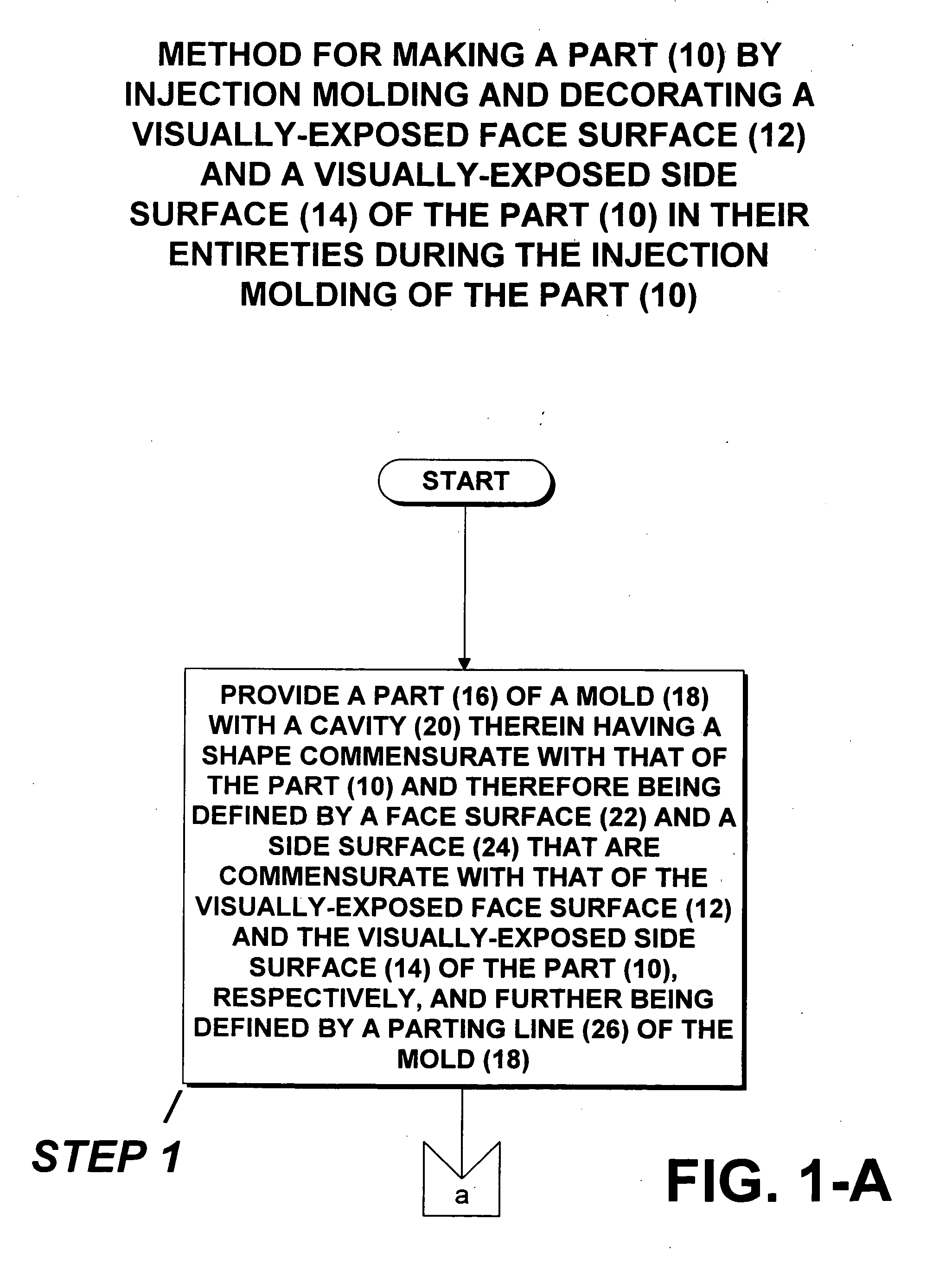

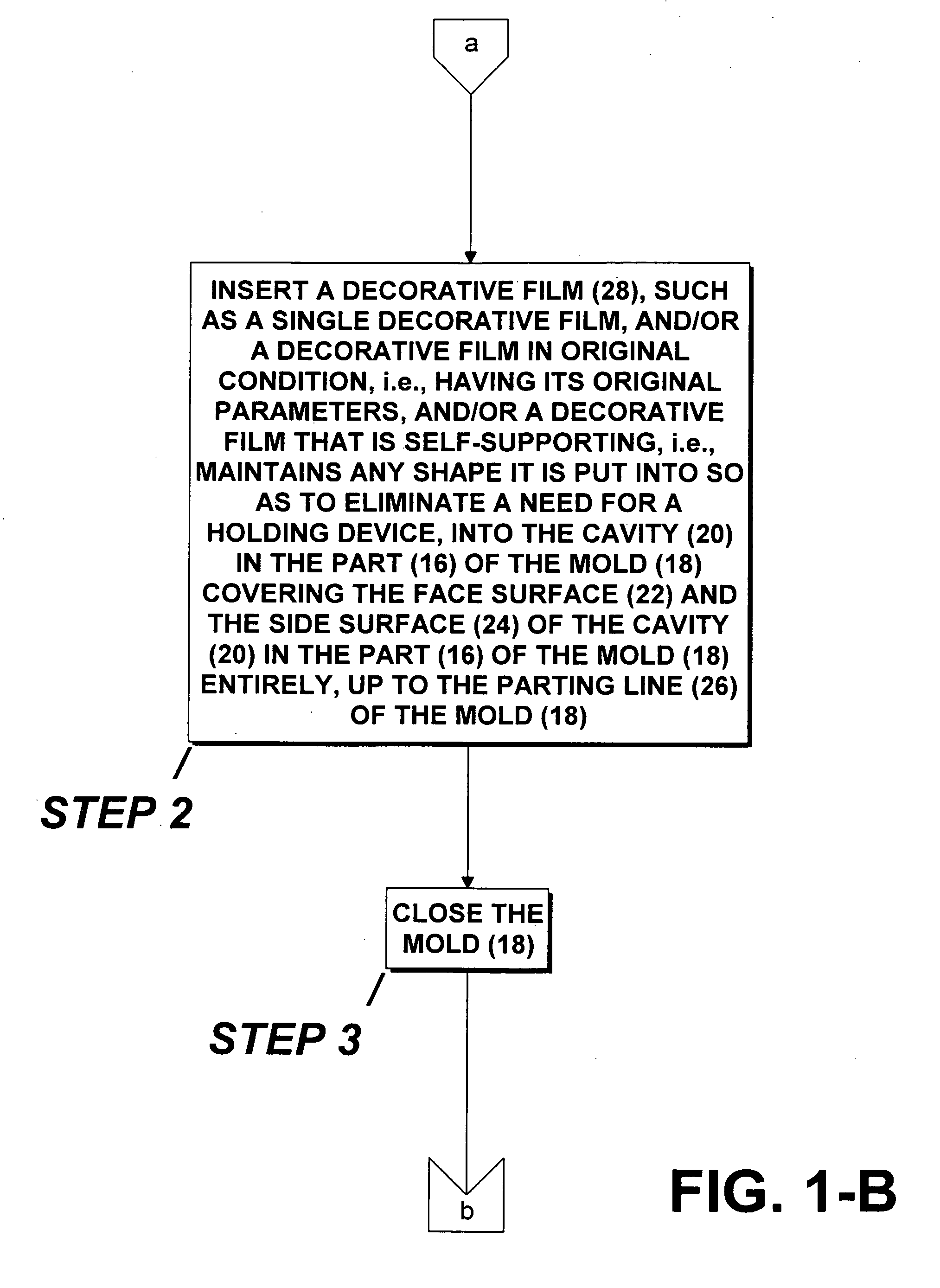

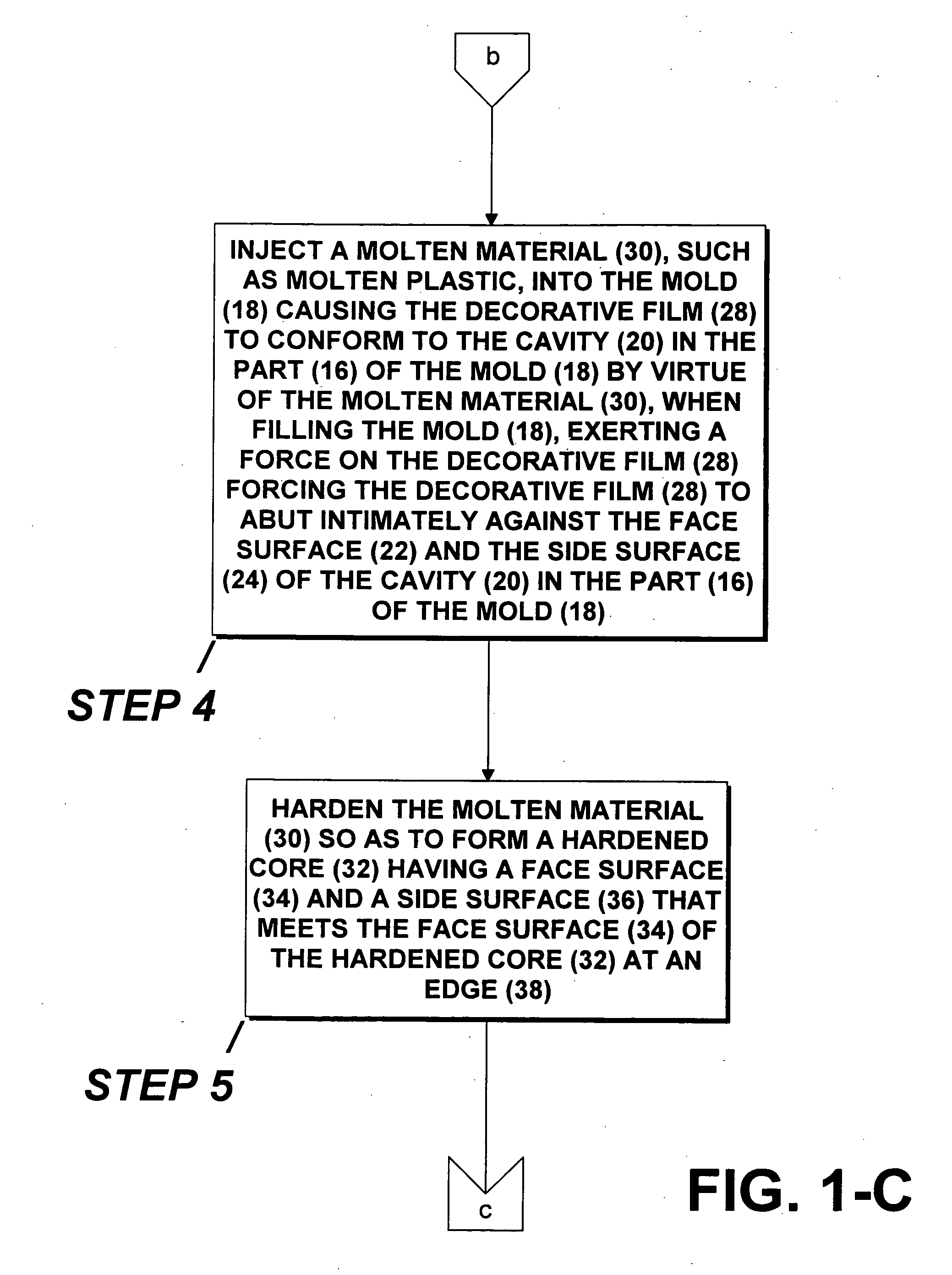

Method for making a part by injection molding and decorating visually-exposed face and side surfaces of the part in their entireties during the injection molding of the part

A method for making a part by injection molding and decorating a visually-exposed face surface and a visually-exposed side surface of the part in their entireties during the injection molding of the part. The method includes the steps of providing a mold, inserting a decorative film into the mold, closing the mold, injecting a molten material into the mold causing the decorative film to conform to the mold by virtue of the molten material, when filling the mold, exerting a force on the decorative film forcing the decorative film to abut intimately against the mold, hardening the molten material so as to form a hardened core, and forming the part with the decorative film being adhered to the hardened core, by virtue of the decorative film being possessed by the hardened core when the molten material hardens and becomes the hardened core, so as to allow the decorative film to cover the hardened core and thereby eliminate a concern for color inconsistency of the hardened core caused by color variations of the molten material by virtue of the hardened core being covered by the decorative film.

