Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

37results about How to "No change in traffic" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Mass transmission method and device based on elliptic curve

ActiveCN112055021ATransmission Content Length ExtensionMeet the needs of actual scenariosKey distribution for secure communicationPublic key for secure communicationAlgorithmCiphertext

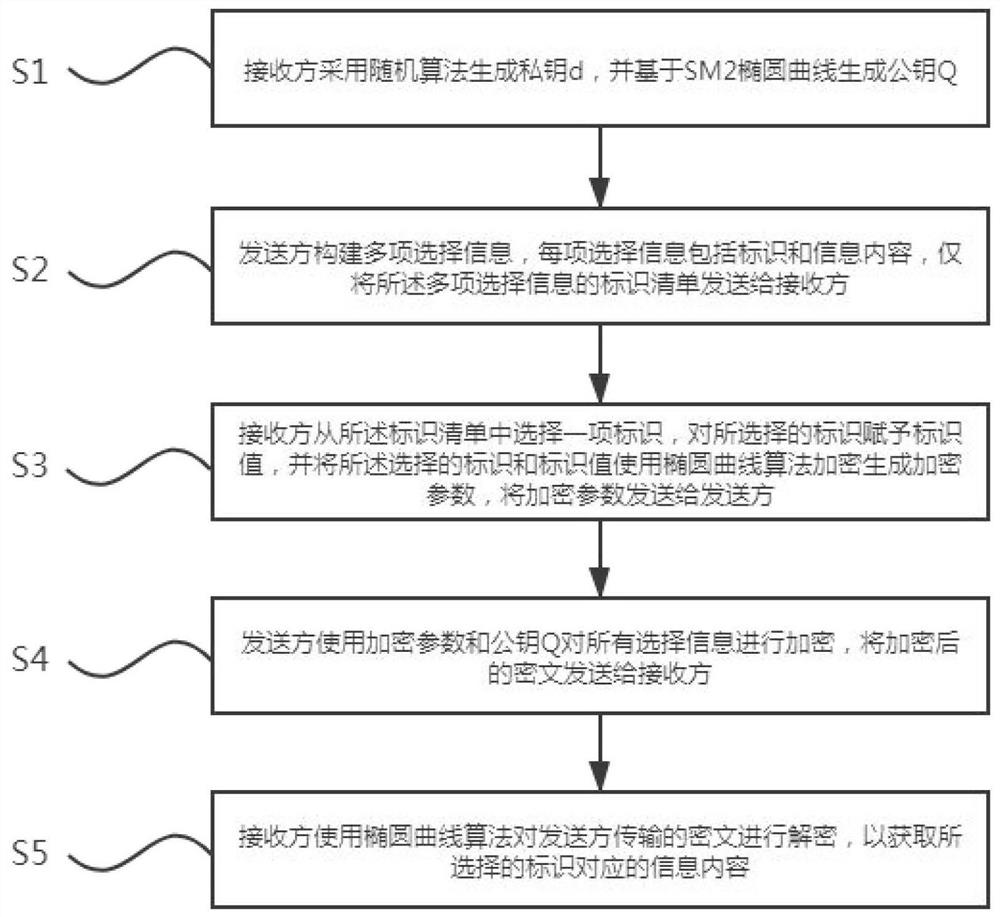

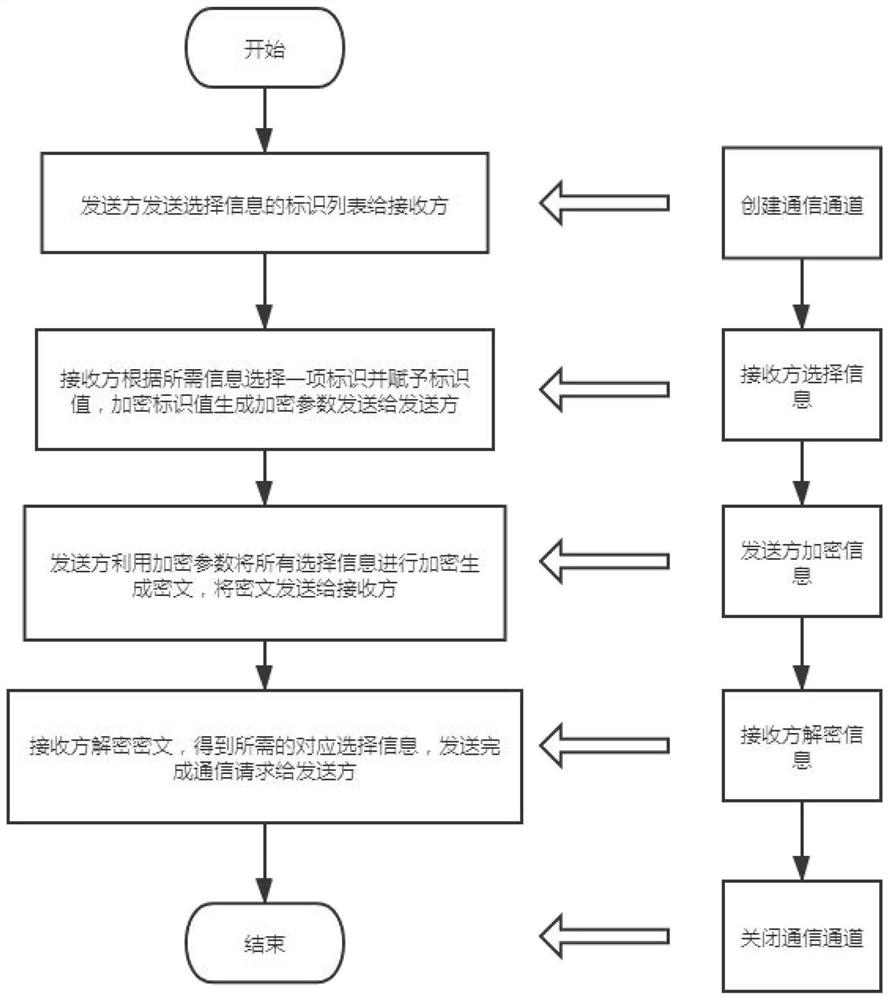

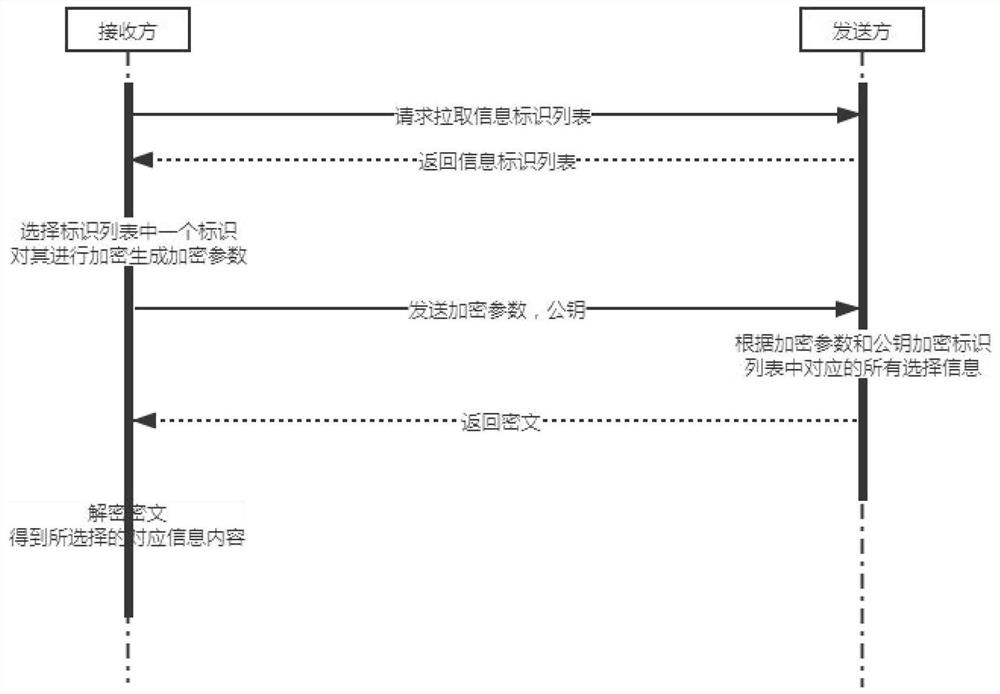

The invention relates to a mass transmission method and device based on an elliptic curve, and the method comprises the steps that S1, a receiver generates a private key d through employing a random algorithm, and generates a public key Q based on an SM2 elliptic curve; S2, a sender constructs multiple pieces of selection information, each piece of selection information comprises an identifier andinformation content, and only an identifier list of the multiple pieces of selection information is sent to the receiver; S3, the receiver selects an identifier from the identifier list, gives an identifier value to the selected identifier, encrypts the selected identifier and the identifier value by using an elliptic curve algorithm to generate an encryption parameter, and sends the encryption parameter to the sender; S4, the sender encrypts all the selection information by using the encryption parameter and the public key Q, and sends the encrypted ciphertext to the receiver; and S5, the receiver decrypts the ciphertext transmitted by the sender by using an elliptic curve algorithm to obtain the information content corresponding to the selected identifier. According to the method, the problems of privacy data protection and the like involved in a blockchain project scene can be solved.

Owner:梧桐链数字科技研究院(苏州)有限公司

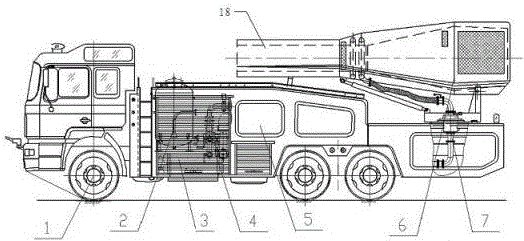

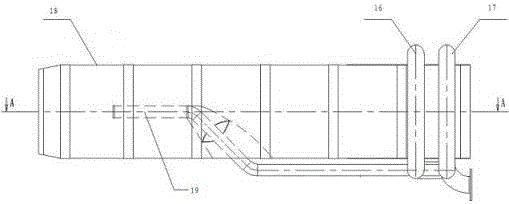

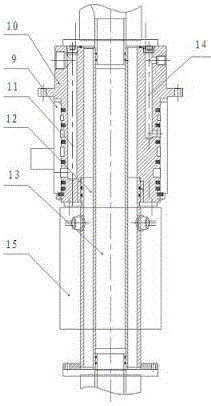

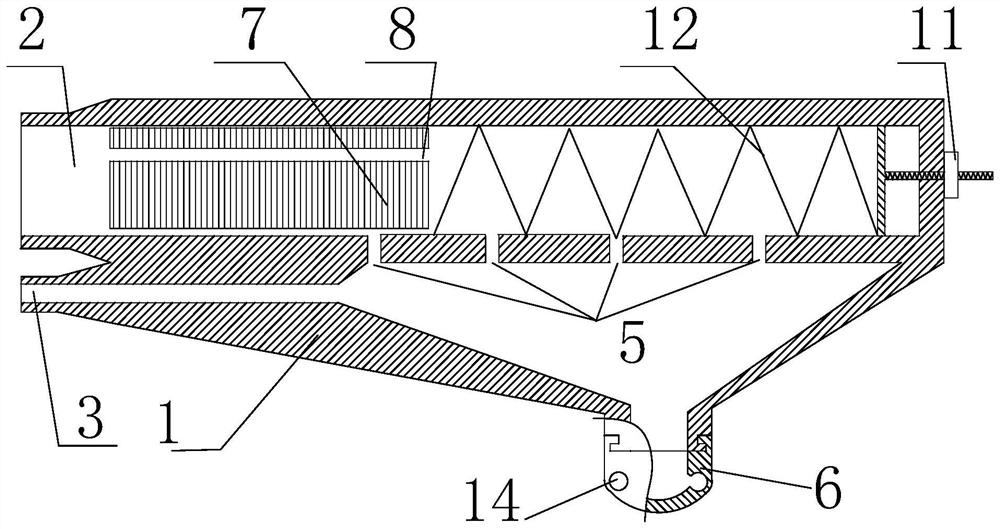

A kind of urban turbojet fire truck

The invention provides an urban turbojet fire vehicle. The fire vehicle comprises a vehicle chassis. An ultrafine dry powder tank is arranged on the vehicle chassis. The ultrafine dry powder tank is connected with a nitrogen cylinder pressure vessel. The nitrogen cylinder pressure vessel is connected with a water pump system. The water pump system is connected with a liquid tank assembly. The liquid tank assembly is connected with a turbojet engine jet assembly. A jet device for fire extinguishing comprises a jet device. The jet device is connected with a central revolved body through a connection pipe. The urban turbojet fire vehicle has large jet power, can jet out a mass flow of 'tail gas-water spray-ultrafine dry powder' three-phase jet flow fire extinguishing agents in a short time, and has excellent capabilities of controlling fire behavior, extinguishing big fires and cooling fire scenes by aeration from the three-dimensional space. The urban turbojet fire vehicle plays an important role in extinguishing high-rise building fire disasters, unattended dangerous chemical warehouse fire disasters, underground garage fire disasters, cable trench fire disasters, tunnel fire disasters, historic building fire disasters and steamship cabin fire disasters.

Owner:JIANGSU KAWEI SPECIAL PURPOSE VEHICLE MFG

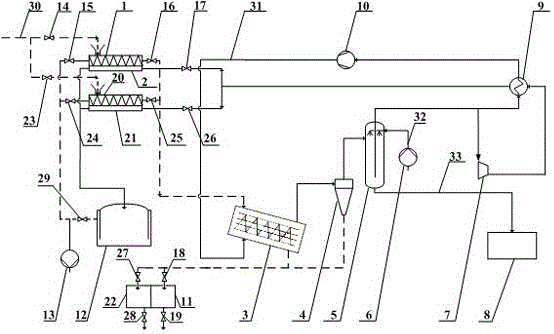

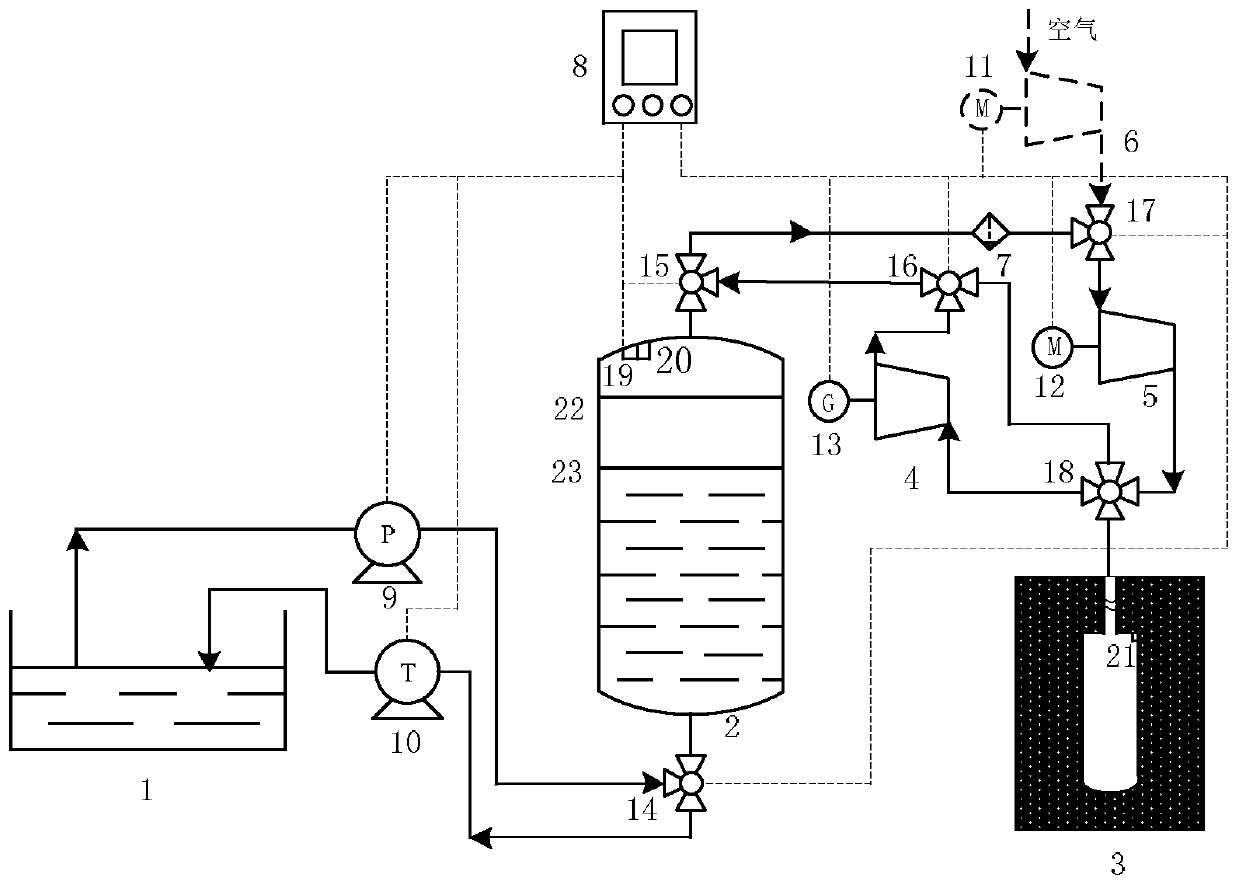

MVR (Mechanical Vapor Recompression) superheated steam sludge continuous drying system and working method

InactiveCN106495427ANo change in trafficImprove drying rateSludge treatment by de-watering/drying/thickeningSpecific water treatment objectivesWater vaporSludge

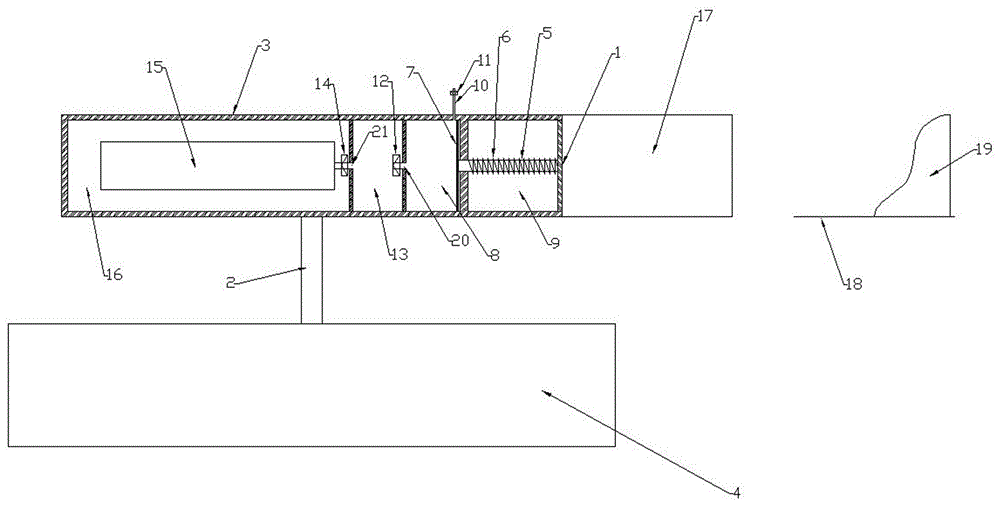

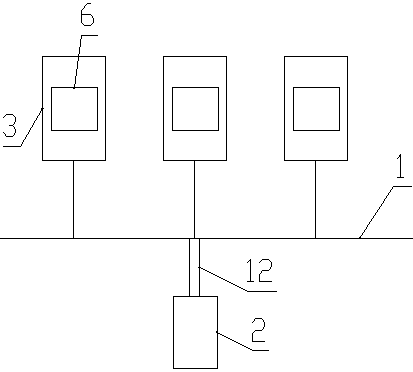

The invention provides an MVR (Mechanical Vapor Recompression) superheated steam sludge continuous drying system and a working method and belongs to the field of energy sources, power and the like. Compared with a traditional sludge drying system, the system is characterized in that a dryer (3) is adopted; superheated steam (31) and sludge to be dried are subjected to direct heat exchange, and a control valve is switched on and off to enable a first feeding device (1), a first pre-heater (2), a second feeding device (20), a second pre-heater (21), a first sludge storage tank (11) and a second sludge storage tank (22) to alternately work, so that negative-pressure continuous operation in the dryer (3) is realized; according to the system provided by the invention, the superheated steam (31) with a relatively strong moisture absorption capability is used as a drying medium under a negative-pressure environment, so that the sludge drying speed is greatly improved; meanwhile, the system only consumes less power consumption of a compressor (7) and a draught fan (10) and latent heat of most steam evaporated from sludge (30) is recycled through a heat exchanger (9); and an efficient and energy-saving sludge drying method is provided.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

