Patents

Literature

59results about How to "Promote sufficiency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

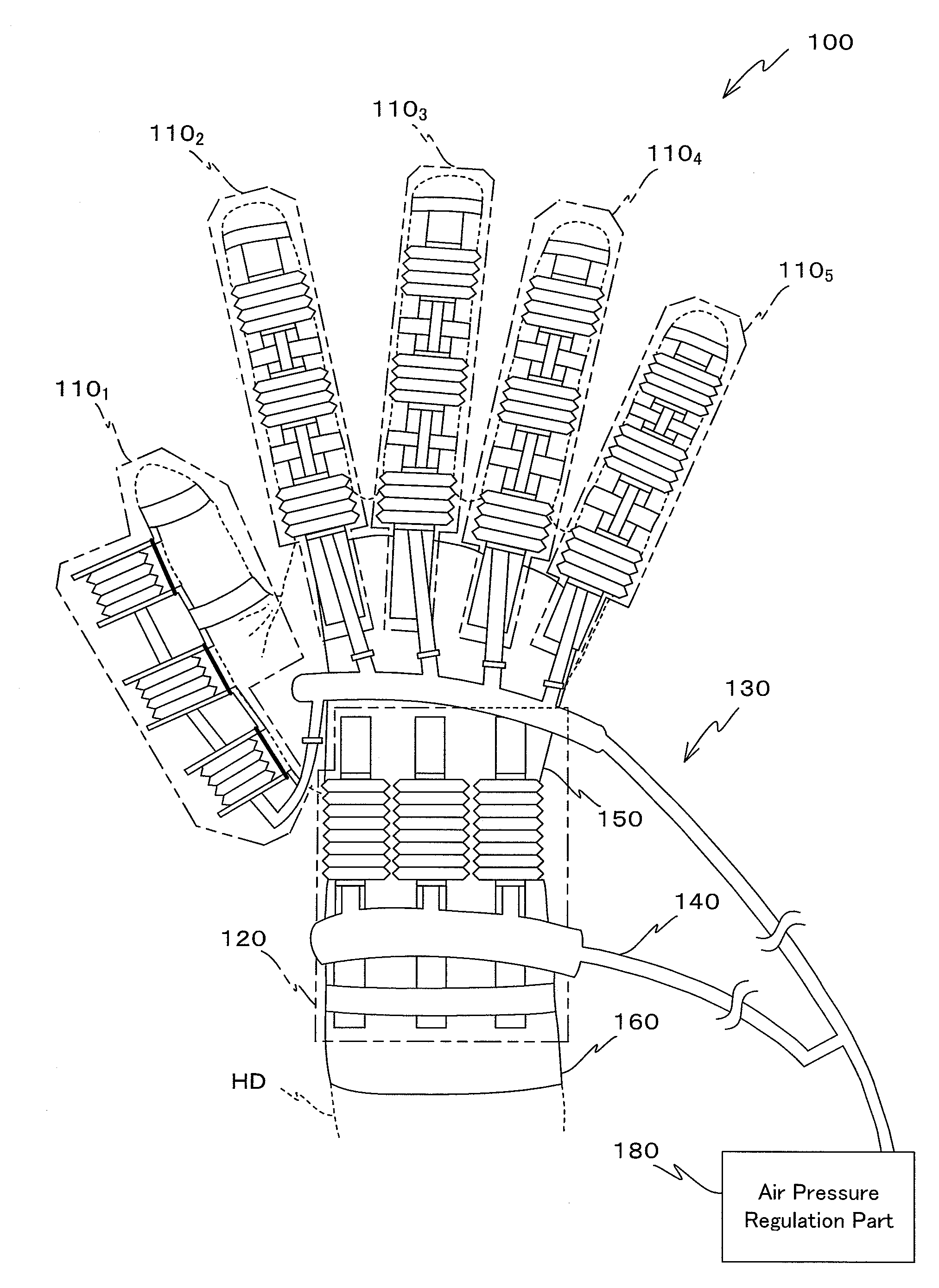

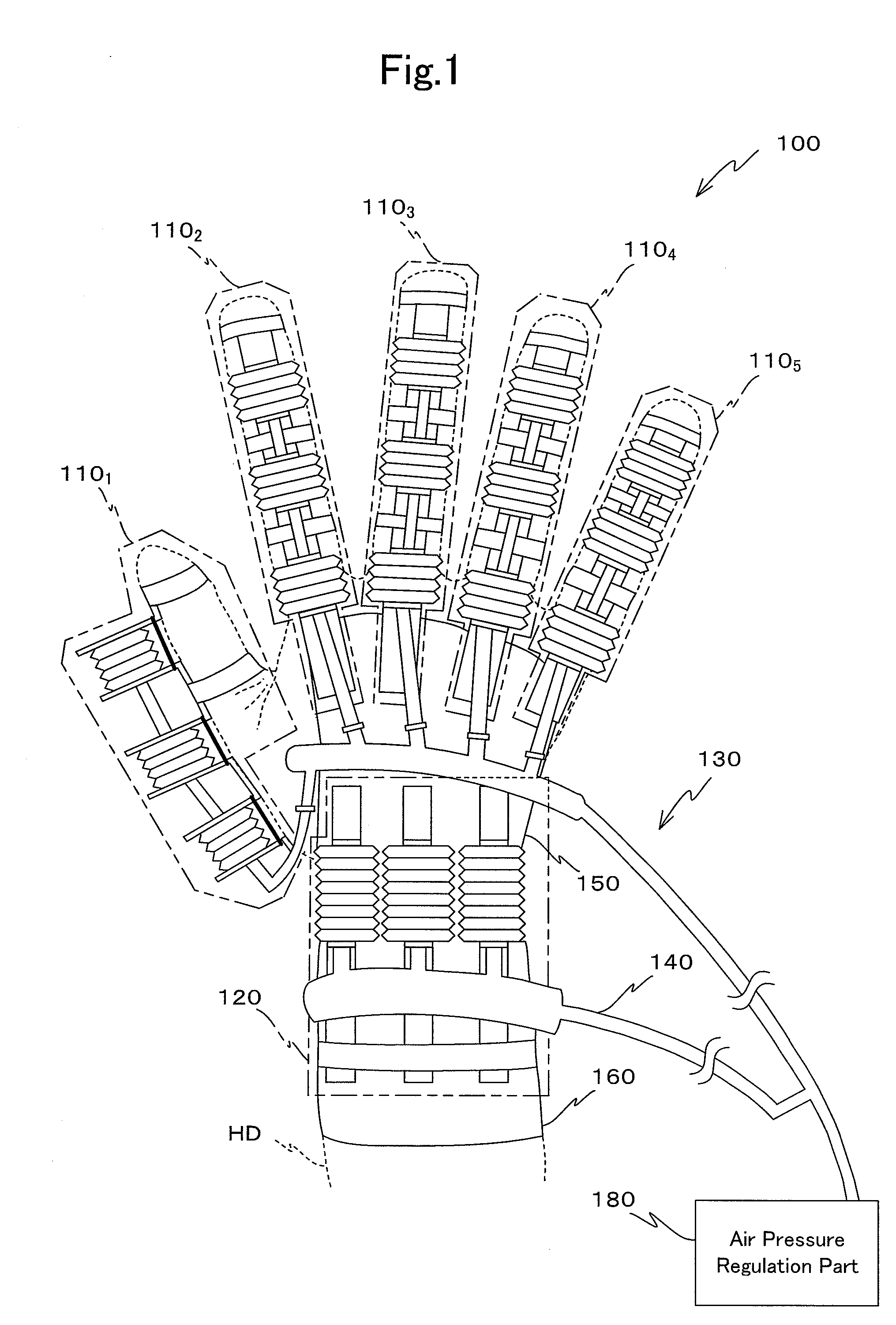

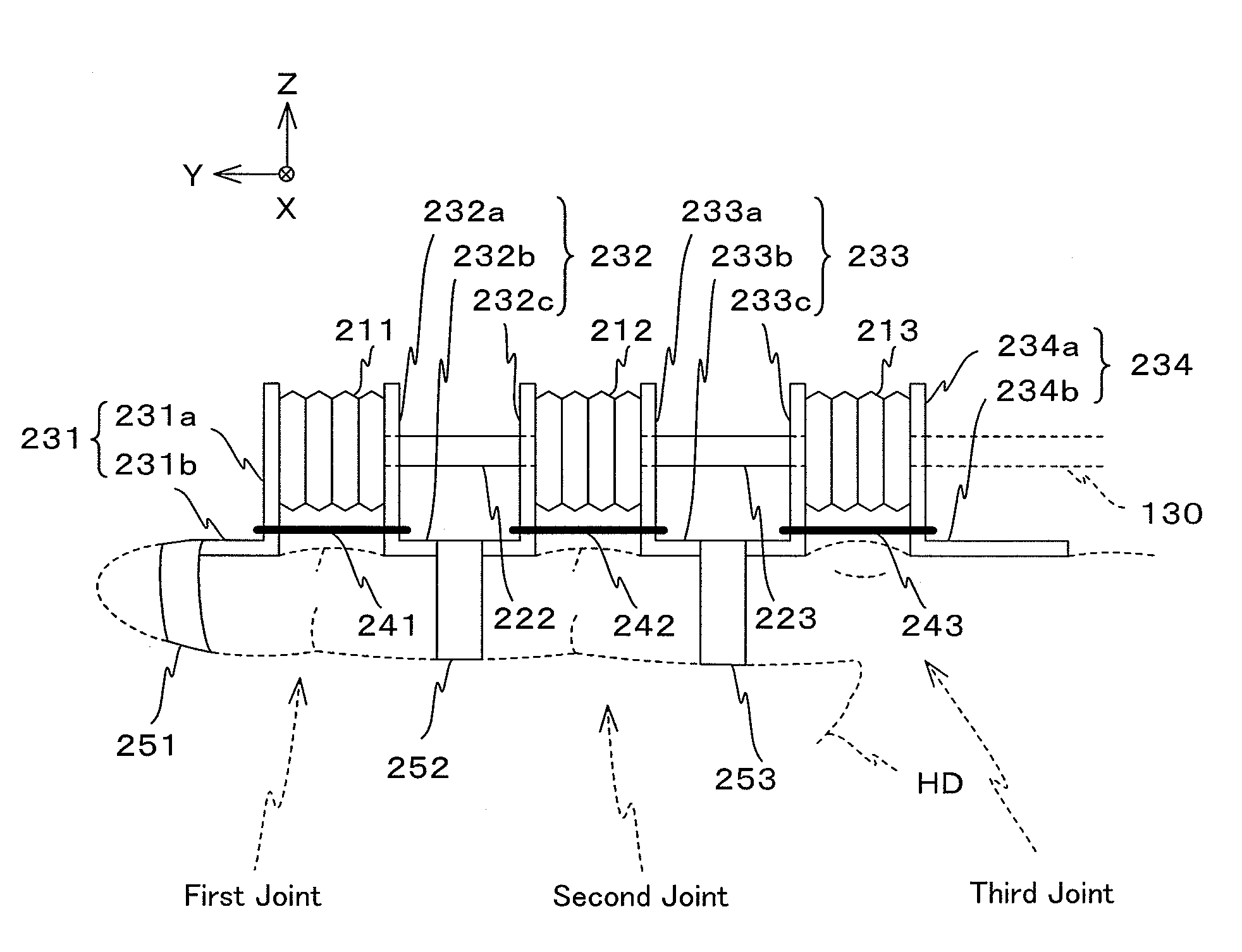

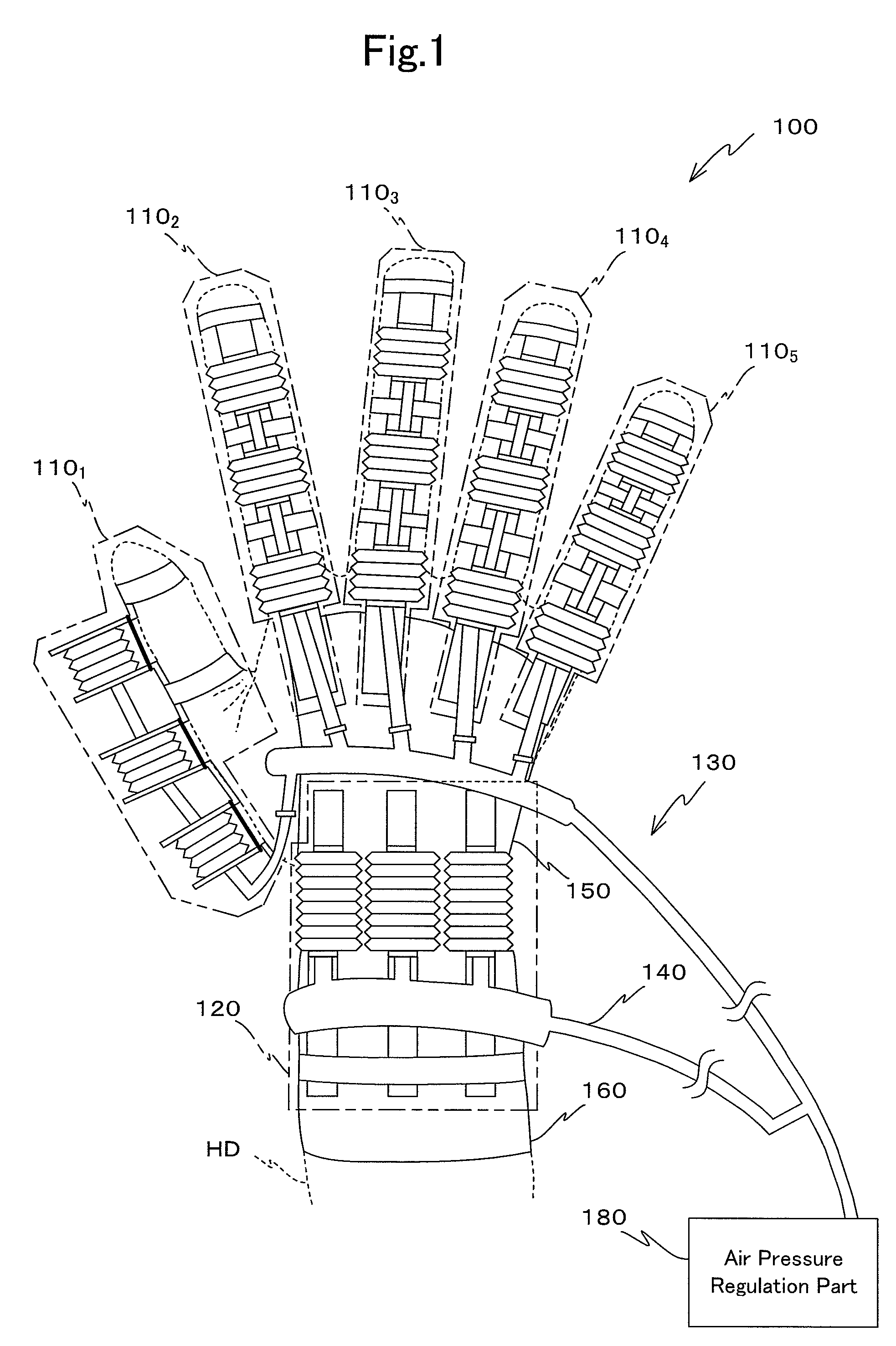

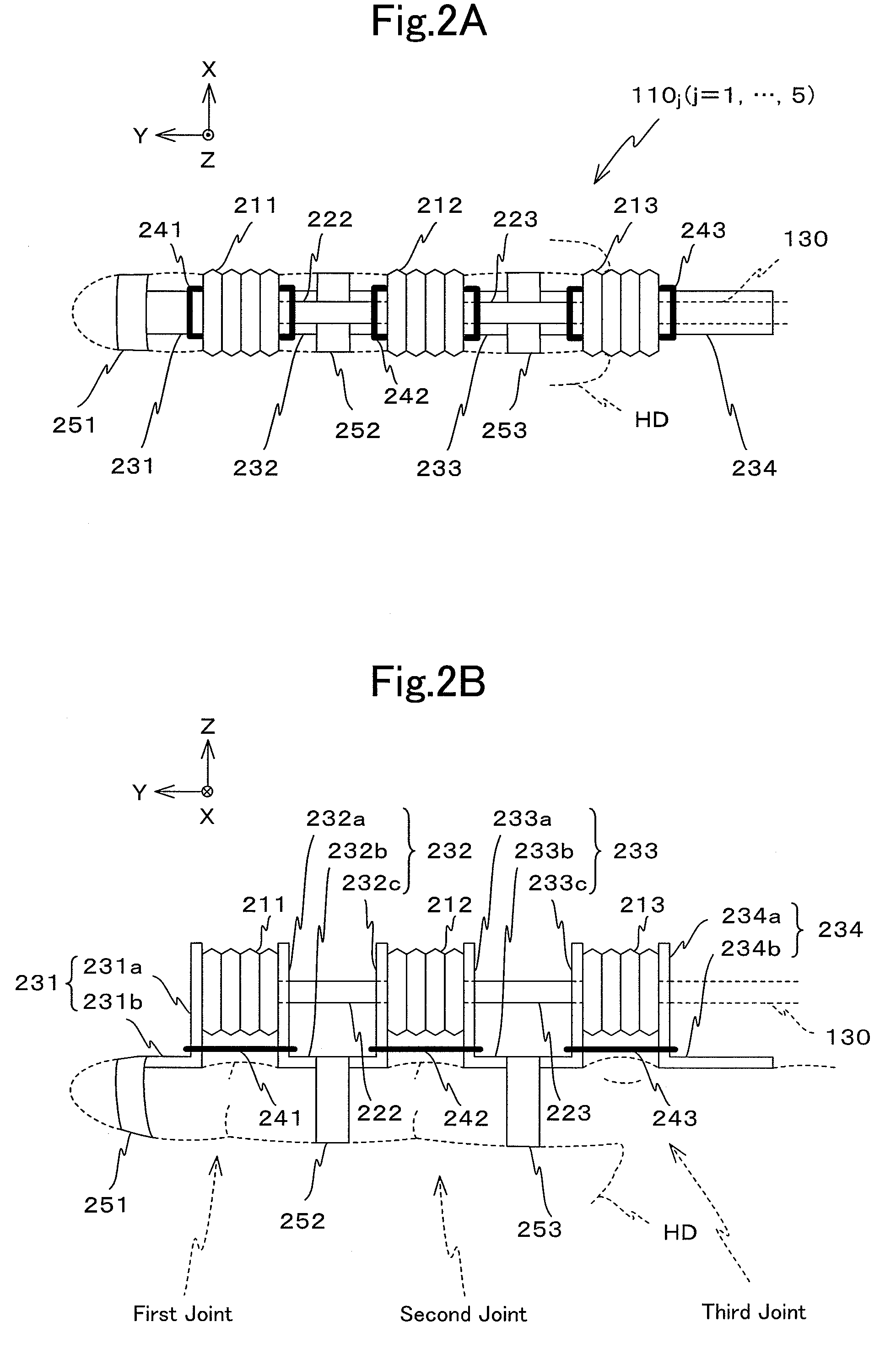

Joint motion facilitation device

ActiveUS20110118635A1Promote sufficiencyEasy to installChiropractic devicesEye exercisersFinger jointEngineering

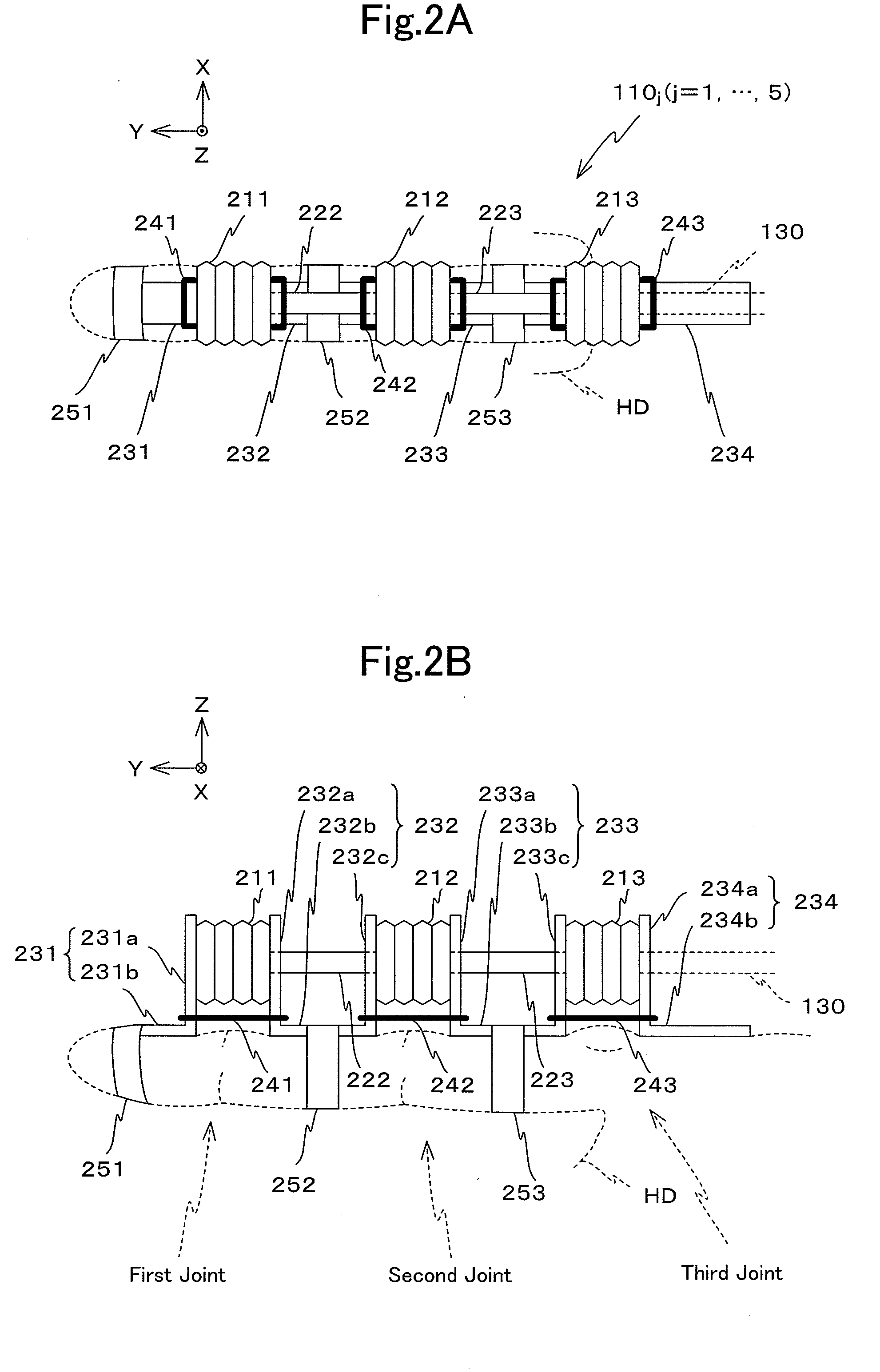

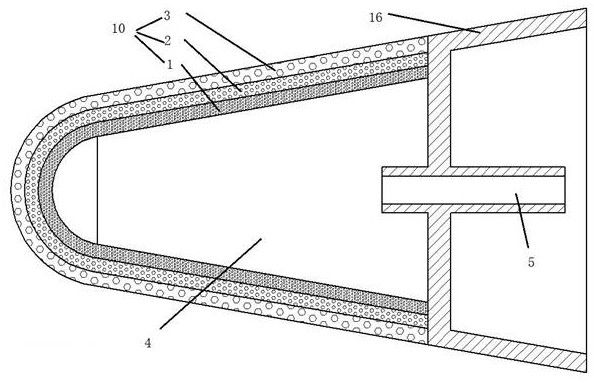

When air is supplied by an air pressure regulation part to bellows 211 through 213 of finger joint motion facilitation parts 110j (where j=1, . . . , 5), the bellows 211 through 213 expand approximately in the shape of circular arcs, since annular grooves on the side of the bellows 211 through 213 opposing a joint are elastically restrained by elastic members 241 through 243. Due to this, the bellows 211 through 213 cooperate, and exert force in the rotational direction to flex the first through the third joints of a finger from their extended states. Next, when air is exhausted from the bellows by the air pressure regulation part, the bellows 211 through 213 contract. Due to this, the bellows 211 through 213 cooperate, and exert force in the rotational direction to extend the first through the third joints of a finger from their flexed states. The forces generated in this manner are transmitted to the joints by transmission members 231 through 234. As a result mounting becomes simple, and also it is possible to facilitate sufficient joint movement for each joint.

