Patents

Literature

32results about How to "Burn clean" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Compression-molded vegetable wax-based candle

InactiveUS20070144058A1Burn cleanSuperior compressed candle productSolid fuelsCandle ingredientsParaffin waxCompression molding

Prilled wax particles are formed from a vegetable wax-based composition. After compression, a predominantly paraffin wax-based composition is optionally poured over the vegetable wax-based composition to form an encased candle. The method of the present invention offers the possibility to incorporate a high fragrance load to the candle.

Owner:CHEN QIN +4

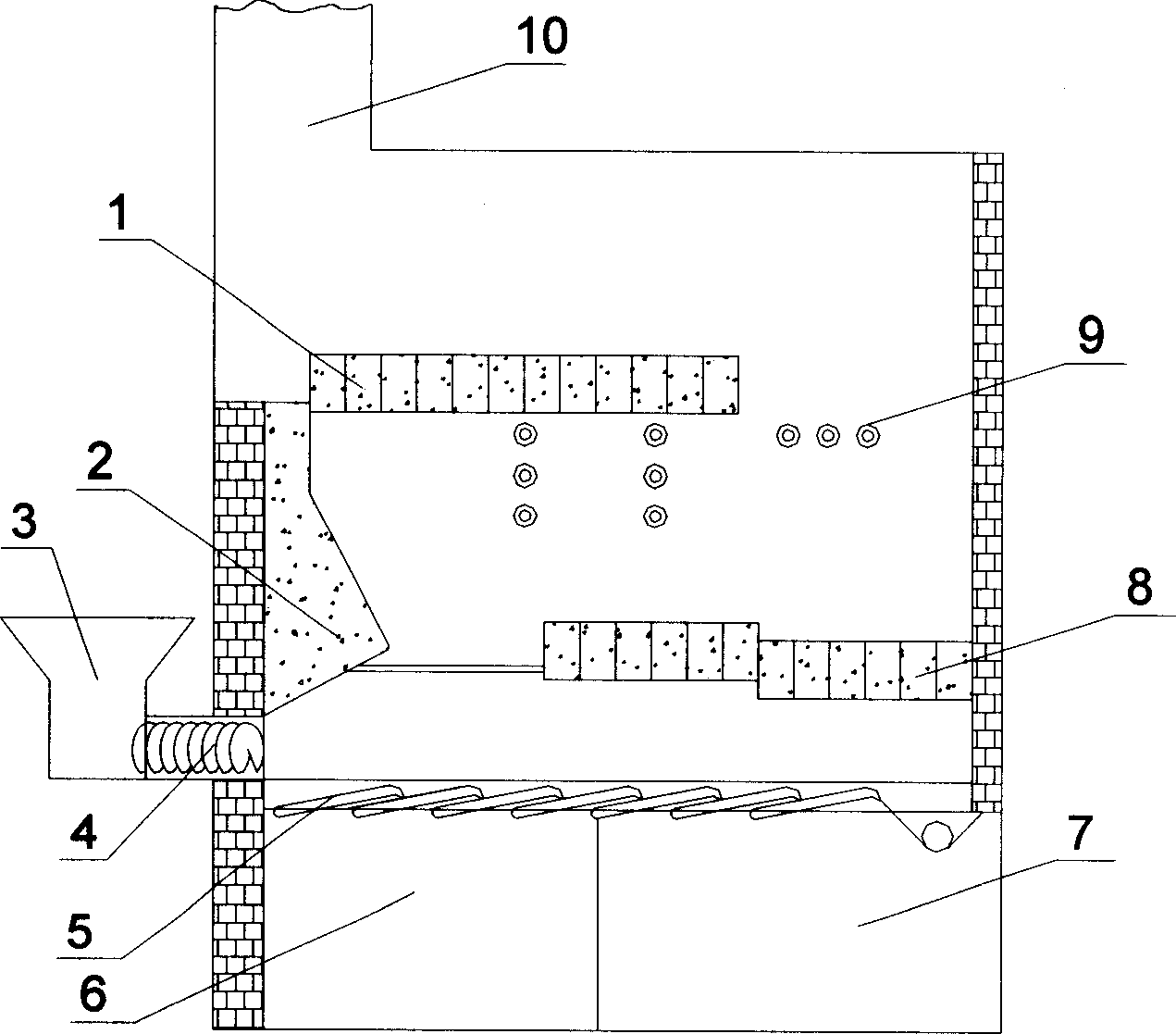

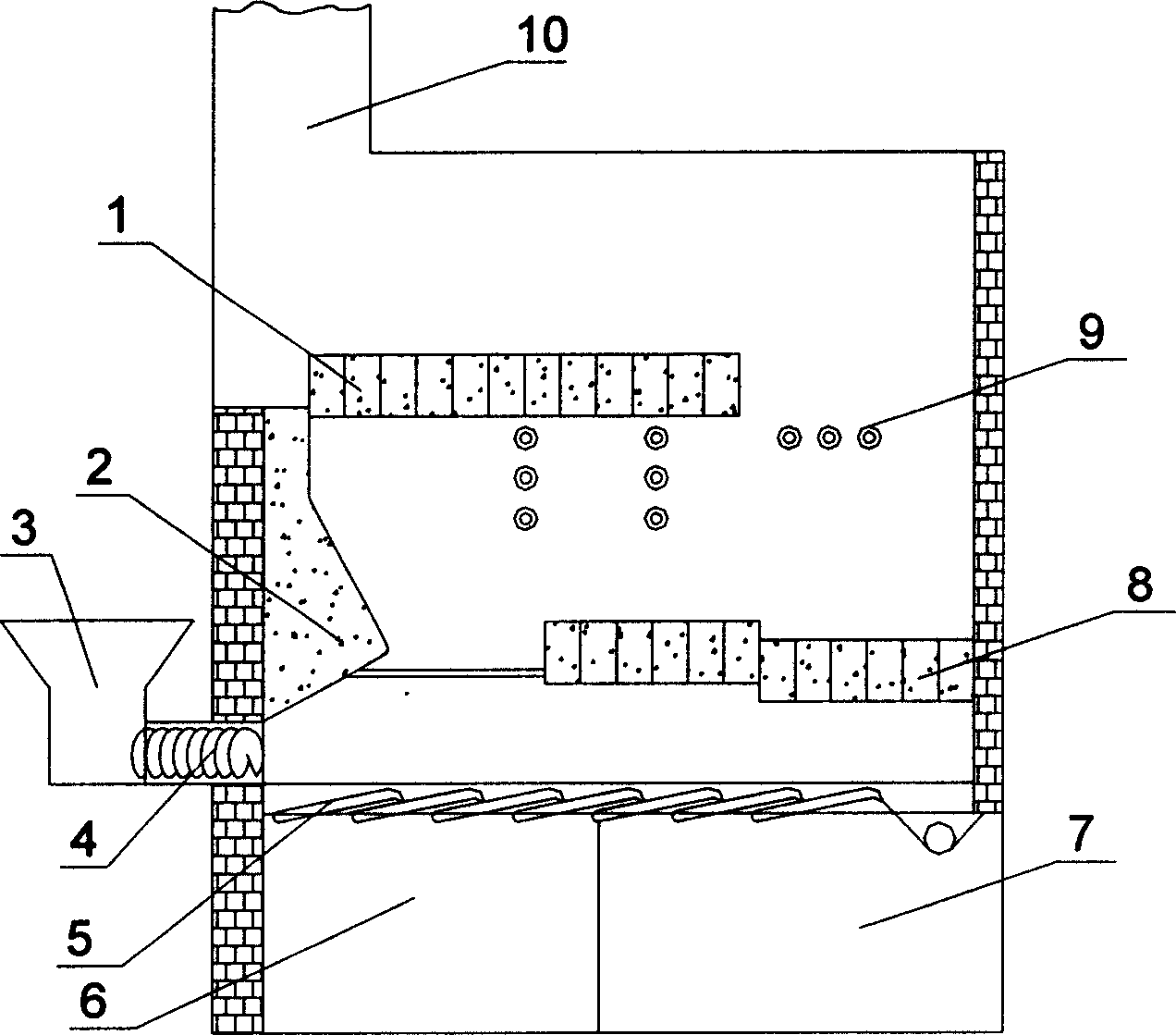

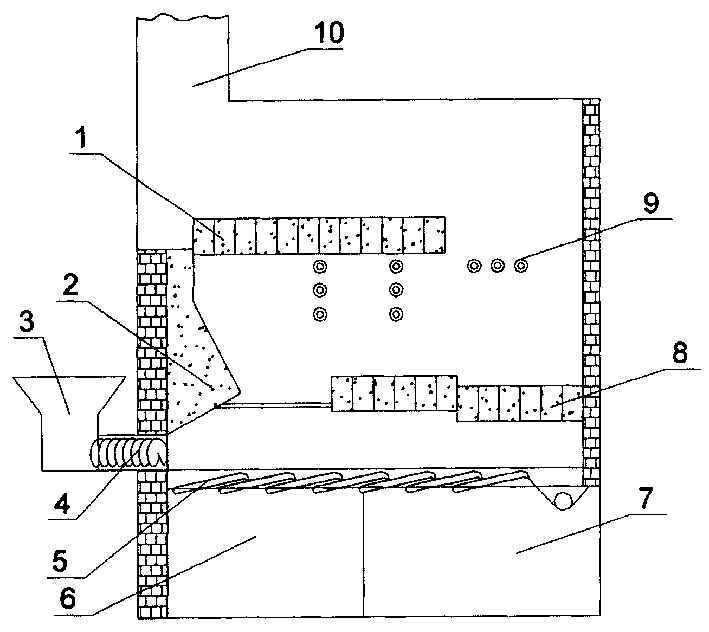

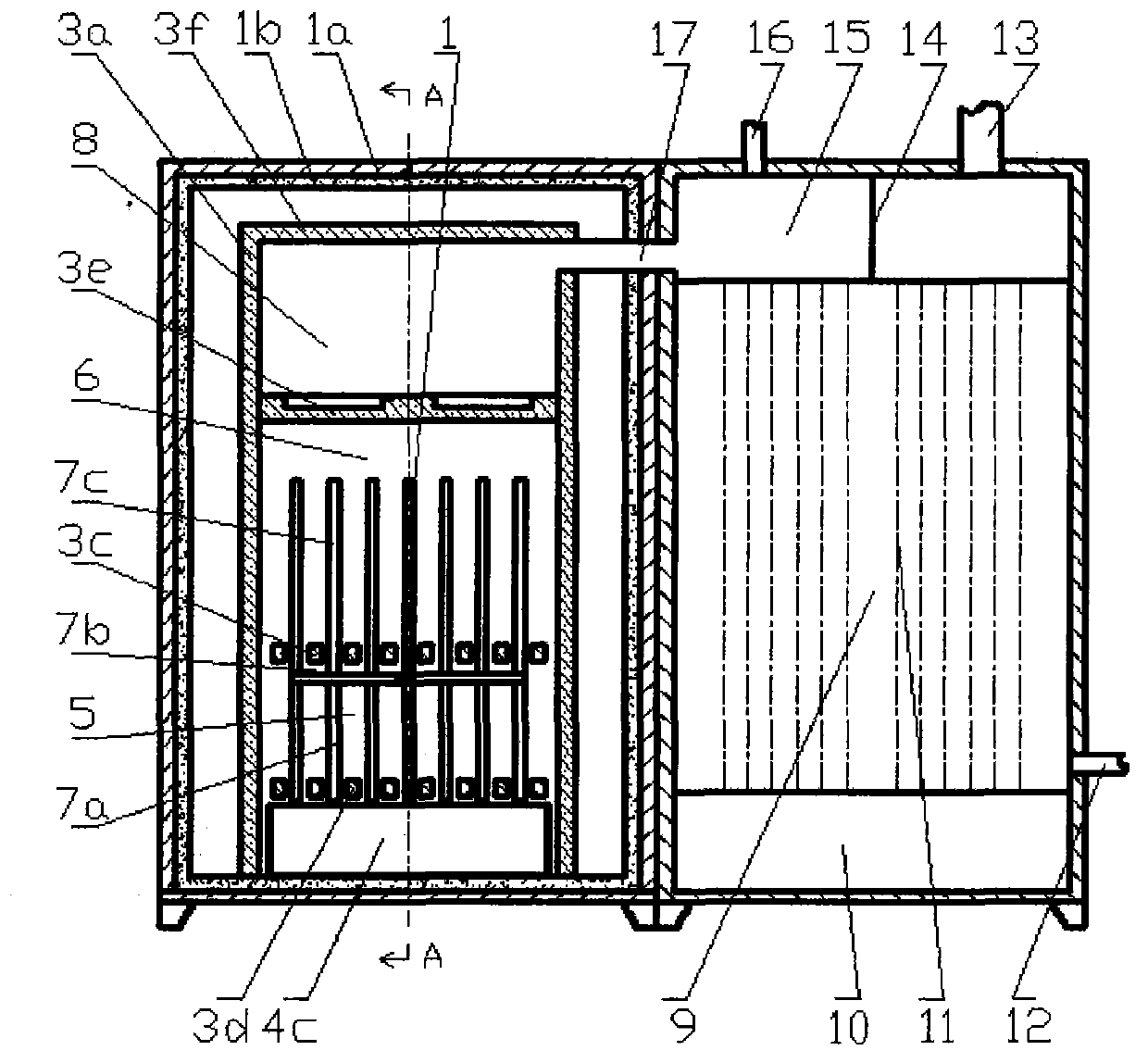

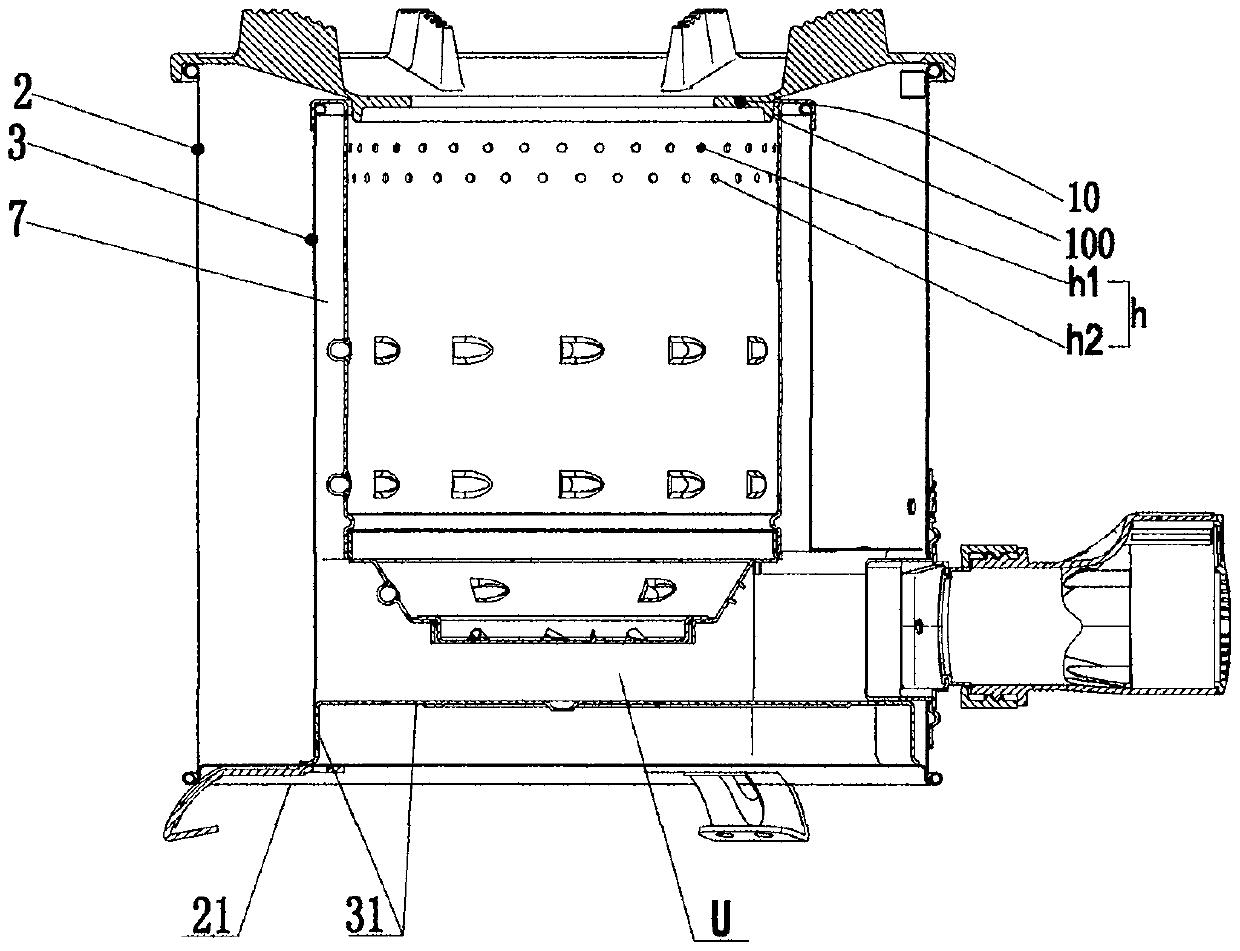

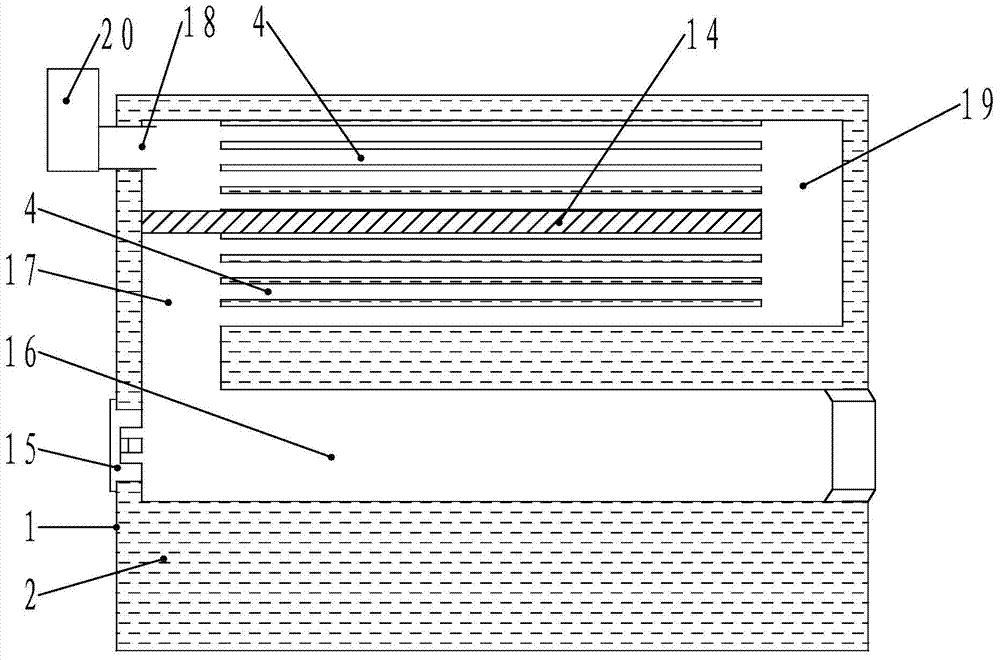

Low nitrogen oxide biomass boiler with variable furnace arch structure

InactiveCN1488889ARich varietyAdapt to many types of biomassIncinerator apparatusFirebridgesLow nitrogenEngineering

The present invention relates to a low-nitrogen oxide biomass boiler with variable furnace arch structure, including front and rear zoned-air chambers, reciprocating grate, combined arch formed from front arch, rear arch and upper arch and zoned-air nozzles. The bottom portion of the boiler is equipped with front zone air chamber and rear zone air chamber to implement zoned-air distribution, and the reciprocating grate is arranged over the front and rear zound-air chambers, and in the interior of furnace cavity wall between upper arch and rear arch air inlaid several zoned-air nozzles whose inlets are connected with main air channel. Said boiler can extensively utilize biomass fuel, and can obtain good combustion effect.

Owner:SHANGHAI JIAO TONG UNIV

Creosote and soot destroying fire log

Owner:SCHAEFER CLARK

Creosote and soot destroying fire log

InactiveUS20040168366A1Reduce corrosionImproved creosote and soot removing compositionBiofuelsSolid fuelsCreosoteSolid fuel

A processed solid fuel composition incorporating agents for destroying creosote and soot within flue ducts and chimneys of fireplaces, solid fuel stoves and other heating devices is disclosed, along with a method for its manufacture and a method for its use. The composition is made up of a combination of compressed cellulosic particulate material and a chemical and / or catalytic creosote and soot removing agent, and is molded in the form of a fire log in the preferred embodiment. The composition may be used alone, but is ideally applied to an active fire to treat a chimney flue by combined heating and chemical disaggregation of accumulated creosote and soot deposits.