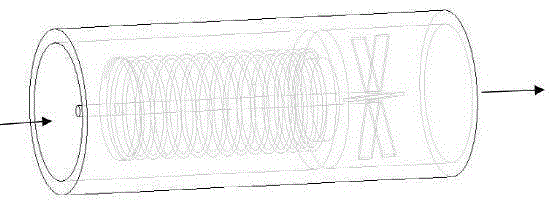

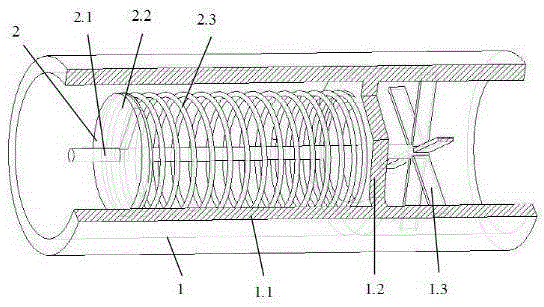

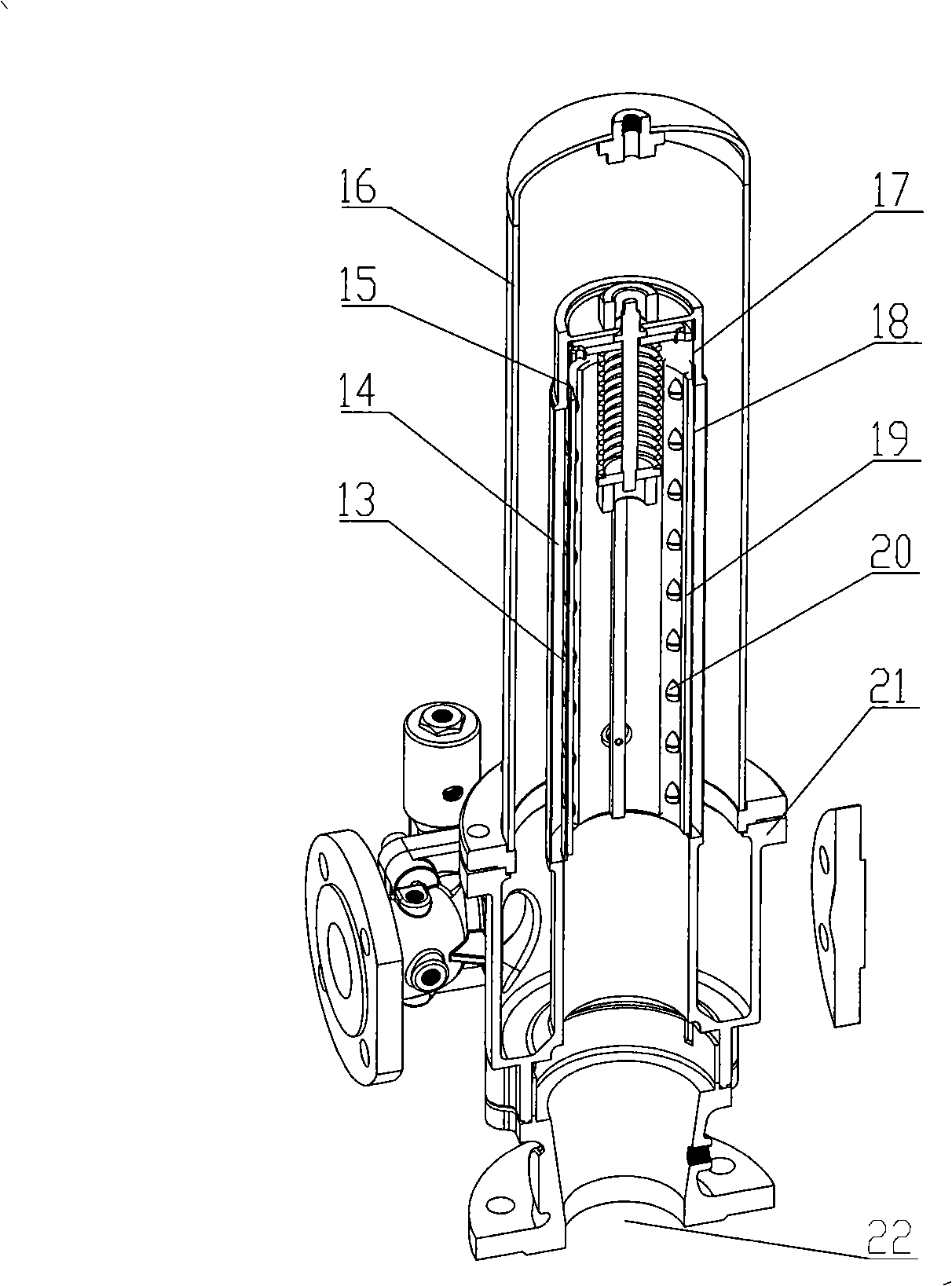

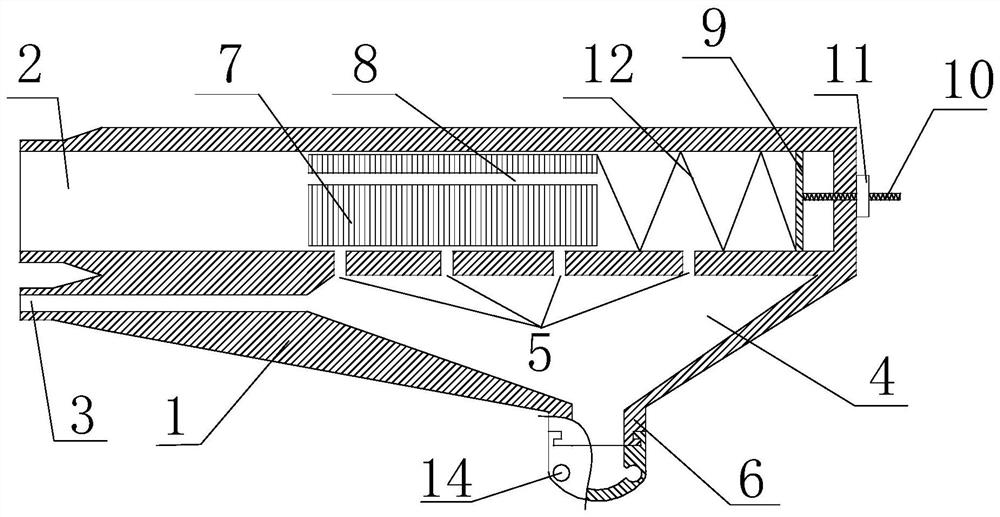

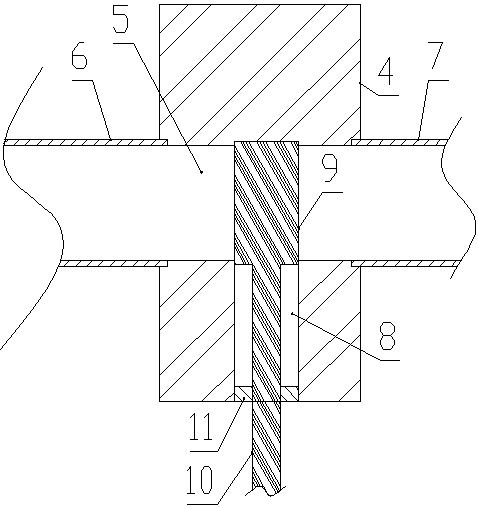

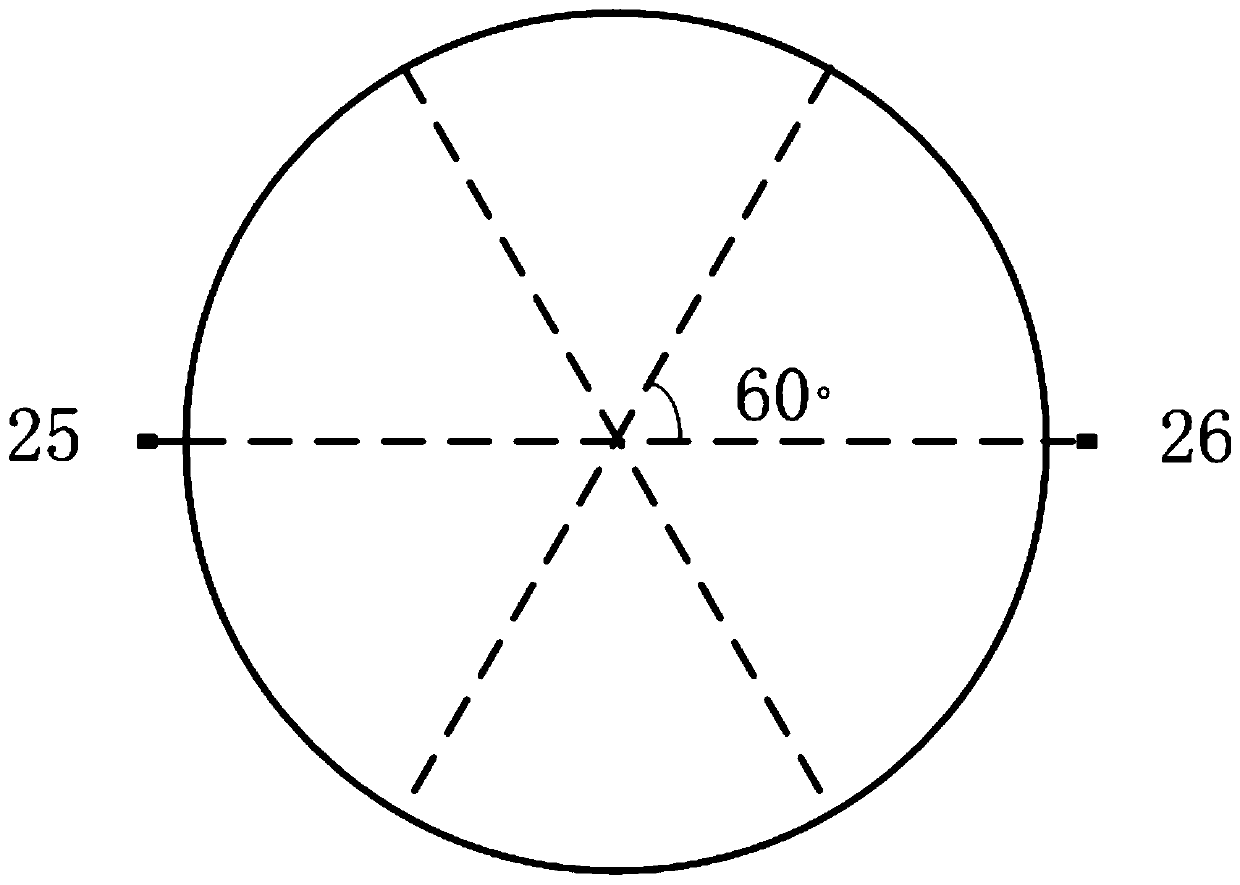

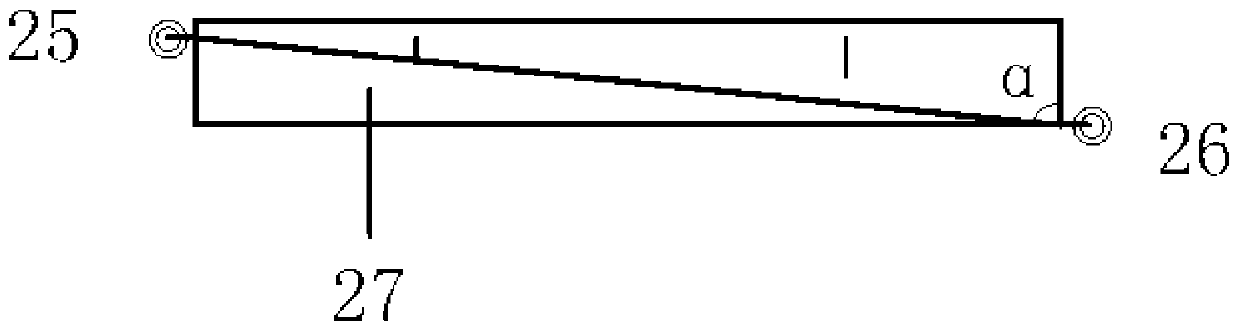

Rigidity-variable spring type constant-flow valve

ActiveCN105351585ASimple flow fieldThe overall structure is simple and reliableEqualizing valvesSafety valvesEngineeringPressure difference

The invention discloses a rigidity-variable spring type constant-flow valve and belongs to the technical field of hydraulic valves. The rigidity-variable spring type constant-flow valve comprises a valve body and a valve element arranged in the valve body. The valve body comprises a cylindrical shell. A baffle ring and a fixing support are sequentially fixed in the shell. The valve element comprises a guide rod fixed to the fixing support. The guide rod penetrates the center of the baffle ring and coincides with the axis of the shell. A baffle capable of sliding along the guide rod is arranged on the guide rod. A rigidity-variable spring is fixed between the baffle and the baffle ring. One end of the rigidity-variable spring is fixed to the baffle and the other end of the rigidity-variable spring is fixed to the baffle ring. When fluid of certain pressure passes seams of the spring, the pressure difference is generated, the pressure difference acts on the baffle at one end of the rigidity-variable spring, the rigidity-variable spring is compressed, the seam height of the rigidity-variable spring is changed, and certain flow is guaranteed. The rigidity-variable spring type constant-flow valve has the beneficial effects of being simple and reliable in structure, convenient to mount, simple in flow field, large in through-flow area, small in flow resistance and the like.

Owner:JIANGSU MINGQUAN IRRIGATION & DRAINAGE EQUIP CO LTD

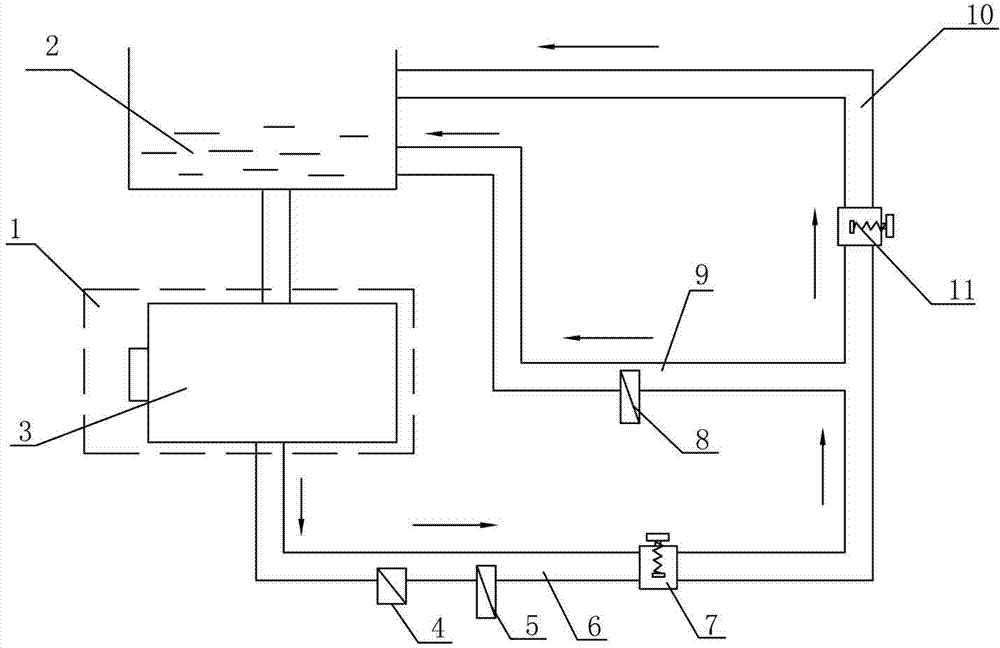

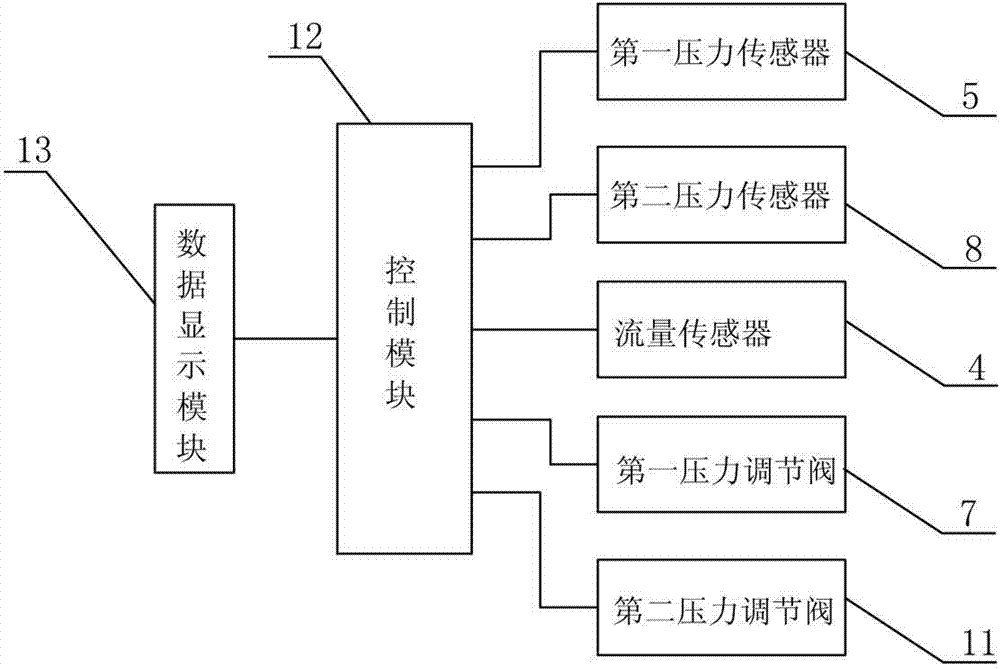

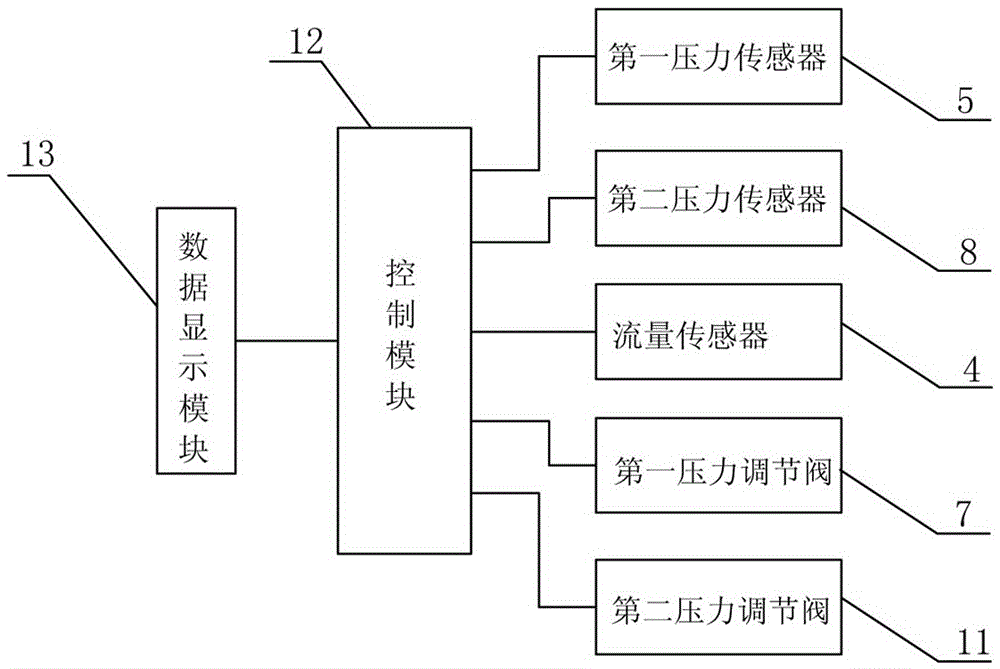

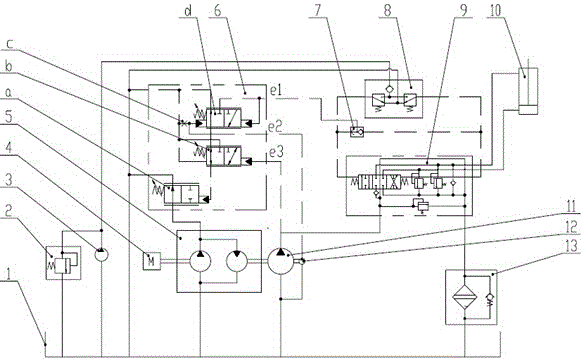

Performance testing device for oil pump

ActiveCN104500381ANo change in trafficShort test timePump testingPositive-displacement liquid enginesData displayTest efficiency

The invention discloses a performance testing device for an oil pump. The device comprises a workbench, an oil tank, a control module and a data display module, wherein the oil tank is communicated with an oil suction port of an oil pump to be detected; an oil outlet of the oil pump to be detected is communicated with an oil discharging pipe; the outlet end of the oil discharging pipe is communicated with a main oil pipe and a return oil pipe; outlets of the main oil pipe and the return oil pipe are communicated with the oil tank; a flow sensor, a first pressure sensor and a first pressure regulation valve are sequentially connected to the oil discharging pipe along an oil discharging direction; a second pressure sensor is connected to the main oil pipe; a second pressure regulation valve is connected to the return oil pipe. According to the performance testing device for the oil pump, a changing relationship between the pressure and the flow of an outlet of the oil pump at different temperature is simulated and tested at the same temperature, and the device is short in testing time and high in testing efficiency.

Owner:NINGBO SHENGLONG AUTOMOTIVE POWERTRAIN SYSTEM CO LTD

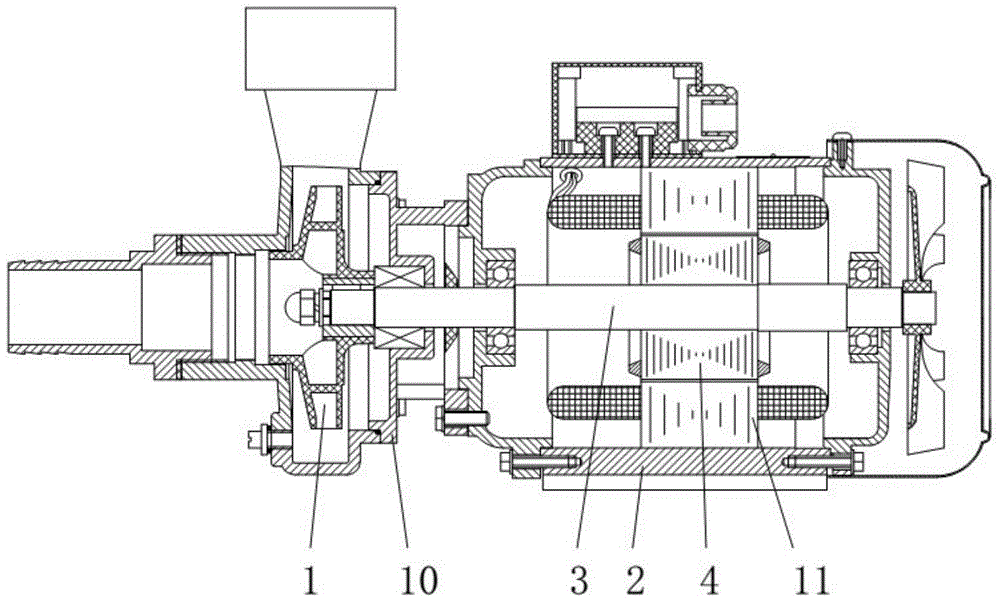

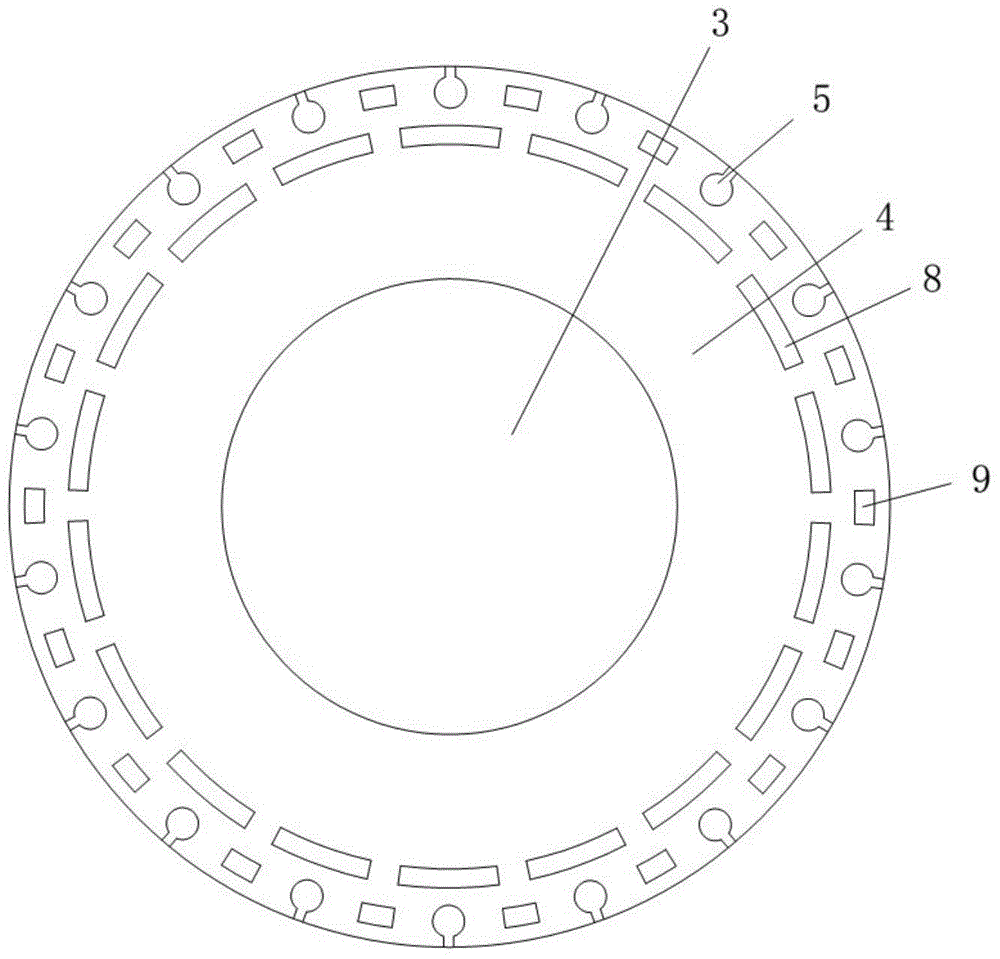

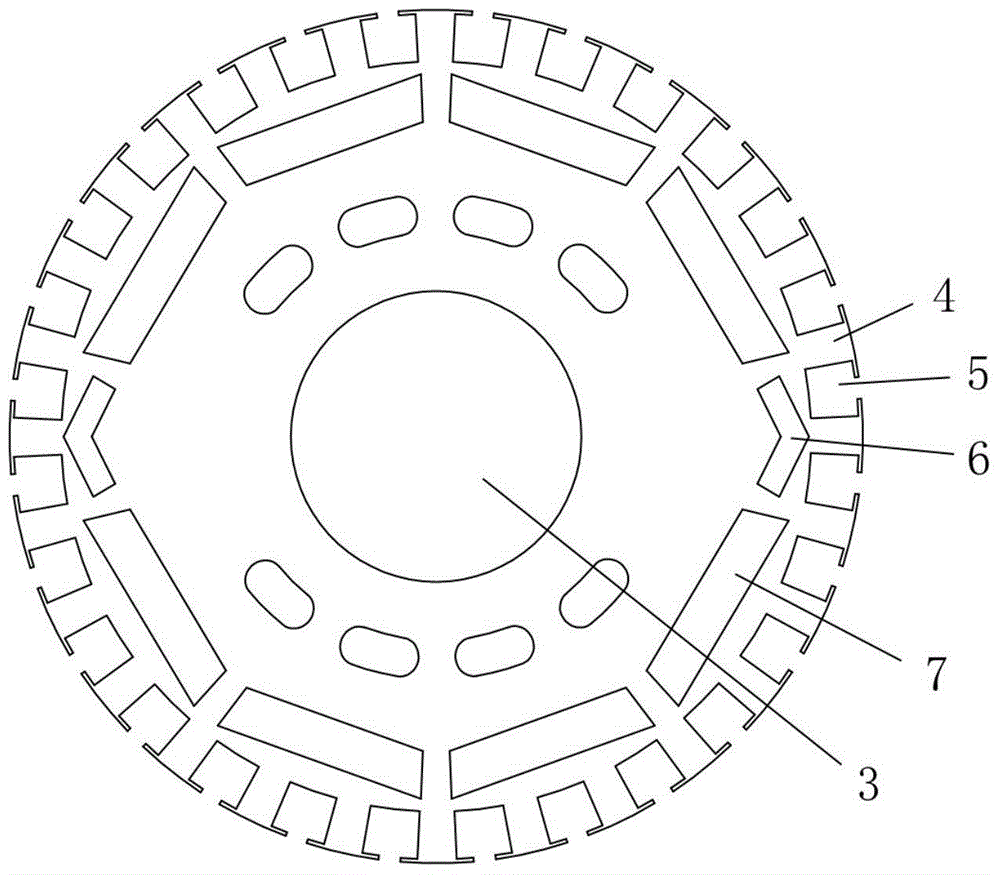

Centrifugal pump of asynchronous-starting permanent-magnet-synchronous motor

InactiveCN105119452ALarge starting torqueImprove unit efficiencySynchronous machinesFrequency changerSynchronous motor

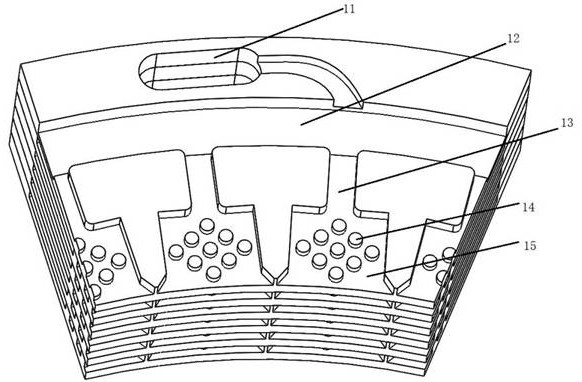

The invention especially relates to a centrifugal pump of an asynchronous-starting permanent-magnet-synchronous motor. The centrifugal pump comprises a pump body and a motor. A rotor iron core of a motor rotor is formed by axial superposition of a plurality of circular silicon steel sheet rotation shafts; a plurality of conducting bar windings are inserted at the periphery of the rotator iron core uniformly and a circular mouse cage structure is formed by encircling of all conducting bar windings. Besides, a group or two groups of permanent magnets are arranged on the rotator iron core; one group or two groups of opposite magnetic poles, distributed symmetrically along the radial central lines of the permanent magnets, of the permanent magnets are formed at the radial cross section of the rotator iron core. Permanent magnets are arranged between the rotor mouse cage bars at intervals and, together with the permanent magnets arranged at the inner layer of the mouse cage structure, form first permanent magnets and second permanent magnets. According to the invention, compared with the high-efficiency YE3 product, the motor efficiency of the centrifugal pump is improved by 5 to 7%; and compared with the common Y2-series motor, the motor efficiency is improved by 10 to 15%. When the power grid voltage and load are changed, the lift and flow of the pump are kept to be unchanged. The innovative concept can be applied to all pumps without frequency converters; and thus high-efficiency and stable work can be realized.