Owner:YAMAMOTO KEIJIROU

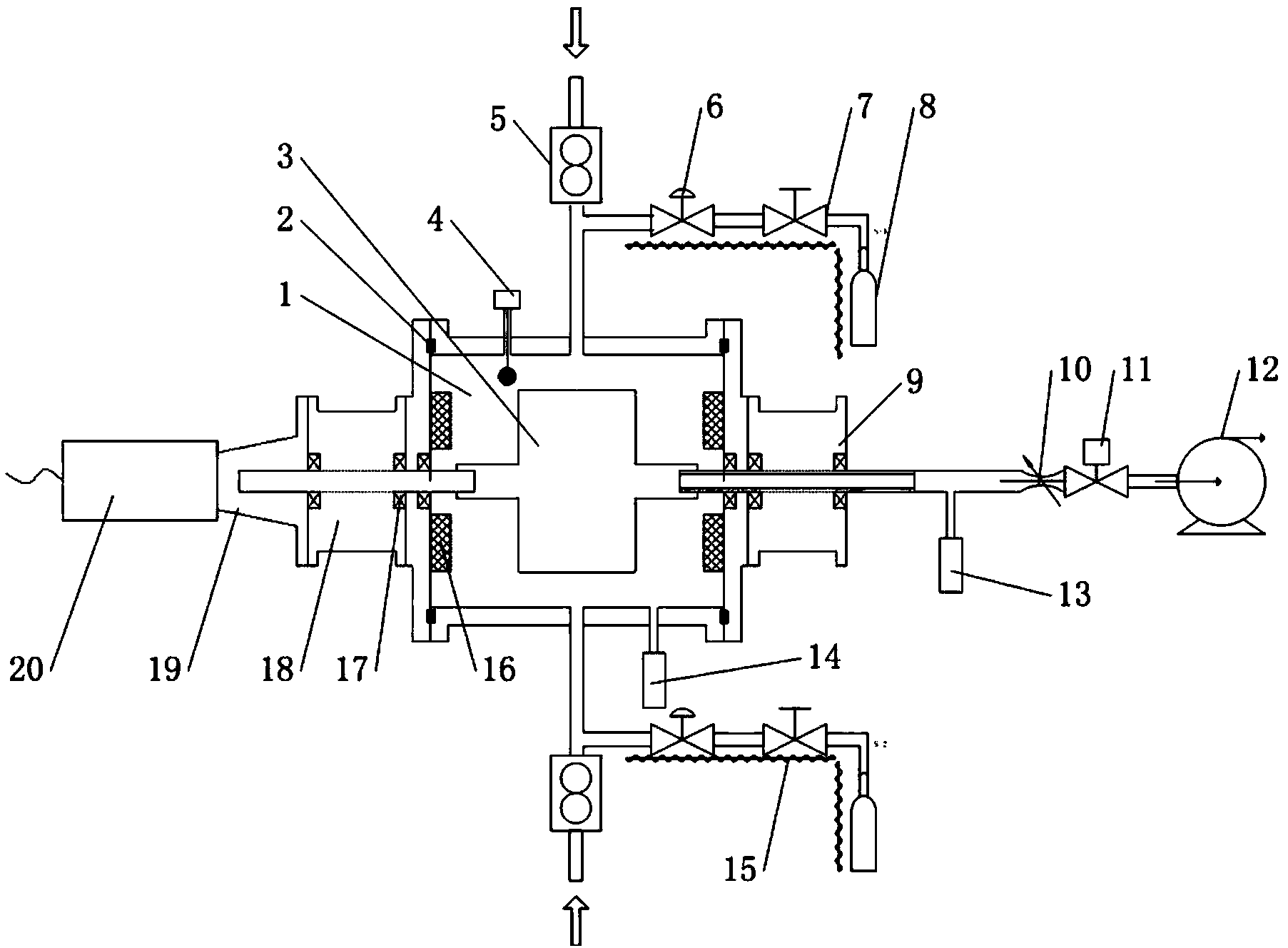

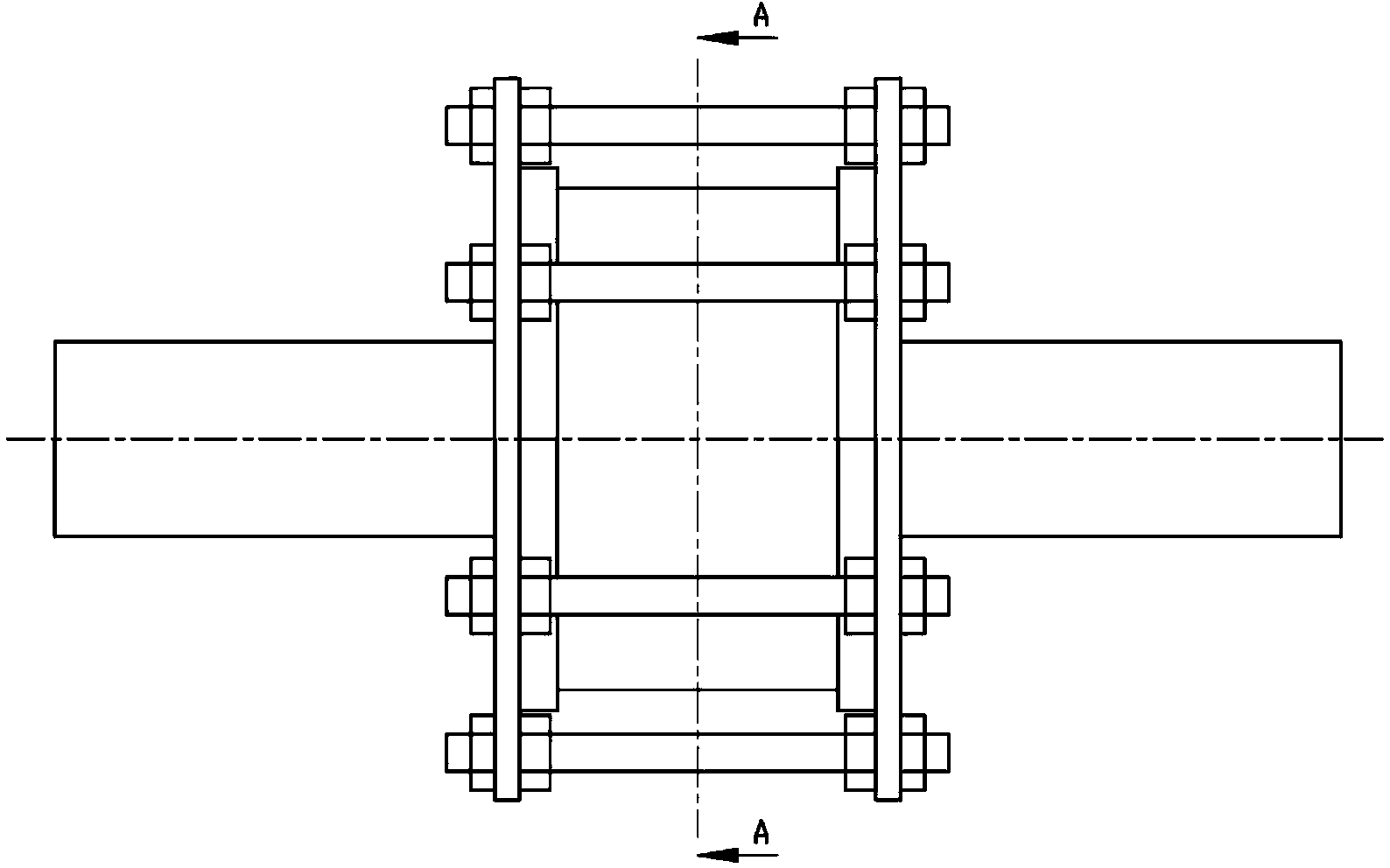

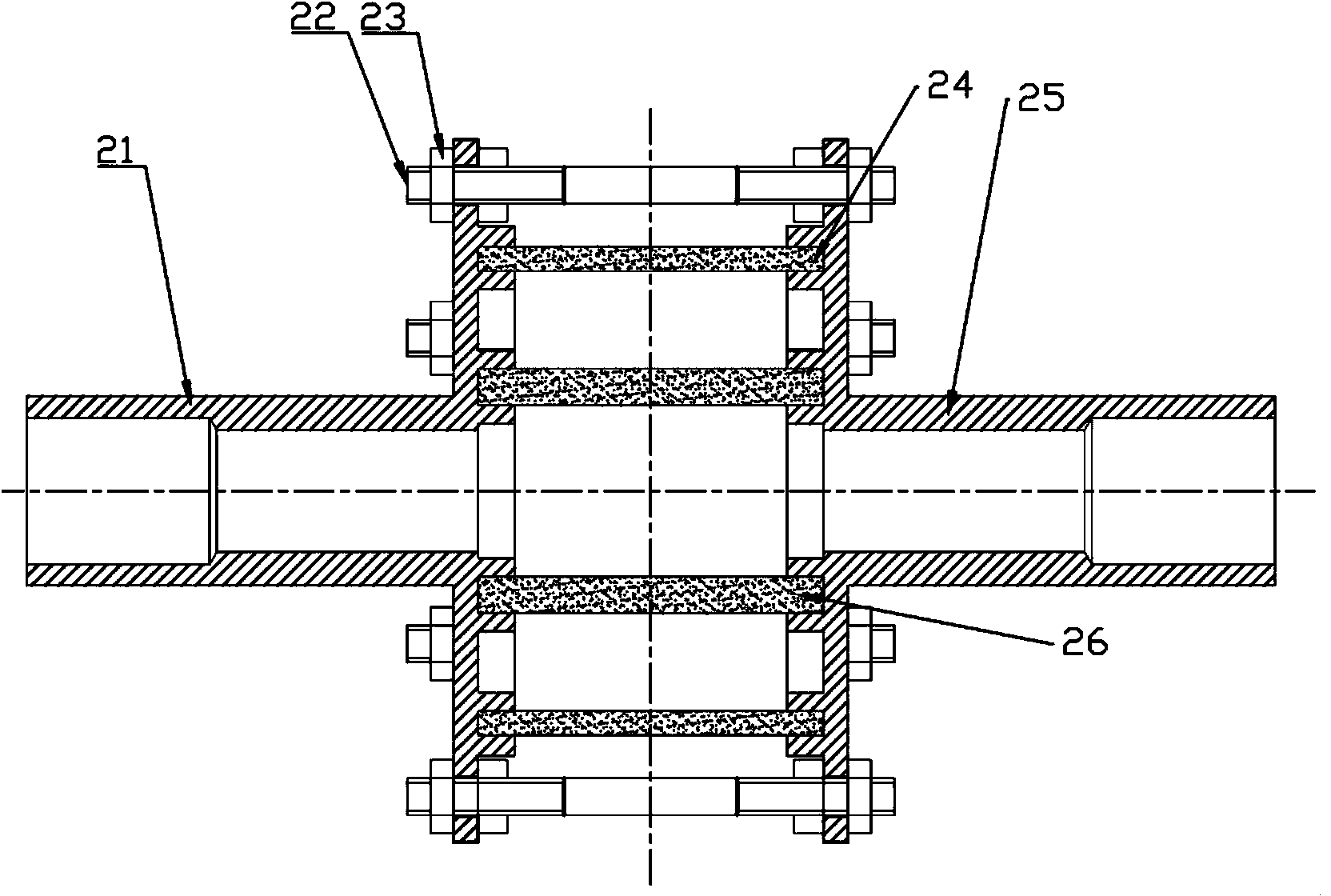

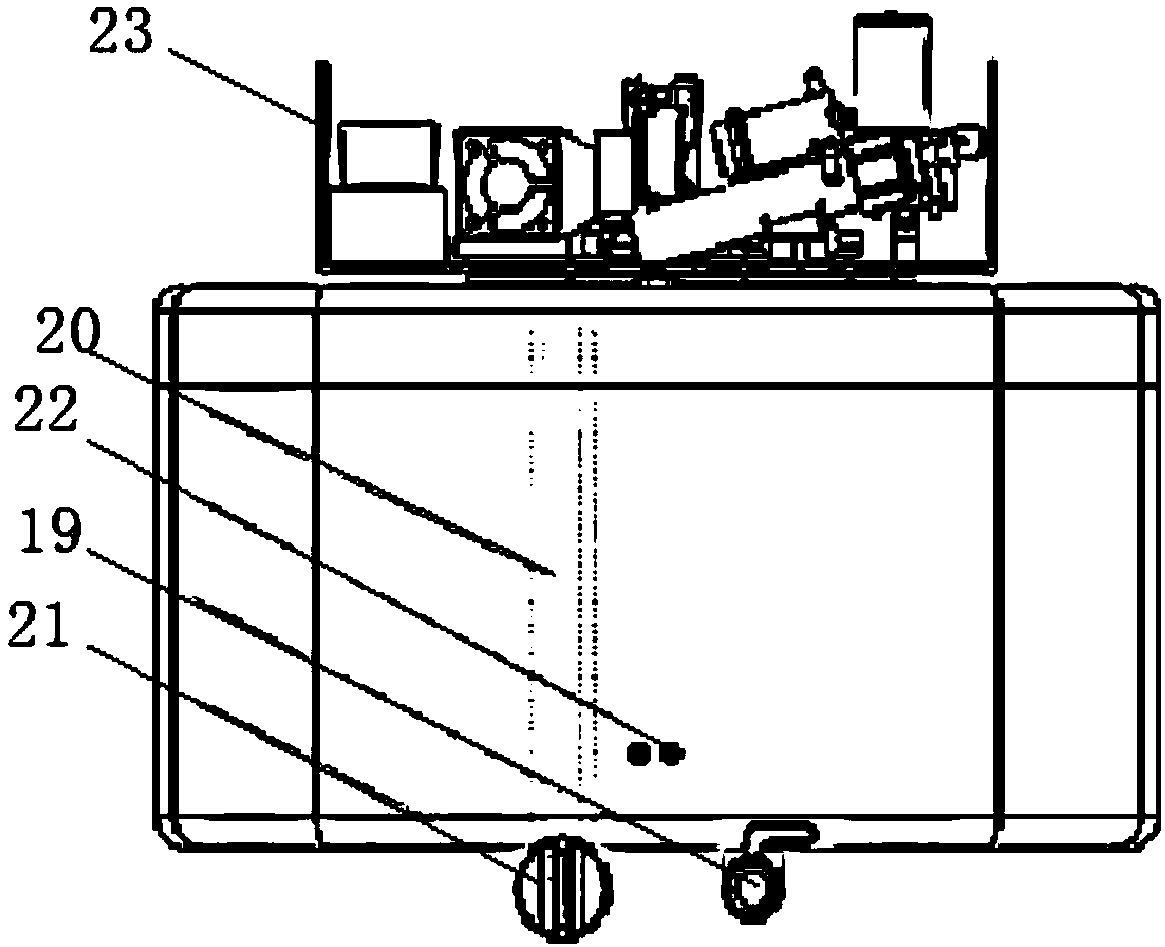

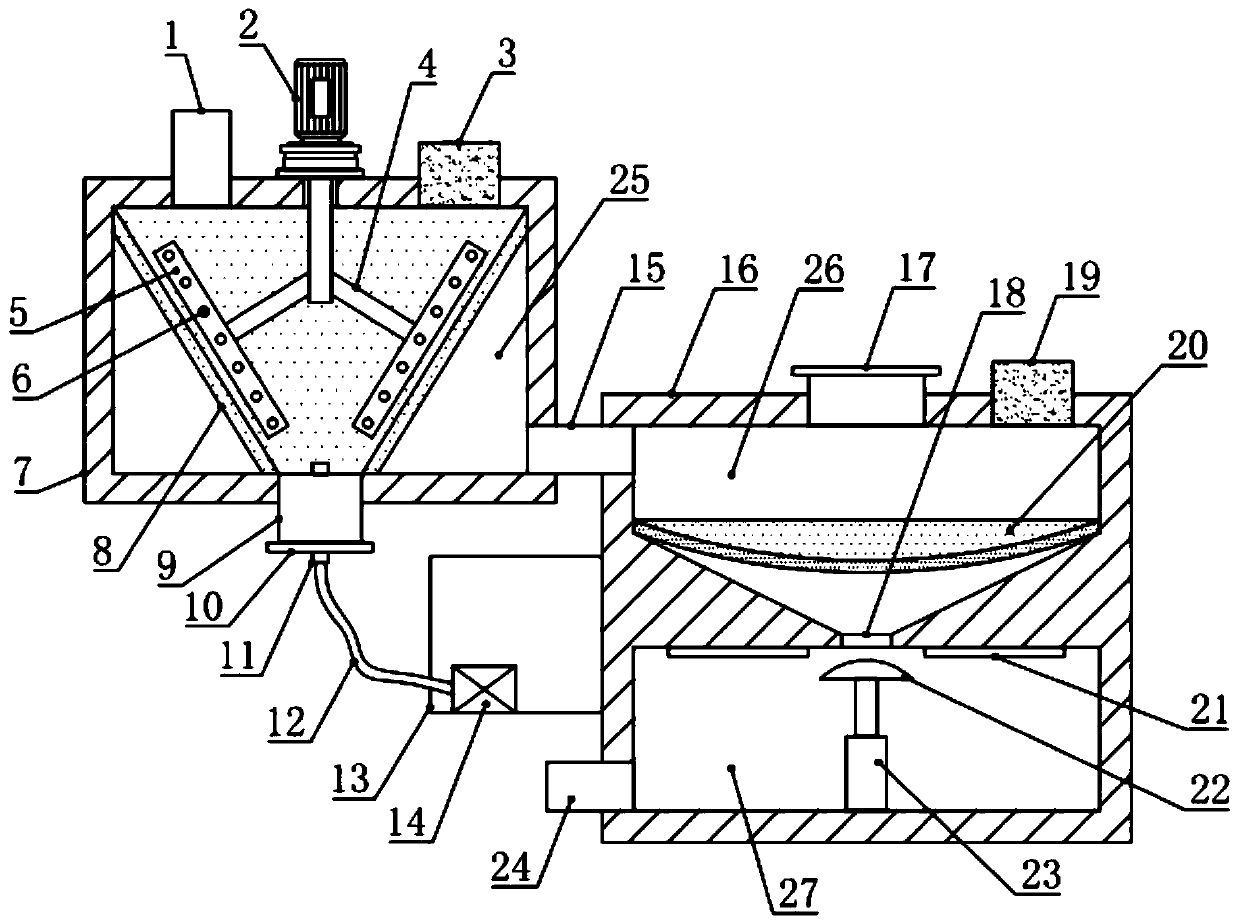

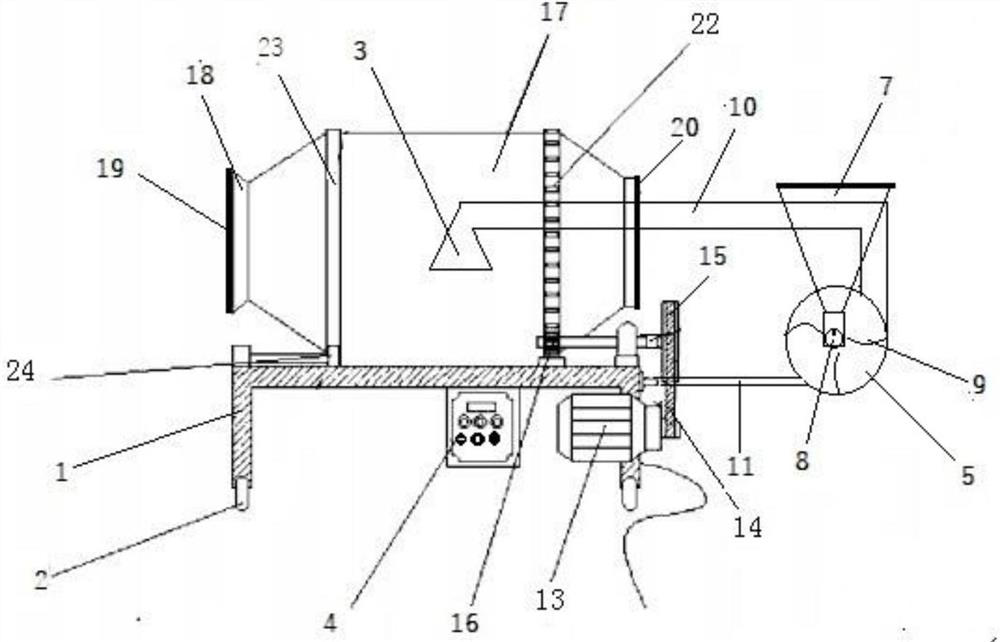

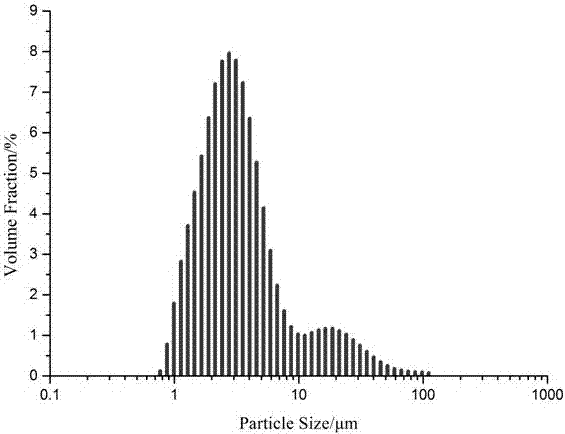

Device and method for surface modification of micro-nano particles

ActiveCN104046958ASufficient and uniform adsorptionIncrease profitMaterial nanotechnologyChemical vapor deposition coatingMicro nanoMicro nanoparticles

The invention discloses a device for surface modification of micro-nano particles. The device comprises a reaction cavity, a plurality of precursor supply devices, a carrier gas conveying system and a powder particle loading device, wherein a cavity formed inside the reaction cavity is used as a reaction space of precursors and the micro-nano particles; the plurality of precursor supply devices are respectively communicated with the reaction cavity by virtue of pipelines to provide different precursors; the precursors are conveyed to the reaction cavity by virtue of carrier gas output by the carrier gas conveying system; the powder particle loading device is used for loading the micro-nano particles to be modified; the precursors are alternately conveyed to the reaction cavity by virtue of the plurality of precursor supply devices respectively, and enter the rotary powder particle loading device so as to be in contact with the surfaces of the micro-nano particles to perform an atomic layer deposition reaction, thus forming a coating thin film on the surfaces of the micro-nano particles and realizing surface modification. The invention also discloses a method for performing surface modification on the micro-nano particles by using the device. The device and method disclosed by the invention can be used for obtaining a coating layer with high particle surface uniformity and improving the overall coating rate of the powder particles and the utilization rate of the precursors.

Owner:HUAZHONG UNIV OF SCI & TECH

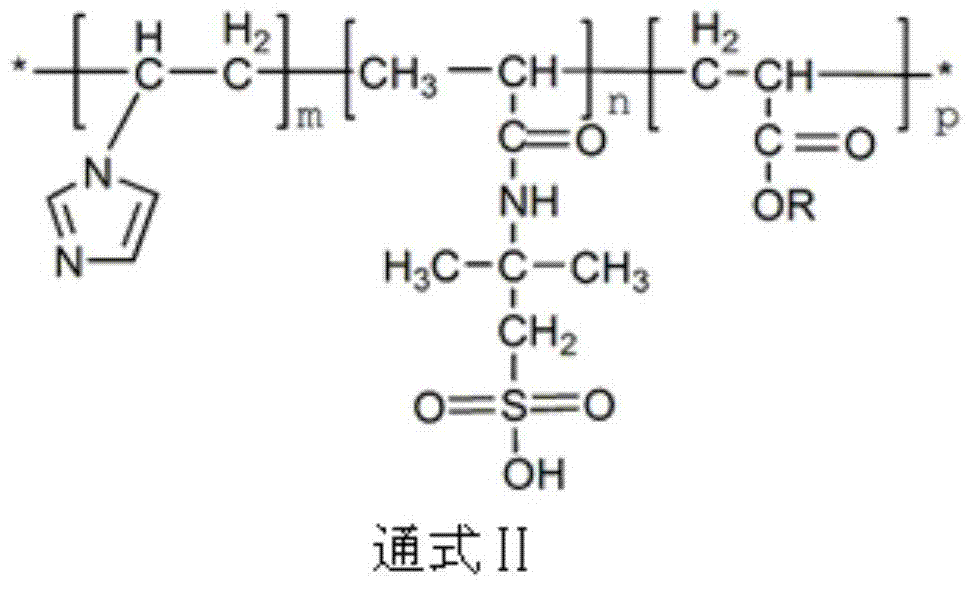

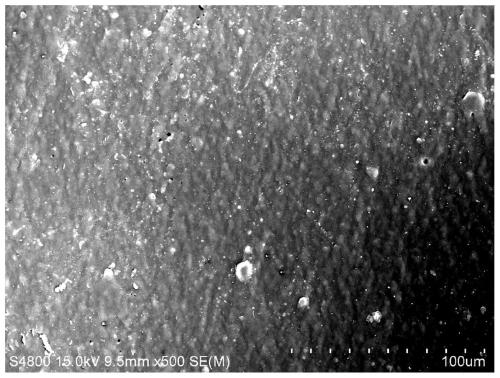

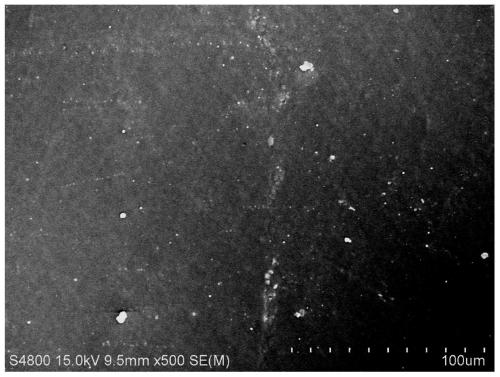

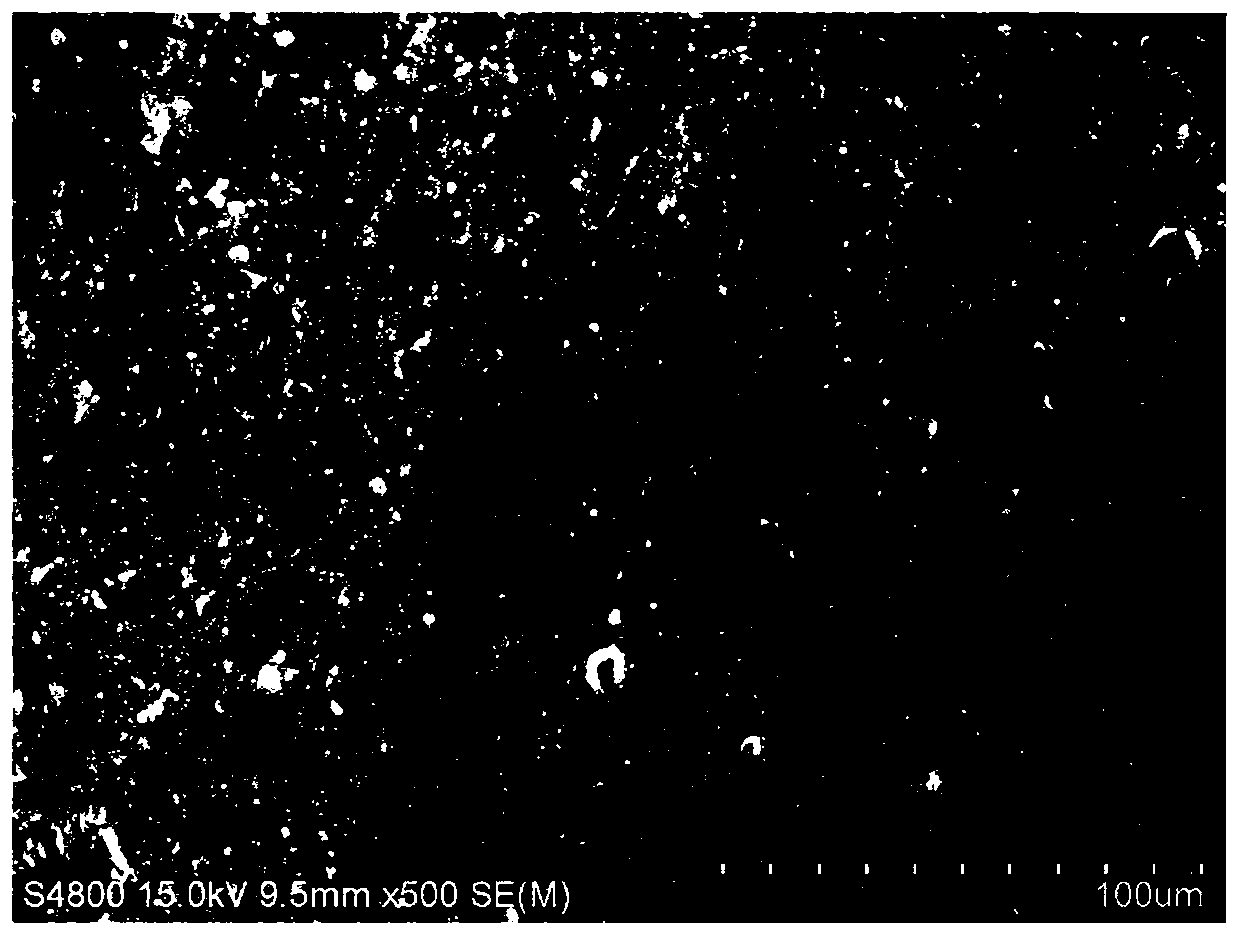

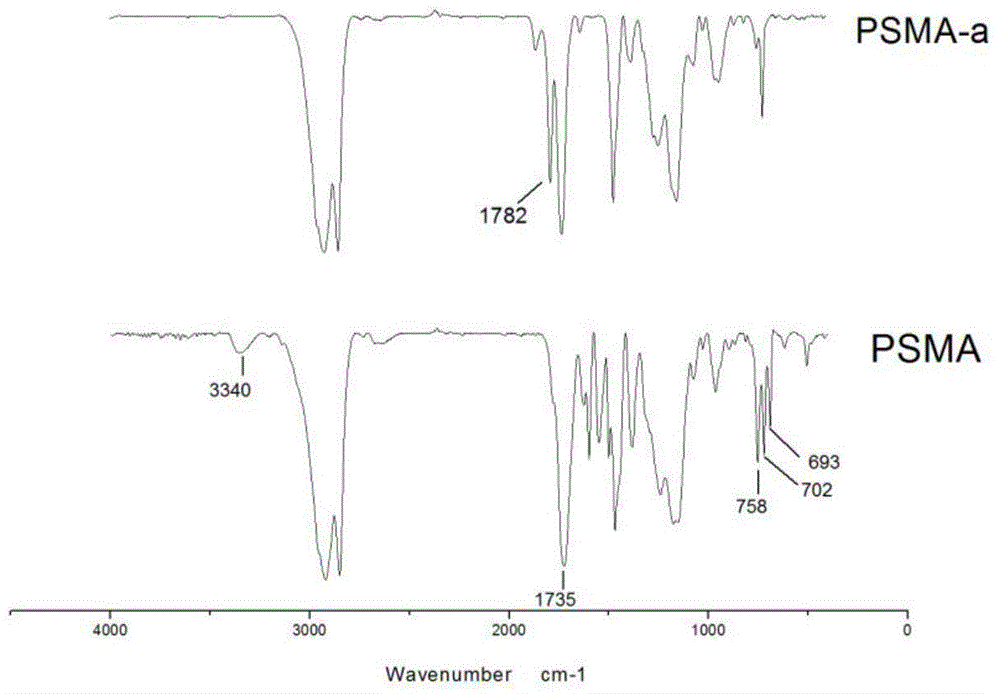

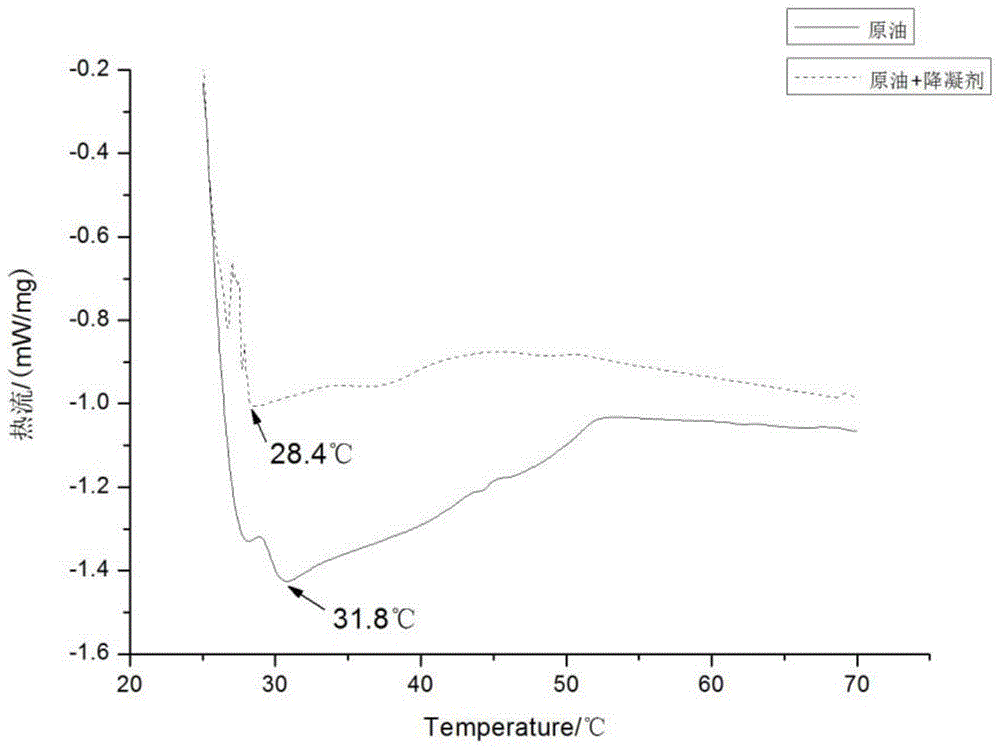

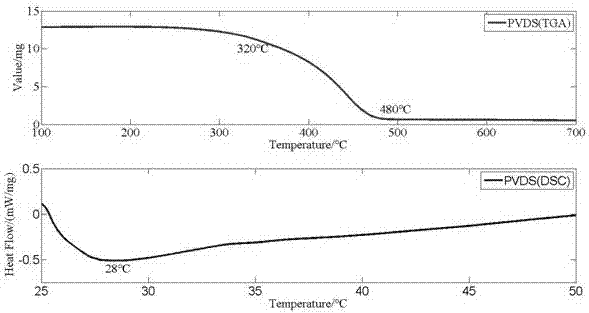

High wax thickened oil nanocomposite pour-point depressant and preparation method thereof

InactiveCN104327213AImprove pour point depressing effectProlong the action timeDrilling compositionMaterials preparationWax

The invention discloses a high wax thickened oil nanocomposite pour-point depressant, which belongs to the high-molecular nano-material preparation field. The material comprises poly(vinyl imidazole-2-acrylamide-2-methyl propane sulfonic acid-higher alkyl methacrylate). The preparation method comprises the following steps: 1)preparing poly(vinyl imidazole-2-acrylamide-2-methyl propane sulfonic acid-higher alkyl methacrylate), and 2)processing a reaction solution of poly(vinyl imidazole-2-acrylamide-2-methyl propane sulfonic acid-higher alkyl methacrylate) to obtain the poly(vinyl imidazole-2-acrylamide-2-methyl propane sulfonic acid-higher alkyl methacrylate) powder. The nano pour-point depressant has the advantages of good depression effect, low cost, simple production, clean process, no pollution, easy acquisition of the products, easy transportation and preservation. Through the experiment, the net pour point depression amplitude of the nano pour-point depressant to high wax thickened oil at Daqing dandong station is 8 DEG C which is better than the pour point depression effect (net pour point depression amplitude is 5 DEG C) of EVA on the market.