Owner:SAGOL SAMI

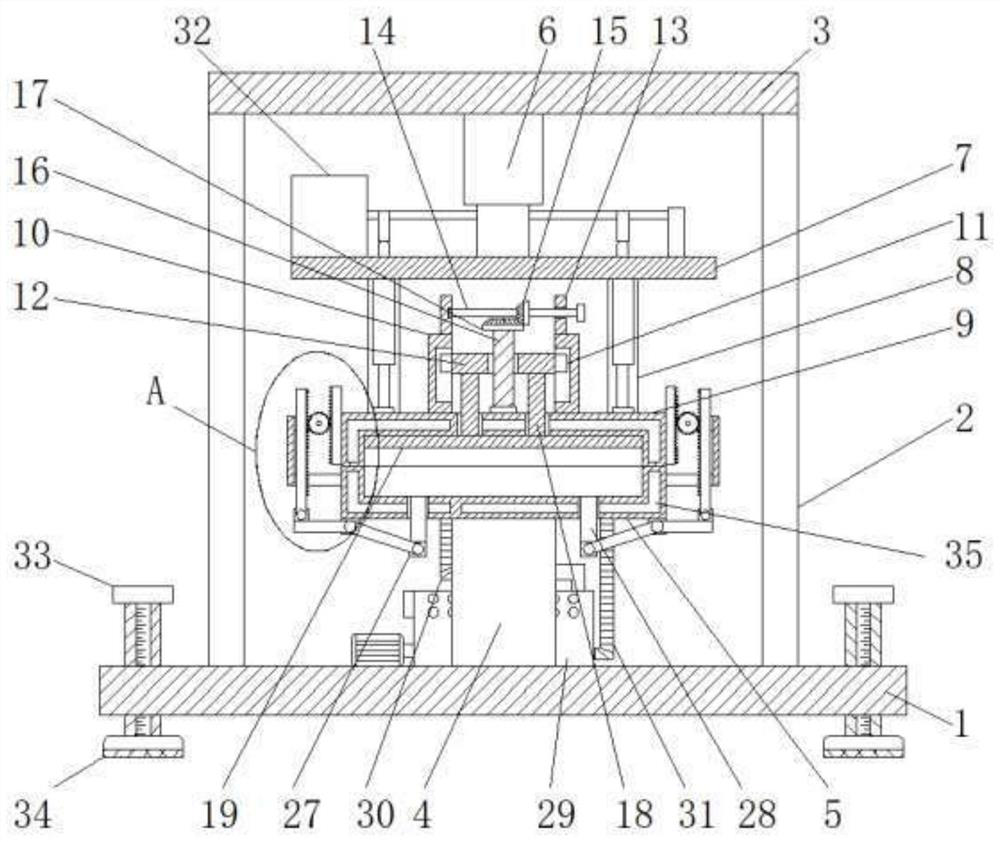

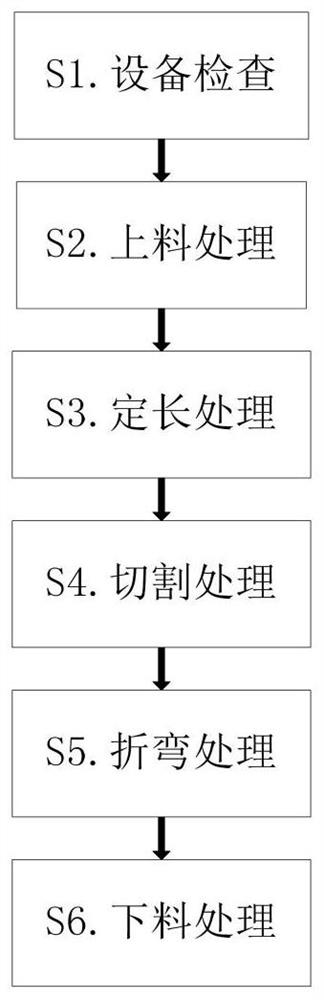

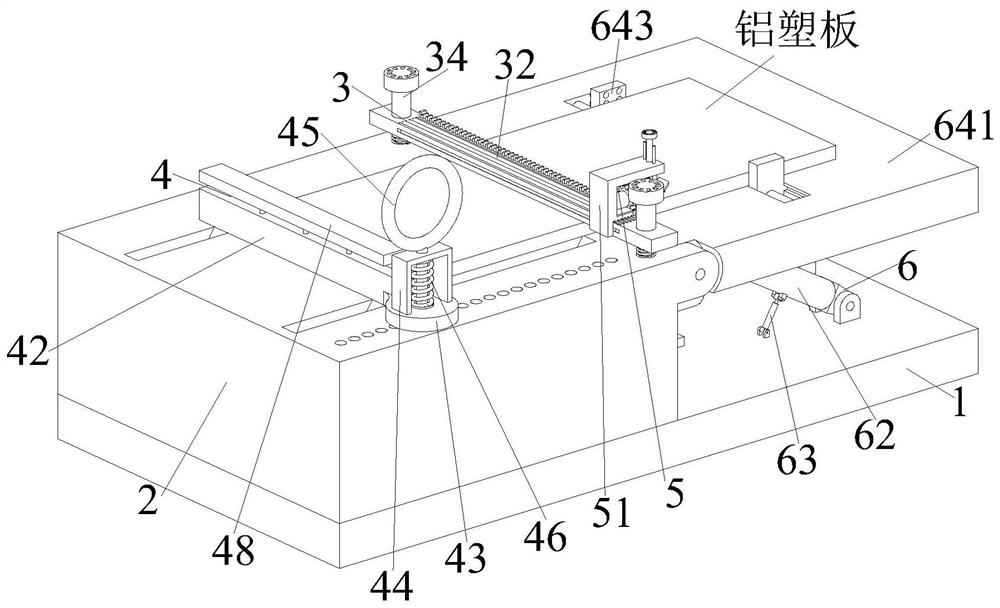

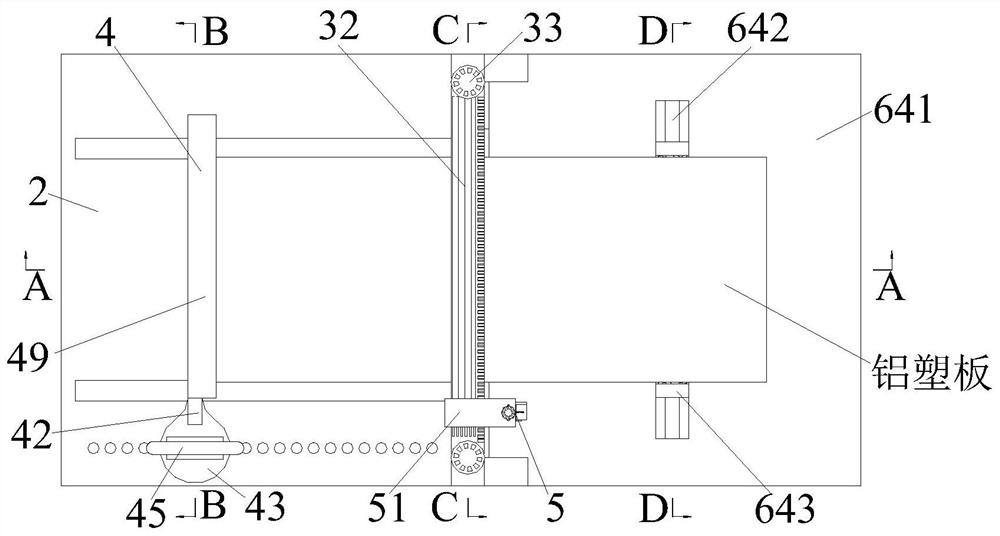

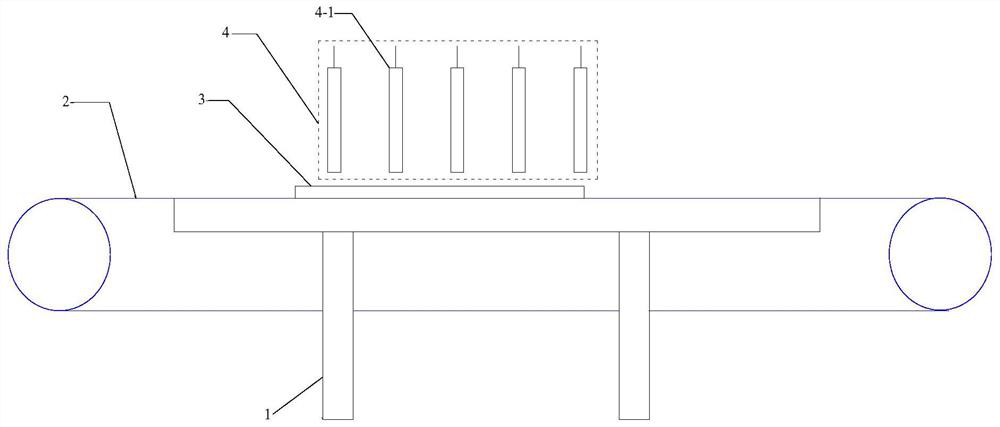

Novel building decorative plate material cutting forming machining method

InactiveCN112405000AImprove bending efficiencyAvoid secondary processingFeeding apparatusOther manufacturing equipments/toolsStructural engineeringMachining

The invention relates to a novel building decoration plate material cutting forming machining method. The bending work of an aluminum-plastic plate is completed through the cooperation of a base plate, a workbench, a fixing device, a length control device, a cutting device and a bending device. According to the novel building decorative plate material cutting forming machining method, the problemsthat a conventional device directly bends the aluminum-plastic plate without fixing, the aluminum-plastic plate is prone to dislocation and wrinkles in the bending process, secondary machining needsto be conducted on the aluminum-plastic plate, and the bending efficiency of the aluminum-plastic plate is reduced are solved, and the problems that according to the conventional device, V-shaped grooves are cut at the inner side of the aluminum-plastic plate and then bent, while the conventional device can only cut the V-shaped grooves of one specification, and different cutters need to be replaced when the V-shaped grooves of different specifications are cut so that the cutting process of the V-shaped grooves is complex, and the bending efficiency of the aluminum-plastic plate is reduced aresolved.

Owner:金巧蒙

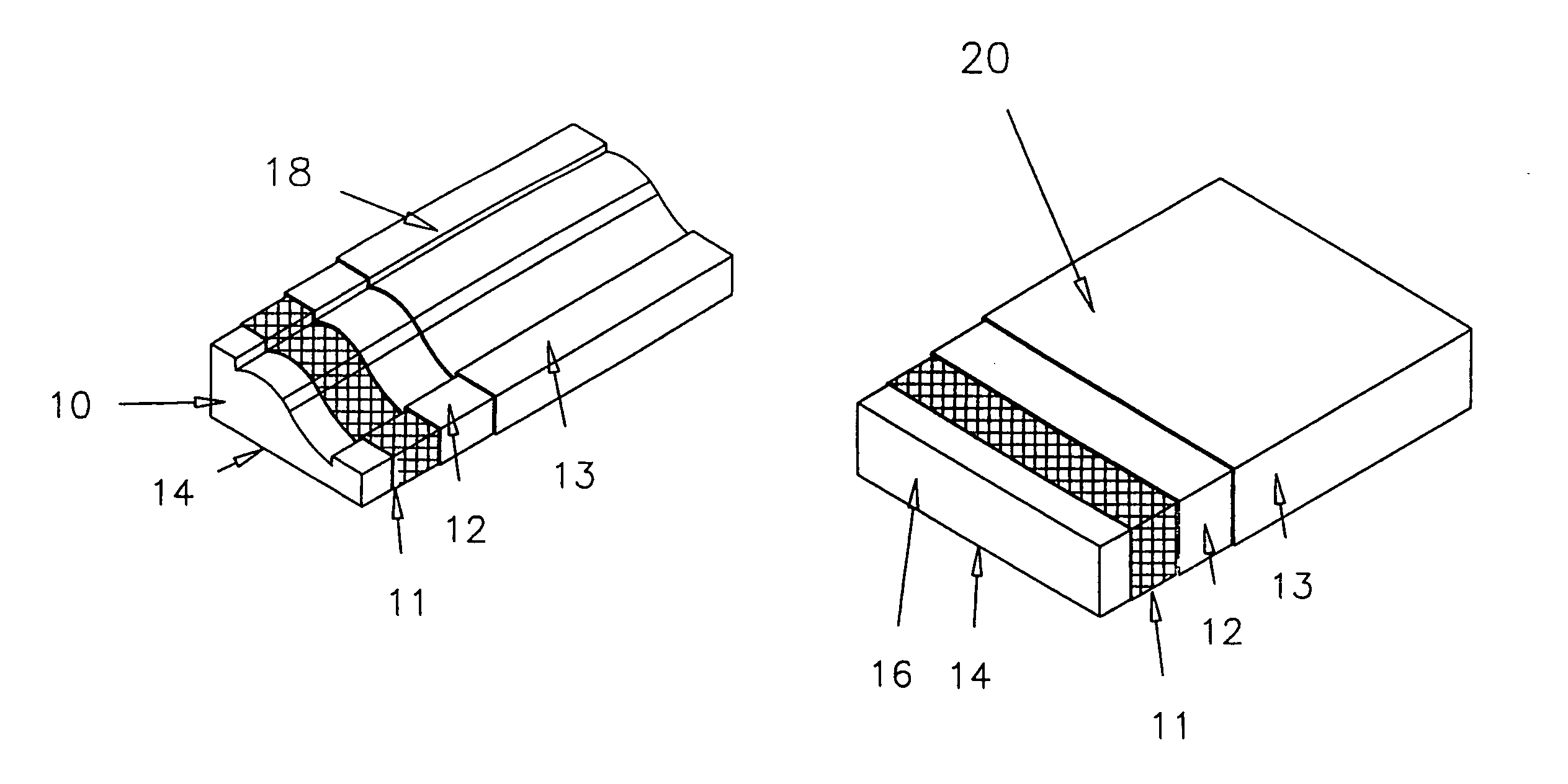

Warm sound-proof decorative materials and prepn. method

This invention is attributed to the field of building materials, concretely speaking, relates to a kind of decoration materials with heat preservation and sound absorption functions and its preparation method. The heat-preserving and sound-absorbing decoration materials comprise a hear-preserving layer, a decoration layer and a mask layer. The heat-preserving layer is made of polybenzene particles, water glass, cement, silica fume, slag powders, fly ash and sand. The decoration layer is made of polybenzene, rubber powders, pigment, cement, silica fume, slag powders and sand. The mask layer is made of organosilicon series of waterproof materials. By the technique of spray stir, layered moulding, compression molding and vapor conservation, the polybenzene particles and the porous structure can help realize highly effective heat preservation. The sound-absorbing structure can be fabricated by compression molding. Fascinating stereo patterns can be organized by alternation of mould shape and pigment. Besides, thanks to the mask layer, wear and decoration properties can be promoted. The product performs excellent heat-preserving, sound-absorbing and decorative functions.

Owner:TONGJI UNIV

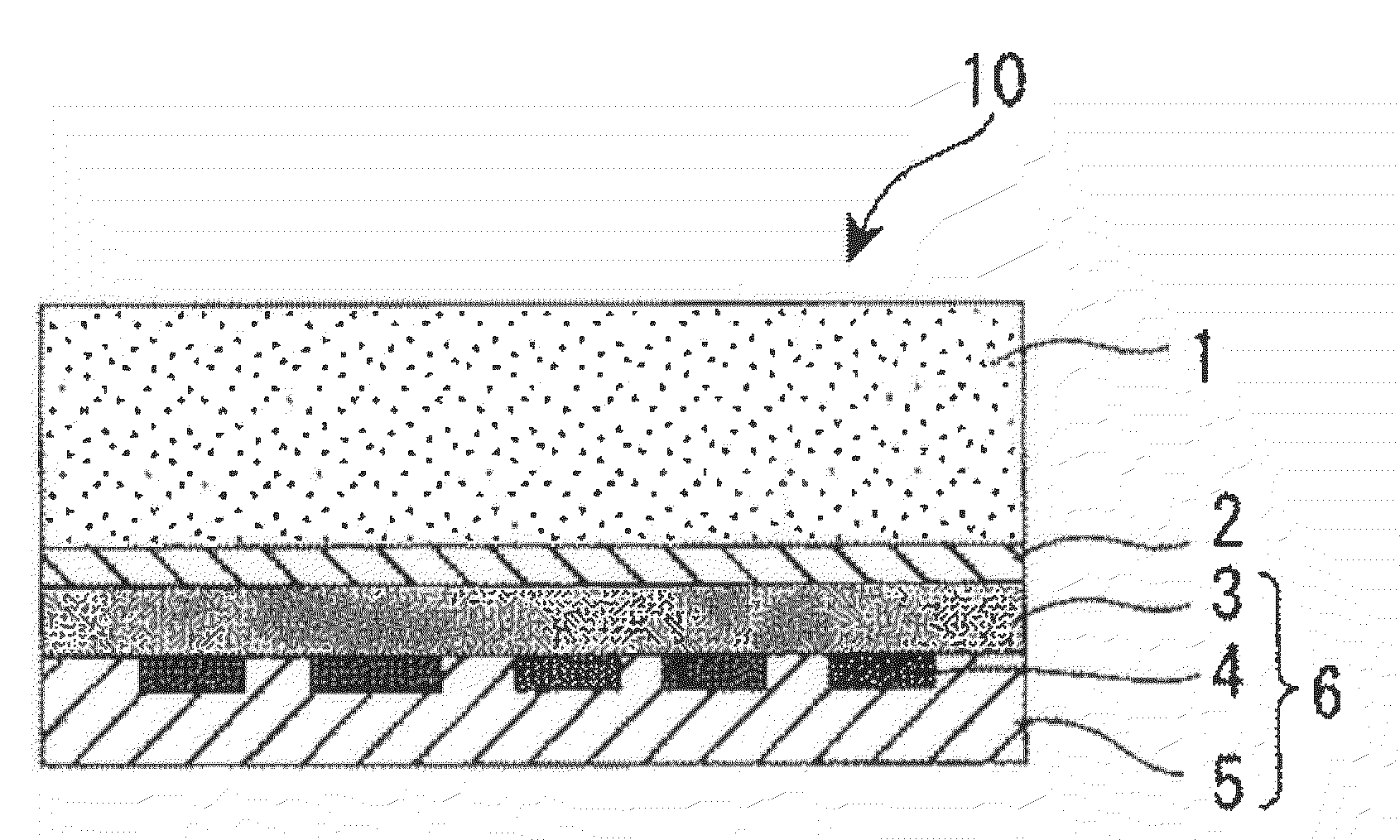

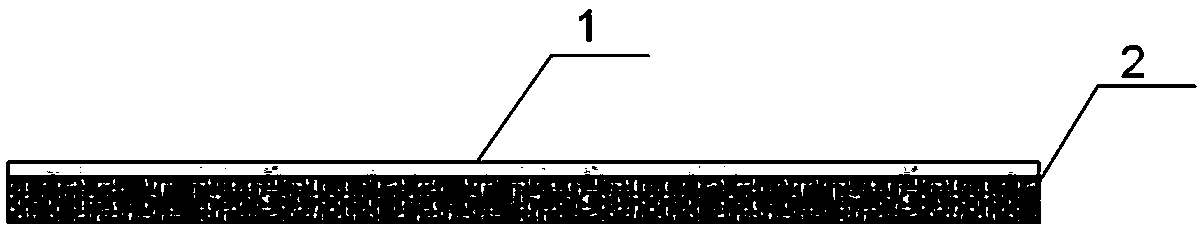

Transfer decorative sheet, process for producing decorated molded product, and decorated molded product

ActiveUS20100062218A1Decorative surface effectsDuplicating/marking methodsWrinkle skinSurface roughness

