Recovery processing technology for waste plastics

A technology for waste plastics and processing technology, applied in the direction of plastic recycling, recycling technology, detergent composition, etc., can solve the problems of poor performance of plastic particles, difficult to remove, etc., to enhance environmental protection performance, increase cleaning effect, and enhance strength. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

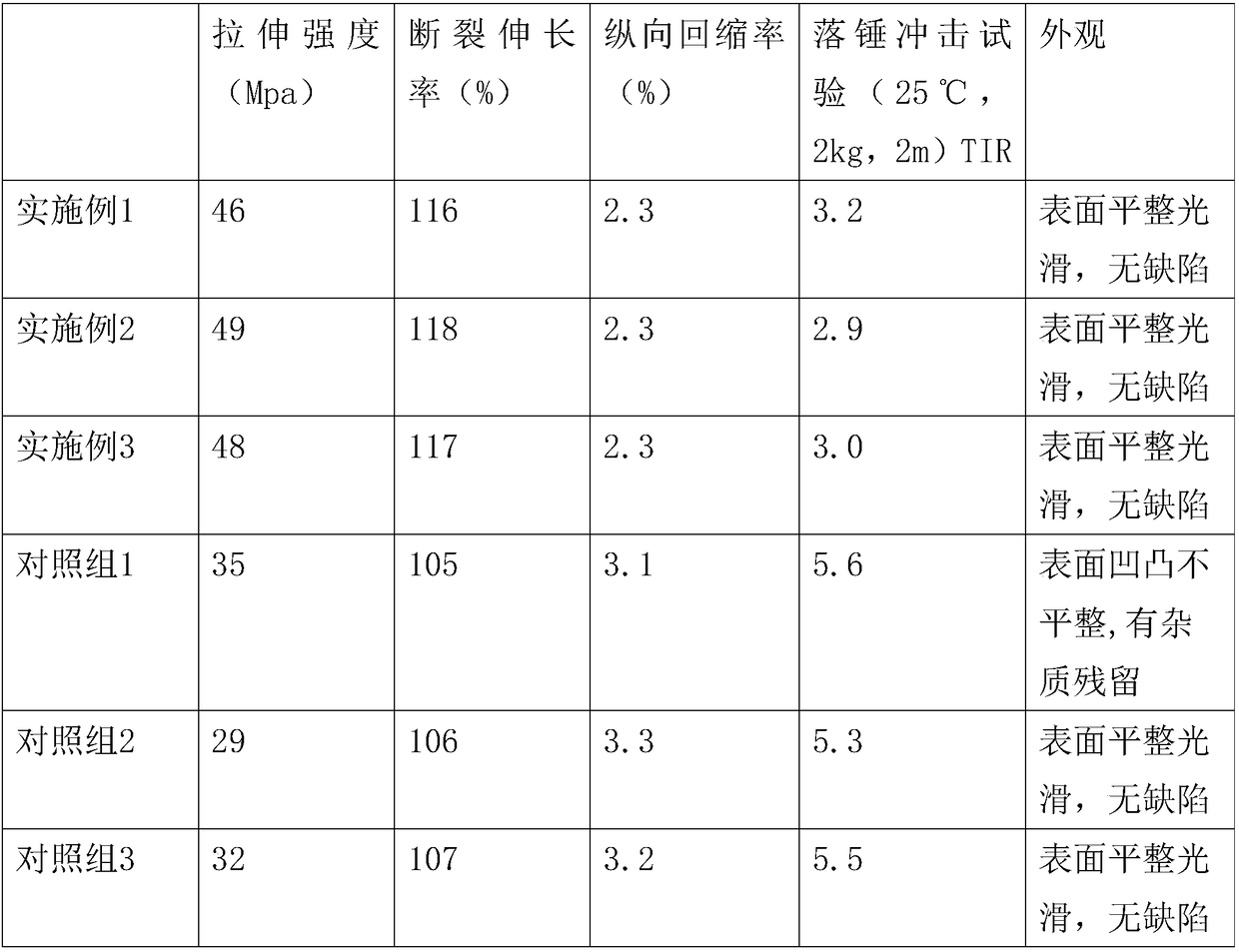

Examples

Embodiment 1

[0031] A process for recycling waste plastics, characterized in that the process steps are as follows:

[0032] (1) Put the collected waste plastics into the cleaning solution, and heat the cleaning solution to 60 degrees, and then clean it with an ultrasonic processor with a frequency of 20KHZ and a power of 900W, and the cleaning time is 20 minutes;

[0033] (2) Spray and rinse the cleaned waste plastics with clear water during the transmission process;

[0034] (3) Dry the rinsed plastic with cold air, and crush the dried plastic into plastic particles of 0.5 cm square;

[0035] (4) Put the crushed plastic particles into the freezer for freezing treatment, and the freezing time is 20 minutes;

[0036] (5) Bake the frozen plastic particles with 120°C hot air for 10 minutes;

[0037] (6) Put the plastic granules processed in step 5 into a high-speed mixer, add modified additives, and knead, the kneading temperature is 180 degrees, and the kneading time is 20 minutes;

[00...

Embodiment 2

[0050] A process for recycling waste plastics, characterized in that the process steps are as follows:

[0051] (1) Put the collected waste plastics into the cleaning solution, heat the cleaning solution to 70 degrees, and then clean it with an ultrasonic processor with a frequency of 20KHZ and a power of 900W, and the cleaning time is 30 minutes;

[0052] (2) Spray and rinse the cleaned waste plastics with clear water during the transmission process;

[0053] (3) Dry the rinsed plastic with cold air, and crush the dried plastic into plastic particles of 0.8 cm square;

[0054] (4) Put the crushed plastic particles into the freezer for freezing treatment, and the freezing time is 40 minutes;

[0055] (5) Bake the frozen plastic particles with 120°C hot air for 15 minutes;

[0056] (6) Put the plastic granules processed in step 5 into a high-speed mixer, add modified additives, and knead, the kneading temperature is 200 degrees, and the kneading time is 30 minutes;

[0057] ...

Embodiment 3

[0069] A process for recycling waste plastics, characterized in that the process steps are as follows:

[0070] (1) Put the collected waste plastics into the cleaning solution, heat the cleaning solution to 80 degrees, and then clean it with an ultrasonic processor with a frequency of 20KHZ and a power of 900W, and the cleaning time is 40 minutes;

[0071] (2) Spray and rinse the cleaned waste plastics with clear water during the transmission process;

[0072] (3) Dry the rinsed plastic with cold air, and crush the dried plastic into 1cm square plastic particles;

[0073] (4) Put the crushed plastic particles into the freezer for freezing treatment, and the freezing time is 50 minutes;

[0074] (5) Dry the frozen plastic particles with 120°C hot air for 20 minutes;

[0075] (6) Put the plastic granules processed in step 5 into a high-speed mixer, add modified additives, and knead. The kneading temperature is 220 degrees, and the kneading time is 40 minutes;

[0076] (7) Put...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com