Owner:SHANDONG UNIV

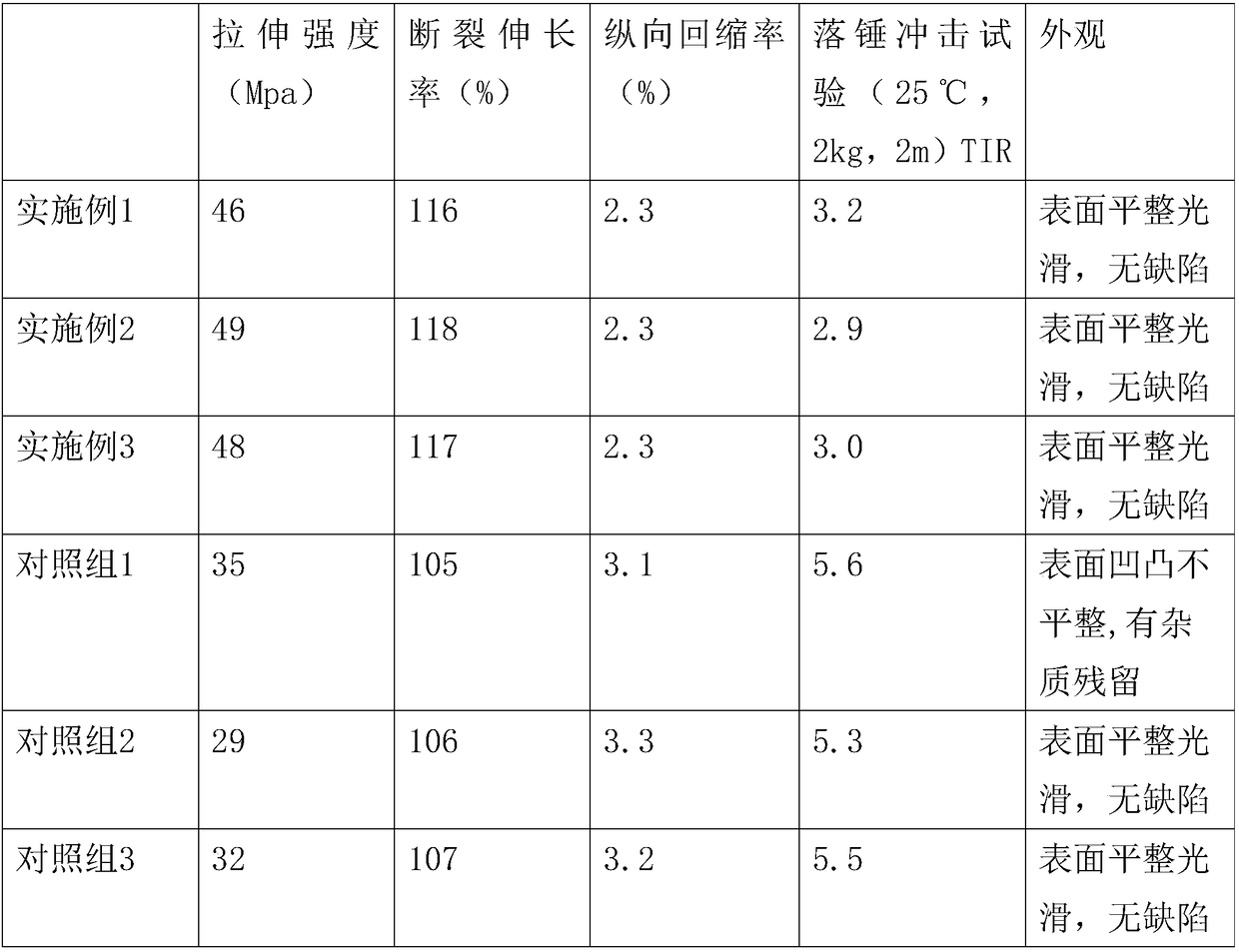

Fertilizer-type biodegradable mulching film and preparation method thereof

ActiveCN111165242AReduce use costEfficient use ofClimate change adaptationFertiliser distributersMicroorganismSoil science

The invention relates to the technical field of biodegradable mulching films, in particular to a fertilizer-type biodegradable mulching film and a preparation method thereof. The fertilizer-type biodegradable mulching film is prepared from raw materials containing the following components in parts by weight: 70.0-95.0 parts of biodegradable plastic, 0.5-30.0 parts of fertilizer, 0-15.0 parts of alubricant, 0-2.0 parts of a light stabilizer, 0-1.5 part of an antioxidant, 0-2.0 parts of a chain extender and 0-6.0 parts of color master batches. The fertilizer-type biodegradable mulching film canprovide or supplement the fertilizer for crops in the growth period, the fertilizer is released after degradation, and a large amount of small holes appear in the mulching film, so that the fertilizer fully reacts with moisture and microorganisms in the environment, the degradation is accelerated, mulching film residues in the crop harvesting period are reduced or avoided, crop harvesting and straw recycling are facilitated, the process of partial crop film uncovering can be removed, and the film uncovering cost is reduced.

Owner:INST OF ENVIRONMENT & SUSTAINABLE DEV IN AGRI CHINESE ACADEMY OF AGRI SCI

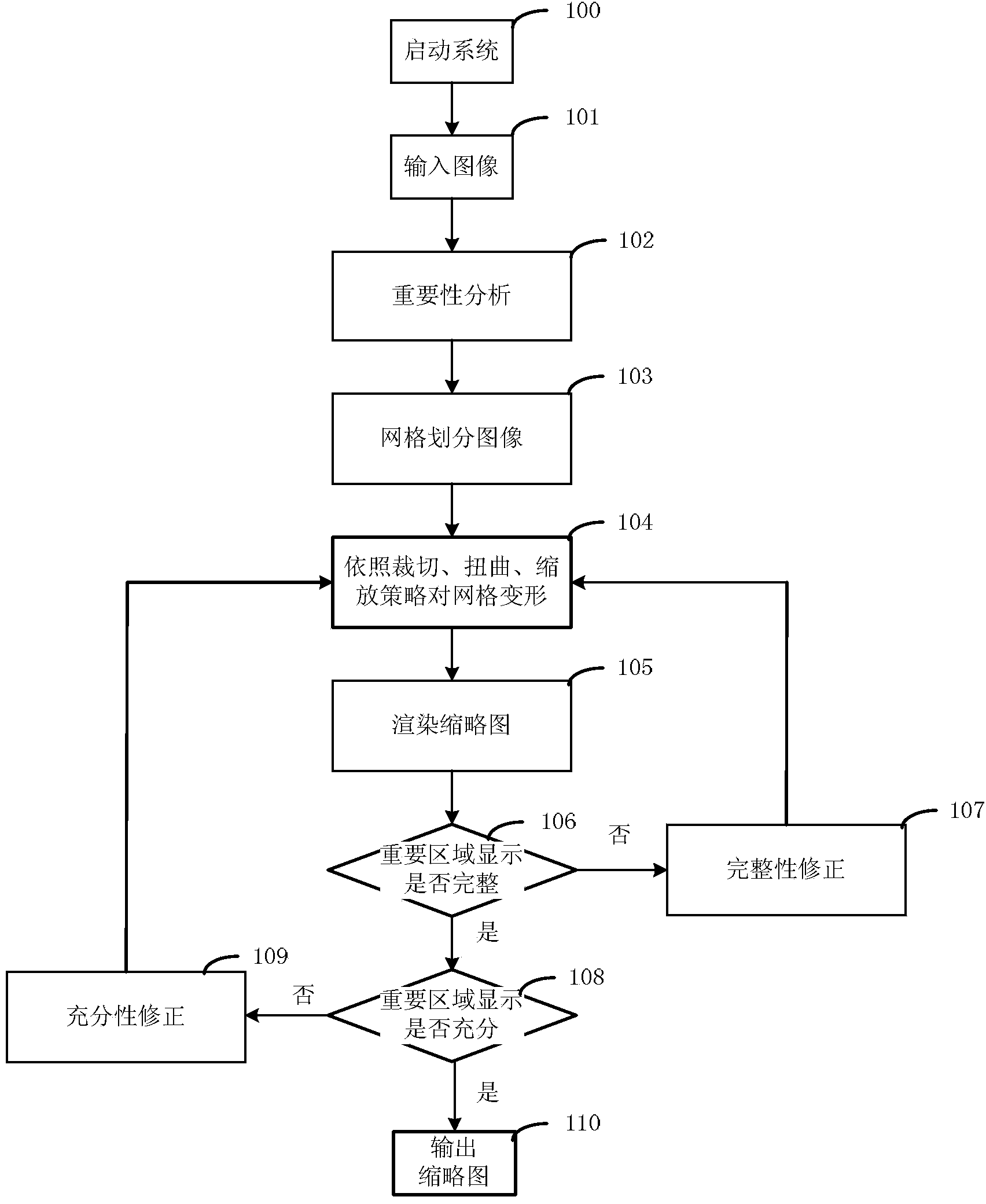

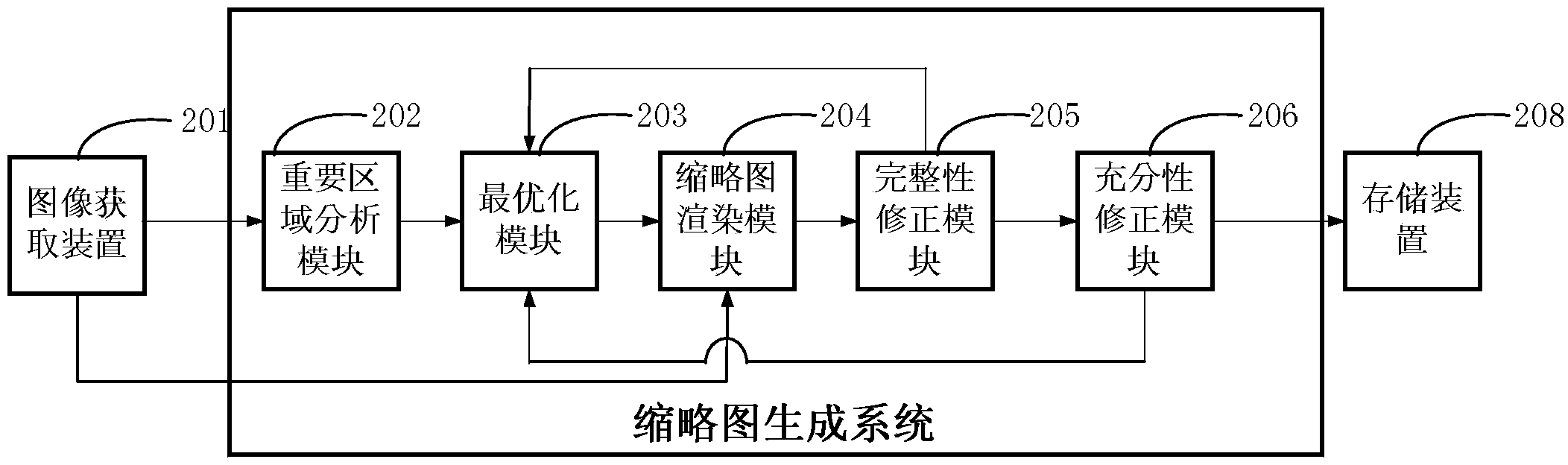

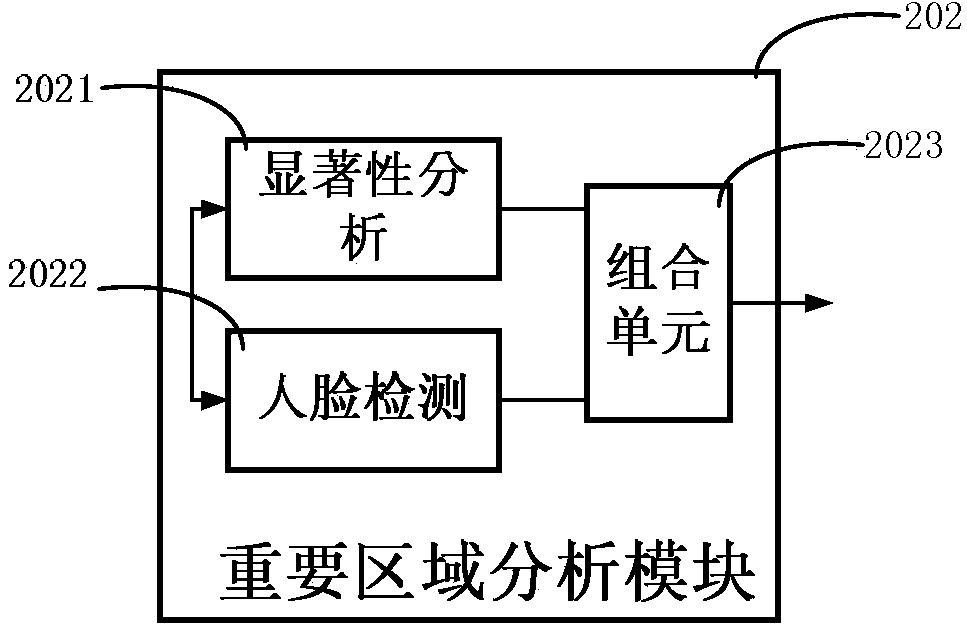

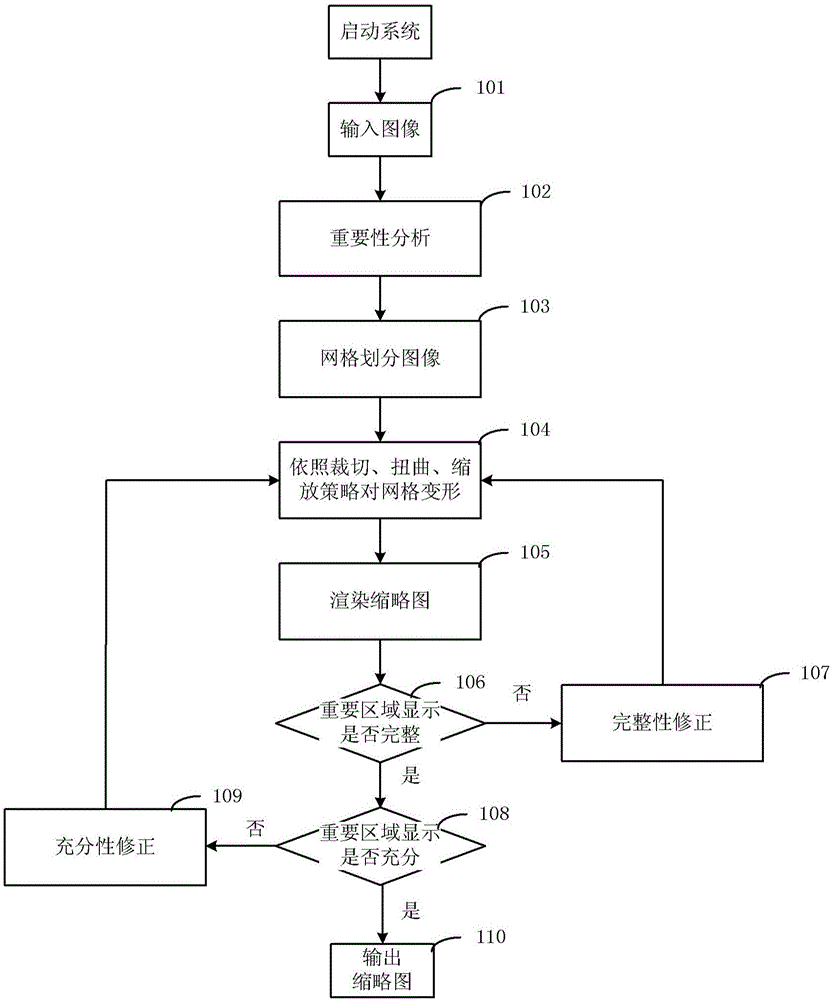

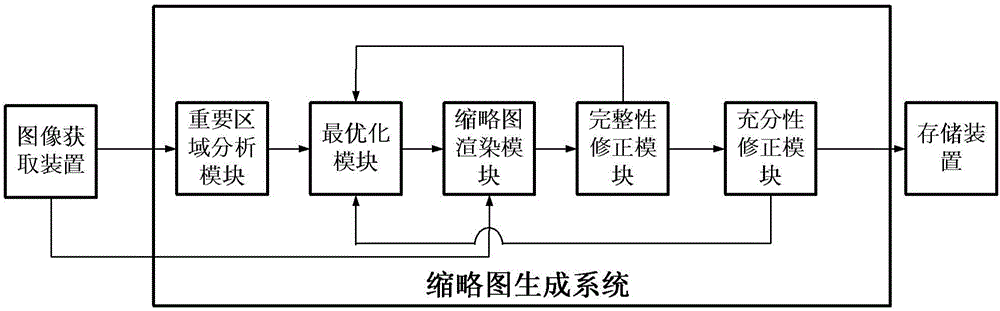

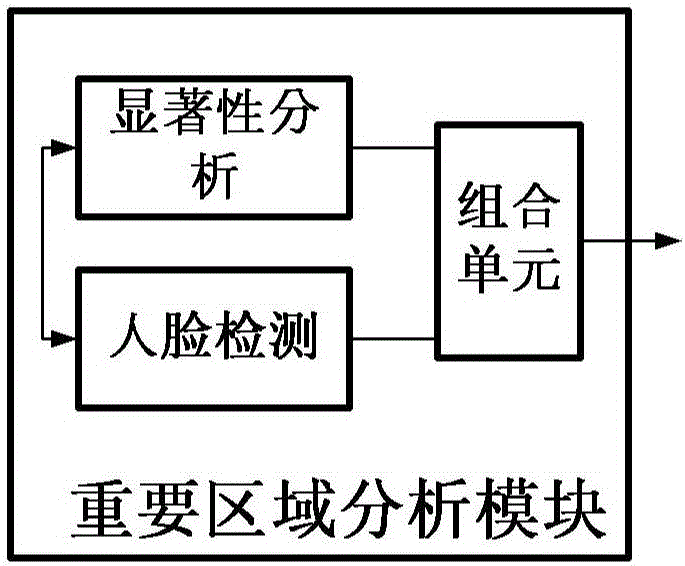

Thumbnail generation method and system

ActiveCN103902730AAdjustment and effectSave spaceImage analysisGeometric image transformationImaging processingThumbnail

The invention discloses a thumbnail generation method and system. By combining the three image processing strategies of cropping, distortion and zooming to generate a thumbnail, advantages of the different strategies are exerted, the different strategies are supplemented by each other, an important region in an image is accurately, completely and fully displayed in the thumbnail, and important information is preserved to the maximum in the limited space of the thumbnail. According to the thumbnail generation method and system, the three image processing strategies are achieved through one uniform optimization process, and therefore the time overhead is small.

Owner:INST OF AUTOMATION CHINESE ACAD OF SCI

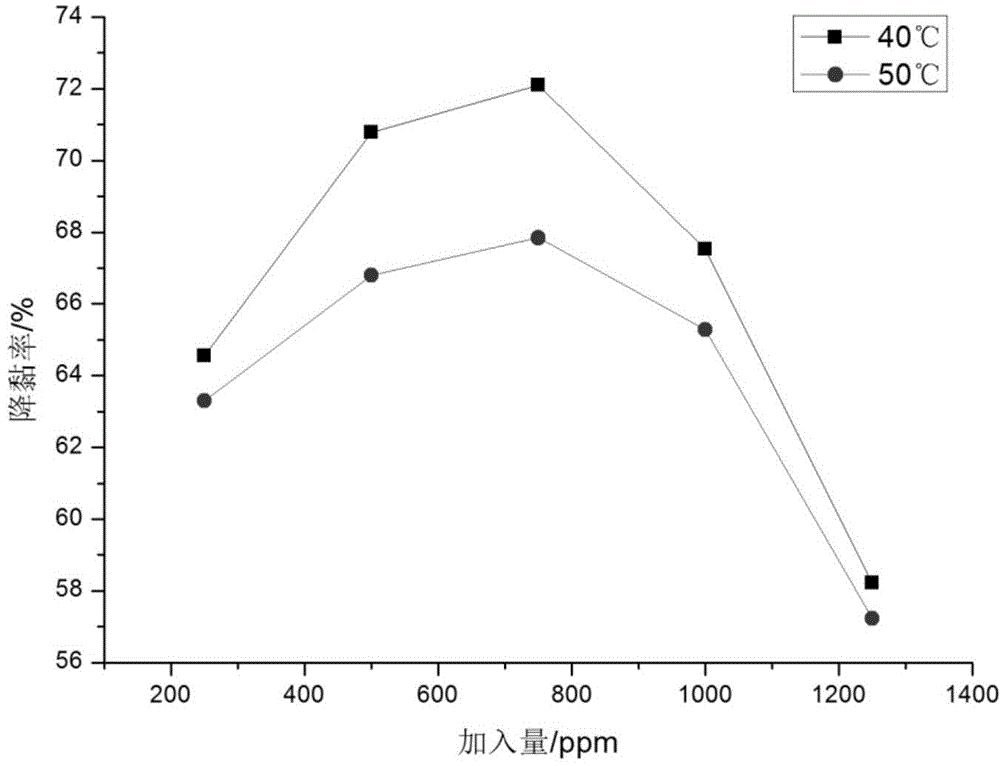

Aminolysis polymer, and preparation method and application thereof

InactiveCN104356296AProlong the action timeLow costPipeline systemsDrilling compositionMaleic anhydrideWax

The invention discloses an aminolysis polymer, and a preparation method and application thereof, belonging to the field of preparation of high polymer materials. The preparation method of the aminolysis polymer comprises the following steps: (1) preparation of poly(maleic anhydride-high carbon methacrylate) intermediate product; (2) pulverization treatment of intermediate product; (3) preparation of aminolysis poly(maleic anhydride-high carbon methacrylate) pour-point depressant; and (4) treatment of target product aminolysis poly(maleic anhydride-high carbon methacrylate) pour-point depressant reaction solution and preparation of powder. The pour-point depressant has the advantages of favorable pour-point depression and visbreaking effects, low cost, simple production and clean and pollution-free process, and the product is easy to obtain, transport and store. The net pour-point depression amplitude for the Daqing high-wax thick oil is up to 8 DEG C, and the apparent visbreaking ratio is up to 72.1%, which are respectively better than the pour-point depression effects of the commercially available EVA (ethylene-vinyl acetate): the net pour-point depression temperature is 4 DEG C, and the apparent visbreaking ratio is 68.7%.

