Mixing device for preparing atriplex canescens cultivation substrate and cultivation substrate

A technology of a Tribulus terrestris and a mixing device, which is applied in the field of agriculture and forestry cultivation, can solve the problems of less research on cultivation substrates of Tribulus terrestris, and achieve the advantages of improving autoimmunity and defense response, increasing autoimmunity, and improving stirring efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

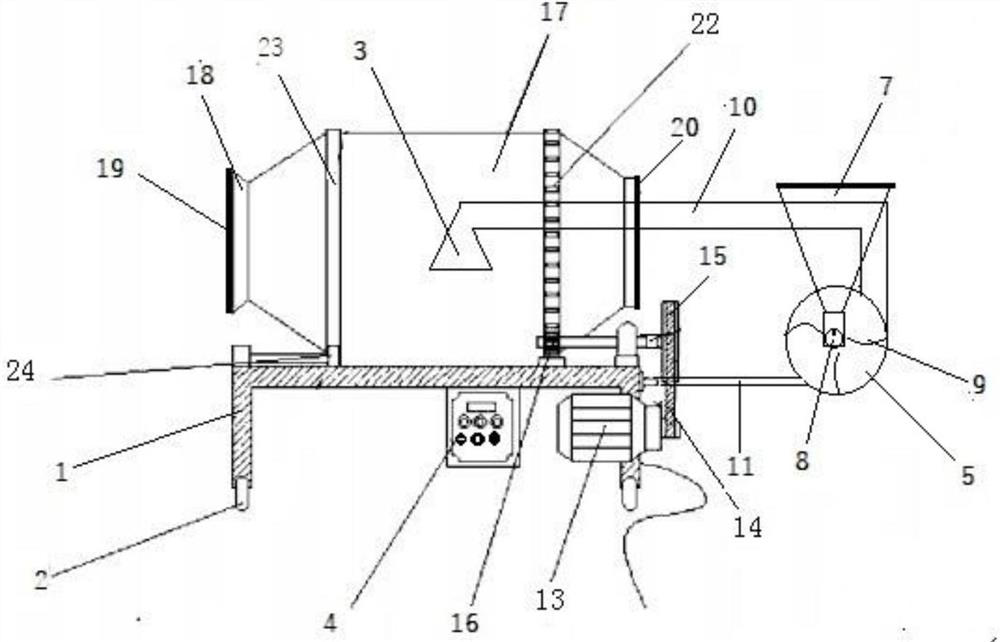

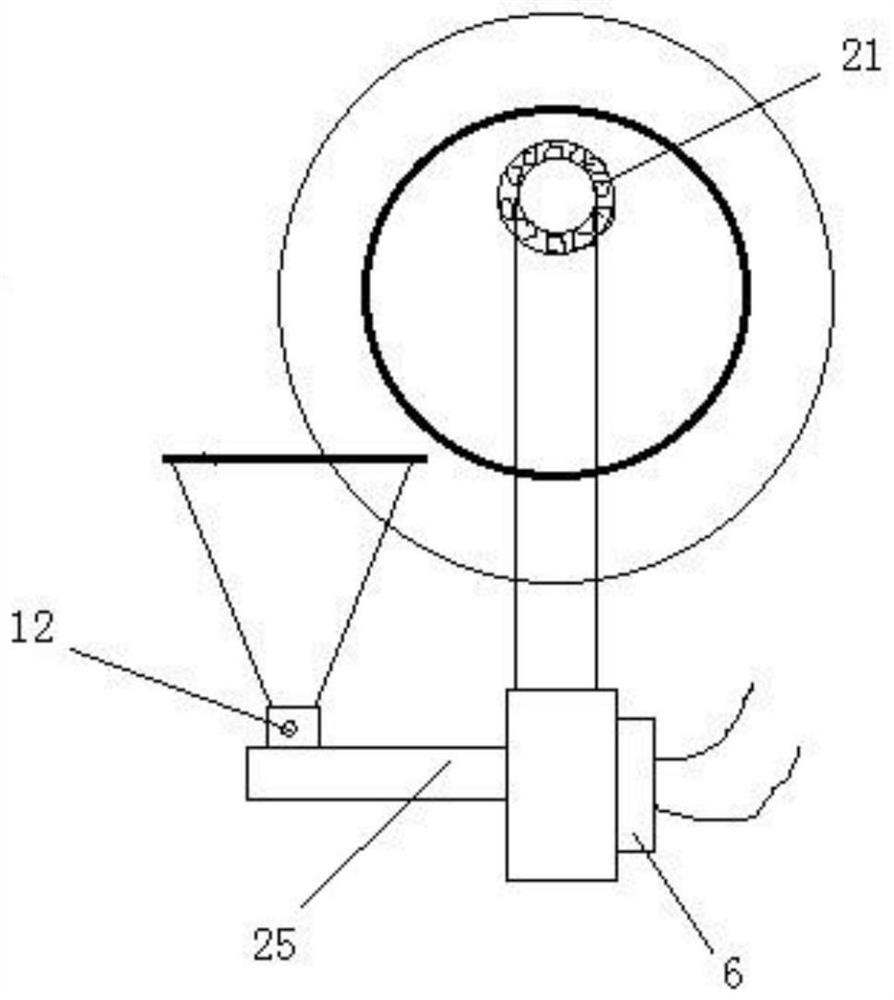

Method used

Image

Examples

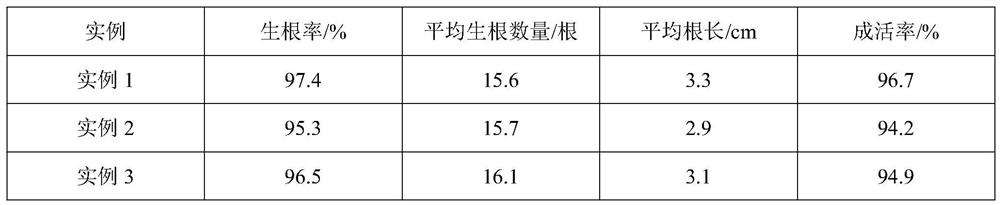

Embodiment 1

[0033]A four-winged cattail cultivation substrate, including the following raw materials in parts by weight: 40 parts of humic acid mixture, 45 parts of peat, 40 parts of sand, 20 parts of vermiculite, 1.0 parts of nano-chitin, 6 parts of polyacrylamide, 0.8 parts of dextran, 0.01 parts of mesyclobutanil, 0.3 parts of sodium lignosulfonate dispersant, 0.3 parts of sodium dodecyl naphthalene sulfonate wetting agent, 0.3 parts of white carbon black and 1.5 parts of diatomaceous earth . The humic acid mixture is a mixture of potassium humate, ammonium humate, iron urea humate, zinc humate and magnesium humate with a mass ratio of 10:15:7:0.5:0.5.

[0034] Its preparation method comprises the following steps:

[0035] S1: Weigh the dextran, dispersant, wetting agent, and inorganic carrier according to the formula, mix them evenly, and then mix them evenly after jet crushing, and pass through a 300-mesh sieve to obtain the mother powder;

[0036] S2: Weigh white carbon black and ...

Embodiment 2

