Method for purifying and removing impurities from ionic rare earth ore leachate

An ionic rare earth ore, purification and impurity removal technology, which is applied in the field of beneficiation and smelting, can solve the problems of low purification and impurity removal efficiency, low rare earth loss rate, and high rare earth loss rate, so as to promote full effect, enhance dispersion force, and strengthen purification and removal. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

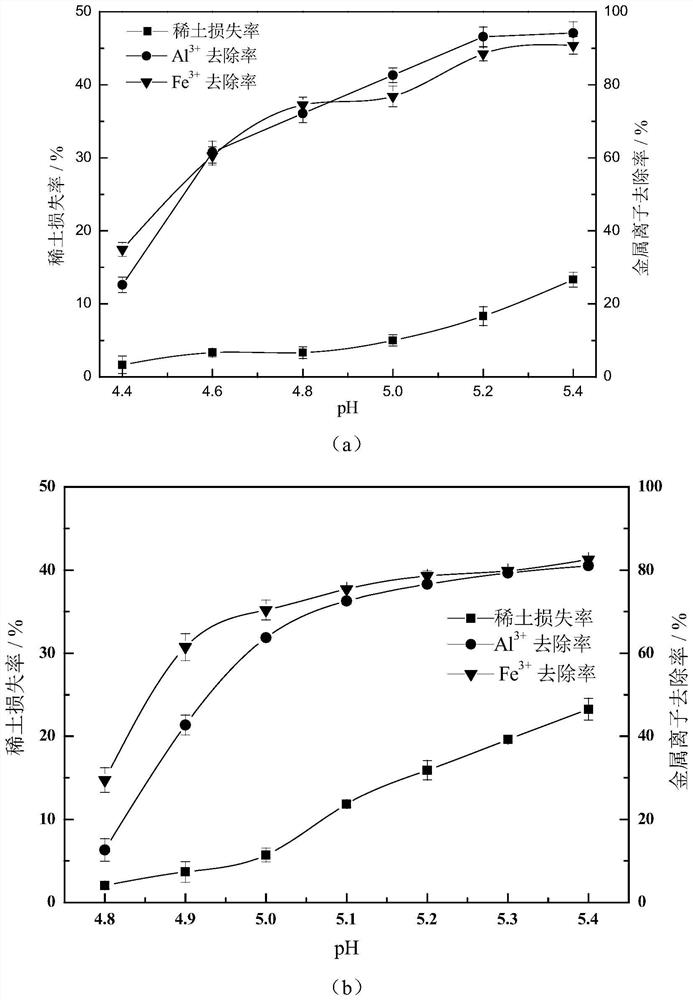

[0033] The leachate of ionic rare earth ore used in the impurity removal test comes from a rare earth mine in Xunwu, Ganzhou City, Jiangxi Province. The total amount of rare earth ions in the leachate is 685.43 mg / L, and the impurity Al 3+ The content is 235.58mg / L, impurity Fe 3+ The content is 56.72mg / L. The impurity Al in the leaching solution obtained by the traditional impurity removal process 3+ The removal rate is 86.32%, Fe 3+ The removal rate is 81.28%, and the loss rate of rare earth in sedimentation residue is 8.74%.

[0034] Adopt the method for purifying and removing impurities of a kind of ionic rare earth ore leachate of the present invention to carry out impurity removal, the impurity removal process comprises adding cocoyl glucoside as impurity remover, and its impurity removal step is:

[0035] (1) Mix and stir the ionic rare earth ore leaching solution in a beaker, and the stirring intensity is 200r / min;

[0036] (2) Add 50% of the liquid-phase impurity-...

Embodiment 2

[0040]The ionic rare earth ore leachate used in the impurity removal test comes from a rare earth mine in Xunwu, Ganzhou City, Jiangxi Province. The total amount of rare earth ions in the leachate is 648.26mg / L, the content of impurity aluminum ions is 214.45mg / L, and the content of impurity iron ions is 48.66mg / L. The impurity Al in the leaching solution obtained by the traditional impurity removal process 3+ The removal rate is 88.53%, Fe 3+ The removal rate was 84.31%, and the rare earth loss rate in the sedimentation residue was 7.15%.

[0041] Adopt the method for purifying and removing impurities of a kind of ionic rare earth ore leachate of the present invention to carry out impurity removal, the impurity removal process comprises adding cocoyl glucoside as impurity remover, and its impurity removal step is:

[0042] (1) Mix and stir the ionic rare earth ore leaching solution in a beaker, and the stirring intensity is 300r / min;

[0043] (2) Add 55% liquid-phase impu...

Embodiment 3

[0047] The ionic rare earth ore leachate used in the impurity removal test comes from a rare earth mine in Xunwu, Ganzhou City, Jiangxi Province. The total amount of rare earth ions in the leachate is 672.48mg / L, the content of impurity aluminum ions is 232.76mg / L, and the content of impurity iron ions is 52.15mg / L. The impurity Al in the leaching solution obtained by the traditional impurity removal process 3+ The removal rate is 85.26%, Fe 3+ The removal rate is 83.15%, and the loss rate of rare earth in sedimentation residue is 8.27%.

[0048] Adopt the method for purifying and removing impurities of a kind of ionic rare earth ore leachate of the present invention to carry out impurity removal, the impurity removal process comprises adding cocoyl glucoside as impurity remover, and its impurity removal step is:

[0049] (1) Mix and stir the ionic rare earth ore leaching solution in a beaker, and the stirring intensity is 200r / min;

[0050] (2) Add 60% of the liquid-phase...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com