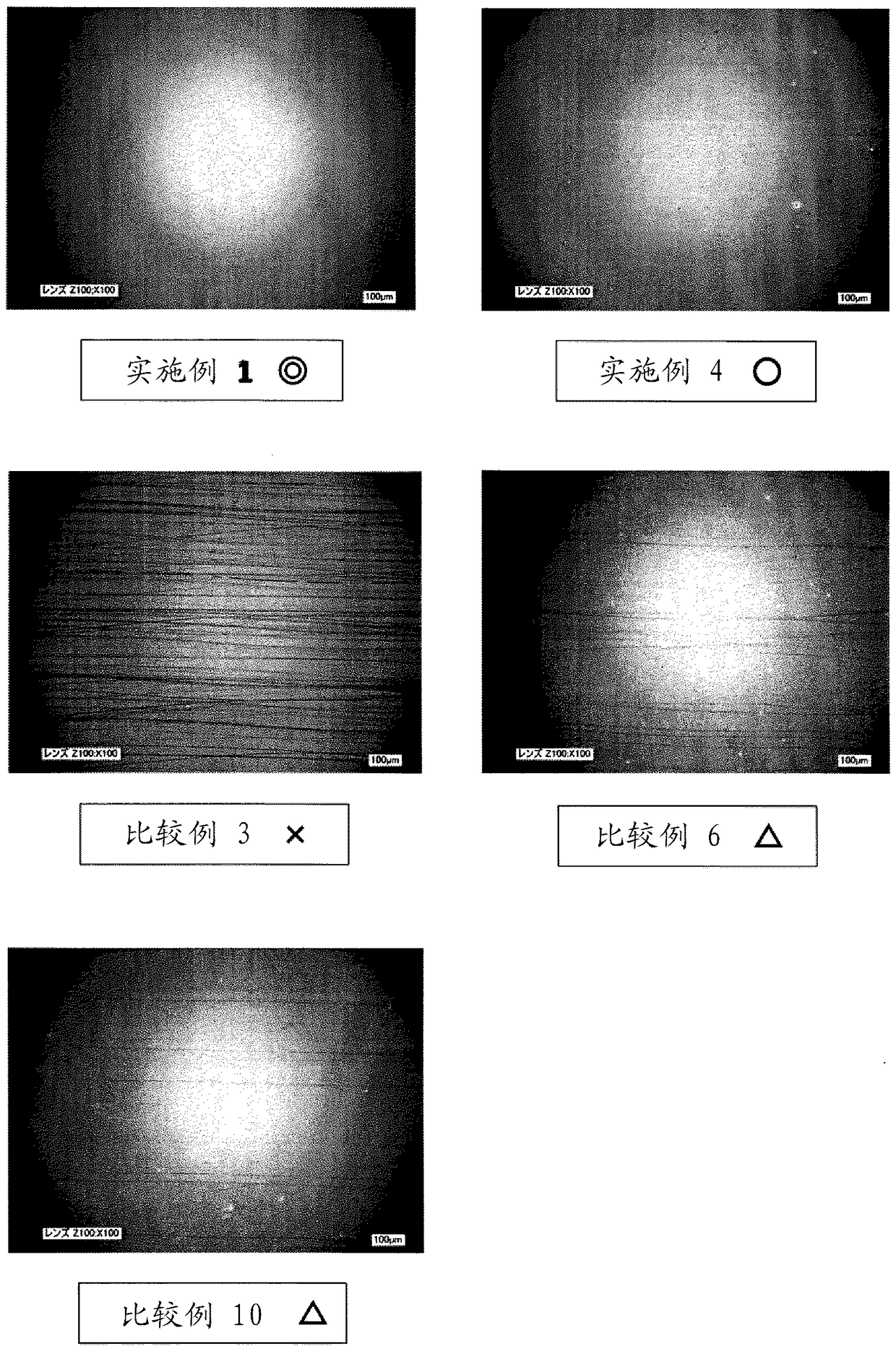

Provided is a transfer decorative sheet comprising a base film and at least a peel layer provided on one surface thereof, wherein a surface of the base film at a peel layer side is subjected to release treatment, and the other surface of the base film brought into contact with a metal die has an average surface roughness Ra of 0.08 μm or more.A transfer decorative sheet which does not produce wrinkles on an injected molding can be provided.

Owner:DAI NIPPON PRINTING CO LTD

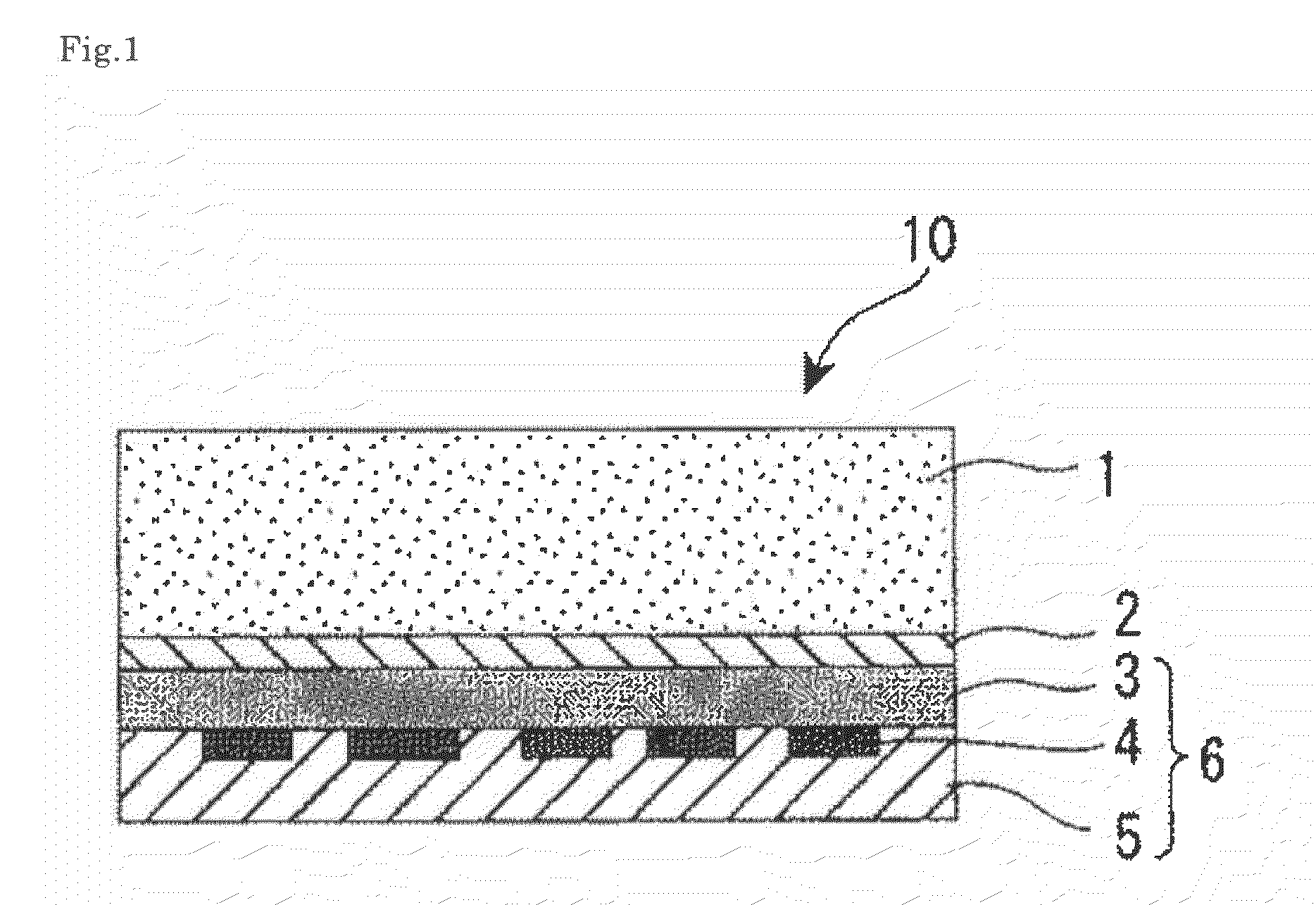

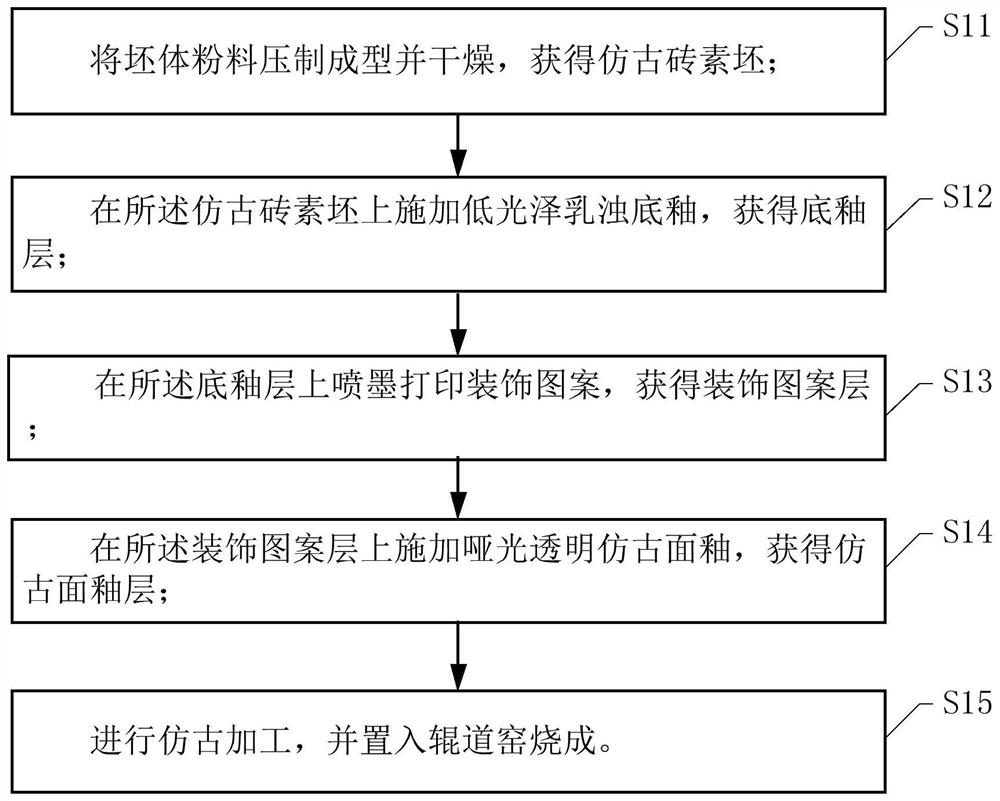

Porcelain matte archaized brick and manufacturing method thereof

The invention discloses a porcelain matte archaized brick and a manufacturing method thereof, and the manufacturing method of the porcelain matte archaized brick comprises the following steps: pressing, molding and drying green body powder to obtain an archaized brick biscuit; applying low-gloss opacified ground coat to the archaized brick biscuit to obtain a ground coat layer; printing a decorative pattern on the ground coat layer in an ink-jet mode to obtain a decorative pattern layer; applying matte transparent archaistic surface glaze to the decorative pattern layer to obtain an archaisticsurface glaze layer; and performing archaistic processing, and placing the mixture in a roller kiln for firing. By applying the low-gloss opacified ground coat to the archaized brick biscuit, the high-temperature loading capacity can be guaranteed, the brick shape can be improved, the flatness of the brick surface can be improved, and the influence on the performances such as the brick shape, thestick grain and the corner falling can be reduced; and then, pattern decoration is carried out on the low-gloss opacified ground coat, and finally, the decorative pattern layer is covered with the matte antique finish coat, so that the design and color of the decorative pattern are effectively protected, the texture is effectively adjusted, and the wear resistance of the antique brick is improved.

Owner:CHONGQING WONDERFUL CERAMICS CO LTD +2

Colorful flexible ceramic decorative material and preparation method thereof

The invention relates to a colorful flexible ceramic decorative material and a preparation method thereof. The preparation method is characterized by comprising the following steps: (1) preparing a colorful surface material; (2) preparing bottom layer powder; (3) preparing a bottom layer mixed material; (4) building a mold; and (5) solidifying, molding, drying and demolding, thus obtaining the colorful flexible ceramic decorative material. The colorful flexible ceramic decorative material has the characteristics that a colorful surface layer has great art sense, the colorful surface layer is gorgeous in color, the chromatic aberration gradation is bright, the color distribution is uniform, the fixedness of the colorful surface layer with a bottom layer is strong, the service life is long and the production cost is low.

Owner:万卓(江苏)新材料有限公司

Laminate film for molded decoration

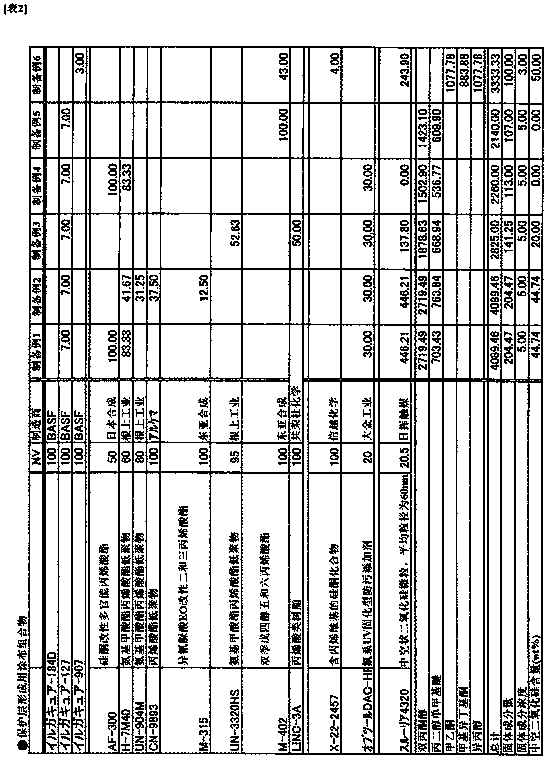

ActiveCN108883614AHigh hardnessImprove scratch resistanceOrnamental structuresSynthetic resin layered productsPolymer scienceCrazing

Owner:นิปปอน เพนท์ ออโตโมทีฟ โคทติ้งส์ โค แอลทีดี

Alternative molding system and method of installation

ActiveUS7836644B2Eliminate needEasy to installWallsWindow/door framesBaseboardStructural engineering

Owner:COOPER WILLIAM J

Decorative rock plate with naturally pushed-aside textures and production method of decorative rock plate

ActiveCN114538966AIncrease friction lossExtended service lifeCeramic shaping apparatusCeramic materials productionMetallurgyGlaze

The invention discloses a production method of a decorative rock plate with naturally-opened textures. The production method comprises the following steps: A, preparing green body powder according to a conventional method; b, preparing slurry for a digital slurry distribution system; c, forming; d, drying the green body; e, digital slurry distribution; f, drying again; g, pattern decoration; h, spraying glaze stripping ink; i, applying a transparent plane material; j, drying for the third time; k, firing; and L, edge grinding is carried out, and the decorative rock plate with the naturally-pushed-aside textures is obtained. Water-based ceramic slurry can be applied in a positioned mode according to the preset pattern texture, the obvious concave-convex three-dimensional texture is achieved, the poking glaze ink and the transparent plane material are matched to form poking effect three-dimensional texture, lines of slurry for a digital slurry distribution system can be arranged at will, and the production efficiency is improved. The matching of a plurality of nozzle arrays enables the texture of the imitated natural stone formed by slurry distribution to be clearer and more vivid, three-dimensional and fine, the pattern and line effect to be richer, and the gradual transition effect to be good.