Owner:SHANDONG UNIV

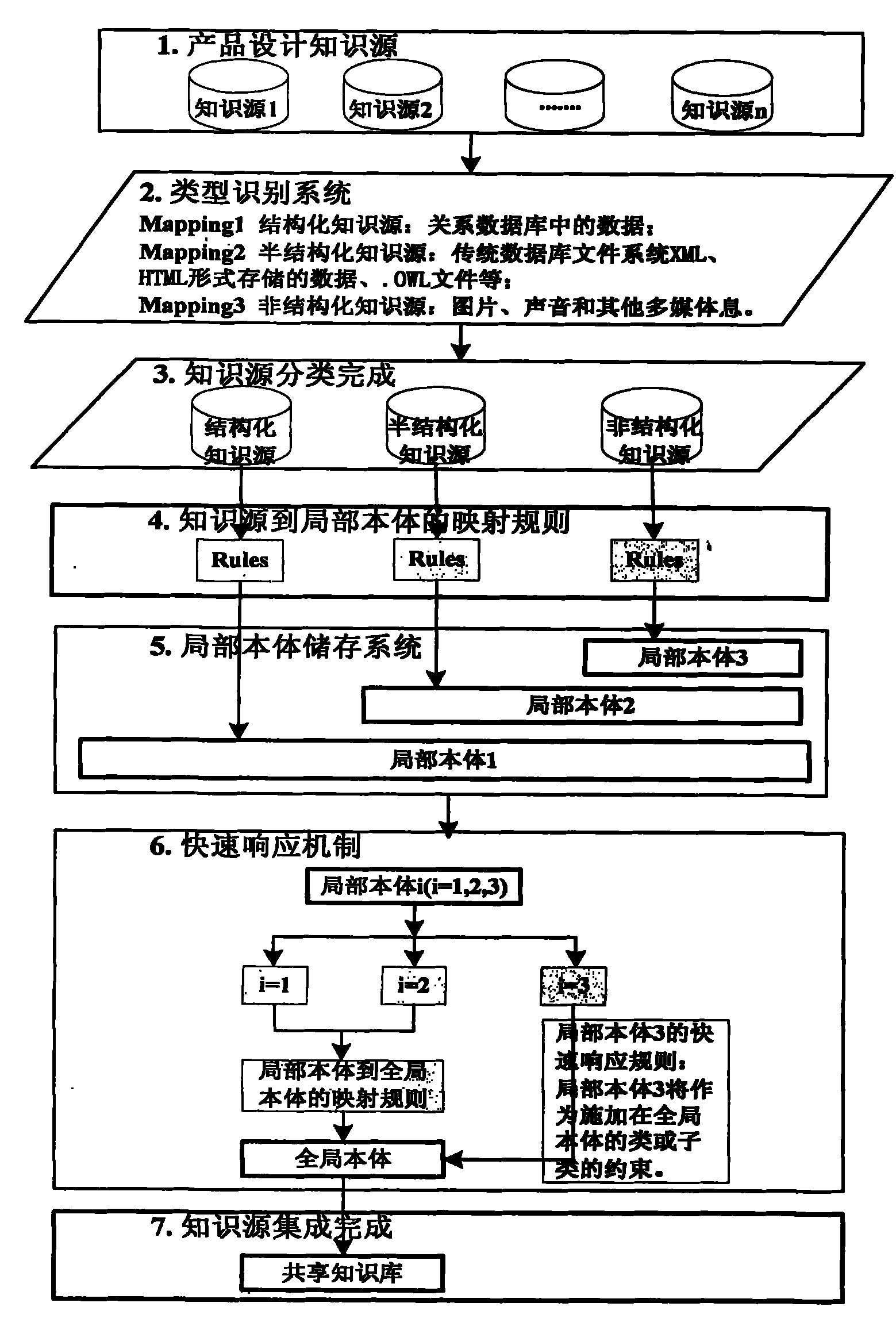

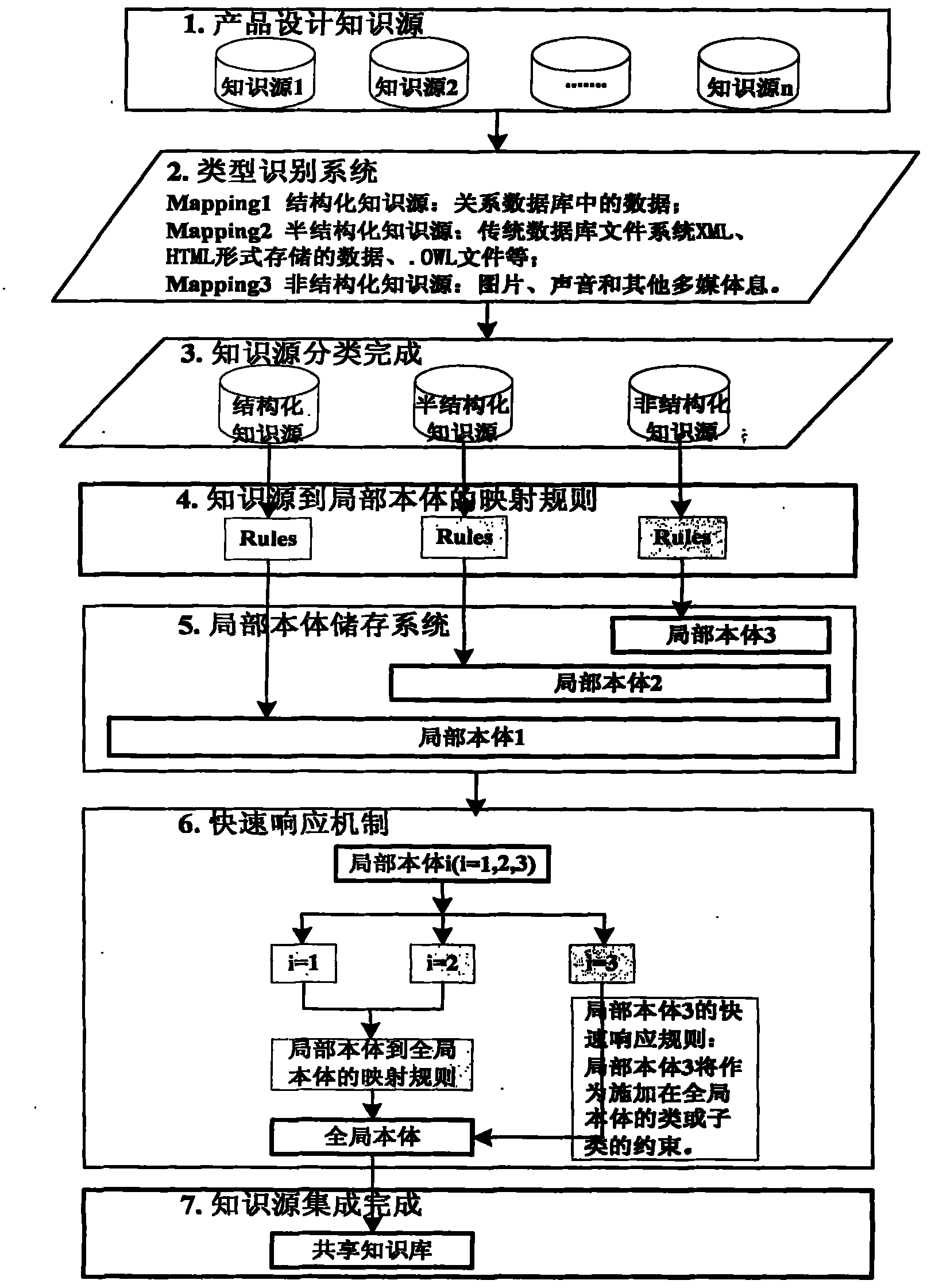

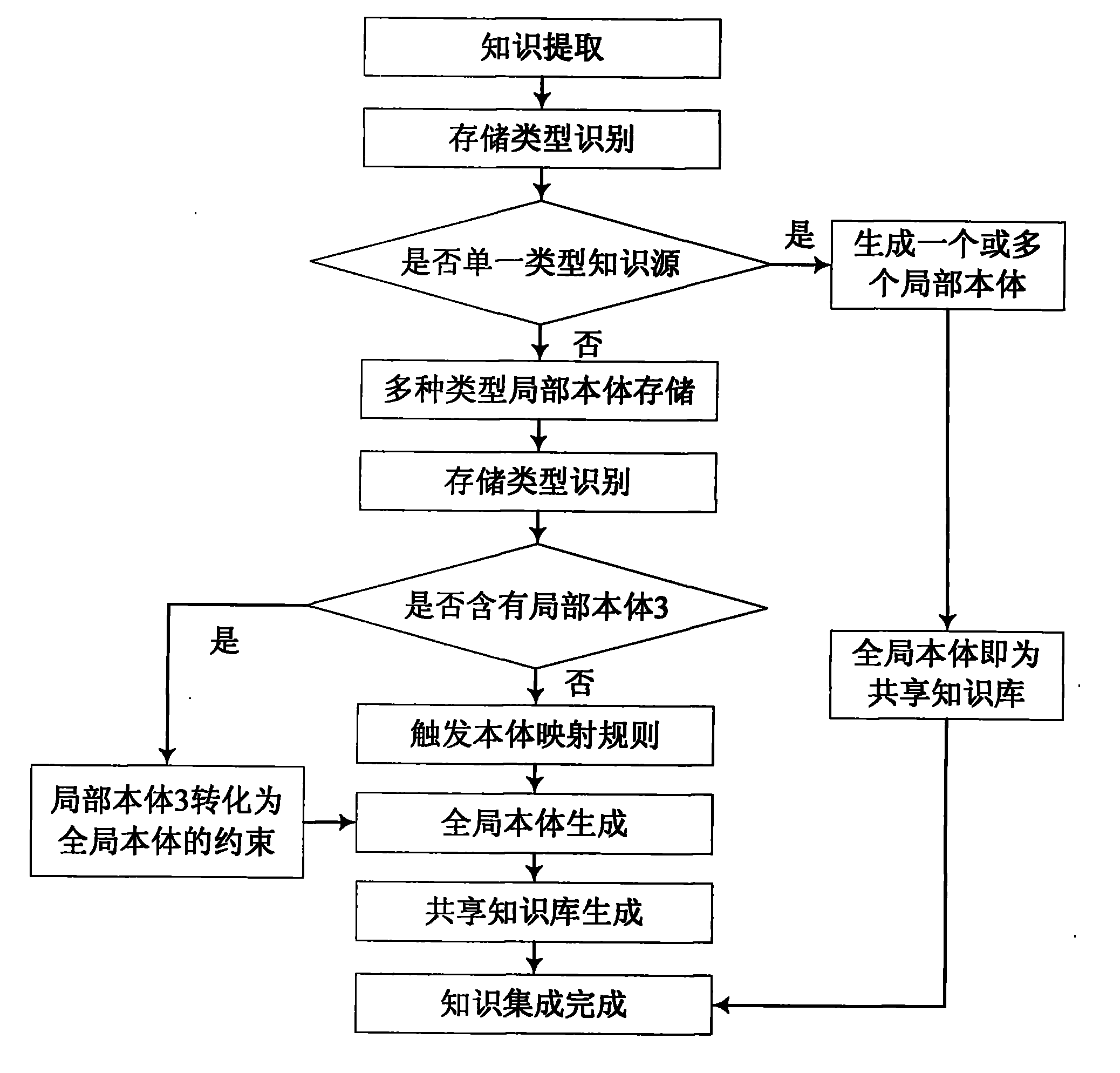

Knowledge integration method for body-based product-oriented design process

InactiveCN101814092AHigh feasibilityOvercome singlenessSpecial data processing applicationsKnowledge integrationKnowledge sources

The invention relates to a knowledge integration method for a body-based product-oriented design process, which comprises the following steps in sequence: reading a knowledge source, identifying and classifying the knowledge source, generating a local bodies of a corresponding category by an original knowledge source according to mapping rules, integrating the local bodies to form a whole body, and generating a shared knowledge base corresponding to the whole body. Compared with the prior art, the invention fully considers the diversity of knowledge representation forms in the product design process, overcomes the simplicity of conventional integrated knowledge sources, and demonstrates excellent universality and completeness. Simultaneously, the invention provides an integrated rapid response mechanism for effective integration of knowledge sources with various storage forms and further demonstrates the feasibility of the mechanism.

Owner:SHENYANG LIGONG UNIV

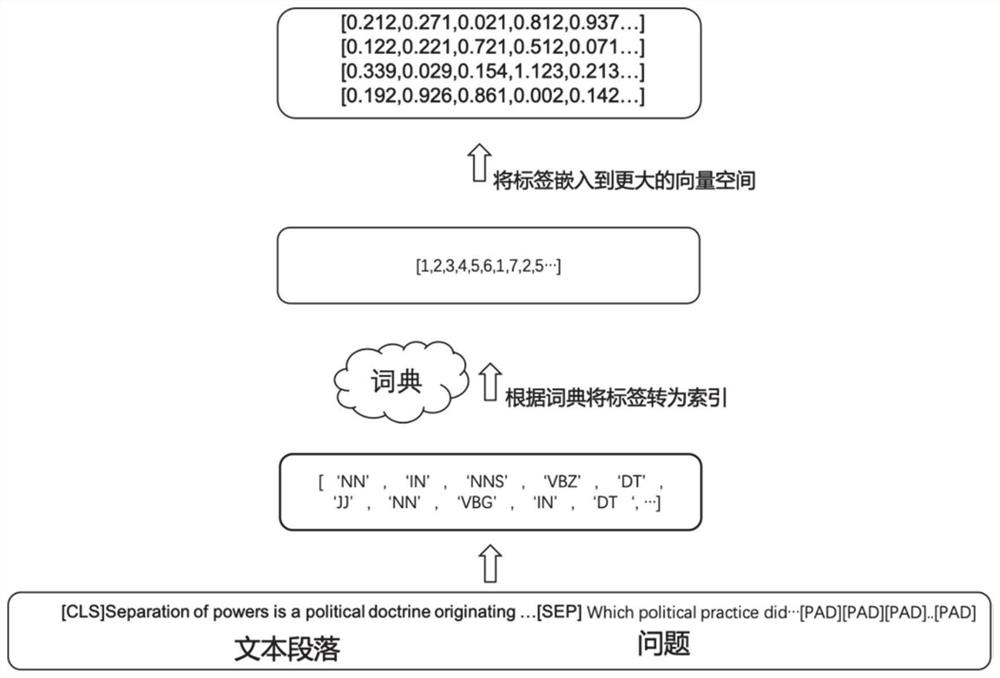

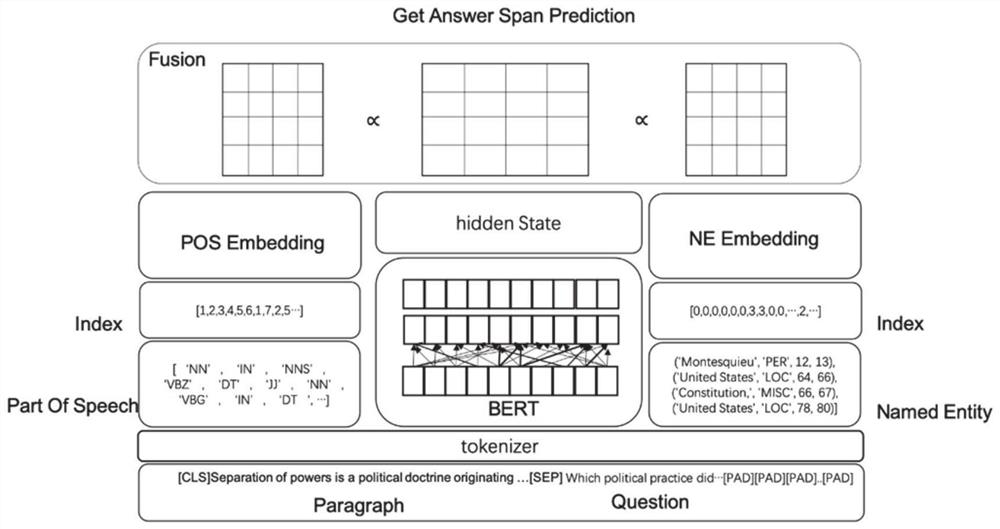

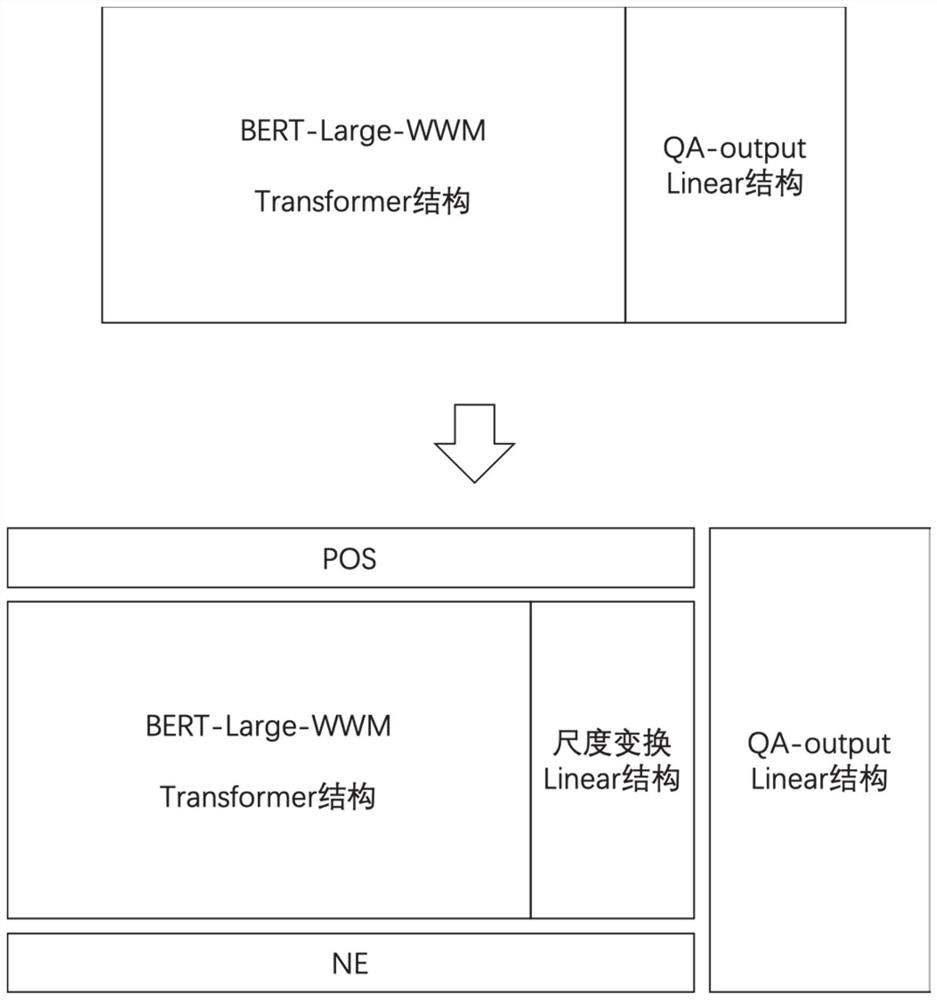

Machine reading understanding method based on pre-training model

PendingCN112541347AAvoid ignoringImprove reading skillsSemantic analysisNeural architecturesEngineeringData mining

The invention relates to a machine reading understanding method based on a pre-training model. The machine reading understanding method comprises the following steps: 1, preprocessing data, 2, performing advanced semantic fusion through an advanced semantic fusion network layer according to the output of the pre-training model, 3, further performing capability learning on the machine reading modelafter semantic fusion, and 4, calculating the mean square error loss of the named entity, and training the machine reading model. The method has the advantages that high-level semantic information isextracted from the text, higher-dimension information is provided for the model, and meanwhile, the high accuracy of the method has more reference significance compared with the mode that the model tries to extract the information in the training process, according to the method, through capability learning, under the condition that the scale of the model can be kept unchanged, the machine reading capability is improved, so that the model can quickly complete an inference task on the premise of relatively high performance.

Owner:ZHEJIANG UNIV CITY COLLEGE

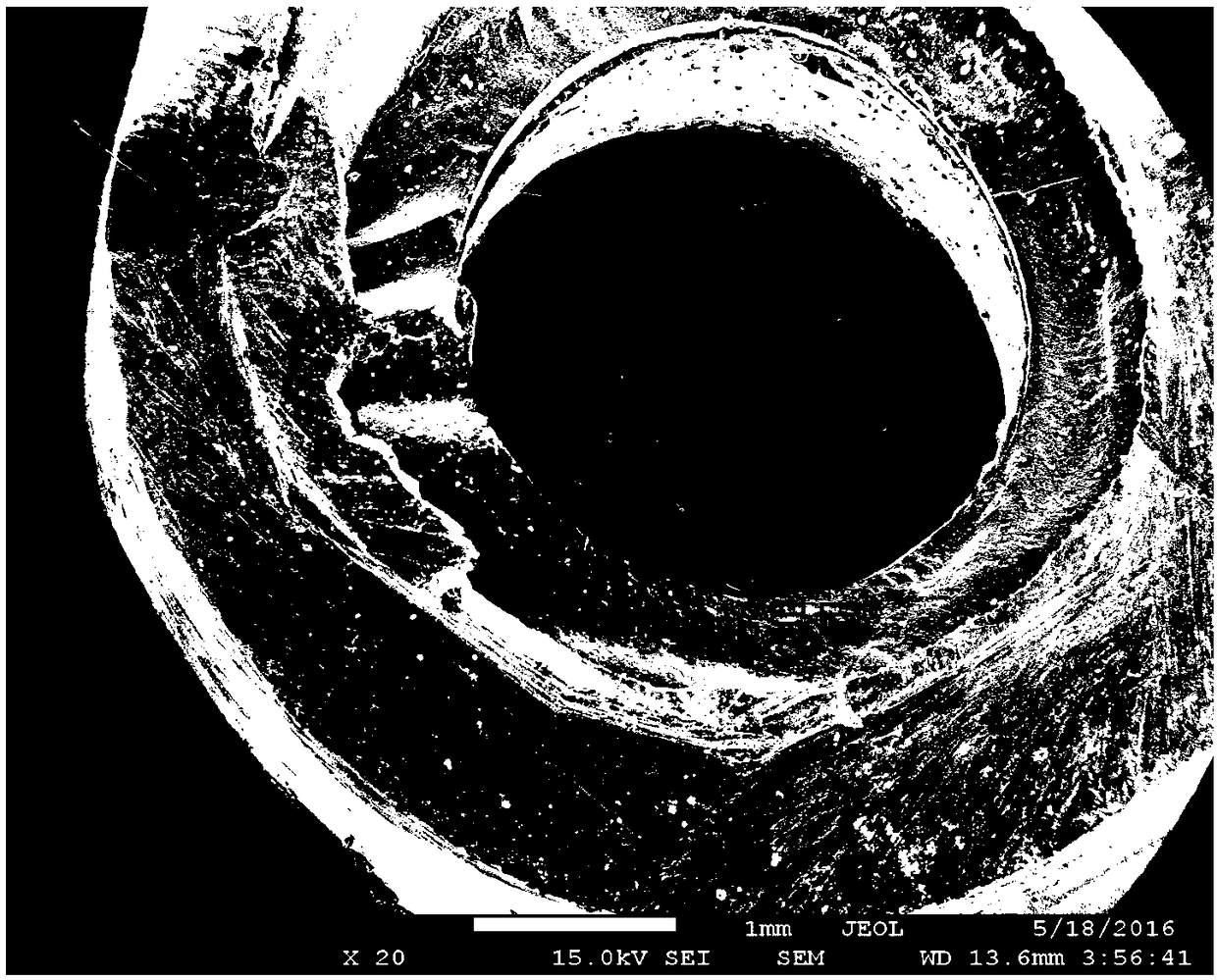

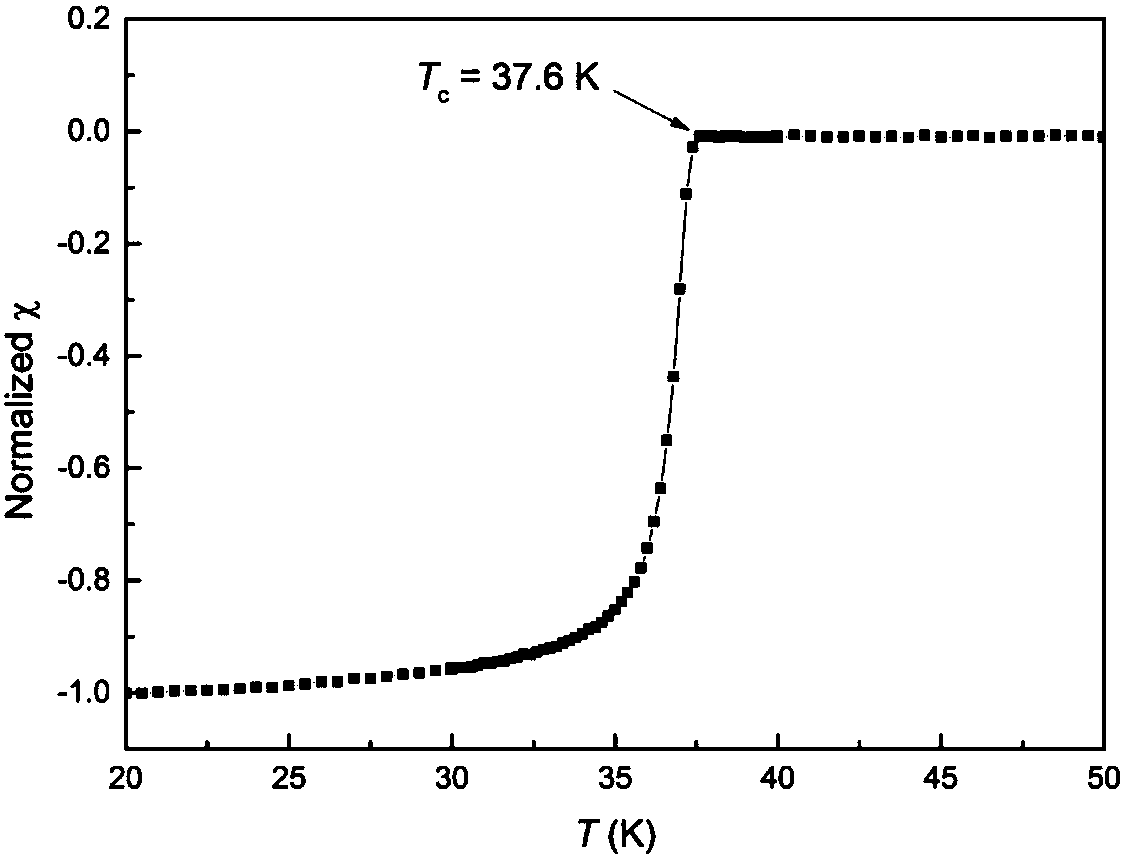

Preparation method of low-cost high-density MgB2 super-conducting wire rod

InactiveCN108133787ASolve churnAdjust volumeSuperconductors/hyperconductorsReduction of cables/conductors sizeWire rodHigh density

The invention discloses a preparation method of a low-cost high-density MgB2 super-conducting wire rod. The preparation method comprises the following steps: firstly preparing precursor powder in tube, and then inserting a high-purity magnesium rod into the center of a stainless steel tube to fix, filling the precursor powder around the magnesium rod of the stainless steel tube, taking out the assembled stainless steel tube, processing the stainless steel tube in a rotary swaging into filaments on a rotary swaging machine, and then placing the prepared wire rods into a tubular furnace for circulating argon gas to heat to obtain the MgB2 super-conducting wire rod. The MgB2 super-conducting wire rod prepared through the preparation method is high in purity, high in density, simple in step, easy to operate and high in practical value.

