Preparation method and application of decorative material

A technology for decoration materials and base materials, applied in the field of preparation of decoration materials, can solve the problems of high cost of ink and printing equipment, inability to make digital printers, deep lines, etc., to reduce material costs, low equipment costs, and low material costs. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

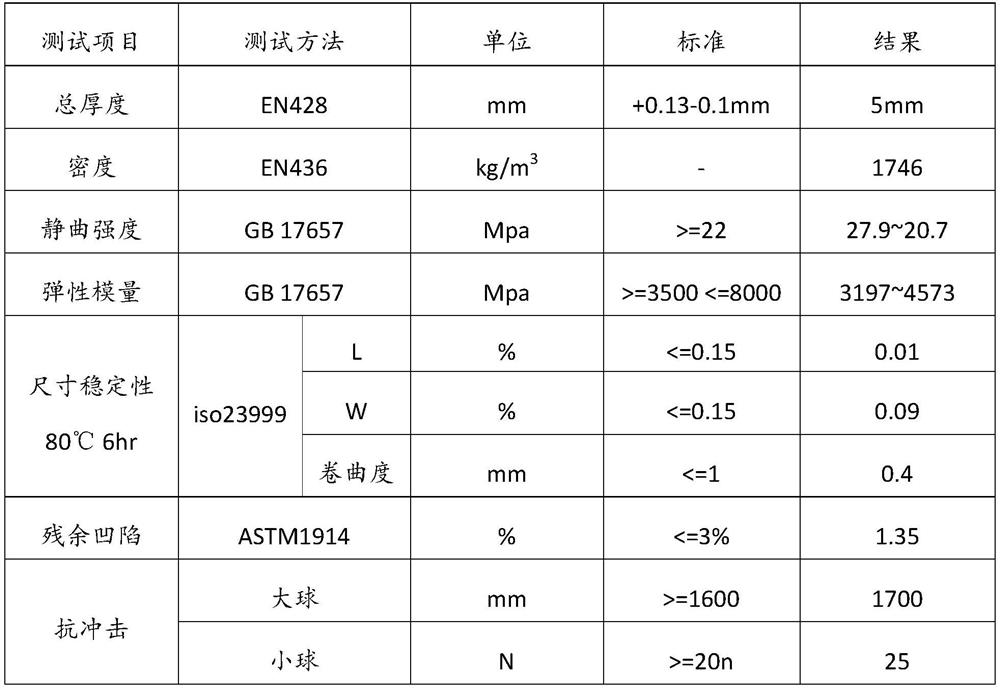

Examples

Embodiment 1

[0033] In this embodiment, a full body decorative board is prepared, and the specific process is as follows:

[0034] (1) Granulation: in parts by weight, 18 parts of PP, 73 parts of calcium carbonate filler, 1 part of stabilizer, 7 parts of plasticizer and an appropriate amount of toner are mixed, extruded and granulated, pulverized and sieved to obtain The particle size is 15-200 mesh main base material;

[0035] (2) Digital cloth: Import the design pattern to be made into the control computer of the digital cloth machine, use the main base material to fabricate in the cloth frame to form a main base material layer of a certain thickness, and then follow the preset surface texture on the main base material layer. Sprinkle fine sand on the corresponding place on the upper surface of the cladding to obtain the blank;

[0036] (3) Hot press forming: Push the fabric frame into the multi-laminator, and heat the blank for 16 minutes at 185°C, then press it for 40 minutes under a ...

Embodiment 2

[0042] This embodiment prepares a kind of semi-through body decorative board, and the specific process is as follows:

[0043](1) Granulation: by weight, 13 parts of PET, 70 parts of calcium carbonate filler, 9 parts of talc, 1 part of stabilizer, 4 parts of plasticizer and an appropriate amount of toner are mixed, extruded granulation, pulverized and sieving to obtain the main base material with a particle size of 15-200 mesh;

[0044] (2) Digital cloth: The digital cloth machine is connected to the sheet extrusion production line, and the single-color PVC board produced by the sheet extrusion production line is used as the base layer. The texture sprinkles fine sand on the corresponding place on the upper surface of the main base material layer to obtain a blank composed of a single-color PVC board, a main base material and fine sand;

[0045] (3) Hot press forming: Push the fabric frame into the multi-laminator, and heat the blank for 16 minutes at 140°C, then press it for...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com