Molded part having a plurality of different decorative regions that abut on each other and a method and a device for the production thereof

A technology for decorative areas and moldings, applied to household components, household appliances, and other household appliances, which can solve the problems of waste, irregular seam patterns, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

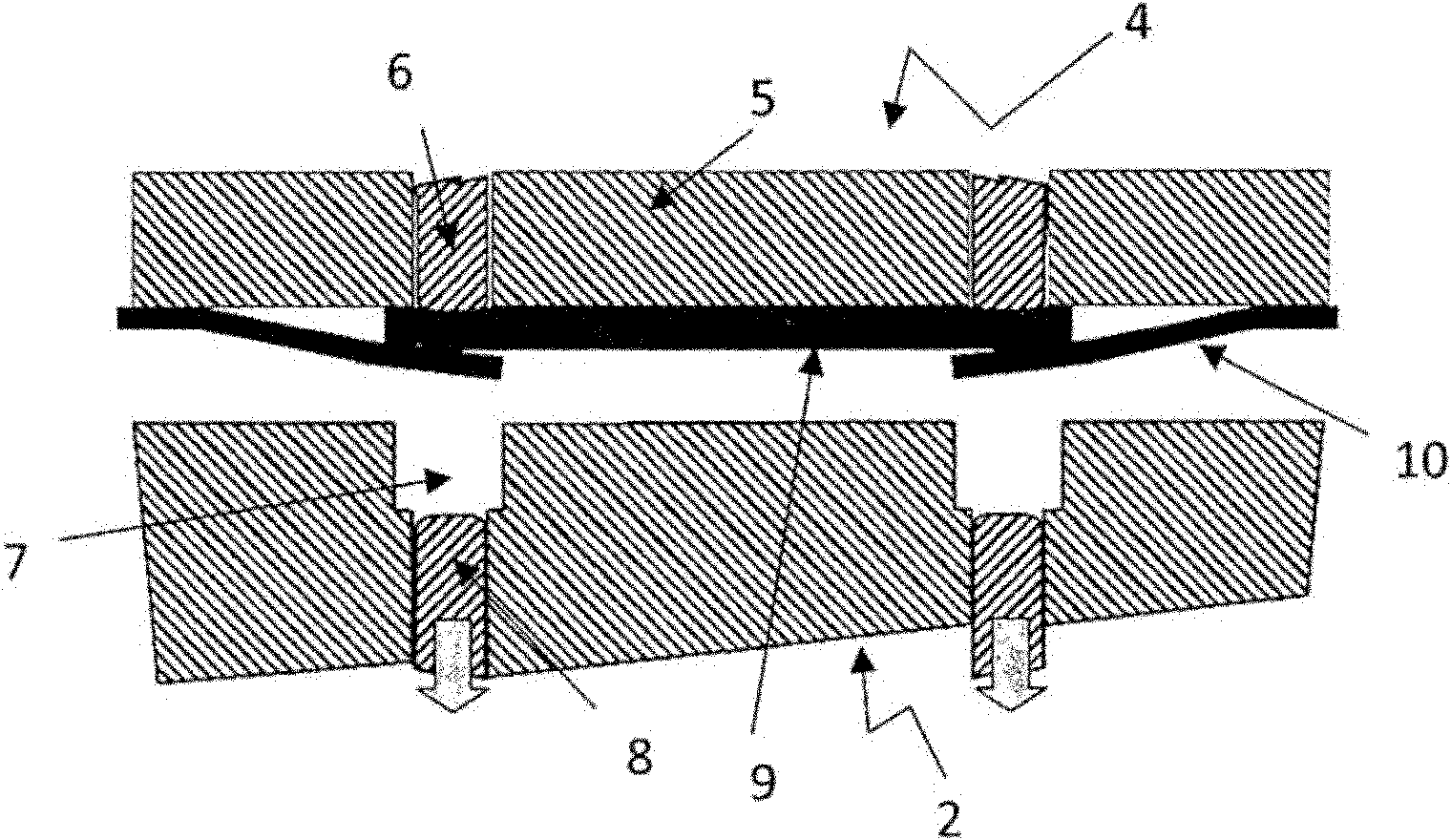

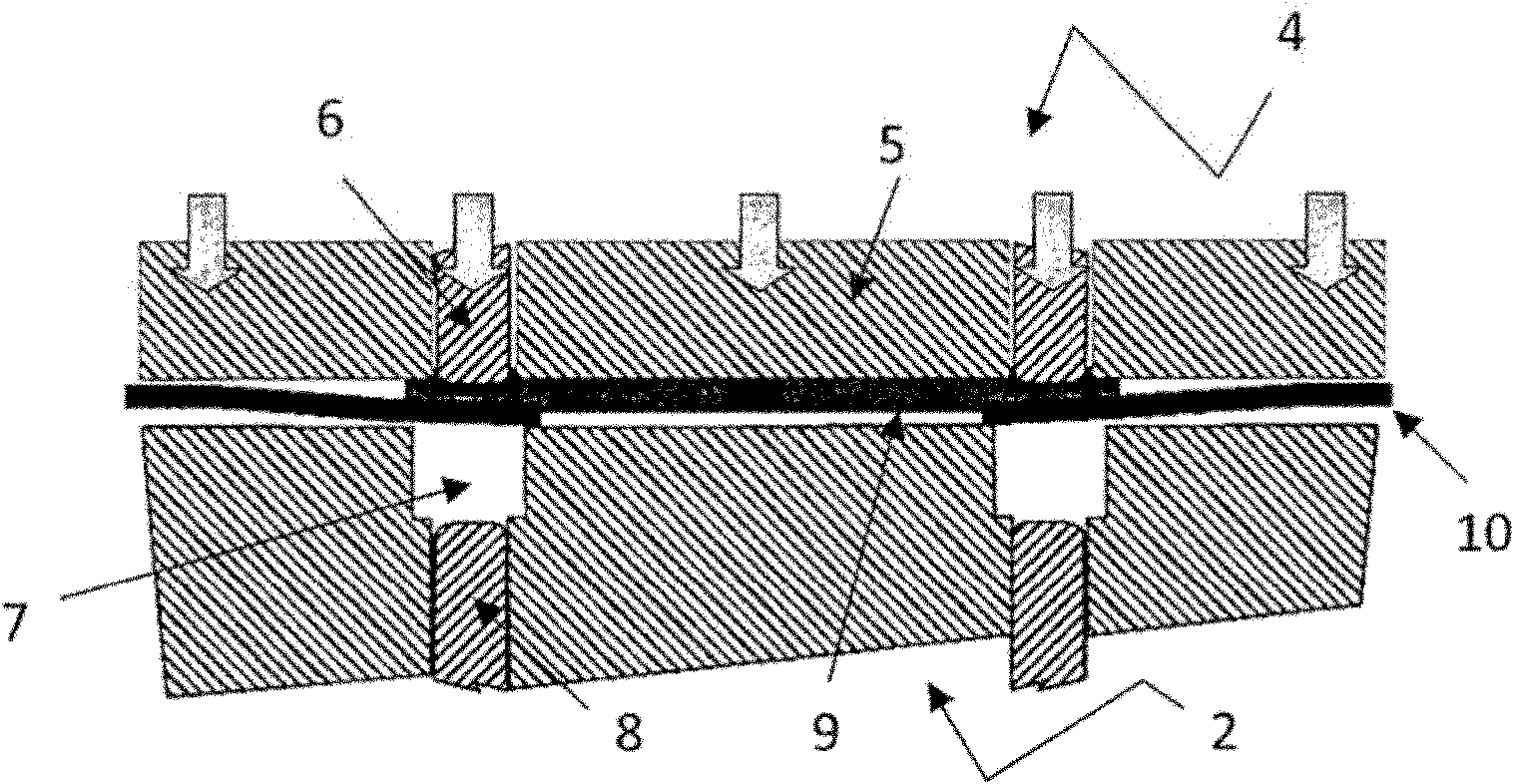

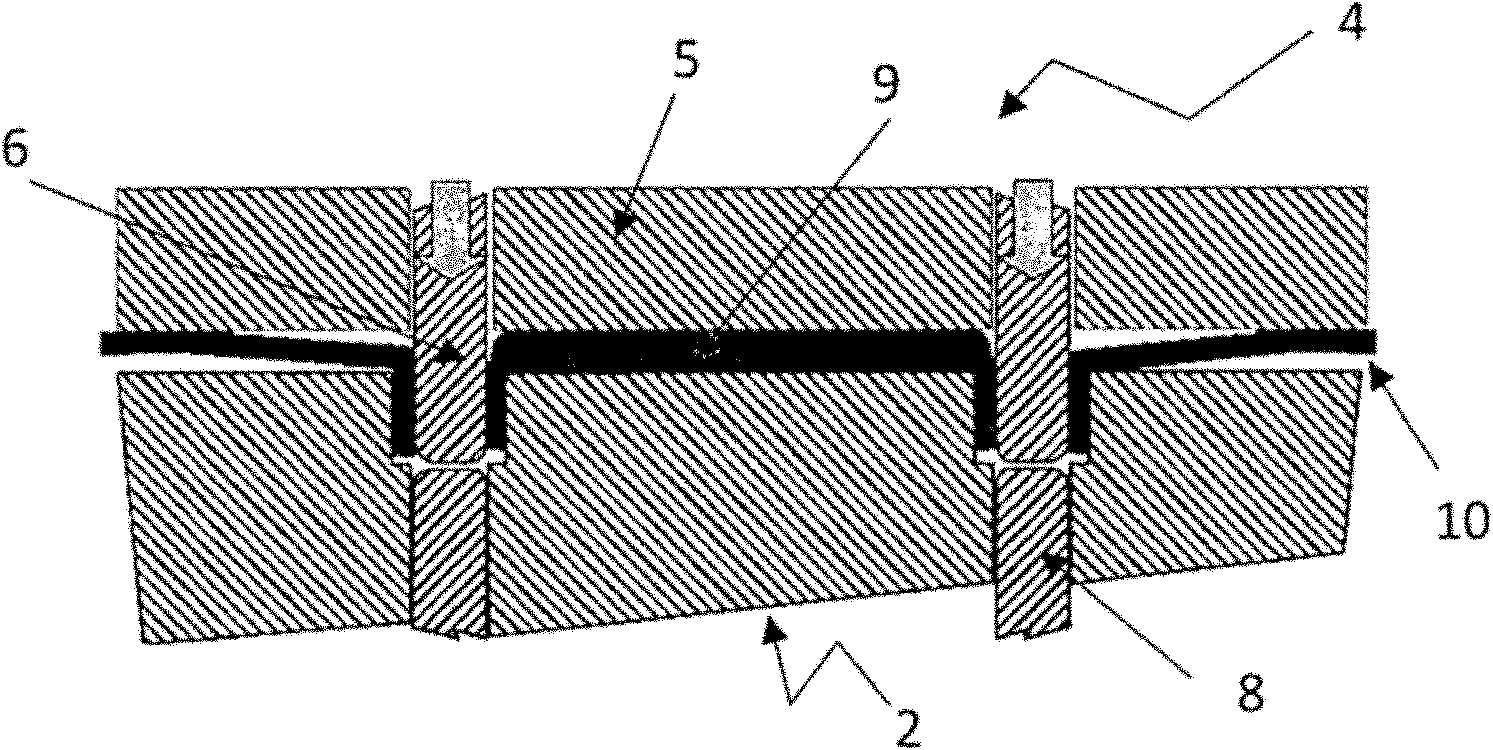

[0028] exist Figures 1 to 5 The typical sequence of the method according to the invention up to the completion of the insertion of the different decorative films is shown in a partial cross-sectional view of the forming tool core 2 and the holder 4 . For example in figure 1 A detail of the holder 4 is shown in , on which different decorative films 9 and 10 are arranged, the edges of which overlap one another in the region of the holder frame 6 . The figure relates to a photograph of a moment shortly before the decorative film 9, 10 is inserted into the molding tool, partially showing the molding tool core 2 of the molding tool with recesses 7 arranged therein. The grooves are provided corresponding to the holder frame 6 . Slides 8 , which correspond to the gripper frame 6 or the grooves 7 , are respectively integrated in the forming tool core 2 in the region of the grooves 7 .

[0029] figure 2 The next method step is shown in the same diagram, in which the decorative fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com