Owner:SOUTHWEST JIAOTONG UNIV

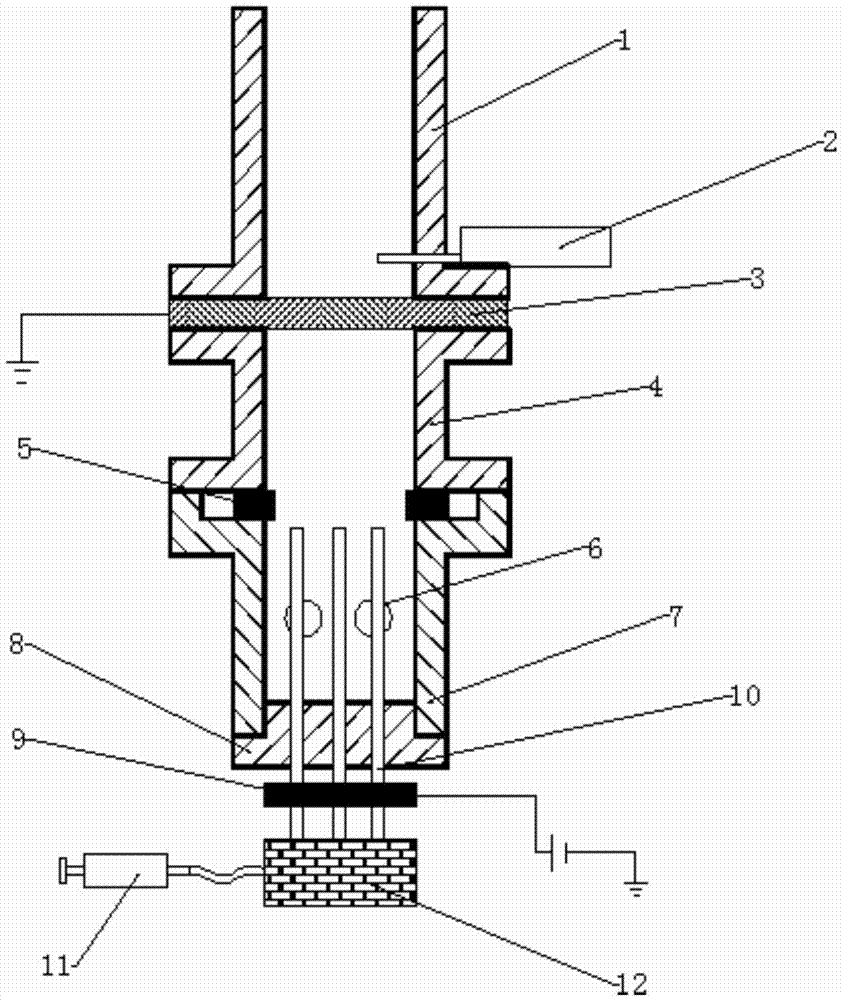

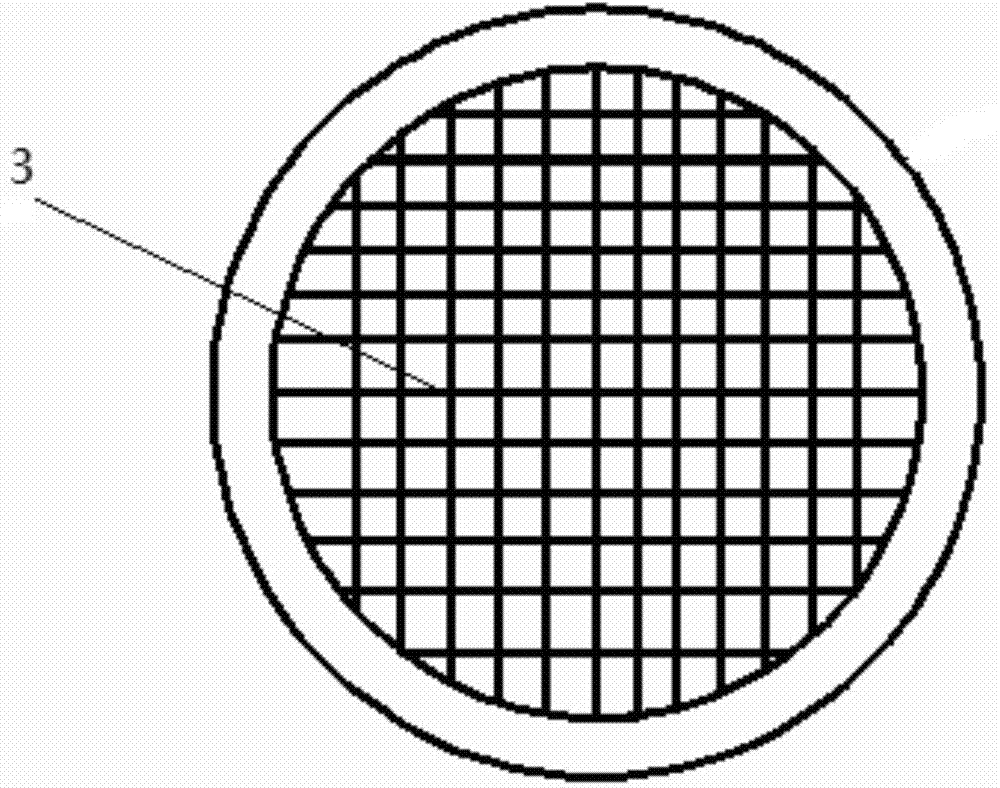

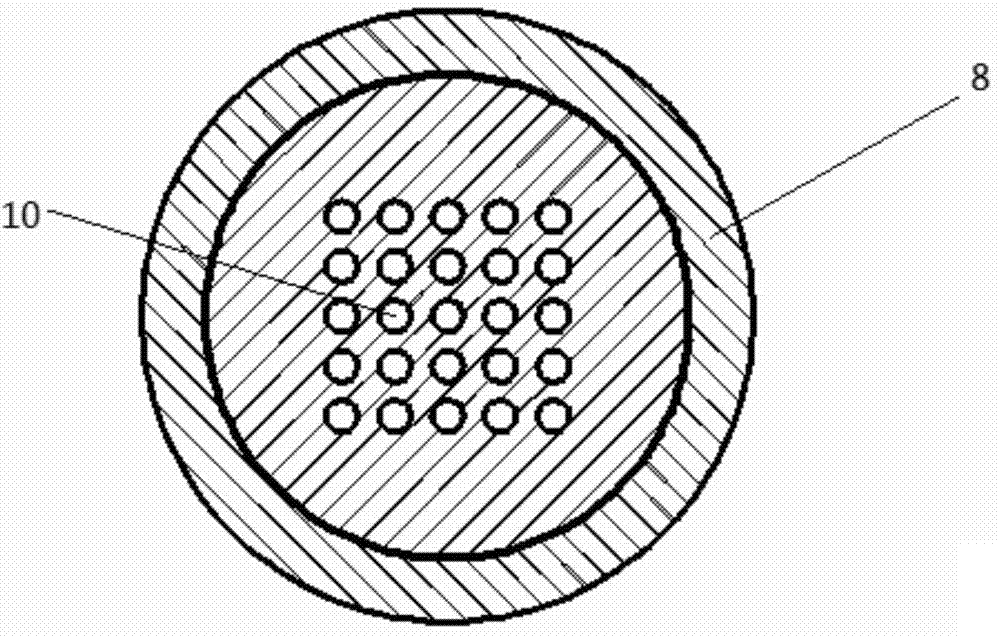

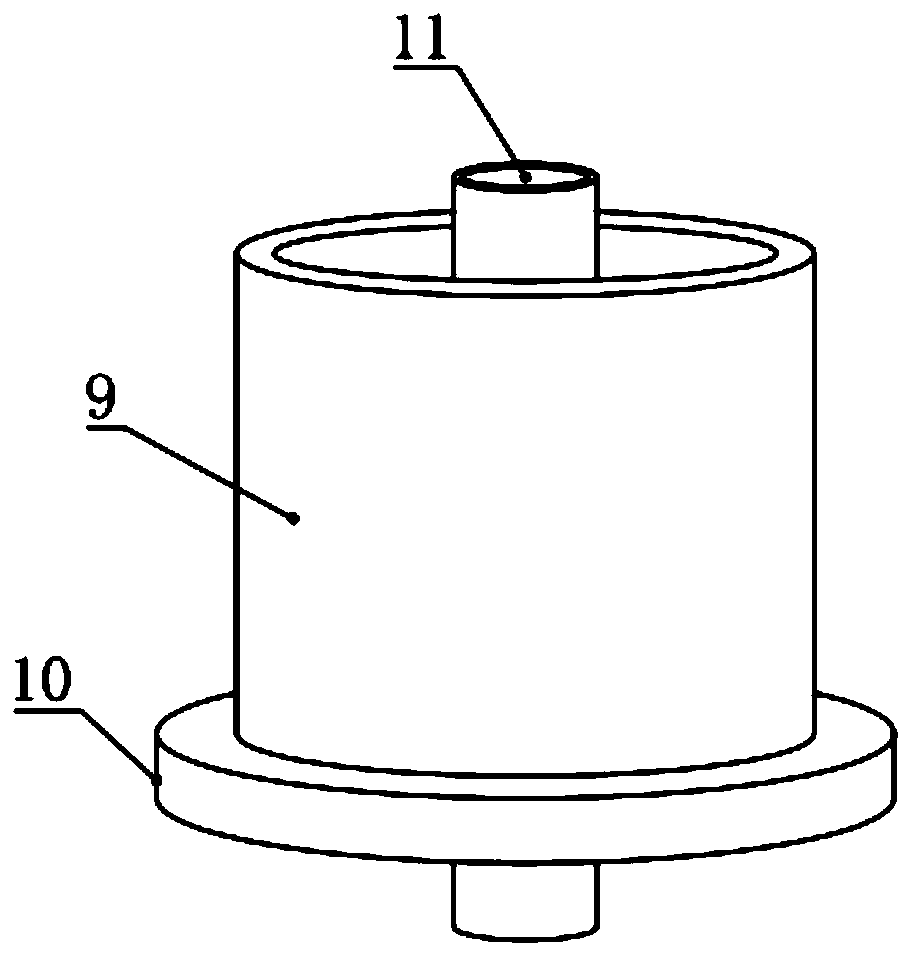

Charged spray catalytic micro burner

InactiveCN103791498AEnhanced uniform atomizationPromote adequacy and stabilityBurnersElectric fieldMesh grid

The invention discloses a charged spray catalytic micro burner which mainly comprises an upper barrel, a middle barrel, a lower barrel and an igniter. Liquid fuel spay pipes are arranged in the lower barrel, a catalytic combustion gird coated with catalysts in a spraying mode is arranged between the upper barrel and the middle barrel, and an ignition needle of the igniter penetrates through the wall face of the upper barrel, and is arranged above a grid inside the upper barrel. An annular electrode is arranged between the middle barrel and the lower barrel, and a highfield area is formed between the grid and the annular electrode. A spray pipe fixing plug is arranged below the lower barrel, and the spray pipes are fixed to the plug. According to the characteristic of liquid fuel combustion under a microscale condition, the double-electrode structure is designed, the annular electrode is combined with spray pipe electrodes, a charged spray technology is combined with a catalytic combustion technology, and the multiplexing spray pipes are designed. Efficient, stable and low-pollution combustion of the liquid fuel can be achieved under the microscale condition, the aim of controlling the complex combustion process can be achieved by adjusting voltages and other simple electric field parameters, and theoretical innovativeness is achieved.

Owner:SOUTH CHINA UNIV OF TECH

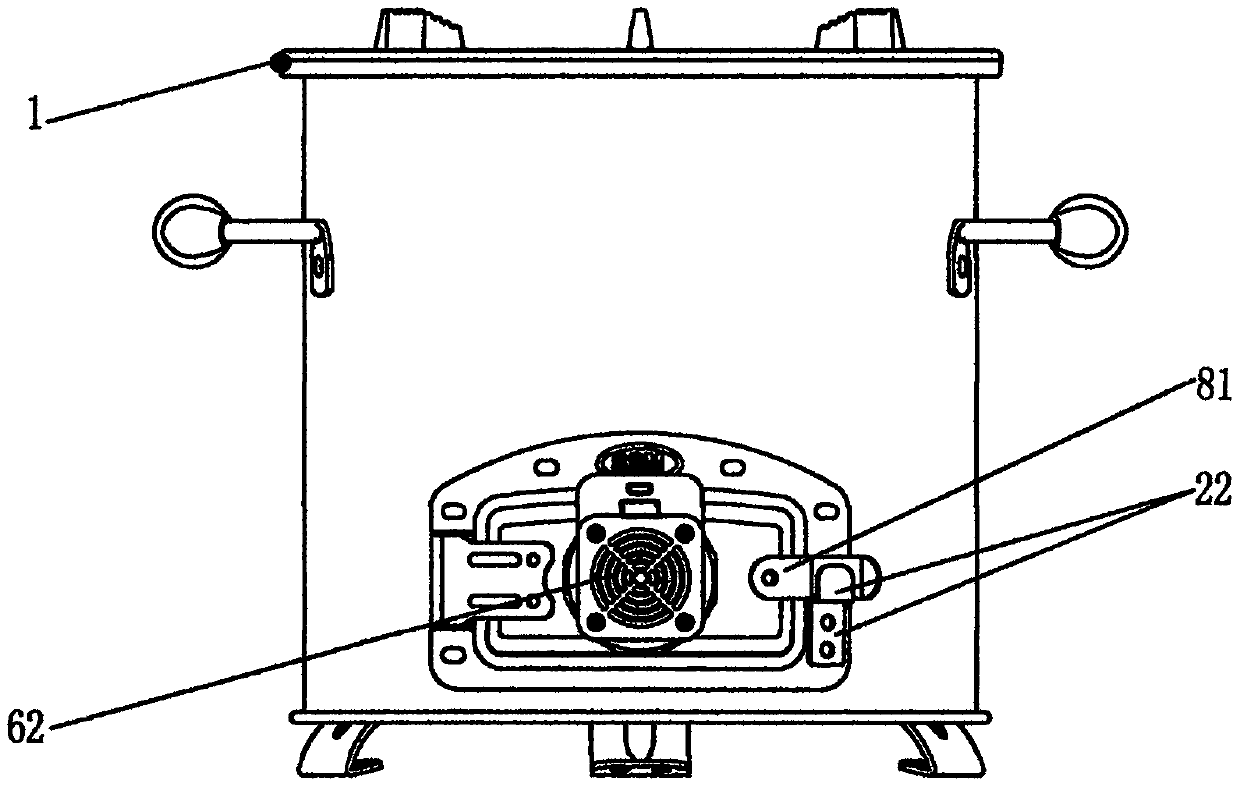

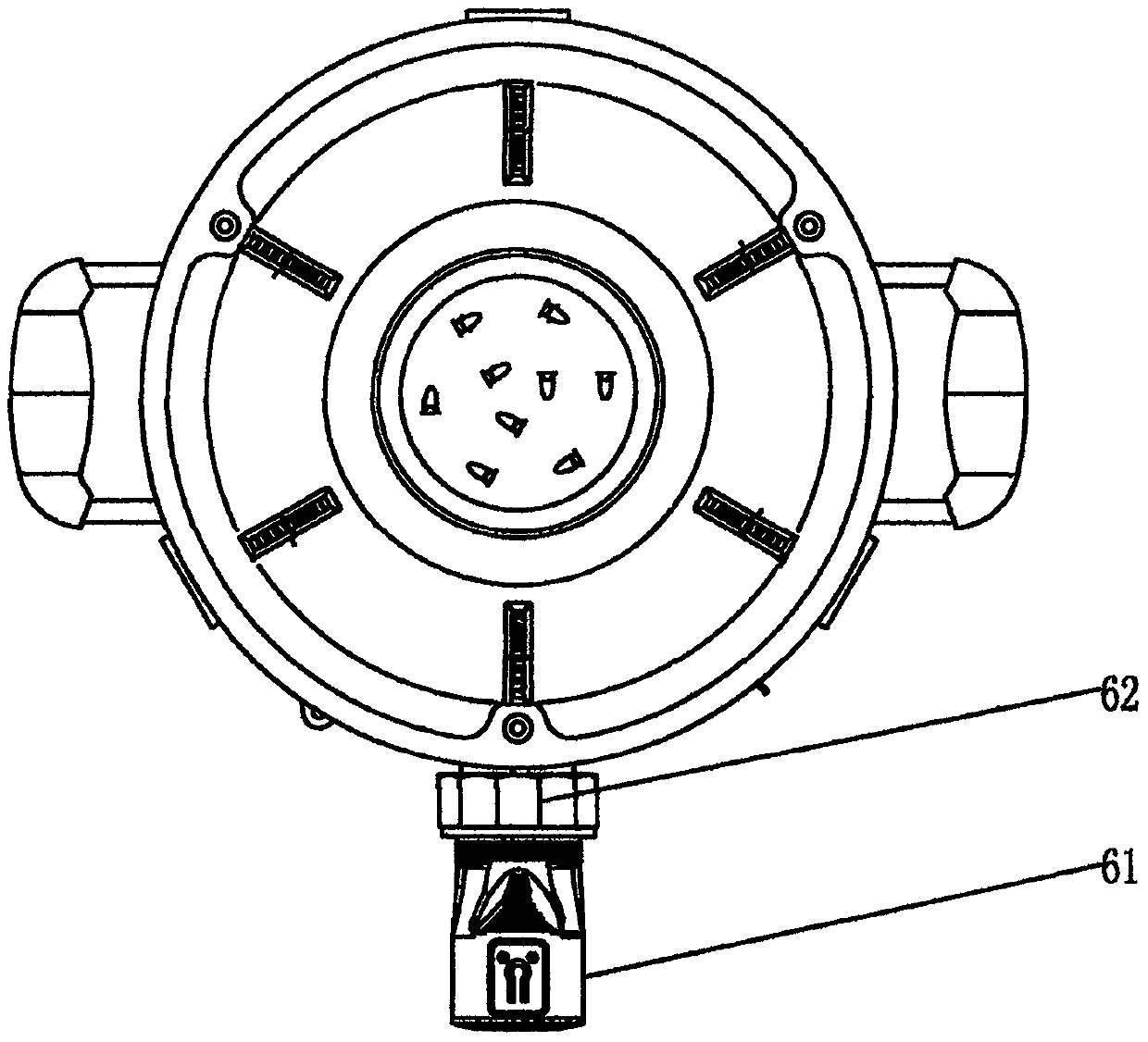

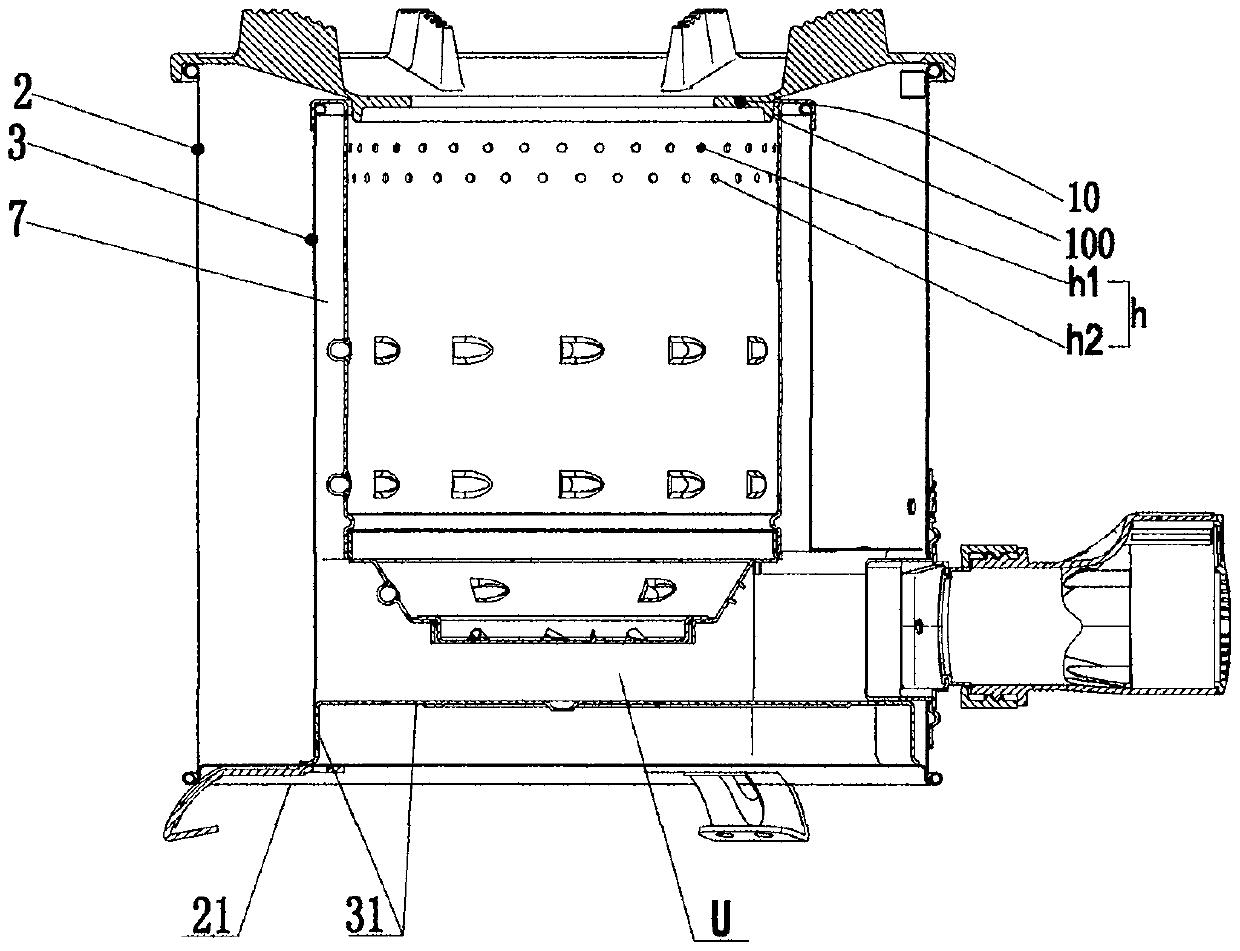

Biomass furnace with forced introduction of combustion air

PendingCN108050507APromote sufficiencySufficient oxygenationSolid fuel combustionAir/fuel supply for combustionCombustible gasEngineering

The invention discloses a biomass furnace with forced introduction of combustion air. The biomass furnace comprises a furnace panel, an outer shell, and a lining barrel; the lining barrel is internally provided with an incendiary cylinder; the incendiary cylinder is composed of a straight barrel body part and a bowl-shaped bottom; the straight barrel body part is arranged at a top end opening of the lining barrel; an air channel is formed between the inner wall of the lining barrel and the outer wall of the incendiary cylinder; once air inlet holes are formed at the lower portion of the straight barrel body part or the side wall of the bowl-shaped bottom or the bottom wall of the bowl-shaped bottom at intervals in the circumferential direction; the once air inlet holes are inclined relative to the barrel circumference wall of the straight barrel body part or inclined relative to the side wall of the bowl-shaped bottom or inclined relative to the bottom wall of the bowl-shaped bottom; once air enters the incendiary cylinder and spirals up along the cylinder wall of the incendiary cylinder; twice air inlet holes are formed at the top portion near the straight barrel body part at intervals in the circumferential direction; and an opening located on the outer shell is provided with a wind leading device used for leading air into an ash chamber opening, and the leaded air sequentially passes through the once air inlet holes and the twice air inlet holes to enter the incendiary cylinder. According to the scheme, the fuel is fully burnt, the combustible gas is fully burned, and the smokeless clean is achieved.

Owner:ZHEJIANG HUIWENMEI STOVE CO LTD

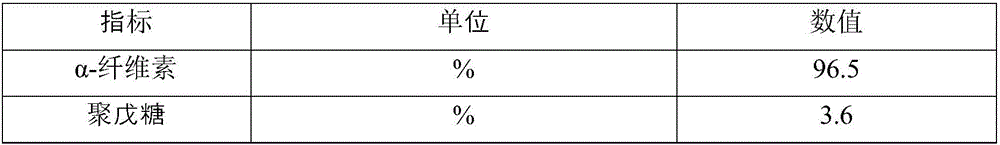

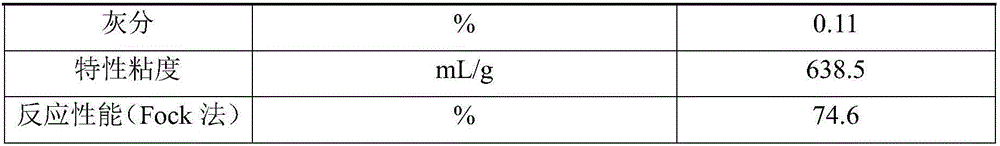

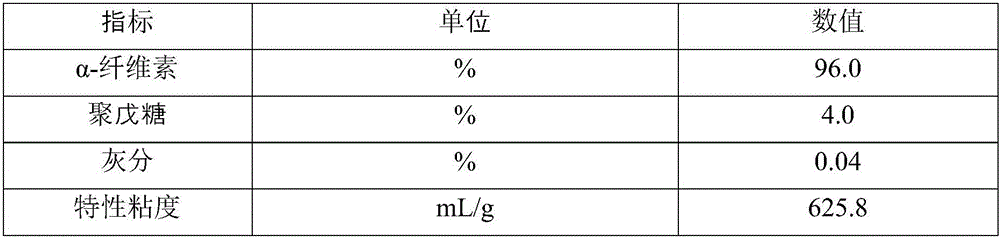

Method for improving viscose bamboo pulp reaction performance

InactiveCN105803841AAvoid degradationAvoid React Performance Negative ImpactPulp beating methodsCellulosePolyethylene glycol

The invention relates to a method for improving a bamboo pulp reaction performance. The method comprises the following steps of (1) pre-processing a pulp board; (2) pre-processing before processing an accessory ingredient; (3) processing the accessory ingredient, wherein the accessory ingredient is one or a mixture of polyglycol ether, polyoxyethylated castor oil, Turkey red oil, polyethylene glycol diamine, polyoxyethylene and sodium tripolyphosphate. The accessory ingredient processing provided by the invention has the advantages that the reaction performance adverse impact brought by cornification effect caused by further removing hemicellulose drying at the same time is avoided, the selectivity is good, and the degradation of cellulose is avoided; under the condition of keeping the pulp viscosity, the reaction performance can be improved by 5 to 20 percent.