[0040] A four-winged cattail cultivation substrate, comprising the following raw materials in parts by weight: 50 parts of humic acid mixture, 35 parts of peat, 45 parts of sand, 25 parts of vermiculite, 1.2 parts of nano-chitin, 5 parts of polyacrylamide, 0.6 parts of dextran, 0.03 parts of mesycloconazole, 0.2 parts of sodium lignosulfonate dispersant, 0.4 parts of sodium lauryl sulfate wetting agent, 0.3 parts of white carbon black and 2.0 parts of kaolin. The humic acid mixture is a mixture of potassium humate, ammonium humate, iron urea humate, zinc humate and magnesium humate with a mass ratio of 10:15:7:0.5:0.5.

[0041] Its preparation method comprises the following steps:

[0042] S1: Weigh the dextran, dispersant, wetting agent, and inorganic carrier according to the formula, mix them evenly, and then mix them evenly after jet crushing, and pass through a 300-mesh sieve to obtain the mother powder;

[0043] S2: Weigh white carbon black and nano-chitin, mix and absor...

Embodiment 3

[0047] A four-winged cattail cultivation substrate, comprising the following raw materials in parts by weight: 60 parts of humic acid mixture, 45 parts of peat, 50 parts of sand, 30 parts of vermiculite, 1.5 parts of nano-chitin, 8 parts of polyacrylamide, 0.7 parts of dextran, 0.02 parts of mesylconazole, 0.4 parts of calcium lignosulfonate dispersant, 0.2 parts of sodium lauryl sulfate wetting agent, 0.15 parts of white carbon black and 3.0 parts of bentonite. The humic acid mixture is a mixture of potassium humate, ammonium humate, iron urea humate, zinc humate and magnesium humate with a mass ratio of 10:15:7:0.5:0.5.

[0048] Its preparation method comprises the following steps:

[0049] S1: Weigh the dextran, dispersant, wetting agent, and inorganic carrier according to the formula, mix them evenly, and then mix them evenly after jet crushing, and pass through a 300-mesh sieve to obtain the mother powder;

[0050] S2: Weigh white carbon black and nano-chitin, mix and ab...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com