Owner:ZHEJIANG CHUANGMEI ELECTROMOTOR

Steady flow spraying device

ActiveCN106475243AGuaranteed stabilityImprove atomization effectWater resource protectionMovable spraying apparatusWater flowEnvironmental engineering

The invention discloses a steady flow spraying device. A water inlet pipe and a gas inlet pipe are arranged on a base. An atomizing chamber is arranged at the front end of the base. The gas inlet pipe communicates with the atomizing chamber. A plurality of water inlets are formed in the positions, corresponding to the atomizing chamber, of the water inlet pipe and form a water inlet zone. An adjusting structure is arranged in the water inlet zone and used for keeping the flow entering the atomizing chamber from the water inlet pipe unchanged. When water flow enters the atomizing chamber through the water inlets of the water inlet pipe, water drops are broken through blowing and dispersed into smaller fog drops through high-pressure gas, and the atomizing effect is improved; meanwhile, when the water pressure in the water inlet pipe is low, the adjusting mechanism enables the multiple water inlets to communicate with the atomizing chamber, the water flow area is increased, and the flow is unchanged under the condition that the water speed is low; and when the water pressure in the water inlet pipe is high, the adjusting mechanism blocks the corresponding water inlets and enables the corresponding water inlets to communicate with the atomizing chamber, the water flow outlet area is decreased, and the flow is unchanged under the condition that the water speed is high, so that the stability of nozzle spraying is ensured.

Owner:SHANDONG UNIV OF SCI & TECH

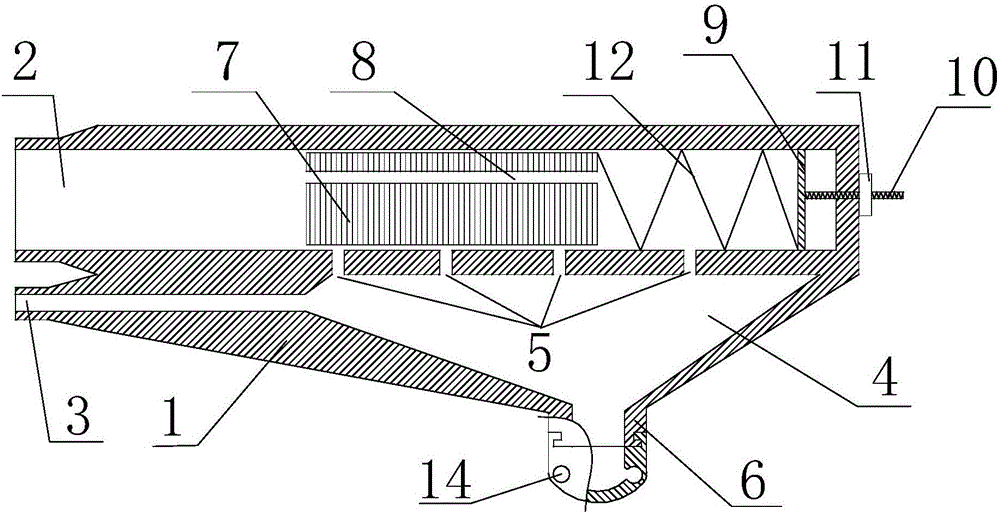

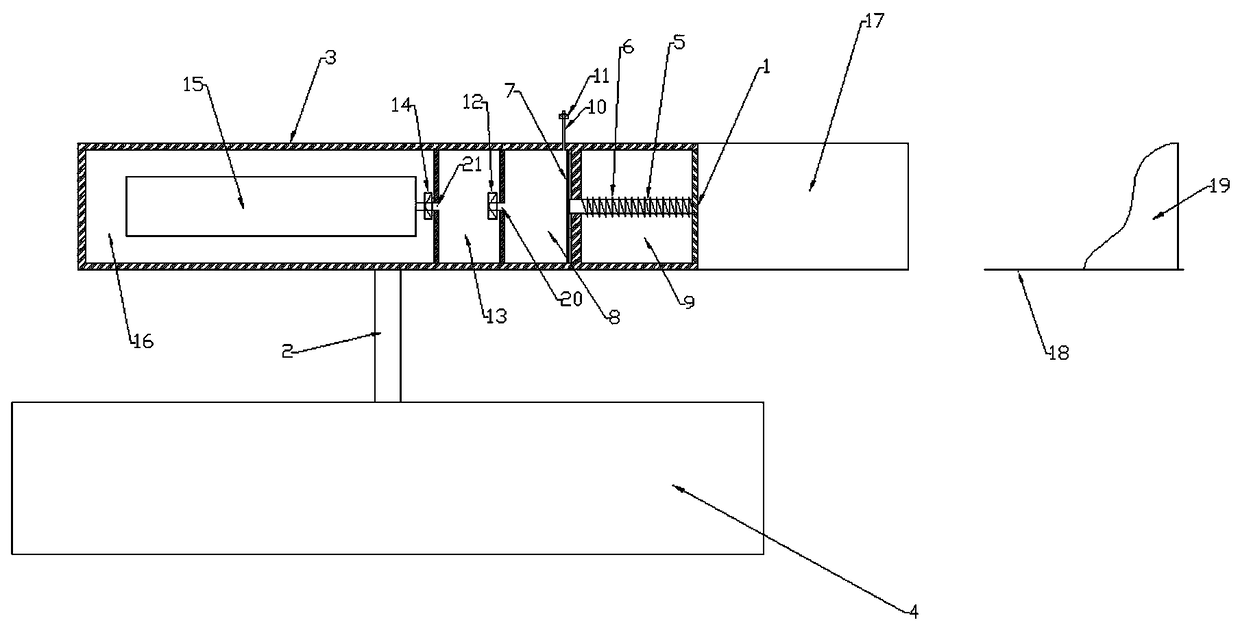

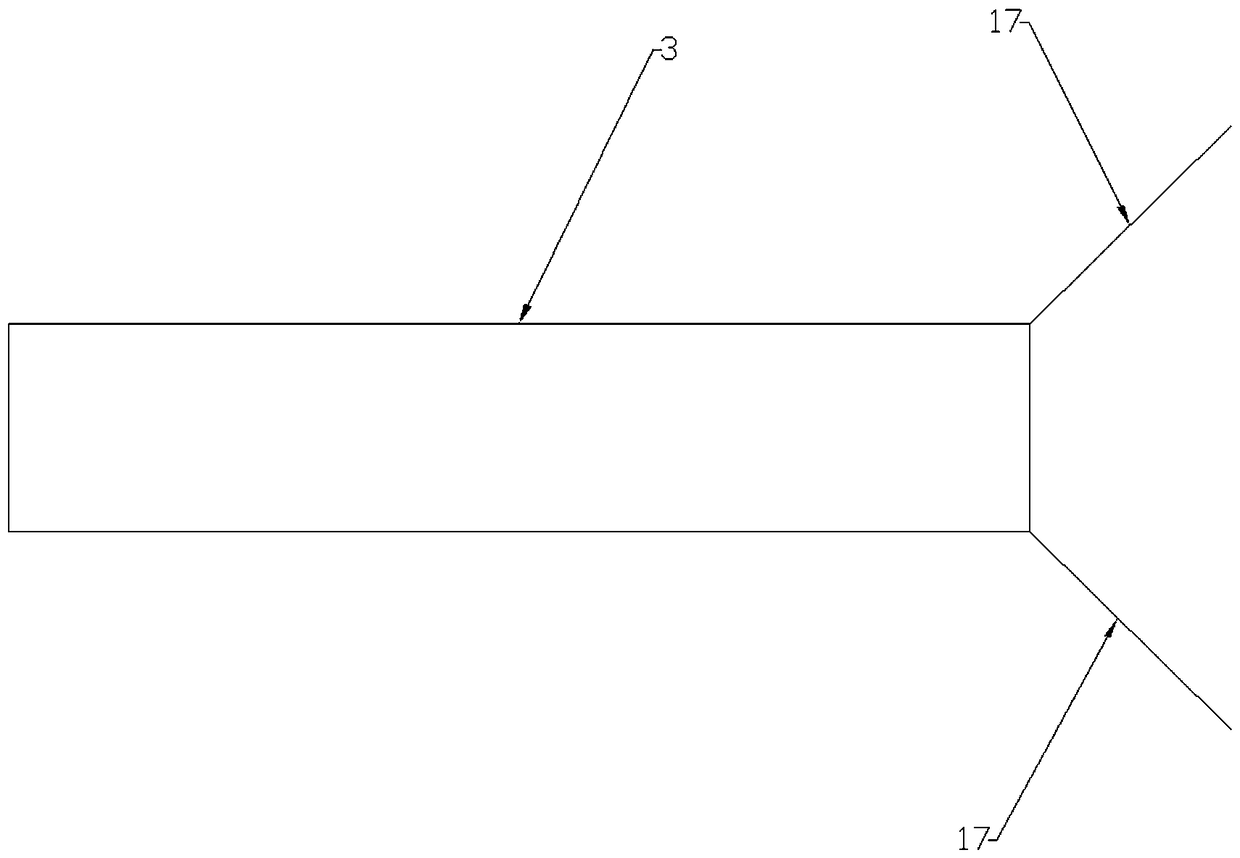

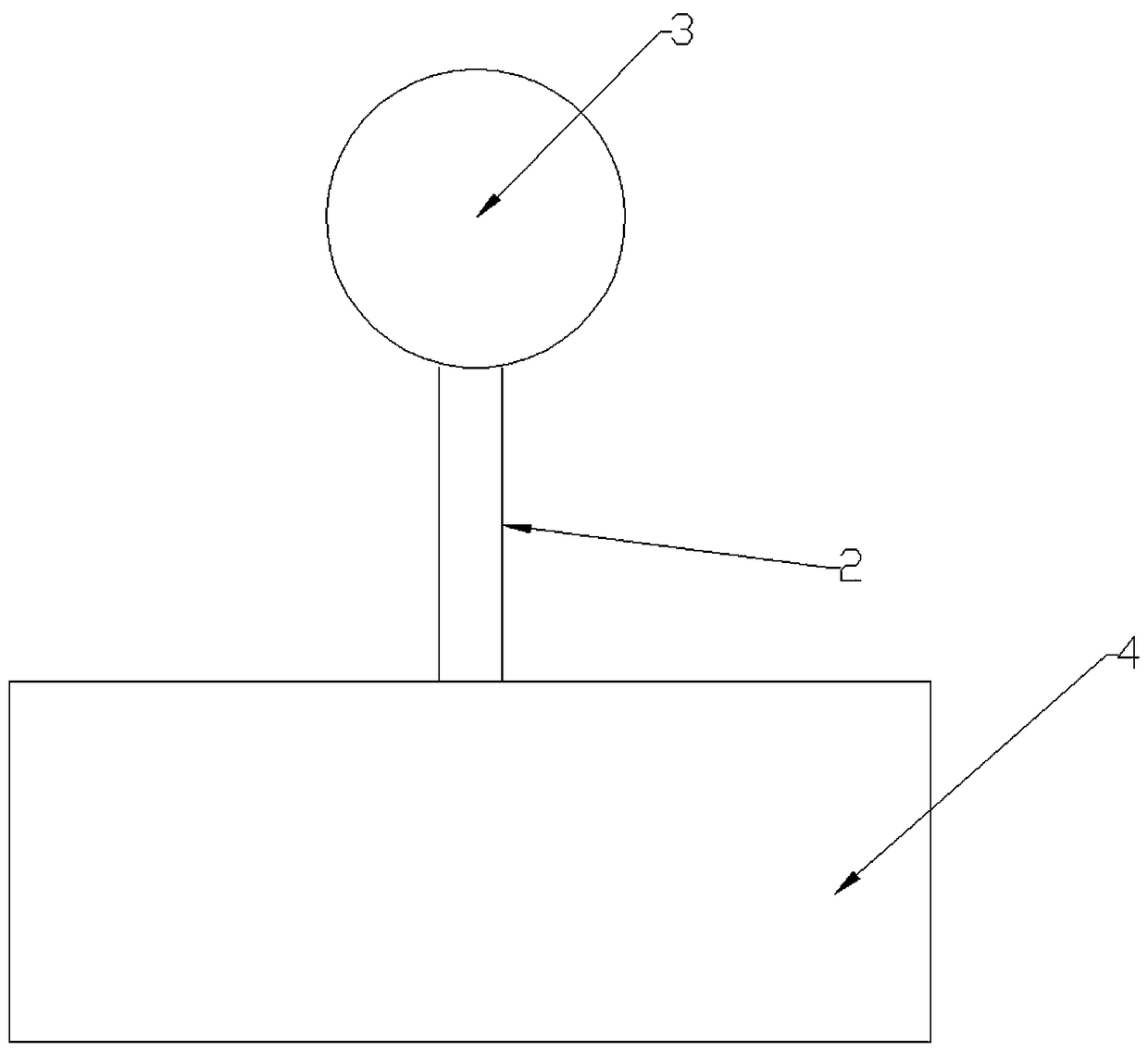

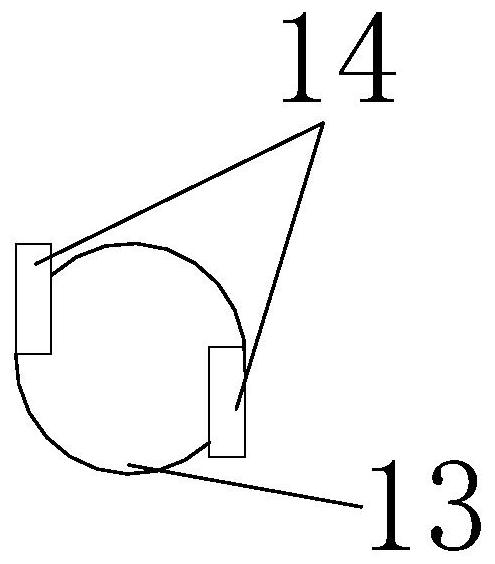

Pneumatic type wave energy power generation device

ActiveCN106246454AStable batteryConstant outputMachines/enginesEngine componentsSea wavesEngineering

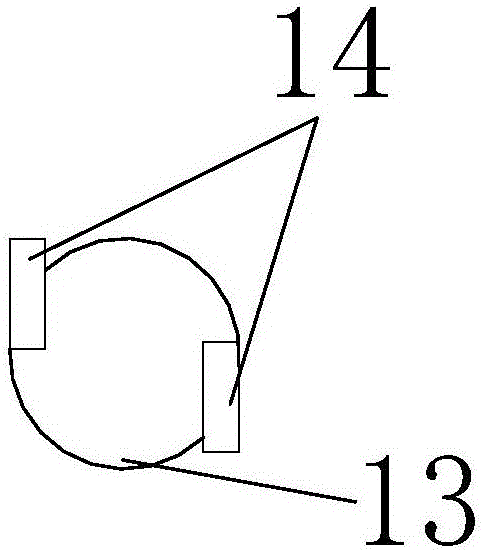

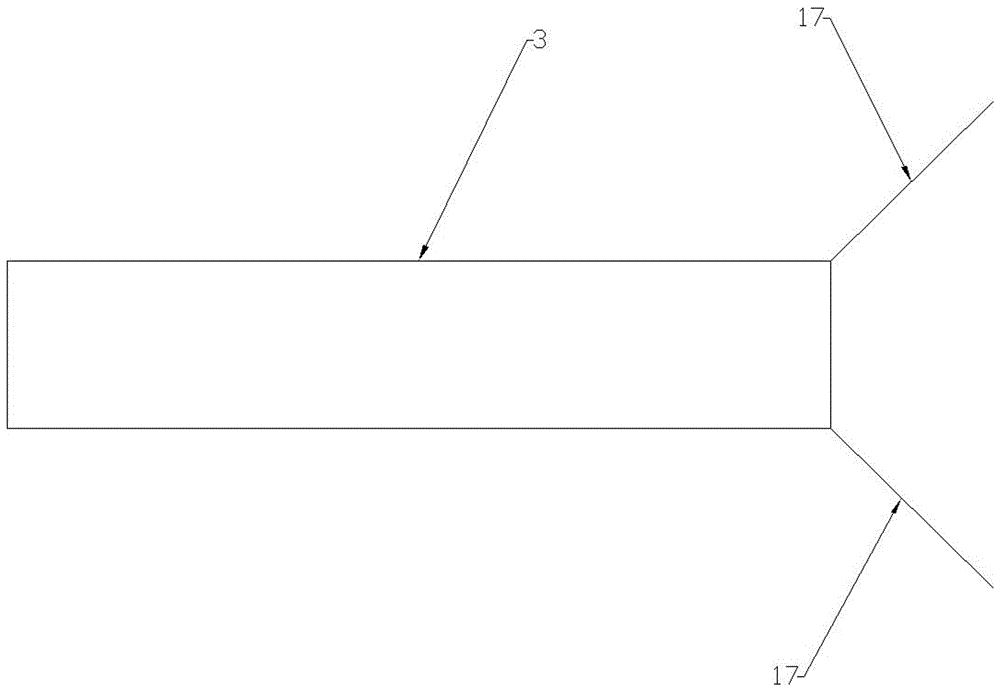

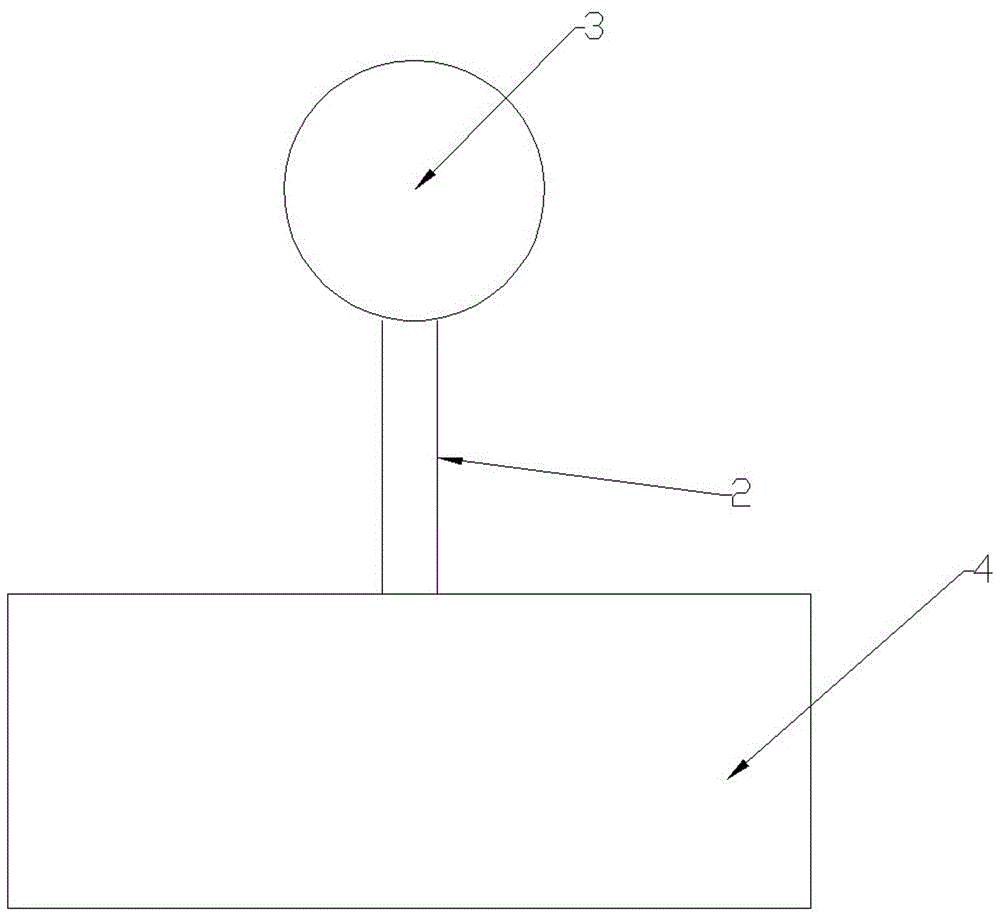

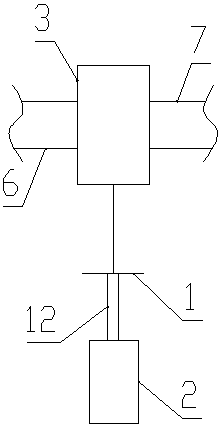

The invention provides a pneumatic type wave energy power generation device which is mainly used for ocean wave energy power generation. According to the pneumatic type wave energy power generation device, large-scale power generation can be achieved, the quantity of generated power is stable, and the power generation device can be directly connected to the national power grid. The pneumatic type wave energy power generation device is mainly composed of a pushing plate 1, a rotating rod 2, a shell 3, a floating box 4, a pushing rod 5, a spring 6, a piston 7, a pneumatic cylinder 8, a pushing chamber 9, an air inlet pipe 10, an air inlet one-way valve 11, a one-way valve 12, an energy storage chamber 13, a constant pressure valve 14, a generator set 15, a generator chamber 16, a deflector 17, a hole A 20 and a hole B 21. The main operating principle of the pneumatic type wave energy power generation device is that sea waves impact the pushing plate 1 to move to the left, the pushing plate 1 pushes the piston 7 to move to the left through the pushing rod 5 so that air in the pneumatic cylinder 8 can be compressed and fed into the energy storage chamber 13, and the compressed air in the energy storage chamber 13 is subjected to equal-pressure releasing through the constant pressure valve 14 to blow a rotor of the generator set 15 to rotate, so that a generator generates power.