Owner:FUJIAN AGRI & FORESTRY UNIV

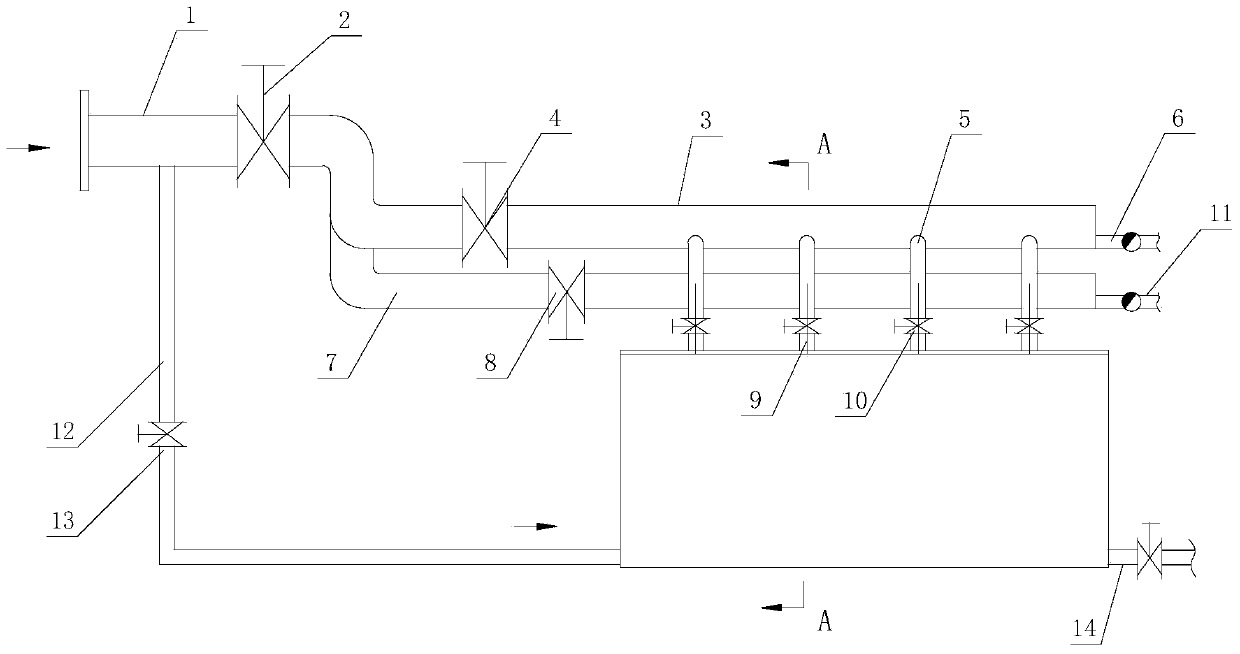

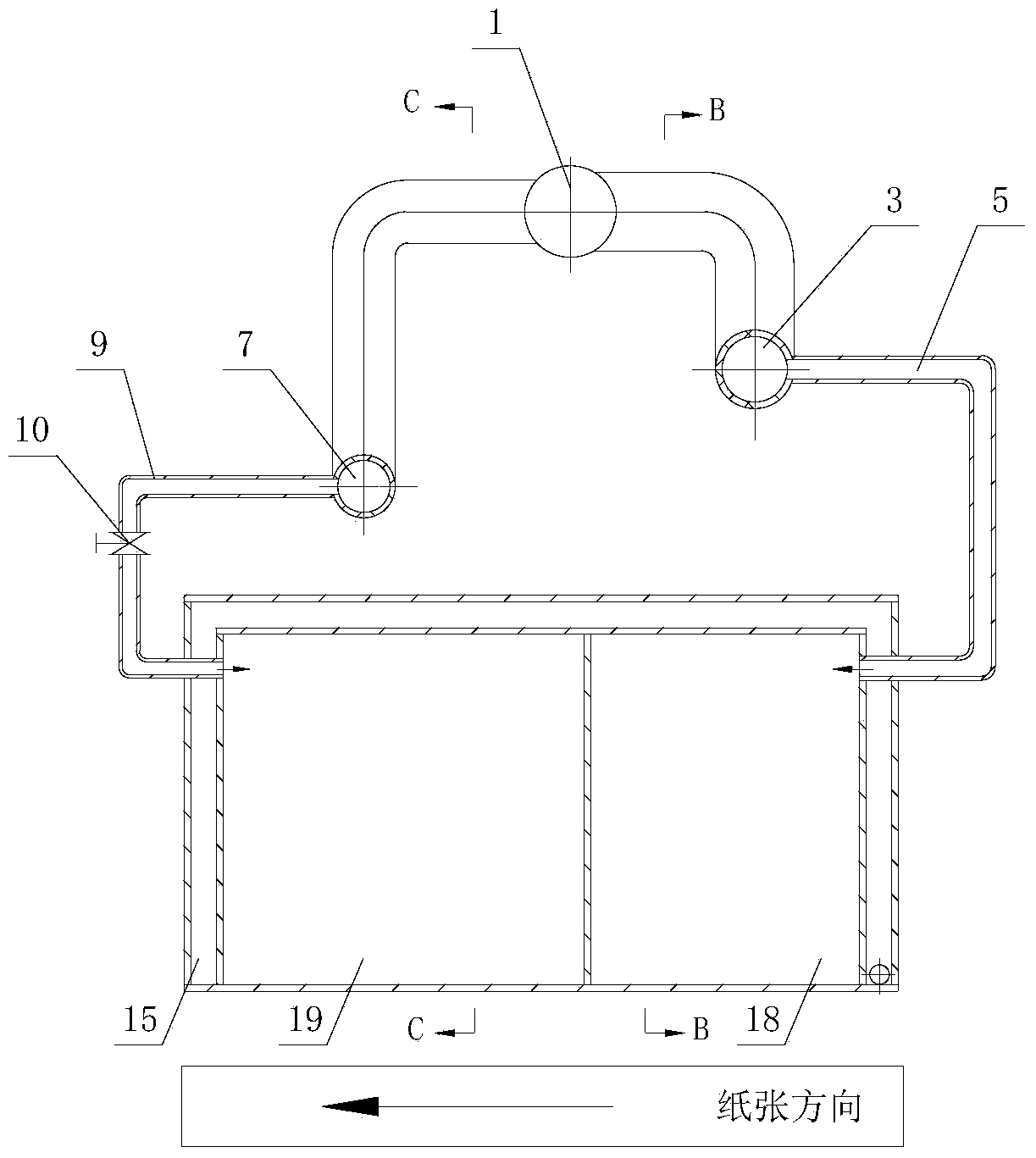

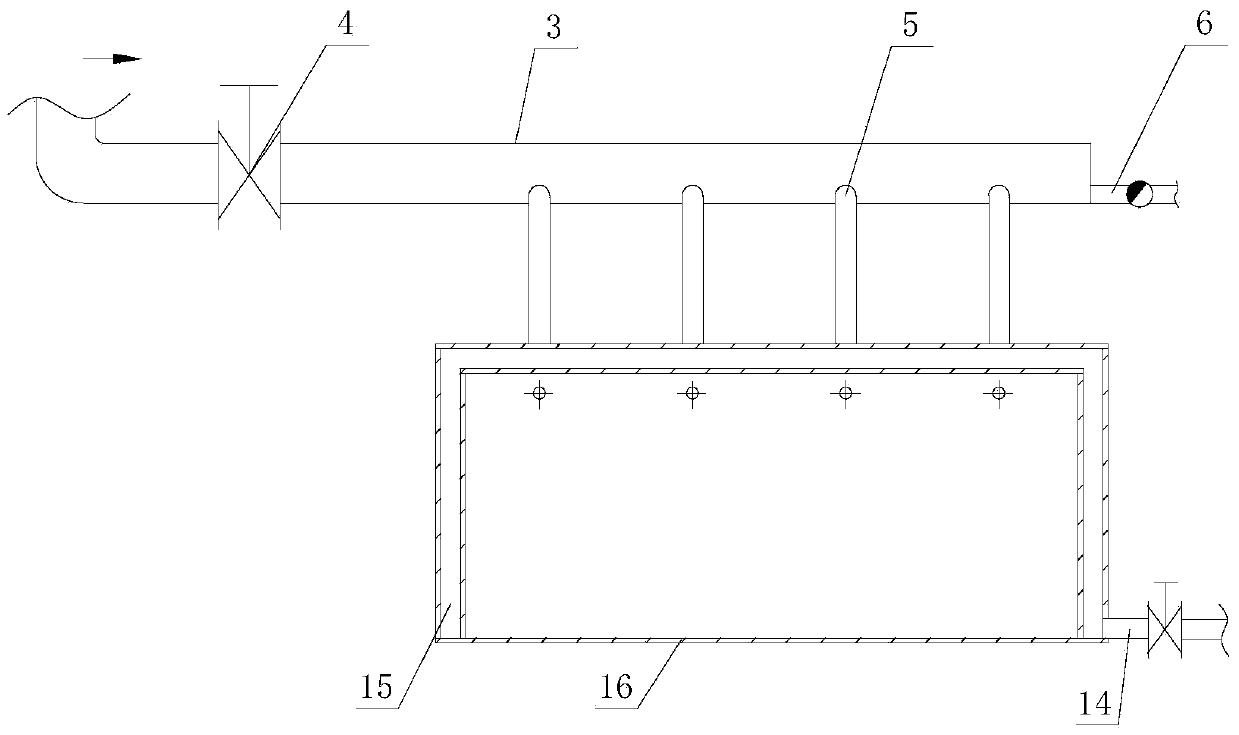

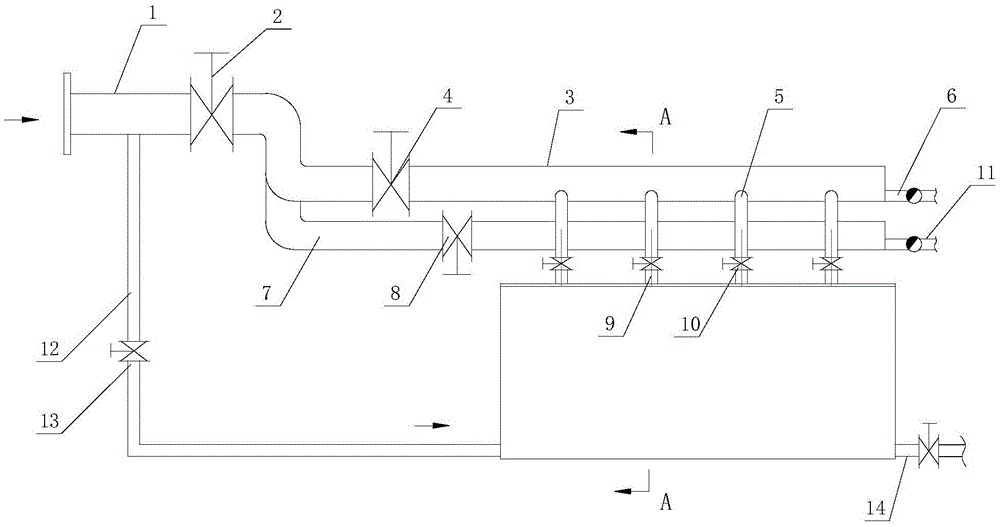

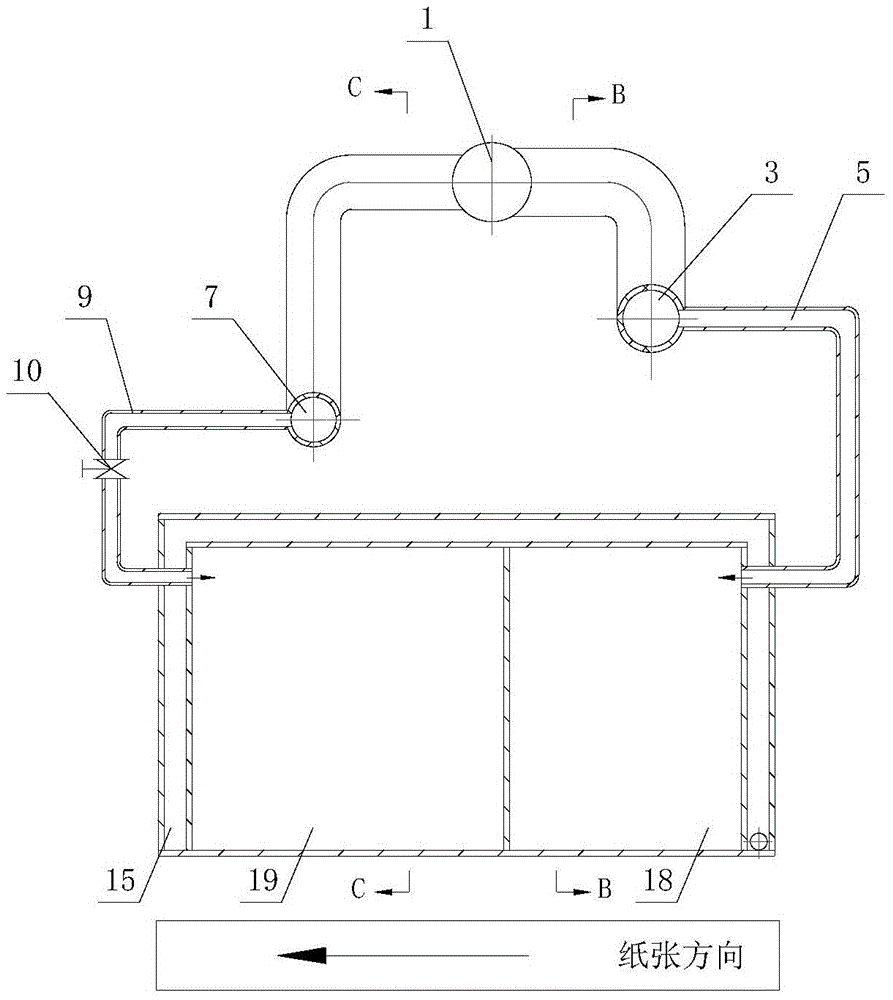

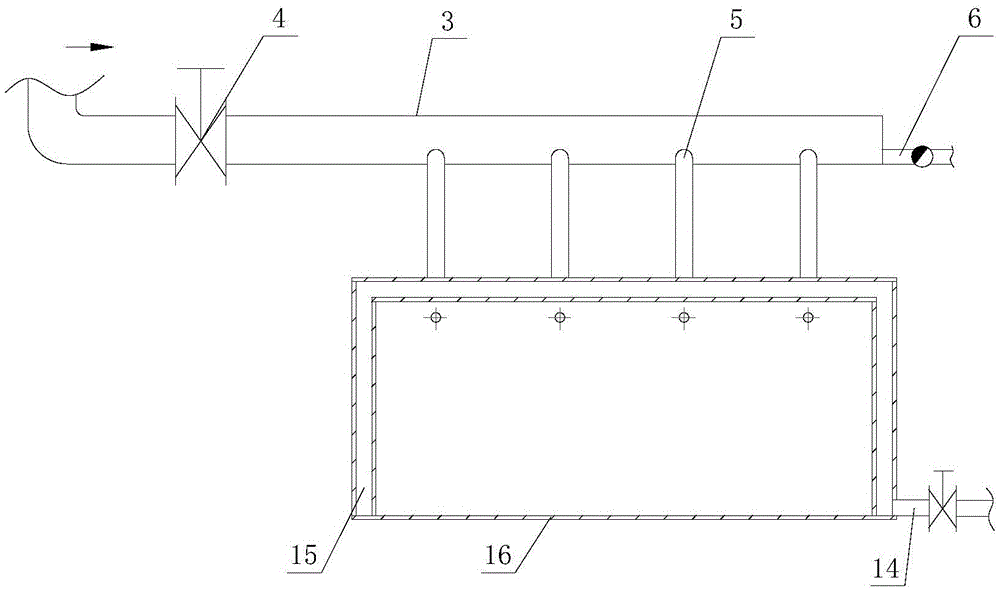

Steam box and method of adjusting temperature and humidity of paper

The invention discloses a steam box and a method of adjusting temperature and humidity of paper. A preheating chamber is arranged outside the steam box; the preheating chamber is connected to an upstream pipeline of a steam manifold through a preheating branch pipe; the steam box comprises a constant current region and a regulation region along an advance direction of the paper in sequence, and a perforated plate is arranged at the bottoms of the constant current region and the regulation region; a downstream pipeline of the stream manifold is divided into a branch pipe of the constant current region and a branch pipe of the regulation region; the constant current region is an independent constant current chamber, and the constant current chamber is communicated with the branch pipe of the constant current region through a constant current branch pipe; the regulation region is divided into a plurality of independent regulation chambers through partition boards and is communicated with the branch pipe of the regulation region through a regulation branch pipe; the constant current region and the regulation region are combined, the caliber of the branch pipe of the constant current region is greater than the caliber of the branch pipe of the regulation region, the stream flow of the regulation region is small, so that the size of a branch pipe control valve is reduced; the length of the regulation region is greater than that of the constant current region so as to be beneficial for full action of the steam and the paper, thereby increasing the utilization efficiency of the stream; the stream overflow is reduced, and the environment of manufacturing the paper with pulp is preferably protected.

Owner:SOUTH CHINA UNIV OF TECH

Joint motion facilitation device

ActiveUS9138368B2Promote sufficiencyEasy to installChiropractic devicesEye exercisersEngineeringAtmospheric pressure

When air is supplied by an air pressure regulation part to bellows 211 through 213 of finger joint motion facilitation parts 110j (where j=1, . . . , 5), the bellows 211 through 213 expand approximately in the shape of circular arcs, since annular grooves on the side of the bellows 211 through 213 opposing a joint are elastically restrained by elastic members 241 through 243. Due to this, the bellows 211 through 213 cooperate, and exert force in the rotational direction to flex the first through the third joints of a finger from their extended states. Next, when air is exhausted from the bellows by the air pressure regulation part, the bellows 211 through 213 contract. Due to this, the bellows 211 through 213 cooperate, and exert force in the rotational direction to extend the first through the third joints of a finger from their flexed states. The forces generated in this manner are transmitted to the joints by transmission members 231 through 234. As a result mounting becomes simple, and also it is possible to facilitate sufficient joint movement for each joint.

Owner:YAMAMOTO KEIJIROU

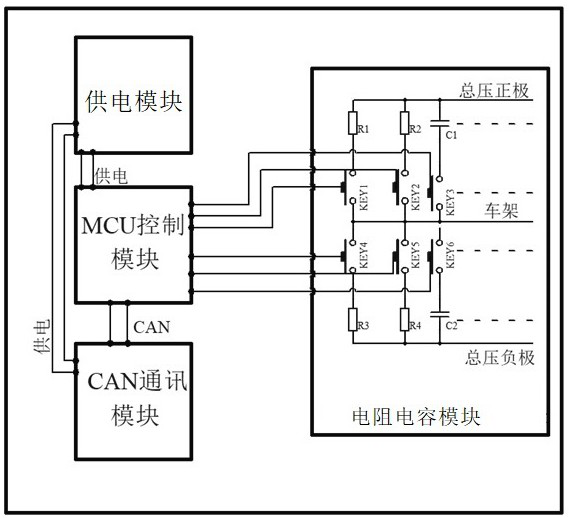

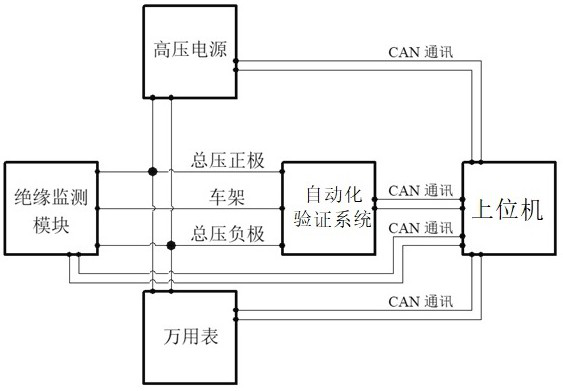

Automatic verification system for performance of insulation monitoring module

PendingCN112698259AImprove efficiencySimple and fast operationElectrical measurementsCapacitanceAutomatic control

The invention discloses an automatic verification system for the performance of an insulation monitoring module. The automatic verification system comprises a power supply module, a resistance-capacitance module, a CAN communication module and an MCU control module, wherein the resistance-capacitance module comprises a plurality of resistors, a plurality of capacitors and a plurality of electric control switches, and is electrically connected with the insulation monitoring module, a total positive electrode and a total negative electrode of the high-voltage power supply and a frame ground wire to form a test loop; the MCU control module communicates with an upper computer through the CAN communication module; and meanwhile, on-off of each electric control switch connected with the resistance-capacitance module is controlled, and the performance of the insulation monitoring module is verified by switching on different combinations of resistors and capacitors. The system provided by the invention can automatically control the set voltage, resistance and Y capacitor to access the test loop, and can feed back to the system in a CAN communication mode after the insulation module is tested. The verification system not only solves the problems of low manual test efficiency and complicated process, but also can test the performance of the insulation module under the conditions of different voltage platforms, insulation conditions and whole vehicle Y capacitance.

Owner:BAFANG ELECTRIC (SUZHOU) CO LTD

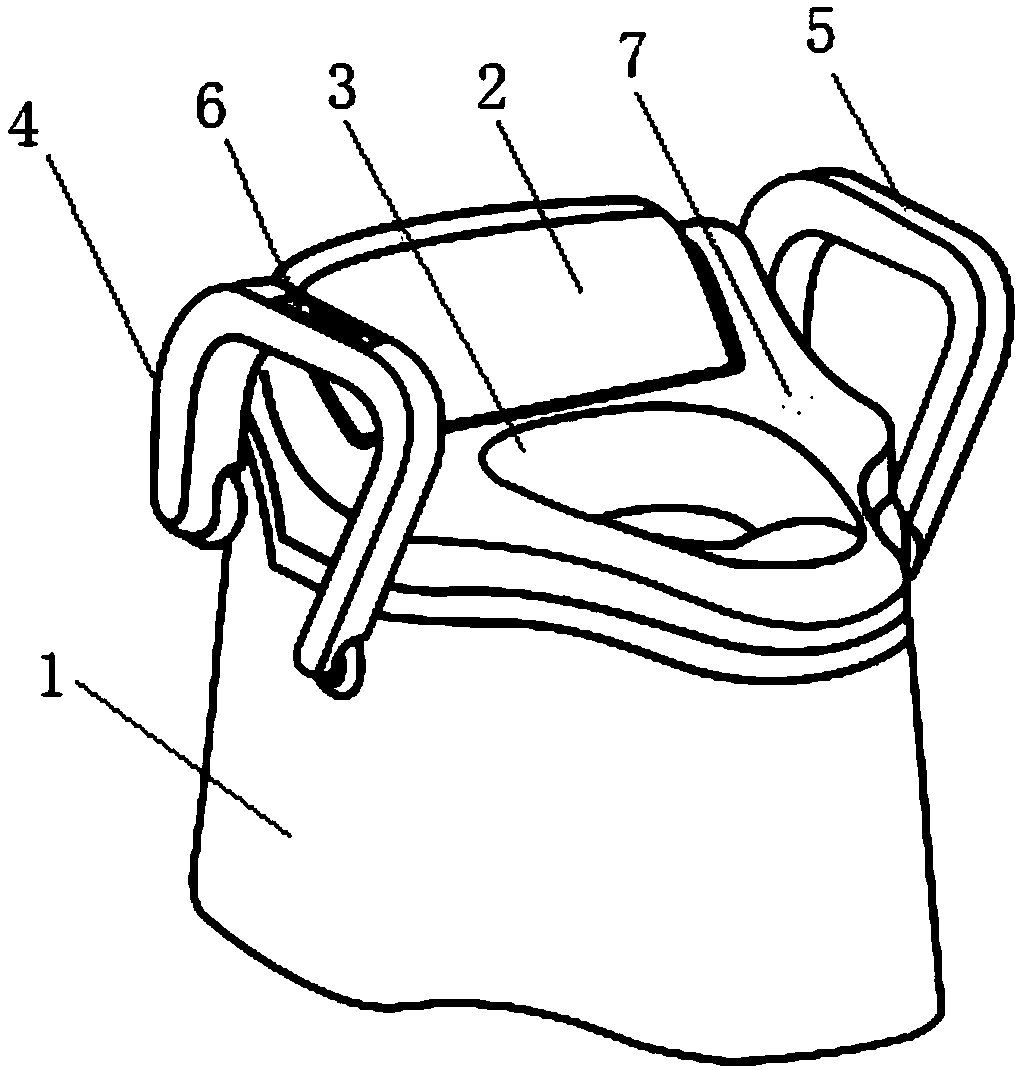

Portable smart seat type toilet for child

InactiveCN107713885ADesigned for convenience, while taking waterproof into accountTaking into account waterproofBathroom coversWater storageKey pressing

The invention discloses a portable smart seat type toilet for a child. The toilet comprises a main body shell; a backrest, a seat ring, a left handrail, a right handrail, a key pressing panel, a sitting induction sensor, a part for flushing an anus, a part for drying a hip and an ion deodorizing part. A seat ring heating component is connected with the seat ring; a water storage component comprises a water storage container and a water filling and discharging component for realizing water filling and discharging of the water storage container and is positioned inside the main body shell. The portable smart seat type toilet disclosed by the invention has the beneficial effects that as the size of the seat ring is adjusted and designed, and the design of the backrest and the handrails is added, the child more comfortably sits when defecating; through the design of taking and placing manners of an excrement holding device and an overall structure, after the child defecates, the treatmentof the excrement holding device and the placement after excrement holding device treatment are more convenient; as a special waterway that the water storage container fills and discharges water is designed, so that the adequacy of cleaning inside the container and the convenience during water replacement are significantly improved.

Owner:佛山市聪喜智能卫浴科技有限公司

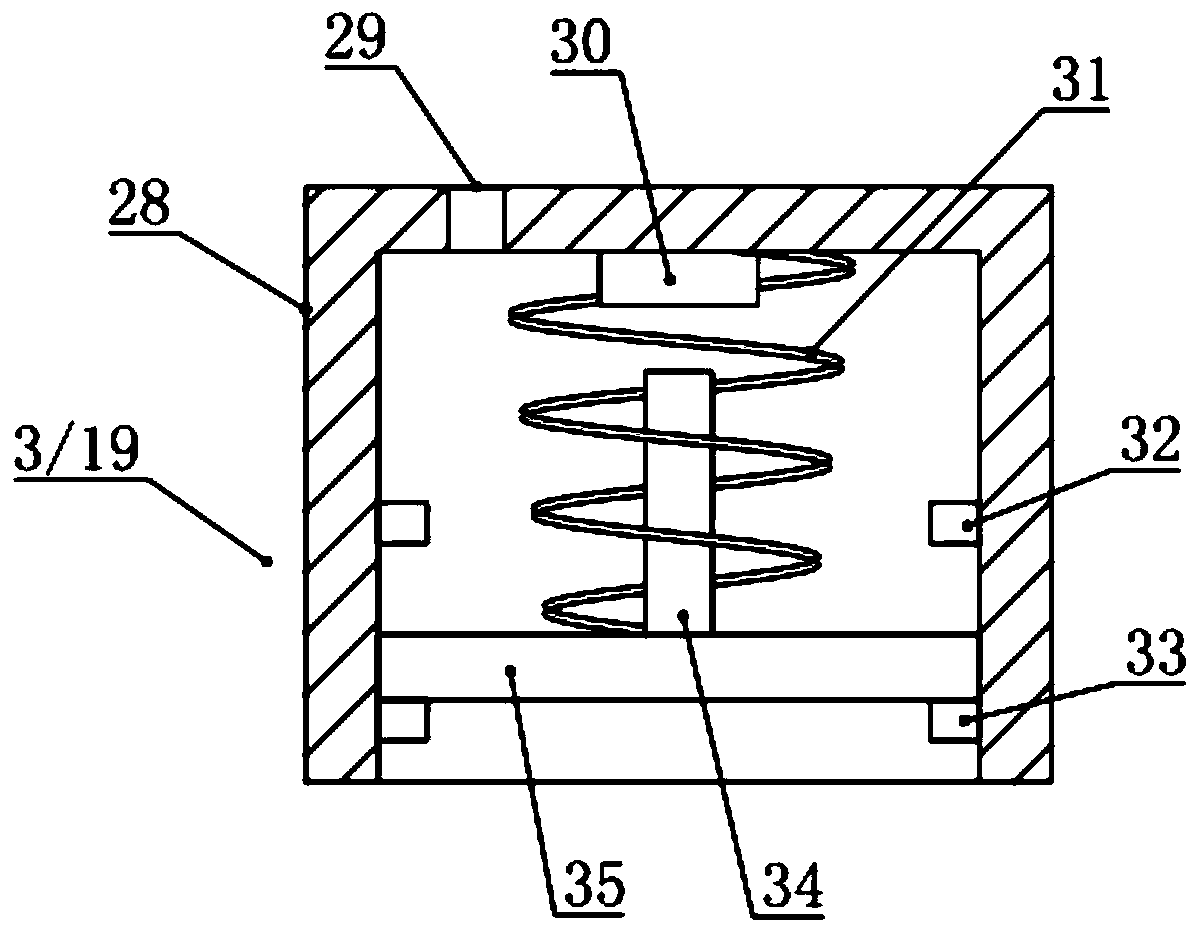

Double-layer backheating type micro-combustor

The invention provides a double-layer backheating type micro-combustor and belongs to the field of energy combustion and utilization. The double-layer backheating type micro-combustor comprises combustor walls, a transverse heat-conducting partition board, a longitudinal heat-conducting partition board, an air inlet and an air outlet. The combustor walls include the upper wall, the lower wall, the left wall, the right wall and the front wall. A rectangular through hole is formed in the right side of the front wall of the combustor. The transverse heat-conducting partition board and the longitudinal heat-conducting partition board are arranged in the combustor. According to the double-layer backheating type micro-combustor, the heat-conducting partition boards are arranged transversely and longitudinally, so that the internal space of the combustor is evenly divided into four areas; non-combusted gas is preheated both in the transverse direction and the longitudinal direction, and the energy utilization rate is remarkably increased; meanwhile, the space of the combustor is greatly utilized, the uniformity of the wall surface temperature is also improved. In addition, the detention time of mixed gas is greatly prolonged due to the fact that the mixed gas flow around the combustor three times, and accordingly the mixed gas is combusted more sufficiently, and more heat can be absorbed by the wall surfaces. The double-layer backheating design way has a positive effect on improving the output performance of a micro thermal photovoltaic system.

