Solid-appearing fence system

a fence system and solid-looking technology, applied in fencing, building types, constructions, etc., can solve the problems of inability to build fences made of soil-based materials, prohibitive labor and soil-based materials, and the cost and labor requirements for constructing the solid-looking fence system are substantially lower than the cost and labor requirements for typical fences, so as to facilitate the horizontal engagement of members, easy to be lifted, and easy to construct

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

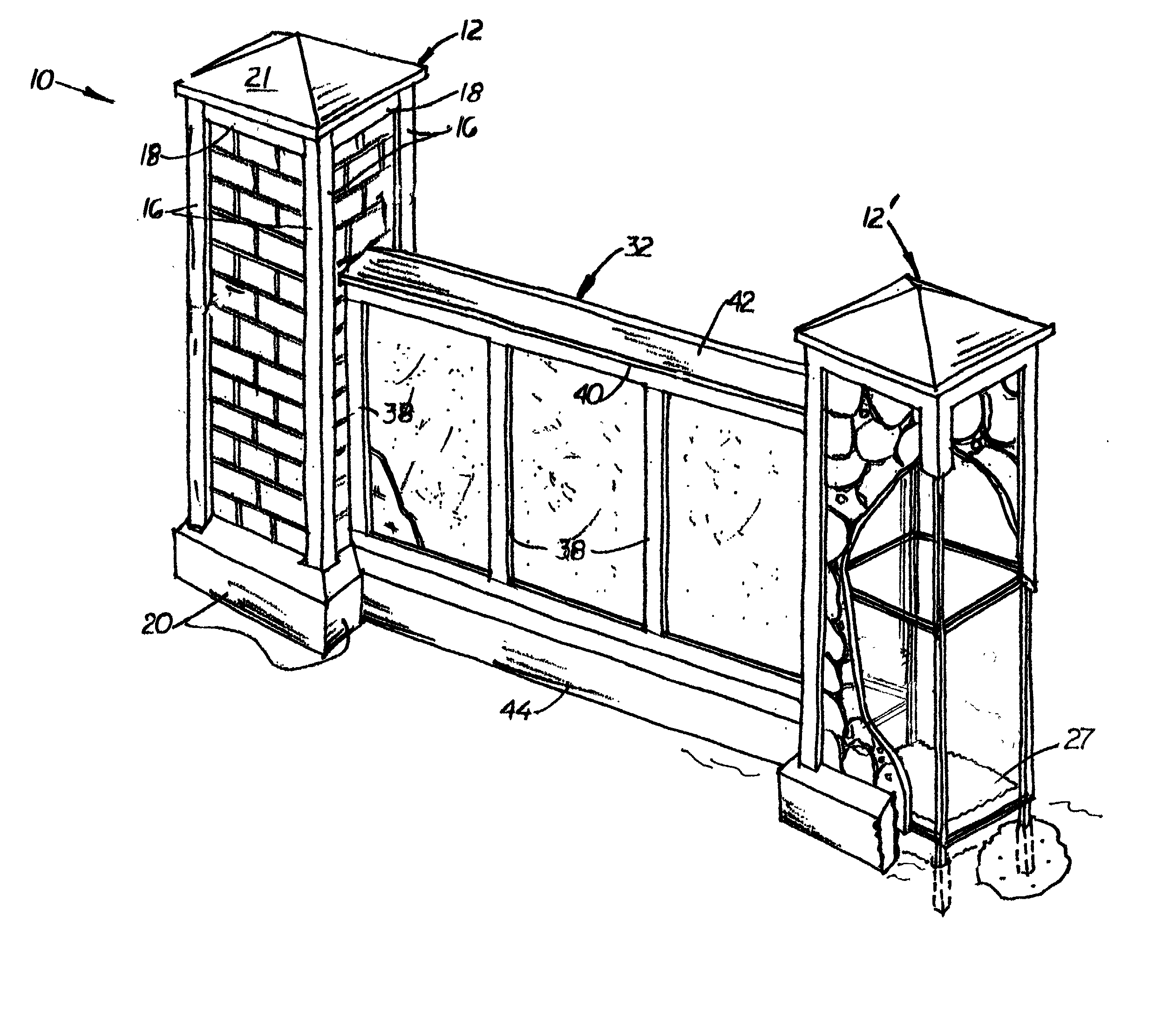

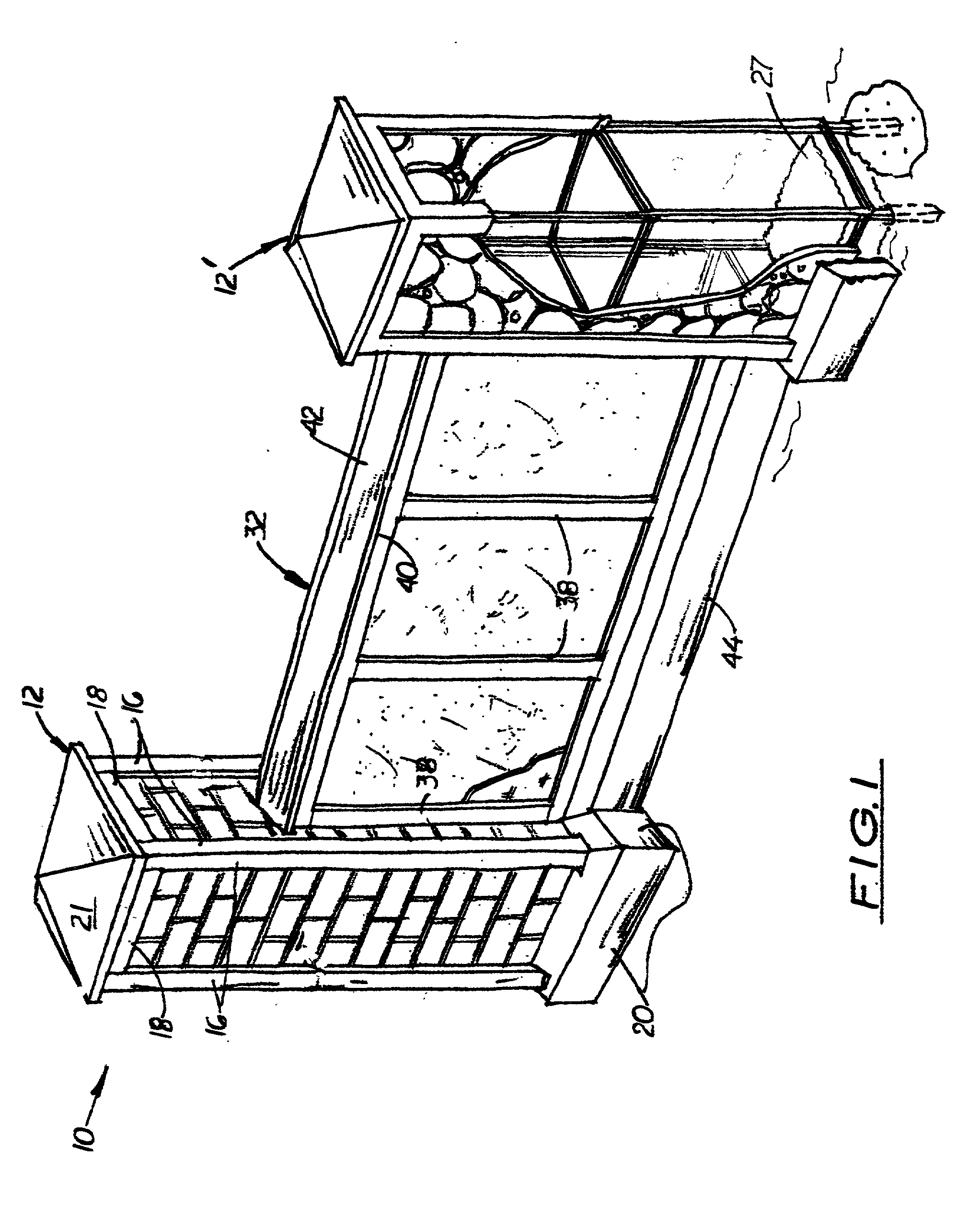

[0032] In the first embodiment, panels 29, 60 are made of thin concrete with are exposed outer surfaces, thereby making the columns 12 and wall members 32 appear to be a solid structures made of concrete. In other embodiments, an optional layer of brick 65, rock 67, or stucco 69 may be constructed over the outer surfaces of panels 29, 60, as shown in FIGS. 3-4. Removable caps 21 or 42 or lighting fixture (not shown) may be attached to the top of each column 12, or wall member 32, respectively, to create fully enclosed structures. Wood moldings 16, 18, 20, and 38, 40, 44 may also be attached to the sides of the columns 12 and wall members 32, respectively, to provide a more finished, attractive appearance.