Owner:济南海川投资集团有限公司

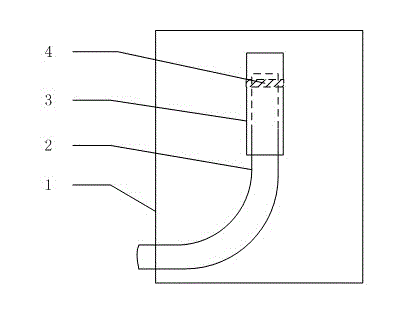

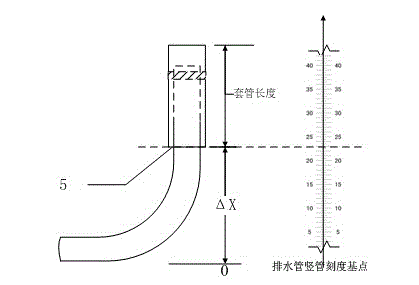

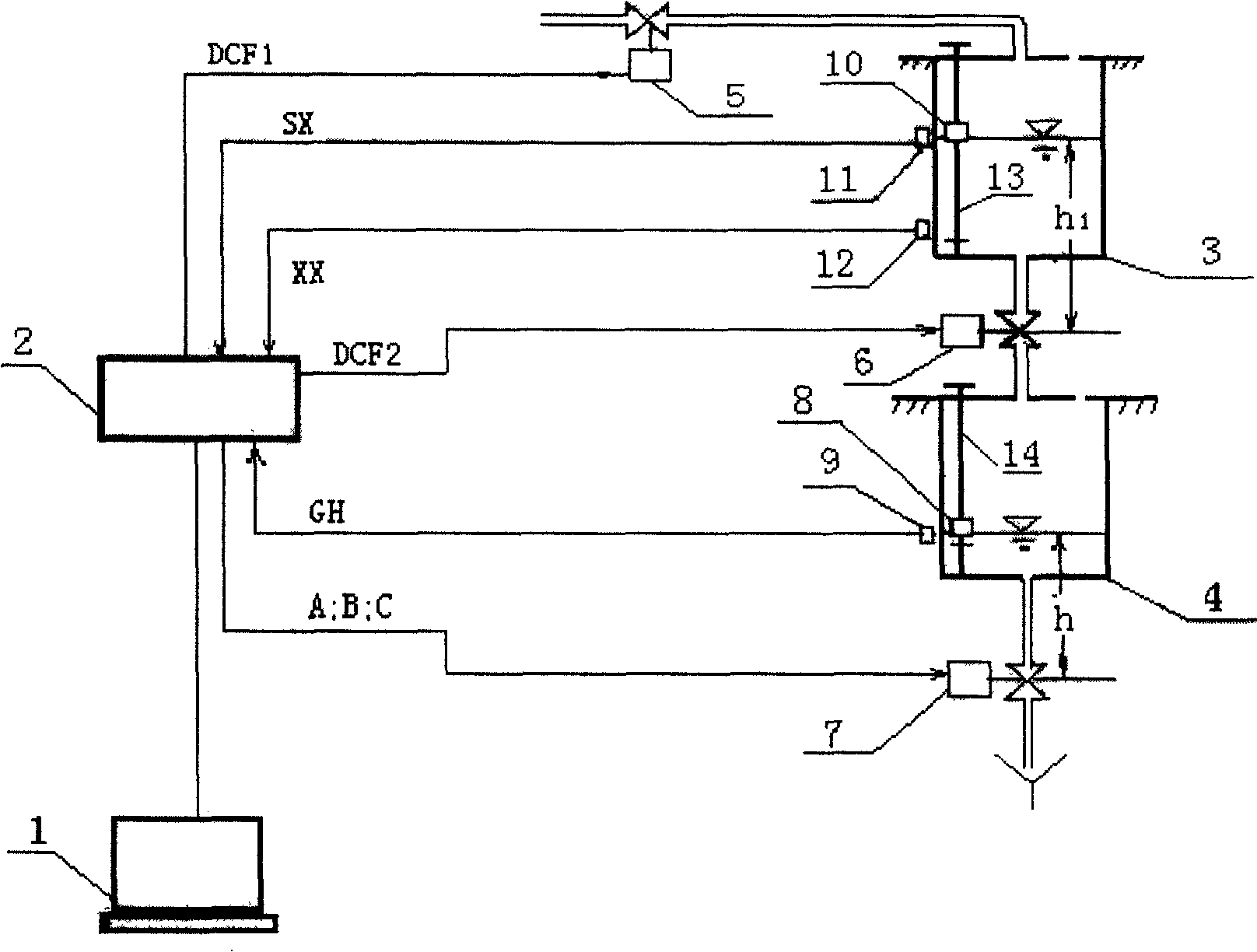

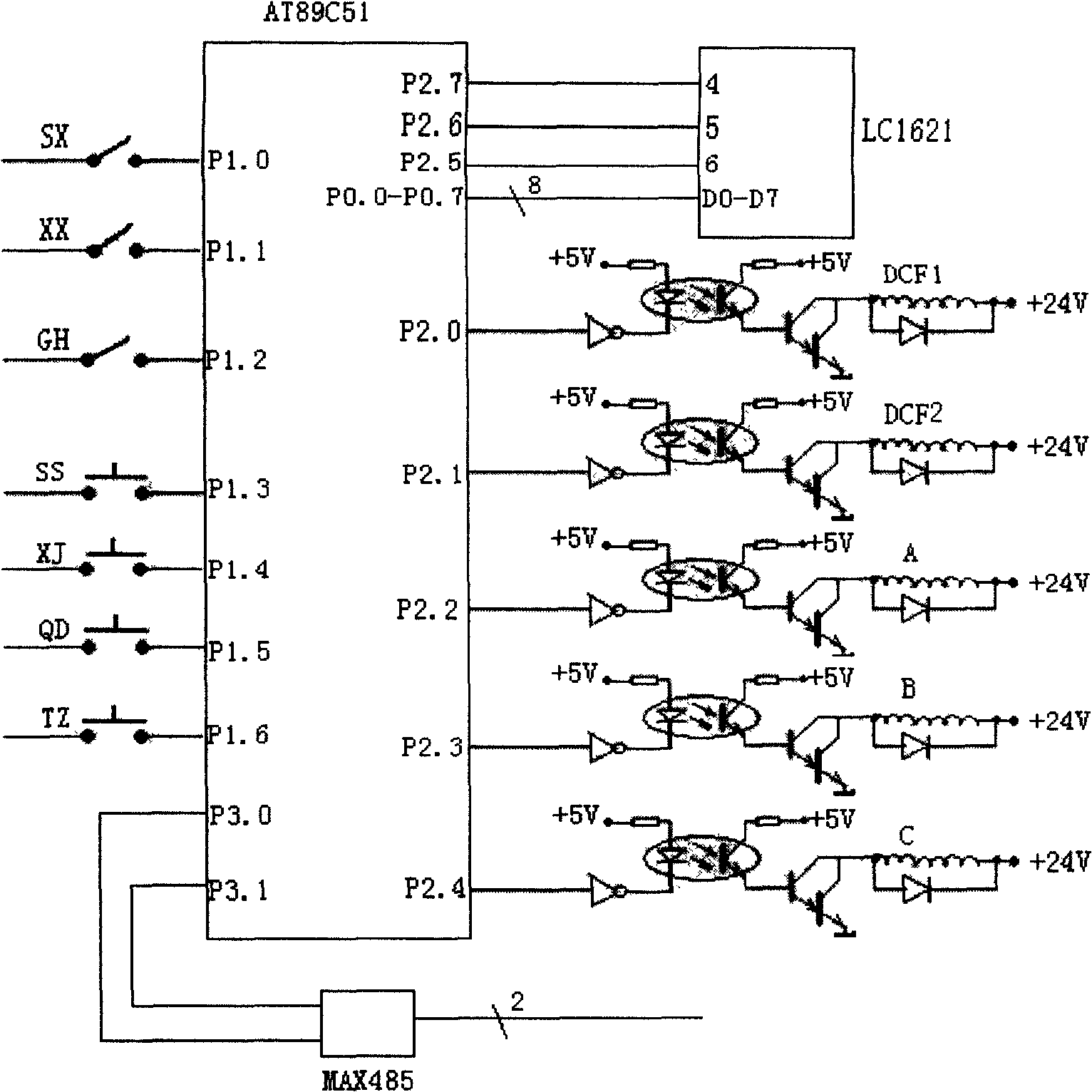

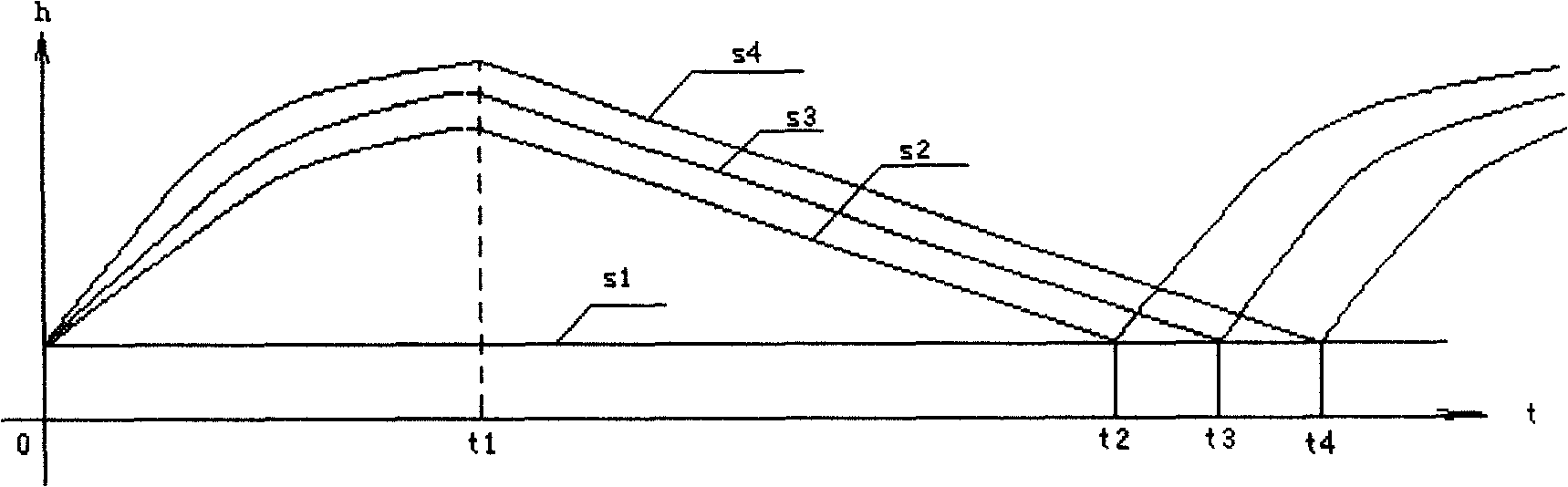

Device for quantificationally regulating water level of constructed wetlands

InactiveCN102718324AIntuitive and effective quantitative controlNo change in trafficBiological water/sewage treatmentConstructed wetlandVertical tube

The invention discloses a device for quantificationally regulating the water level of constructed wetlands. The device comprises a wetland drain-pipe, a water level regulating casing pipe and a water distribution trough, wherein the constructed wetland drain-pipe is arranged on the water distribution trough; the water level regulating casing pipe is sleeved on the drain pipe; and a sealing pad is arranged at the place where the drain pipe is sleeved with the water level regulating casing pipe. With the adoption of a casing pipe type water level regulating device, a communicator is formed between the drain pipe and the constructed wetland; the water in the constructed wetland is drained into the water distribution trough; when the water level regulating casing pipe is well positioned, the water in the wetland is higher than the height of the water outlet of the water level regulating casing pipe, the water flows out from the water outlet of the water level regulating casing pipe, then the water in the wetland is kept still the same as the height of the water level regulating casing pipe. As the drain pipe is provided with mark scales, the water level of the constructed wetland is the sum of the length of the casing pipe and the scale of a vertical tube. Therefore, the water level of the wetland can be regulated quantificationally by regulating the position of the casing pipe.

Owner:JIANGXI ACADEMY OF ENVIRONMENTAL PROTECTION SCI

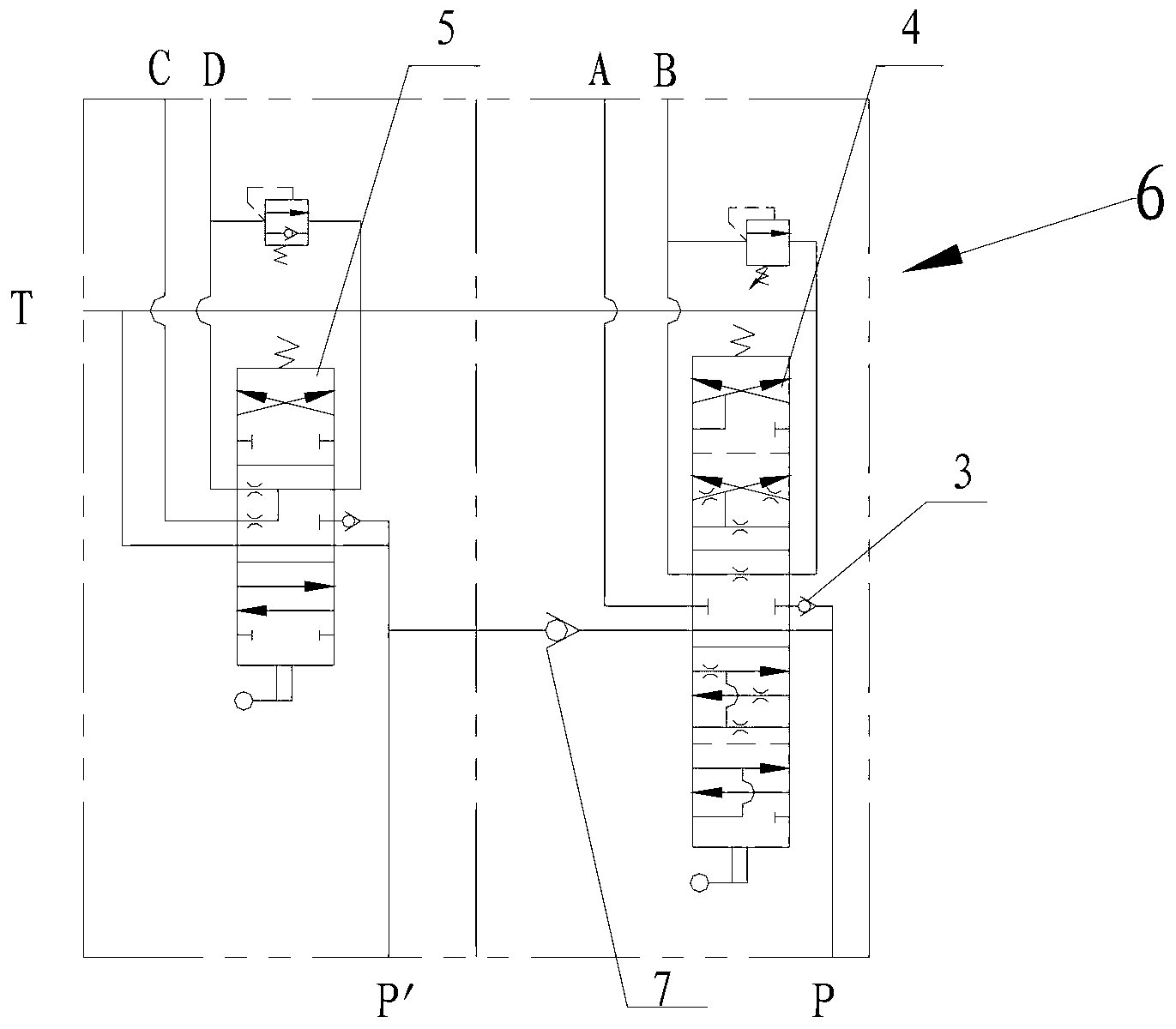

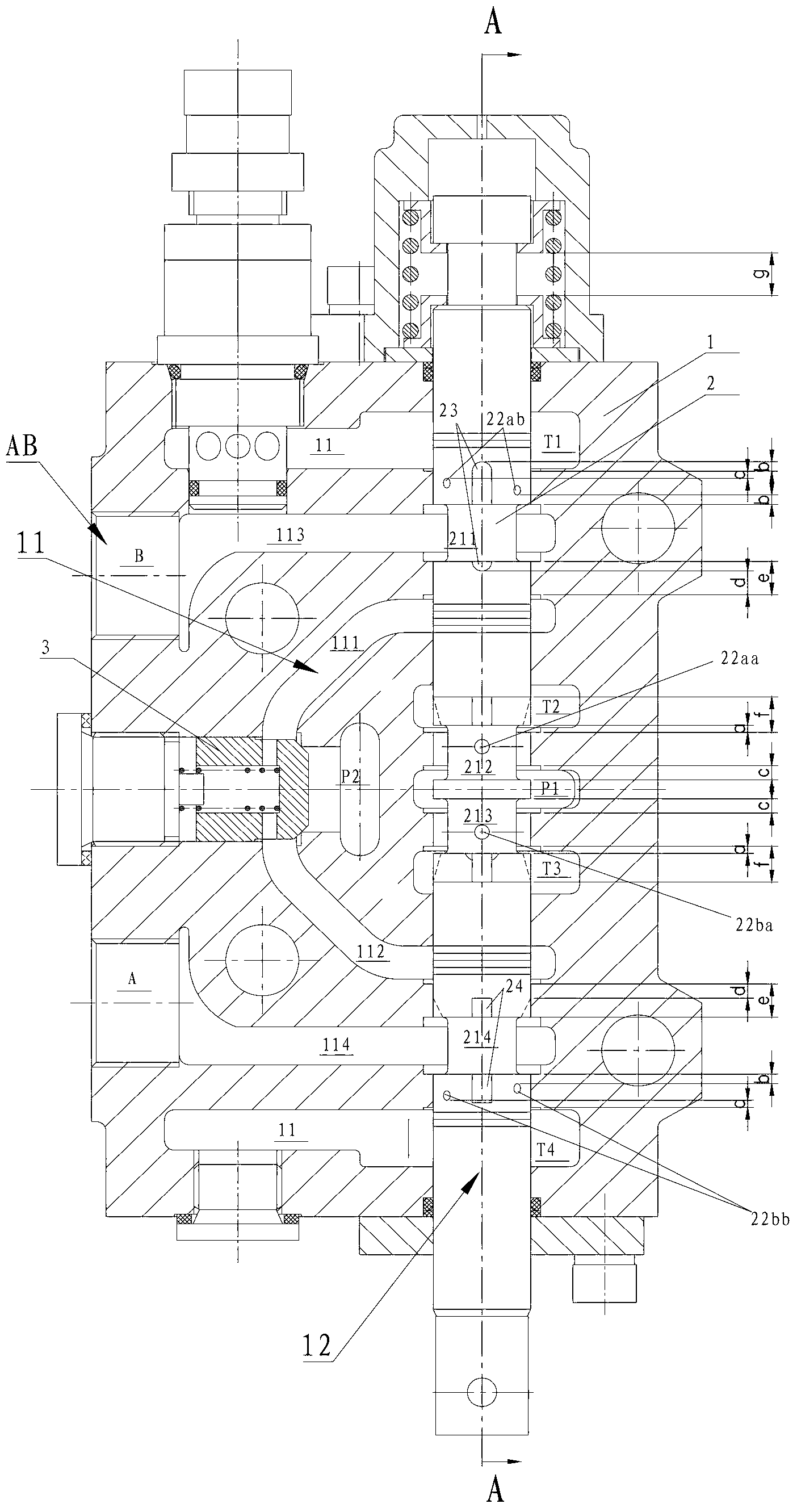

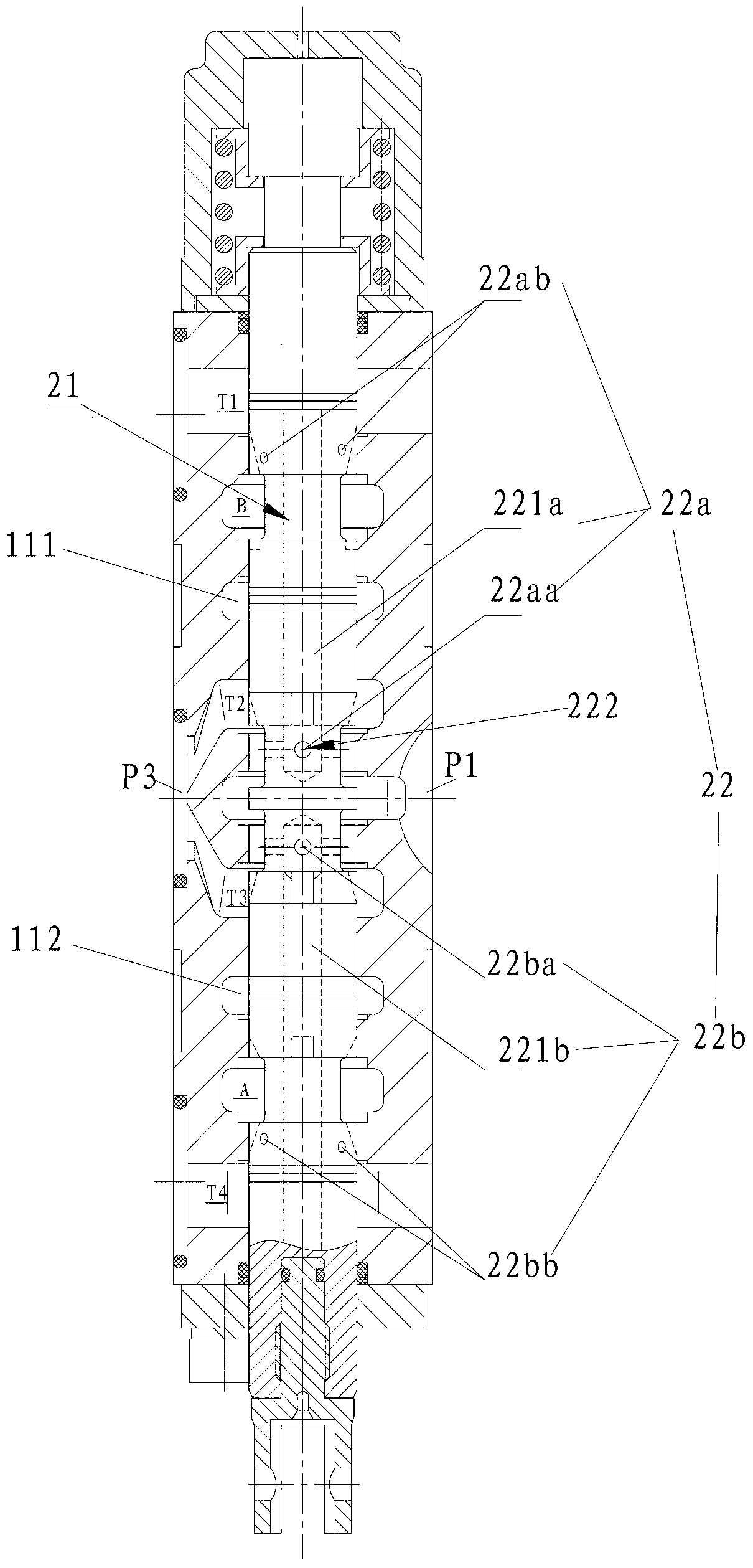

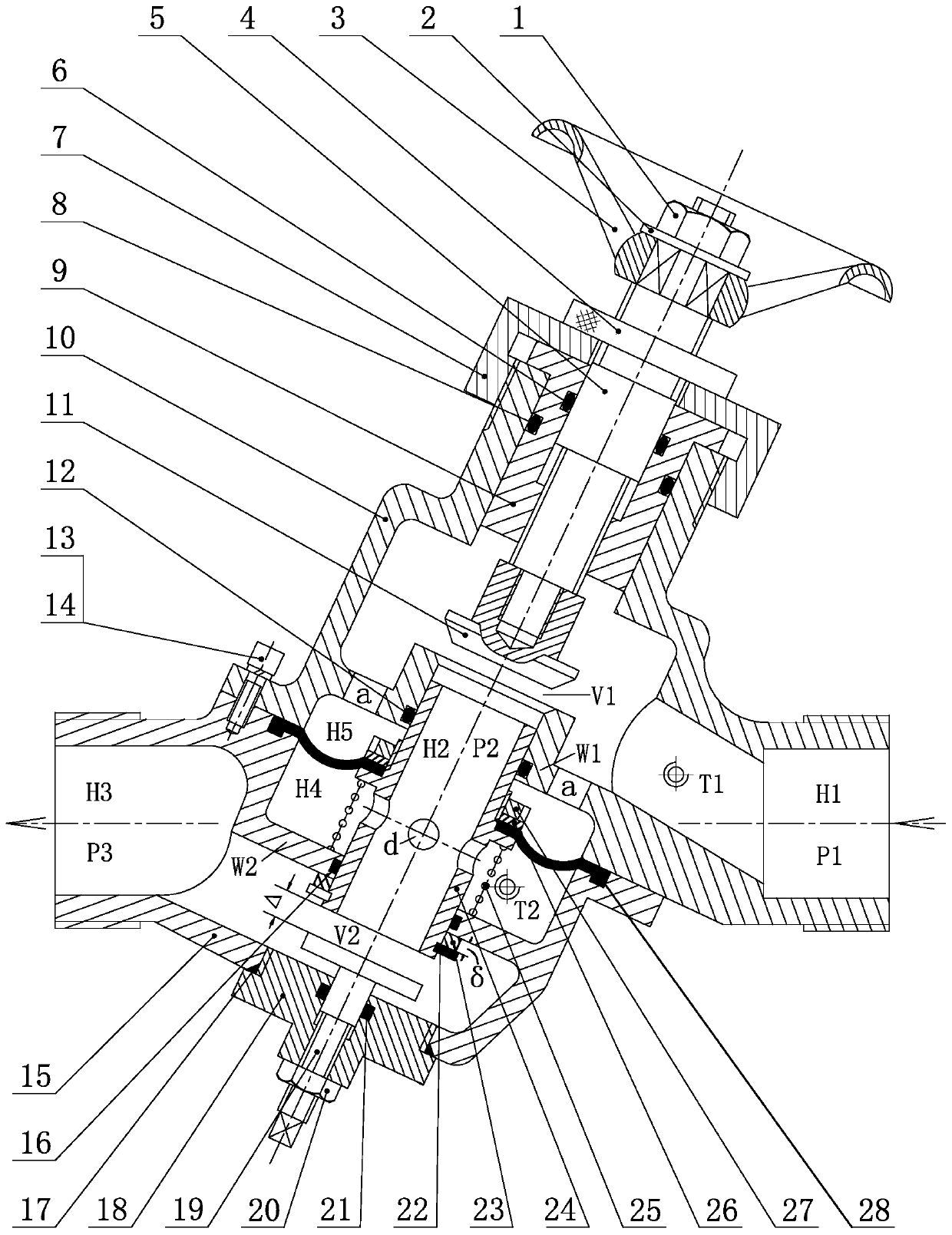

Hydraulic direction-changing valve, hydraulic direction-changing valve set and engineering machinery

ActiveCN103225633AImprove practicalityNo change in trafficServomotor componentsMechanical engineering

The invention discloses a hydraulic direction-changing valve, a hydraulic direction-changing valve set and engineering machinery. The hydraulic direction-changing valve comprises a valve body and a valve rod; a plurality of inner flow channels and a valve port used for communicating the plurality of flow channels, as well as an oil inlet, an oil return port and working oil ports all communicated with the corresponding inner flow channels, are formed in the valve body; diversion trenches are formed in the outer side of the valve body; the valve rod can move axially in the valve port to open or close corresponding inner channel, so that the hydraulic oil of the hydraulic direction-changing valve can perform oil returning; a valve rod flow channel is formed inside the valve rod; when shifting from the middle station to other stations, the valve rod flow channel can communicate the oil inlet and the corresponding working oil port which is supplied by the oil inlet; or communicate the oil inlet and the oil return port; the hydraulic direction-changing valve set adopts the hydraulic direction-changing valve provided by the invention; and the engineering machinery adopts the hydraulic direction-changing valve set provided by the invention.