Owner:SCHAEFER CLARK

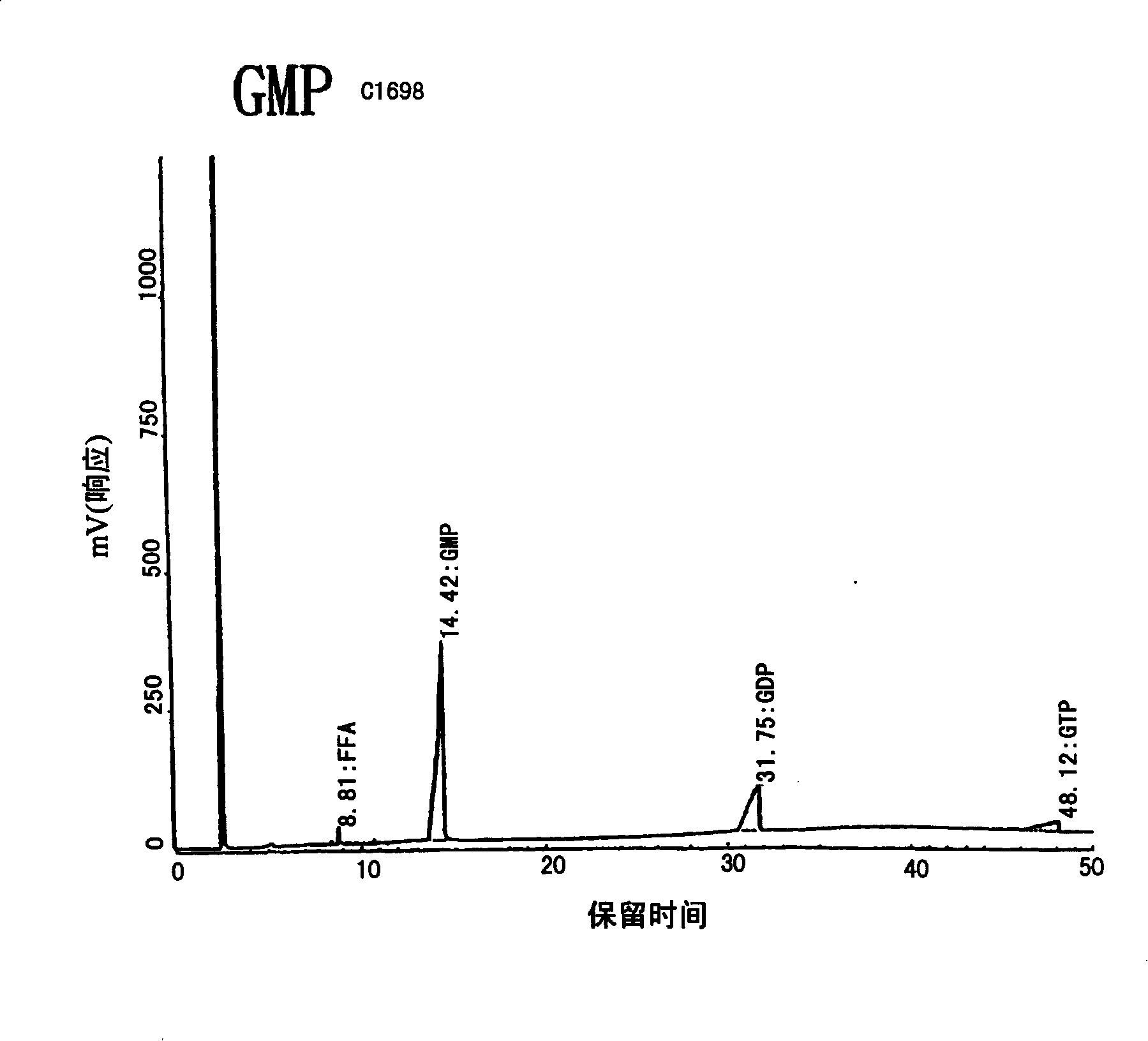

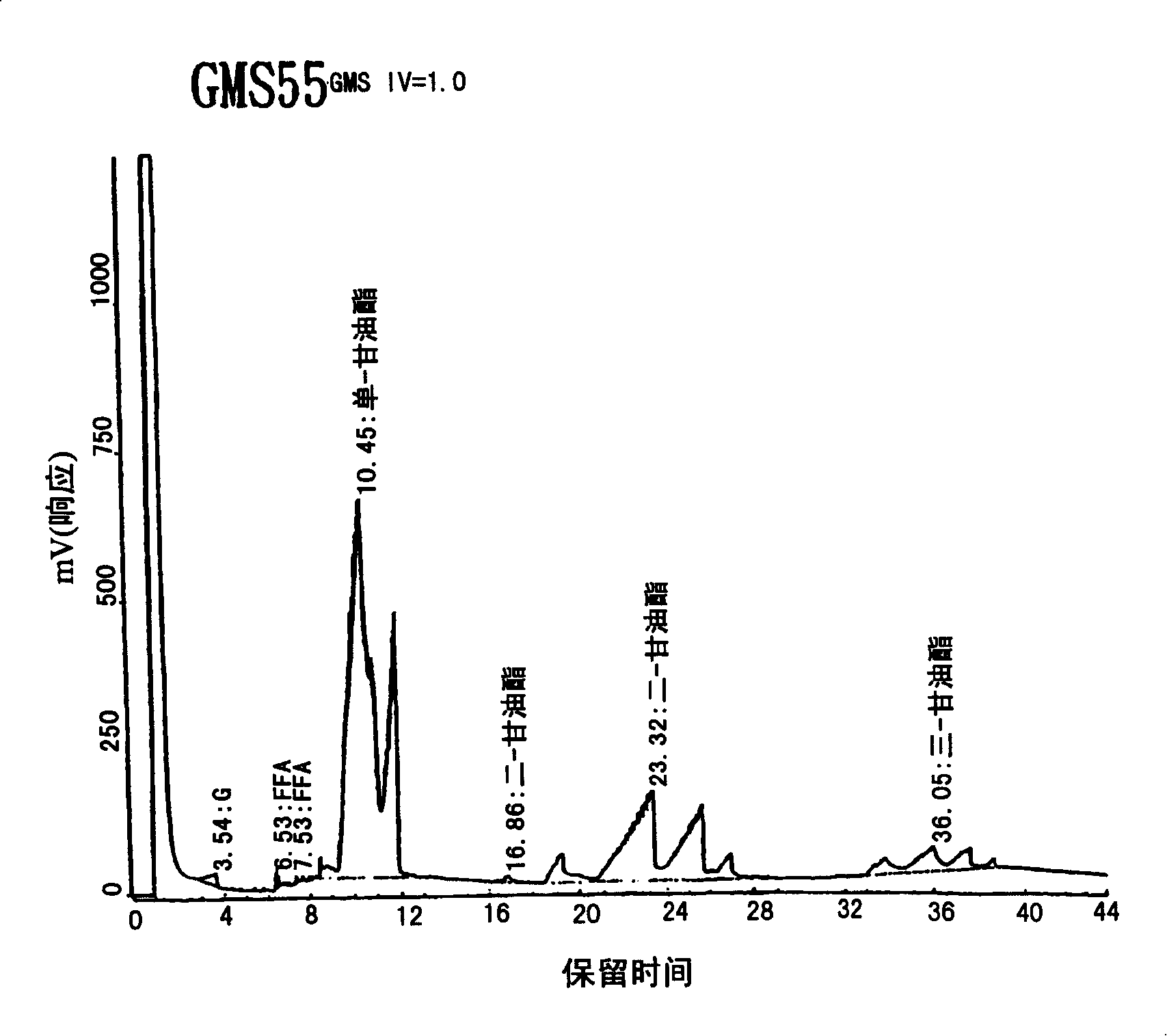

Partial acyl glyceride based biowaxes, biocandles prepared therefrom and their preparation

The present invention relates to a biowax comprising a partial acyl glyceride selected from the group consisting of a monoacylglyceride, a diacylglyceride and the combination thereof. The present invention also relates to a biocandle comprising a biowax and a wick, and to a method of producing the same.

Owner:CHANT OIL

Energy source using hydrogenated vegetable oil diluted into diesel fuel

InactiveUS7201837B2Burn cleanLow costLiquid organic insulatorsLiquid carbonaceous fuelsVegetable oilPartial hydrogenation

An alternative fuel source, preferably for use in a boiler, is provided. The fuel source is comprised of a partially hydrogenated vegetable oil and diesel fuel. Preferably, the partially hydrogenated vegetable oil has a Iodine Value (IV) ranging from approximately 50 to approximately 120.

Owner:BUNGE NORTH AMERICA

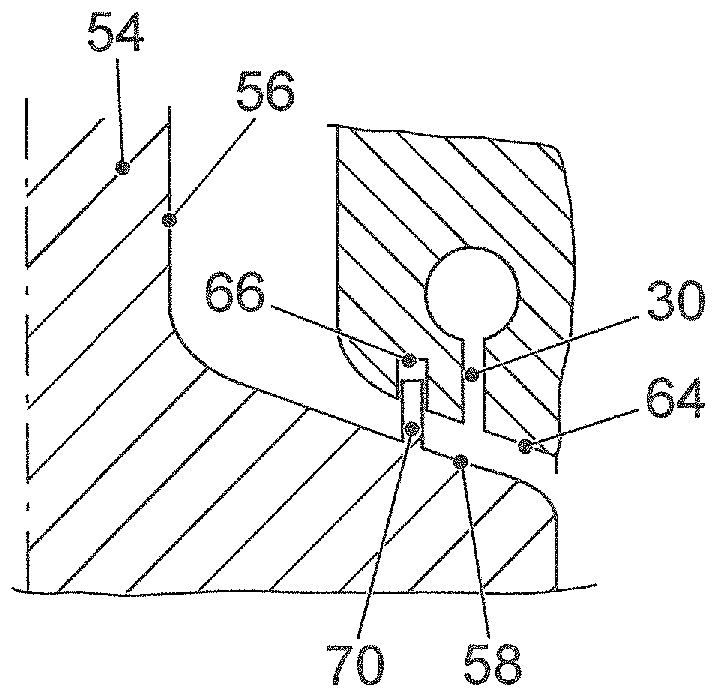

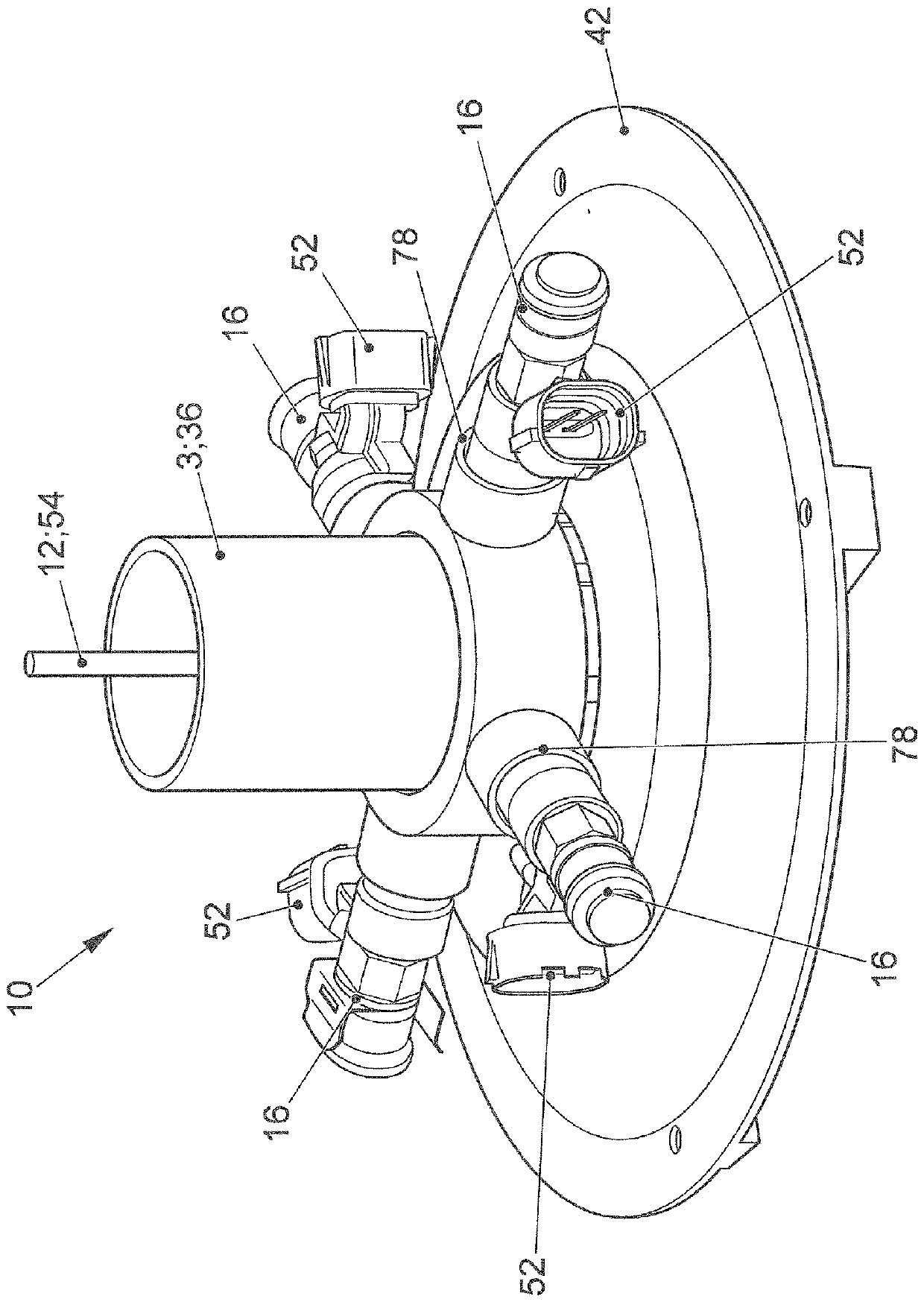

Mixture formation device for a gas engine and the gas engine

ActiveCN110023613AEmission reductionBurn cleanInternal combustion piston enginesFuel supply apparatusCompressed natural gasExternal combustion engine

The invention relates to a mixture formation device for an internal combustion engine operated with a burnable gas, preferably compressed natural gas CNG. The mixture formation device comprises a combination of a quantity regulator, a gas mixer, a flow-guiding element for pressure recovery, and a connection possibility for exhaust gas recirculation of the internal combustion engine. The mixture formation device according to the invention can empty a gas tank to a comparatively low pressure of about 2 bar, an excellent mixture formation being achieved over the entire range of speed and load range of the internal combustion engine. According to the invention, such a mixture formation device can reduce production costs as well as space requirements compared to known solutions. The invention also relates to an internal combustion engine operated with a burnable gas, particularly compressed natural gas (CNG), comprising such a mixture formation device in the intake tract thereof.

Owner:VOLKSWAGEN AG

Low nitrogen oxide biomass boiler with variable furnace arch structure

InactiveCN1195173CRich varietyAdapt to many types of biomassSolid fuel combustionIncinerator apparatusLow nitrogenEngineering

The present invention relates to a low-nitrogen oxide biomass boiler with variable furnace arch structure, including front and rear zoned-air chambers, reciprocating grate, combined arch formed from front arch, rear arch and upper arch and zoned-air nozzles. The bottom portion of the boiler is equipped with front zone air chamber and rear zone air chamber to implement zoned-air distribution, and the reciprocating grate is arranged over the front and rear zound-air chambers, and in the interior of furnace cavity wall between upper arch and rear arch air inlaid several zoned-air nozzles whose inlets are connected with main air channel. Said boiler can extensively utilize biomass fuel, and can obtain good combustion effect.

