Fertilizer-type biodegradable mulching film and preparation method thereof

A biodegradable and biodegradable plastic technology is applied in the field of fertilizer-type biodegradable plastic film and its preparation, which can solve the problems that the function of temperature increase and moisture preservation does not meet the needs of crop growth, increase the processing cost, and be difficult to practical application, etc. Conducive to recycling and improving the effect of application value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

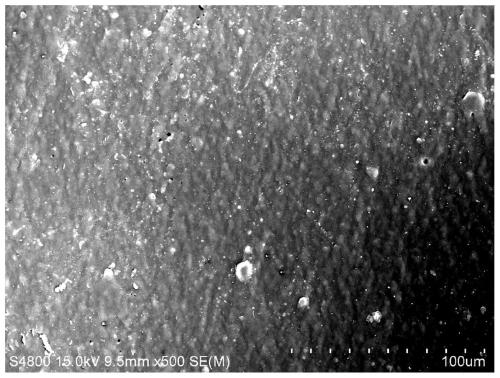

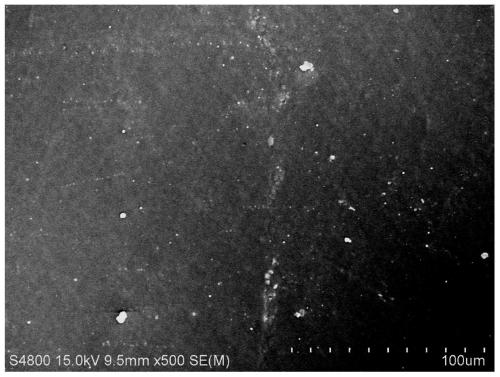

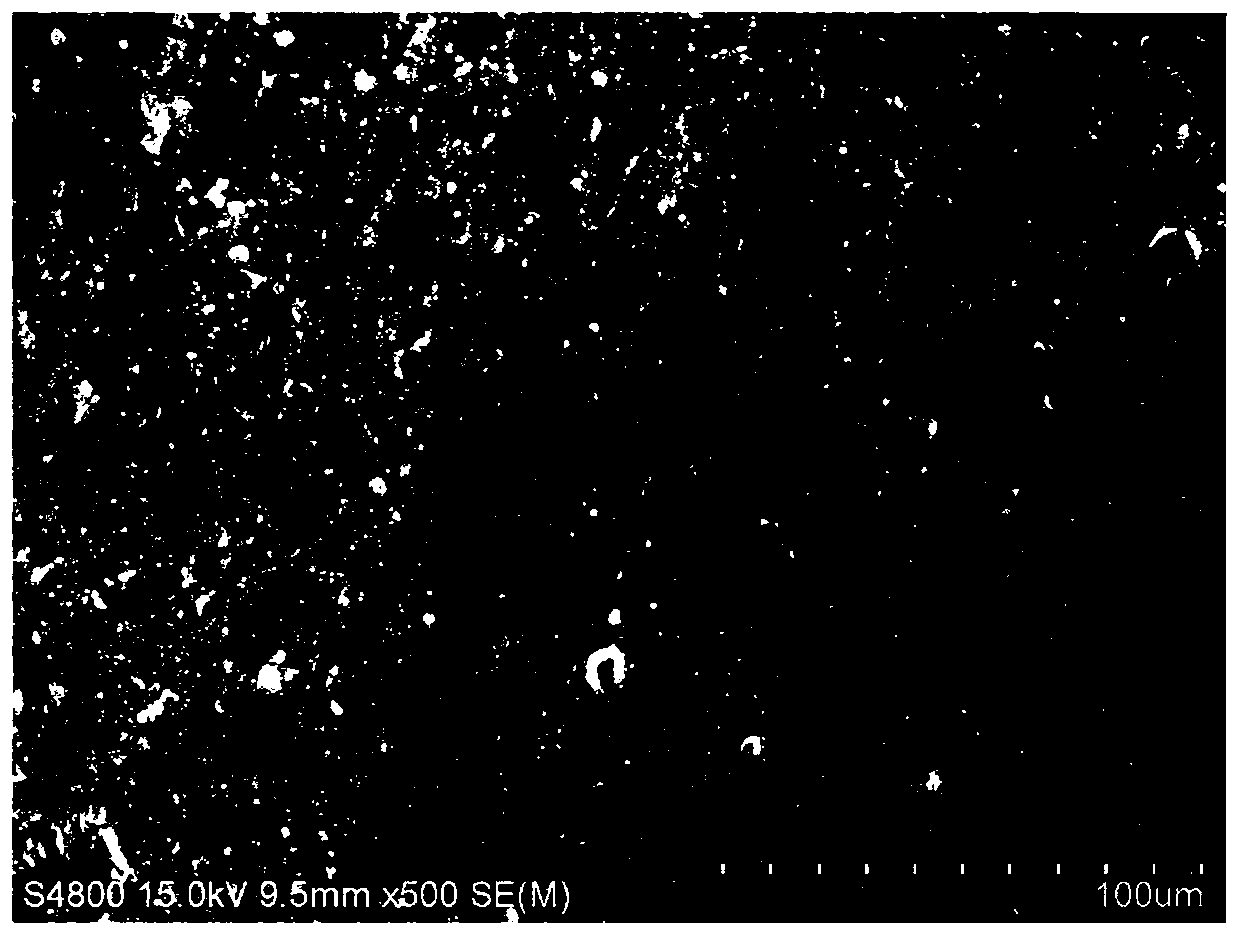

Image

Examples

Embodiment 1

[0031] A kind of biodegradable film, raw material is composed of: PBAT 73.0 parts by weight, sodium alginate coated urea (2000 mesh, urea content is 50%) 20.0 parts by weight, talcum powder 5.0 parts by weight, ultraviolet stabilizer UV3853 1.0 parts by weight, anti- Oxidant B900 1.0 parts by weight.

[0032] The preparation method of sodium alginate coated urea (2000 mesh) is as follows:

[0033] (1) Take 2% sodium alginate solution as the water phase, add urea, and stir evenly;

[0034] (2) Use isooctane solution as the oil phase, add Span-80, stir evenly, and preheat in a 40°C water bath for 10 minutes;

[0035] (3) Add the sodium alginate solution containing urea dropwise into the oil phase, stir while adding dropwise, continue stirring at high speed for 60 minutes after the dropwise addition, and then add 8% CaCl dropwise 2 solution and continue to stir the emulsion for 30 minutes, fully washed with absolute ethanol and distilled water, dried at room temperature and the...

Embodiment 2