Owner:DEQING NABEL CERAMIC +2

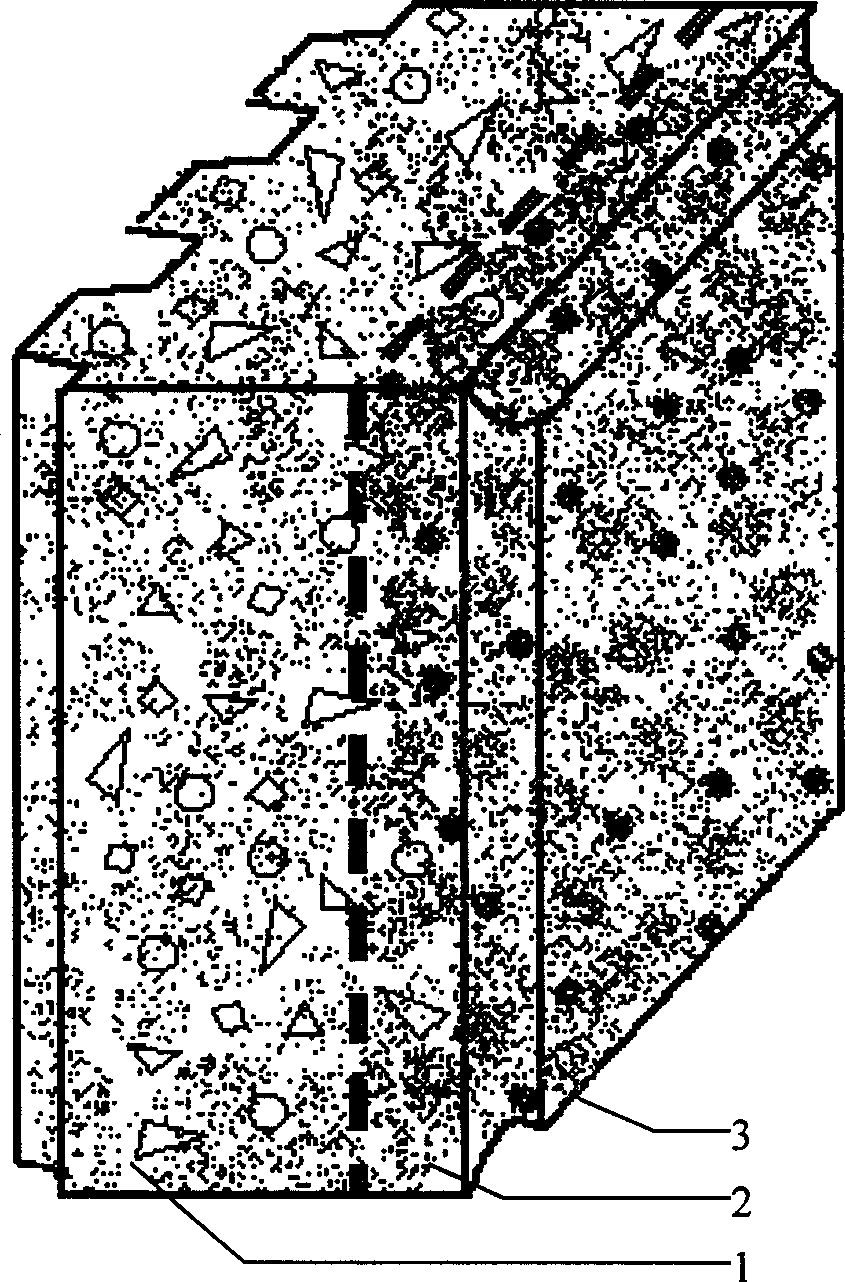

Fragmentation modeling type sculpture processing method

The invention discloses a fragmentation modeling type sculpture processing method. The method comprises the following steps: preparing a plurality of slicing plates according to the sculpture shape, assembling the slicing plates in sequence to obtain a fragmentation type frame, and correspondingly mounting steel pipes along the outer edge surface of the fragmentation type frame to obtain a steel pipe framework; and paving decorative plates on the steel pipe framework to obtain a sculpture finished product. A worker only needs to bend and clamp the steel pipes into clamping grooves in sequenceaccording to the positions of the clamping grooves and carry out welding and fixing, then the steel pipe framework shape of the sculpture is formed, the clamping grooves are used for completing the accurate molding of the steel pipes, therefore, a traditional manual forging and beating molding mode is replaced, the steel pipe framework can be formed in a high-quality mode without depending on experience of the worker, thus the molding difficulty is reduced, the product quality is effectively improved, meanwhile, the repeated multi-time beating modification is not needed, so that the productionefficiency can be greatly improved, the production period can be greatly shortened, further, a large amount of labor cost can be reduced, and the overall production cost is indirectly reduced.

Owner:浙江盛元文化艺术有限公司

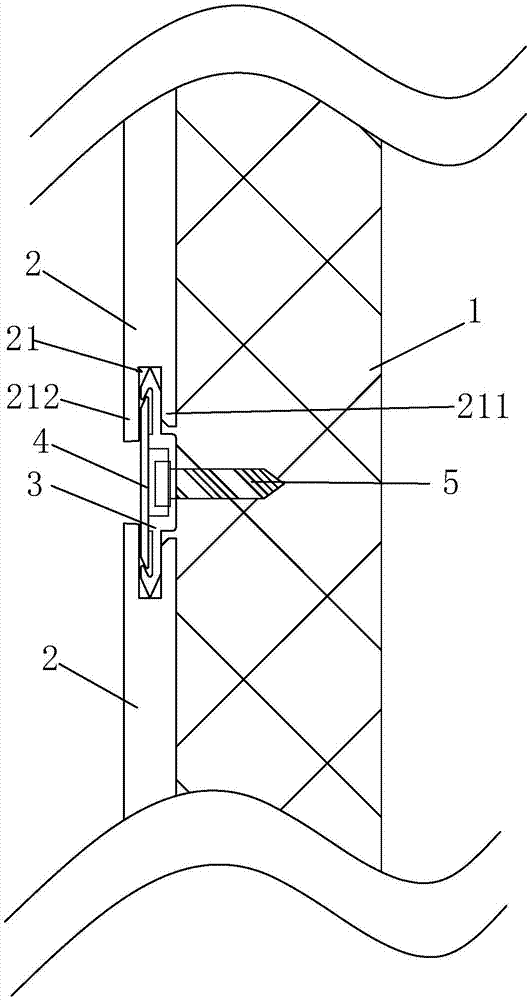

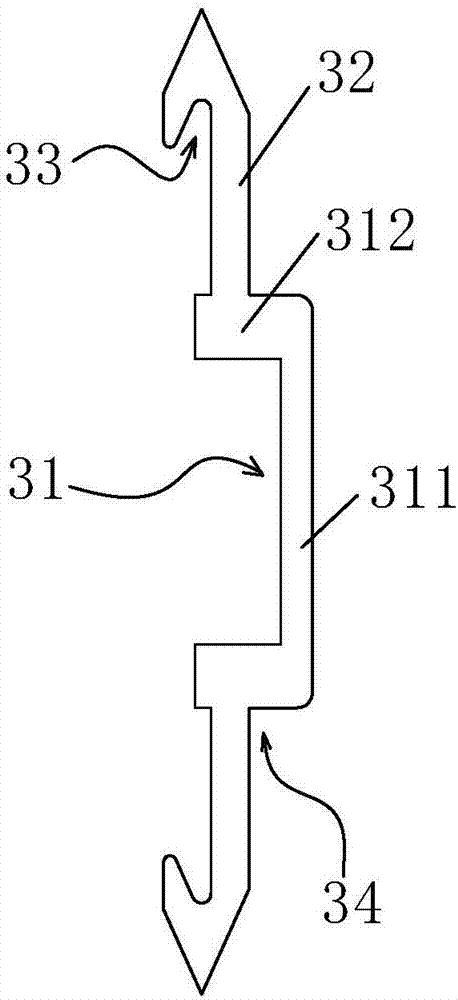

Mounting structure and method for wall boards

The invention discloses a mounting structure for wall boards. The mounting structure comprises the wall boards mounted on a wall body, connecting buckles and decorative pieces; the wall boards are solid wood-plastic boards; connecting grooves are machined to be formed in the upper ends and the lower ends of the wall boards; and every two up-down adjacent wall boards are connected through the connecting buckles. Mounting grooves and convex strips are formed / arranged on the connecting buckles; the ends, away from the mounting grooves, of the convex strips are reversely bent to form clamping hook parts towards the outer side; the decorative pieces are independently-arranged strip-shaped plates, and decorative patterns are arranged on the decorative pieces; the decorative pieces are mounted on the outer sides of the connecting buckles; and the upper ends and the lower ends of the decorative pieces are clamped into the clamping hook parts of the connecting buckles to be positioned. The invention discloses a mounting method for the wall boards simultaneously. An independent decorative structure is adopted, the size of a printing product can be decreased, and the decorative structure is made to be diversified.

Owner:ZHEJIANG HUAXIAJIE MACROMOLECULE BUILDING MATERIAL

Calcium silicate building material and preparation method thereof

The invention provides a calcium silicate building material. A preparation method for the calcium silicate building material comprises the following steps: (1) grinding of raw materials; (2) stirringand mixing; (3) a high-pressure reaction; (4) adding of fibers; and (5) compression molding. According to the invention, raw materials are easy to obtain, and operation is simple; silica sand powder and quicklime powder are fully reacted through a high-pressure reaction; compression molding can be achieved after reinforced fibers are added; and burrs are trimmed after demolding so as to obtain thecalcium silicate building material. The material has multiple purposes, and can be made into building materials in the forms of plates, decorative lines, door pockets, window pockets, eaves tiles, building decorative parts with concave-convex patterns and the like through corresponding molds.

Owner:湖南愿景住宅工业科技有限公司

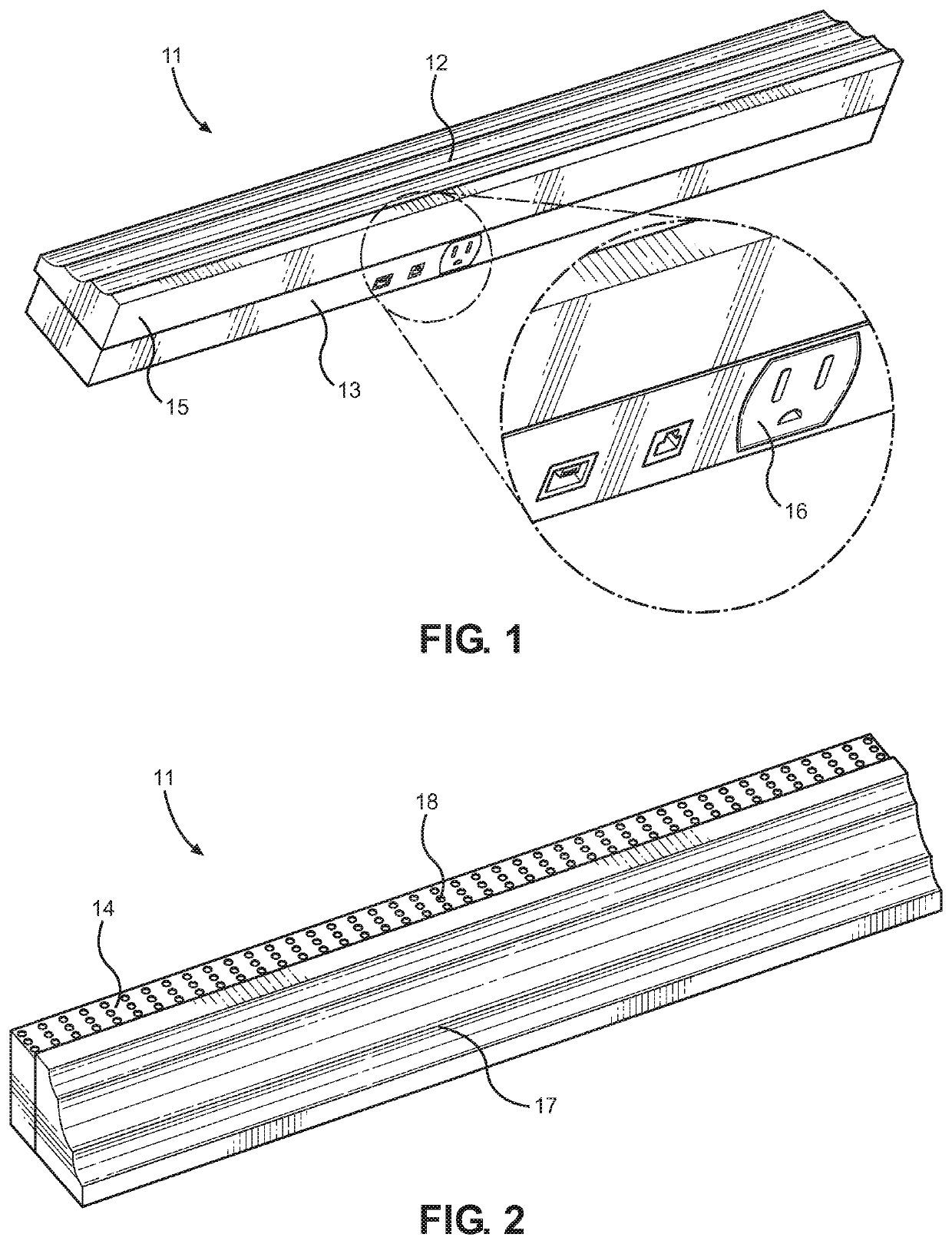

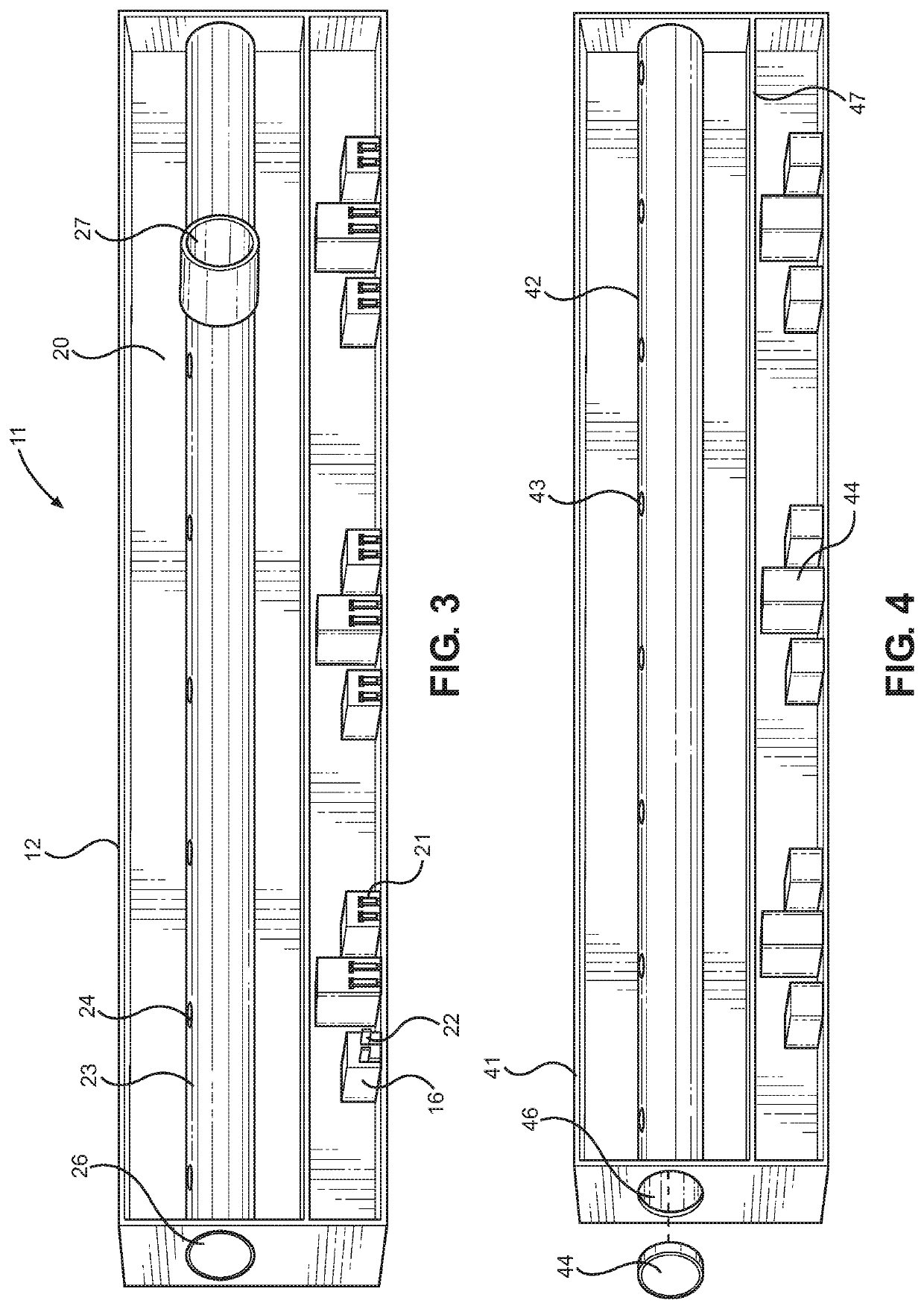

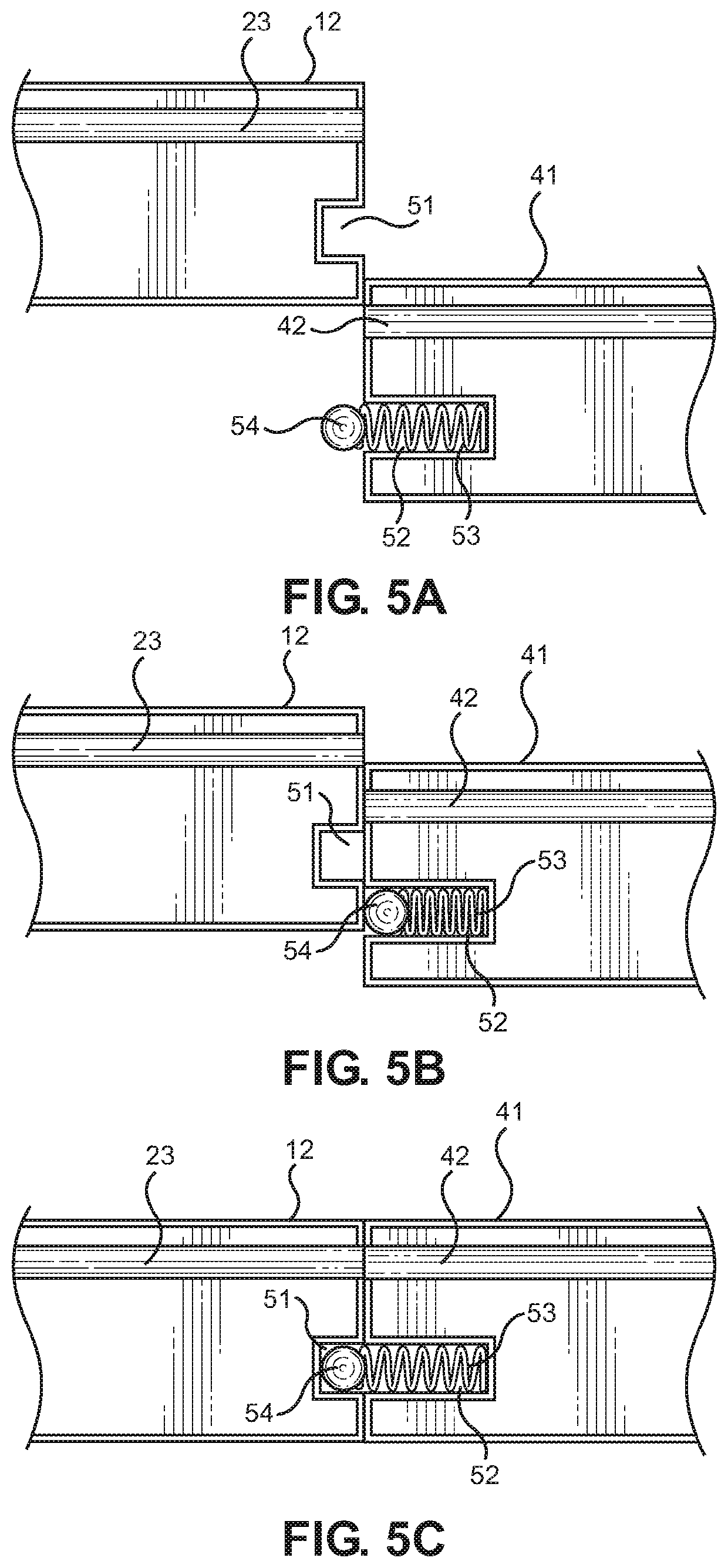

Wall mounted rail system

A wall mounted rail system for providing additional air flow and electrical outlets to a room. The system includes a first rail removably securable to a second rail, wherein each rail includes a front surface and a rear surface. The rear surface can secure to a wall and a decorative molding, such as chair rail molding, is secured to the front surface. A plurality of ports are disposed on a bottom face of the front surface and can supply power to a device connected to each port. Further, each port is electrically connected to one another. Tubing extends through an interior volume of each rail and plurality of apertures are disposed on a top face of the front surface thereof. Each aperture is in fluid communication with the tubing to allow air to flow from the tubing, through the apertures, and into the room.