Owner:JIANGSU UNIV

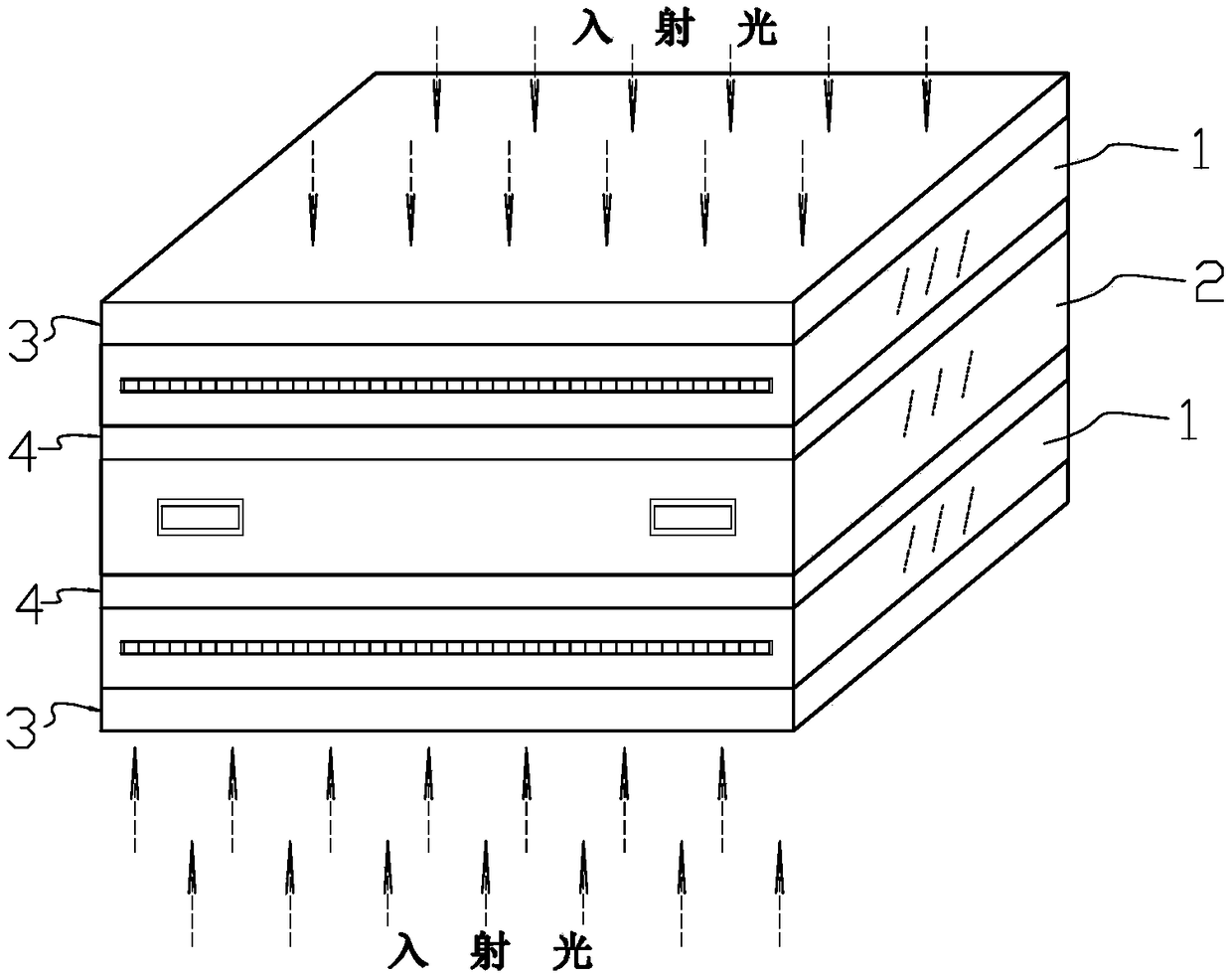

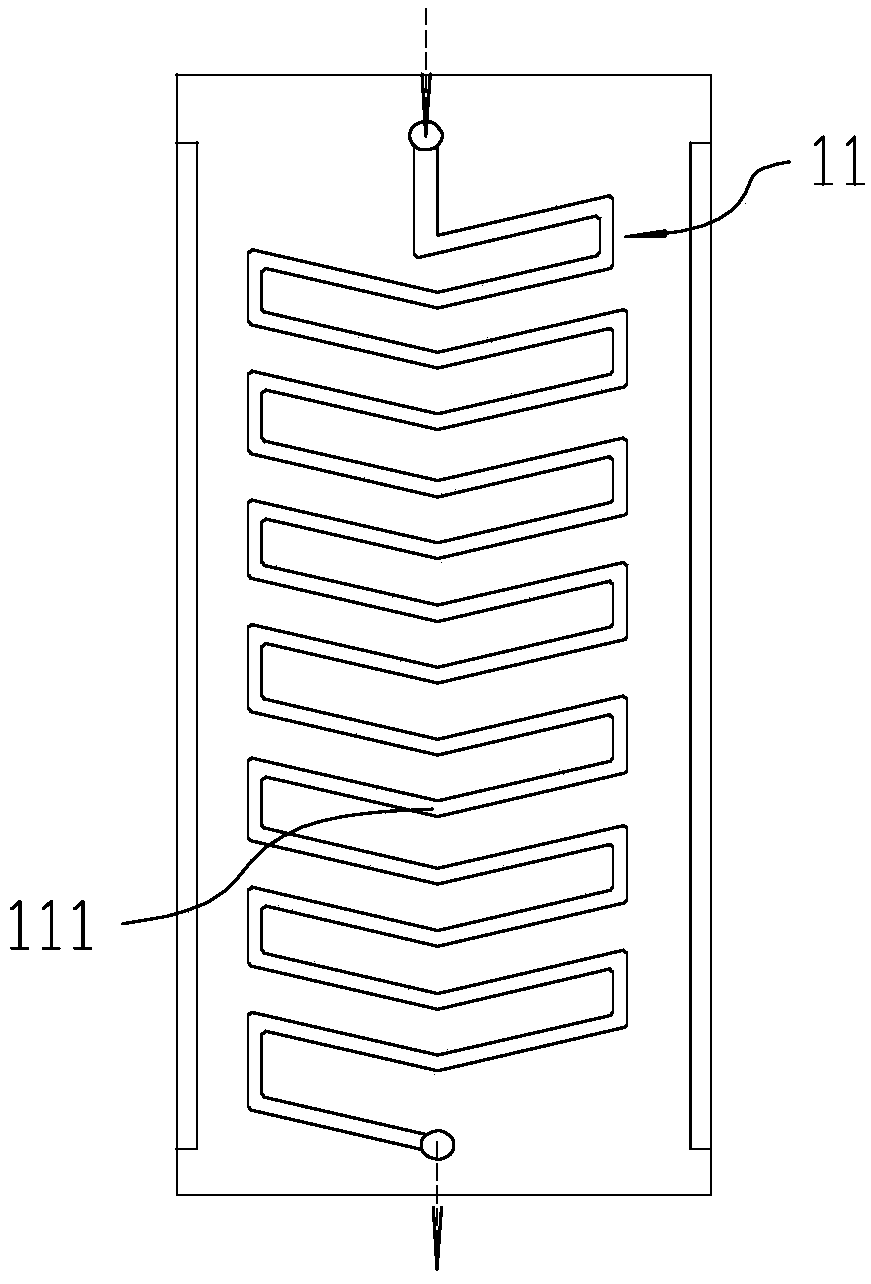

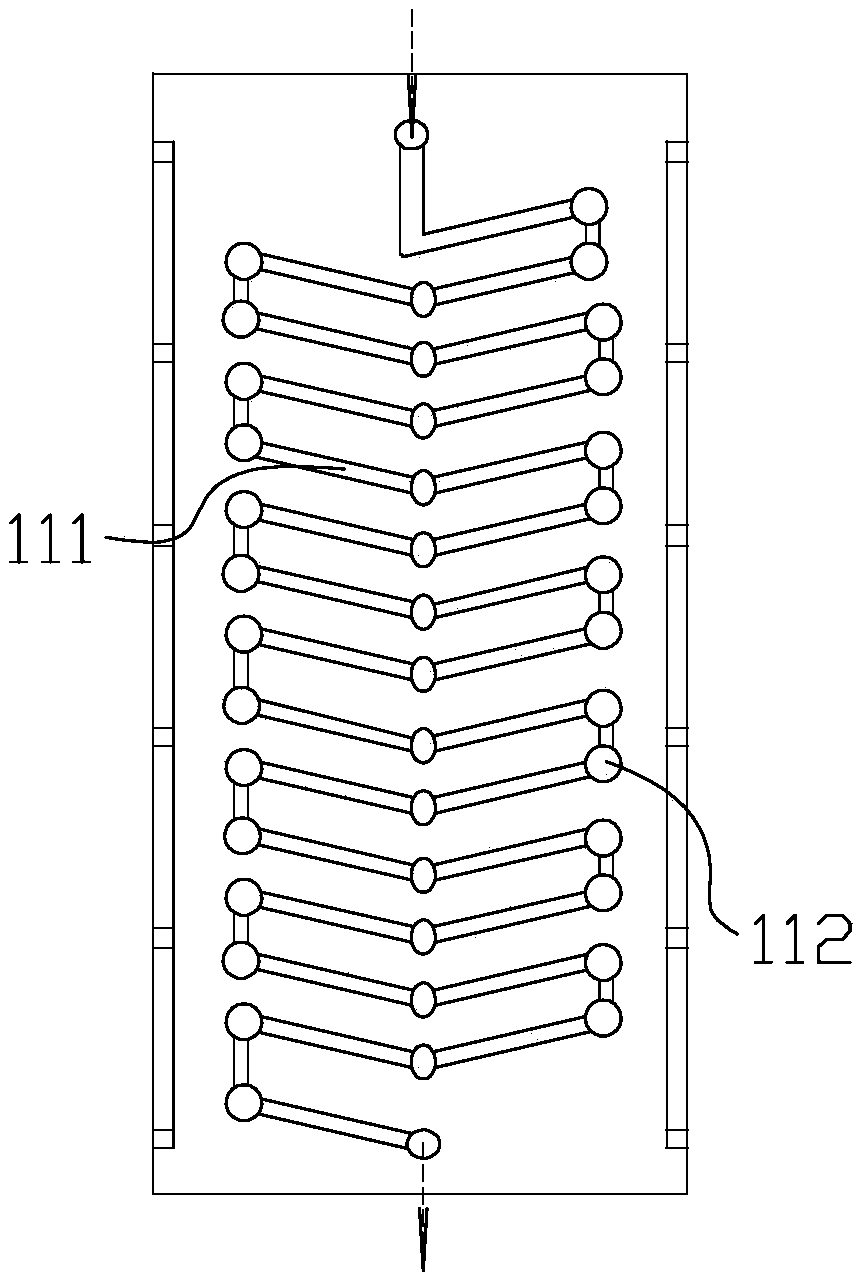

Continuous flow photochemical reaction module

PendingCN108686599AImprove heat transfer performanceImprove thermal conductivityEnergy based chemical/physical/physico-chemical processesChemical reactionConductive materials

The invention relates to a continuous flow photochemical reaction module which comprises three or four layers of wall bodies overlapped alternately up and down. In the four-layer wall body structure,wall bodies at the topmost layer and the lowermost layer are light-permeable glass plates, and wall bodies of two layers at the middle are heat conductive plates made of heat conductive materials. Cavities formed between the glass plates and the heat conductive plates are reaction liquid cavities, and a cavity formed between the two heat conductive plates is a heat transfer medium cavity. Incidentlight emitted by light sources arranged at the upper part and the lower part of the reaction module almost only needs to penetrate a layer of glass plate and can reach the reaction liquid cavities directly, so as to help to improve the utilization of light efficiency and improve the reaction efficiency. The inner sides of the reaction liquid cavities are the heat transfer medium cavity, the reaction liquid cavities and the heat transfer medium cavity are separated only by the heat conduction plates, heat generated by the reaction can be quickly transferred out and the heat conduction performance is improved. In the three-layer wall body structure, the upper layer is a glass plate, and at least one layer at the middle is a heat conductive plate. A reaction liquid cavity and a heat exchangecavity are formed from upper and lower at intervals.

Owner:SHANGHAI CAN YI BIOTECH

A thumbnail generation method and system

ActiveCN103902730BAdjustment and effectSave spaceGeometric image transformationSpecial data processing applicationsImaging processingThumbnail

The invention discloses a thumbnail generation method and system, which generates thumbnails by jointly using three image processing strategies of cropping, distortion, and scaling, taking advantage of different strategies and complementing each other to make important areas in the image It is accurately, completely and fully displayed in the thumbnails, and important information is maximized in the limited space of the thumbnails. The present invention realizes the above three image processing strategies through a unified optimization process with less time overhead.

Owner:INST OF AUTOMATION CHINESE ACAD OF SCI

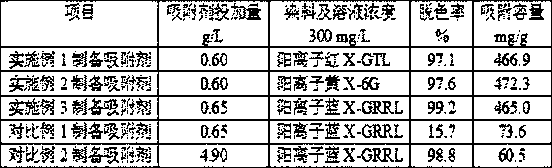

Method for improving adsorption capacity of adsorbent prepared from printing waste liquid extract

PendingCN109126703AHigh adsorption capacityIncrease profitOther chemical processesWater contaminantsLiquid wasteSorbent

The invention discloses a method for improving adsorption capacity of an adsorbent prepared from printing waste liquid extract. The method includes steps: (1) adding chemical substances capable of releasing hydrogen ions into printing waste liquid, and performing stirring reaction; (2) feeding an appropriate quantity of a chemical agent for generating tiny bubbles through reaction with the waste liquid; (3) continuing ultrasonic-assisted stirring and heating until the temperature is 0-20 DEG C higher than a softening point of a connection material; (4) stopping stirring, only keeping ultrasonic treatment, and keeping the temperature for a period of time; (5) after a block extract is completely contracted in volume, performing solid-liquid separation, and removing water; (6) adding saturated potassium hydroxide solution, and stopping ultrasonic treatment after the block extract completely absorbs potassium hydroxide; (7) taking out the block extract, cooling, crushing, and drying at a low temperature; (8) performing further carbonizing and activating for 1-4h under nitrogen protection, and crushing to obtain the adsorbent. By adoption of the method, adsorption capacity of the adsorbent prepared from the extract is improved, and the cationic dye adsorption capacity reaches 460mg / g or above.

Owner:QINGDAO UNIV

Water conservancy device with automatic information acquisition function

InactiveCN111285516AImprove processing effectImprovement and effectWater/sewage treatment by irradiationSpecific water treatment objectivesPhysicsWater treatment

The invention relates to the field of water conservancy equipment, and in particular, relates to a water conservancy device with an automatic information acquisition function, wherein the water conservancy device comprises a first-stage treatment chamber and a second-stage treatment chamber, a first treatment cavity is arranged in the first-stage treatment chamber, and a second treatment cavity and a third treatment cavity are respectively arranged at the upper part and the lower part of the inner side of the second-stage treatment chamber; a filter screen cylinder and a dirt scraping assemblyfor scraping dirt on the inner wall of the filter screen cylinder are mounted in the first treatment cavity; a dirt collecting pipe used for collecting settled dirt in the filter screen cylinder is arranged at the bottom of the first-stage treatment chamber, a medicine conveying assembly used for conveying a medicine to the lower end of the filter screen cylinder is further arranged on the second-stage treatment chamber, a filter screen plate is arranged in the second treatment cavity, an ultraviolet lamp tube is arranged at the top in the third treatment cavity, and a plugging assembly is further arranged in the third treatment cavity. The water conservancy device is thorough in water treatment effect, convenient to clean and maintain and high in automation degree.

Owner:NORTH CHINA UNIV OF WATER RESOURCES & ELECTRIC POWER

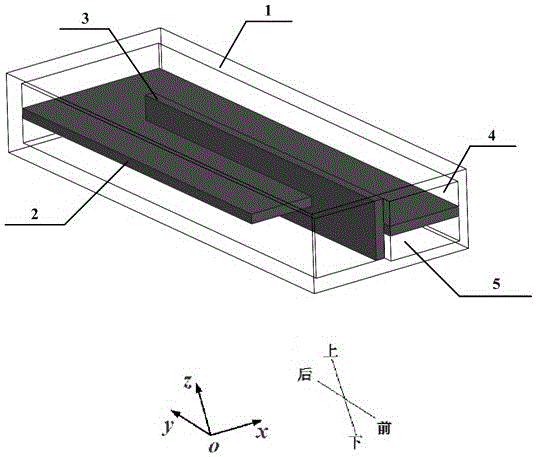

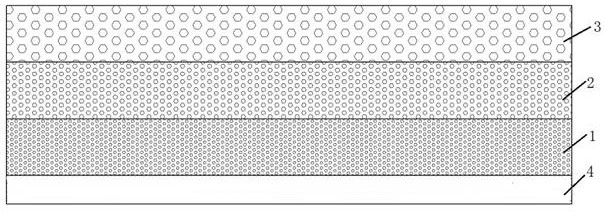

A layered gradient porous material sweat cooling structure and aircraft

ActiveCN112765913BNo change in trafficConstant supplyGeometric CADDesign optimisation/simulationPorosityFlight vehicle

The invention discloses a layered gradient porous material sweating cooling structure and an aircraft. The sweating cooling structure comprises N layers of porous material layers and a cooling cavity arranged on one side of the porous material layer. A coolant supply unit is arranged in the cooling cavity , the coolant supply unit is used to supply coolant to the cooling cavity, the porosity of the porous material layer decreases layer by layer along the direction close to the cooling cavity, wherein, N is an integer, N≥2. The invention solves the problems of uneven heat dissipation, poor heat protection effect, high cost and the like existing in the sweating cooling structure in the prior art.

Owner:CALCULATION AERODYNAMICS INST CHINA AERODYNAMICS RES & DEV CENT

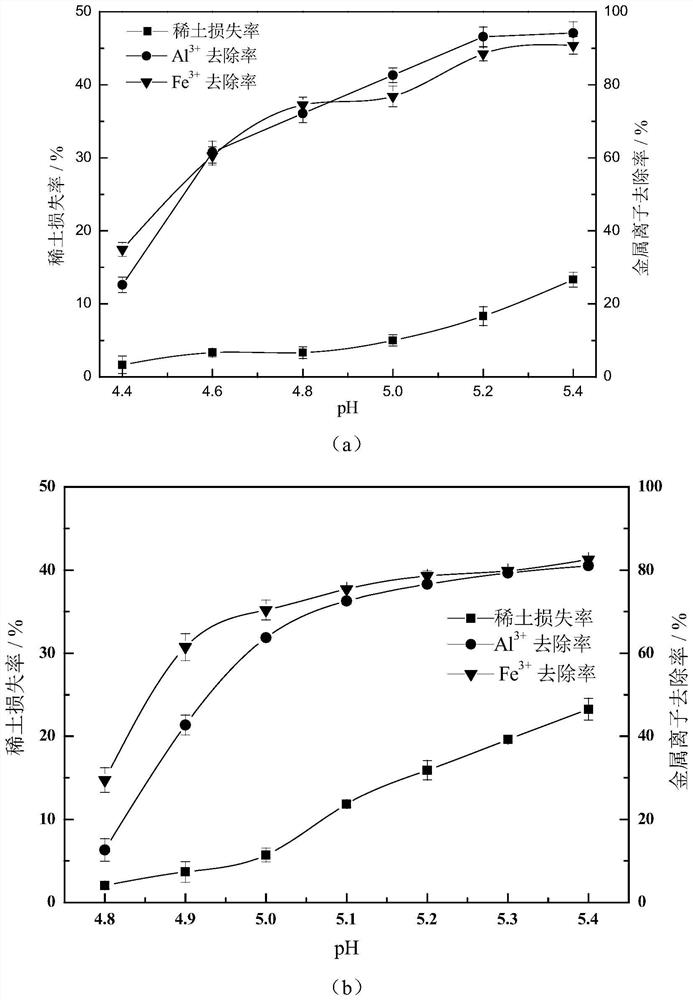

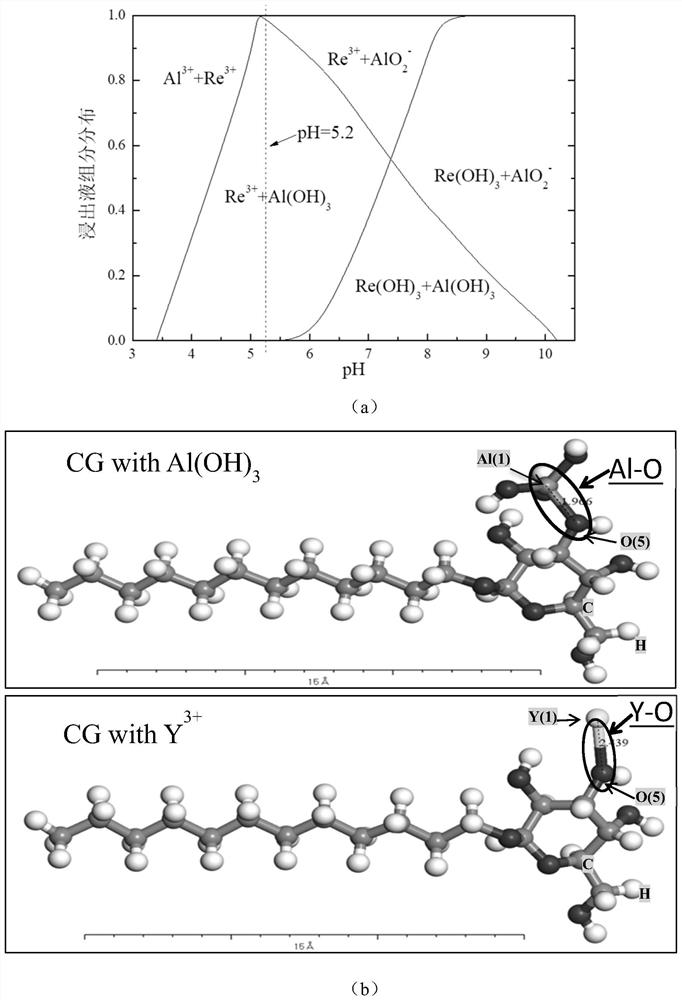

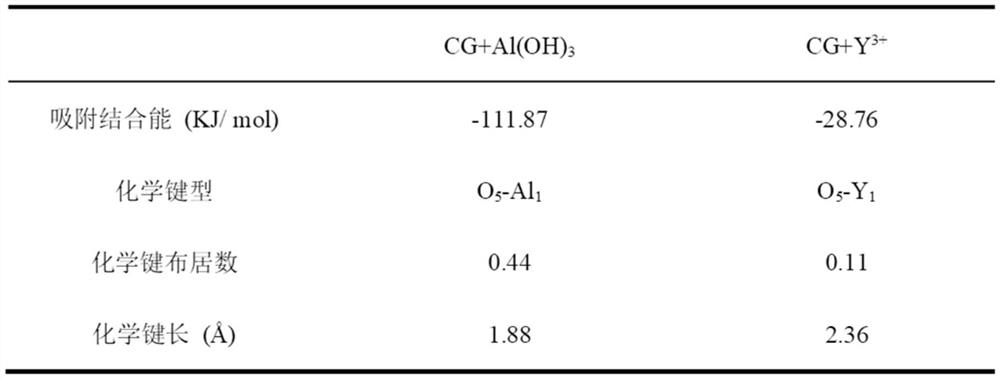

Method for purifying and removing impurities from ionic rare earth ore leachate

ActiveCN114107706AEfficient PurificationIncrease production capacityProcess efficiency improvementAmmoniacal nitrogenPregnant leach solution

The invention provides a method for purifying and removing impurities from ionic rare earth ore leachate. The method comprises the following steps: uniformly stirring and mixing the ionic rare earth ore leachate, adding coco-glucoside as an impurity removing agent to regulate and control the pH value of the leachate, and carrying out solid-liquid separation after complete reaction to obtain purified leachate and precipitation residues. By adopting the purification and impurity removal method disclosed by the invention, the problems of high impurity ion content, difficulty in removal, high rare earth loss rate in the impurity removal process, serious ammonia nitrogen pollution and the like in the rare earth leaching solution can be obviously solved, and the novel purification and impurity removal method for the rare earth leaching solution is safe, environment-friendly, low in impurity removal cost, high in purification efficiency, free of ammonia nitrogen pollution and low in rare earth loss rate; popularization and application are facilitated.

Owner:JIANGXI UNIV OF SCI & TECH

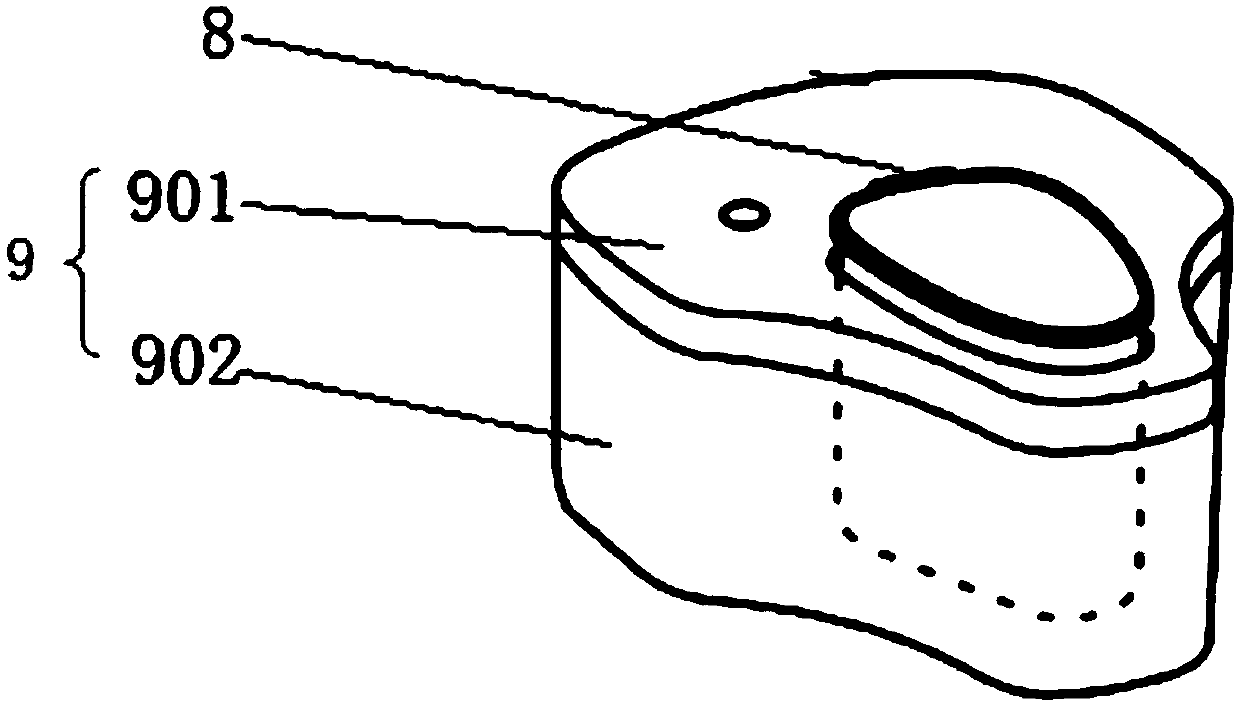

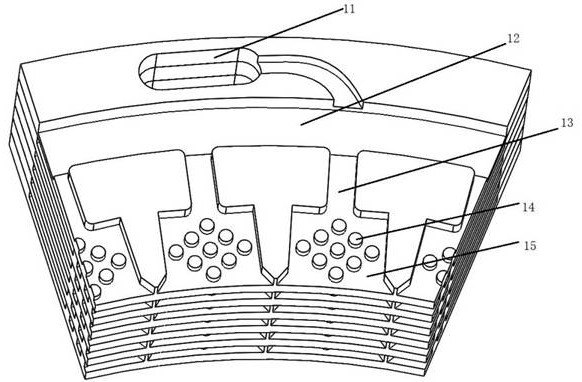

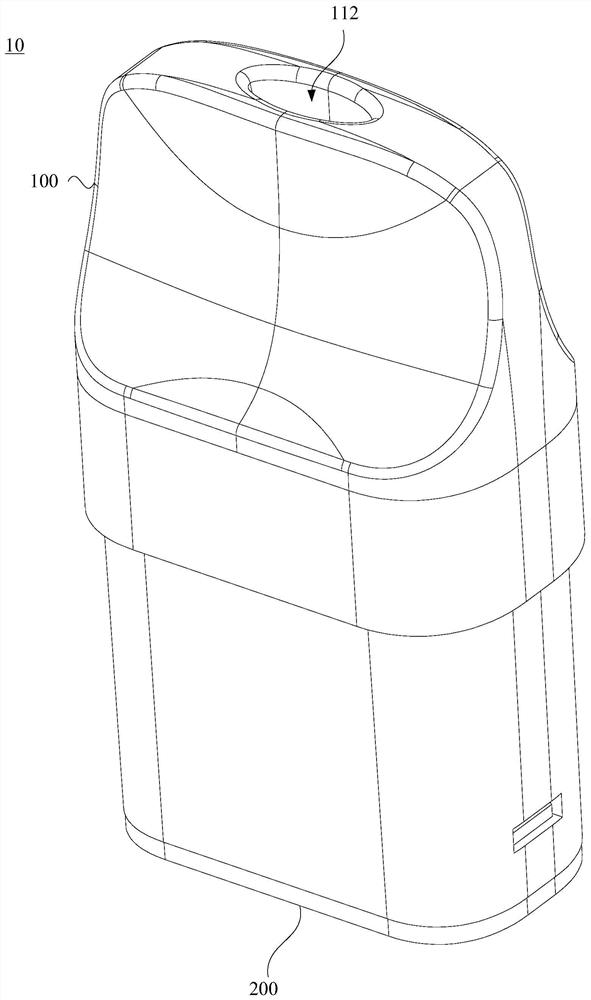

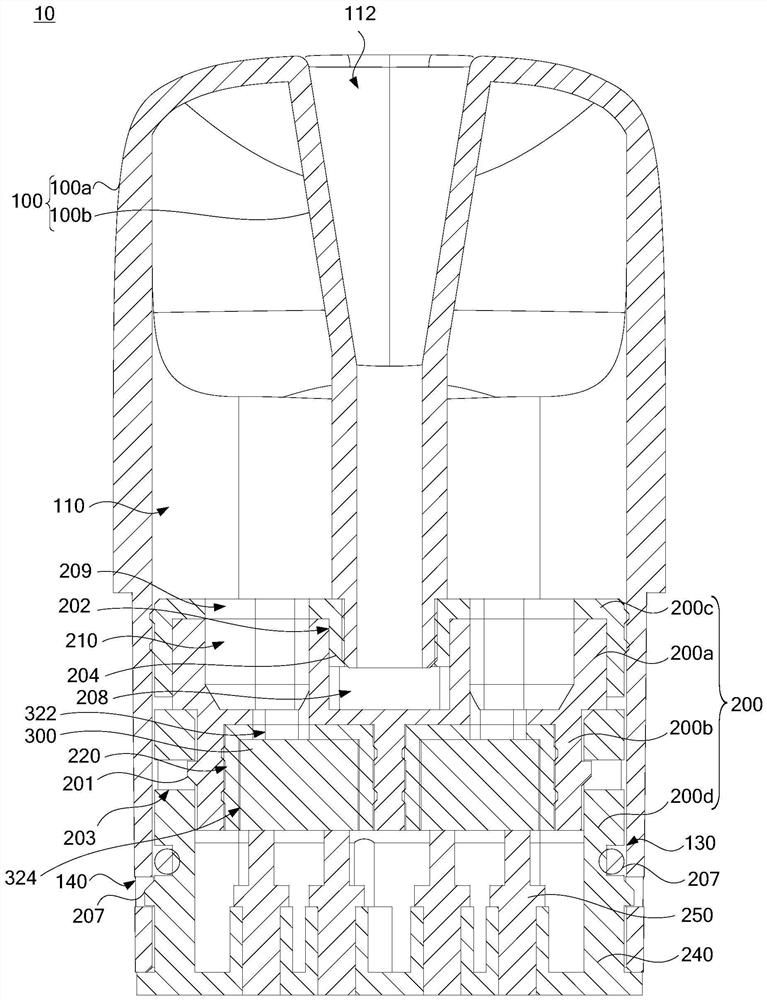

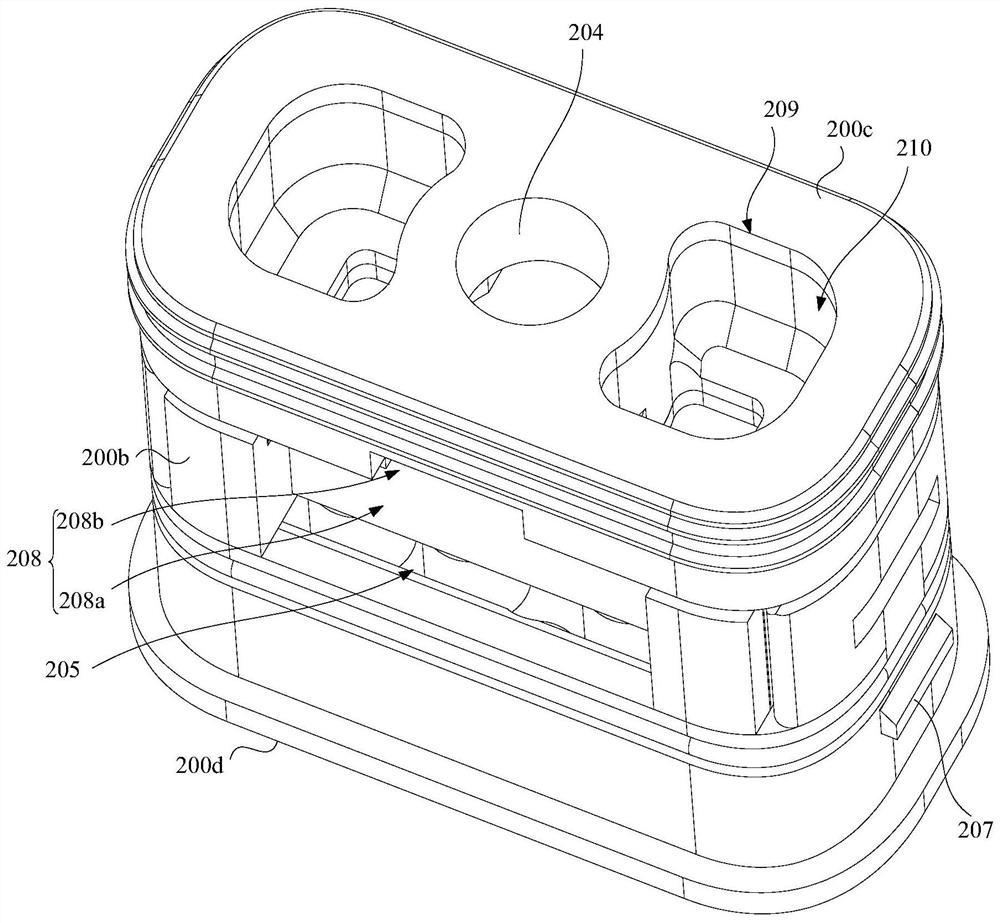

Atomizer and electronic atomization device

ActiveCN113100492AImprove heating atomization efficiencyImprove heating uniformityTobaccoAerosolizeMechanical engineering

The invention provides an atomizer and an electronic atomization device. The atomizer comprises an tar cup piece, a sealed atomization assembly and atomization cores, wherein an tar storage cavity is formed in the tar cup piece; the sealed atomization assembly is located in the tar storage cavity and connected with the tar cup piece in a sealed mode, the sealed atomization assembly is provided with two tar inlet holes and two atomization cavities, the two tar inlet holes communicate with the tar storage cavity, and the two atomization cavities communicate with the two tar inlet holes correspondingly; the number of the atomizing cores is two, and the two atomizing cores are arranged in the two atomizing cavities in a one-to-one correspondence mode. Due to the fact that the two tar inlet holes are communicated with the tar storage cavity, and the two atomization cavities are communicated with the two tar inlet holes respectively, tobacco tar in the tar storage cavity enters the correspondingly communicated atomization cavities through the tar inlet holes respectively, and due to the fact that the two atomization cores are arranged in the two atomization cavities in a one-to-one correspondence mode, the two atomizing cores can heat and atomize the tobacco tar in the corresponding atomizing cavities, and the heating and atomizing efficiency of the tobacco tar is improved.