Owner:SHANGHAI JIAOTONG UNIV

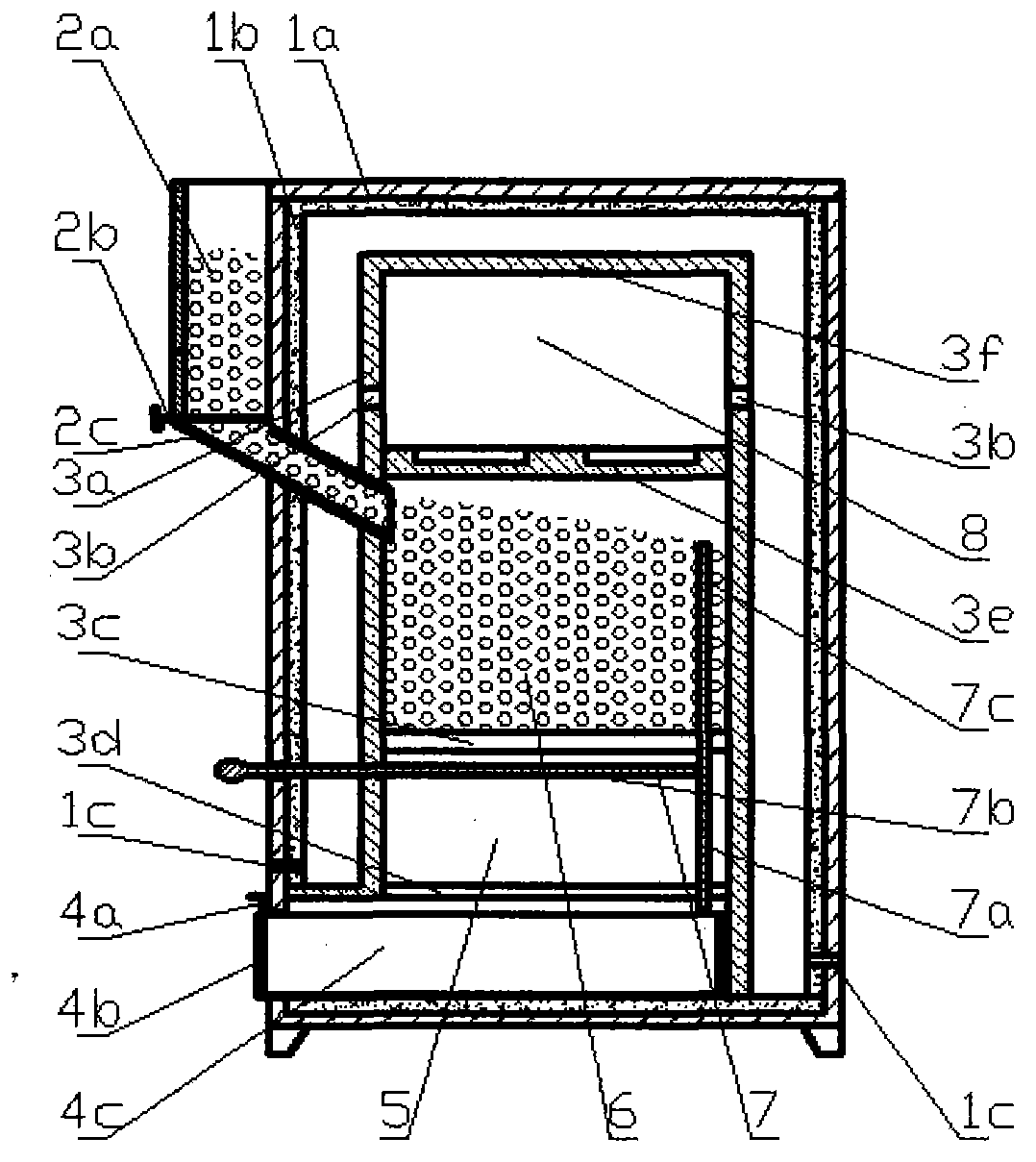

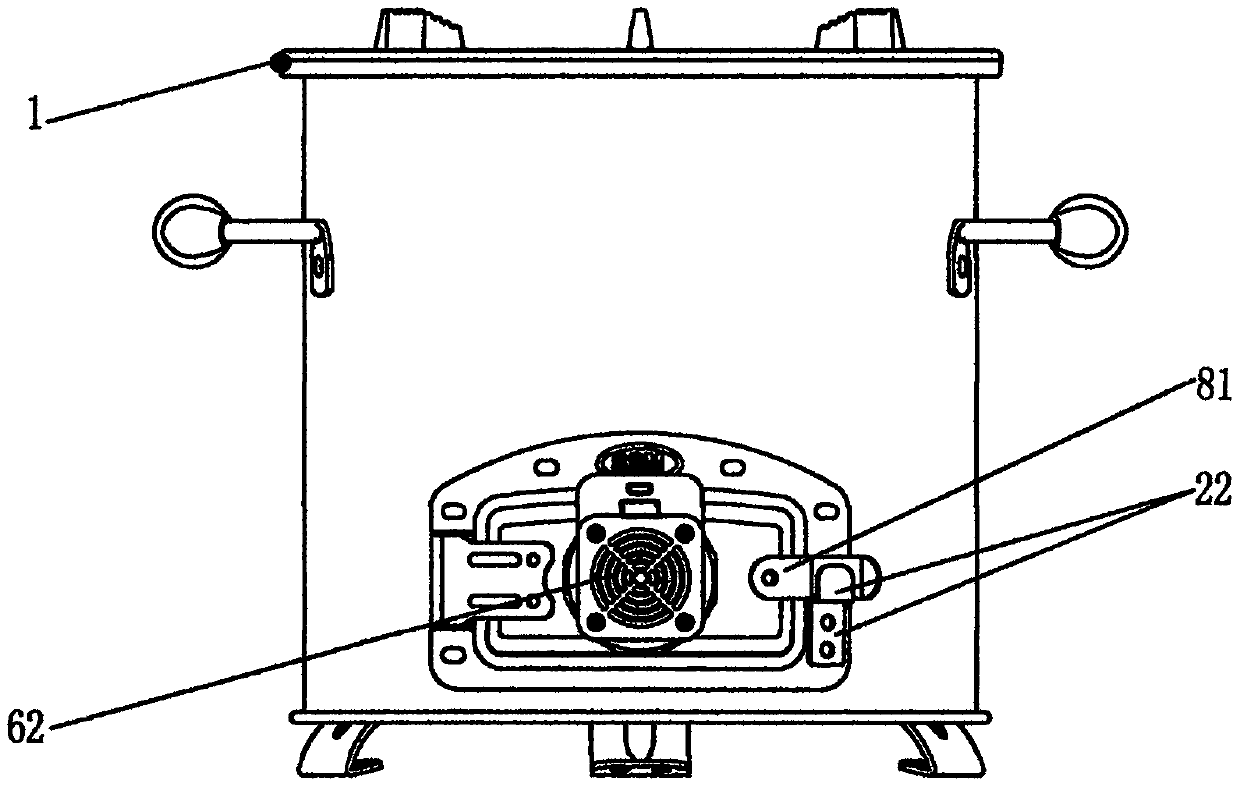

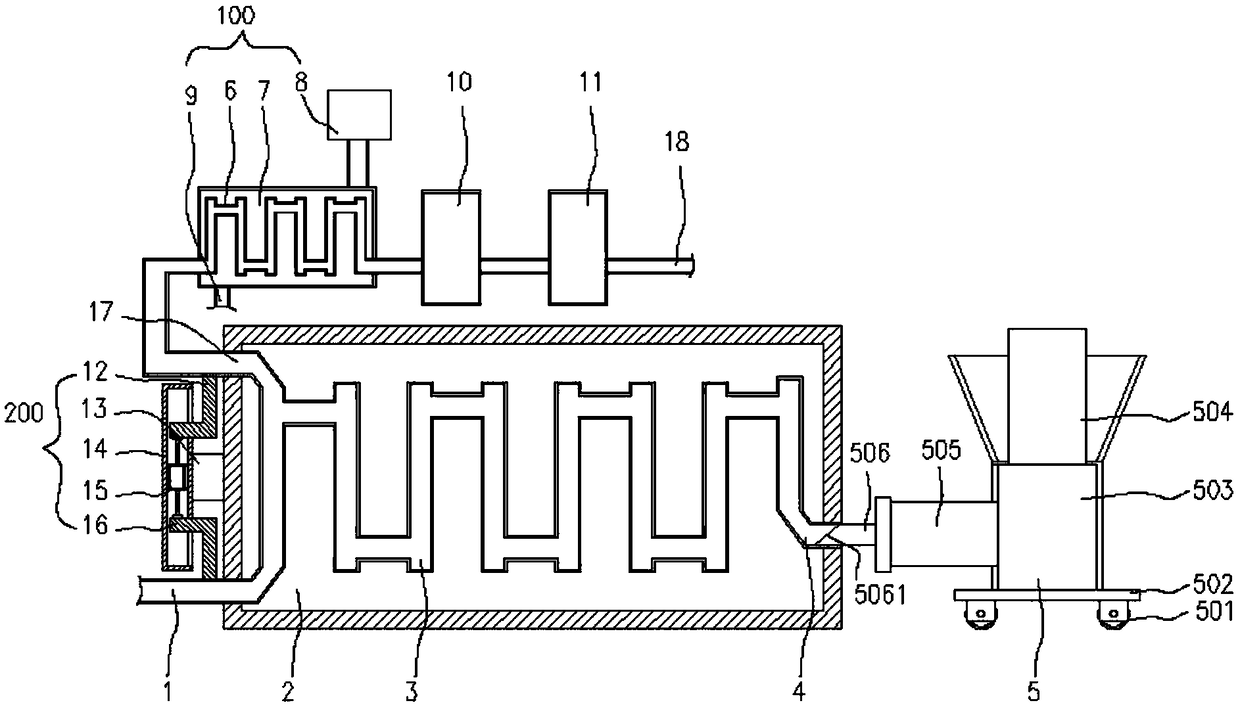

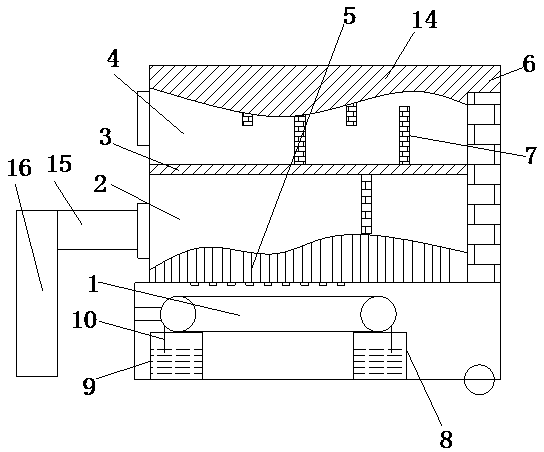

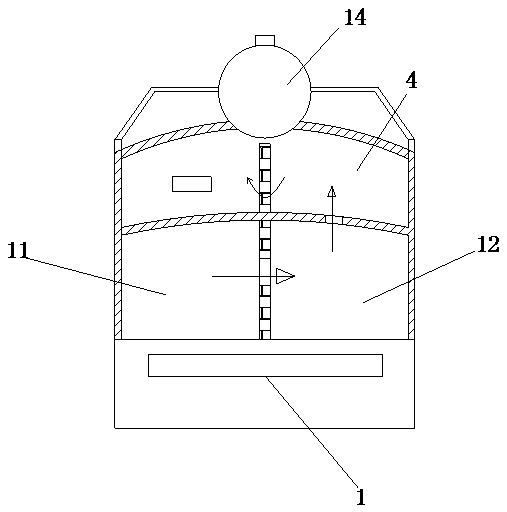

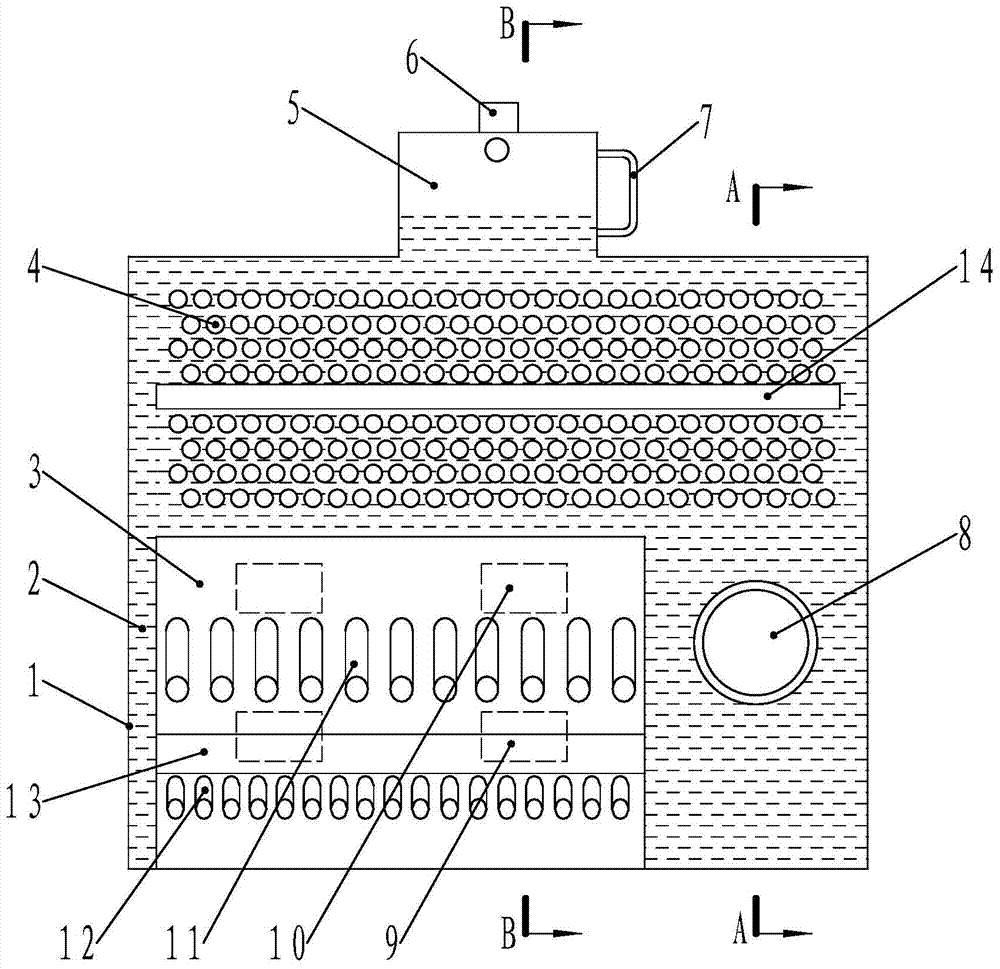

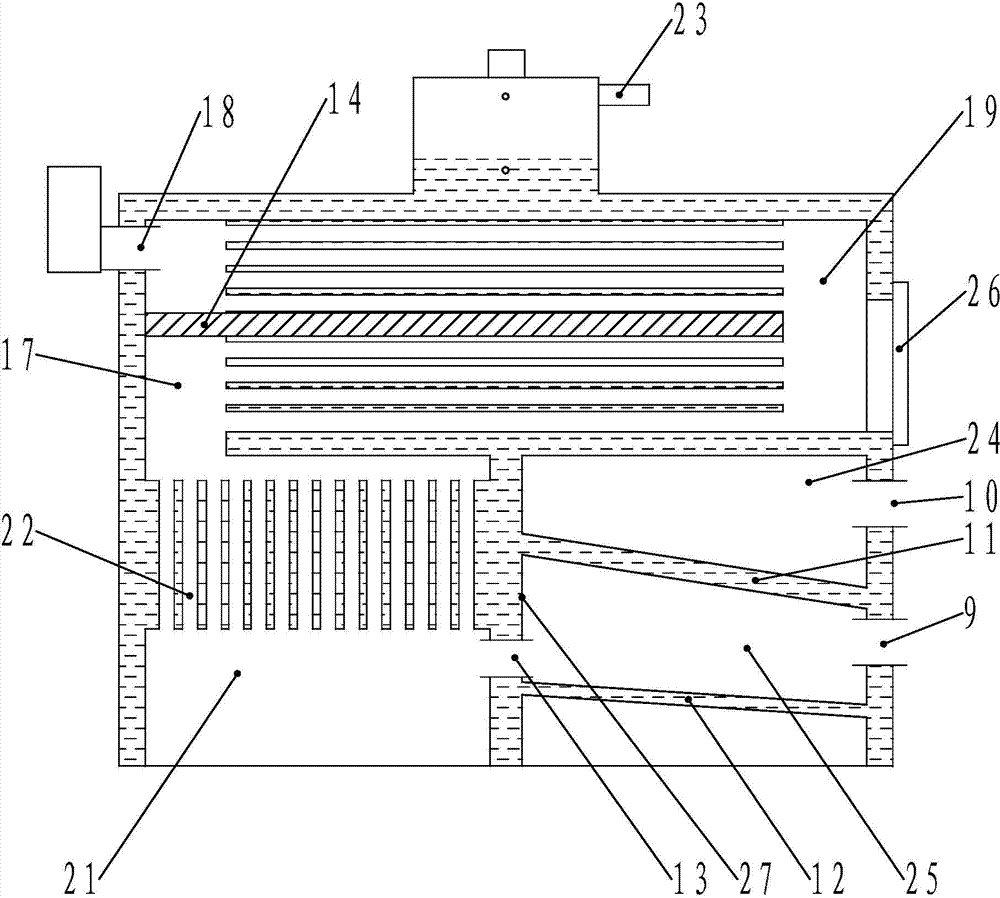

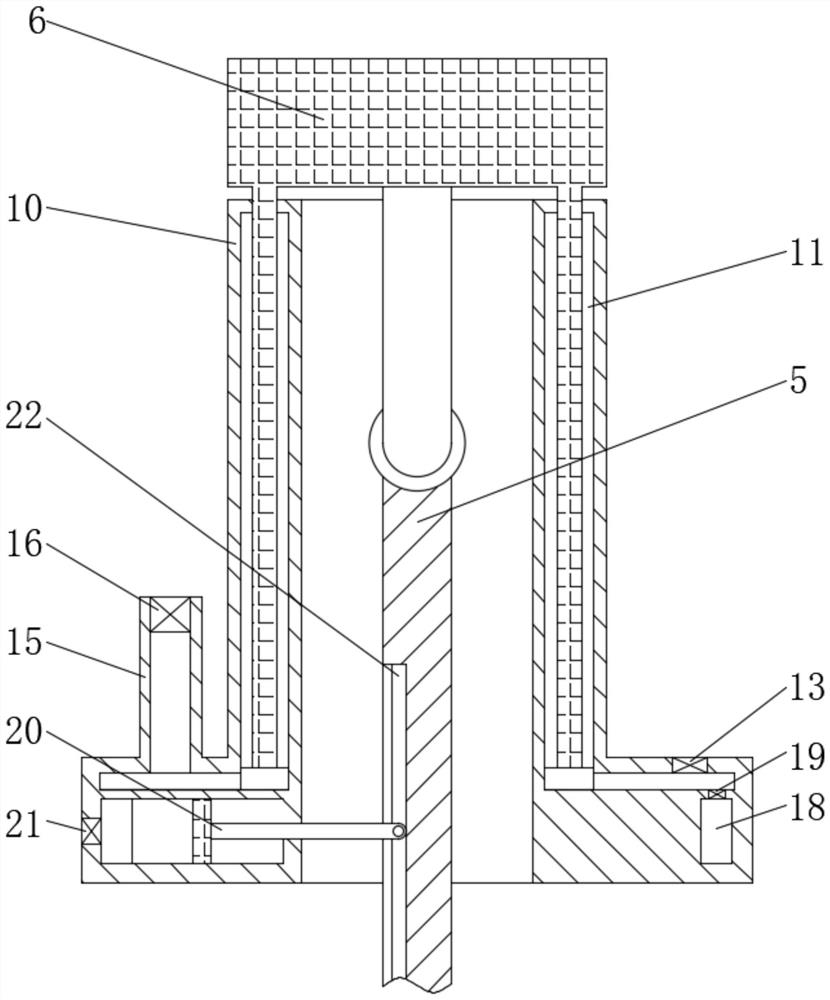

Biomass particle fuel clean combustion stove

InactiveCN103277790AReduce soot contentImprove combustion efficiencySolid fuel combustionCombustion apparatusCombustion chamberEngineering

Disclosed is a biomass particle fuel clean combustion stove. The biomass particle fuel clean combustion stove is composed of a combustion stove body and a smoke water heat exchanger which are arranged in parallel, and is characterized in that a liner is divided into a fuel combustion chamber, a vaporizing chamber and an ash accumulating chamber through an upper cover plate, a flame stabilization plate, an upper stove grate and a lower stove grate; a feeding pipe arranged at the bottom of a feeding bin penetrates through the lateral wall of an outer cover and the lateral wall of the liner, and is inserted in the vaporizing chamber from outside to inside in an inclined mode; a primary air inlet is formed in the outer lateral side of an ash discharge drawer; a secondary air inlet is formed in the lower portion of the peripheral lateral wall of the outer cover; air vents are formed in the lower portion of the peripheral lateral wall of the combustion chamber of the liner; a smoke duct is arranged on the upper portion of the lateral wall of the combustion chamber of the liner. The biomass particle fuel clean combustion stove ensures that biomass particle fuel is completely and stably vaporized and is complete in combustion and high in temperature, improves combustion efficiency of the fuel, obviously reduces the dust carrying amount in smoke, ensures that smoke generated after fuel combustion is clean, effectively avoids ash accumulation and slagging, improves heat exchange efficiency of heat exchange equipment, and is simple and compact in structure, convenient to operate and low in operating cost.

