Novel artistic cup candle

A technology of cup wax and cup body, which is applied in the direction of candles, candle holders, fatty acid production, etc. It can solve the problems of affecting the appearance, the wax body is detached from the cup wall, and the wax body shrinks when cold, so as to improve the ornamental value and reduce the cost. , the effect of saving pigment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

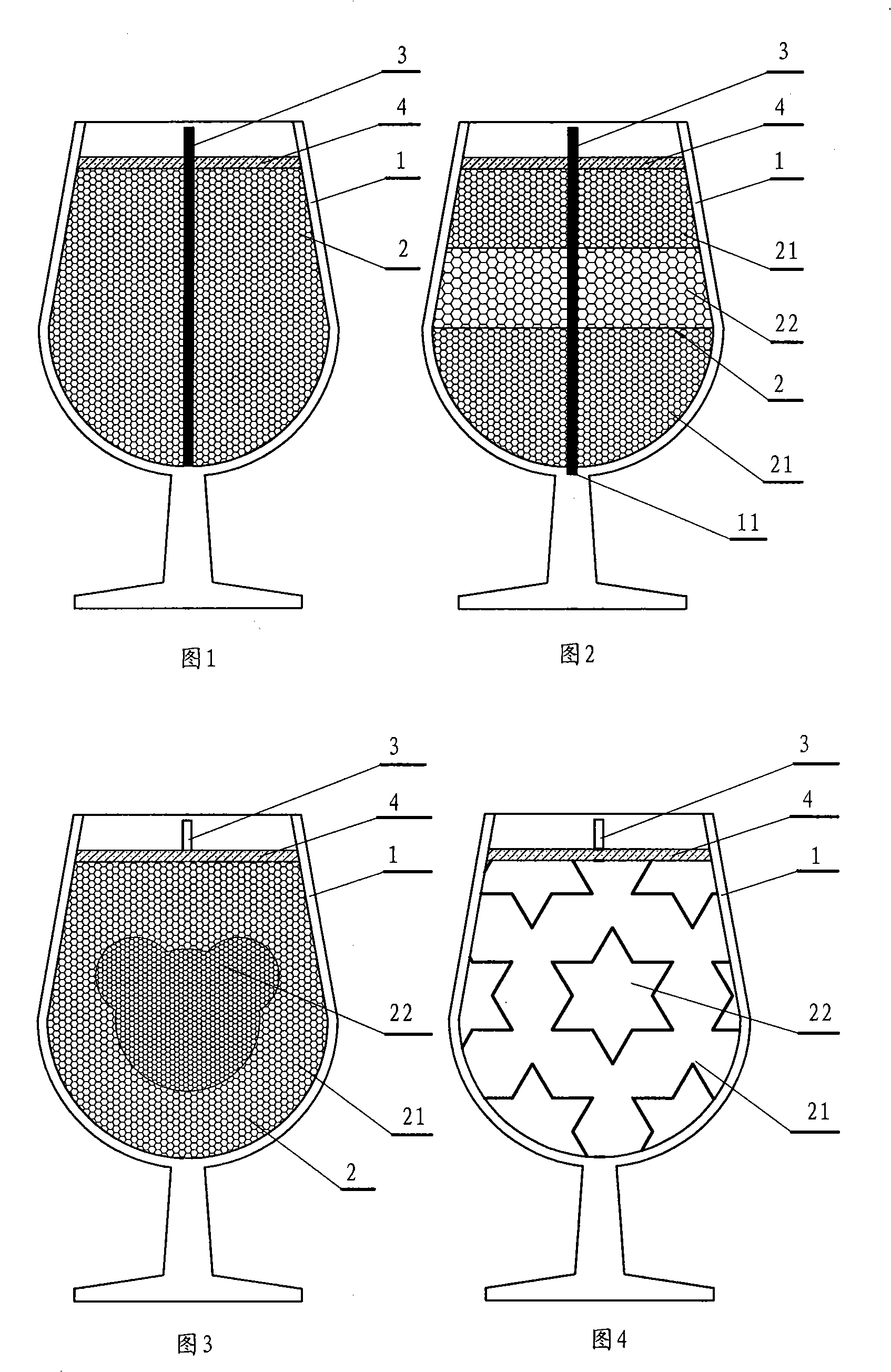

[0024] Reference figure 1 It can be seen that the cup wax of the present invention is composed of a cup body 1, a bead-shaped wax body 2, a wax core 3, and a sealing wax layer 4. The cup body 1 is made of transparent glass, and the wax body is bead-shaped. , The wax core 3 is cotton fiber bundle or can be hemp, wood, bamboo fiber bundle or rush, ie plant stem, the uppermost bead-shaped wax body 2 is covered with a capping wax layer 4 adhered to the cup wall, wax The core 3 is placed in the wax body, one end of which is exposed outside the cover wax layer 4, and the other end is glued and fixed at the center area of the bottom surface of the cup body 1. The wax body 2 is composed of linear high carbon in 100% renewable vegetable oil and processed into fatty alcohols with a saturated melting point above 40°C. During manufacture, it first glues the wax core 3 to the bottom of the transparent glass body 1 with transparent glue. , And then inject the beads that make up the wax bod...

Embodiment 2

[0026] Reference figure 1 It can be seen that the cup wax of the present invention is composed of a cup body 1, a bead-shaped wax body 2, a wax core 3, and a sealing wax layer 4. The cup body 1 is made of transparent glass, and the wax body is bead-shaped. , The wax core 3 is cotton fiber bundle or can be hemp, wood, bamboo fiber bundle or rush, ie plant stem. The uppermost bead-shaped wax body 2 is covered with a capping wax layer 4 that adheres to the cup wall. The core 3 is placed in the wax body, one end of which is exposed outside the cover wax layer 4, and the other end is glued and fixed at the center area of the bottom surface of the cup body 1. The wax body 2 ingredient is 100% renewable vegetable oil, straight-chain high-carbon, processed into fatty alcohols with a saturated melting point above 40°C, fatty acids and hardened oils in a weight ratio of 1:1:1. It is first produced during manufacture. The wax core 3 is glued to the bottom of the transparent glass body 1...

Embodiment 3

[0028] Reference figure 2 It can be seen that the cup wax of the present invention is composed of a cup body 1, a beaded wax body 2, a wax core 3, and a sealing wax layer 4. The cup body 1 is made of transparent glass, and the wax body is beaded. , The wax core 3 is the stem of the plant, and the beads of the wax body 2 are only colored on the outer layer, separated by white 21 and red 22, such as figure 2 As shown in the figure, there is a recess 11 at the bottom of the cup body 1, one end of the plant stem wax core 3 is inserted into, and the other end is exposed outside the cover wax layer 4. The wax body composition is 100% renewable vegetable oil The straight-chain high-carbon in the medium is processed into fatty acids with a saturated melting point above 40°C. During production, it first atomizes part of the wax beads with the ethanol solution of the coloring pigment to red 22, inserts the wax core 2 into the position In the recess 11 at the bottom of the transparent gl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com