Owner:CHANGDE ZHONGLIAN ZHONGKE HYDRAULIC +1

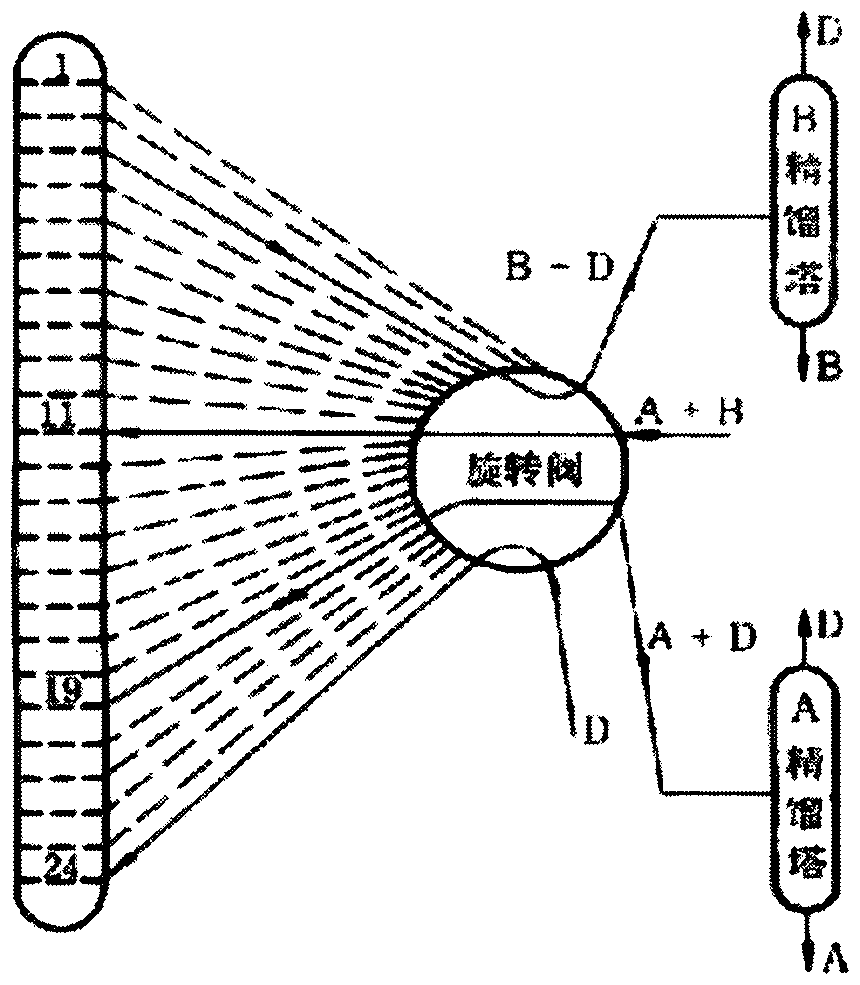

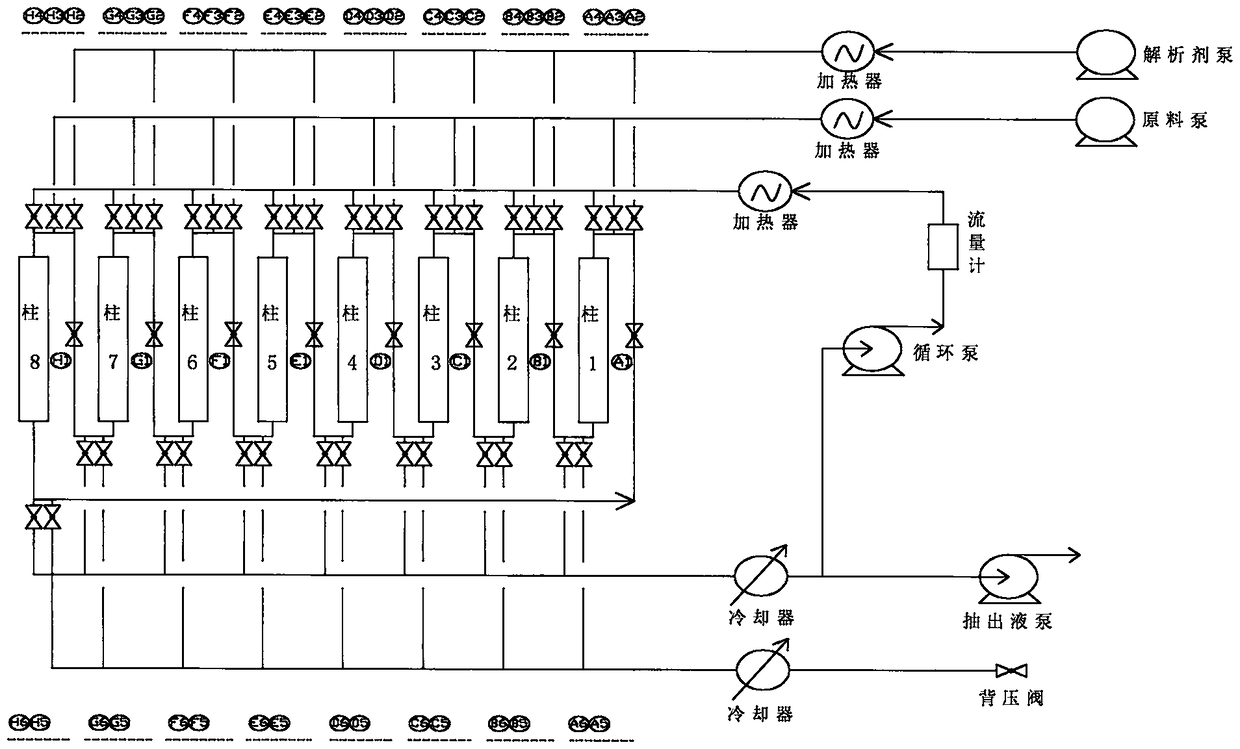

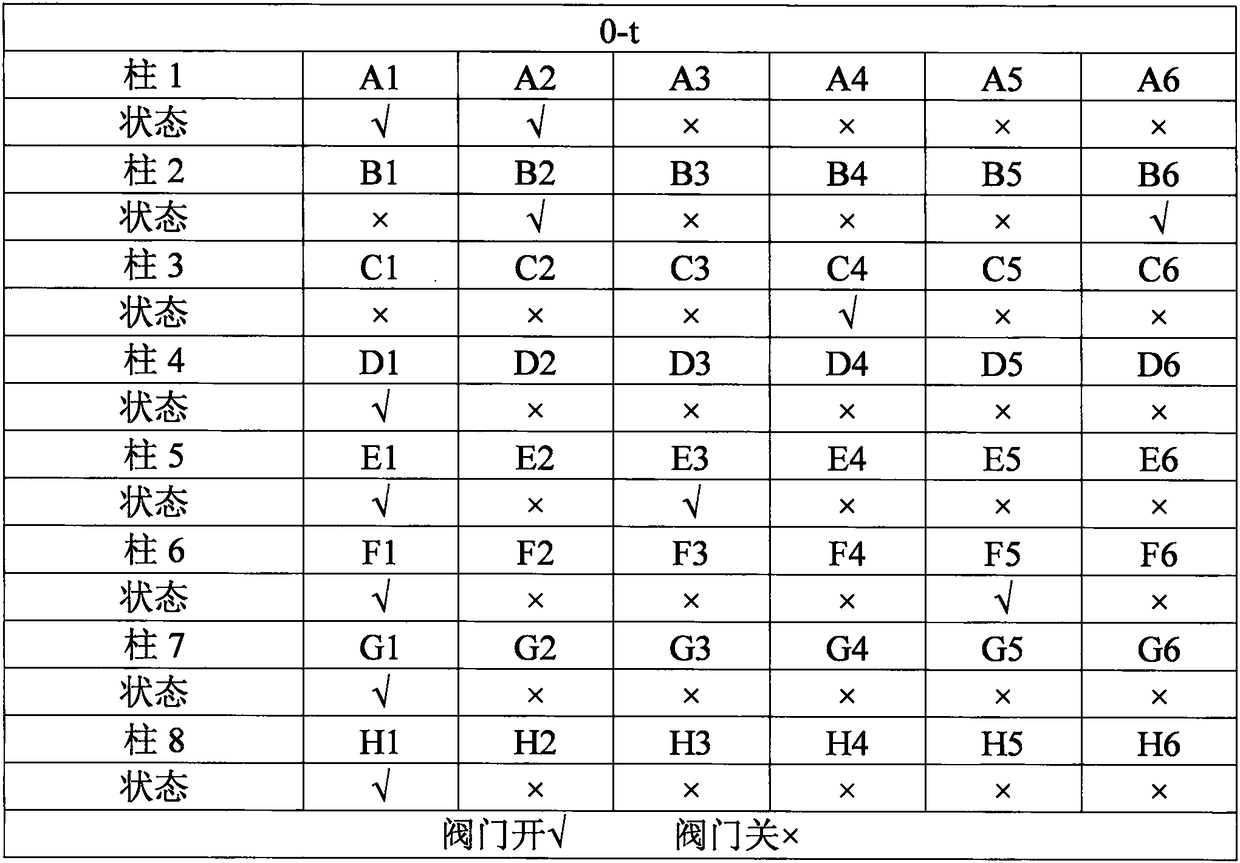

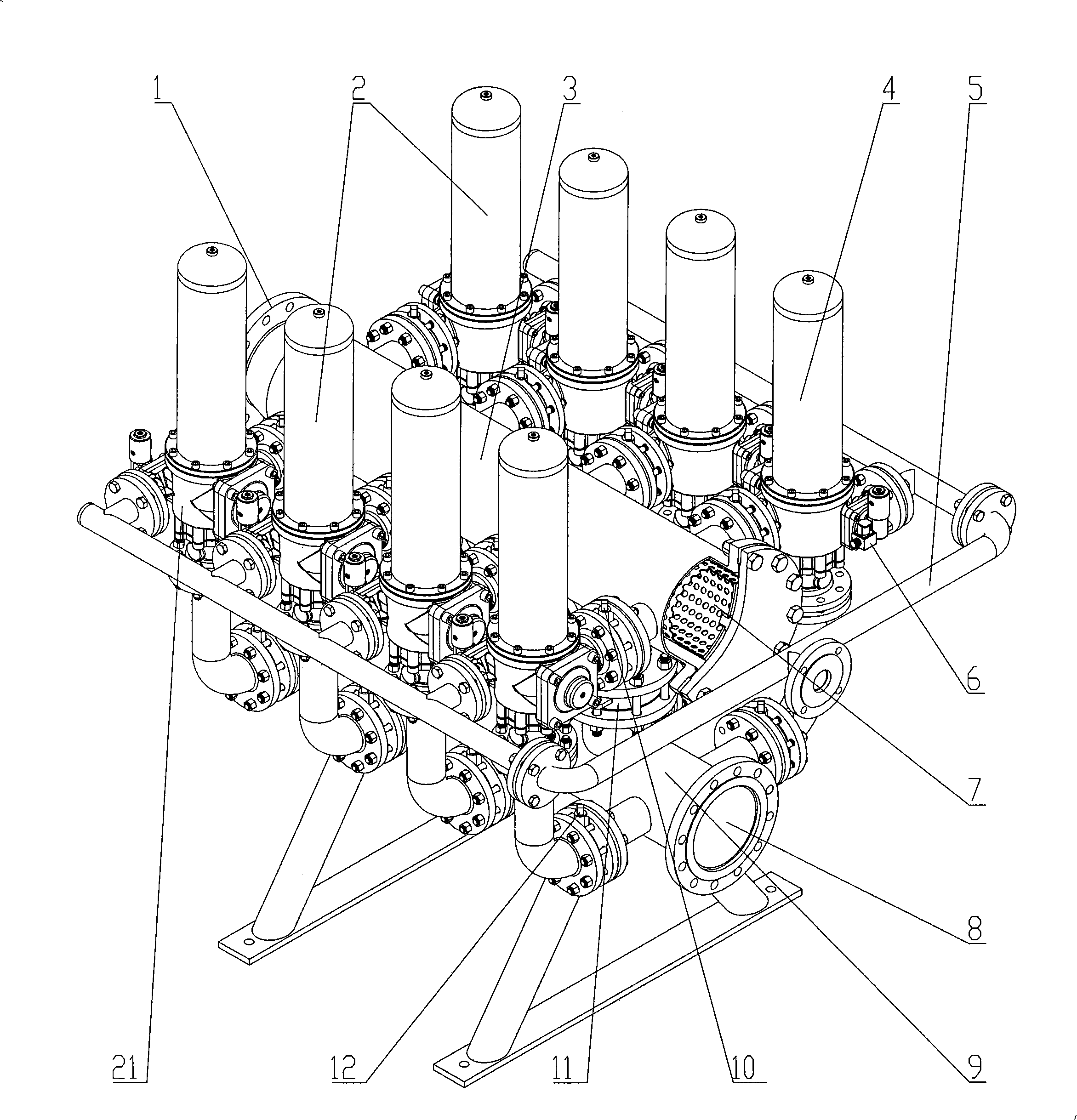

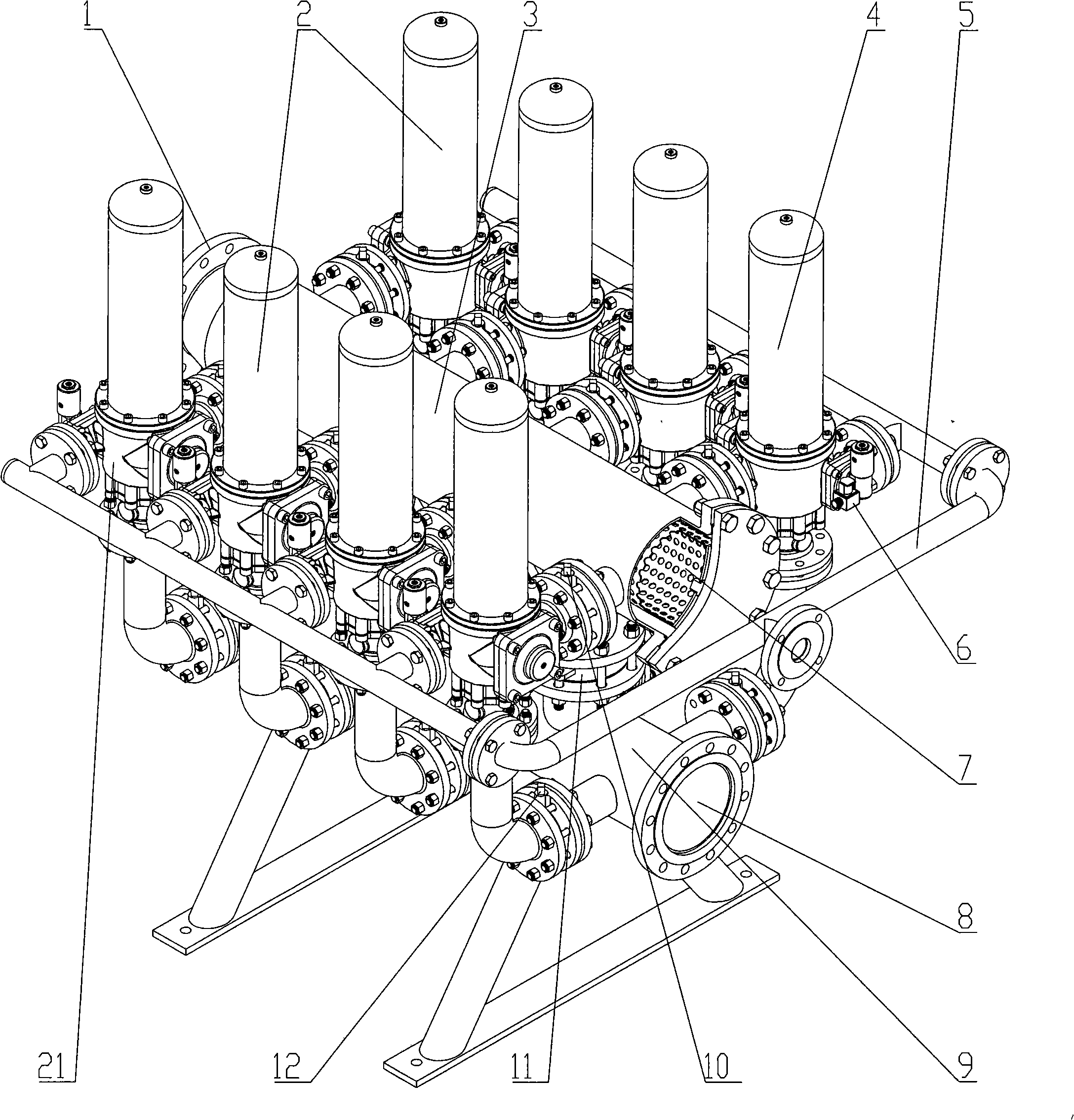

Efficient simulated moving bed equipment and efficient simulated moving bed technology

PendingCN109432822AFlexible cut outNo change in trafficSolid sorbent liquid separationAutomatic train controlAutomatic control

The invention discloses efficient simulated moving bed equipment and an efficient simulated moving bed technology. The equipment comprises an adsorption bed, a material feeding system, an analysis agent feeding system, a circulating system, a liquid extracting system, a residual liquid extracting system, a program control valve group and an automatic control system. The equipment adopts the program control valve group to replace a traditional multichannel rotary valve to control the cycle transformation of a simulated moving bed, and reduces the cost; the volumes of all pipelines connected with an adsorption column are the same, and the position of a circulating pump is not changed in a region, so that the flow of the circulating pump is not changed, pressure fluctuation is small, and theequipment is simple to control.

Owner:INNER MONGOLIA YITAI COAL BASED NEW MATERIALS RES INST CO LTD

Filter

InactiveCN101352628AContinuously workingConstant pressureStationary filtering element filtersLine tubingFiltration