Owner:HEFEI UNIV OF TECH

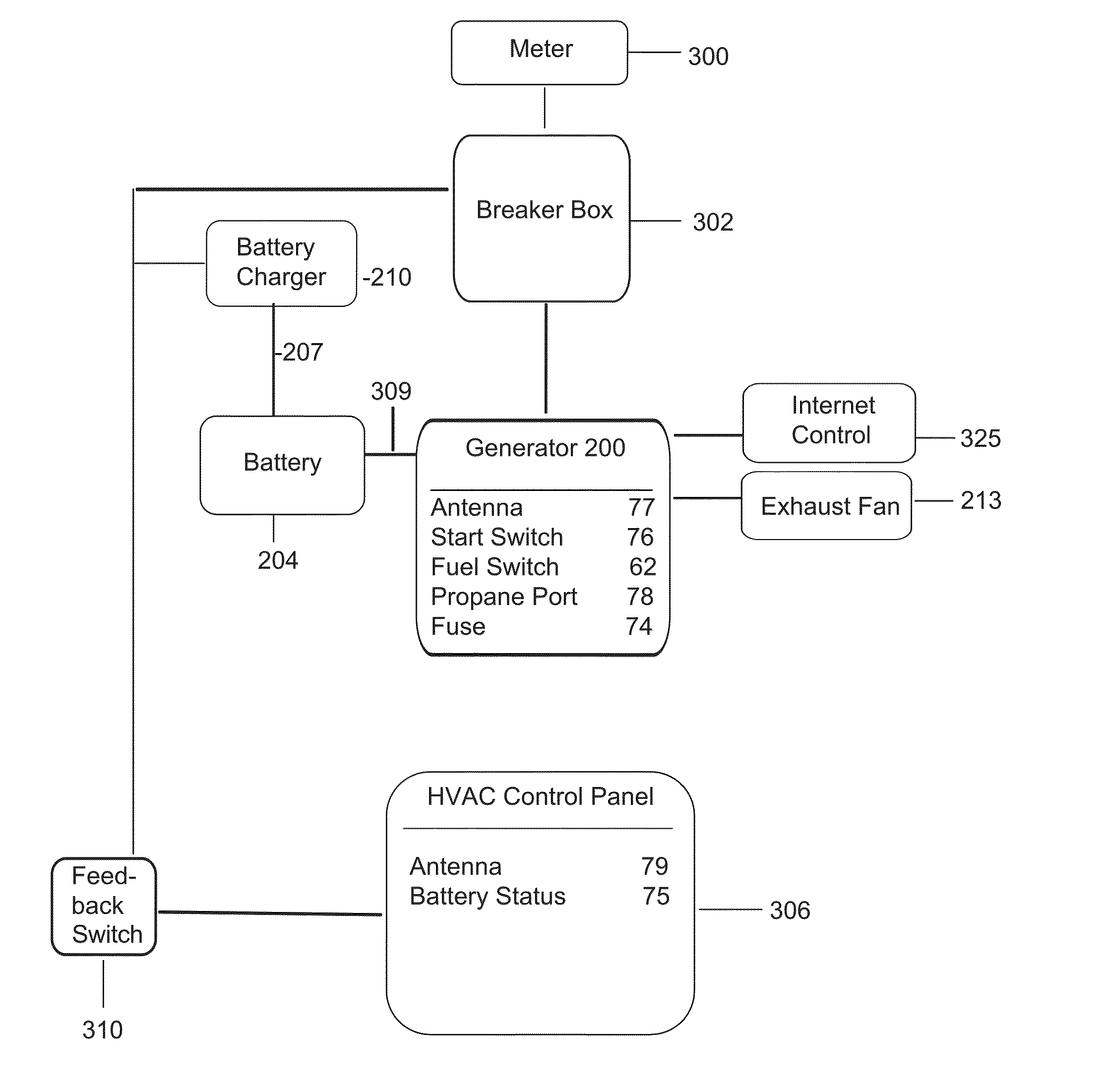

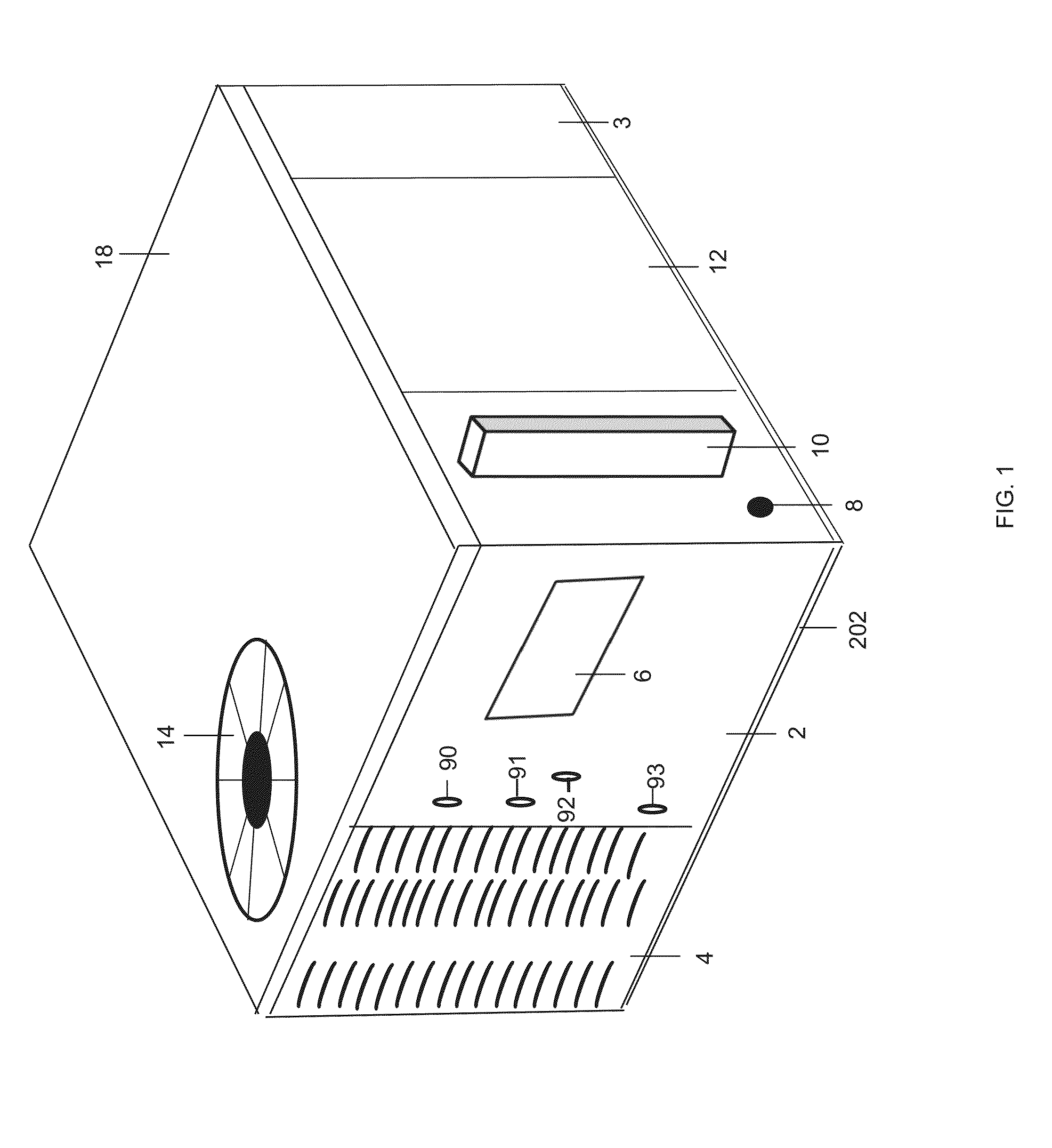

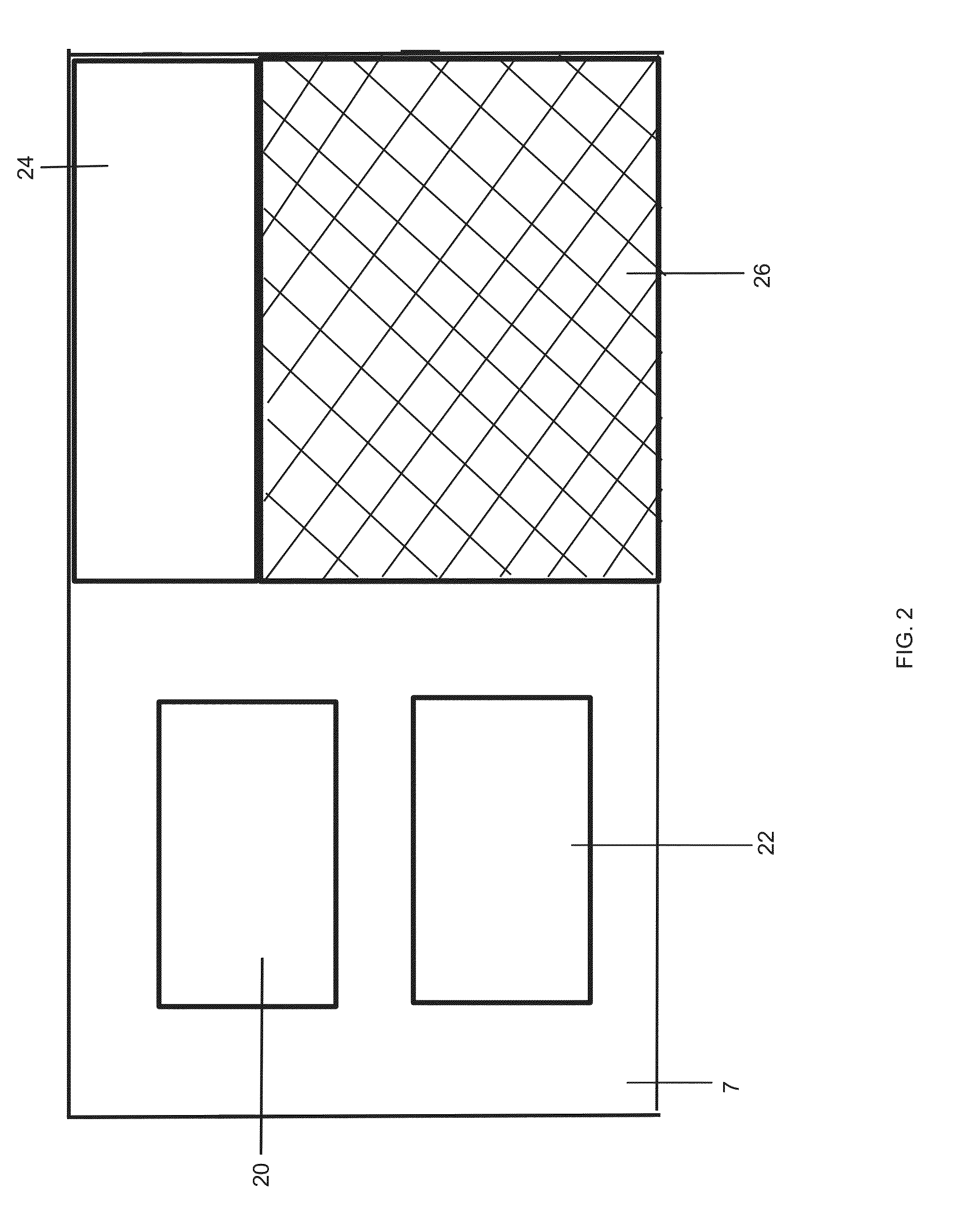

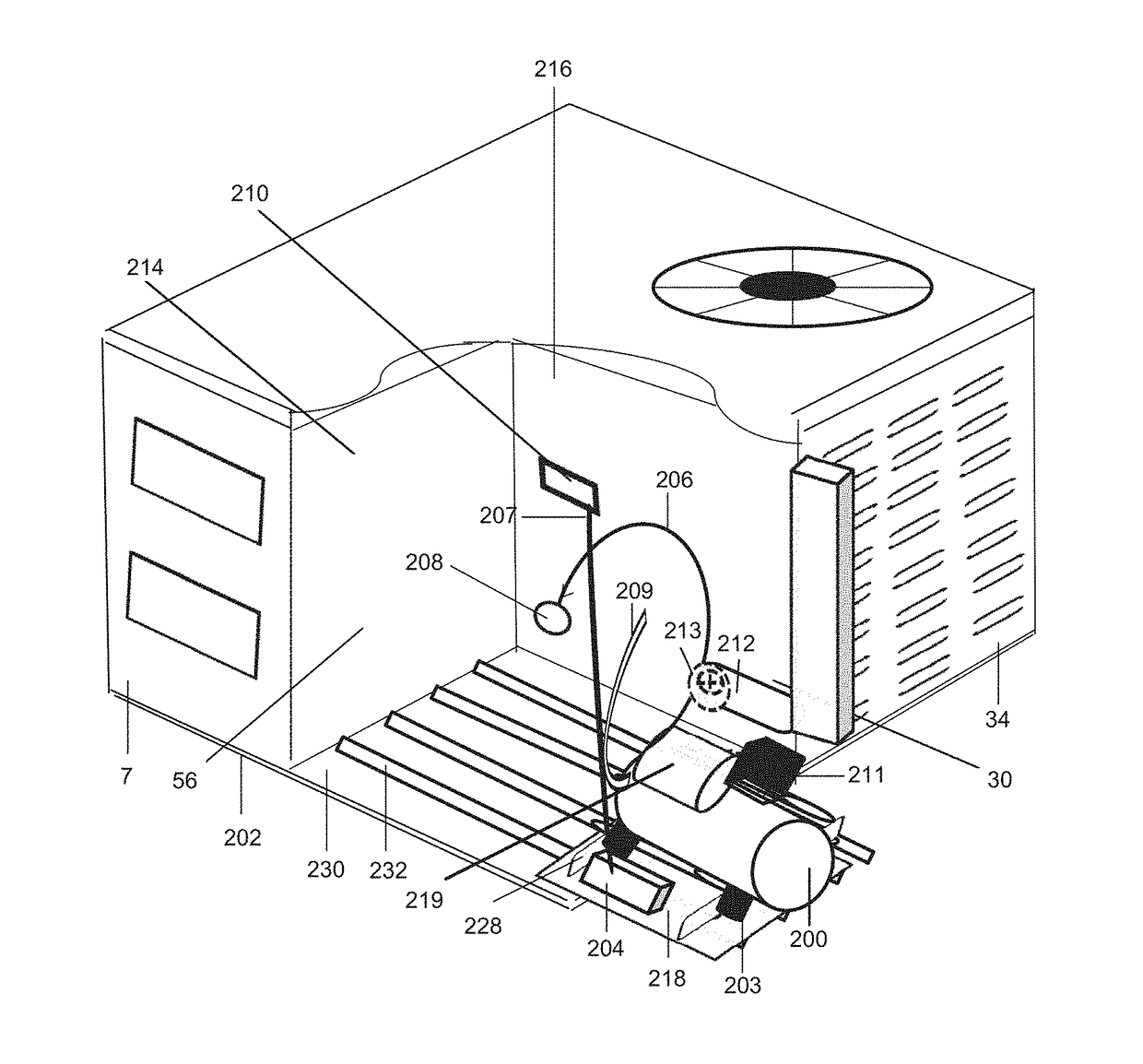

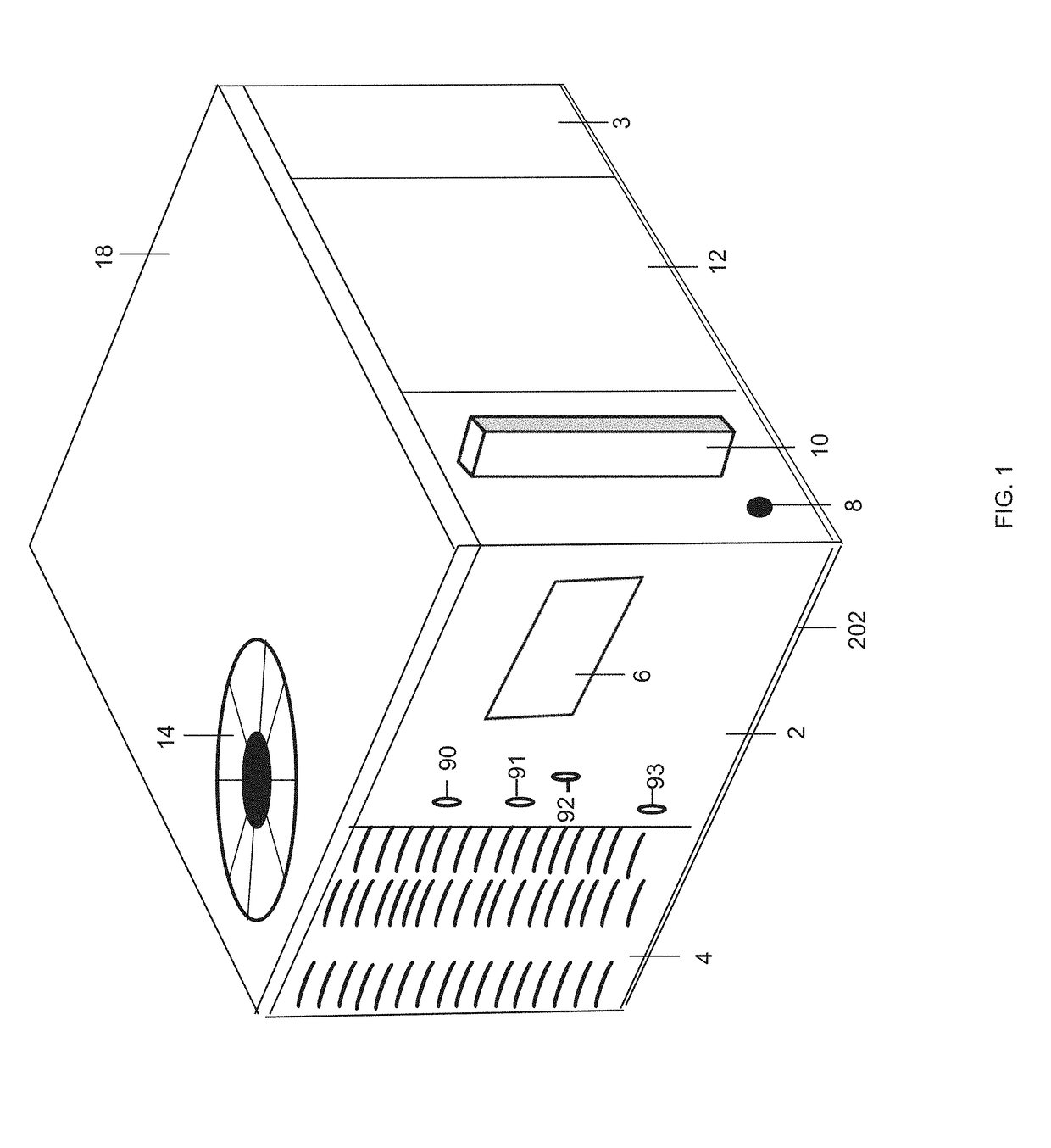

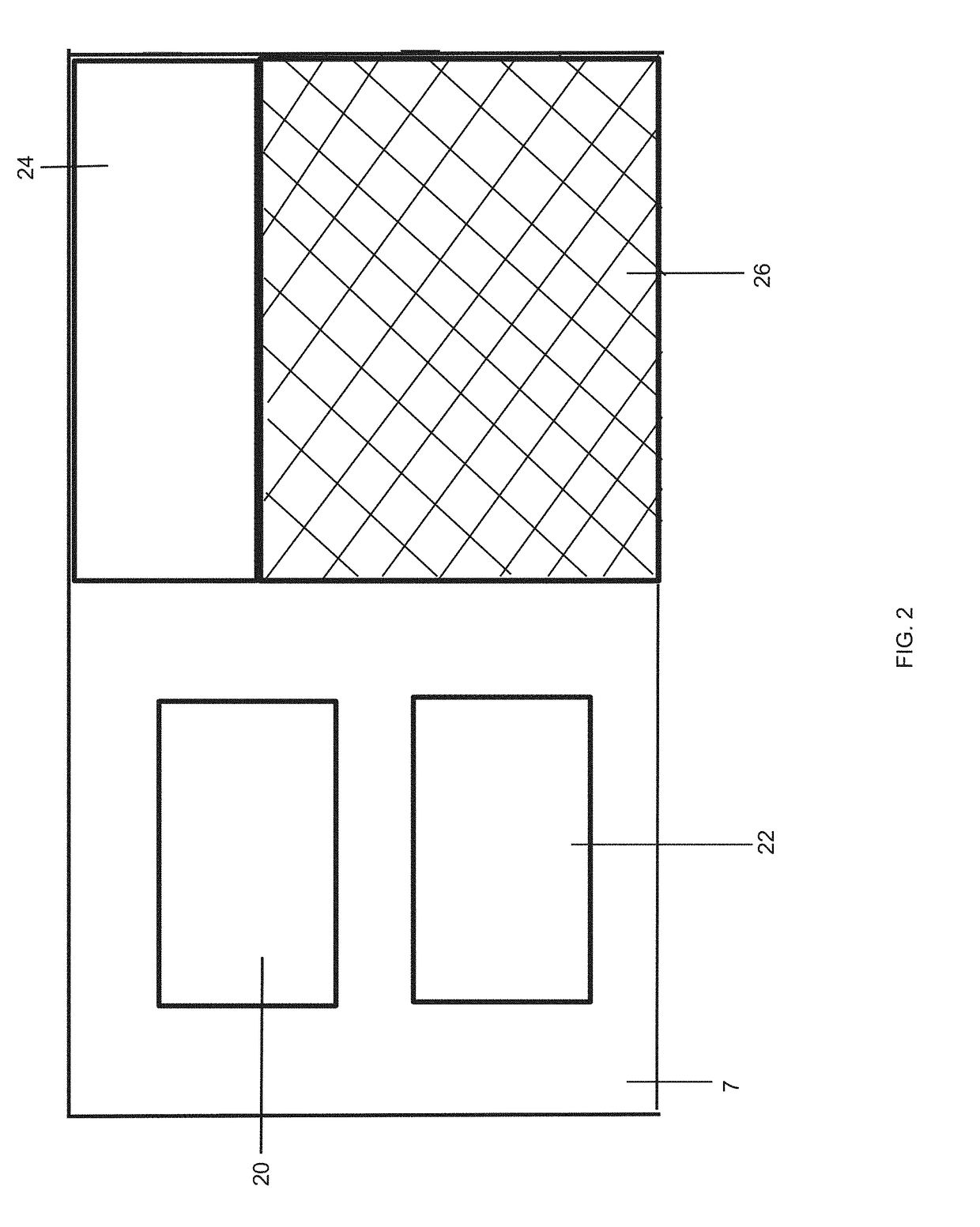

HVAC home generator

ActiveUS20160087435A1Extended electrical outagesCheap and readily availableBatteries circuit arrangementsSingle network parallel feeding arrangementsResidenceTransfer switch

A natural gas or liquified propane powered generator incorporated into a HVAC unit, for supplying emergency power to a residence or commercial business. The generator is contained within an exterior cabinet that houses HVAC components for both packaged and split systems. The packaged unit is arranged so that the generator is included within the exterior cabinet and the split unit is arranged so that the generator is positioned beneath the split unit. The generator operates from natural gas or liquified propane supplied to the home or from a portable liquified propane tank, if the supply of natural gas or liquified propane is terminated. In the event of a power failure, the user manually operates the generator or an automatic transfer switch can be utilized. On-site electronics are included to allow a user to monitor the system from a smart phone or other electronic device.

Owner:ORTNER CHARLES R

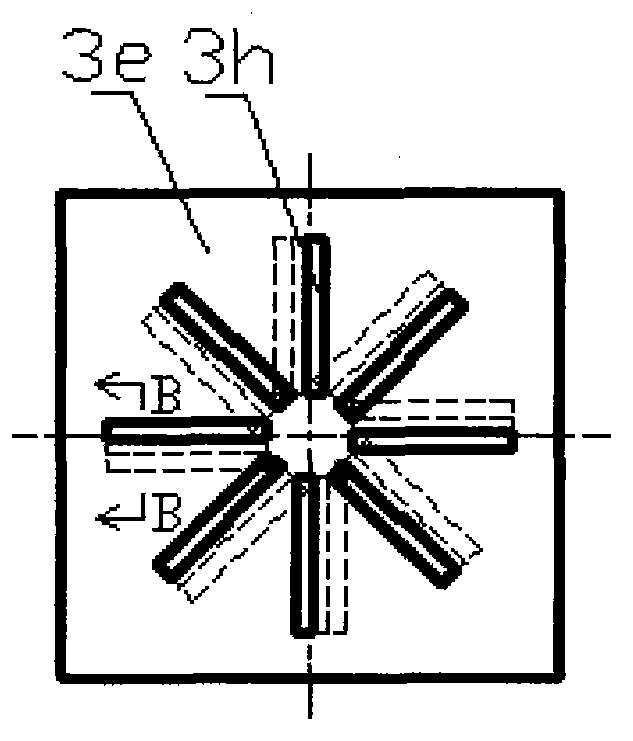

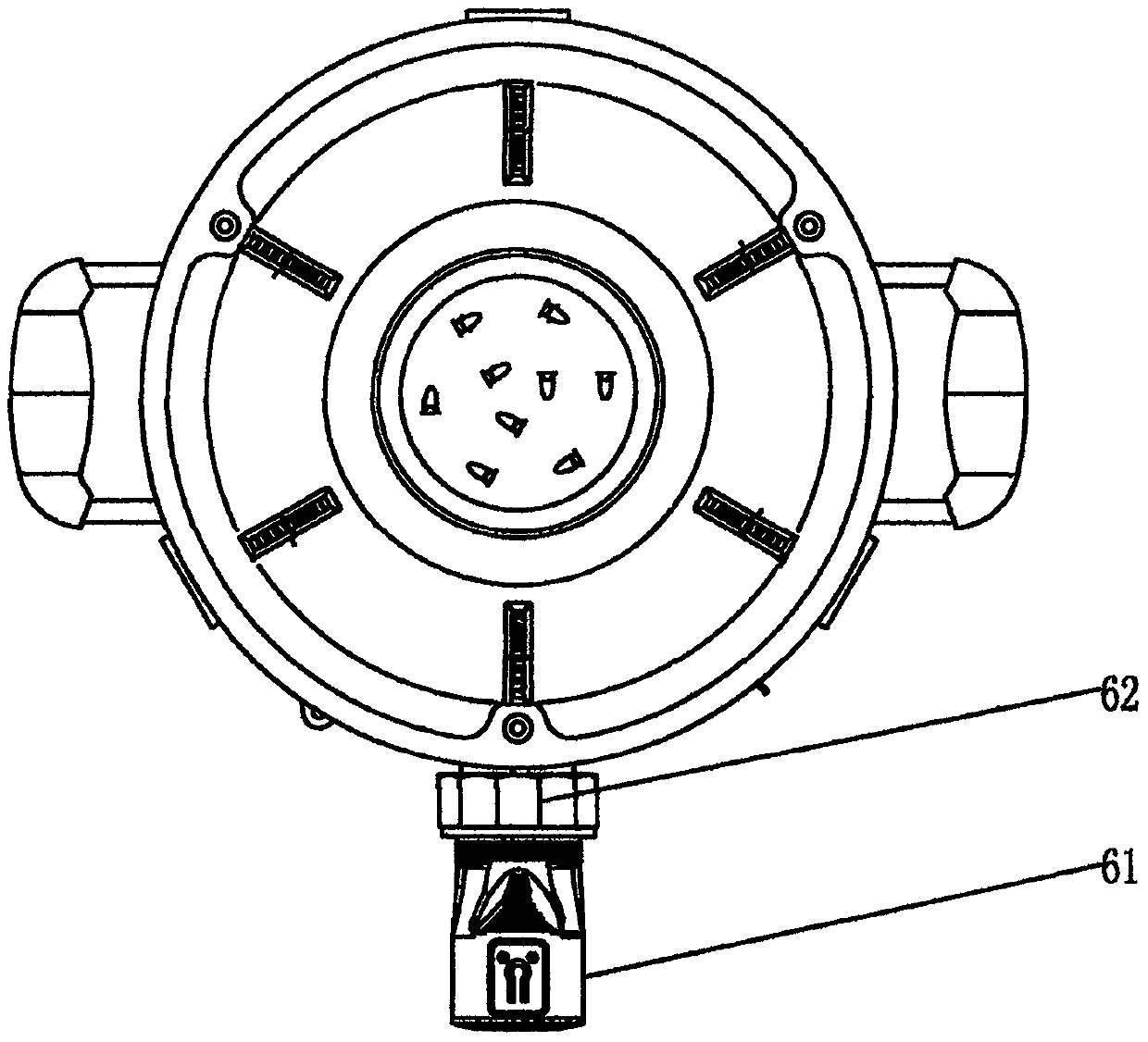

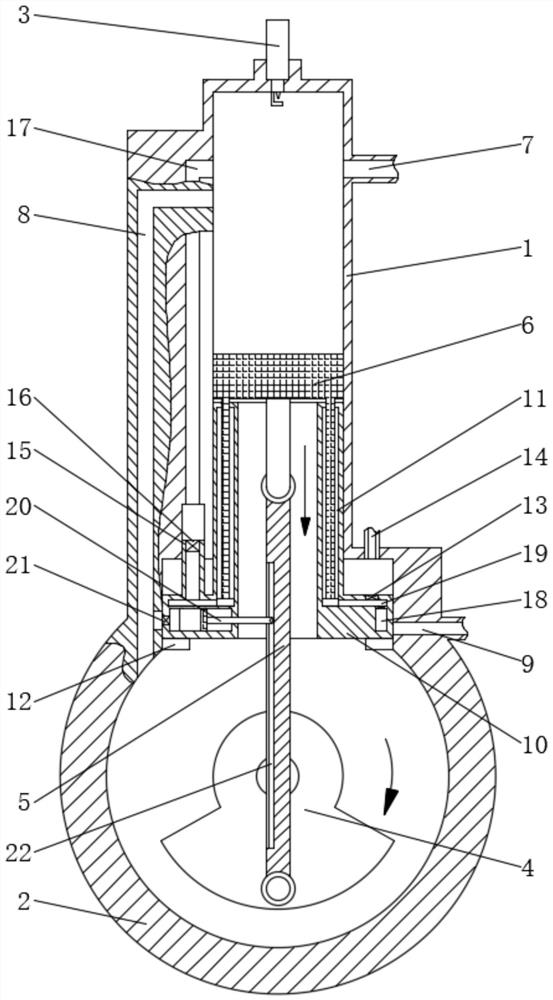

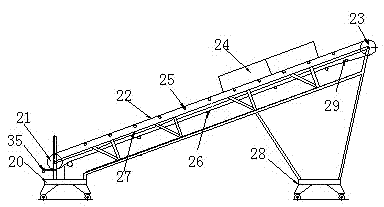

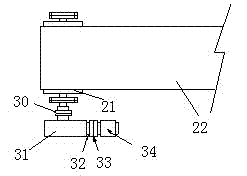

Biomass furnace with forced introduction of combustion air

PendingCN108050507APromote sufficiencySufficient oxygenationSolid fuel combustionAir/fuel supply for combustionCombustible gasEngineering

The invention discloses a biomass furnace with forced introduction of combustion air. The biomass furnace comprises a furnace panel, an outer shell, and a lining barrel; the lining barrel is internally provided with an incendiary cylinder; the incendiary cylinder is composed of a straight barrel body part and a bowl-shaped bottom; the straight barrel body part is arranged at a top end opening of the lining barrel; an air channel is formed between the inner wall of the lining barrel and the outer wall of the incendiary cylinder; once air inlet holes are formed at the lower portion of the straight barrel body part or the side wall of the bowl-shaped bottom or the bottom wall of the bowl-shaped bottom at intervals in the circumferential direction; the once air inlet holes are inclined relative to the barrel circumference wall of the straight barrel body part or inclined relative to the side wall of the bowl-shaped bottom or inclined relative to the bottom wall of the bowl-shaped bottom; once air enters the incendiary cylinder and spirals up along the cylinder wall of the incendiary cylinder; twice air inlet holes are formed at the top portion near the straight barrel body part at intervals in the circumferential direction; and an opening located on the outer shell is provided with a wind leading device used for leading air into an ash chamber opening, and the leaded air sequentially passes through the once air inlet holes and the twice air inlet holes to enter the incendiary cylinder. According to the scheme, the fuel is fully burnt, the combustible gas is fully burned, and the smokeless clean is achieved.