Owner:JAIN SANJEEV

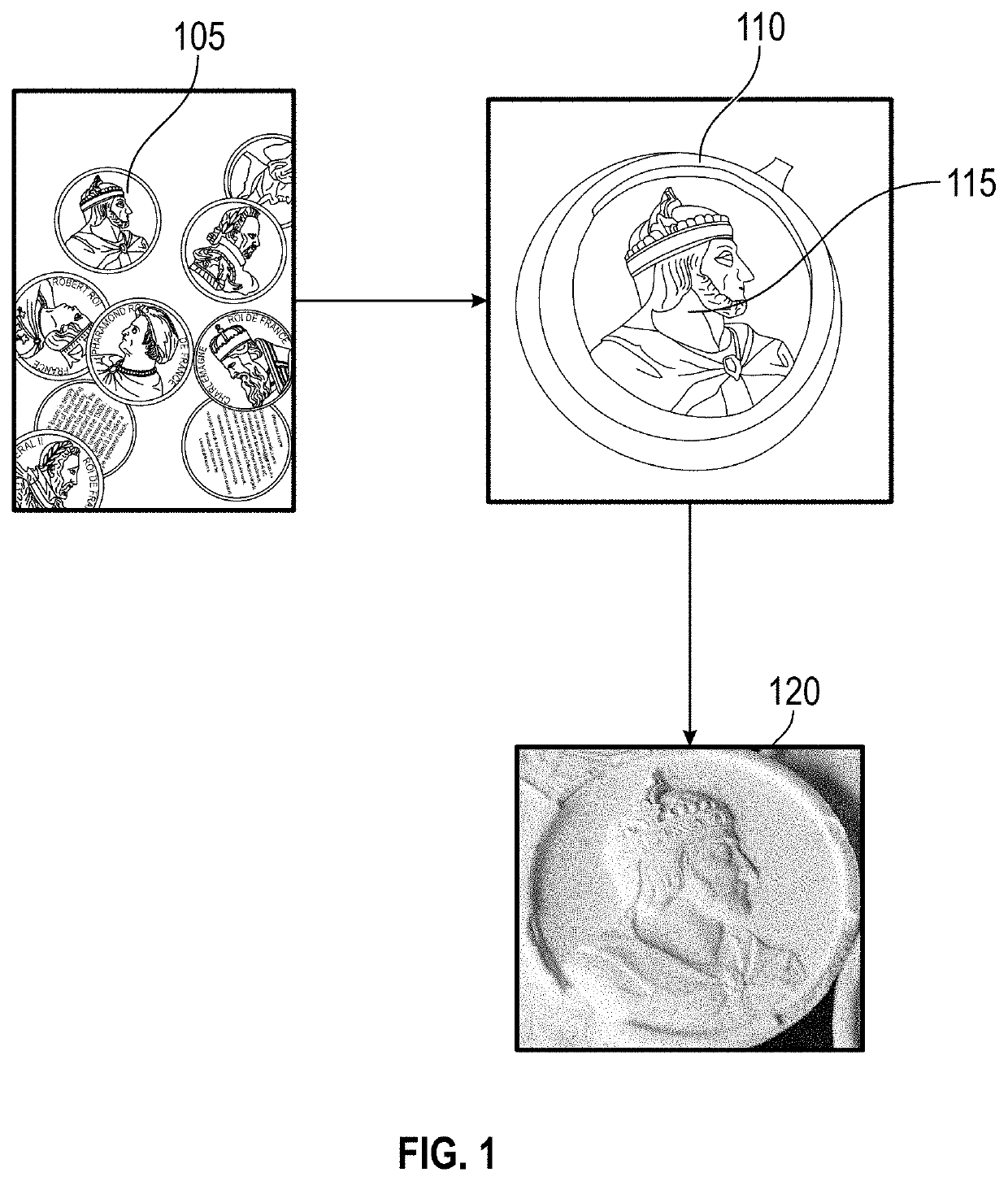

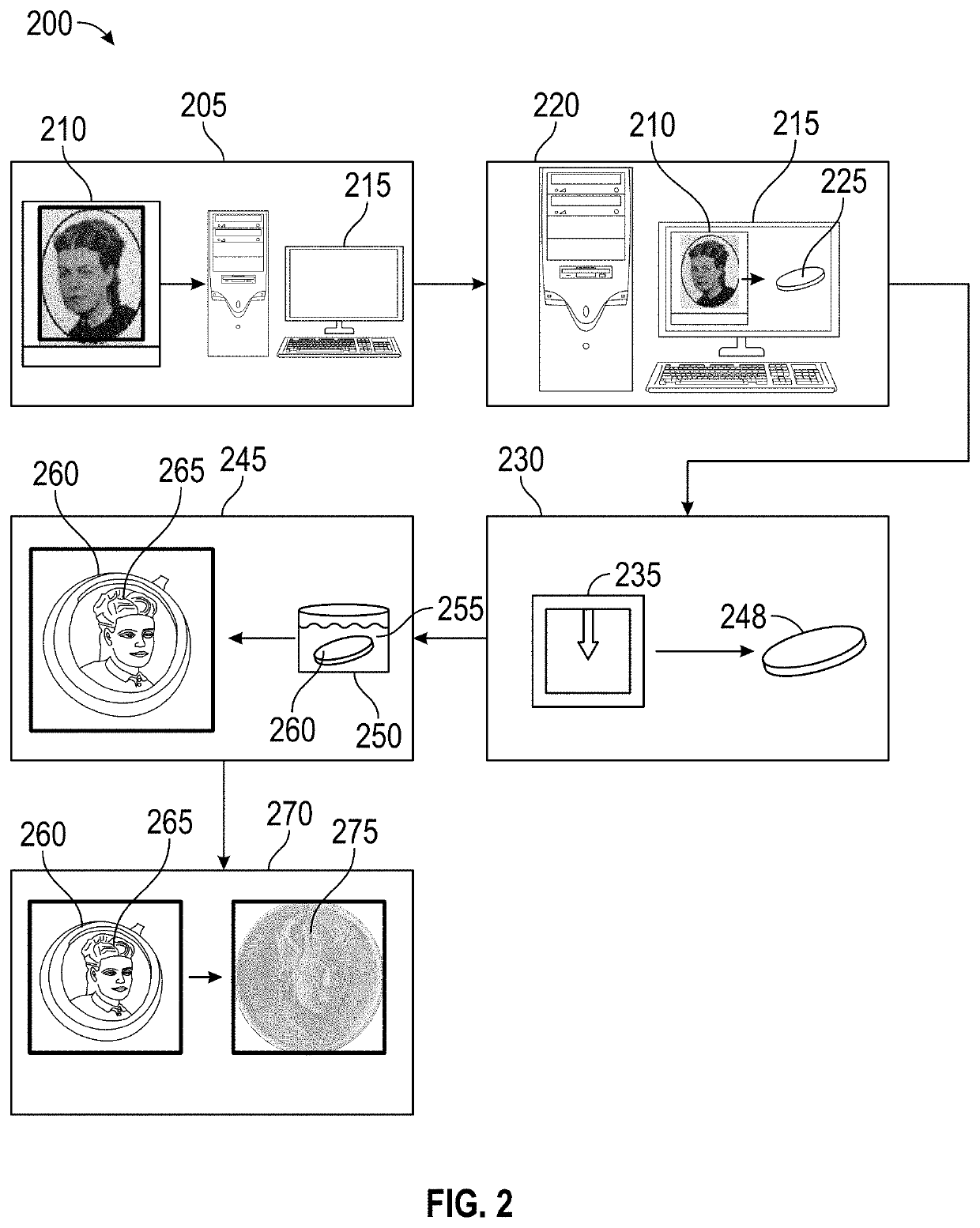

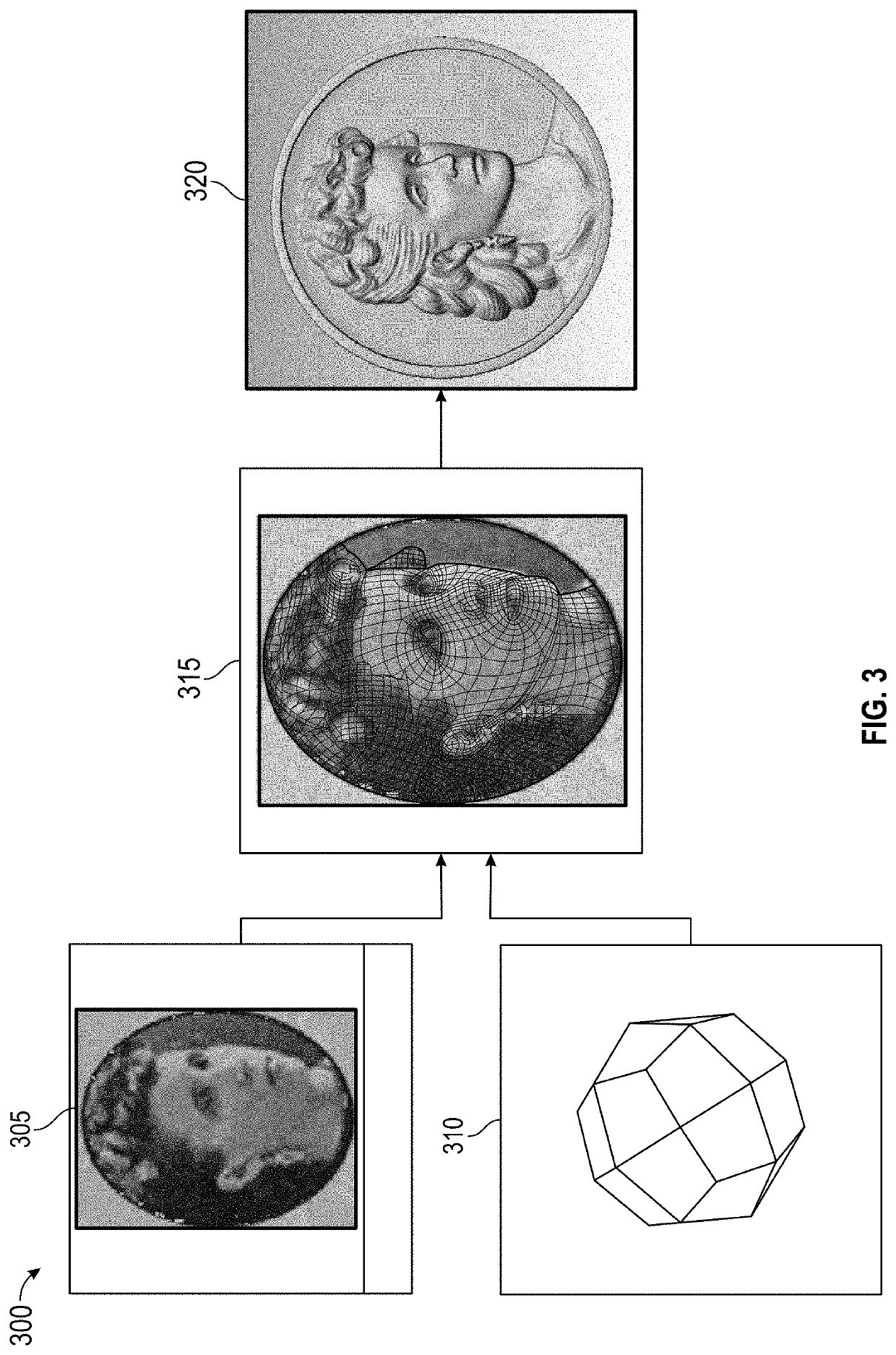

Method for Creating a Three-Dimensional Decorative Sculpture

A method for creating a sculpture is disclosed. Such a method may include importing a two-dimensional image into a computer having a 3D sculpting program, and using said program to create a three-dimensional model of the two-dimensional image. A prototype of the three-dimensional model may then be printed with a 3D printer. The prototype may then be placed into a container and submerged in a casting solution. Once the casting solution cures, forming a mold, the prototype is removed, and a molding material may be poured or inserted into the void resulting from the removal of the prototype. Once the molding material is cured, it may be removed from the mold, forming a three-dimensional sculpture. Such methods may be used for casting such decorative objects as intaglios, reliefs, plaques, cameos, busts, silhouettes, medallions, and coins.