[0048] A biodegradable mulching film, the raw materials are: 70.0 parts by weight of PBAT, 13.0 parts by weight of PLA, 10.0 parts by weight of chitosan-coated ammonium monohydrogen phosphate microspheres (2500 mesh, content of ammonium monohydrogen phosphate is 20%), mica 5.0 parts by weight of tablet, 0.5 parts by weight of oleic acid, 0.5 parts by weight of chain extender ADR-4400, 0.5 parts by weight of ultraviolet stabilizer UV 326, and 0.5 parts by weight of antioxidant B215.

[0049] The preparation method of chitosan-coated ammonia monohydrogen phosphate microspheres is as follows:

[0050] (1) dissolve chitosan with 2% glacial acetic acid, add ammonium monohydrogen phosphate, stir;

[0051] (2) Use liquid paraffin as the oil phase, add Span-80, stir evenly, then slowly add the spare mixed solution described in step (1) in a 40°C constant temperature water bath under the stirring condition of 1500r / min, and continue Stir for 1h;

[0052] (3) Add a certain amount of g...

Embodiment 3

[0064] A kind of biodegradable film, raw material is composed of: 60.0 parts by weight of PBAT, 10.0 parts of PPC, polyvinyl alcohol-coated ammonium monohydrogen phosphate microspheres (5000 mesh, ammonium monohydrogen phosphate content is 50%) 10.0 parts by weight, potassium sulfate ( 5000 mesh) 10.0 parts by weight, 5.0 parts by weight of modified talcum powder, 1.0 parts by weight of ultraviolet stabilizer UV3853, 1.0 parts by weight of antioxidant B225, 3.0 parts by weight of carrier-free black masterbatch 330BK.

[0065] The preparation method of polyvinyl alcohol coated monohydrogen ammonia phosphate microspheres is as follows:

[0066] (1) Configure the PVA solution with a mass fraction of 5% as the water phase, add ammonium monohydrogen phosphate, and stir evenly;

[0067] (2) Use liquid paraffin as the oil phase, add Span-80, and stir evenly;

[0068] (3) Add fully mixed and uniform water phase to the oil phase, add 2.0g STMP crosslinking agent, add 1mL NaOH as a cat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com