Owner:王克涛

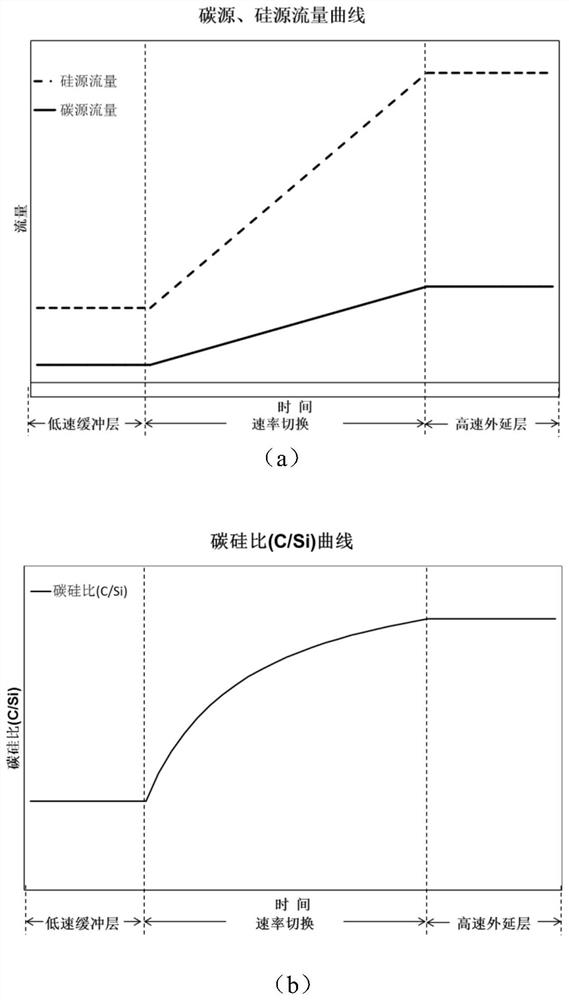

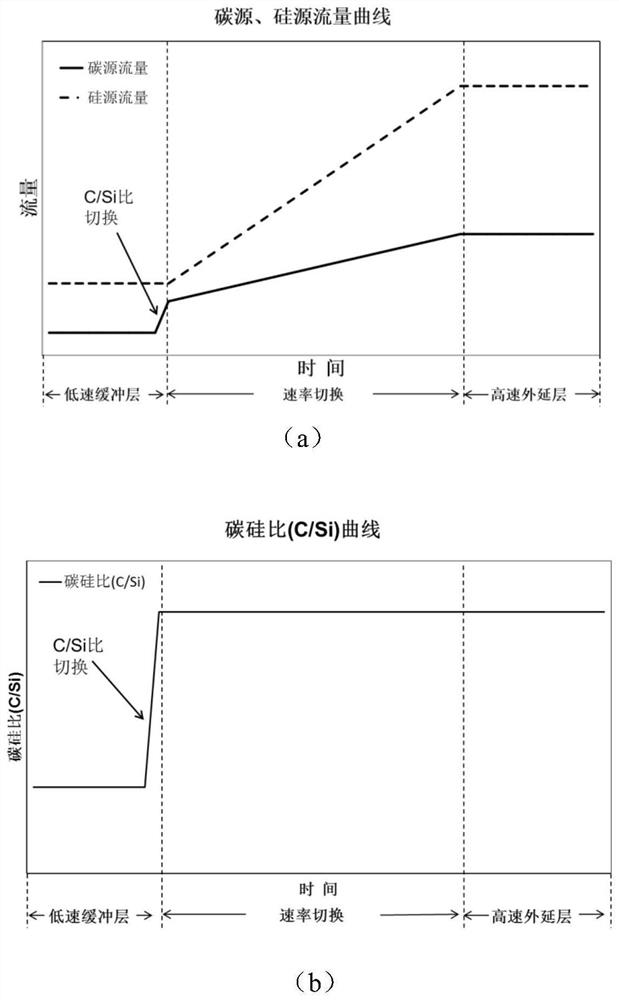

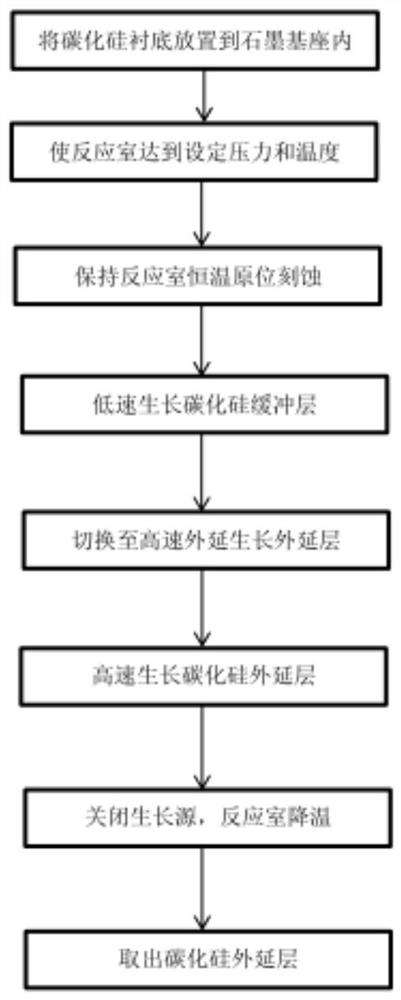

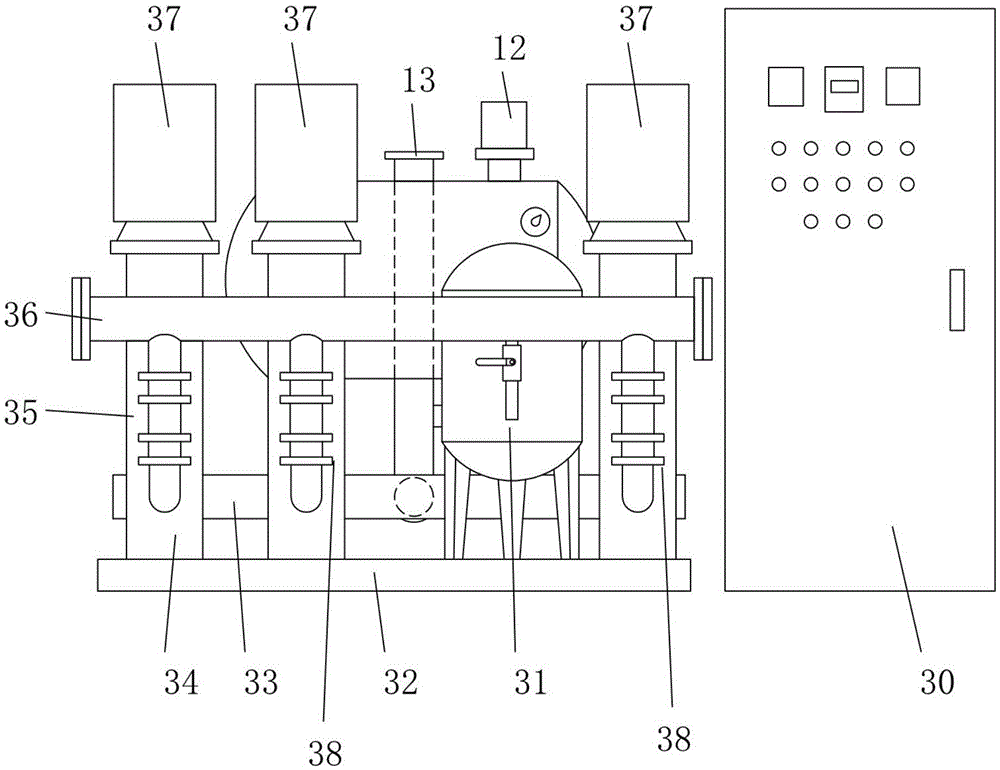

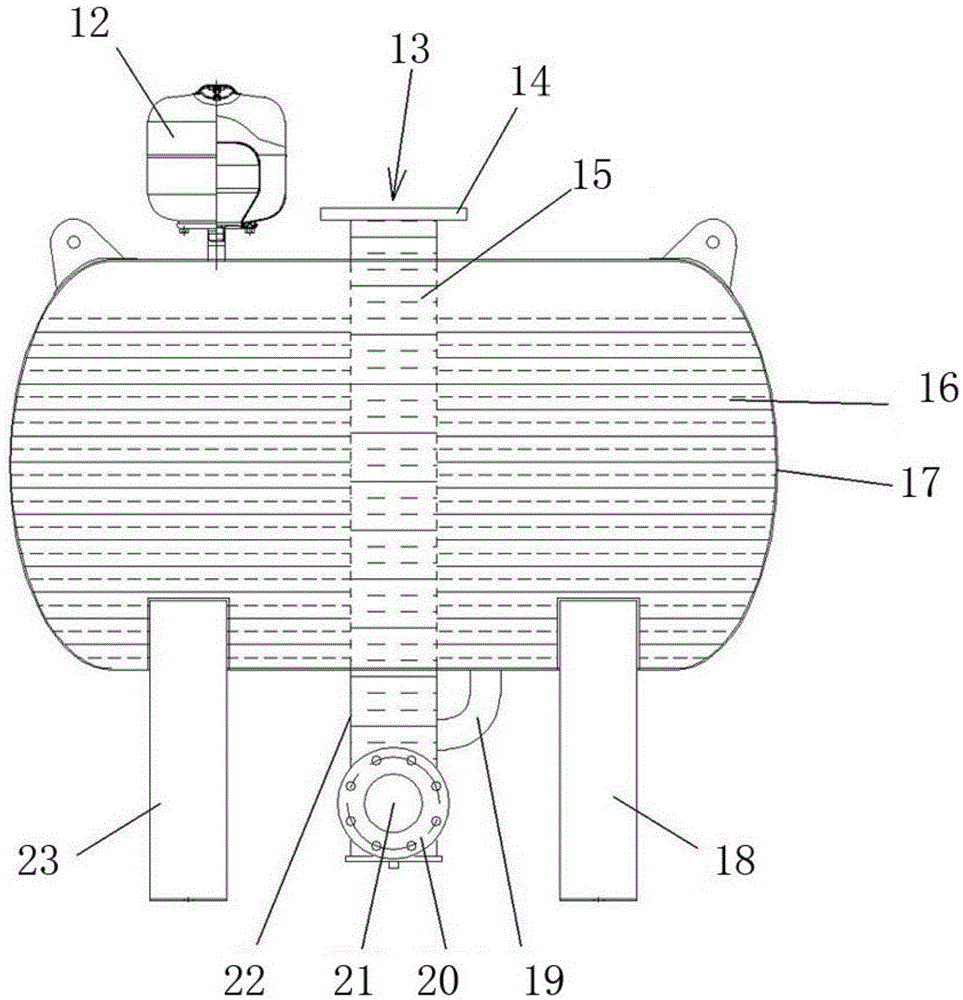

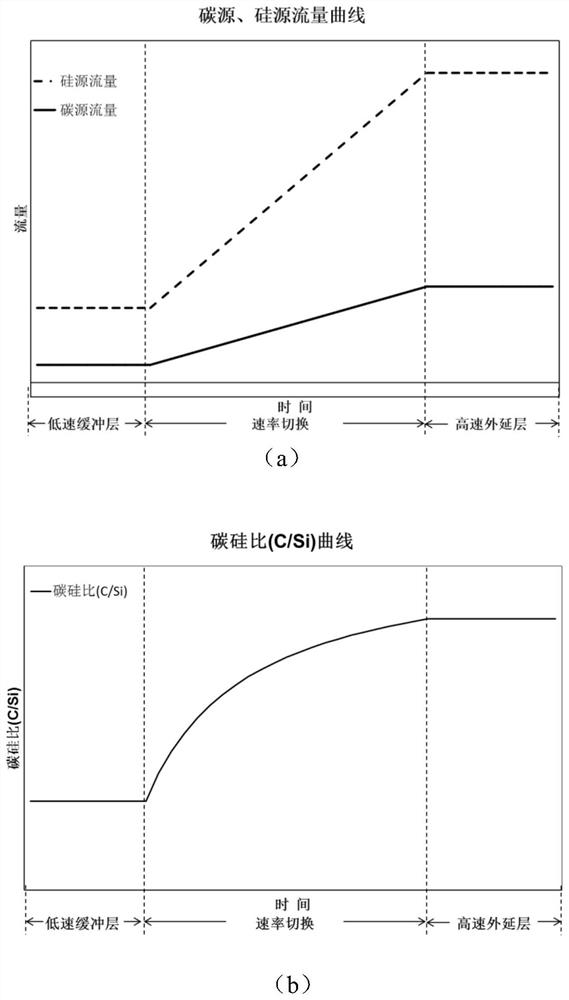

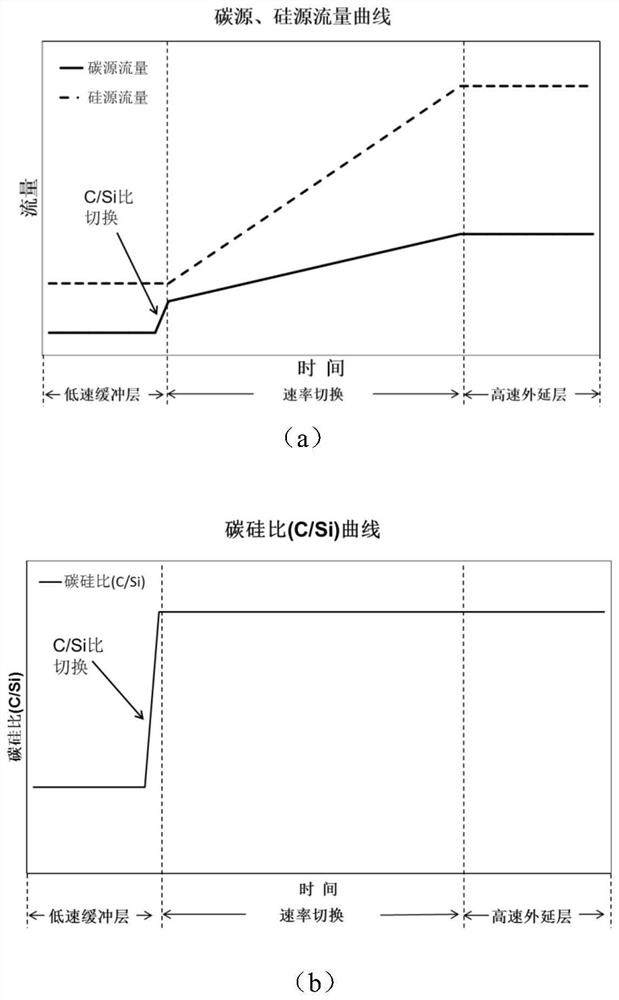

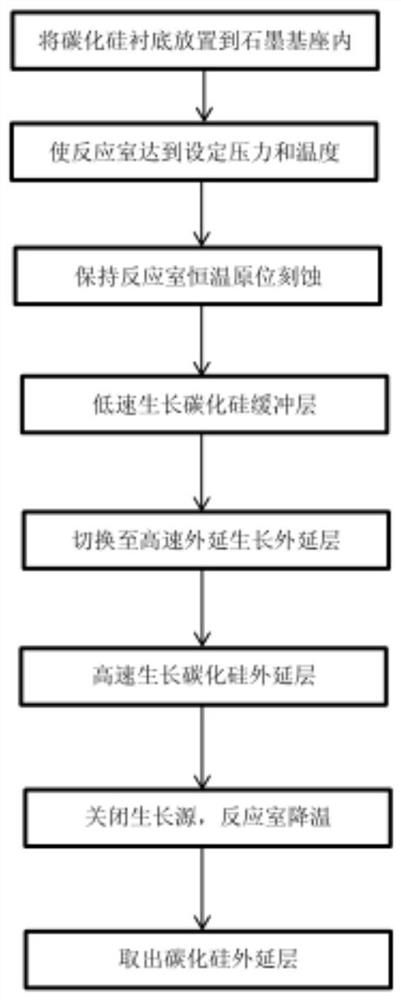

Method for growing buffer layer of silicon carbide epitaxial material

ActiveCN112701031AImprove doping efficiencyEase lattice adaptation to reduce stressSemiconductor/solid-state device manufacturingCarbide siliconEpitaxial material

The invention discloses a method for growing a buffer layer of a silicon carbide epitaxial material. The comprises the following steps: switching between low C / Si ratio and high C / Si ratio at the end of the growth of a low-speed buffer layer, and quickly finishing the switching in a short time so as to quickly improve the C / Si ratio. By adopting the optimized process switching process between the buffer layer and the epitaxial layer, the carbon-silicon ratio (C / Si) is kept stable along with time in the switching process of low-speed buffer layer growth and high-speed epitaxial layer growth, and the carbon source flow and the silicon source flow adopted in the low-speed epitaxial stage are very low, so the increasing requirement of the C / Si ratio can be met by relatively small carbon source flow amplification, defects and stress introduced in the speed switching process from low speed to high speed are reduced, the defect density of the epitaxial material is reduced, and the growth of the high-quality silicon carbide epitaxial material is realized.

Owner:NO 55 INST CHINA ELECTRONIC SCI & TECHNOLOGYGROUP CO LTD

Constant-pressure non-negative pressure water supplying unit adopting permanent magnet synchronous motors

InactiveCN105604136AImprove motor efficiencyImprove unit efficiencyService pipe systemsWater mainsPermanent magnet synchronous motorWater supply

The invention provides a constant-pressure non-negative pressure water supplying unit adopting permanent magnet synchronous motors. The constant-pressure non-negative pressure water supplying unit adopting the permanent magnet synchronous motors, provided by the invention, has the beneficial effects that the permanent magnet synchronous motors are adopted; when only one pump motor exists or two pump motors exist, variable frequency drivers are adopted to match with variable frequency driving permanent magnet synchronous motors; when two or more pump motors exist, a pump of one variable frequency driving permanent magnet synchronous motor is adopted as a main pump, several other motors which are used as auxiliary pumps adopt asynchronous starting permanent magnet synchronous motors, and a power-frequency power supply is directly used for supplying power, so that the trouble that common permanent magnet synchronous motors need mated variable frequency drivers is omitted, the cost is reduced, and the efficiency is increased; according to the scheme, the application problem of the permanent magnet synchronous motors on configuration of constant-pressure non-negative pressure multi-pump water supplying devices is solved, asynchronous motors in the constant-pressure non-negative pressure water supplying unit can be comprehensively replaced with the permanent magnet synchronous motors, and the maximum energy saving effect of the constant-pressure non-negative pressure water supplying unit can be achieved.

Owner:ZHEJIANG CHUANGMEI ELECTROMOTOR

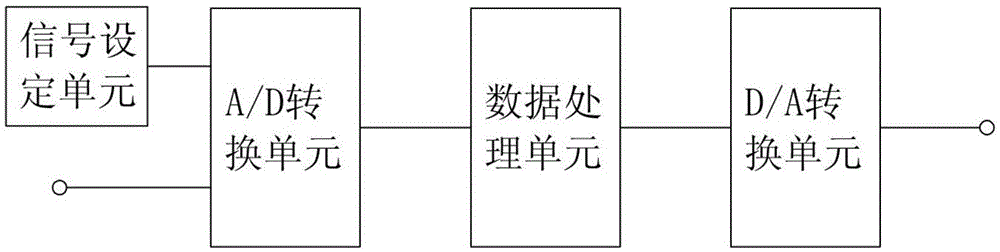

Intelligent type volume type constant-current flow gauge and measuring control method

The invention pertains to high precision continuous liquid flow testing and controlling technique. The invention provides a flow controller with high testing and controlling precision which can be used in deep-etching liquid. A volume metering and constant-current regulation manner is used to measure and control flow. A time difference correcting algorithm can realize that the flow cumulative error tends towards zero when the time difference correcting algorithm is used. In the invention, a liquid inlet constant volume control is composed of a measuring tank, two bit electromagnetic valves, dried reed pipes, a circular disc magnetic float and a float conductive pole; and a liquid outlet constant volume control is composed of a constant-current tank, a dried reed pipe, a circular disc magnetic float, a float conductive pole and a step-by-step motion electric activator. The measuring tank is controlled by a liquid level dried reed pipe under the constant-current tank to have timing liquid discharge and renewable liquid inlet. The constant-current tank liquid level ascends, the outlet flow increases, and the step-by-step motion electric activator gradually closes. The constant-current tank liquid level descends, the outlet flow reduces, and the step-by-step motion electric activator gradually opens to maintaining the constant of flow quantity.

Owner:王磊

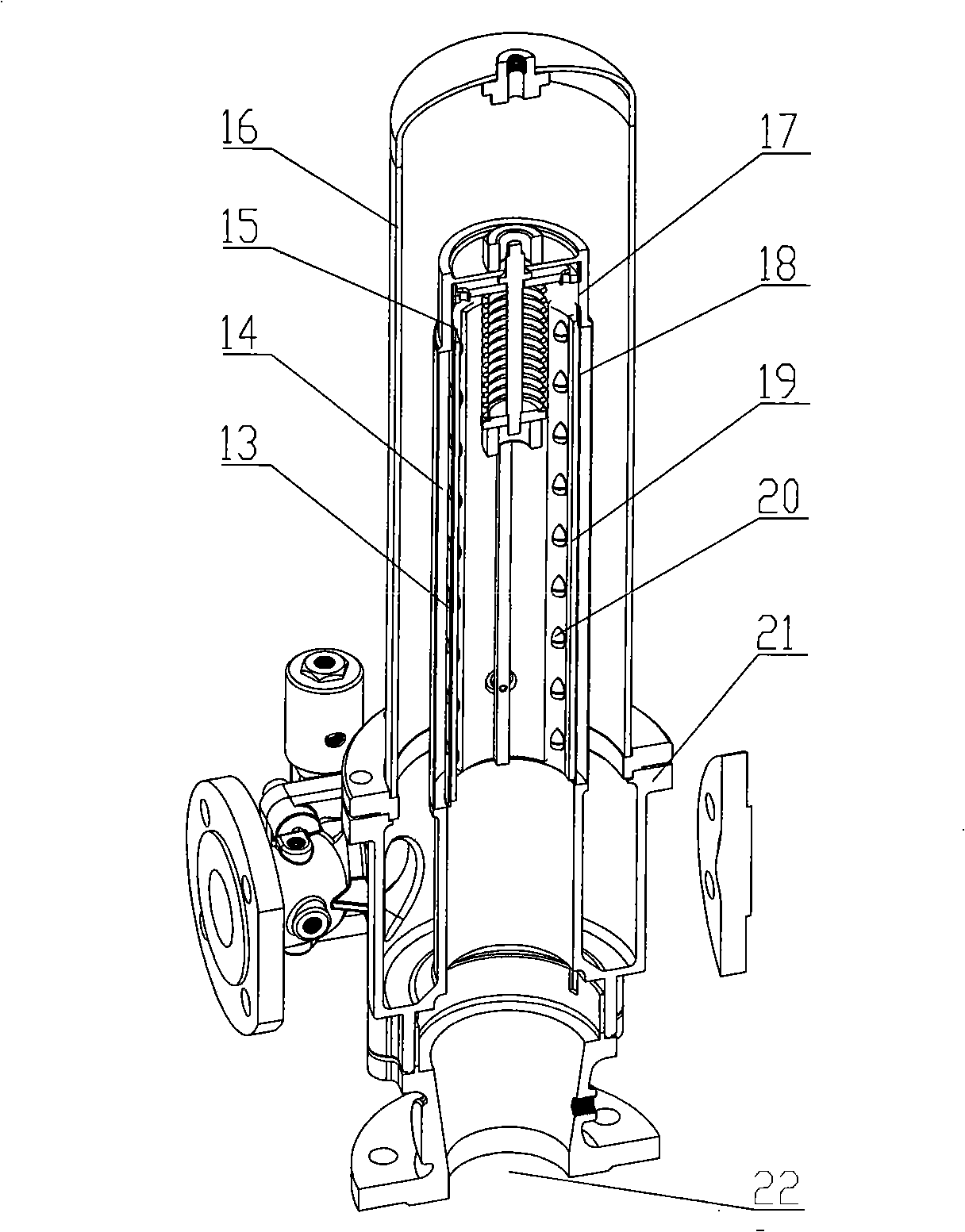

Filter

InactiveCN101352627AReduce filter loadReduce lossesStationary filtering element filtersFiltrationBiochemical engineering

The invention relates to a device which carries out the filtration on the fluid medium conveyed by the pipeline, in particular to a cleanable filter which can realize the hydrocyclone separation, surface interception and deep filtration of the impurity in the fluid medium at the same time. The filter is provided with a filter unit which consists of a filter unit shell and a valve body which are connected with each other; one side of the valve body is provided with a unit medium inlet and the other side thereof is provided with a sewage outlet; the internal side of the valve body is provided with a hydrocyclone passage; one side of the hydrocyclone passage is provided with a diaphragm valve port which is provided with an inlet diaphragm sheet; the other side of the hydrocyclone passage is provided with a sewage drainage diaphragm valve port which is provided with the sewage drainage port diaphragm sheet. Due to the design of the hydrocyclone passage, the device of the invention leads the medium to form the hydrocyclone when entering the filter unit, leads most impurities in the medium to be thrown towards the internal wall of the filter unit shell by the hydrocyclone centrifuging and be far away from a disc column, thus greatly lightening the filter load of the disc column and prolonging the service life of the filter.

Owner:王克涛

Oil pump performance test device

ActiveCN104500381BNo change in trafficShort test timePump testingPositive-displacement liquid enginesData displayTest efficiency

Owner:NINGBO SHENGLONG AUTOMOTIVE POWERTRAIN SYSTEM CO LTD

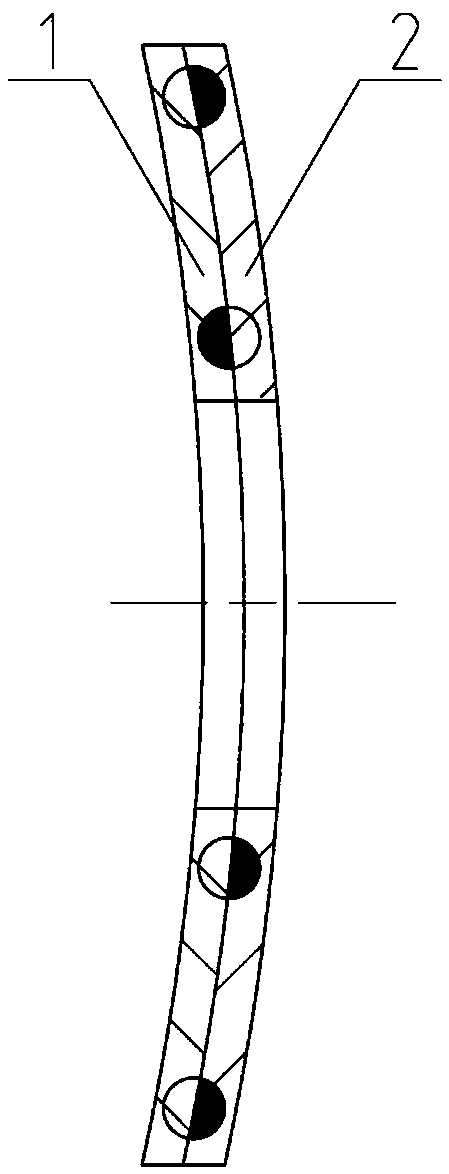

Rebound valve plate and damper valve system

PendingCN109236935AGap unchangedNo change in trafficSpringsShock absorbersEngineeringThermal expansion

The invention discloses a rebound valve plate. A first valve plate part is fixedly connected with a second valve plate part, the thermal expansion coefficient of the first valve plate part is alpha 1,the thermal expansion coefficient of the second valve plate part is alpha 2, and alpha 1 is not equal to alpha 2. The invention further discloses a damper valve system applying the rebound valve plate. As the working temperature rises, the viscosity of oil liquid is reduced, the rebound valve plate is arced towards the second valve plate part, the force of squeezing a piston valve body by the rebound valve plate is gradually reduced, so that a throttling valve plate moves towards the piston valve body along a connecting rod, a gap between the throttling valve plate and the piston valve body is reduced, then the flow passing through the gap is kept unchanged, and it is ensured that the damping force is constant; on the contrary, when the working temperature falls, the viscosity of the oilliquid is increased, the rebound valve plate is arced towards the first valve plate part, the rebound valve plate squeezes the piston valve body, so that the throttling valve plate moves towards a first limiting plate along the connecting rod, the gap between the throttling valve plate and the piston valve body is enlarged, then the flow passing through the gap is kept unchanged, and it is ensuredthat damping force is constant.