Owner:ZHEJIANG HUIWENMEI STOVE CO LTD

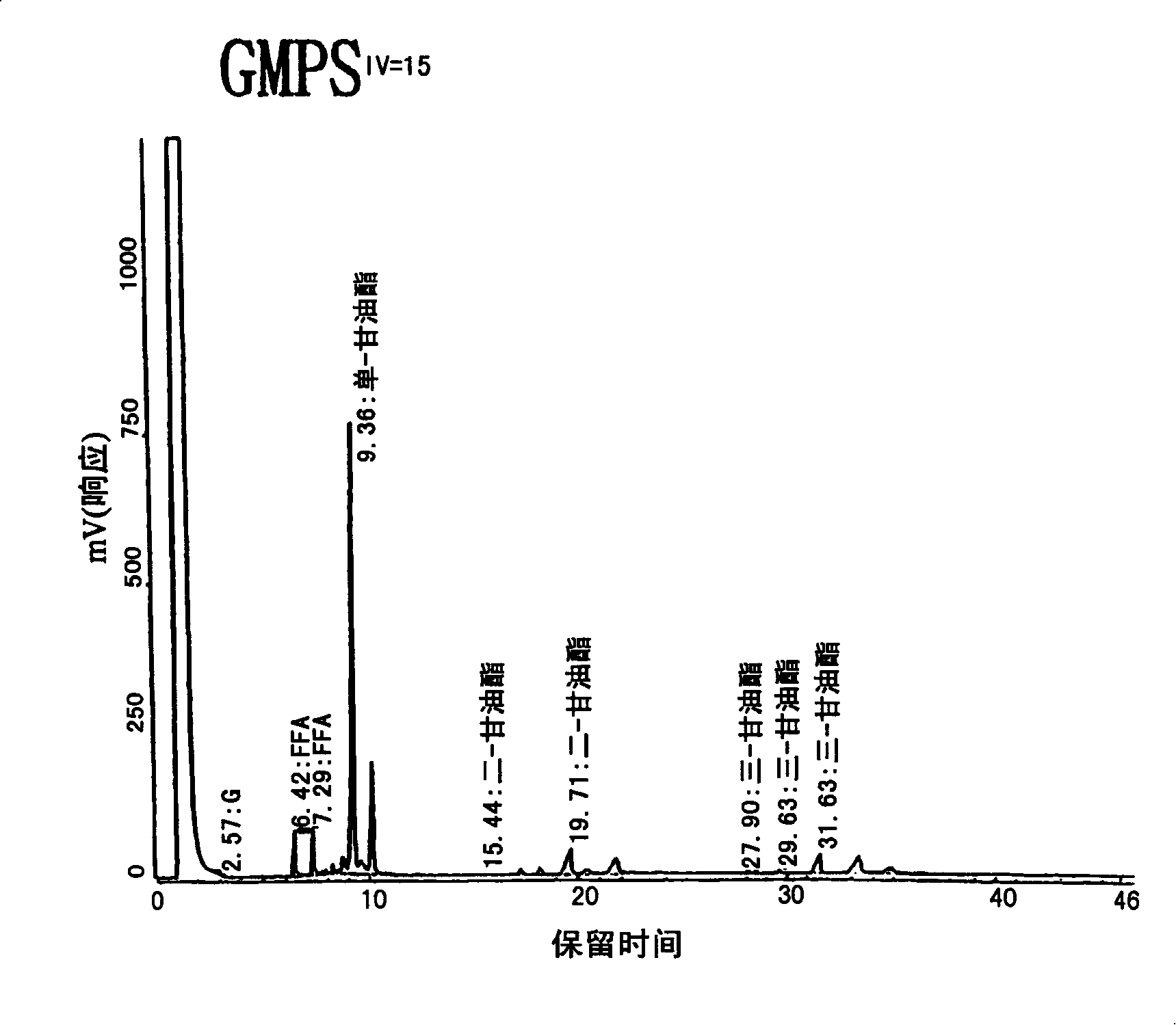

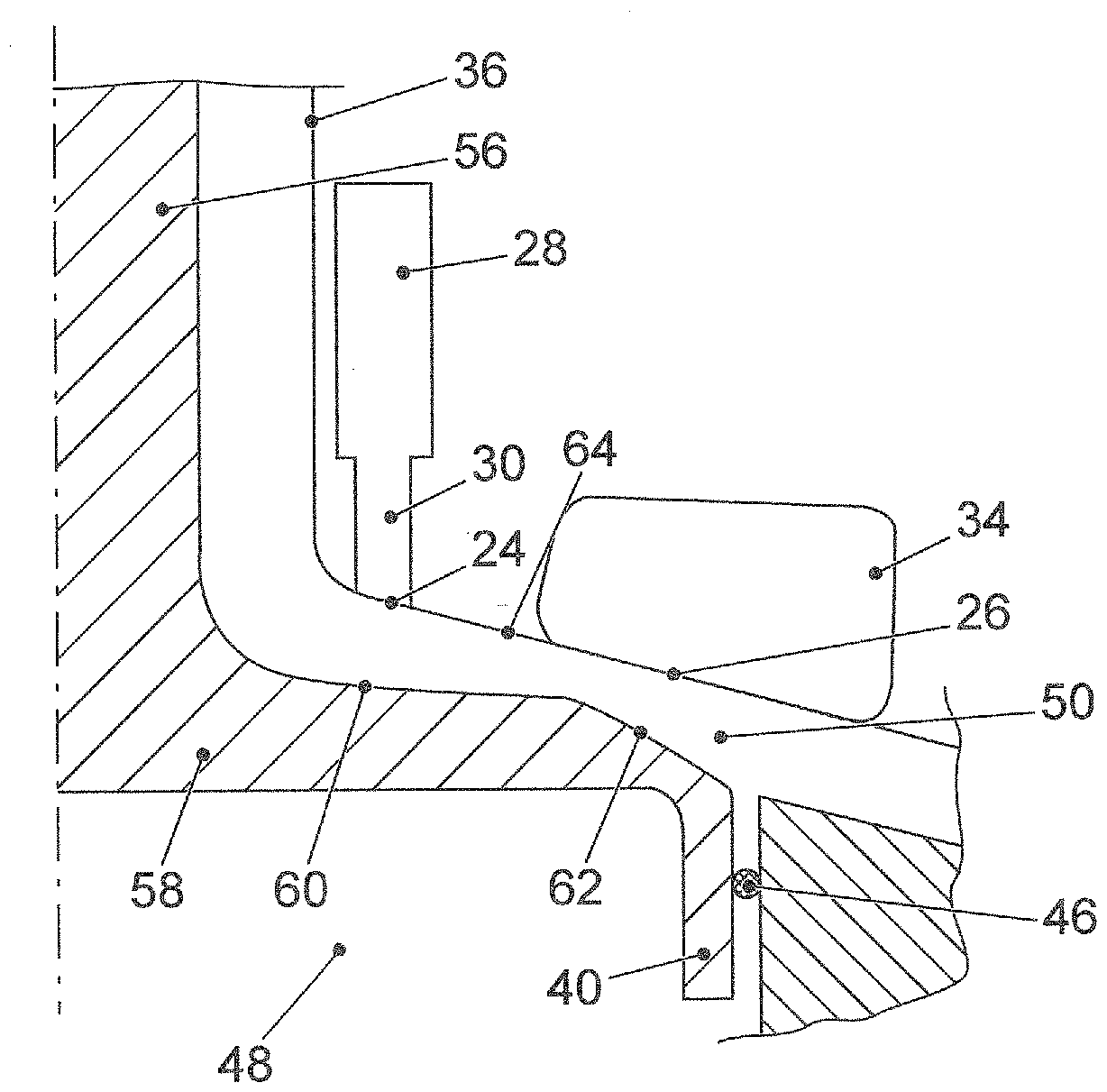

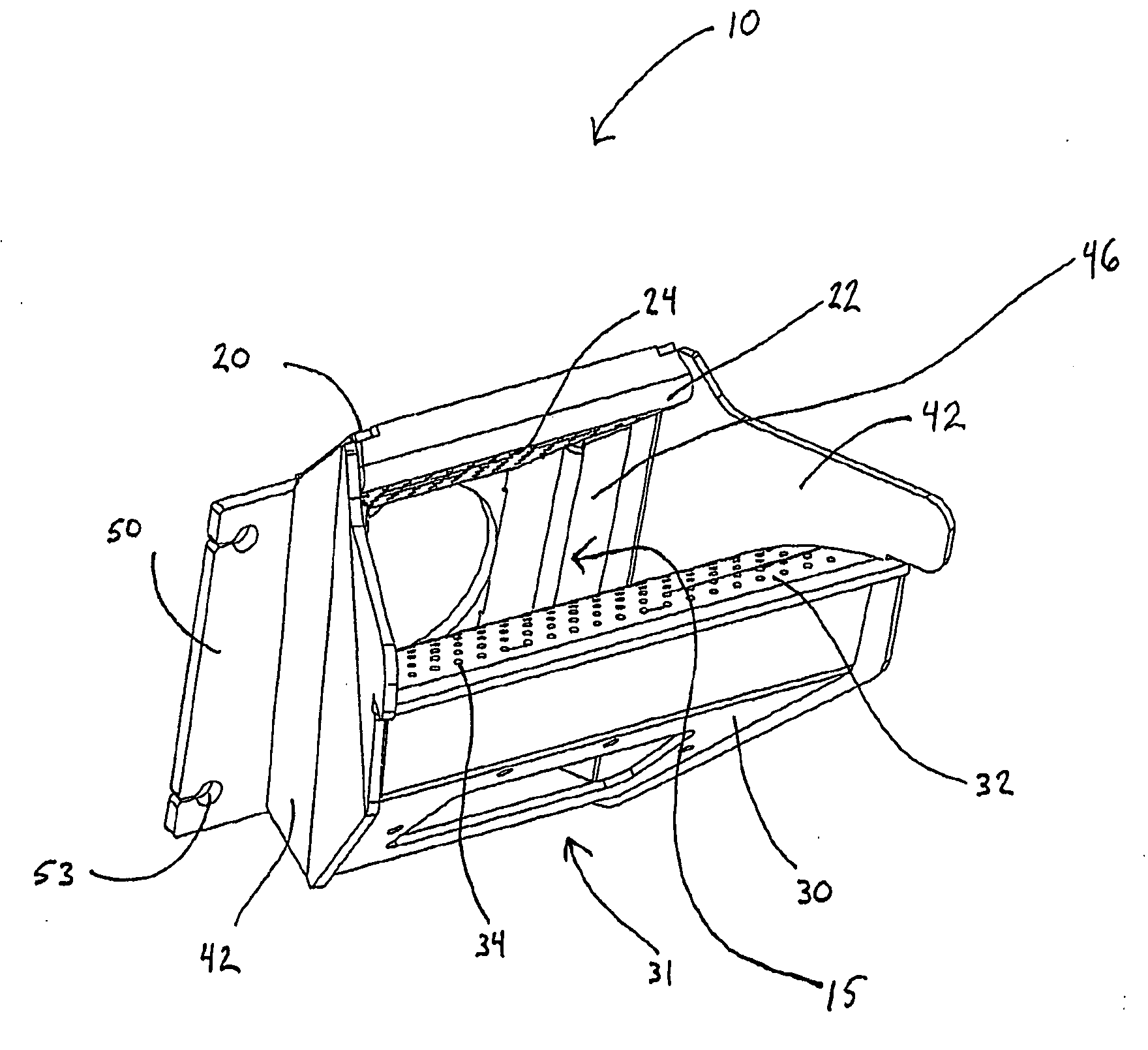

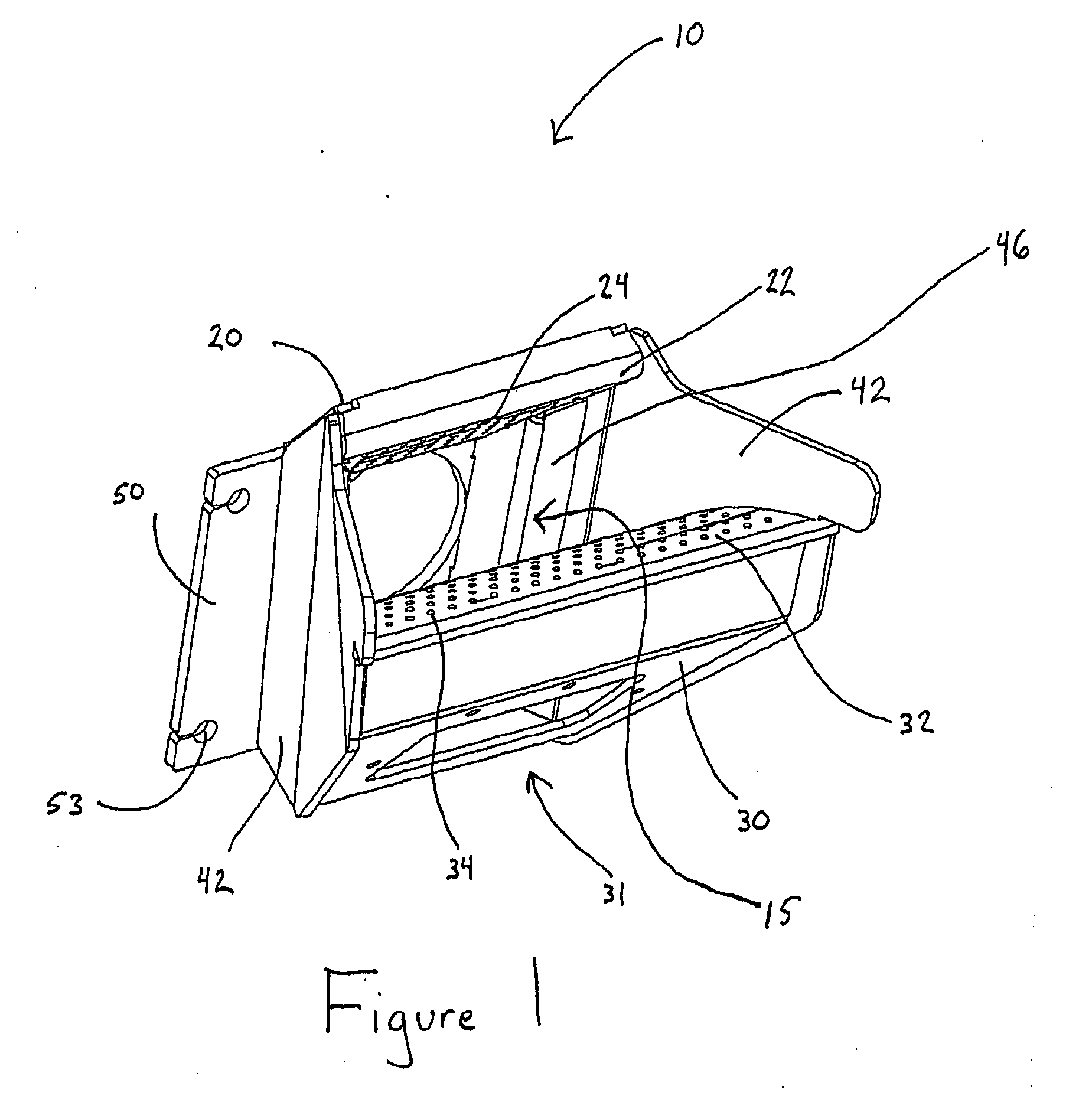

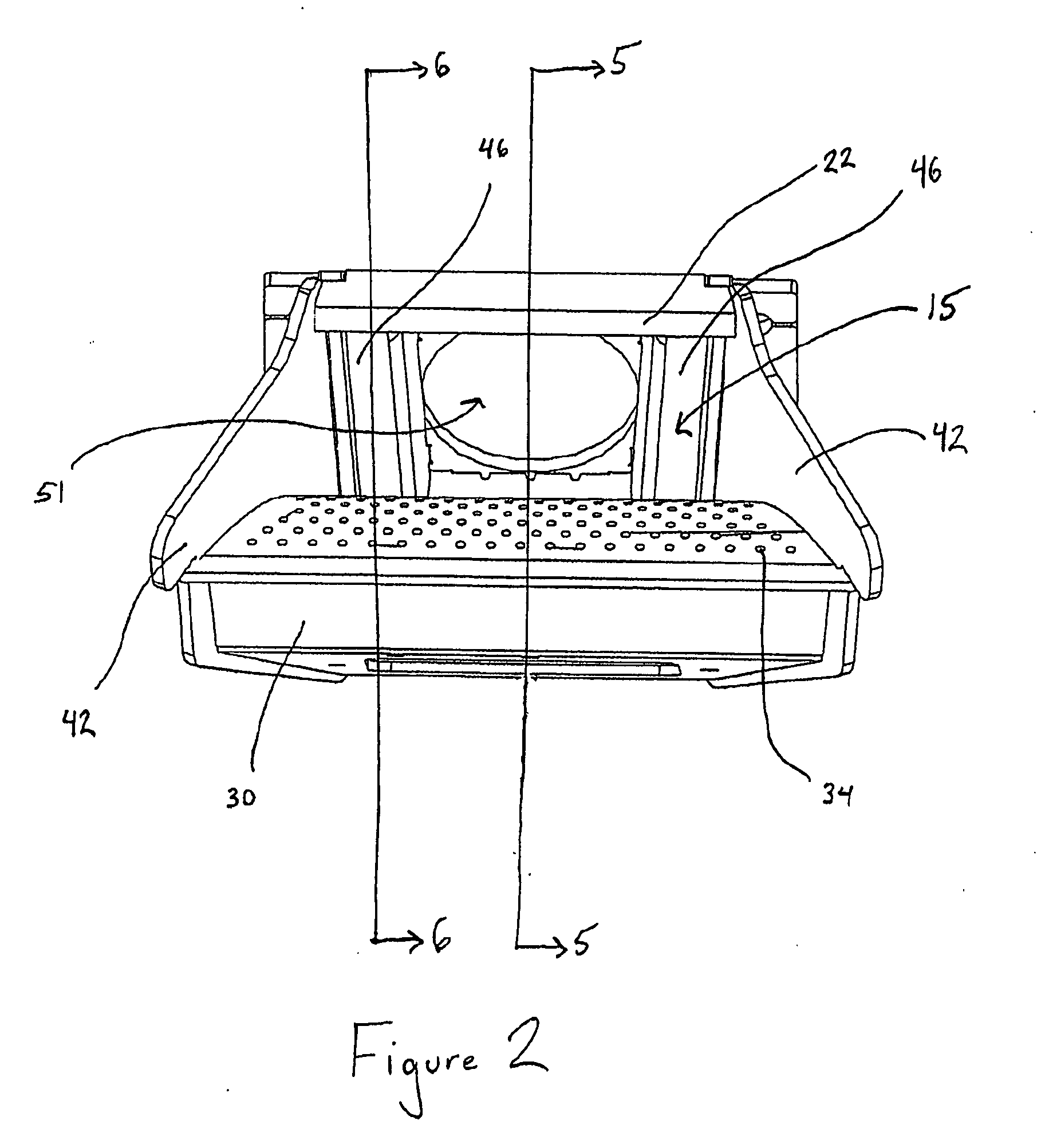

Burnpot for solid particulate stove

InactiveUS20080110448A1Reduce carbon buildupReduce cleaningDomestic stoves or rangesSolid fuel combustionCombustion chamberSolid particle

A burnpot for a solid particulate stove is disclosed. The burnpot includes a bottom cover, a top cover, two side plates connecting the top cover and the bottom cover, a bottom grate having a plurality of bottom grate apertures disposed therein and positioned intermediate the bottom cover and the top cover, a top grate having a plurality of top grate apertures disposed therein and positioned intermediate the bottom grate and the top cover and an air passageway configured to direct air to a burn chamber of the burnpot through the bottom grate and the top grate.

