Full digitalization decorative porcelain polished tile and production method thereof

A fully digital, production method technology, applied in the direction of ceramic molding machines, manufacturing tools, etc., can solve the problems of reducing the decorative effect and affecting the aesthetic feeling, and achieve the effect of fine and realistic texture and improve work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

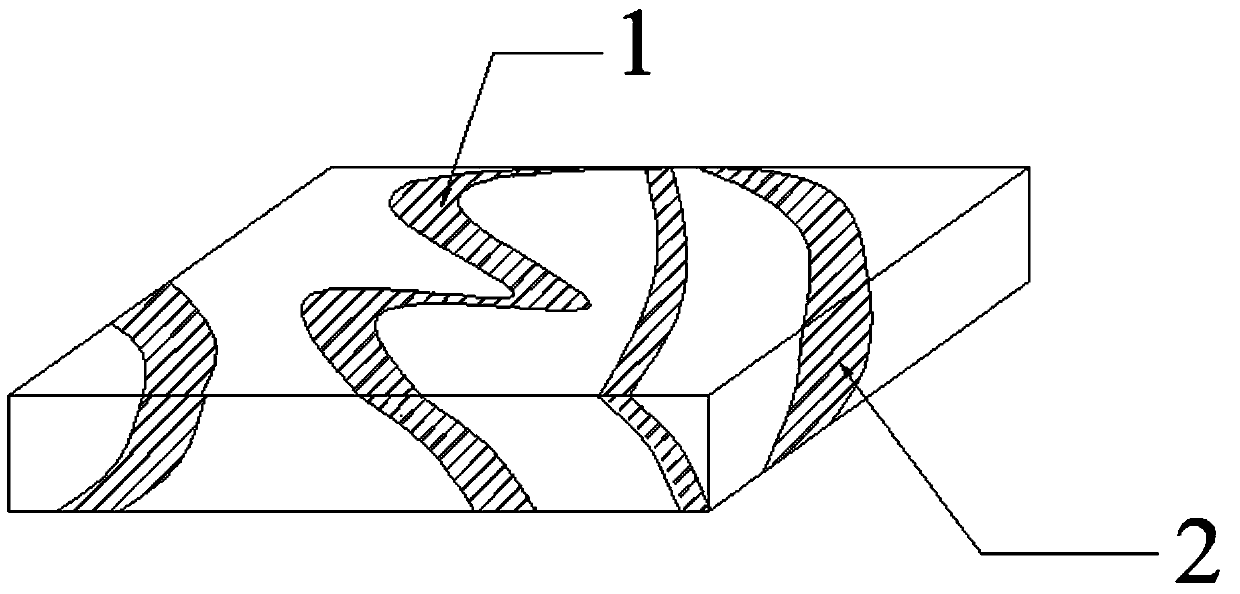

[0057] The present invention will be specifically described below with reference to the accompanying drawings and in combination with embodiments.

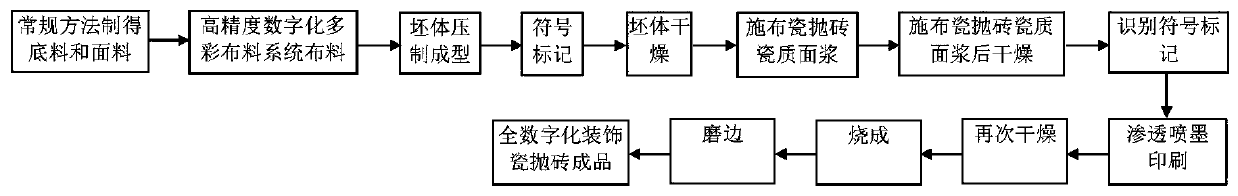

[0058] Such as Figure 1~6 Shown, the present invention adopts following steps to realize:

[0059] a) Prepare the base material and the lining of the ceramic tile body according to the conventional method, and set aside;

[0060] b) Use high-precision digital colorful cloth system and cloth technology to carry out the cloth, and form the powder material layer of the tile body with the thickness required for molding, and send the powder layer of the body into the cavity of the press;

[0061] The high-precision digital colorful cloth system includes a computer hardware control system, a computer software control system and a high-precision digital colorful cloth device; the computer hardware control system provides an operating environment for the computer software control system; the computer software control system is After in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com