Owner:SHANGHAI BAOLONG AUTOMOTIVE CORP +1

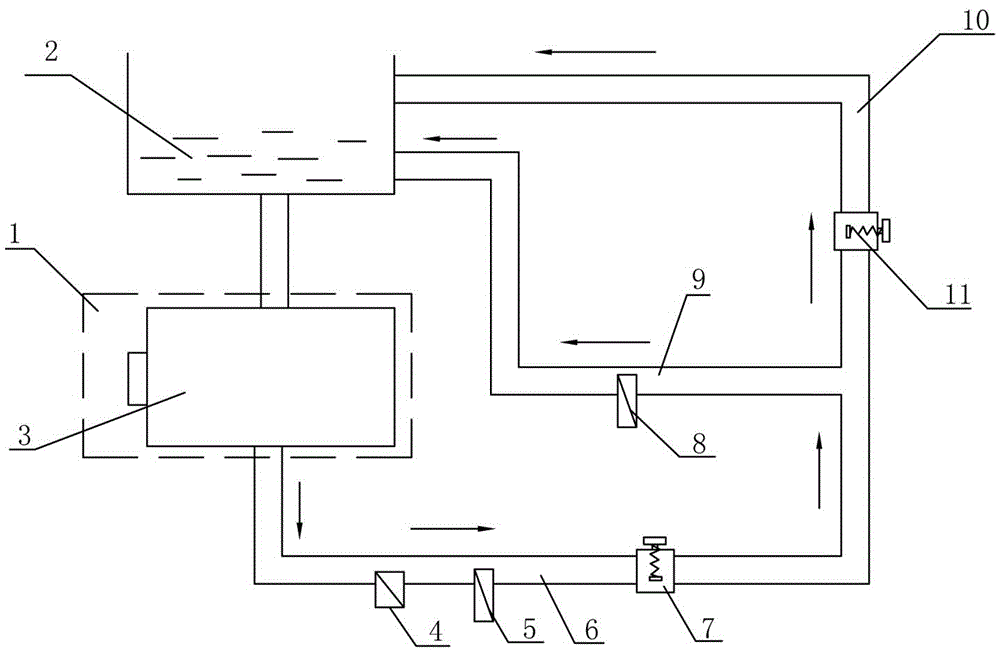

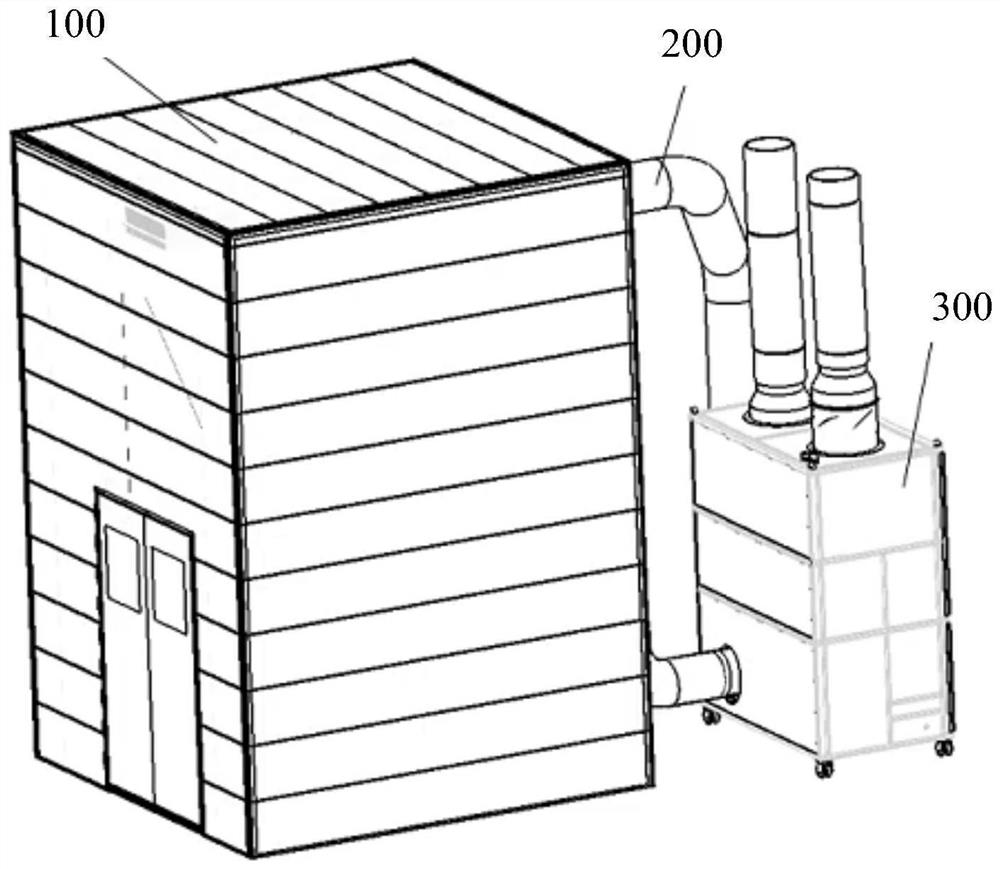

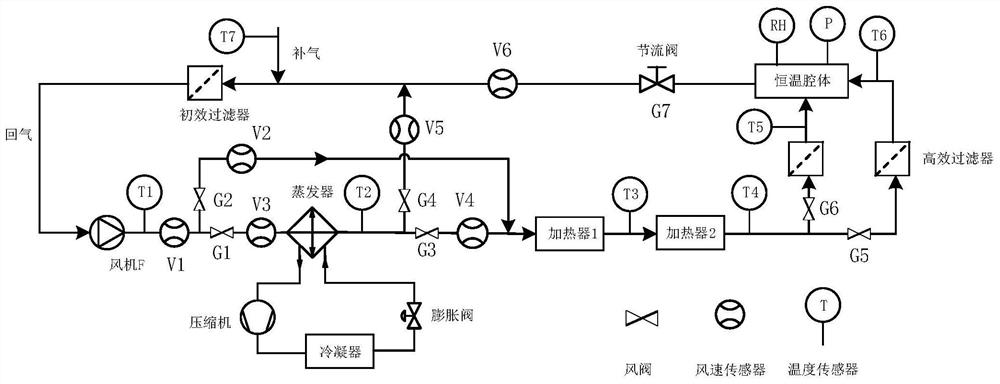

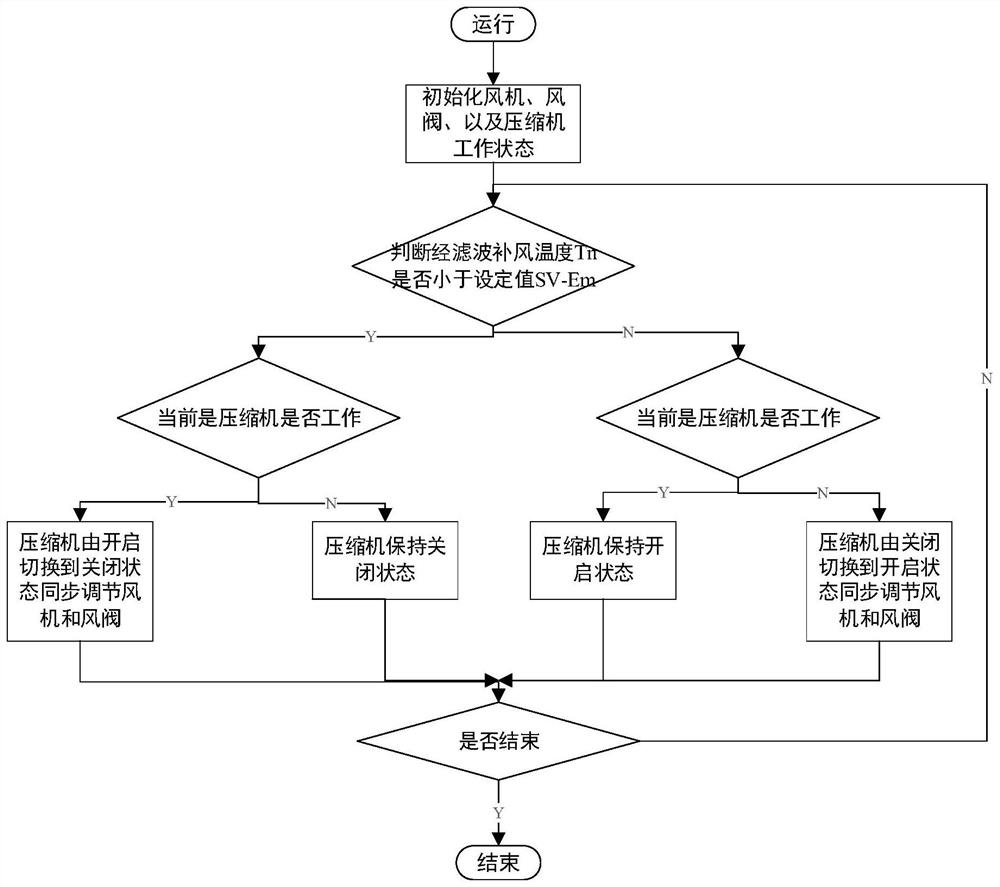

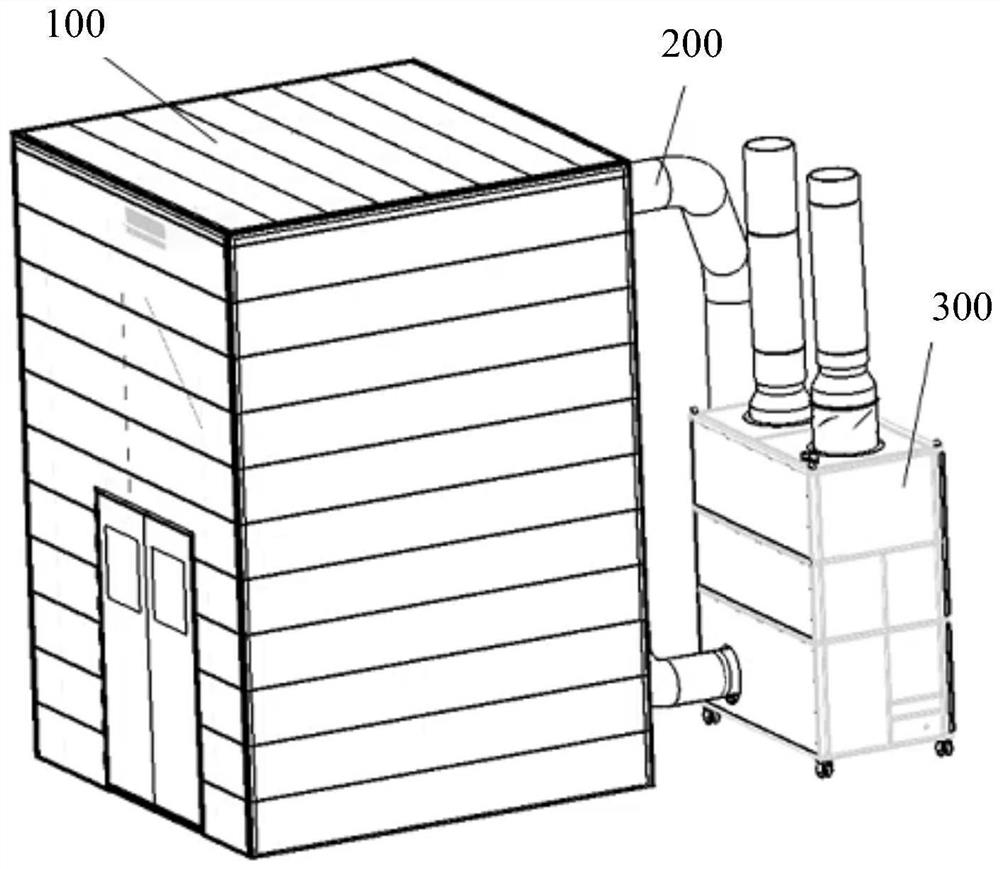

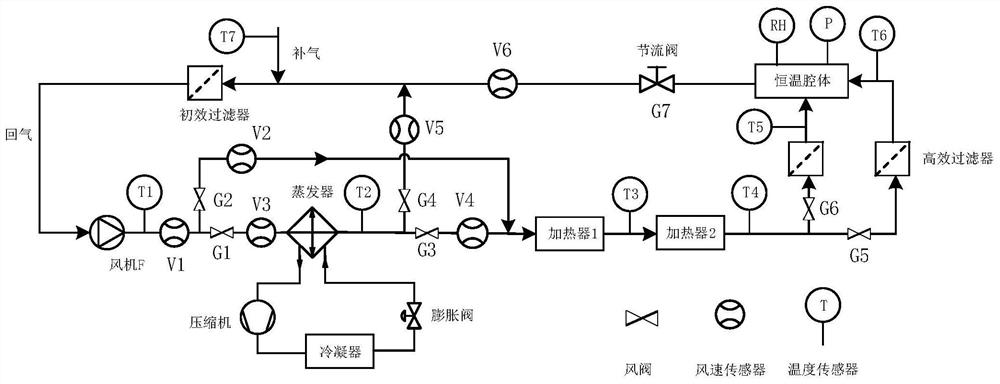

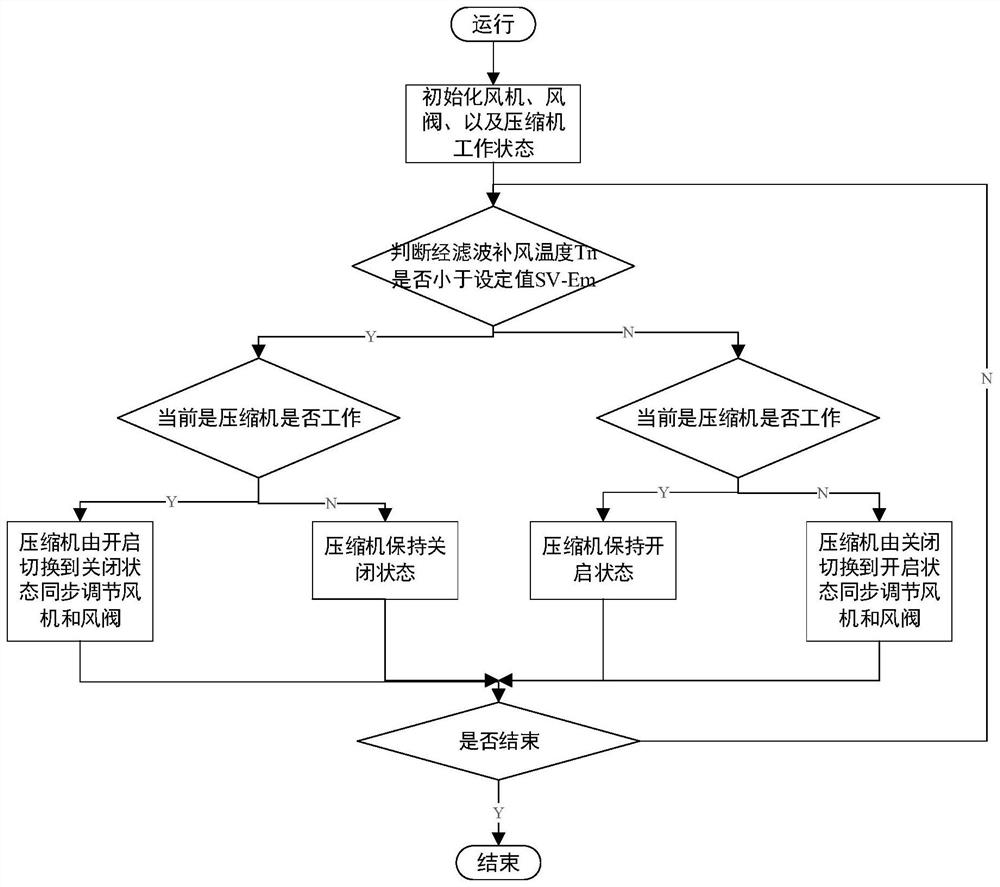

Constant-temperature air circulation system

ActiveCN112229094ANo change in trafficTo achieve the purpose of energy savingMechanical apparatusSpace heating and ventilation safety systemsAir cycleAir volume

The invention provides a constant-temperature air circulation system. Air valves are assembled behind two three-way joints of parallel bypasses and a main circulation loop for adjusting the air flow of each branch, and when the current state of a compressor is kept unchanged, a fan and the air valves are not changed. When the compressor in the turn-on state needs to be turned off , the air volumeof the fan is adjusted, and the flow of the bypasses and the main path is synchronously adjusted until all air valves controlling the flow of an evaporator are closed and all the air valves of the bypasses are opened. When the compressor in the turn-off state needs to be turned on, the air volume of the fan is adjusted, and the flow of the bypasses and the main path is synchronously adjusted untilall the air valves controlling the flow of the evaporator are opened and all the air valves of the bypasses are closed. Air valve adjustment is matched with compressor state switching to always guaranteed that the flow from a heater to a cavity is unchanged. The working state of a refrigeration heat exchange device is switched through bypass assistance to save energy for the system, and the flowand temperature of gas flowing through the constant-temperature cavity are not affected while it is guaranteed that the working state of the refrigeration heat exchange device is switched.

Owner:武汉微环控技术有限公司

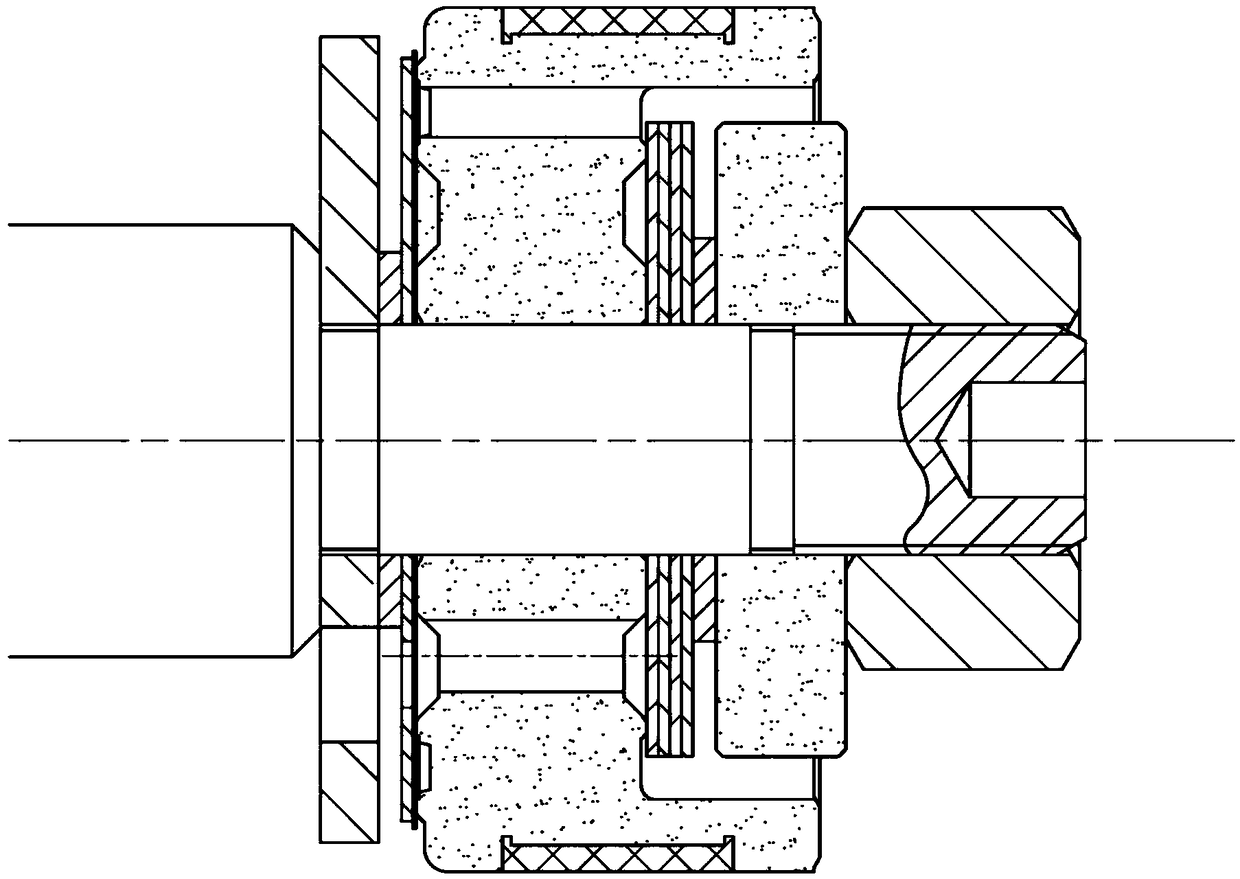

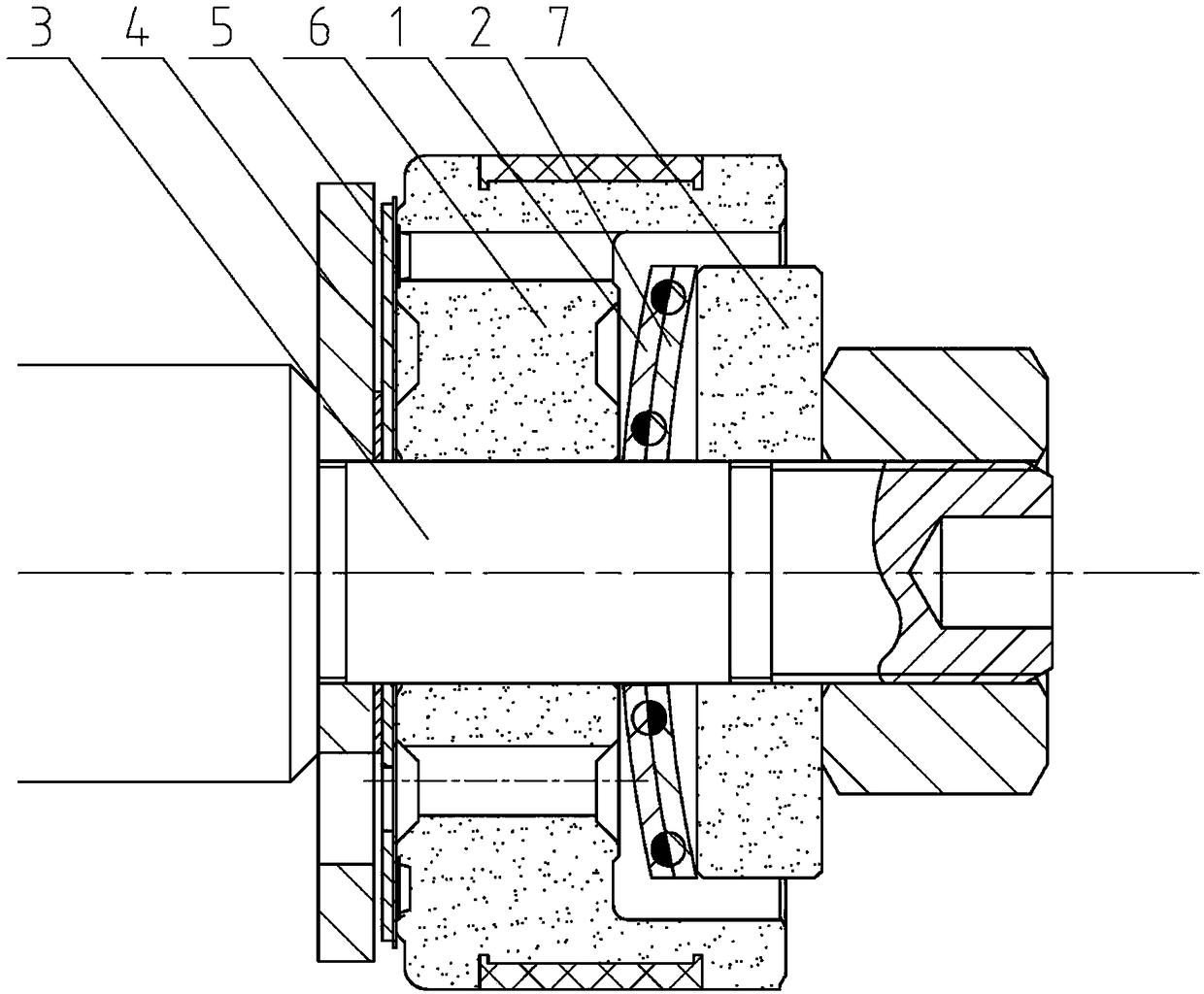

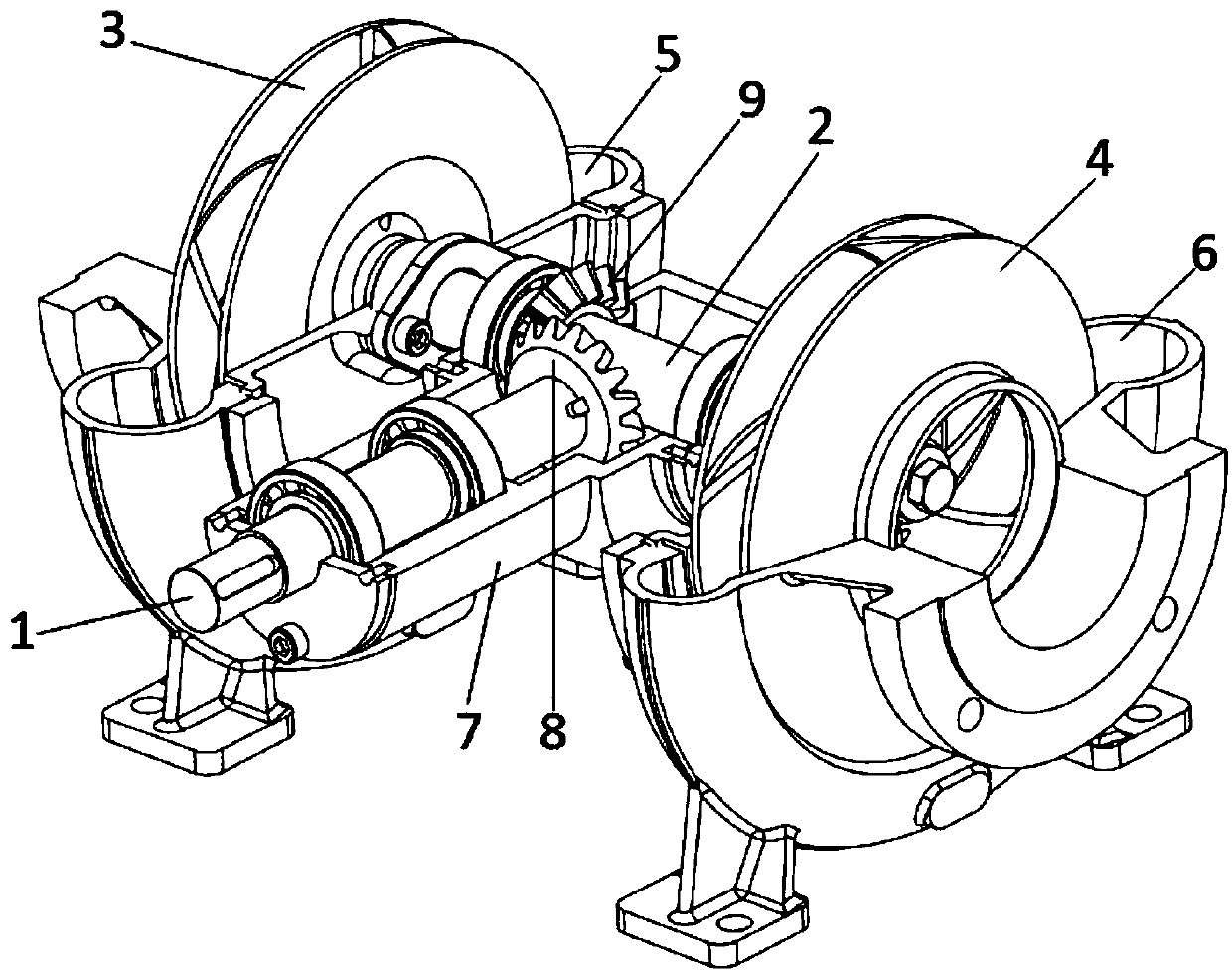

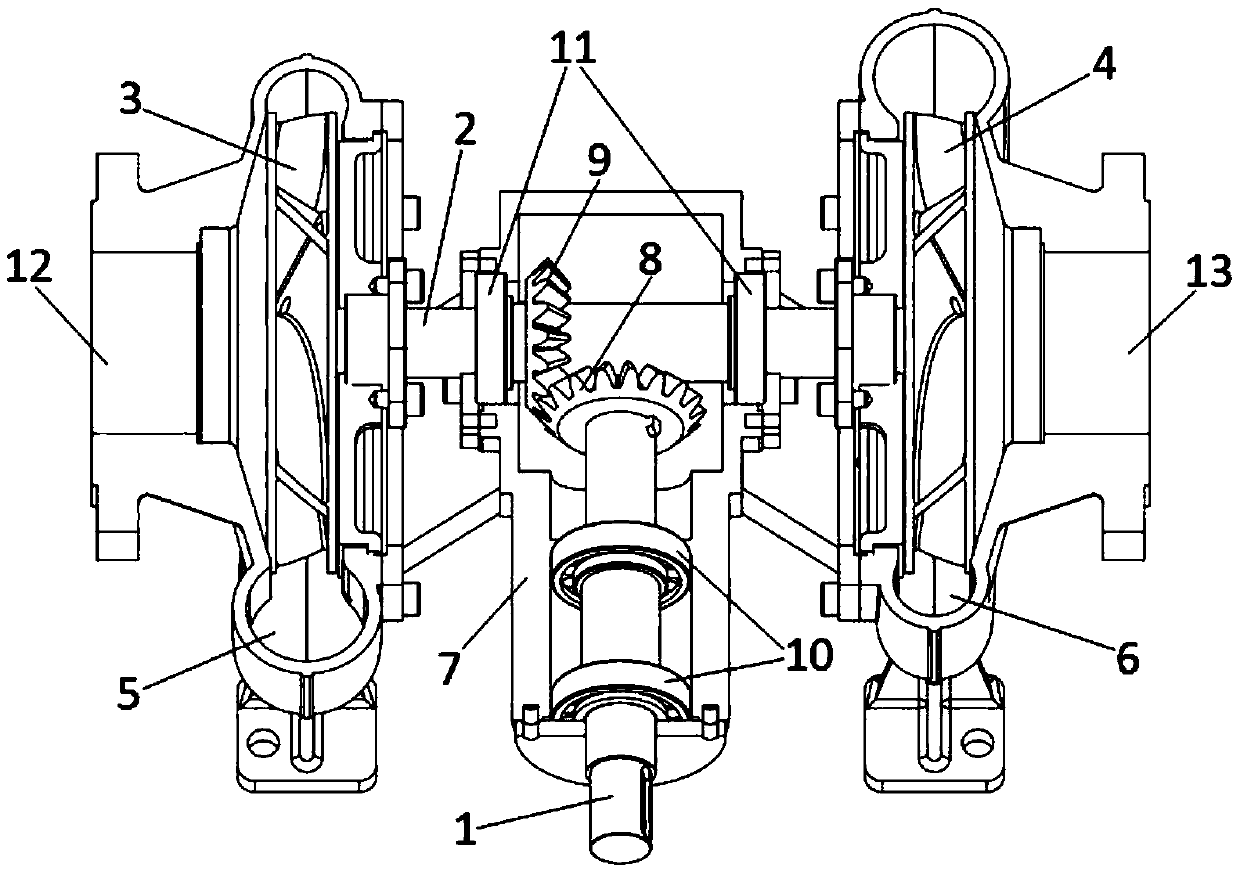

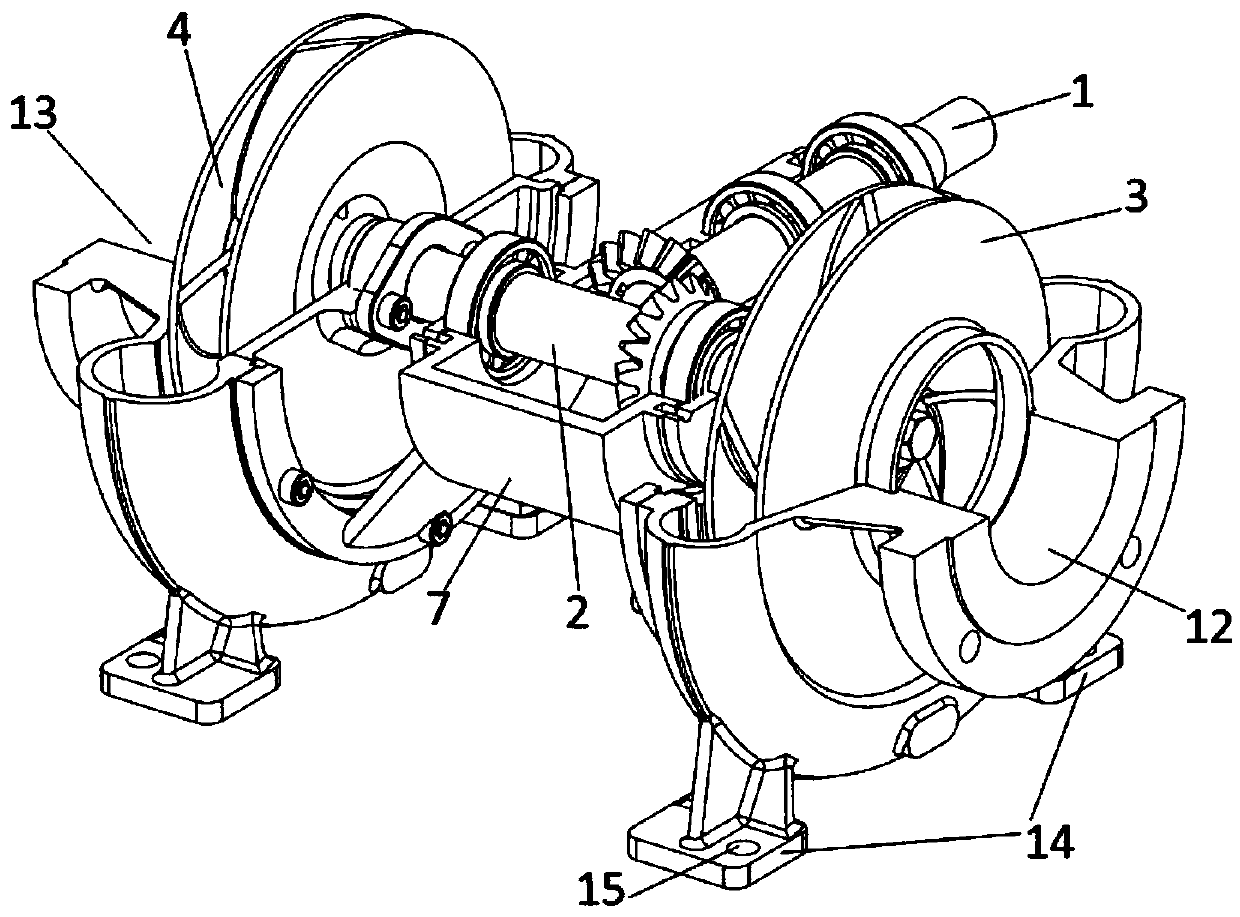

New structure multifunctional composite pumping device

PendingCN107939698AMeet delivery requirementsOvercome installation space limitationsPump componentsPump installationsDrive shaftClassical mechanics