Owner:HNI TECH INC

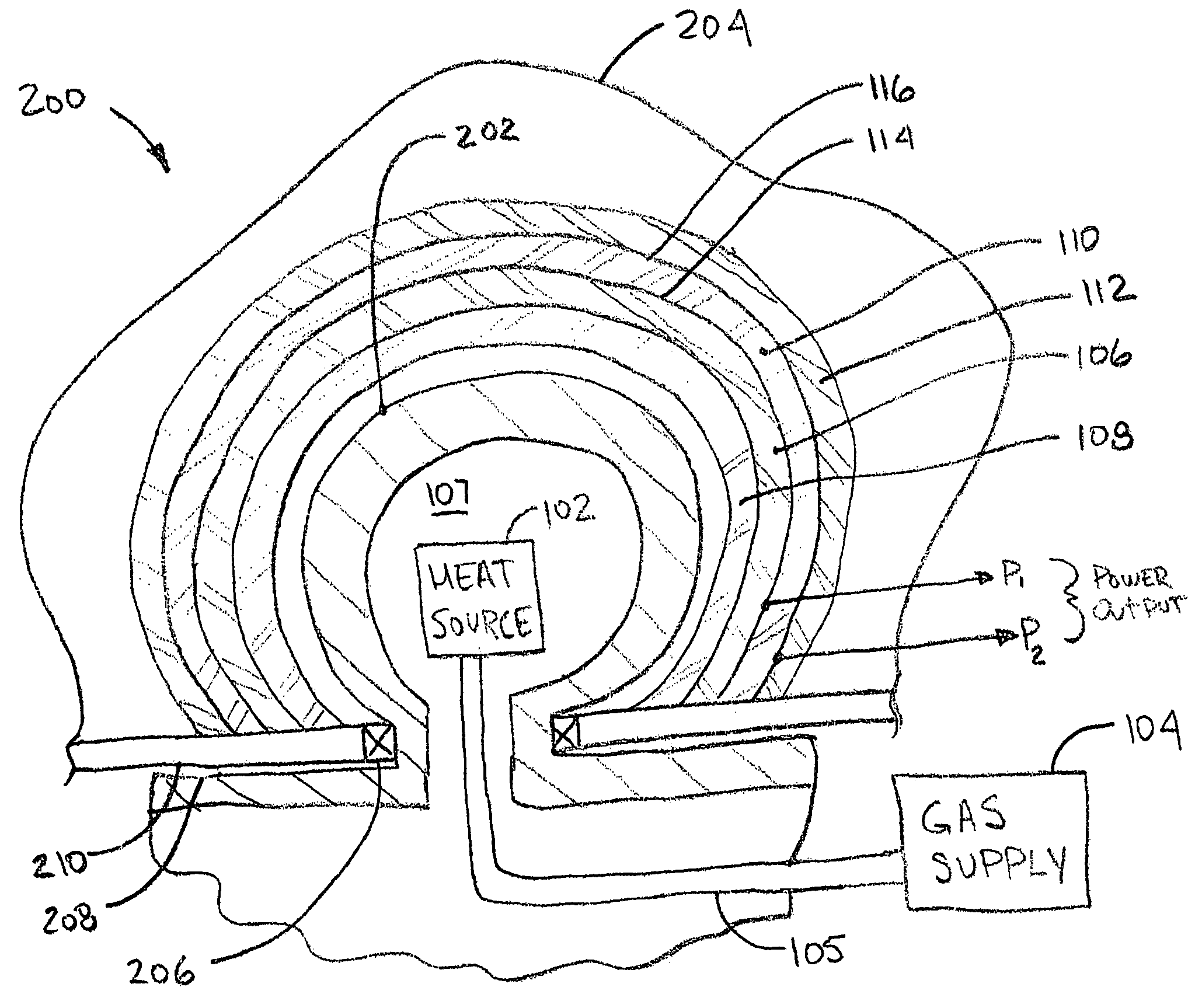

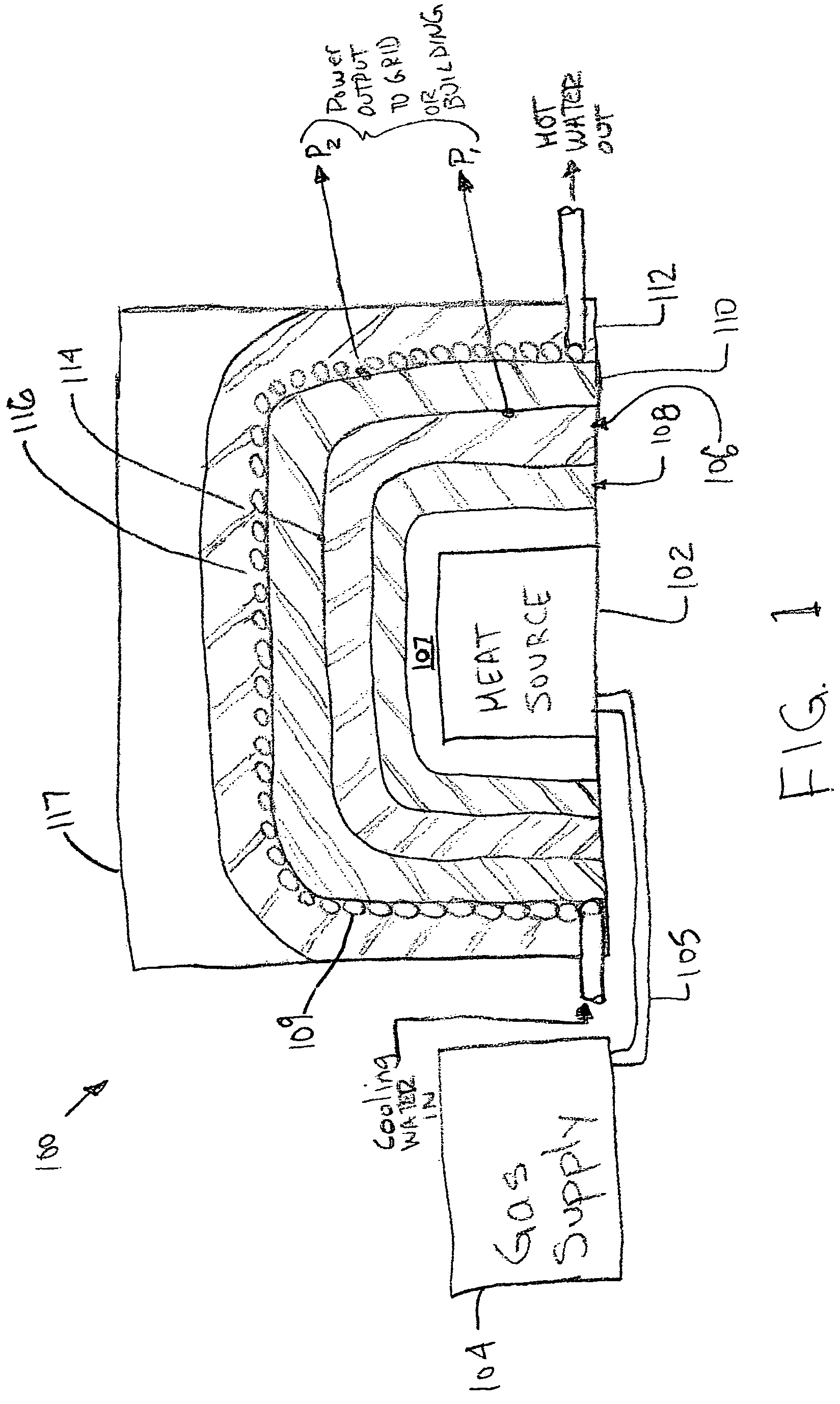

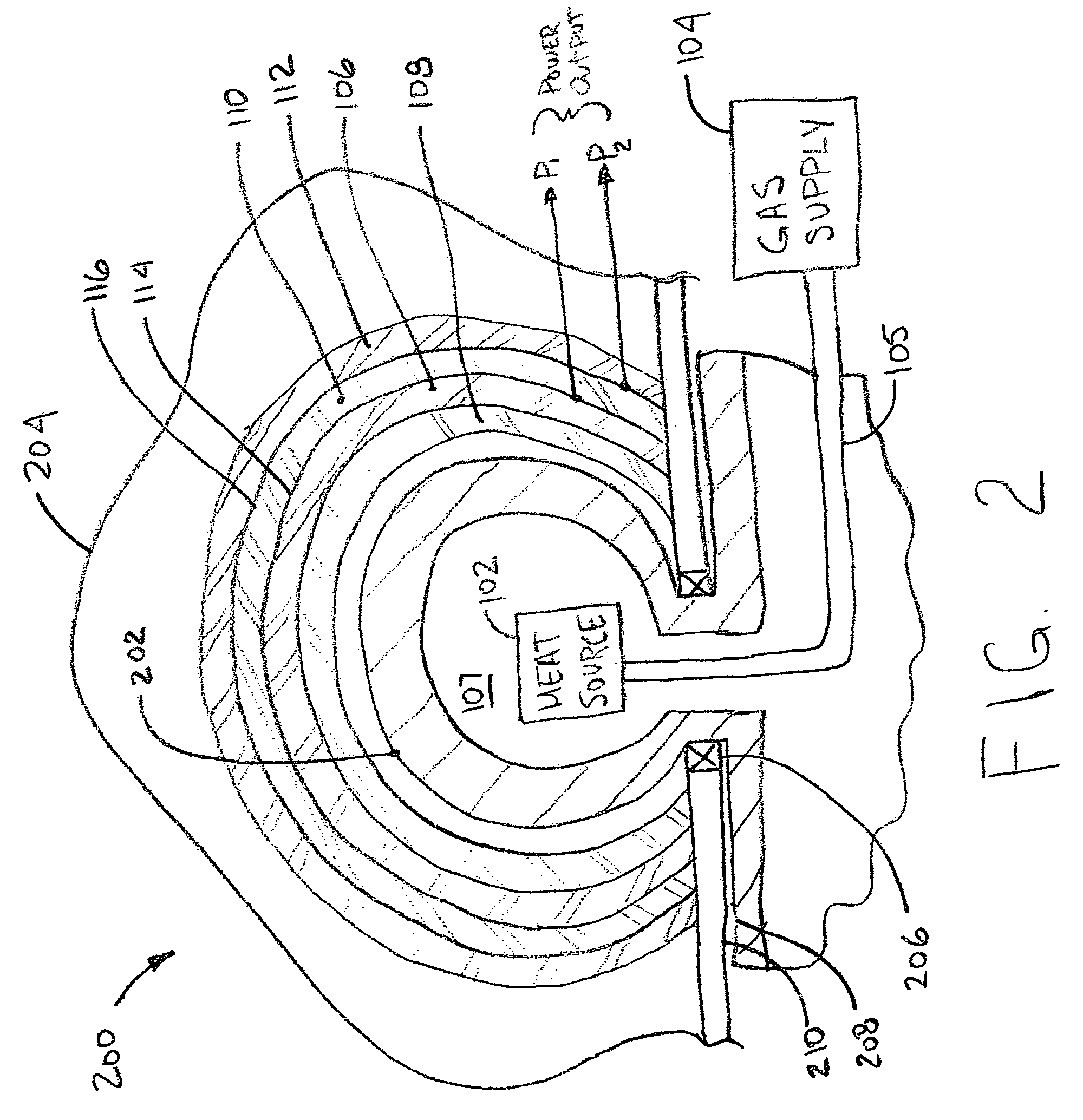

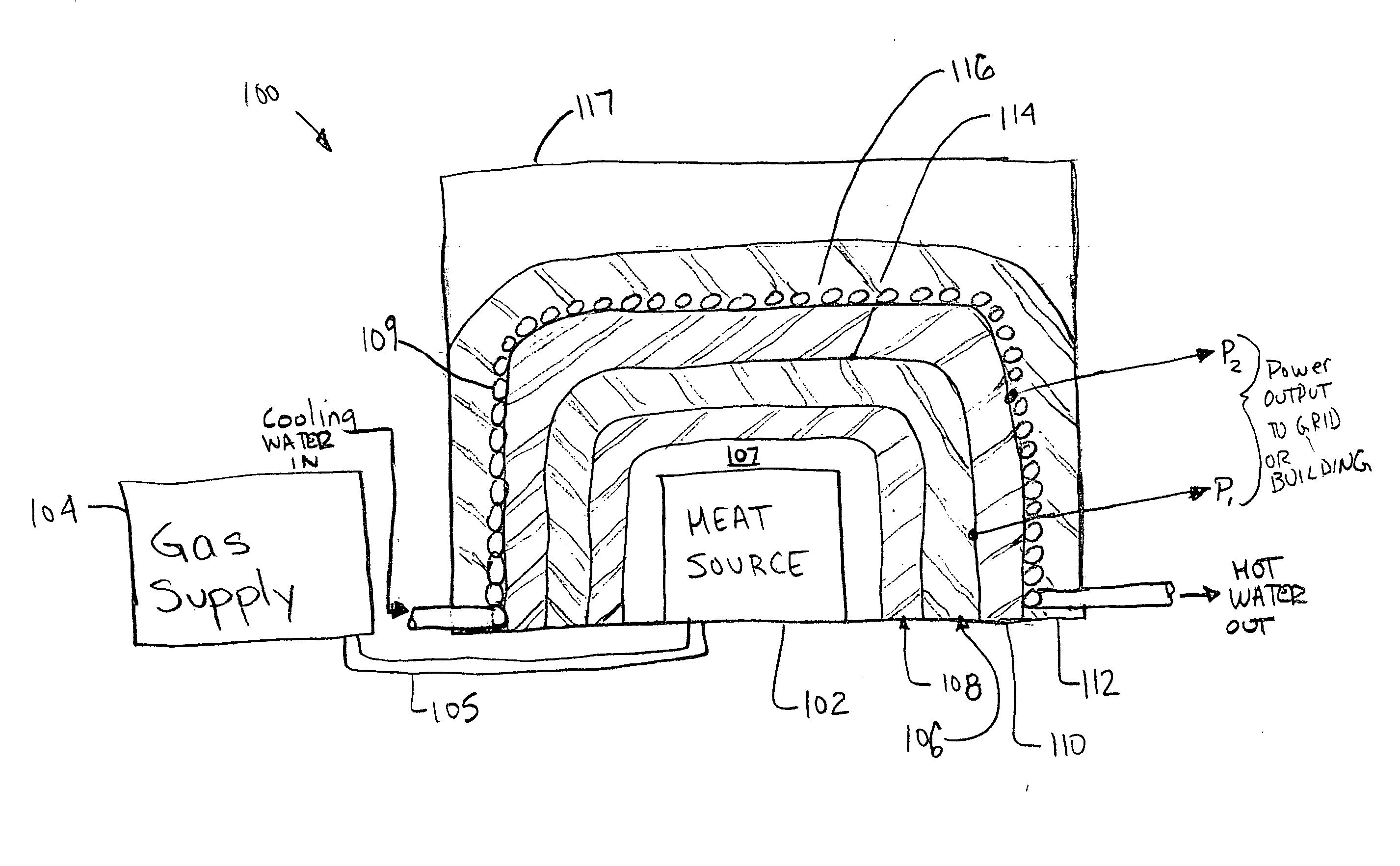

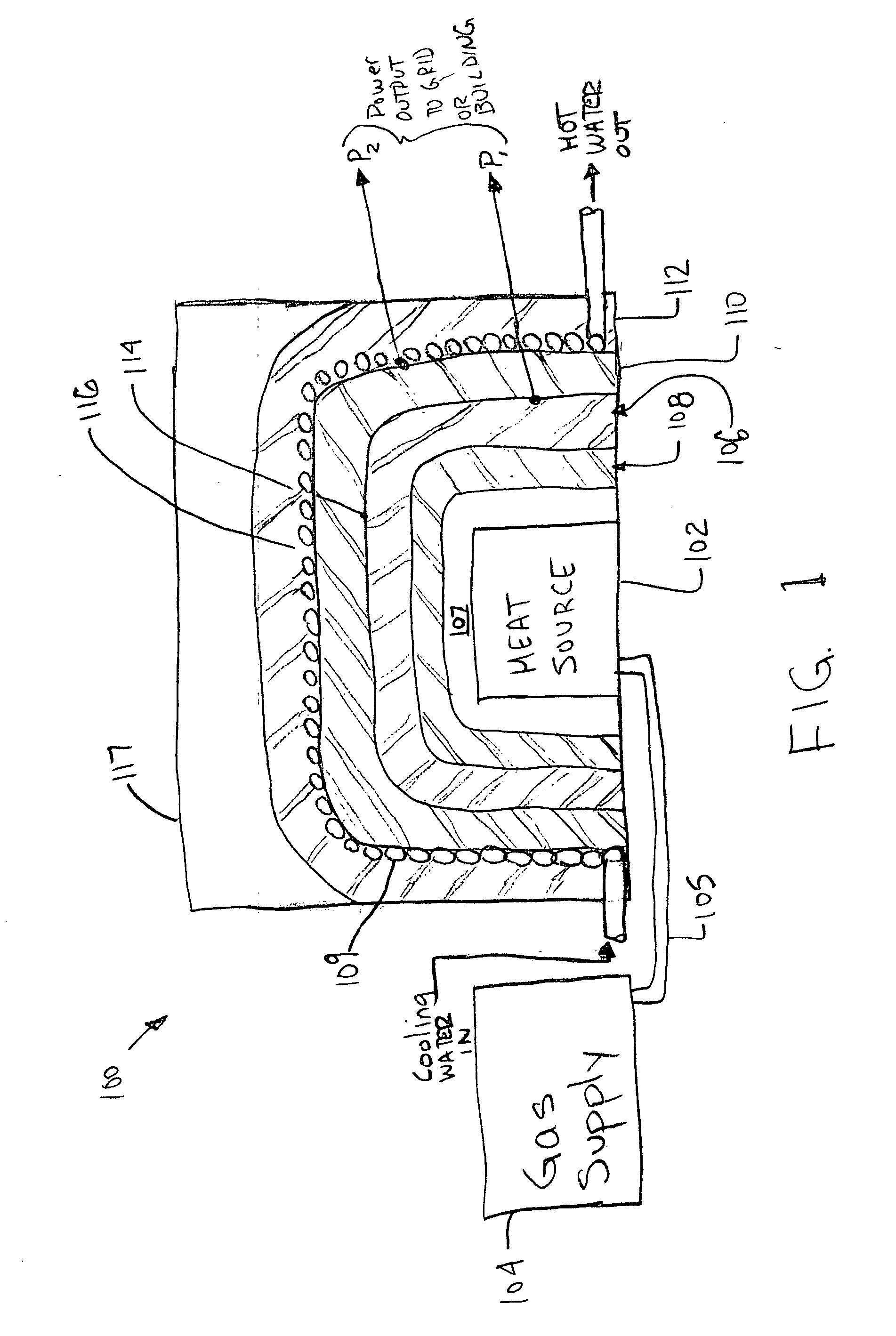

Method and devices for generating energy from photovoltaics and temperature differentials

InactiveUS7326850B2Burn cleanLess expensiveThermoelectric device with peltier/seeback effectMowersNuclear engineeringTemperature difference

A method for generating power is provided. The method including: providing a heat source with an output of radiation in a predetermined spectrum; generating a first portion of the power from the absorption of the radiation; and generating a second portion of the power from a temperature difference between a first element heated by the heat source and a second element at least partially thermally insulated from the first element.

Owner:OMNITEK PARTNERS LLC

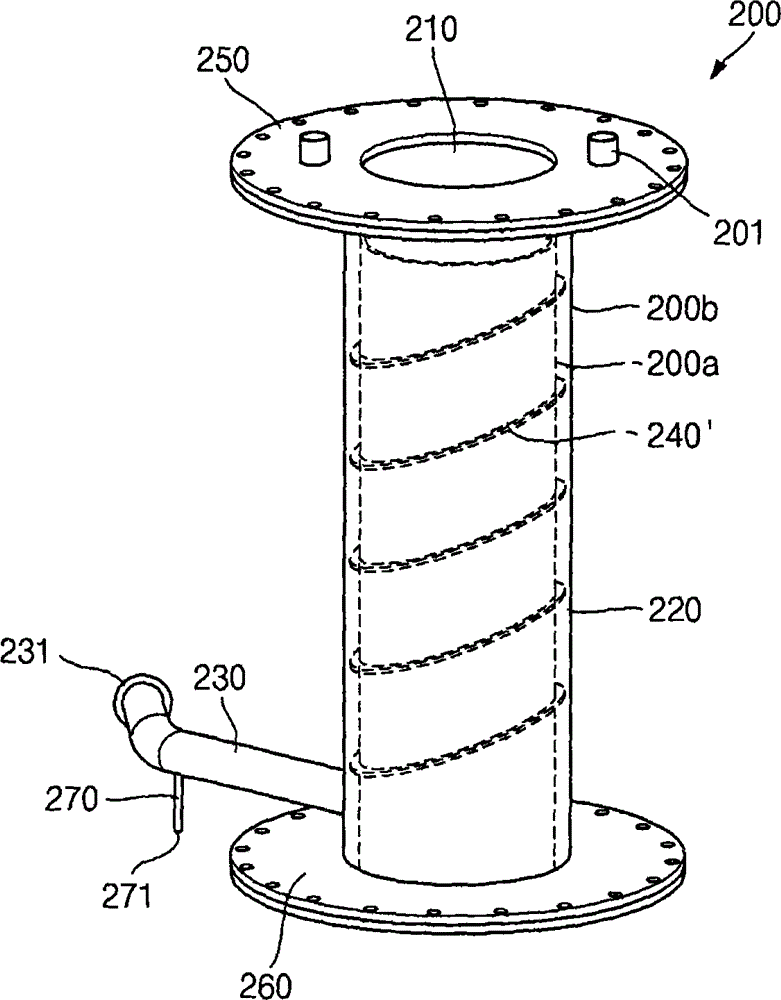

Odor treatment device for harmless treatment on animals died of diseases

InactiveCN109092026AThorough treatmentThe odor of the treatment is thoroughly treatedGas treatmentDispersed particle separationCombustionEngineering

The invention discloses an odor treatment device for harmless treatment on animals died of diseases. The odor treatment device comprises a gas inlet, wherein the gas inlet is formed in the head part of a first coiled tube; the first coiled tube is arranged inside a high-temperature combustion furnace; an exhaust hole is formed in the upper end of the head of the coiled tube; valve devices are arranged at side ends of the exhaust hole and the gas inlet; a cooling device is communicated; a first bacterium treatment device and a second bacterium treatment device are arranged at the rear end of the cooling device; the second bacterium treatment device is communicated with a gas outlet; a vent hole is formed in the tail part of the first coiled tube; an air return device is arranged at the venthole. The invention provides the odor treatment device for harmless treatment on animals died of diseases, the device is simple in structure, convenient to use, thorough in odor treatment and good inpracticability, and the energy consumption and the cost can be reduced since heat exchange can be implemented when treated ozone is cooled.

Owner:桃江县裕农生物科技有限公司

Environment-friendly formula of high-calorie biomass charcoal

The invention discloses an environment-friendly formula of high-calorie biomass charcoal, aiming at providing high-temperature charcoal which takes biomass charcoal as a main raw material, is easy to catch fire, can burn clearly and is not easy to loose during high-temperature burning. The formula mainly comprises the following components by weight percent: no more than 60% and no less than 95% of biomass charcoal powder, no more than 0% and no less than 30% of anthracite powder and no more than 5% and less than 15% of cement.

Owner:湖南创则通能源有限公司

Gasification heat-accumulation combustion device for garage and use method of gasification heat-accumulation combustion device

InactiveCN105509063AImprove heating efficiencyReduce energy consumptionWater heatersIncinerator apparatusWater pipeHeat conservation

The invention discloses a gasification heat-accumulation combustion device for garage. The gasification heat-accumulation combustion device comprises a water pipe wall furnace body, wherein a boiler is arranged on the water pipe wall furnace body; an upper-layer heat-accumulation chamber and a lower-layer heat-accumulation chamber are formed in the water pipe wall furnace body through a water pipe partition layer; the lower-layer heat-accumulation chamber comprises a combustion chamber and shunt-wound heat-accumulation chambers; a fire grate is arranged below the combustion chamber, and a garbage feeding mechanism is arranged at the side part of the combustion chamber; the shunt-wound heat-accumulation chambers include a heat-accumulation chamber A and a heat-accumulation chamber B which are communicated with each other, the heat-accumulation chamber A is communicated with the combustion chamber, and the heat-accumulation chamber B is communicated with the upper-layer heat-accumulation chamber. According to a use method of the gasification heat-accumulation combustion device, garbage is combusted on the fire grate, and hot gas enters the shunt-wound heat-accumulation chambers through a combustion region to warm and remove impurities and simultaneously heat the water pipe wall furnace body and the water pipe partition layer; then hot gas enters the upper-layer heat-accumulation chamber to be subjected to heat accumulation and simultaneously heat the water pipe wall furnace body and the water pipe partition layer, and produced waste heat is used by other equipment.

Owner:吴慧文

Formula of environment-friendly biomass briquette

The invention discloses a formula of an environment-friendly biomass briquette. The formula comprises fuel and an additive, wherein the additive is water glass and the fuel is the mixture of biomass powdered carbon and fine anthracite. The concentration of the water glass is set to be 3.2 moduli. The water glass is 12-30% of the environment-friendly biomass briquette by weight and the fuel is 70-88% of the environment-friendly biomass briquette by weight. If the concentration of the water glass is less than 3.2 moduli, the proportion is correspondingly increased.

Owner:肖国雄

Briquette formula with high calorific value

InactiveCN101798536AHigh calorific valueImprove thermal efficiencySolid fuelsBriquettePhotochemistry

The invention discloses a briquette formula with high calorific value. The formula comprises coal and water glass. The concentration of the water glass additive is set to be 3.2 moduli. The water glass is 10-30% of the briquette by weight and the coal is 70-90% of the briquette by weight. If the concentration of the water glass additive is less than 3.2 moduli, the proportion is correspondingly increased.

