Mixture formation device for a gas engine and the gas engine

A gas engine and mixture technology, applied in combustion engines, internal combustion piston engines, combustion air/combustion-air processing, etc., can solve the problems of control and regulation cost, dynamic operation is not suitable, etc., to reduce emissions, low manufacturing cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

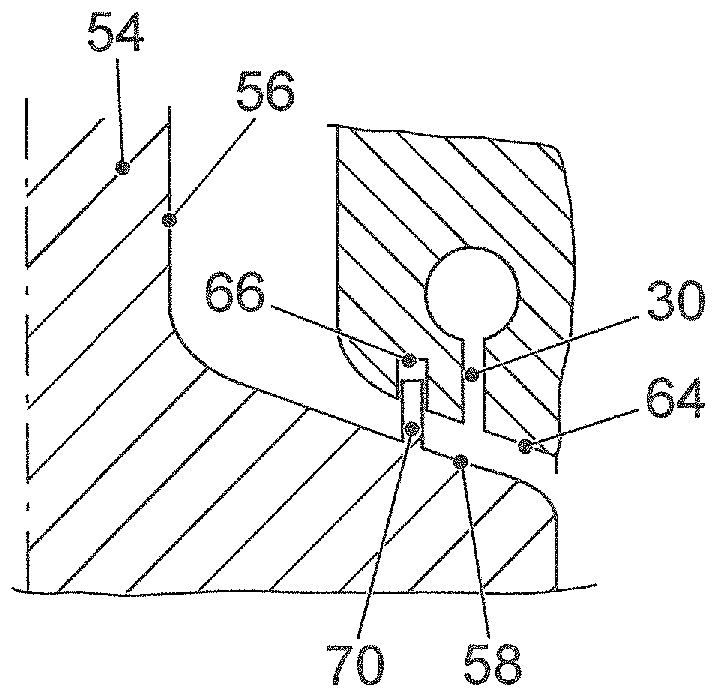

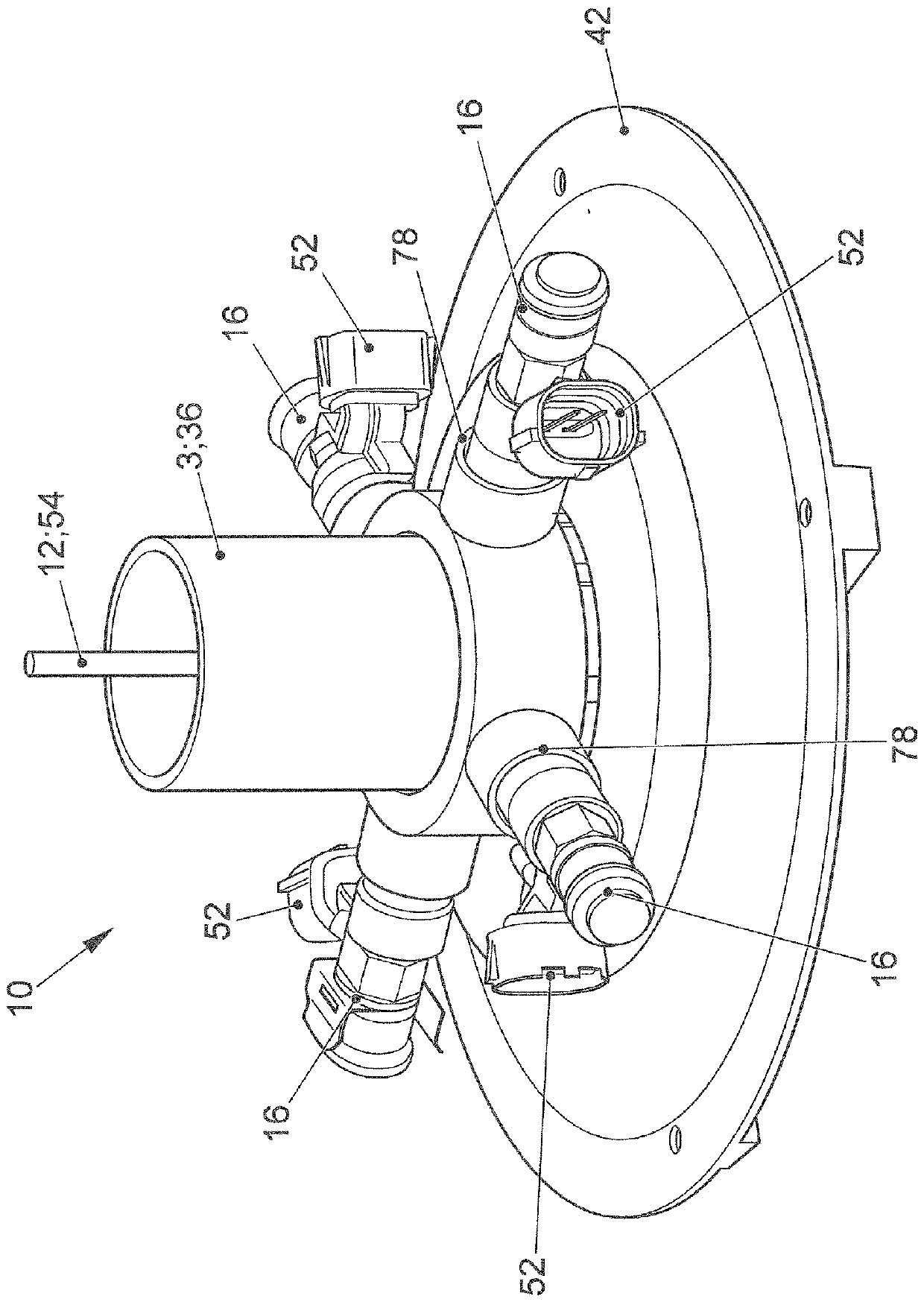

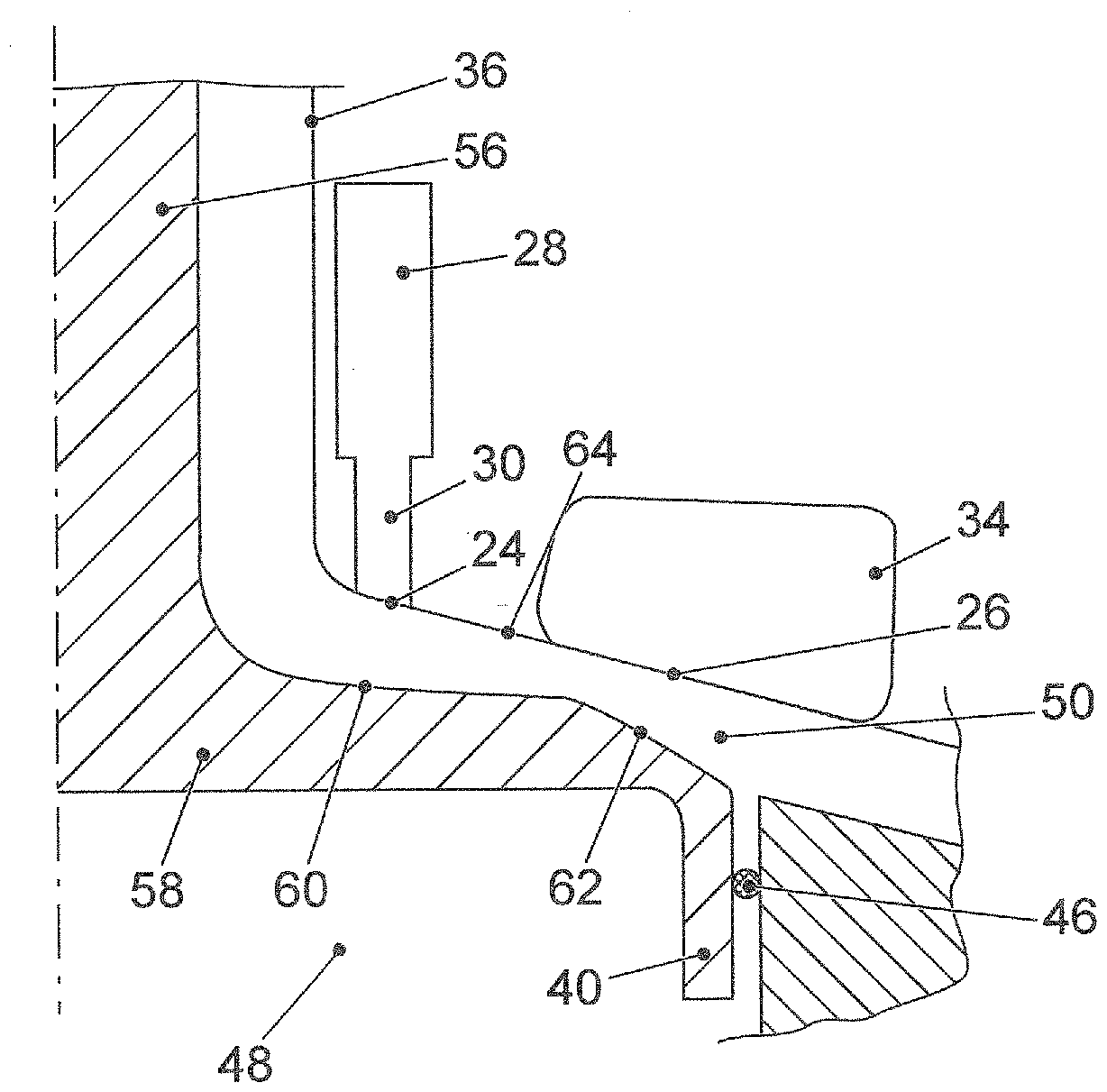

[0039] figure 1 A strongly simplified design of an internal combustion engine 1 is shown with four combustion chambers 2 , intake channels 3 and exhaust gas channels 4 . Here, an exhaust gas recirculation device 5 is provided, which connects the exhaust gas duct 4 with the intake duct 3 and thus enables the recirculation of burned fuel components into the intake duct 3 of the internal combustion engine 1 . In the exemplary embodiment described below, the internal combustion engine 1 is designed as a gas engine 1 and is operated with a gaseous combustion substance, preferably natural gas (CNG—compressed natural gas). Alternatively, operation with liquefied gas (LNG—liquefied natural gas) is also possible. The gas engine 1 is distinguished from a conventional internal combustion engine in that liquid fuel is introduced into the intake duct 3 or the combustion chamber 2 in such a way that the combustion substance is gaseous at ambient temperature and pressure and thus Can be st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com