The invention discloses a new structure multifunctional composite pumping device. The new structure multifunctional composite pumping device comprises a transmission device, a conveying device and anauxiliary device. The transmission device is mainly composed of a driving shaft and a driven shaft which are in a pair, the installing direction of the driving shaft is perpendicular to the installingdirection of the driven shaft, and torque is transmitted between the driving shaft and the driven shaft through a pair of bevel gears. The two bevel gears are arranged on the driving shaft and the driven shaft correspondingly. The conveying device is mainly composed of two impellers and two volutes. The two impellers are arranged at the two ends of the driven shaft correspondingly and matched with the two volutes correspondingly. The auxiliary device is mainly composed of a bridge frame, bearings and sealing covers. The driving shaft and the driven shaft are arranged in the bridge frame through the bearings. Due to lubricating oil in the bridge frame, the lubricating function is ensured. Due to the sealing covers at the upper portion and the front portion of the bridge frame, it is ensured that lubricating oil does not leak. The bridge frame and the two volutes are connected into a whole through bolts. The new structure multifunctional composite pumping device is simple in structure,small in size and capable of automatically balancing the axial force of the impellers; the conveying amount is increased; and different media can be conveyed and mixed.

Owner:QUZHOU UNIV

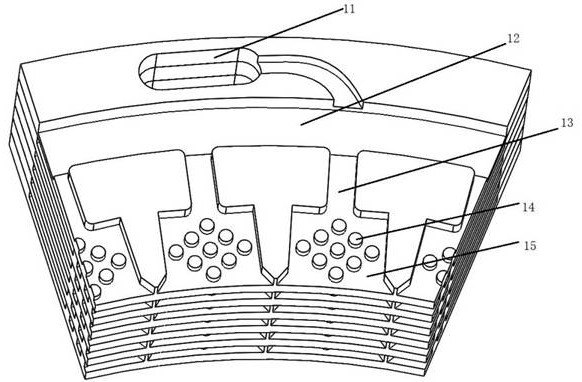

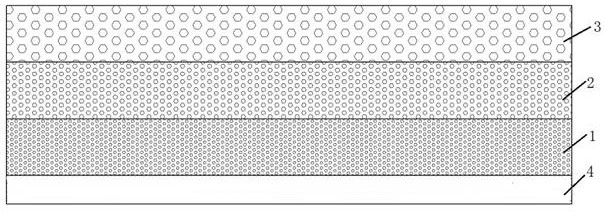

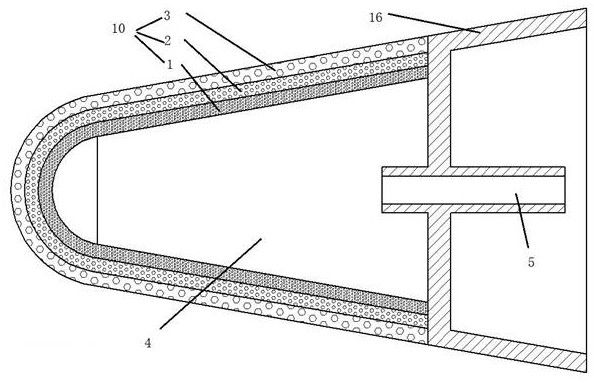

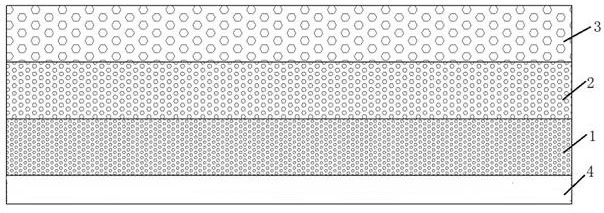

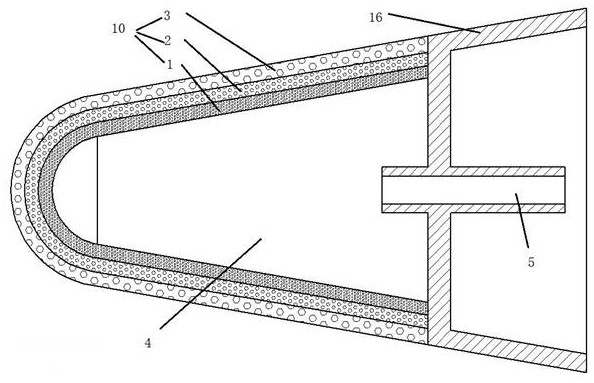

A layered gradient porous material sweat cooling structure and aircraft

ActiveCN112765913BNo change in trafficConstant supplyGeometric CADDesign optimisation/simulationPorosityFlight vehicle

The invention discloses a layered gradient porous material sweating cooling structure and an aircraft. The sweating cooling structure comprises N layers of porous material layers and a cooling cavity arranged on one side of the porous material layer. A coolant supply unit is arranged in the cooling cavity , the coolant supply unit is used to supply coolant to the cooling cavity, the porosity of the porous material layer decreases layer by layer along the direction close to the cooling cavity, wherein, N is an integer, N≥2. The invention solves the problems of uneven heat dissipation, poor heat protection effect, high cost and the like existing in the sweating cooling structure in the prior art.

Owner:CALCULATION AERODYNAMICS INST CHINA AERODYNAMICS RES & DEV CENT

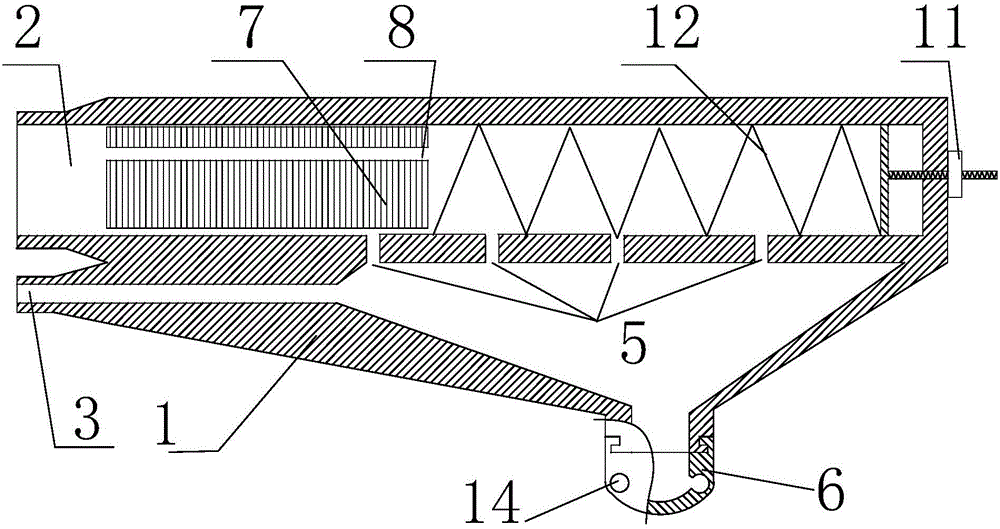

A pneumatic wave energy generator

ActiveCN106246454BStable batteryConstant outputMachines/enginesEngine componentsSea wavesEngineering

The invention provides a pneumatic type wave energy power generation device which is mainly used for ocean wave energy power generation. According to the pneumatic type wave energy power generation device, large-scale power generation can be achieved, the quantity of generated power is stable, and the power generation device can be directly connected to the national power grid. The pneumatic type wave energy power generation device is mainly composed of a pushing plate 1, a rotating rod 2, a shell 3, a floating box 4, a pushing rod 5, a spring 6, a piston 7, a pneumatic cylinder 8, a pushing chamber 9, an air inlet pipe 10, an air inlet one-way valve 11, a one-way valve 12, an energy storage chamber 13, a constant pressure valve 14, a generator set 15, a generator chamber 16, a deflector 17, a hole A 20 and a hole B 21. The main operating principle of the pneumatic type wave energy power generation device is that sea waves impact the pushing plate 1 to move to the left, the pushing plate 1 pushes the piston 7 to move to the left through the pushing rod 5 so that air in the pneumatic cylinder 8 can be compressed and fed into the energy storage chamber 13, and the compressed air in the energy storage chamber 13 is subjected to equal-pressure releasing through the constant pressure valve 14 to blow a rotor of the generator set 15 to rotate, so that a generator generates power.

Owner:济南海川投资集团有限公司

A constant temperature air circulation system

ActiveCN112229094BNo change in trafficTo achieve the purpose of energy savingMechanical apparatusSpace heating and ventilation safety systemsAir cycleAir volume

The present invention provides a constant temperature air circulation system. Air valves are installed behind the main circulation loop and the two three-way nodes of the parallel bypass to adjust the gas flow of each branch. When the compressor keeps the current state unchanged, the fan and wind The valve does not change. When the compressor needs to be turned from on to off, adjust the air volume of the fan and adjust the flow of the bypass and main road synchronously until the air valves controlling the flow of the evaporator are all closed and the bypass air valves are fully opened; when the compressor needs to be turned from off to on , adjust the air volume of the fan, and adjust the flow of the bypass and main road synchronously until the air valves controlling the flow of the evaporator are all opened and the bypass air valves are all closed. The adjustment of the air valve and the switching of the compressor state always ensure that the flow through the heater to the cavity remains unchanged. The invention saves energy on the system by auxiliary switching of the working state of the refrigeration heat exchange device through the bypass, and ensures that the switching of the working state of the refrigeration heat exchange device does not affect the flow rate and temperature of the gas flowing through the constant temperature chamber.

Owner:武汉微环控技术有限公司

A steady flow spray device

ActiveCN106475243BGuaranteed stabilityImprove atomization effectWater resource protectionMovable spraying apparatusStream flowAqueous droplet

Owner:SHANDONG UNIV OF SCI & TECH

A hydraulic system for regulating the speed of constant pumps in construction machinery

Owner:XCMG CONSTR MACHINERY

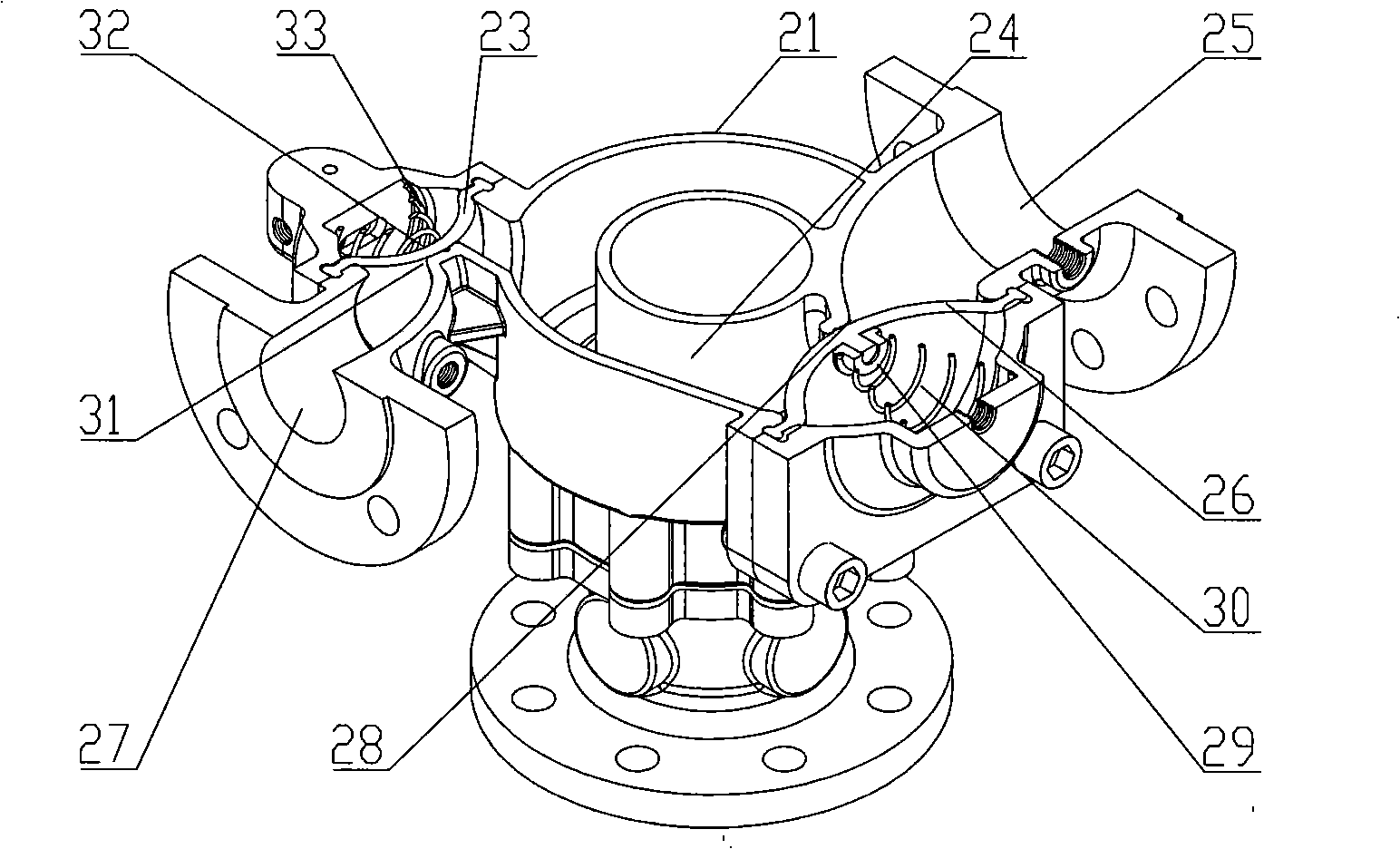

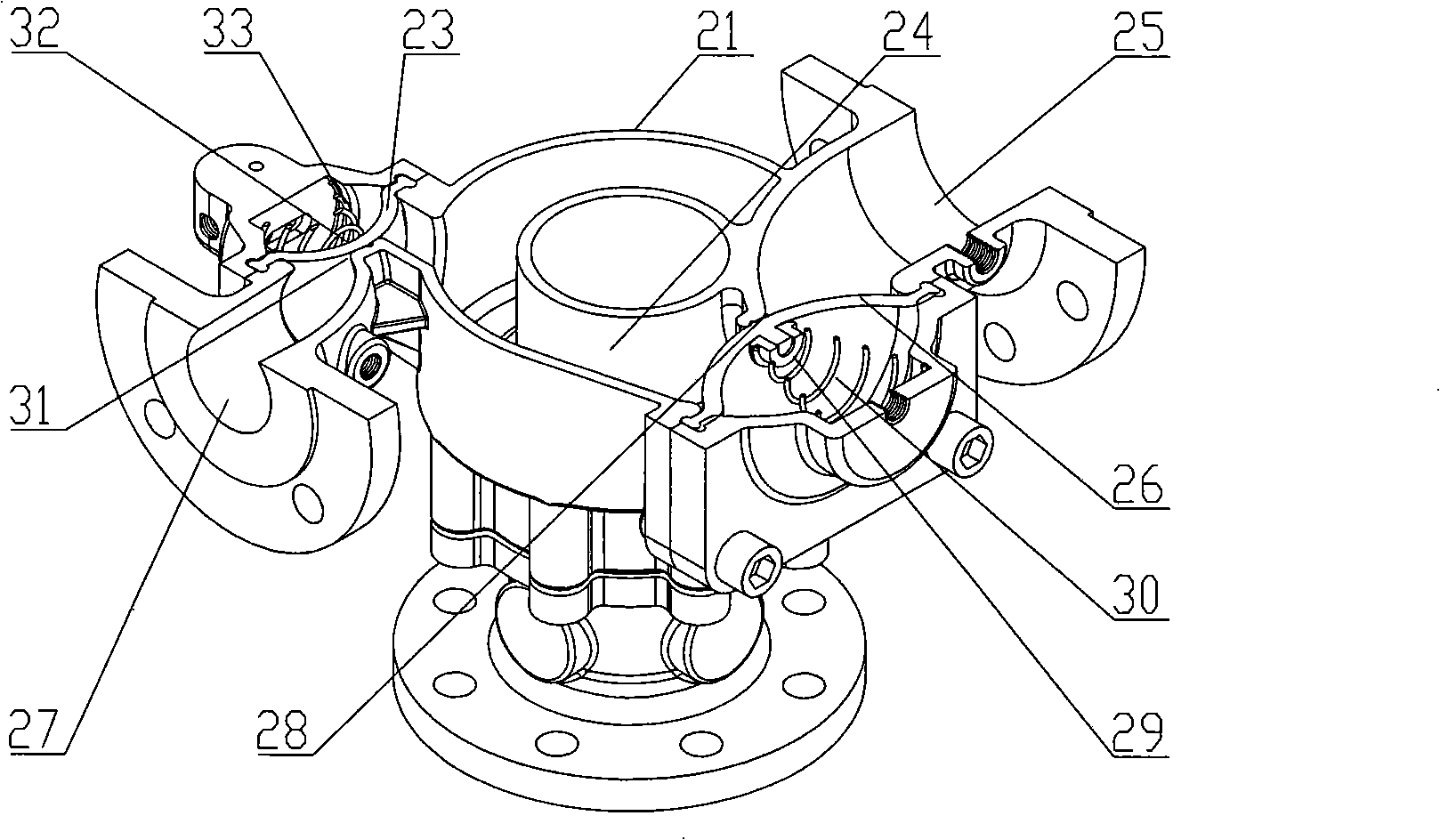

Linkage and separate type water distribution mechanism, pressure-equalization water distribution system and water distribution method

ActiveCN109084051AGuaranteed reliabilityEasy to operateOperating means/releasing devices for valvesMultiple way valvesSurface phaseWater use

The invention discloses a linkage and separate type water distribution mechanism. The water distribution mechanism comprises a linkage plate, a power device in transmission connection with the linkageplate and multiple water distribution valves; valve rods of the water distribution valves are all connected with the linkage plate, and an extension rod of the power device is connected to the lowersurface of the linkage plate. The invention also discloses a pressure-equalization water distribution system using the linkage and separate type water distribution mechanism. The pressure-equalizationwater distribution system includes a main water inlet pipe and a pressure-equalization water tank, the main water inlet pipe is connected with a water distribution pipe, and water inlet pipes of thewater distribution valves are all connected with the water distribution pipe; the pressure-equalization water tank comprises a tank body, and water blocking plates are uniformly arranged in the tank body at intervals and provided with elastic water blocking cloths and uniformly divide the pressure-equalization water tank into multiple pressure-equalization water cavities. The invention also discloses a water distribution method. Linkage water distribution and pressure-equalization water distribution can be achieved at the same time, and not only is the water distribution operation simplified,but also the system pressure is stabilized so that the water distribution system can work more stably, and the water use demands of each water use unit are better guaranteed.

Owner:河南省水务规划设计研究有限公司

Layered gradient porous material sweating cooling structure and aircraft

ActiveCN112765913ANo change in trafficConstant supplyGeometric CADDesign optimisation/simulationPorosityFlight vehicle

The invention discloses a layered gradient porous material sweating cooling structure and an aircraft, the sweating cooling structure comprises N porous material layers and a cooling cavity arranged on one side of the porous material layers, a coolant supply unit is arranged in the cooling cavity, the coolant supply unit is used for supplying a coolant to the cooling cavity, the porosity of the porous material layers is sequentially reduced layer by layer in the direction close to the cooling cavity, and N is an integer and is larger than or equal to 2. The problems that in the prior art, a sweating cooling structure is uneven in heat dissipation, poor in thermal protection effect, high in cost and the like are solved.

Owner:CALCULATION AERODYNAMICS INST CHINA AERODYNAMICS RES & DEV CENT

A kind of buffer layer growth method of silicon carbide epitaxial material

ActiveCN112701031BImprove doping efficiencyEase lattice adaptation to reduce stressSemiconductor/solid-state device manufacturingCarbide siliconPhysical chemistry

The invention discloses a buffer layer growth method of silicon carbide epitaxial material, which adopts low-high C / Si ratio switching at the end of low-speed buffer layer growth, and quickly completes the switching in a short time, so as to increase the C / Si ratio more quickly. . By adopting an optimized process switching process between the buffer layer and the epitaxial layer, the present invention realizes that the carbon-to-silicon ratio (C / Si) remains stable over time during the switching process between the growth of the low-speed buffer layer and the growth of the high-speed epitaxial layer. The carbon source flow rate and the silicon source flow rate are both very low, and a relatively small increase in the carbon source flow rate can meet the requirements for improving the C / Si ratio, reduce the defects and stress introduced by the low-speed to high-speed rate switching process, and reduce the defects of epitaxial materials. Density to achieve high-quality SiC epitaxial material growth.

Owner:NO 55 INST CHINA ELECTRONIC SCI & TECHNOLOGYGROUP CO LTD

Self-operated type bevel valve

PendingCN110822158ANo change in trafficOperating means/releasing devices for valvesEqualizing valvesSpool valveMechanics

The invention discloses a self-operated type bevel valve. The self-operated type bevel valve comprises a regulating valve and a fixed differential reducing valve, wherein the regulating valve is arranged in an upper valve body cavity, the fixed differential reducing valve is arranged in a lower valve body cavity, the fixed differential reducing valve is arranged behind the regulating valve; the upper and lower valve bodies are connected into a whole through fasteners, center lines of the upper and lower valve bodies are on the same axis, and the center lines are provided with certain bevel angles with the horizontal axes of water inlet and outlet holes, the regulating valve comprises a handwheel, a guide sleeve, a valve rod and a valve clack; and the fixed differential reducing valve comprises a sliding valve, a spring, a diaphragm, a lower valve cover, a regulating screw rod, a regulating gasket, a pressing plate and a compression nut. According to the self-operated type bevel valve,when a medium flows, if the pressure of water inlet or outlet chambers fluctuates, the fixed differential reducing valve compensates the pressure at the outlet end of the regulating valve, so that thedifferential pressure at two ends of the regulating valve remains unchanged, and it can be further ensured that the passed flow is constant.

Owner:HANGZHOU CHUNJIANG VALVE

A high-pressure adiabatic gas storage pumped compressed air energy storage system

ActiveCN108571415BShorten the payback periodConstant flowHydro energy generationEngine componentsThermal energyThermal energy storage

Owner:XI AN JIAOTONG UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com