Owner:肖国雄

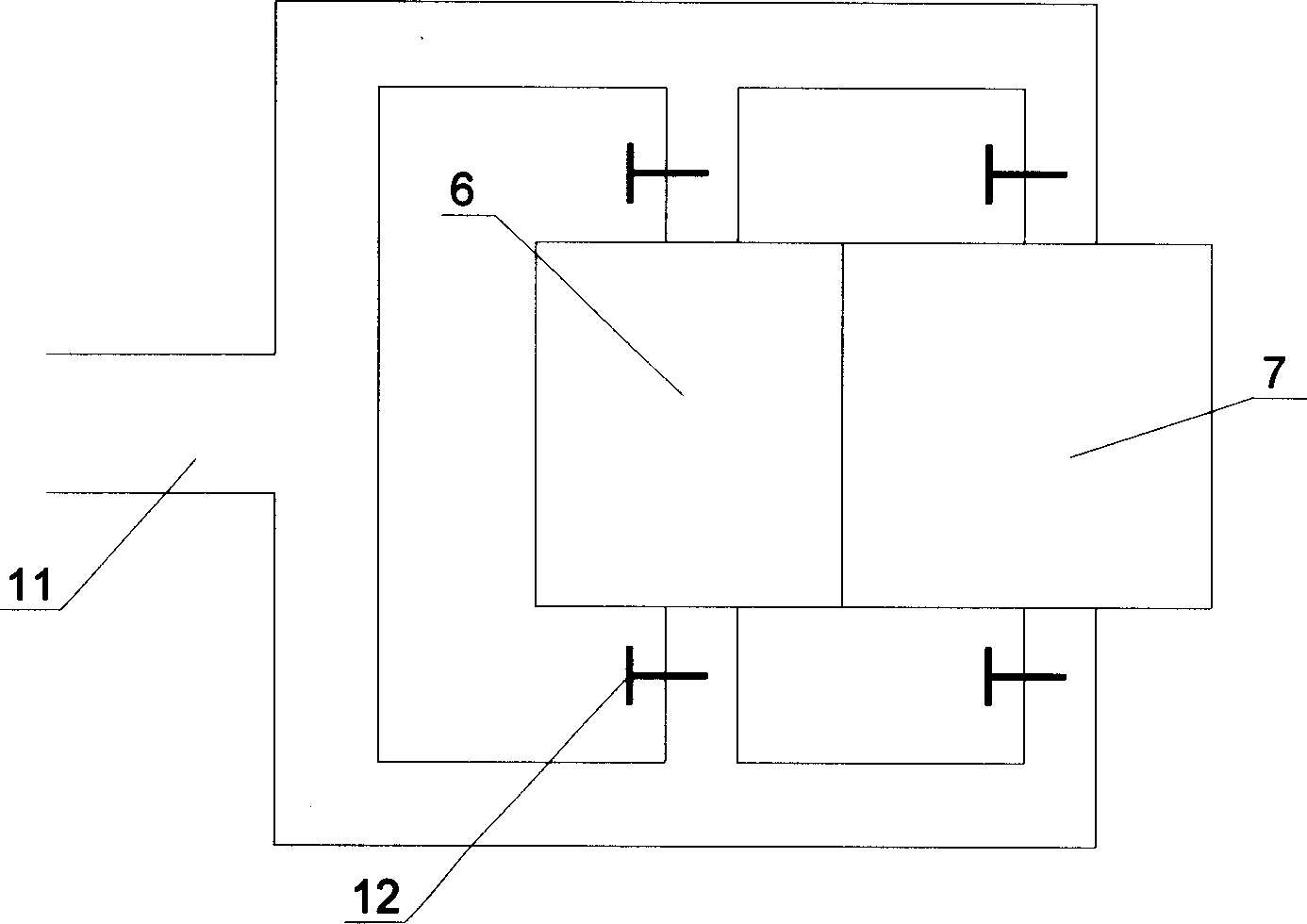

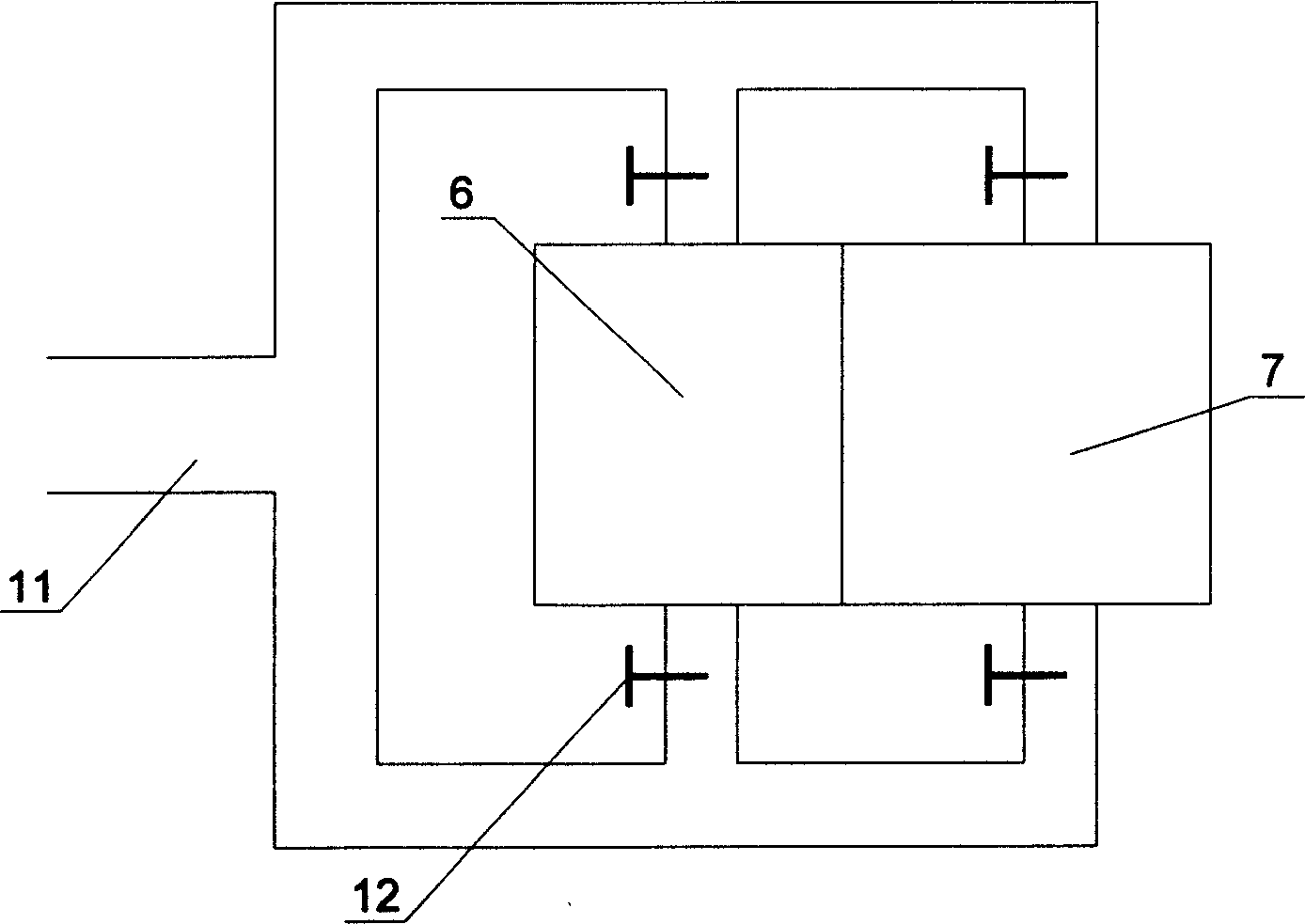

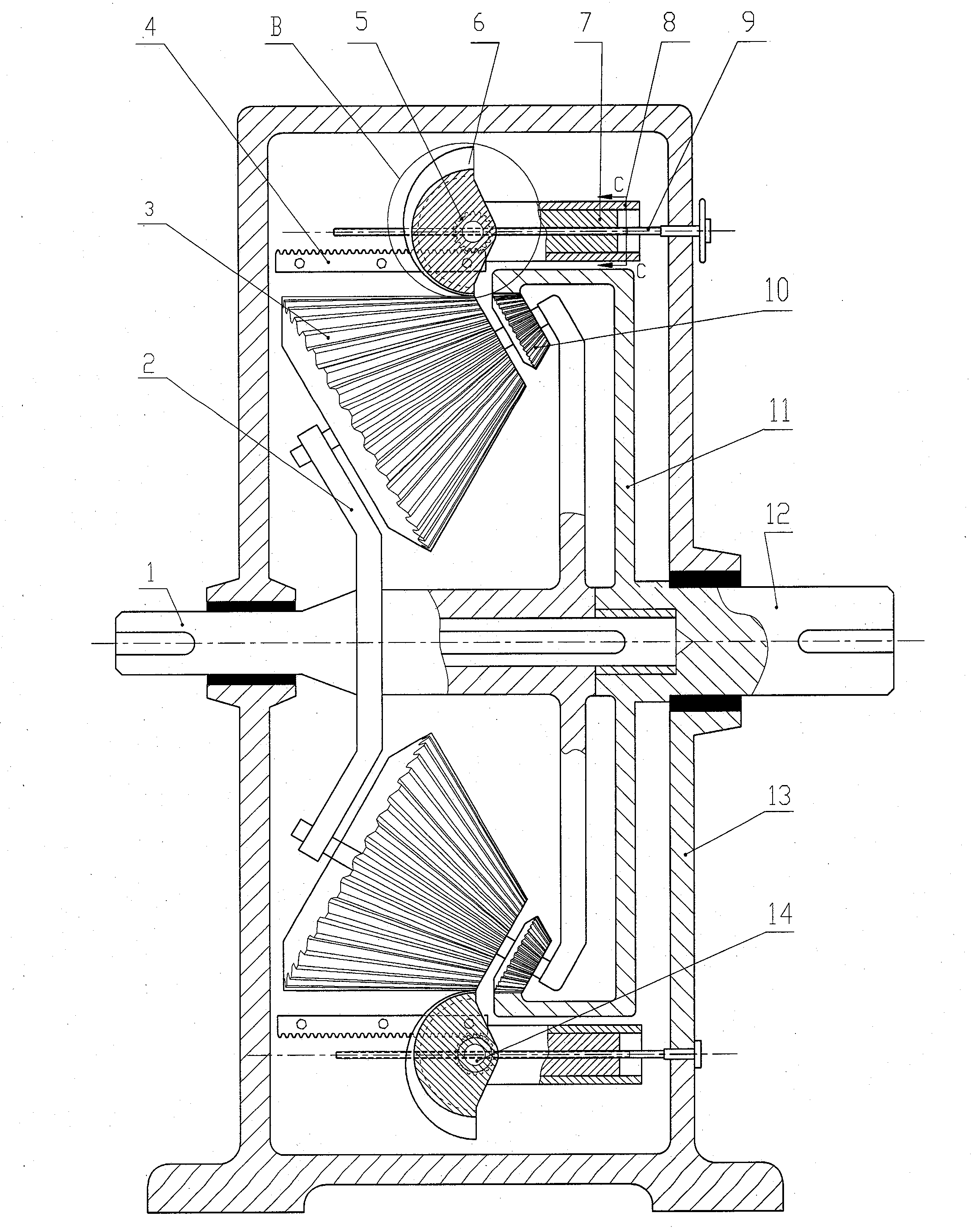

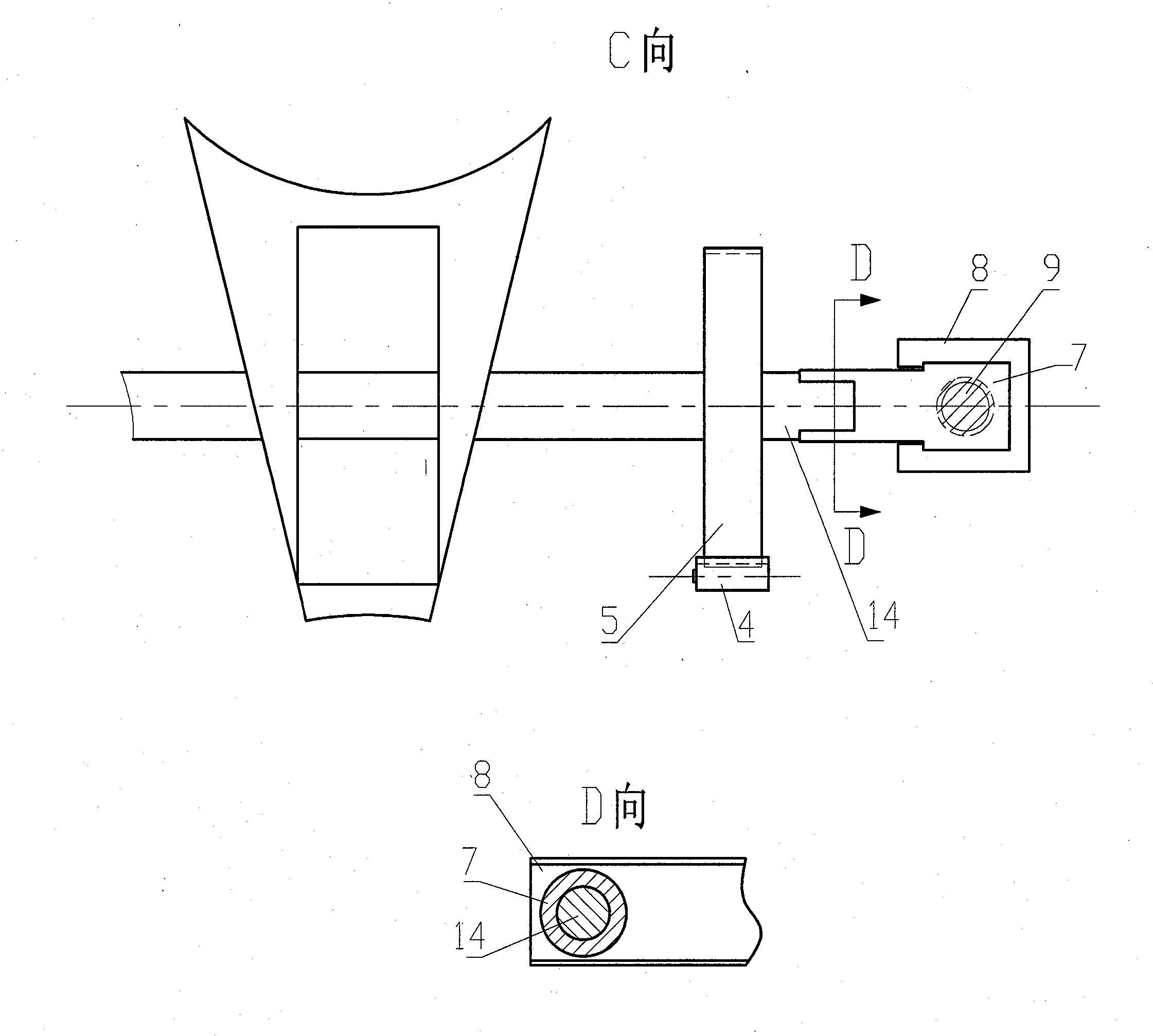

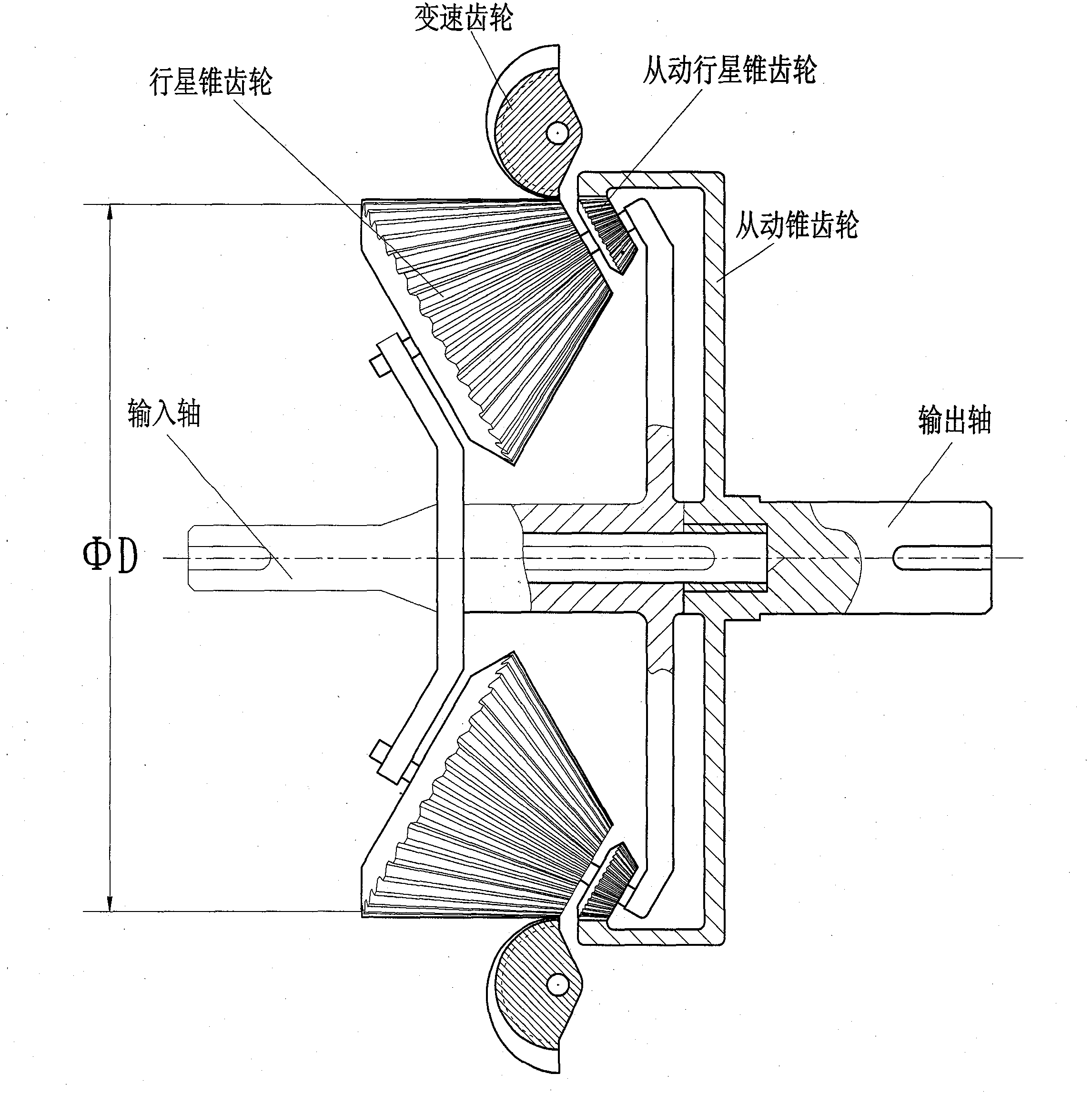

Tooth number variable gear stepless transmission

The invention relates to a mechanical stepless transmission, in particular to a pure gear engaged mechanical stepless transmission. As shown in figure 1, power drives planet bevel gears (3) via an input shaft (1) and a retainer (2) so that each planet bevel gear performs revolution around a central axial line along with the input shaft (1) on the one hand, and, on the other hand, itself rotates around the equally-divided hole axial line of the retainer (2), and planet movement resulting from revolution and rotation drives a driven bevel gear (11) via a driven planet bevel gear (10) to transmit the power to an output shaft (12). In speed variation, a speed change gear (6) makes pure rolling movement on a cylindrical surface (formed of the generatrix of the outermost planet bevel gear of several uniformly-distributed planet bevel gears), to realize speed variation. The mechanical stepless transmission provided by the invention has the advantages of high transmission power and efficiency, simple structure and low cost. For an automobile, improvement on transmission efficiency means fuel saving, and the engine works under an ideal condition to achieve full fuel combustion and clean emission and reduce pollution to environment.

Owner:ZHONGBEI UNIV

Energy source using hydrogenated vegetable oil diluted into diesel fuel

InactiveUS20040221505A1Burn cleanLow costLiquid organic insulatorsLiquid carbonaceous fuelsVegetable oilPartial hydrogenation

An alternative fuel source, preferably for use in a boiler, is provided. The fuel source is comprised of a partially hydrogenated vegetable oil and diesel fuel. Preferably, the partially hydrogenated vegetable oil has a Iodine Value (IV) ranging from approximately 50 to approximately 120.

Owner:BUNGE NORTH AMERICA

HVAC home generator

ActiveUS9871411B2Extended electrical outagesCheap and readily availableAc network circuit arrangementsEmergency power supply arrangementsResidenceTransfer switch

A natural gas or liquified propane powered generator incorporated into a HVAC unit, for supplying emergency power to a residence or commercial business. The generator is contained within an exterior cabinet that houses HVAC components for both packaged and split systems. The packaged unit is arranged so that the generator is included within the exterior cabinet and the split unit is arranged so that the generator is positioned beneath the split unit. The generator operates from natural gas or liquified propane supplied to the home or from a portable liquified propane tank, if the supply of natural gas or liquified propane is terminated. In the event of a power failure, the user manually operates the generator or an automatic transfer switch can be utilized. On-site electronics are included to allow a user to monitor the system from a smart phone or other electronic device.

Owner:ORTNER CHARLES R

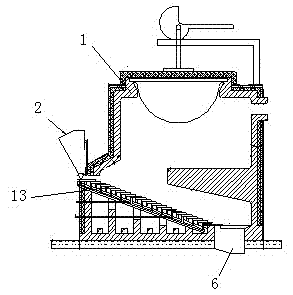

Coal-burning oil-burning gas-burning boiler

InactiveCN103759251AIncrease heat exchange rateBurn fullyCombustion using multiple fuelsWater heatersCombustionCoal fired

A disclosed coal-burning oil-burning gas-burning boiler comprises a furnace body, the furnace body is inside provided with a heat exchange zone at the upper part and is inside provided with a combustion zone at the lower part; the heat exchange zone is provided with multiple horizontally arranged transverse heat-exchange fire tubes, the central part of the heat exchange zone is provided with a separation plate dividing the multiple transverse heat-exchange fire tubes into an upper layer and a lower layer; a front-end return chamber and a rear-end return chamber are respectively arranged between the furnace body and the end faces of two ends of the transverse heat-exchange fire tubes; the combustion zone is provided with a coal burning zone and an oil and gas burning zone which are distributed in a parallel manner; the outer top of the furnace body is provided with an expanding pressure-release water tank; the upper part of the lateral side of the furnace body is provided with a smoke discharging port; and the outer end of the smoke discharging port is provided with an induced draught fan. Coal and gas in the boiler are combusted in different chambers, layer combustion and chamber combustion are perfectly combined, coal, oil and gas can be combusted singly, and can be merged for simultaneous combustion, and the multi-functionalization of the boiler is realized.

Owner:范高峰

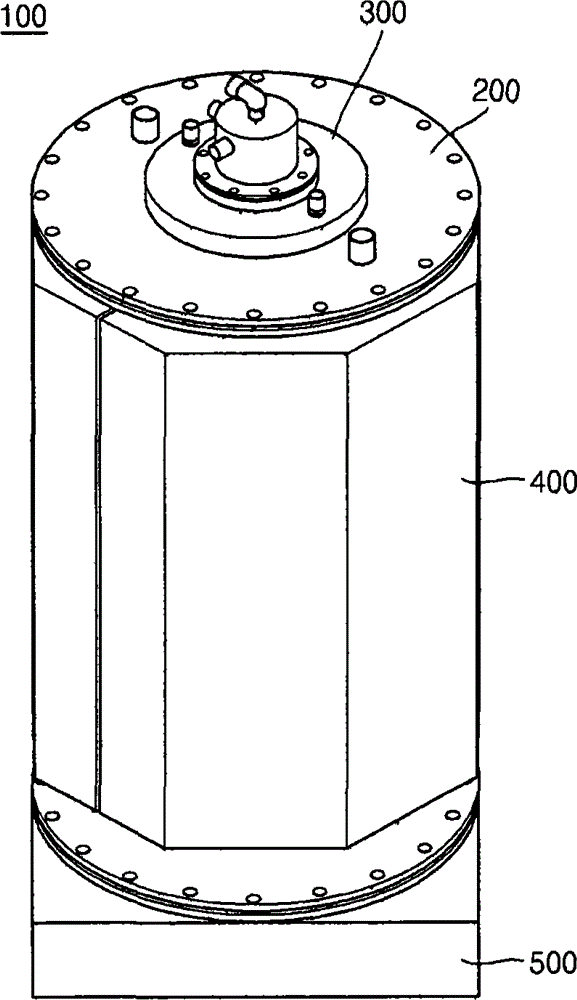

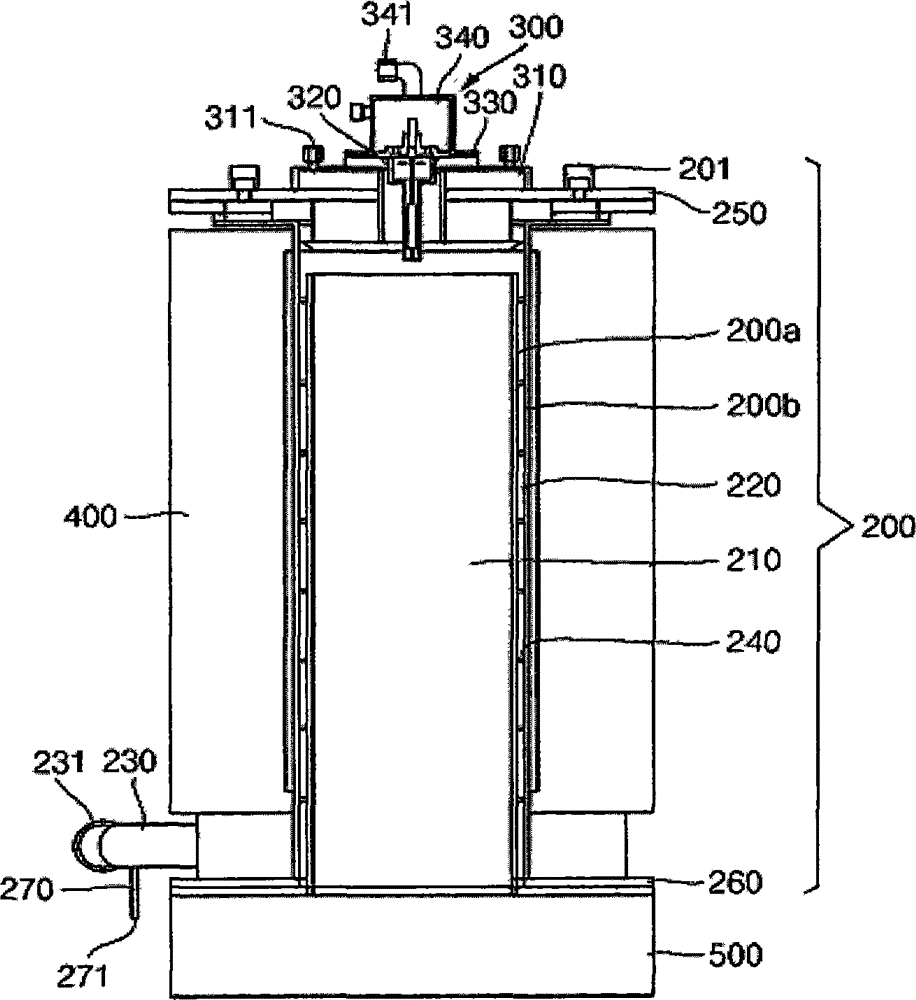

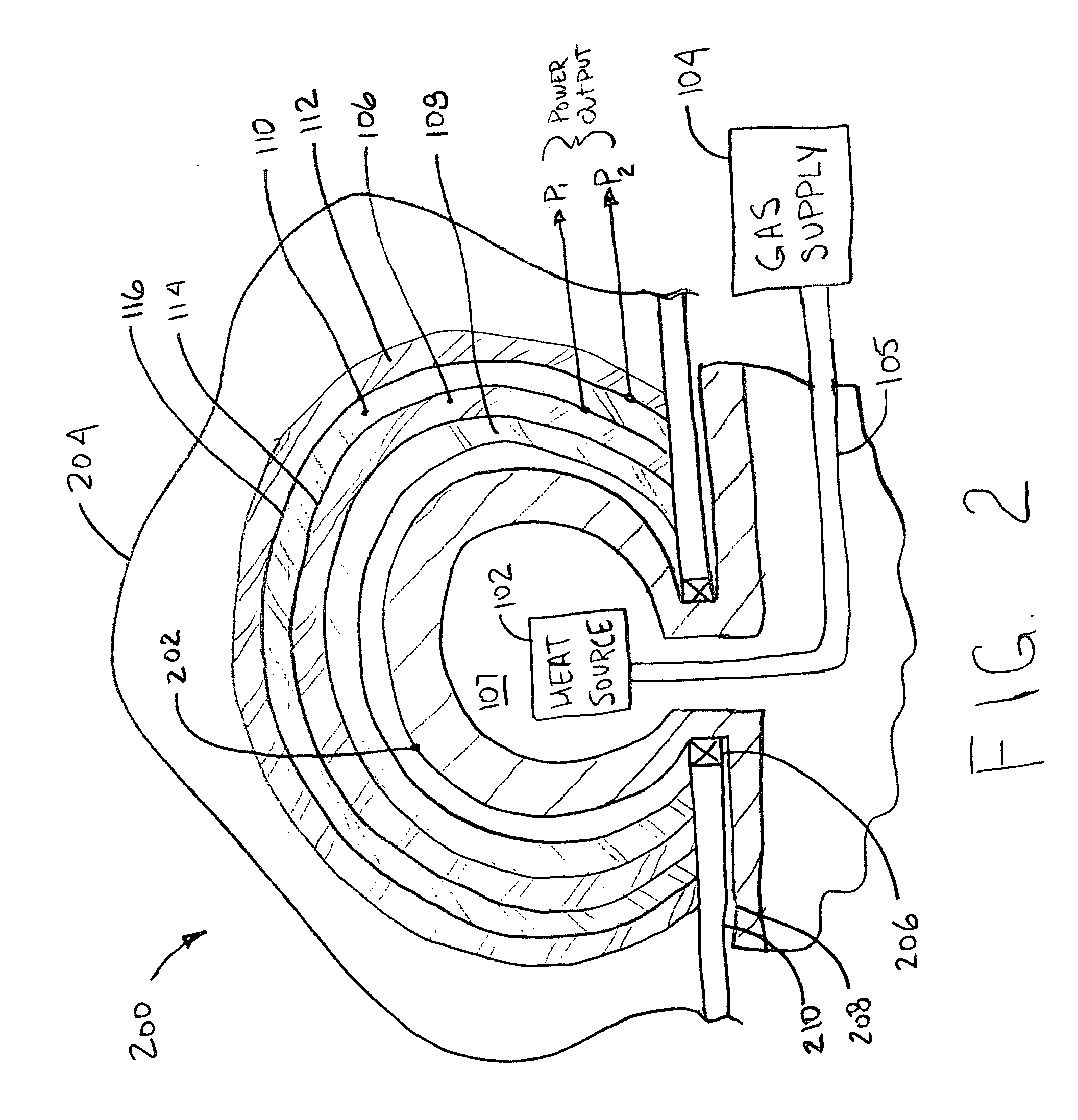

Tail gas treatment device for treating process exhaust gas of LED MOCVD equipment

InactiveCN105276592AExtended combustion rangeBurn safely and thoroughlyIncinerator apparatusCombustion chamberExhaust fumes

A tail gas treatment device for treating process exhaust gas of LED MOCVD equipment comprises a combustion chamber for combusting exhaust gas and a heating tape for packaging the combustion chamber. The combustion chamber comprises an outer chamber and an inner chamber which are annularly nested together. The outer chamber and the inner chamber which are nested together have a common top end cap. The end cap locks the outer chamber and the inner chamber together through screws and a sealing pad. The outer wall of the outer chamber is provided with two surrounding type heating tape. The heating tape packages the whole outer chamber. The tail gas treatment device sufficiently utilizes combustion heat and realizes relatively small amount of consumed electric energy. The tail gas treatment device has advantages of high safety, thorough combustion and no waste water through combusting the waste gases of H2 and NH3, energy-saving and environment-friendly performance, low cost, long maintenance period, simple structure and easy mounting.

Owner:SHANGHAI XIEWEI PRECISION MACHINERY

Method for manufacturing energy-saving and environment-friendly heating boiler

The invention relates to the field of boiler manufacturing technology manufacturing, in particular to a method for manufacturing an energy-saving and environment-friendly heating boiler. The method is characterized by including the following steps: 1, three burners are arranged in a boiler body from top to bottom; 2, the burners are in inverted-cone shapes, and an ash outlet hole is formed below each inverted-cone shape; 3, a ventilation opening is formed in the middle of the lateral side of each burner, and a discharging opening is formed in the left side of the boiler body. The method has the advantages that due to the boiler arrangement, fuel can be more thoroughly burnt, generated ash is reduced by more than 60% compared with the normal condition, the use fuel is greatly saved, cost can be saved, and the environment is also protected.

Owner:QINGDAO SHENGLI BOILER

Method and devices for generating energy from photovoltaics and temperature differentials

InactiveUS20080115820A1Burn cleanLess expensiveThermoelectric device with peltier/seeback effectPV power plantsNuclear engineeringTemperature difference

A method for generating power is provided. The method including: providing a heat source with an output of radiation in a predetermined spectrum; generating a first portion of the power from the absorption of the radiation; and generating a second portion of the power from a temperature difference between a first element heated by the heat source and a second element at least partially thermally insulated from the first element.