Owner:JURGENS LILAH +1

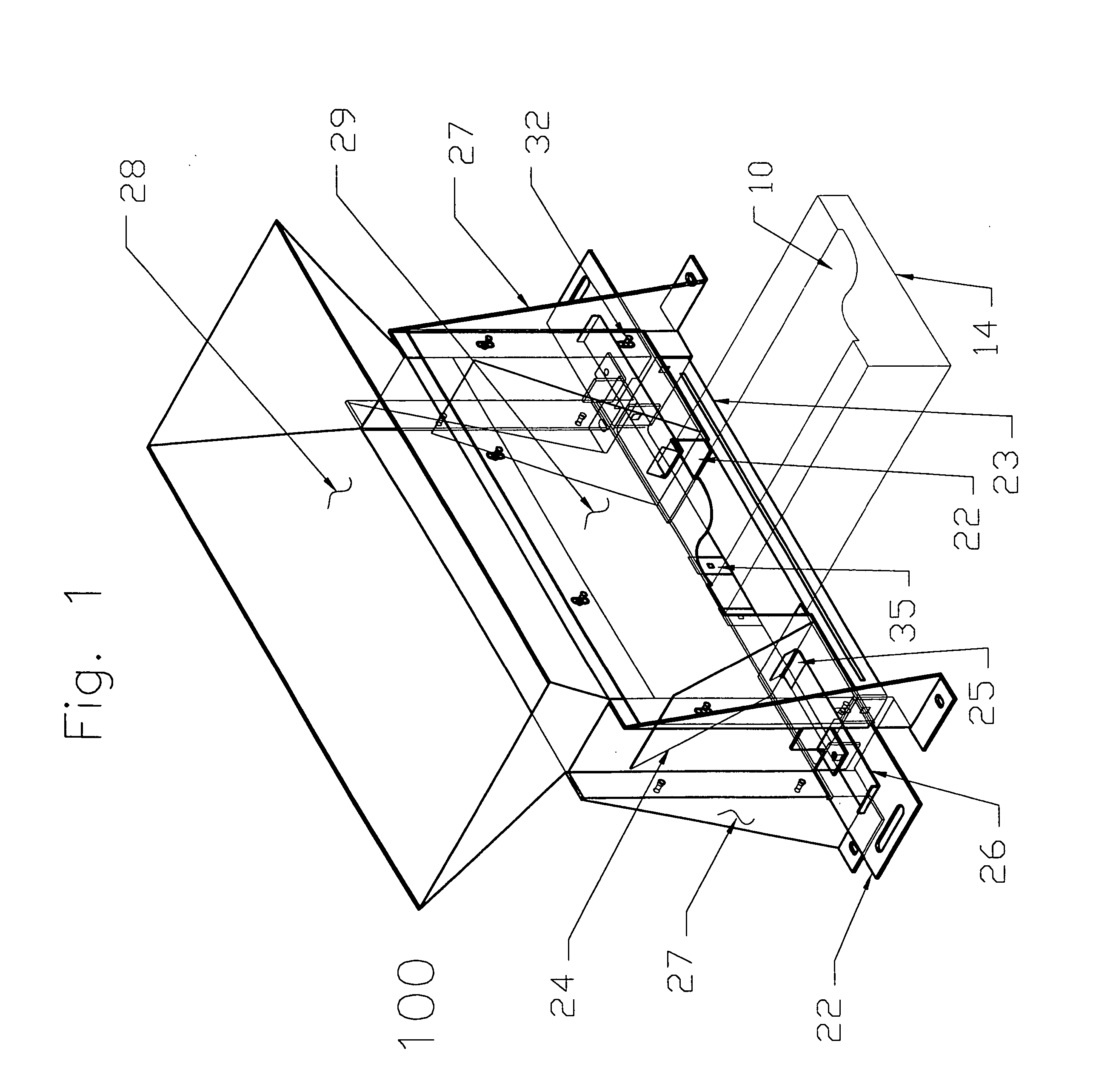

Method for applying a coating material to the surface of foam cores

InactiveUS20060083862A1Eliminate dead spaceOrnamental structuresPretreated surfacesPolystyreneEngineering

The invention provides a method and apparatus to impart a coating layer on the surface of decorative mouldings that are widely used in the externally insulated finishing systems (EIFS) in the construction industry. The method is a sequence of mechanically advancing a core, constructed from pre-formed expanded polystyrene (EPS, in a straight horizontal plane through a coating chamber / hopper with templates conforming to the desired decorative profile. The apparatus is a rectangular box with a funneled opening at the top with adjustable internal plates to direct the material from the sides of the box toward the pre-formed core that is being coated. Two plates on the bottom of the box support the pre-formed core and are adjustable to leave an opening in the center so that excess material can fall through the bottom after coating the last core. The templates are designed to be interchangeable with other coating apparatus designed by the inventor to produce start strips, decorative mouldings, wall panel sections and columns commonly used in the construction industry.

Owner:SANTO P RAPONE

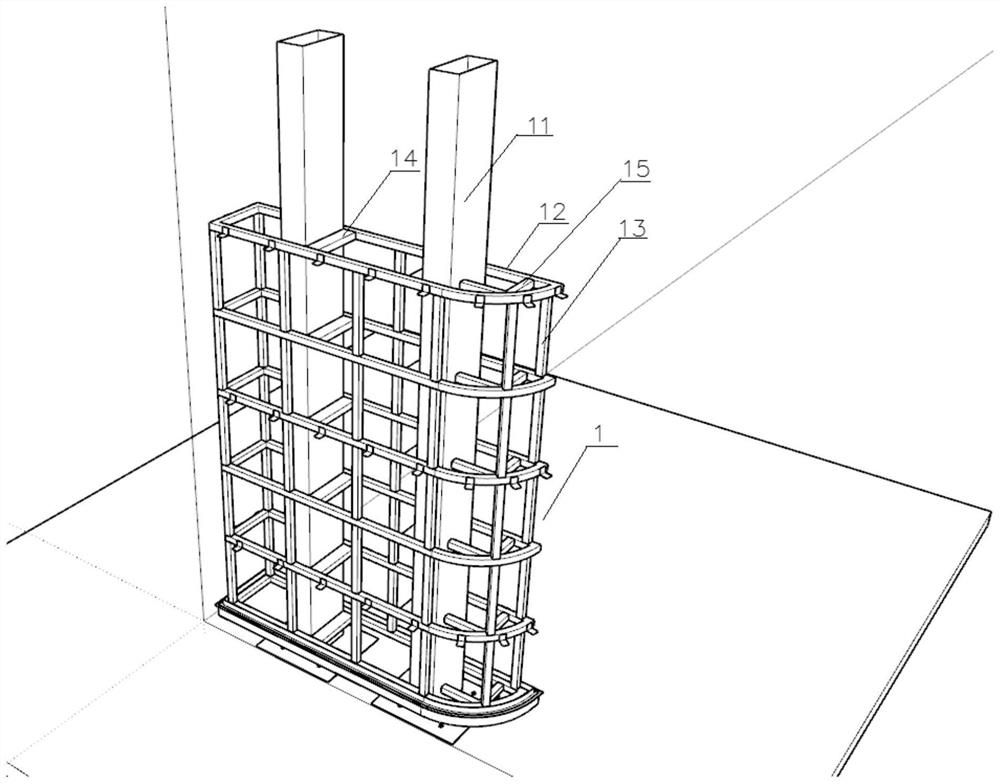

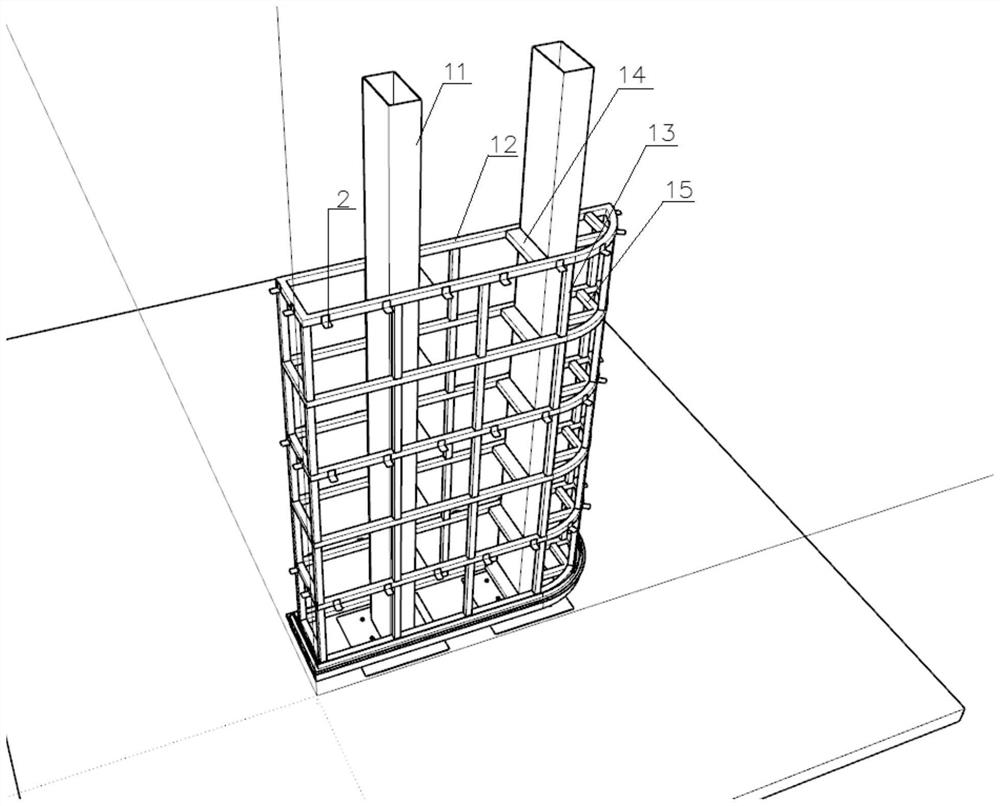

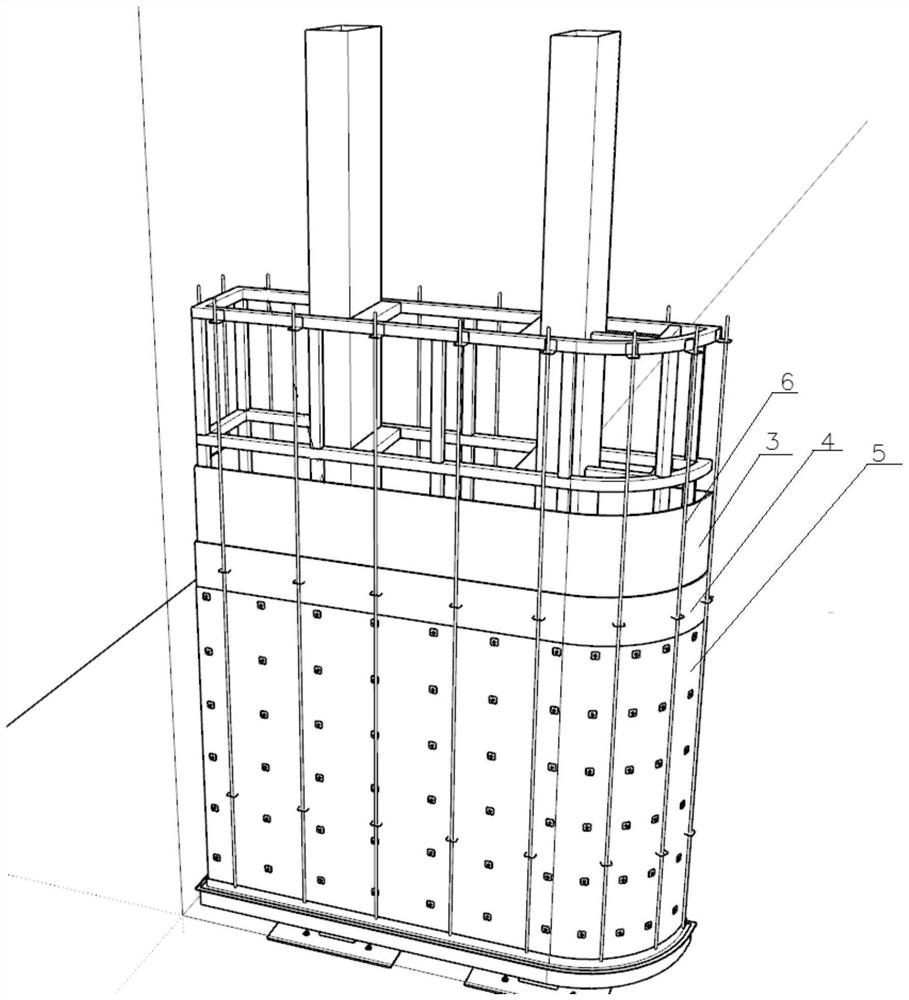

Manufacturing technology of decorative indoor rammed earth column

PendingCN113565236AGuaranteed molding effectReduce manufacturing costCovering/liningsWallsManufacturing technologyConstruction engineering

The invention provides a manufacturing technology of a decorative indoor rammed earth column. The manufacturing technology comprises the following steps that S1, a decorative main frame is installed, and the bottom of the decorative main frame is welded to an embedded plate; S2, corner connectors are welded to the corresponding point positions of the decoration main frame; S3, a base layer panel is arranged on the periphery of the decoration main frame; S4, a steel wire mesh is laid on the outer side of the base layer panel; S5, skirting is arranged on the periphery of the decoration main frame, a pouring mold is erected on the skirting, and a pouring cavity is formed between the pouring mold and the base layer panel; S6, rammed earth material is put into the mold in a layered mode and tamped layer by layer, and the pouring mold is dismantled after tamping and condensation are completed; S7, the pouring mold is moved to the upper end of the coagulated rammed earth structure, and the lower end of the pouring mold is attached to the outer side of the rammed earth structure; and S8, S6 and S7 are repeated till pouring is completed. The method of pouring layer by layer from bottom to top is adopted, the forming effect of the rammed earth layer is guaranteed, the manufacturing cost of the mold is reduced, and the construction difficulty is reduced.

Owner:SHANGHAI BUILDING DECORATION ENG GRP

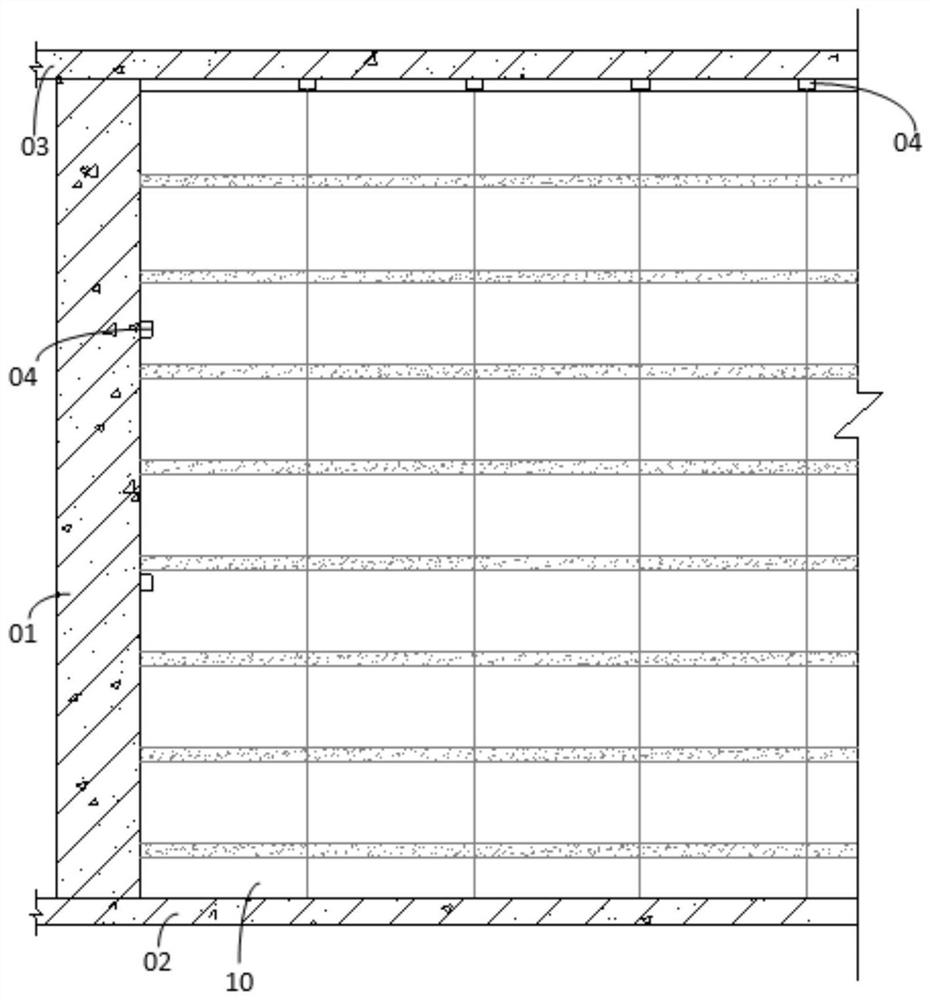

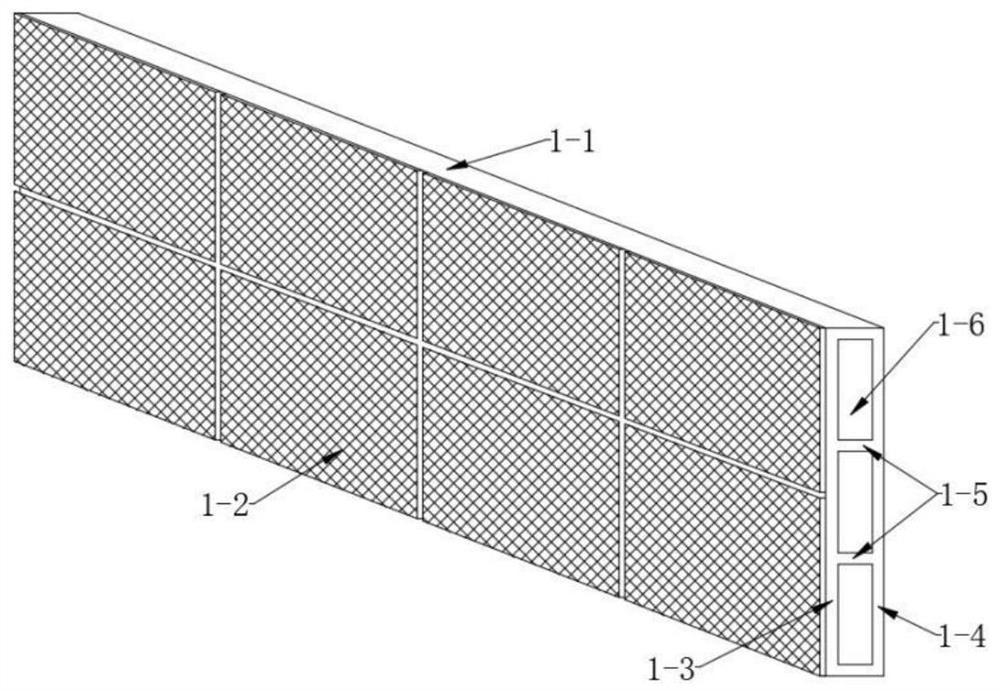

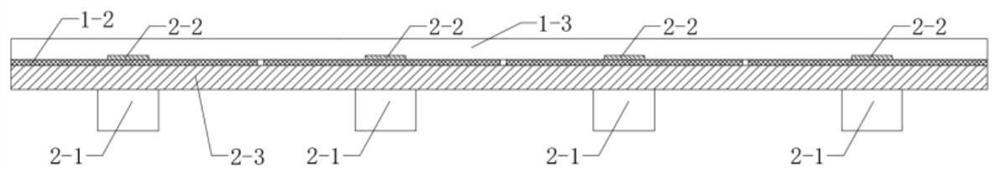

Fabricated point type connection wall structure

PendingCN112982880ARealize quick disassembly and quick assemblyReduce dosageCovering/liningsMaterial consumptionEngineering

The invention discloses a fabricated point type connection wall structure which at least comprises a first wall formed by splicing a plurality of battens and a second wall formed by splicing a plurality of decorative plates; the first wall and the second wall are arranged in parallel and fixed through a U-shaped clamping groove formed in a building supporting structure; a cushion block is arranged between the first wall and the second wall; the cushion block is fixed on the battens through first screws; and each decorative plate is fixed on the cushion block through a connecting part. Through the structural design of the fabricated wall structure, keel-free support, dry construction and glue-free engineering are realized, the material consumption is low, the cost is saved, the quality problems of cracking, bulging and the like of a traditional decoration wall surface can be solved, and quick disassembly and quick assembly of the walls are realized. As the battens have small deviation, the battens do not need to be adjusted greatly after being installed and formed. Therefore, the construction and installation efficiency can be greatly improved.