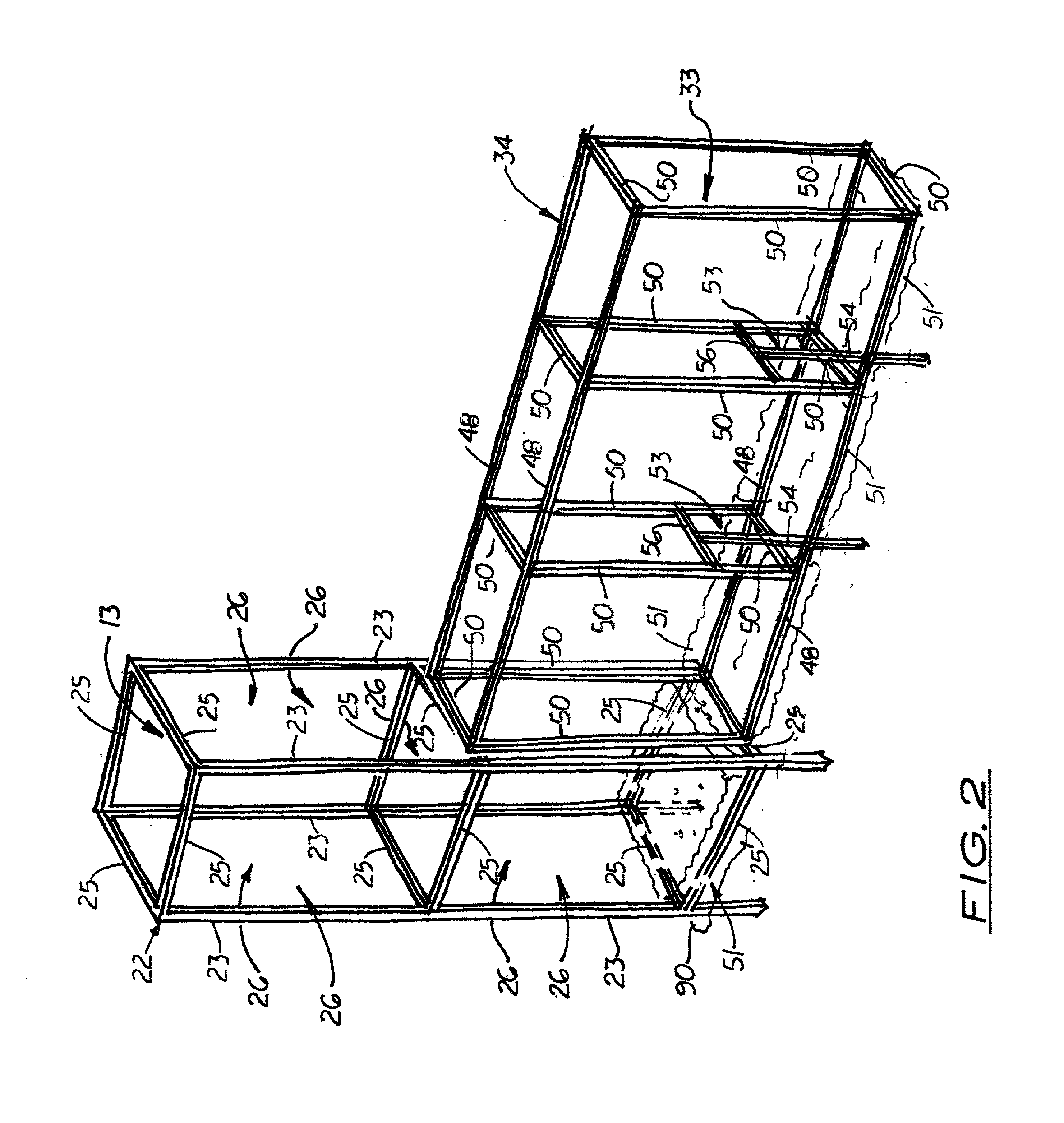

[0033] The column's interior cage 22 includes four longitudinal legs 23 and a plurality of transversely aligned cross-members 25. The longitudinal legs 23 and cross-members form a skeleton framework 24, square or rectangular in cross-section with an unobstructed longitudinally align...

third embodiment

[0043] In FIGS. 11 and 12, a panel 84 is shown which includes a plurality of clips 87 that extend inward from the inside surface 85 to engage a vertical or horizontal member on the column or wall. The clips 87 are spaced apart approximately the same distance (12 to 24 inches) as the longitudinally legs and members, and cross-members. In the preferred embodiment, the clips 87 are leg extensions formed on a wire mesh 88 material commonly used to construct concrete slabs. During assembly, the panel 84 is lifted and positioned in a vertical orientation adjacent to the surface of the column 12 or wall member 32 to be covered. The panel 84 is then lifted and pressed inward so that some or all of the clips 87 may engage the adjacent member. The clips 87 are L-shaped so that gravitational forces hold the panel in place on the horizontal member. Suitable connectors similar to the connectors used with panels 29, 60, 72, may then be used to more securely attach the panels 87 to the column 12 o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com