Precise molding method of spatial curved surface GRC curtain wall

A molding method and curtain wall technology, applied in the direction of wall, building material processing, building components, etc., can solve the problems of quality and safety hidden danger, anchoring disc falling off, low tensile strength guarantee rate, etc., to achieve easy operation and improve production quality. , the effect of improving production accuracy and quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0049] The present invention will be further described below through the accompanying drawings in the description and in conjunction with specific embodiments.

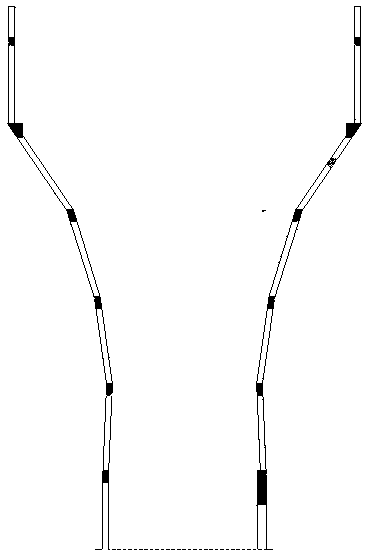

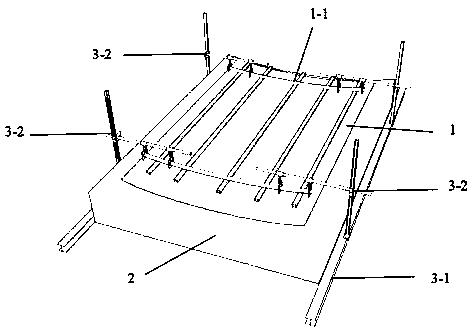

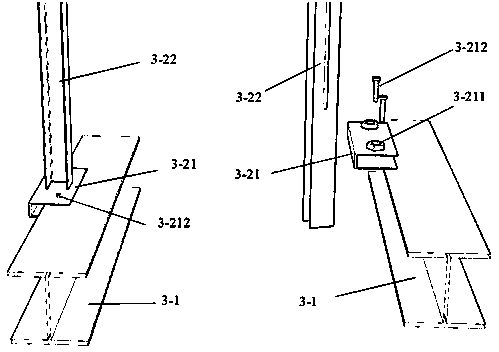

[0050] A preferred example of the present invention is a special-shaped building structure with a curved surface in space. The main body of the structure has been completed, and the construction stage of the curtain wall has entered. The curtain wall adopts GRC curtain wall, figure 1 The pavement diagram of one of the main structure shapes is given. The exterior adopts GRC curtain wall, and the curtain wall presents a space-expanding hyperboloid shape in space. The size of each GRC curtain wall unit plate is different, and the curtain wall processing is extremely difficult. At the same time, the structural entity There is a certain construction error between the design and the design, and the requirements for the spatial positioning of the curtain wall are very high. If it is not handled properly, it will cause great ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com