Owner:CHINA MCC5 GROUP CORP

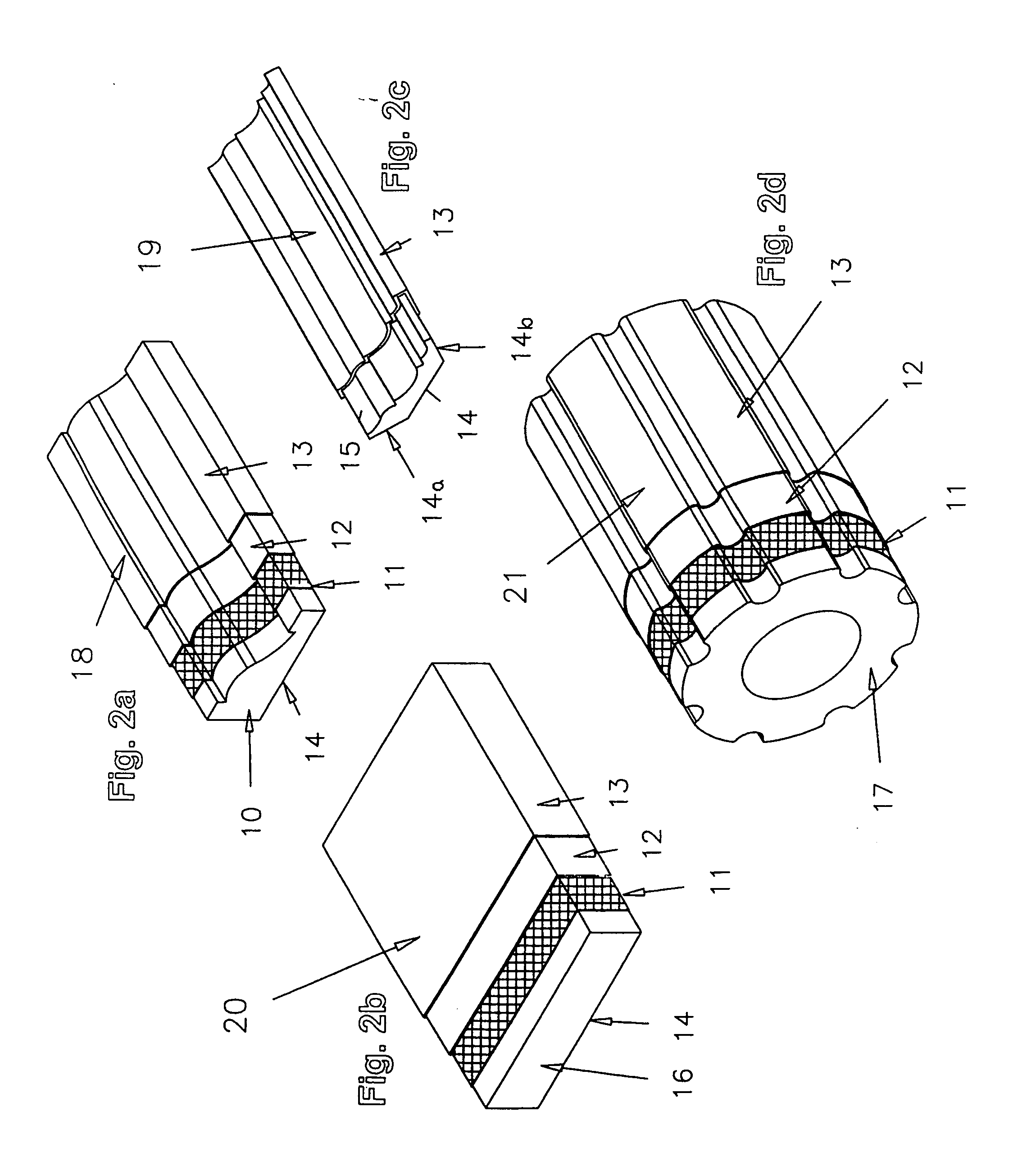

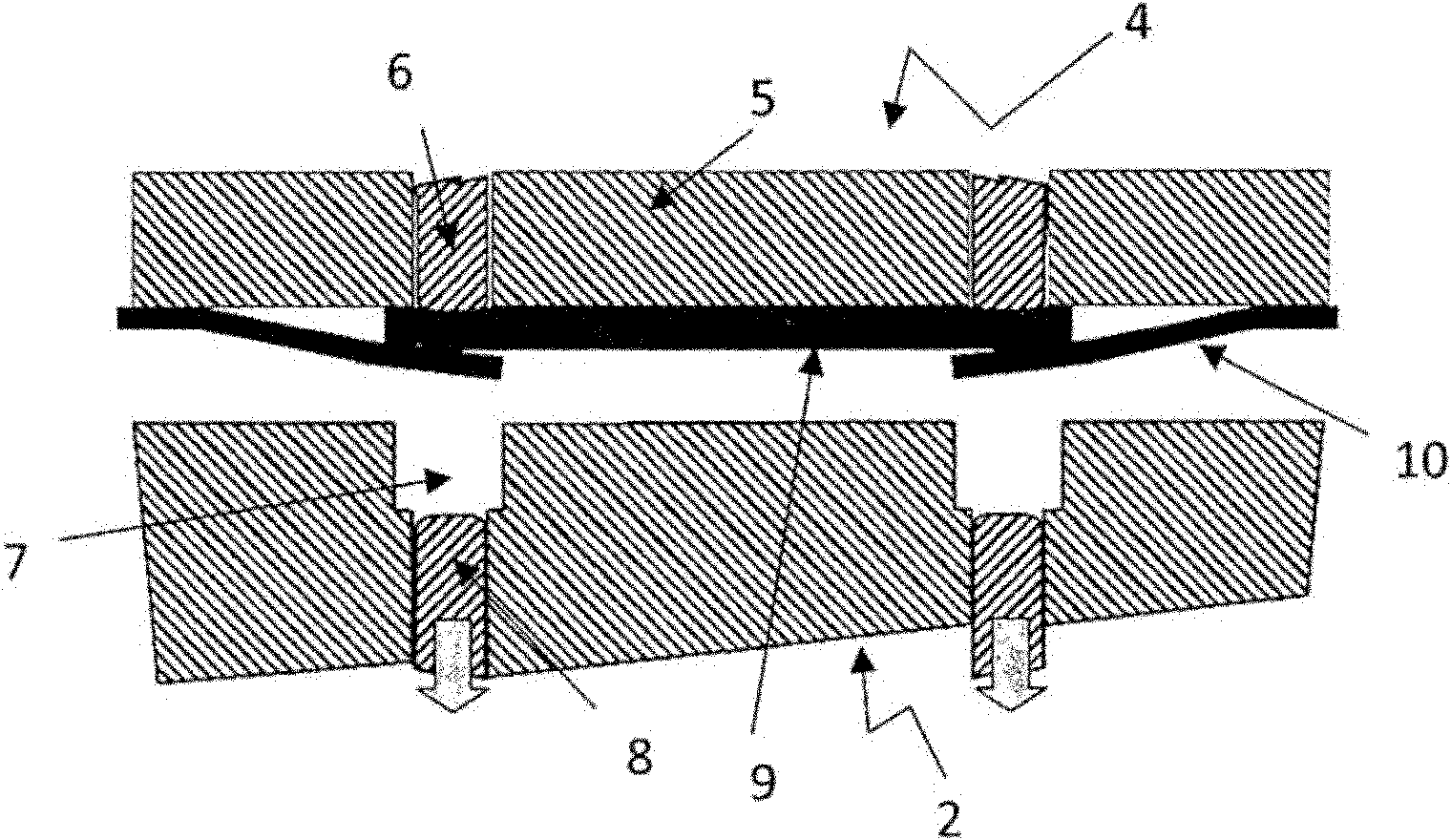

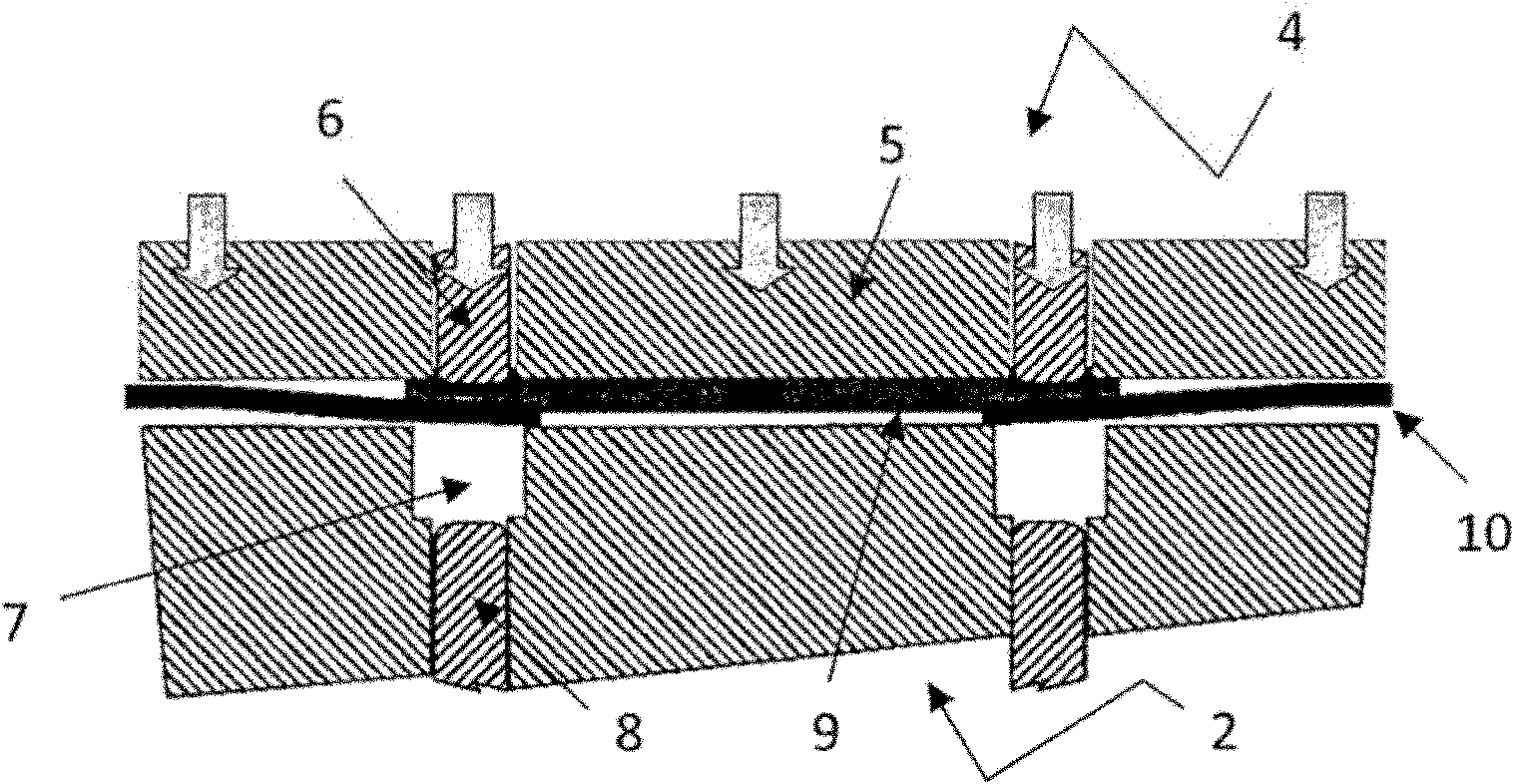

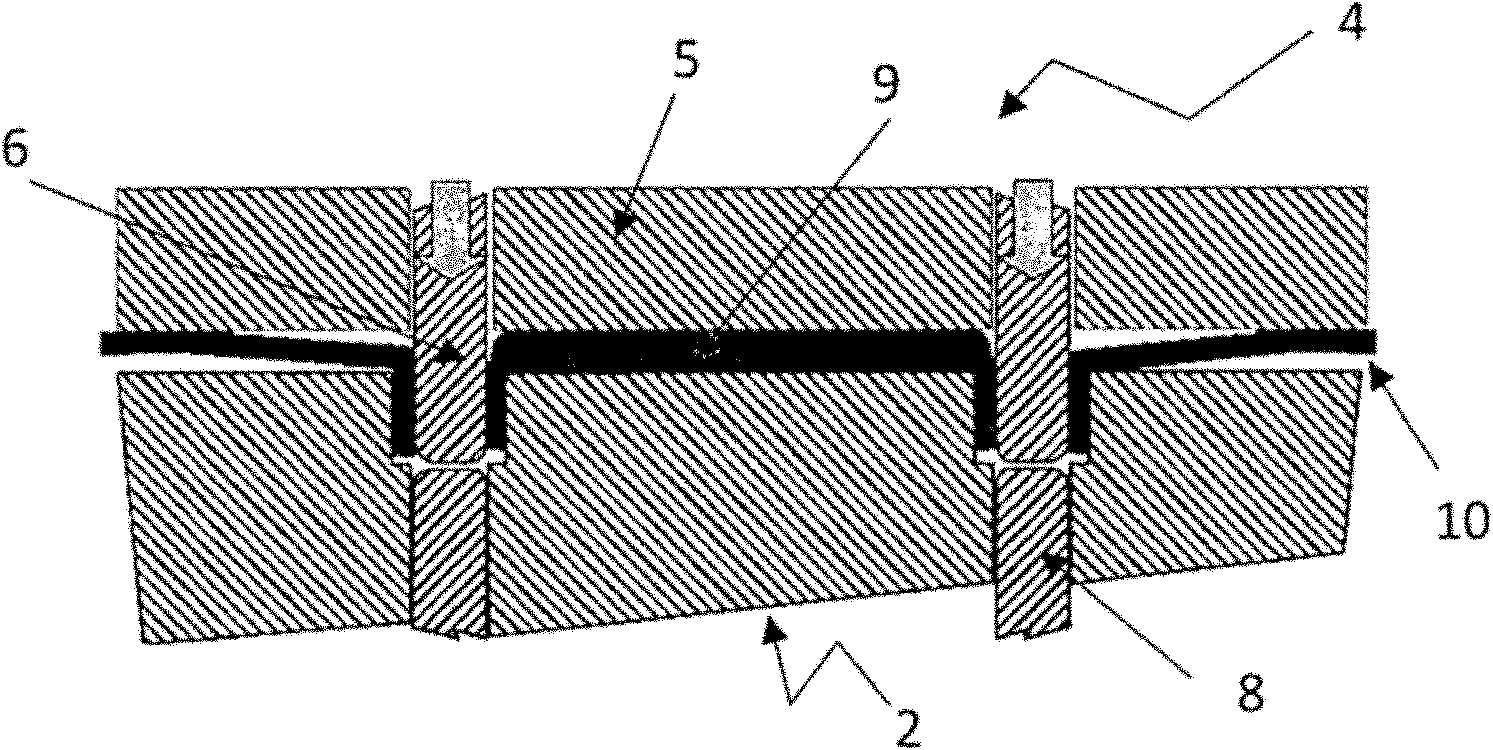

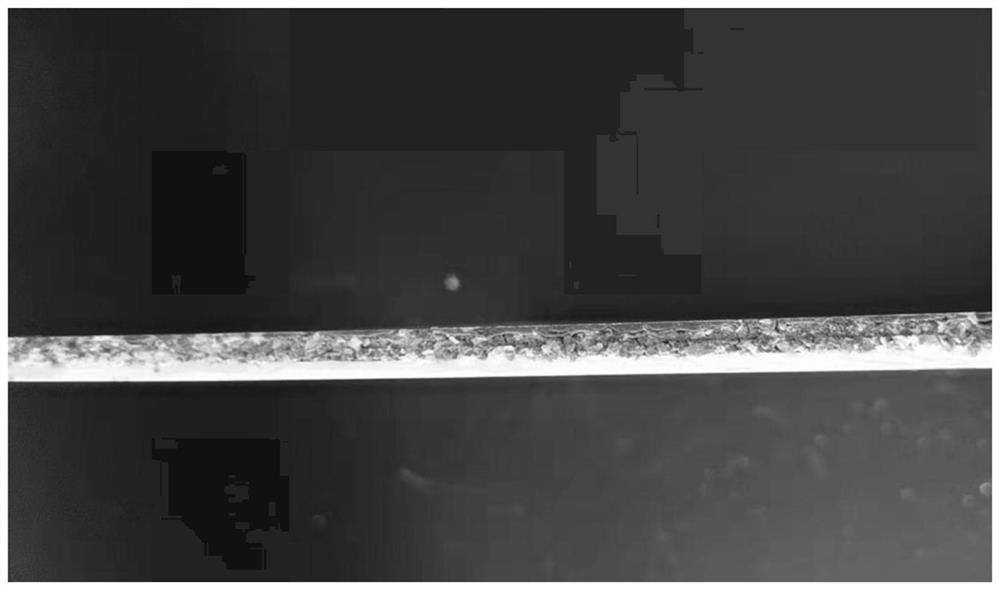

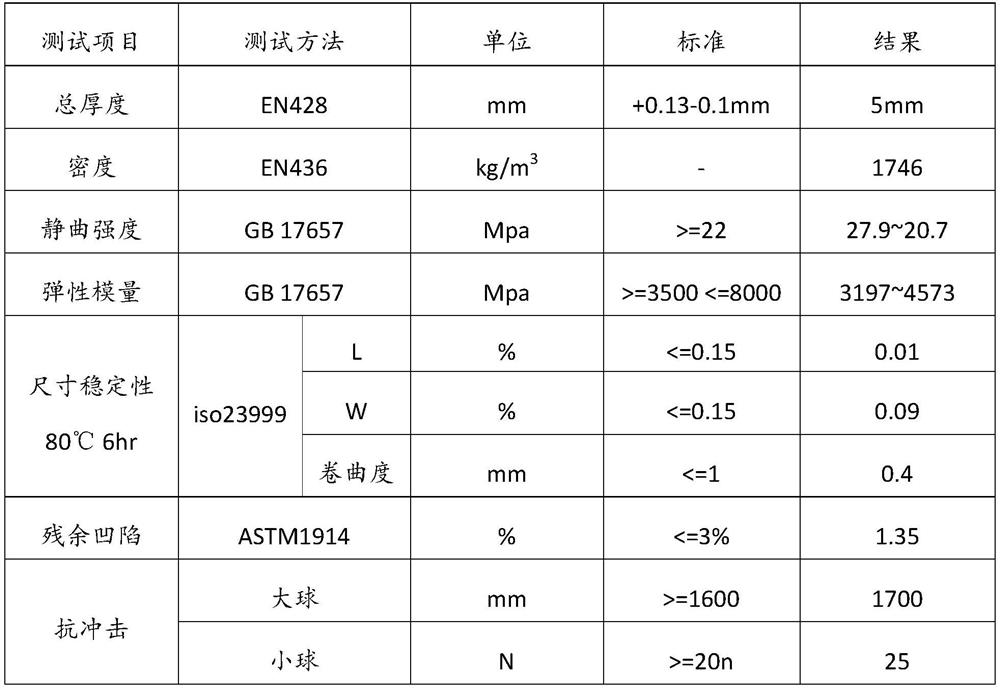

Molded part having a plurality of different decorative regions that abut on each other and a method and a device for the production thereof

The present invention relates to a method and to a device for producing a molded part having a plurality of different decorative regions that abut on each other, wherein the different decorative films (9, 10) are inserted into a molding tool (1) by a gripper (4). There they are fixed by means of sliders (8) and are then back-molded with a thermoplastic material (15).

Owner:派格有限公司

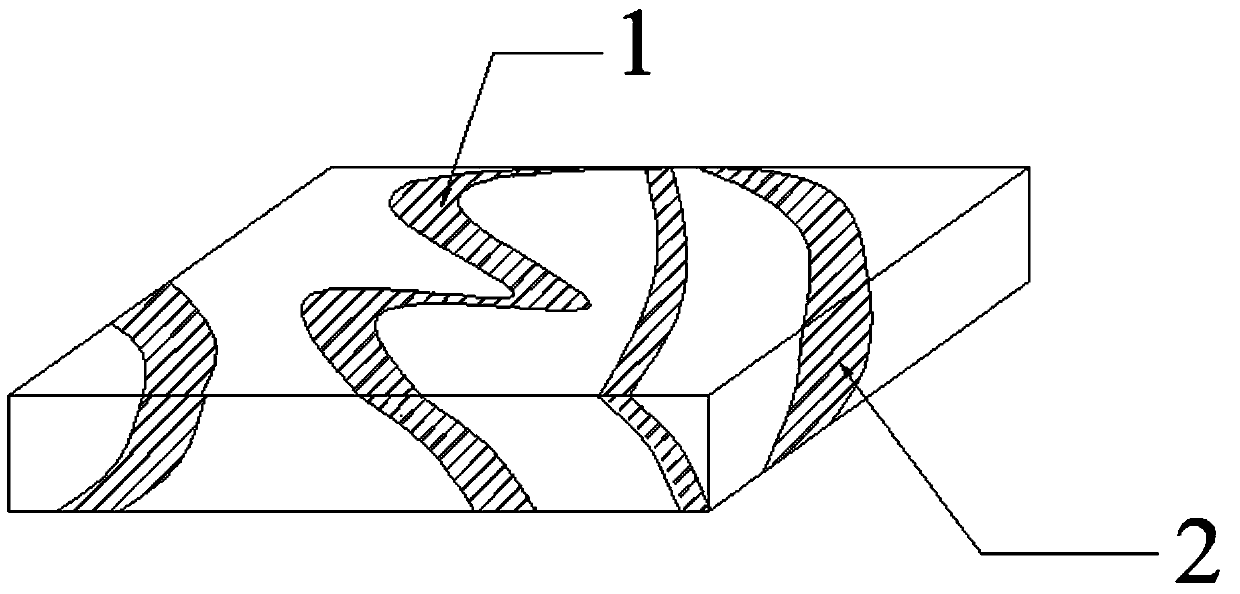

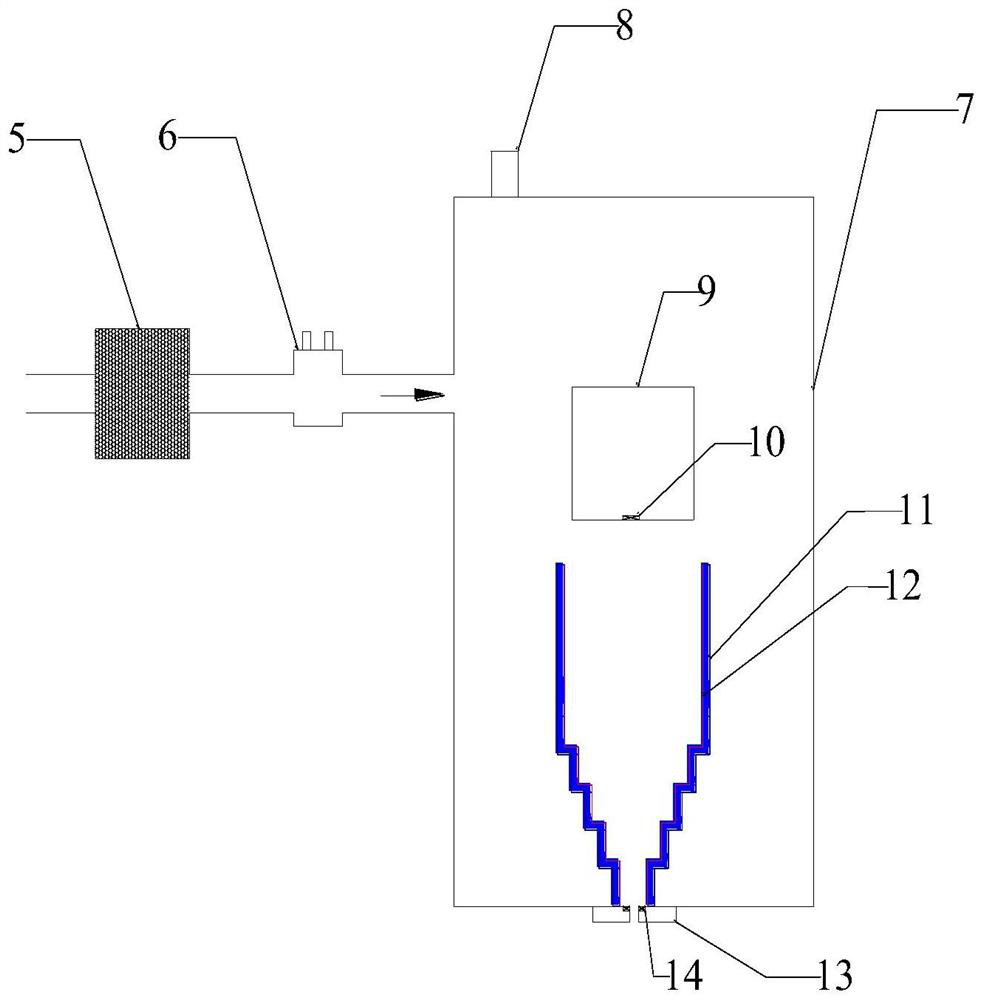

Preparation method and application of decorative material

PendingCN114701152AFlexible adjustment of depthLow costDecorative surface effectsMaterial distributionMolding (decorative)

The invention discloses a preparation method and application of a decorative material.The method comprises the steps that a main base material is adopted for material distribution, a main base material layer is formed, a grain base material is arranged on the upper surface of the main base material layer to form a grain pattern, a blank is obtained, the main base material is a thermoplastic material, the blank is subjected to hot press molding, and a semi-finished product with the grain base material embedded in the surface is obtained; and removing the grain base material on the surface of the semi-finished product to obtain the decorative material. According to the method, the surface grains corresponding to the whole-body grains are distributed on the surface of the main base material through the grain base material, the concave grains can be formed on the surface of the decorative material after hot press molding and removal of the grain base material, the grains are matched with the whole-body grains in pattern, the method is suitable for making marble grains or wood grains, the fidelity is high, the cost of the used materials is low, and the cost is low. Existing equipment can be used for installation, and the equipment cost is low. In addition, the decorative material is provided with whole-body textures, the problem that the pattern layer is abraded off does not exist, so that a wear-resistant layer is not arranged, and the material cost is further reduced.

Owner:无锡同力塑胶贸易有限公司

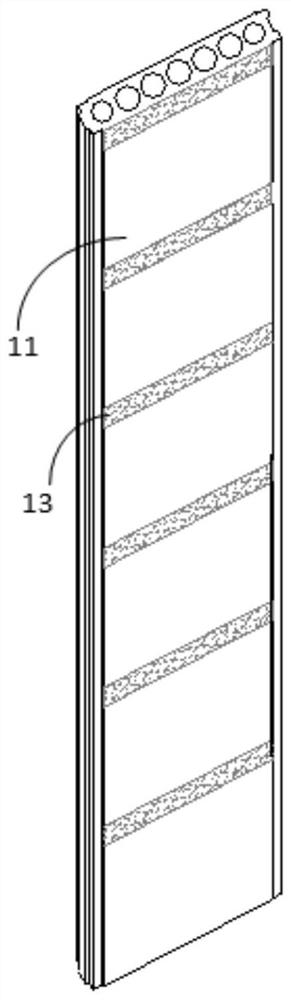

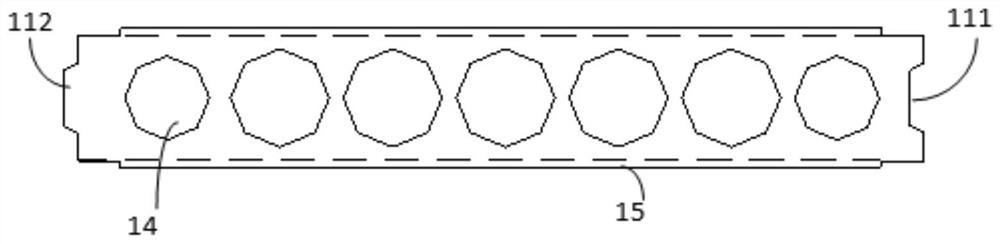

Decorative high-performance wallboard based on formwork back marking process and preparation method thereof

ActiveCN111805697AEasy to fall offHigh bonding strengthCovering/liningsCeramic shaping apparatusSlurryUltimate tensile strength

