Device and method for surface modification of micro-nano particles

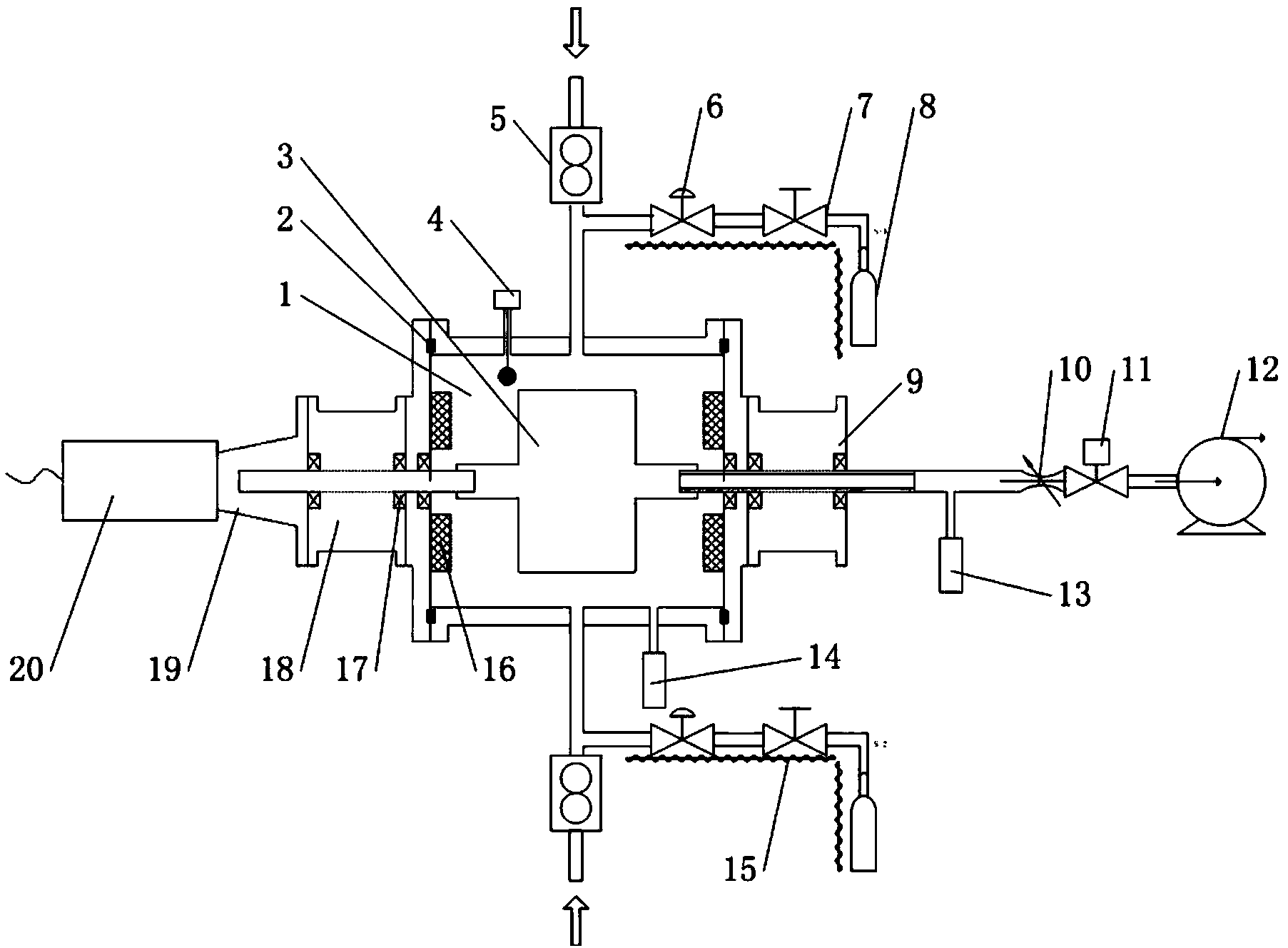

A technology of micro-nano particles and surface modification, which is applied in the direction of nanotechnology, nanotechnology, nanotechnology, etc. for materials and surface science. It can solve the problem that the advantages of high uniformity of atomic layer deposition cannot be fully utilized and the precursors are not fully utilized. , Powder particles are difficult to disperse and other problems, to achieve the effect of promoting sufficient and uniform adsorption, improving deposition uniformity and adequacy, and increasing the area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0082] For AlH with a particle size of 50 μm 3 The particle surface is coated with a layer of 10nm thick Al 2 o 3 Thin film to reduce its impact sensitivity and improve safety. Select trimethylaluminum (TMA) and water (H 2 O) is a precursor, its main anti The response equation is:

[0083] (A)AlOH * +Al(CH 3 ) 3 →AlOAl(CH 3 ) 2 * +CH 4

[0084] (B)AlCH 3 * +H 2 O→AlOH * +CH 4

[0085] Using the above-mentioned micro-nanoparticle surface modification device and the corresponding pressure-packed deposition process method:

