Smokeless combustion system for zinc melting furnace

A combustion system, smokeless technology, applied in combustion methods, combustion equipment, combustion of solid fuels, etc., can solve the problems of low melting capacity of zinc melting furnaces, heavy labor of stoker workers, and black smoke polluting the environment, etc. The effect of energy efficiency, labor reduction, and environmental impact reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

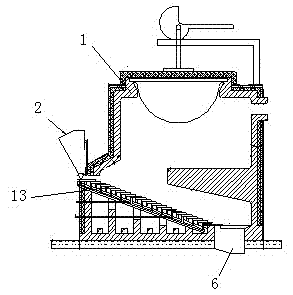

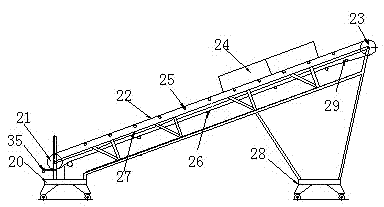

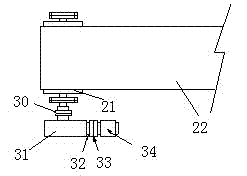

[0022] Such as Figure 1 to Figure 5 As shown, a smokeless zinc melting furnace combustion system of the present invention includes a furnace body 1, a feeding dump 2, a spiral slag wrapping device 36, an automatic feeding device 37, an air preheater 3, a dust collector 4, and an induced draft fan 5. Air blower 10, chimney 12, reciprocating push-feed grate 13, etc.

[0023] The body of furnace 1 is equipped with a reciprocating push-feeding fire grate 13, and a spiral slag revolving device 36 is installed below the slag outlet 6 ( Figure 5 ); 2 feeding openings of the feeding dump are provided with an automatic feeding device 37. The reciprocating push-feed grate 13 is used to replace the original fixed grate, the coal is fed by the tipping bucket, and the slag is discharged by the spiral slag wrapper 36, which greatly reduces the labor of the firema...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com