Owner:SHENZHEN MASON VAP TECH CO LTD

Recovery processing technology for waste plastics

InactiveCN109181345AHigh strengthGood flexibilityOrganic detergent compounding agentsSurface-active detergent compositionsSocial benefitsEconomic benefits

The invention utilizes the quality, such as high strength, flexibility, abrasive resistance, oil resistivity, flatness and glossiness of the plastic grains produced by modifying waste plastics to achieve high integration of economic benefit, social benefit and environmental protection benefit. According to the invention, the collected waste plastics are cleaned with a cleaning fluid and a heatingand ultrasonic processor is utilized to clean the waste plastics, so that the cleaning fluid can fully act on the stains, greasy dirt, glues and the like on the waste plastics, and the cleaning effectis better; the crushed waste plastics are put into a freezing chamber for freezing and then are heated with hot air, so that the low temperature resistance of the regenerated materials can be promoted, the mechanical properties can be improved and the waste plastics are more easily molten; the energy is further saved when the modified additives are subsequently added for blending.

Owner:界首市绿环塑业有限公司

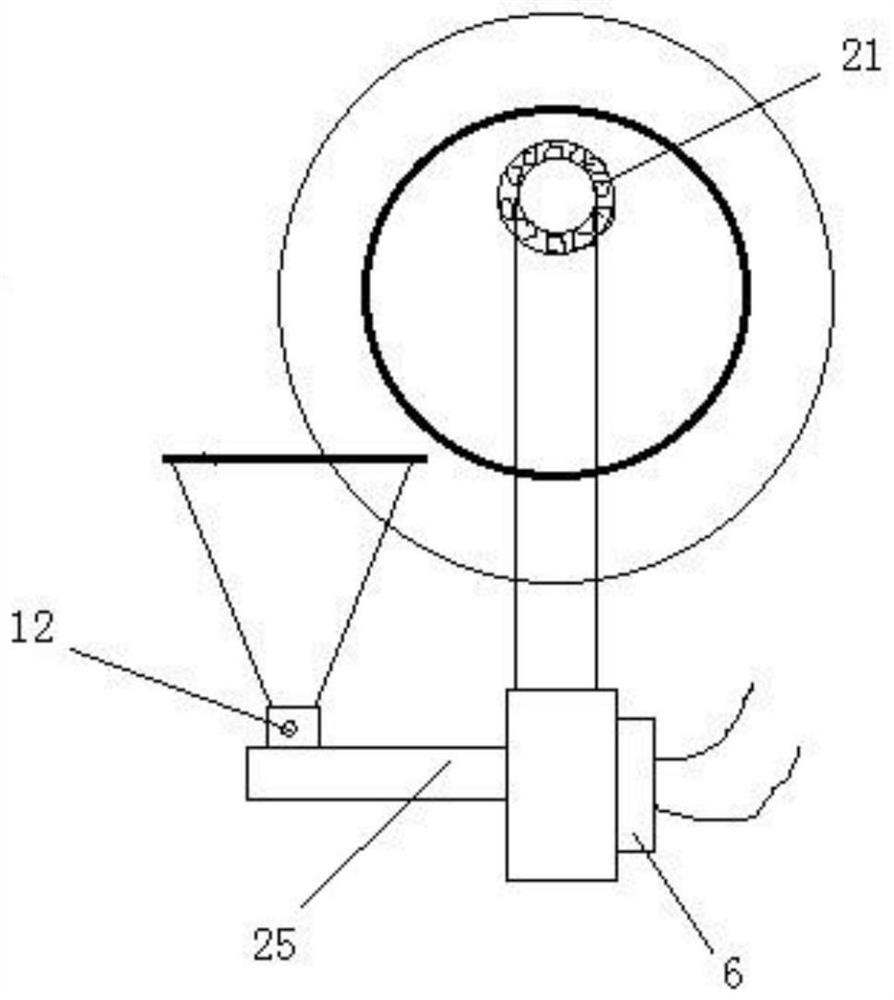

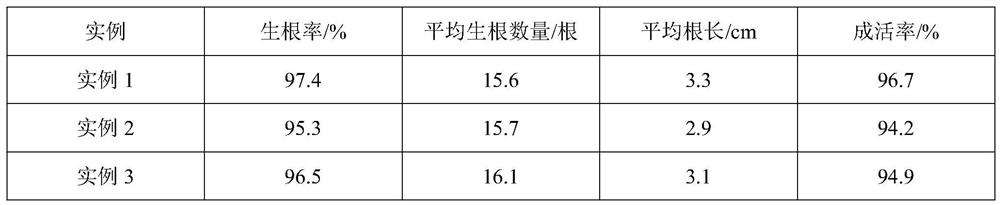

Mixing device for preparing atriplex canescens cultivation substrate and cultivation substrate

PendingCN112403340AImprove stirring efficiencyGood air permeabilityRotating receptacle mixersTransportation and packagingChemistryHumic acid

The invention discloses a mixing device for preparing an atriplex canescens cultivation substrate and the cultivation substrate, the device combines powder spraying, rolling and stirring, the stirringefficiency is improved, the mixing sufficiency is facilitated, and the uneven mixing caused by directly adding a small amount of powder into a large amount of basic substances is avoided. The cultivation substrate is prepared from the following raw materials in parts by weight: 30-90 parts of a humic acid mixture, 30-70 parts of peat, 40-80 parts of sand, 10-40 parts of vermiculite, 0.8-2.0 partsof chitin, 5-10 parts of polyacrylamide, 0.5-1.0 part of Pujuxitang, 0.1-0.5 part of a dispersing agent, 0.2-0.4 part of a wetting agent, 0.1-0.5 part of white carbon black and 1-3 parts of inorganiccarrier. The culture medium provided by the invention is mainly prepared from peat, sand, vermiculite and the like, is good in air permeability, strong in water retention capacity and rich in nutritional ingredients, and is beneficial to enhancing the autoimmunity of the atriplex canescens, reducing the infection of bacteria on the atriplex canescens, improving the survival rate of the atriplex canescens and promoting the growth of seedlings by combining the characteristics of nano chitin, methanesulphonamide and Pujuxitang. And a good foundation is laid for cutting seedling of the atriplex canescens.

Owner:廖志强

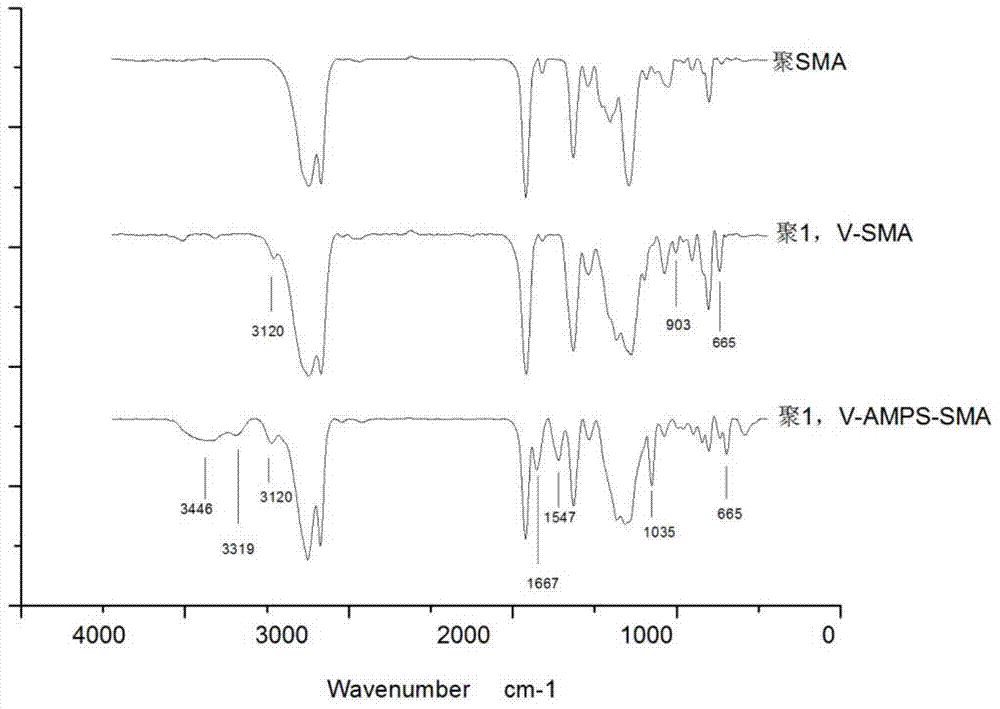

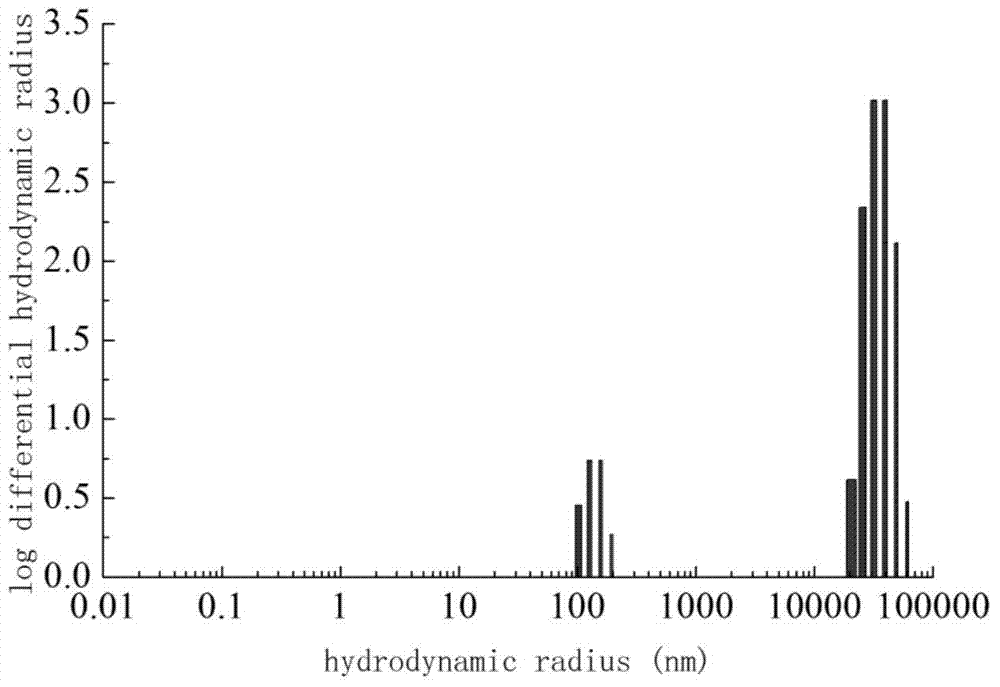

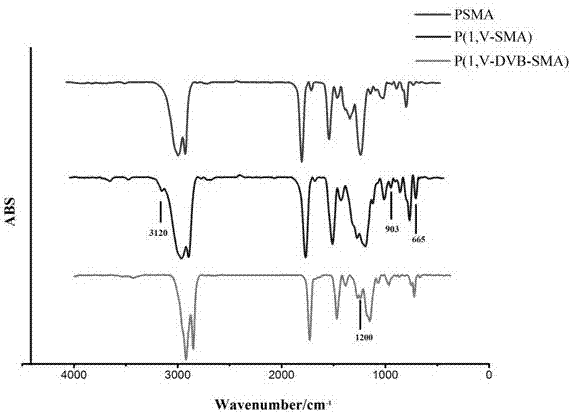

High-wax thickened oil cross-linked polymer nanometer material pour point depressant and preparation method thereof

ActiveCN106986966AImprove pour point depressing effectNot easy to decomposeDrilling compositionCross-linkWax

The invention discloses a method for preparing a high-wax thickened oil cross-linked polymer nanometer material pour point depressant and belongs to the field of preparation of high polymer nanoscale materials. The material comprises poly(vinyl imidazole-divinyl benzene-methylacrylic acid high carbon ester). The preparation method comprises the following steps: (1) preparing the poly(vinyl imidazole-divinyl benzene-methylacrylic acid high carbon ester); (2) treating a reaction solution of poly(vinyl imidazole-divinyl benzene-methylacrylic acid high carbon ester), so as to obtain the poly(vinyl imidazole-divinyl benzene-methylacrylic acid high carbon ester) powder. The nanometer pour point depressant disclosed by the invention is excellent in pour point depressing effect, low in cost, simple in production and clean and pollution-free in process, and the product is easy to obtain, transport and preserve. According to the experiment, the nanometer pour point depressant disclosed by the invention has the net pour point depressing amplitude of 10 DEG C on the high-wax thickened oil in Daqing Dandong station, and has the pour point depressing effect (net pour point depressing of 5 DEG C) superior to that of commercially available EVA (Ethylene-Vinyl Acetate).

Owner:山东蓝城分析测试有限公司

A steam box and a method for adjusting the temperature and humidity of paper

The invention discloses a steam box and a method of adjusting temperature and humidity of paper. A preheating chamber is arranged outside the steam box; the preheating chamber is connected to an upstream pipeline of a steam manifold through a preheating branch pipe; the steam box comprises a constant current region and a regulation region along an advance direction of the paper in sequence, and a perforated plate is arranged at the bottoms of the constant current region and the regulation region; a downstream pipeline of the stream manifold is divided into a branch pipe of the constant current region and a branch pipe of the regulation region; the constant current region is an independent constant current chamber, and the constant current chamber is communicated with the branch pipe of the constant current region through a constant current branch pipe; the regulation region is divided into a plurality of independent regulation chambers through partition boards and is communicated with the branch pipe of the regulation region through a regulation branch pipe; the constant current region and the regulation region are combined, the caliber of the branch pipe of the constant current region is greater than the caliber of the branch pipe of the regulation region, the stream flow of the regulation region is small, so that the size of a branch pipe control valve is reduced; the length of the regulation region is greater than that of the constant current region so as to be beneficial for full action of the steam and the paper, thereby increasing the utilization efficiency of the stream; the stream overflow is reduced, and the environment of manufacturing the paper with pulp is preferably protected.

Owner:SOUTH CHINA UNIV OF TECH

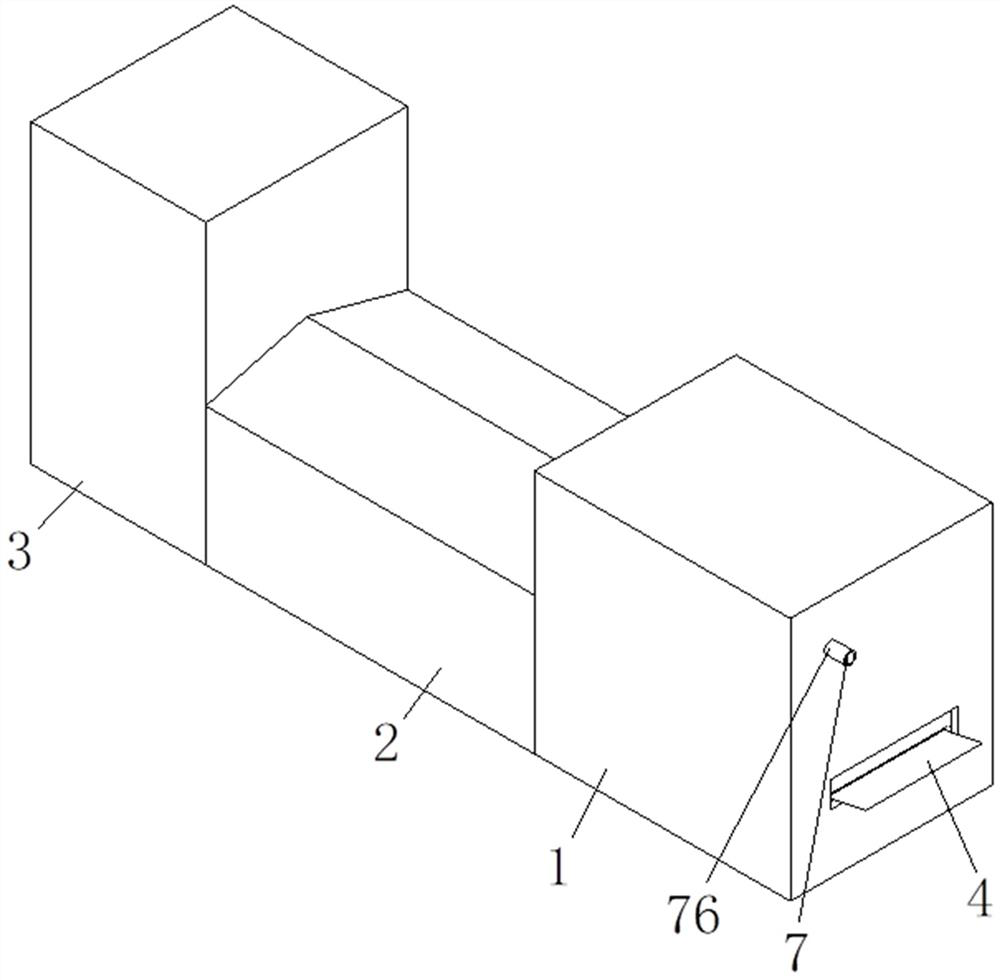

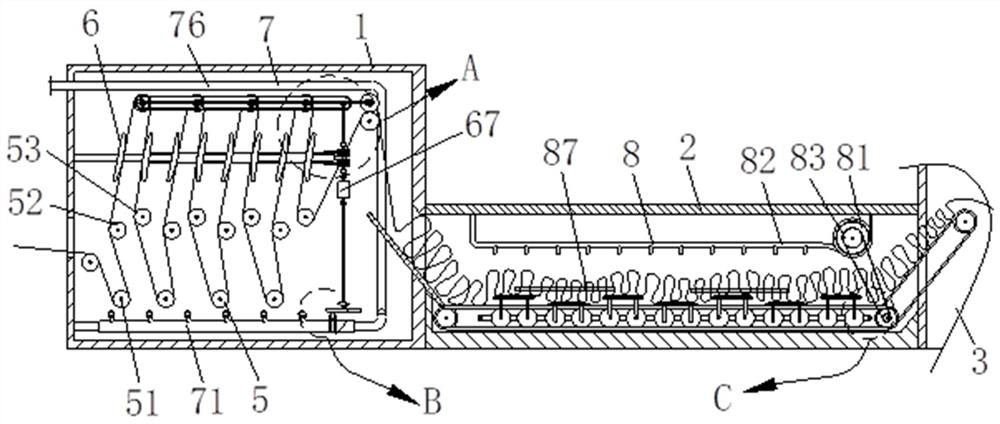

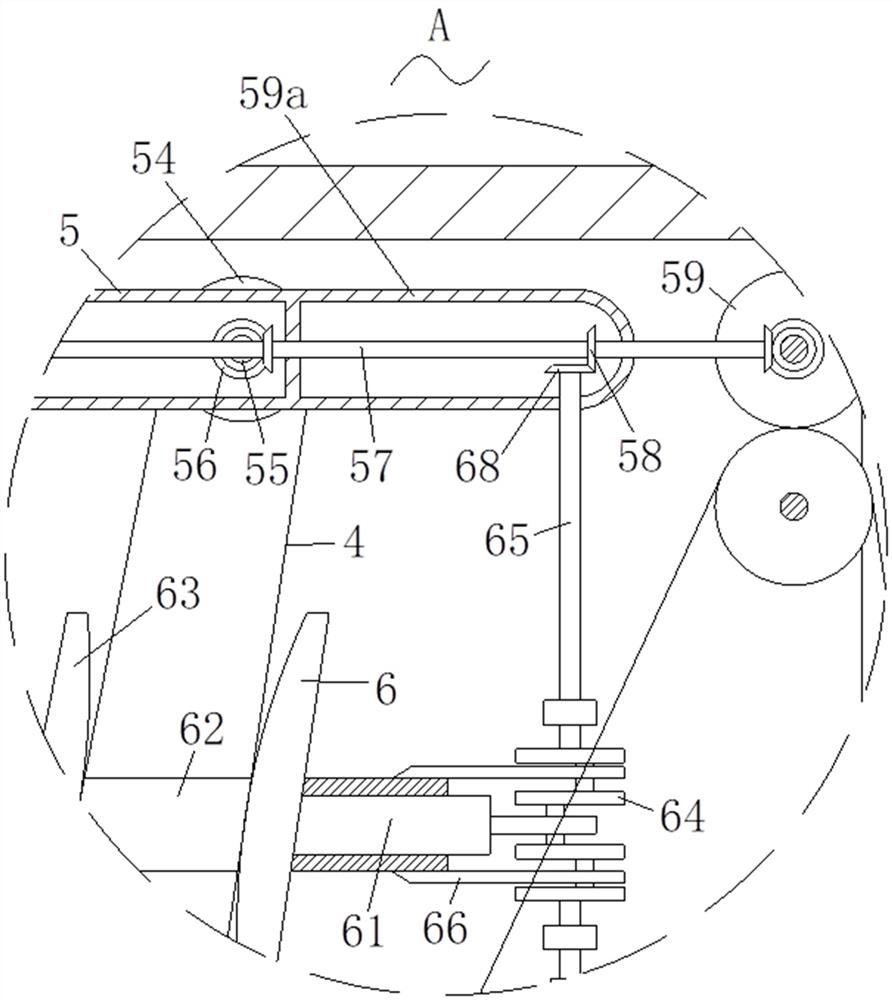

Knitting open-width continuous ultrasonic boiling system and method

PendingCN114657735AGuaranteed tensionAdjustable tensionSucessive textile treatmentsLiquid/gas/vapor treatment machines driving mechanismsEngineeringMechanical engineering

The invention relates to the technical field of knitwear treatment equipment, in particular to a knitting open-width continuous ultrasonic scouring system which comprises a pretreatment box, a tail treatment box is arranged on one side of the pretreatment box, a scouring box is connected between the pretreatment box and the tail treatment box, a conveying mechanism is arranged in the pretreatment box, and a loosening mechanism is arranged at the bottom end of the conveying mechanism. A heating mechanism is arranged at the bottom end of the relaxation mechanism; through the arrangement of the conveying mechanism, the staying time of the cloth in the pretreatment box can be prolonged, and more redundant treatment time is provided for the relaxation mechanism and the heating mechanism; by arranging the loosening mechanism, the knitted fabric can be conveyed without tension, and the cloth seal and gram weight of the finished cloth are guaranteed; through the arrangement of the boiling mechanism and the wriggling mechanism, the wriggling effect is simulated while the knitted fabric is conveyed, the chemical reaction effect between liquid and the fabric is better, the reaction can be more effectively promoted in cooperation with the ultrasonic assembly, and the quality of the finished fabric is improved.

Owner:山东华盛创新纺织科技有限公司

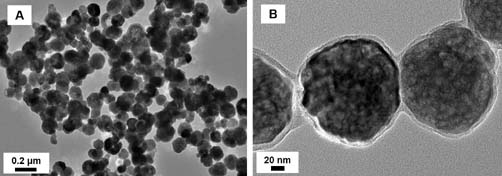

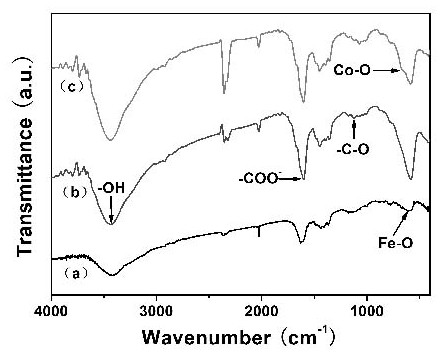

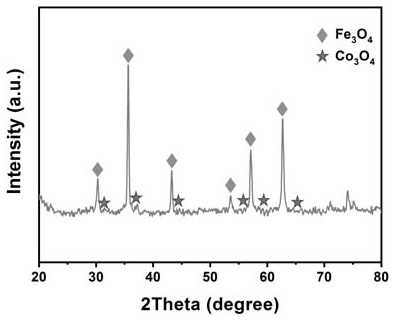

A shell-core magnetic microsphere and its extraction method for clenbuterol in mutton

ActiveCN108889284BEasy extractionEnables selective extractionOther chemical processesPreparing sample for investigationLean meatFluid phase

The invention discloses a magnetic nano-microsphere with a shell-core structure and a method for extracting clenbuterol from mutton, wherein the magnetic nano-microsphere is Fe 3 o 4 @C@Co 3 o 4 , the present invention is based on the magnetic solid-phase extraction technology, using the magnetic nano-microspheres as the adsorbent to extract the clenbuterol in the mutton, and realizes the selective enrichment of the clenbuterol in the mutton sample to be tested, It can significantly improve the sensitivity of high performance liquid chromatography (equipped with ultraviolet detector) to detect clenbuterol in mutton.

Owner:JILIN INST OF CHEM TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com