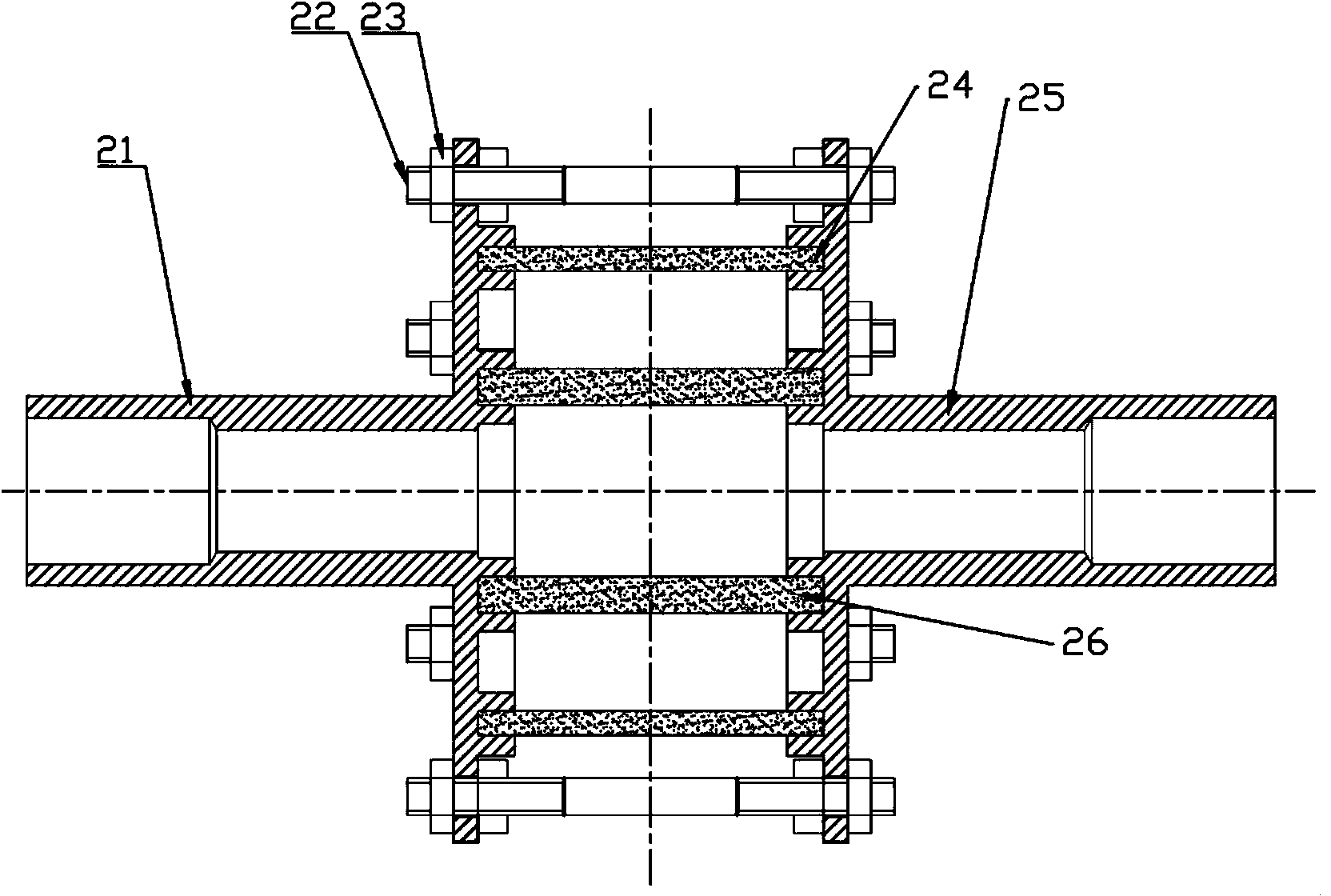

[0086] 0.1g AlH 3 Put the particles into the powder particle loading device and install it in the reaction chamber, and connect it with the magnetic fluid sealing device. The reaction chamber is then sealed.

[0087] Turn on the vacuum pump, open the solenoid valve and the throttle valve to connect the reaction chamber with the vacuum pump, and pump the pressure of the reaction chamber to less than or equal to 1pa. Heat the reaction c...

Embodiment 2

[0091] For SiO with a particle size of 200nm 2 The particle surface is coated with a layer of 5nm thick Al 2 o 3 thin films to study SiO 2 The surface structure of the particles. Select trimethylaluminum (TMA) and water (H 2 17 O) is the precursor.

[0092] Using the above-mentioned micro-nano particle surface modification device and the corresponding equilibrium dispersion deposition process method:

[0093] SiO 2 Put the particles into the powder particle loading device and install it in the reaction chamber, and connect it with the magnetic fluid sealing device. The reaction chamber is then sealed.

[0094] Turn on the vacuum pump, open the solenoid valve and the throttle valve to connect the reaction chamber with the vacuum pump, and pump the pressure of the reaction chamber to less than or equal to 1pa. Heating the reaction chamber to stabilize the internal temperature at 200°C, and heating the precursor steel cylinder, precursor branch pipeline, and precursor qu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com