Owner:OMNITEK PARTNERS LLC

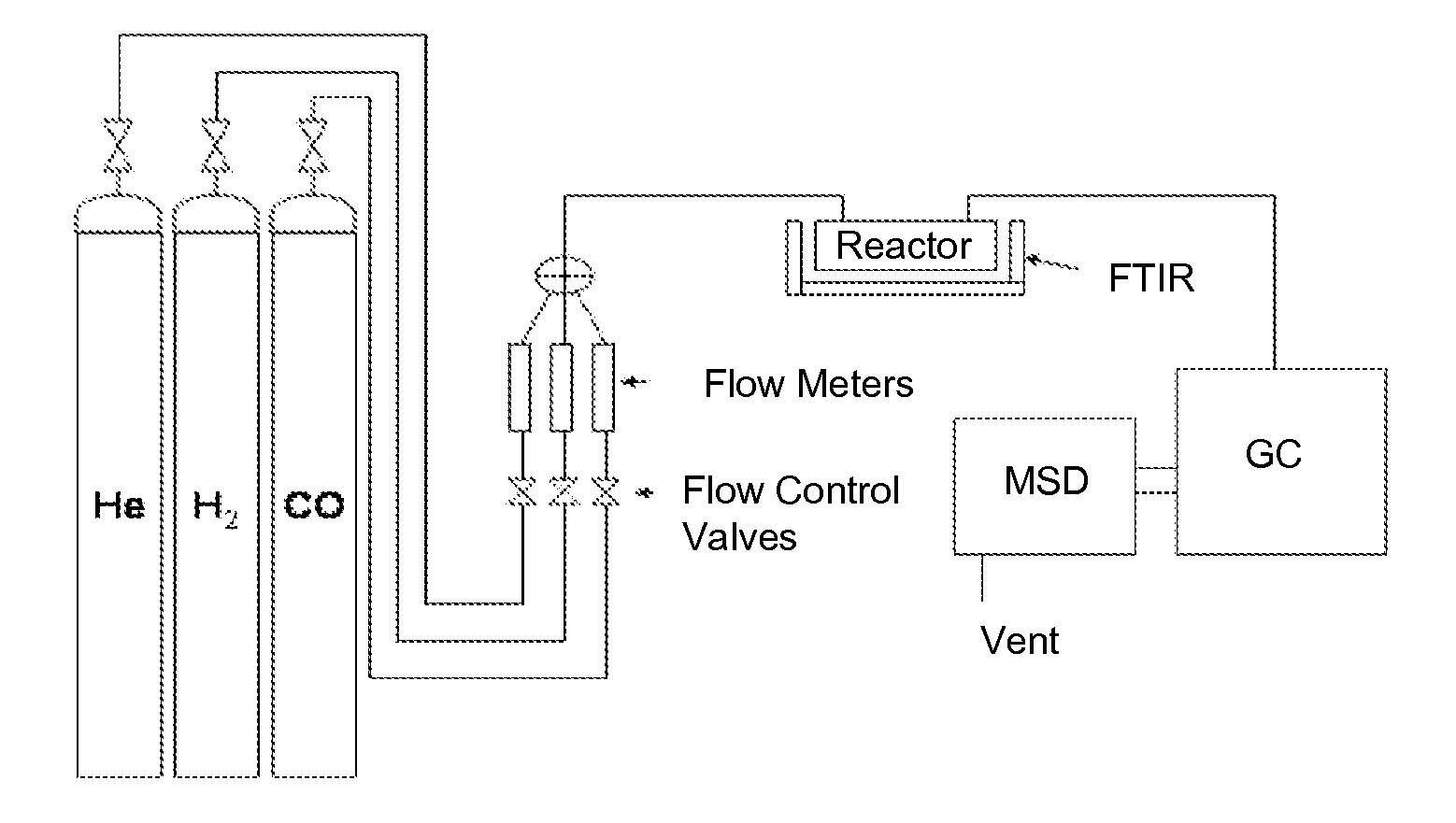

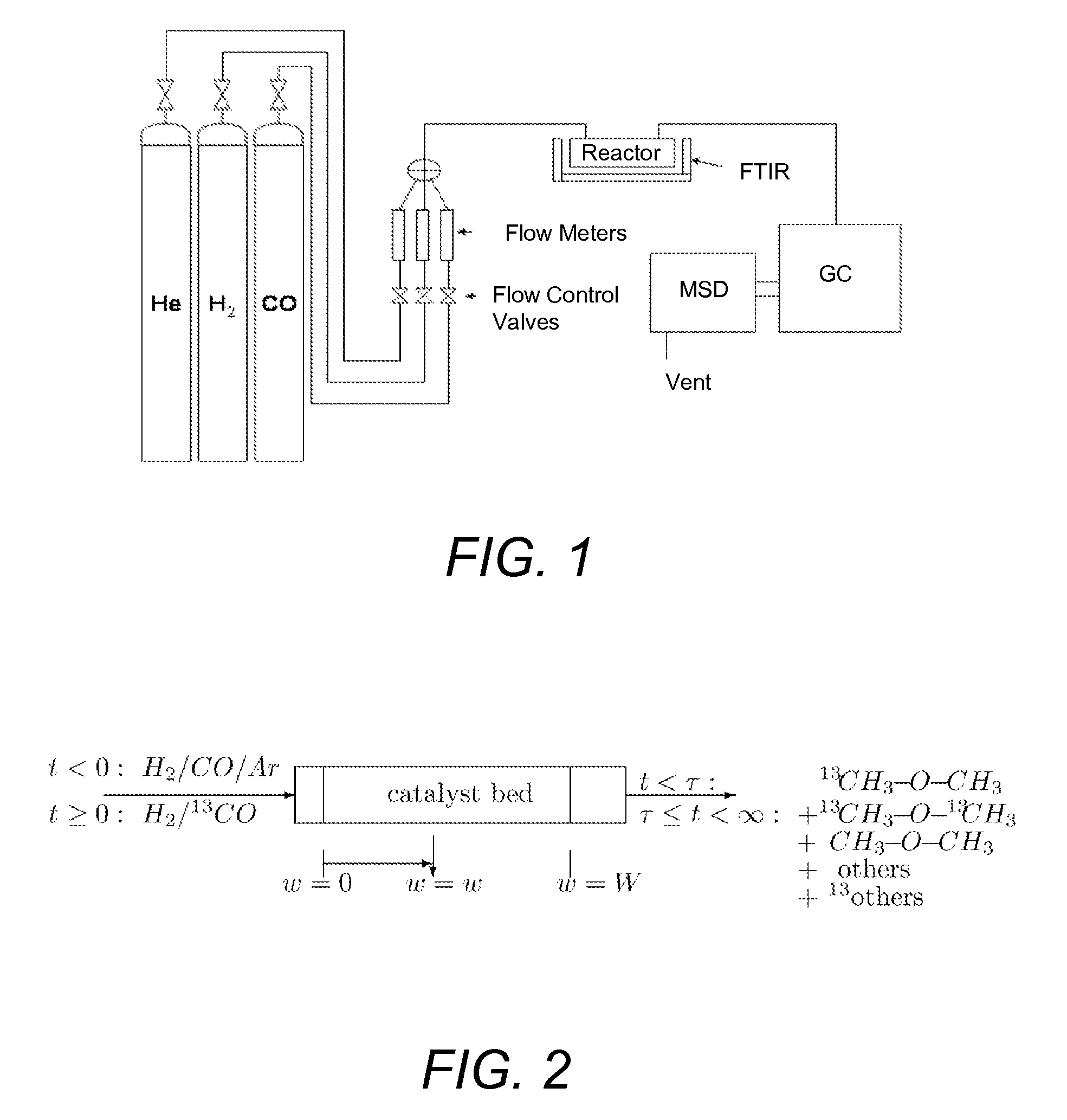

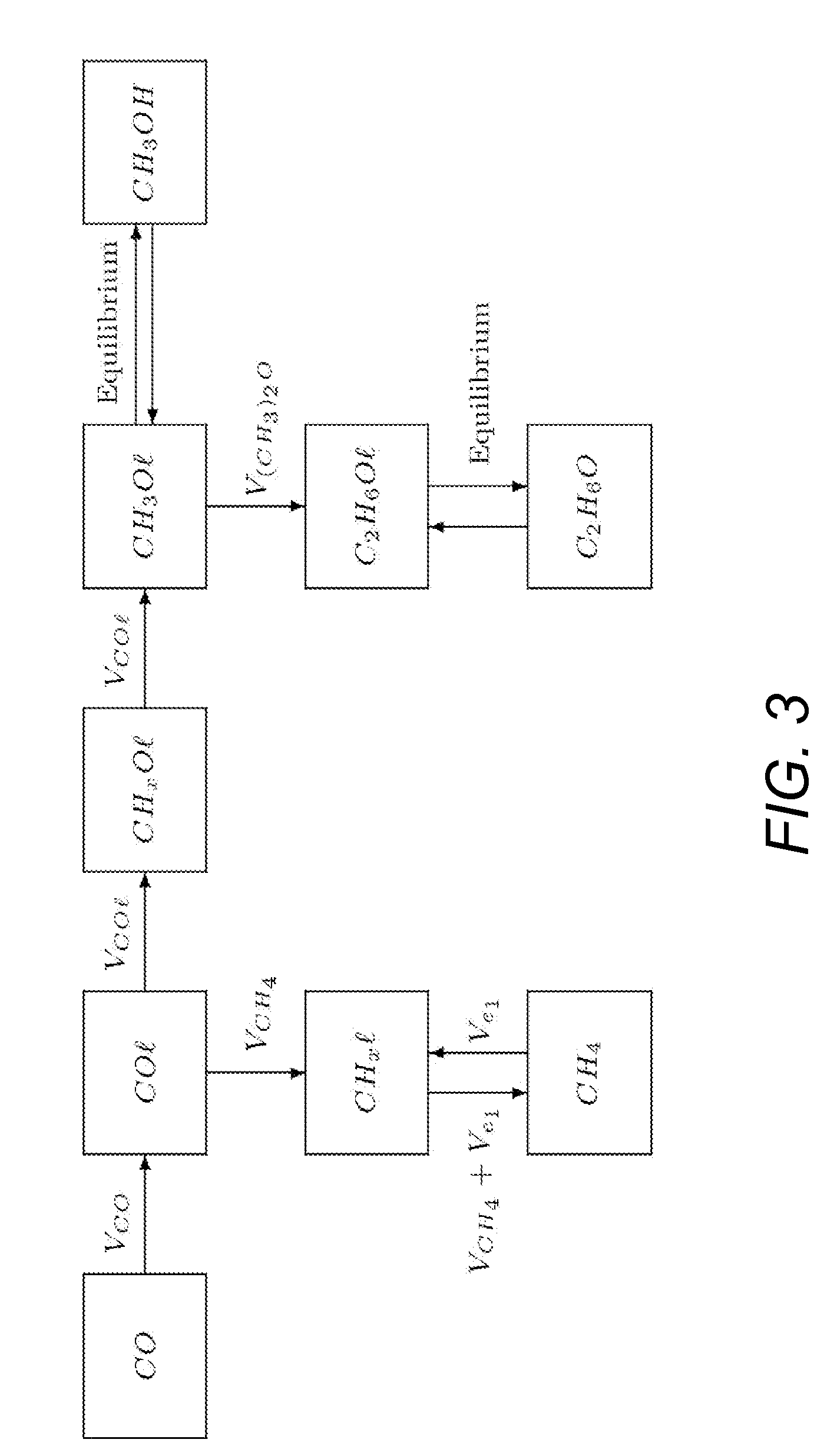

System for creating dimethyl ether

InactiveUS20090023960A1Less costlyBurn cleanOrganic compound preparationEther preparation by compound dehydrationHydrogenDiethyl ether

The present invention includes an improved system for creating dimethyl ether from gases is described. The process includes introducing hydrogen and carbon monoxide or carbon dioxide into a reaction chamber filled with beads covered with a catalyst. The catalyst includes palladium and one of aluminum, copper, zinc, or mixtures of these which includes an acid side of the molecule. The acid side of the molecule dehydrates methanol, reducing the concentration of this unwanted byproduct and increases the production of diethyl ether. The reactor employs very high temperatures, a defined pressure and defined flow rates to optimize the amount of diethyl ether produced.

Owner:UNIVERSITY OF SCRANTON

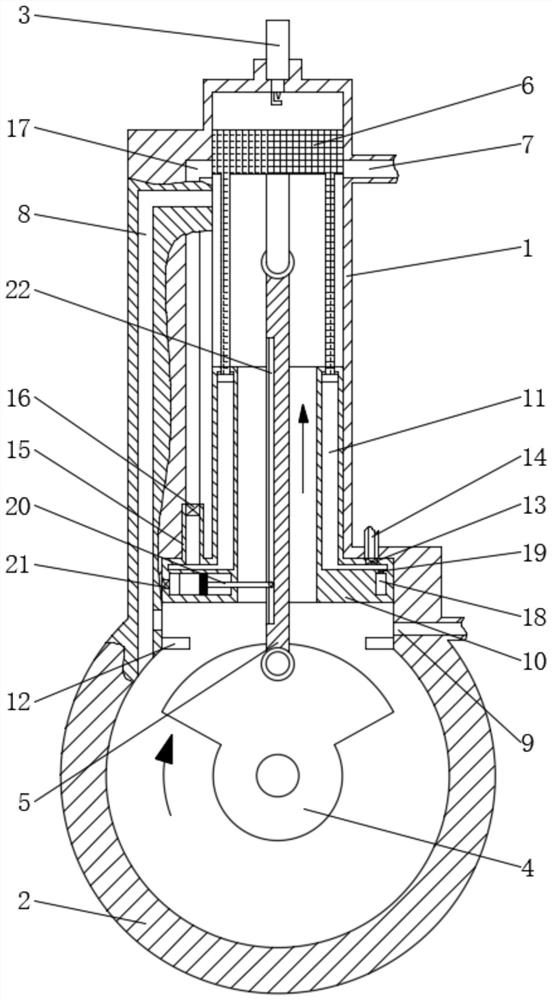

Piston for two-stroke engine

PendingCN113357002AReduce the temperatureBurn cleanMachines/enginesPistonsThermodynamicsTop dead center

The invention relates to the technical field of engines, and discloses a piston for a two-stroke engine. The piston comprises an air cylinder, and a crankcase is integrally formed below the air cylinder. According to the piston for the two-stroke engine, the piston is movably sleeved with a sliding groove, and the sliding groove is matched with a first downward one-way valve and an upward one-way valve for mounting, so that in the process that the piston moves from a lower stop point to an upper stop point, air is sucked into the sliding groove from an air hole to be stored through the first downward one-way valve under the suction action of the piston in the sliding groove; in the process that the piston moves from the upper stop point to the lower stop point, the piston compresses gas in the sliding groove and injects the gas into a scavenging hole from the upward one-way valve, combusted air in the air cylinder is extruded out, the temperature in the air cylinder is reduced, the gas which is compressed and heated in the crankcase enters the air cylinder, is higher than the air in temperature and rises in the air cylinder, mixed gas of the air and the combusted gas is extruded and exhausted from the upper part, less gas is exhausted from an exhaust hole, the combusted gas is exhausted completely, and sufficient combustion of the gas is guaranteed.

Owner:鲍克伦

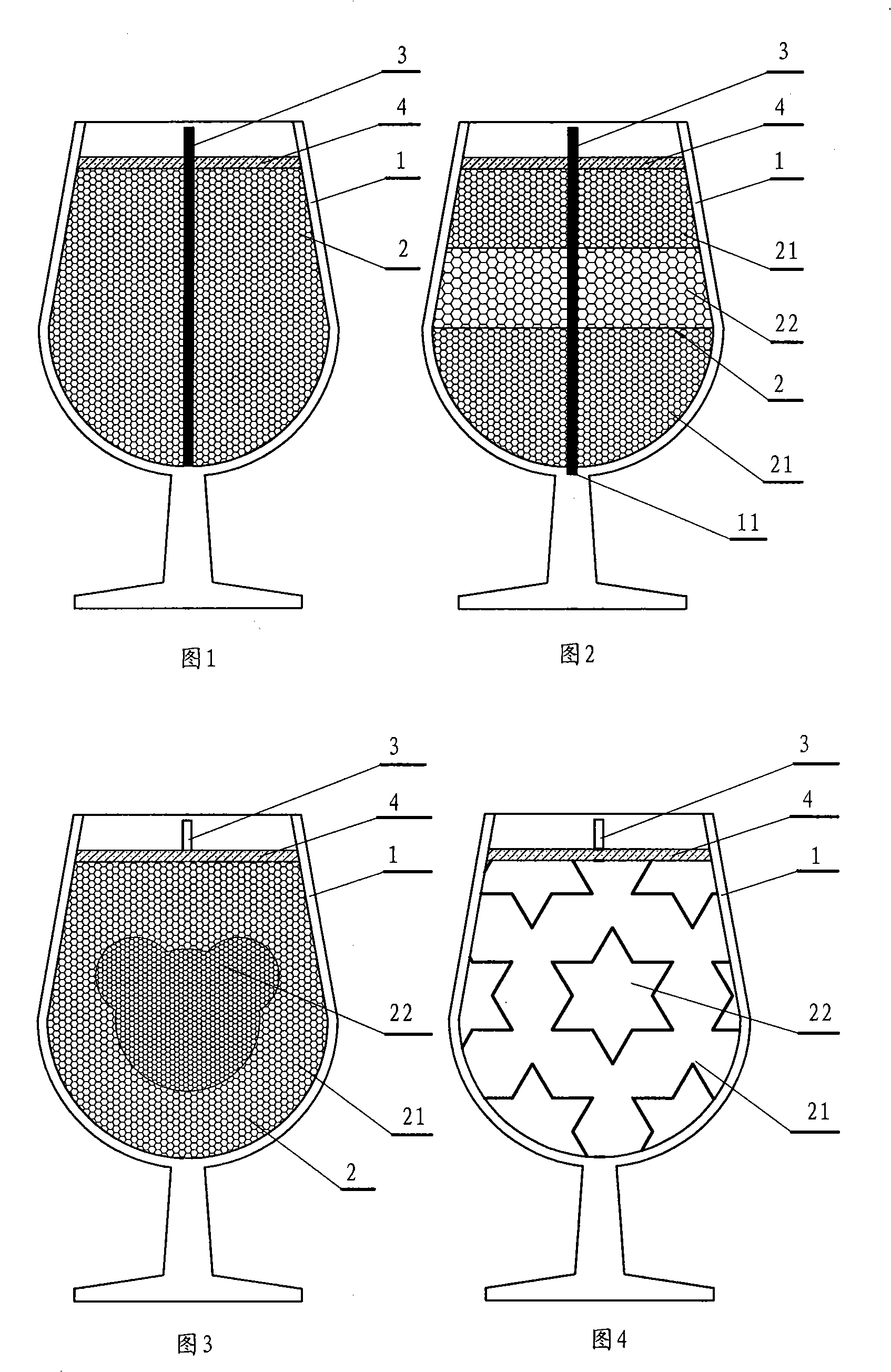

Novel artistic cup candle

The invention relates to a novel artistic cup candle, which consists of a transparent cup, a pearl-shaped candle body accommodated in the cup and a candle core in the middle of the candle body. The surface layer of the pearl-shaped candle body is covered by a seal cover wax layer which is adhered to the wall of the cup. The ingredient of the candle body is natural renewable plant oil; and the surface layer of the dissolved solution of an organic solvent pigment is coldly colored with alternate colors to form various patterns by mixing the colors. A manufacturing method comprises the following steps of: firstly, fixing the candle core at the bottom of the cup; secondly, placing the pearls forming the candle body into the set positions of the cup and compacting the pearls by vibration; and thirdly, melting the pearls of the candle body into liquid and covering the surface layers of the pearls in the cup by pouring at a controlled proper temperature and solidifying the liquid. The pearls are filled directly in the cold solid state so as to save the energy and ensure convenient production, attractive appearance of the patterns and high appreciation; the candle is made of a renewable resource so as not to produce smoke but protect the environment during the burning; and the candle burns without dripping, with a few residues and without waste when placed in a vessel.

Owner:范卸妹 +1

Method of forming a fuel-air mixture for internal combustion engine

InactiveUS20170306875A1Burn cleanFuel efficiencyElectrical controlNon-fuel substance addition to fuelHydrogenPhase formation

A method of serially phased, phase forming a fuel-air mixture for internal combustion engine is disclosed. The technical result increases the compression ratio of the engine, resulting in economical fuel burning and improved environmental characteristics. The method includes a serially-staged, serially-phased formation of the fuel-air mixture for the engine, which includes the following steps: fuel evaporation; obtaining hydrogen-gas fuel by cleavage of the fuel; cooling and optimization of fuel temperature; preparation of air parallel to the preparation of the fuel; direct formation of the fuel-air mixture; mixing of the fuel, containing hydrocarbon gases with air, with an excess air coefficient Kea≧3; enrichment of the desired air-fuel ratio to the excess air coefficient Kea=from 1.0 to 2.8; a mixture enrichment correction; obtaining control conditions of an idling engine power mode by changing the excess air coefficient, as well as by changing the value of the cylinder filling coefficient.

Owner:ASTROTANE LLC

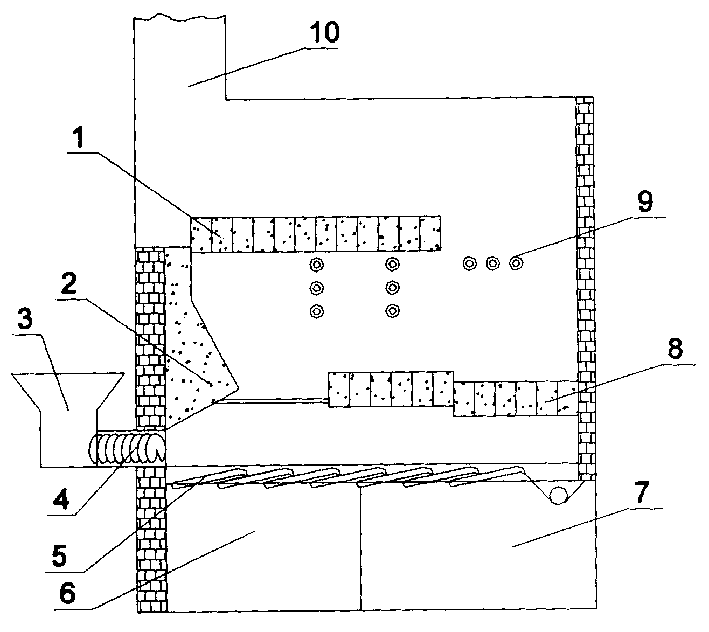

Smokeless combustion system for zinc melting furnace

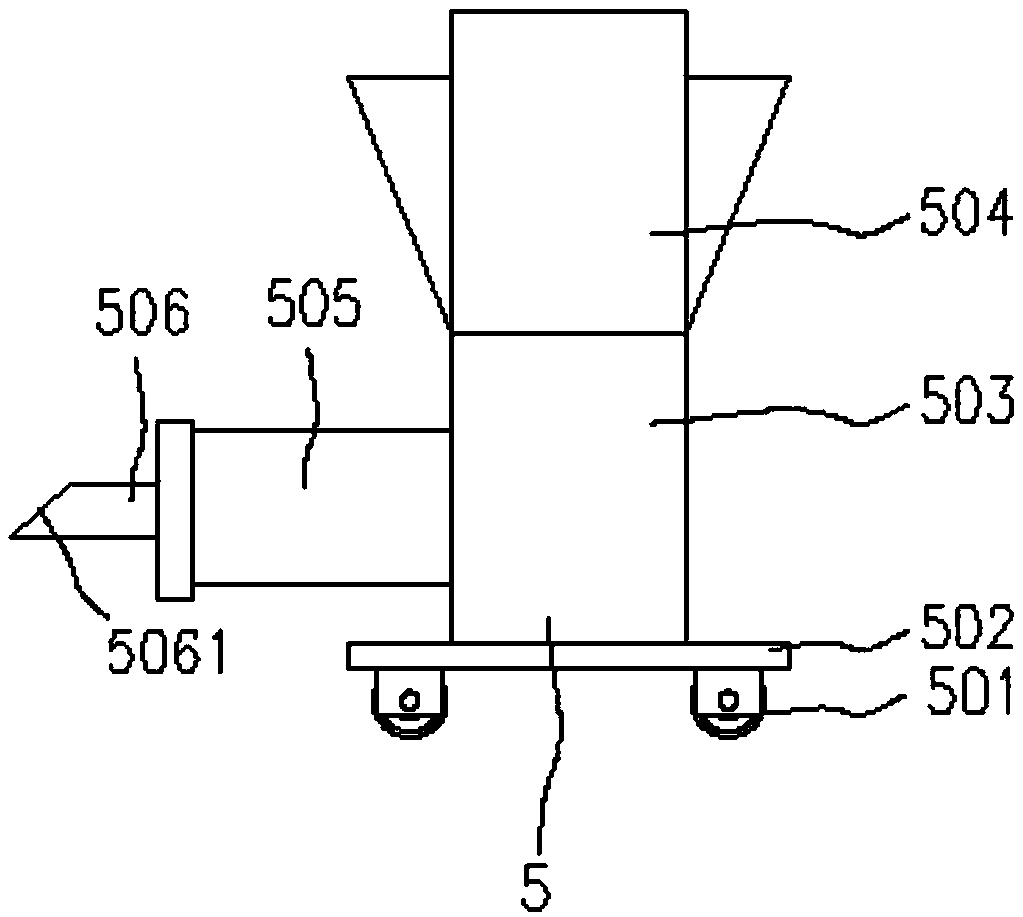

InactiveCN102767823AReduce laborIncrease productivitySolid fuel combustionLump/pulverulent fuel feeder/distributionSlagFlue

The invention relates to a smokeless combustion system for a zinc melting furnace. The combustion system comprises a furnace body and a feeding skip bucket and is characterized in that a reciprocating push feed type fire grate is installed in the furnace body, a spiral slag entrapment device is installed below a slag outlet, and an automatic feeding device is arranged on a feeding port of the feeding skip bucket. The smokeless combustion system for the zinc melting furnace further comprises an air preheater and a deduster, a smoke outlet and an air inlet of the furnace body are connected with the air preheater respectively through a flue and a hot air duct, and the air preheater is connected with a chimney through the deduster and a draught fan. The automatic feeding device, the reciprocating fire grate and an automatic deslagging device are adopted in the smokeless combustion system for the zinc melting furnace, a vicious cycle period can be avoided, the combustion efficiency of the zinc melting furnace is improved, and the problem that black smoke is discharged out of the chimney is solved simultaneously.

Owner:SHANGHAI APPLIED TECHNOLOGIES COLLEGE

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com