Decorative high-performance wallboard based on formwork back marking process and preparation method thereof

A high-performance, decorative board technology, applied in the direction of manufacturing tools, ceramic molding machines, building structures, etc., can solve the problems of easy falling off of decorative boards, poor durability, and heavy wall panels

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

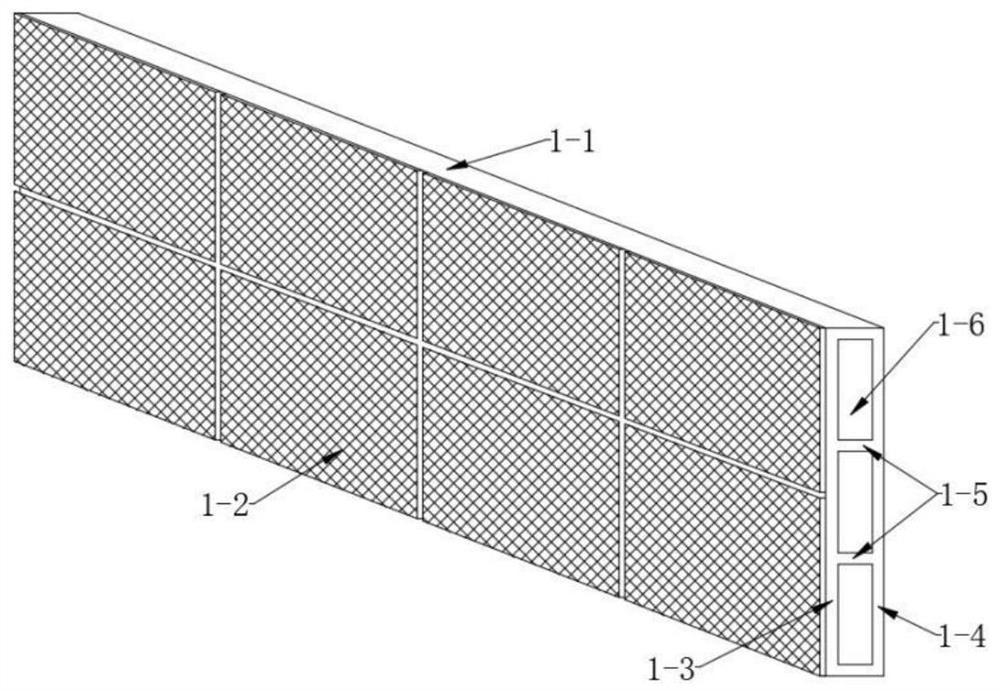

[0027] A decorative high-performance wallboard based on the vertical formwork reverse technology and its preparation method are as follows:

[0028] (1) Fixing of the decorative plate: The decorative plate is spliced by ceramic plates of the same size. During the mold assembly process, an electromagnet is installed on the outside of the mold for fixing the decorative plate, and the ceramic plate is assembled in the inner layer, and the The stainless steel iron sheet is attached inside, and each time a ceramic plate is assembled, the electromagnet at the corresponding position on the outside of the part of the mold is energized, and the position of the ceramic plate is quickly fixed by the electromagnetic force of the electromagnet and the metal sheet. According to this method, the assembling of the decorative board of the whole mold is completed.

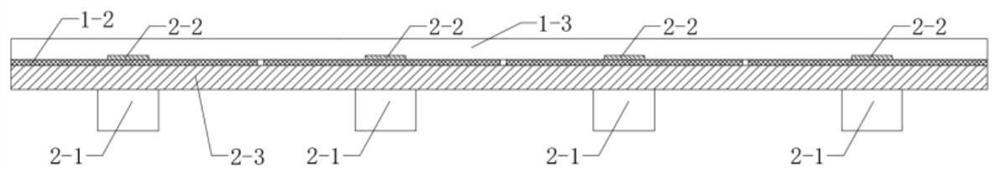

[0029] (2) Mold assembly: assemble the bottom mold, the upper bottom mold, the lower bottom mold, the left mold, the right mold,...

Embodiment 2

[0044] A preparation method of a decorative high-performance wallboard based on the vertical formwork reverse technology is as follows:

[0045] (1) Fixing of the decorative plate: the decorative plate is spliced by rock decorative panels of the same size. During the mold assembly process, an electromagnet is installed at a specific position on the outside of the mold for fixing the decorative plate, and the rock decorative panel is assembled on the inside. And attach the aluminum sheet in the rock veneer, and each time a rock veneer is assembled, the electromagnet at the corresponding position on the outside of the part mold is energized, so that the position of the rock veneer is fixed by the electromagnetic force between the electromagnet and the aluminum sheet. According to this method, the splicing of the decorative panels of the entire mold is completed.

[0046](2) Mold assembly: assemble the bottom mold, the upper bottom mold, the lower bottom mold, the left mold, th...

Embodiment 3

[0070] A preparation method of a decorative high-performance wallboard based on the vertical formwork reverse technology is as follows:

[0071] (1) Fixing of the decorative plate: the decorative plate is spliced by rock decorative panels of the same size. During the mold assembly process, an electromagnet is installed at a specific position on the outside of the mold for fixing the decorative plate, and the rock decorative panel is assembled on the inside. And attach the aluminum sheet in the rock veneer, and each time a rock veneer is assembled, the electromagnet at the corresponding position on the outside of the part mold is energized, so that the position of the rock veneer is fixed by the electromagnetic force between the electromagnet and the aluminum sheet. According to this method, the splicing of the decorative panels of the entire mold is completed.

[0072] (2) Mold assembly: assemble the bottom mold, the upper bottom mold, the lower bottom mold, the left mold, t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Compressive strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Flexural strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com