The invention discloses a decorative high-performance wallboard based on a formwork back marking process, and the decorative high-performance wallboard is characterized in that the decorative high-performance wallboard comprises a decorative board and a large-cavity wallboard, wherein the hollow rate of the large-cavity wallboard is greater than and equal to 65% and prepared by fiber-reinforced cement-based composite materials through a grouting extrusion process. The invention further discloses a preparation method for the decorative high-performance wallboard based on the formwork back marking process. The decorative board of the decorative high-performance wallboard is quickly fixed on the side of a mold through electromagnetic force, so the problem of fixing the decorative board quickly when a formwork mold uses the back marking process; and the problems of sliding, incomplete spicing and slurry dripping of the decorative board when the fiber-reinforced cement-based composite material is grouted and extruded are effectively solved, and meanwhile, the large cavity wallboard adopts the grouting extrusion process to improve the bonding strength of the decorative board and the large cavity wallboard effectively.

Owner:CHINA WEST CONSTR ACAD OF BUILDING MATERIALS CO LTD +1

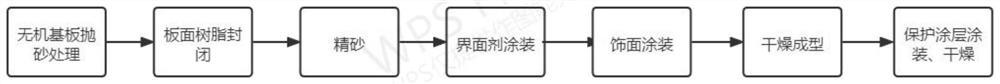

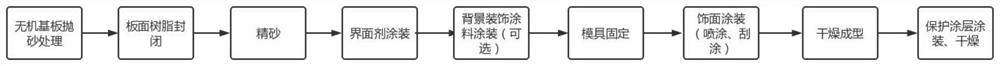

Coating method of imitation brick veneer

PendingCN114273175ARealize mass productionRich typePretreated surfacesCoatingsBrickMolding (decorative)

The invention relates to a coating method of an imitation brick veneer. The coating method mainly comprises the following steps in sequence: (1) carrying out surface slinging treatment on the veneer; (2) coating resin on the surface of the veneer for sealing until the veneer is dry; after closing is completed, fine sanding treatment is conducted on the surface of the veneer; (3) brushing a layer of adhesion agent on the surface of the veneer until the adhesion agent is dry; (4) the imitation brick mold is tightly attached and fixed to the surface of the facing base plate, then facing paint is coated on the surface, and after coating is completed, the imitation brick mold is immediately removed to be dried and formed at the constant temperature; and (5) brushing a protective coating on the surface of the veneer to obtain the imitation brick veneer. The method overcomes the defect that the imitation brick facing of an existing heat preservation decorative plate cannot be produced in batches, the needed imitation brick effect can be obtained by using the imitation brick mold, covering the surface part of the heat preservation decorative plate facing base plate, then coating and removing the mold after coating is completed, and the method has the advantages that operation is easy and convenient, and the imitation brick facing can be produced in batches.

Owner:福建省三棵树新材料有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com