Filter

A filter and filter unit technology, applied in the direction of filtration separation, fixed filter element filter, chemical instrument and method, etc., can solve the problems of the pressure and flow of the supply medium, the pipeline cannot supply the medium normally, and the troubleshooting rate is high. , to achieve the effect of improving the service life, prolonging the backwash cycle, reducing losses and operating costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

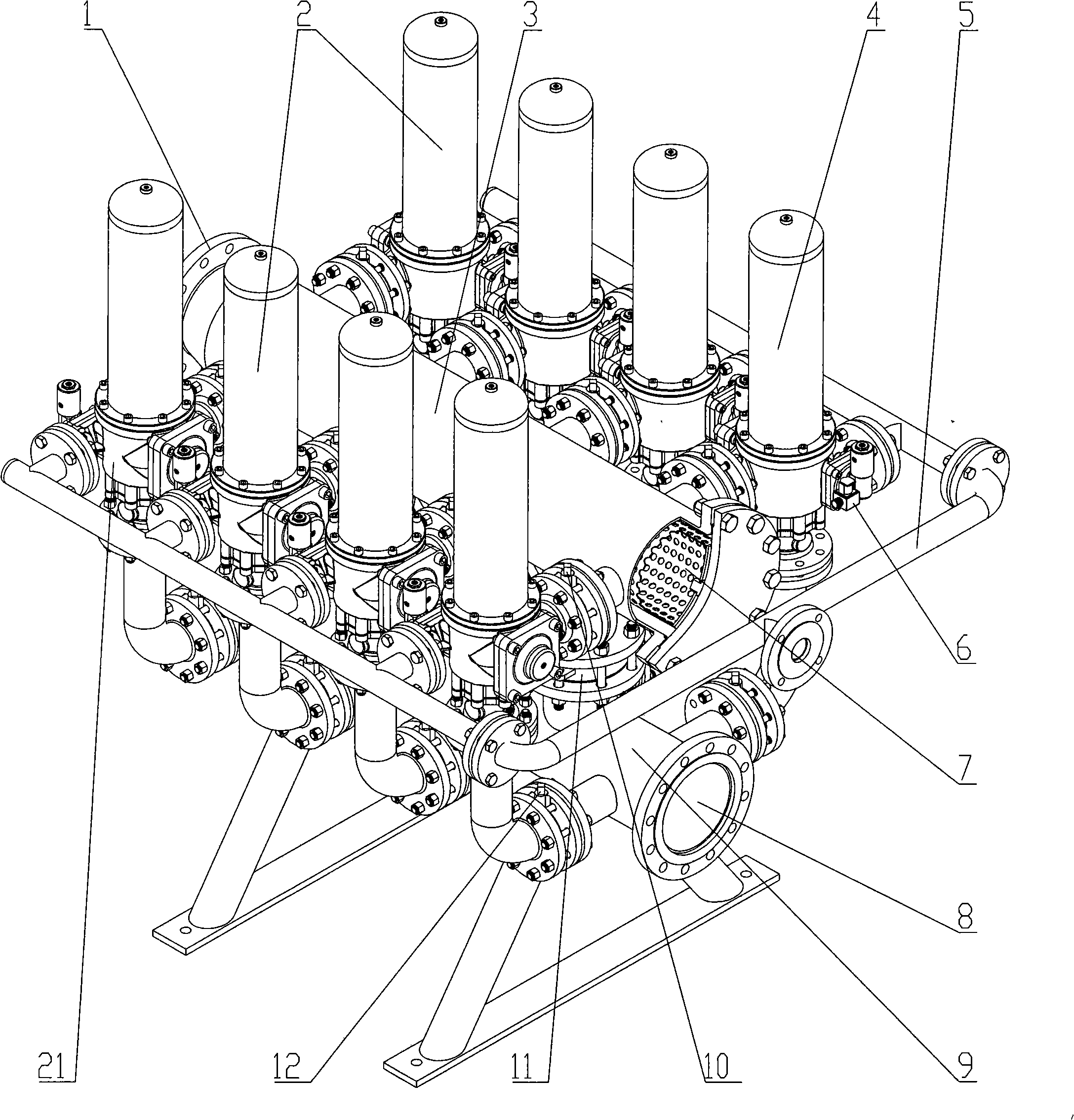

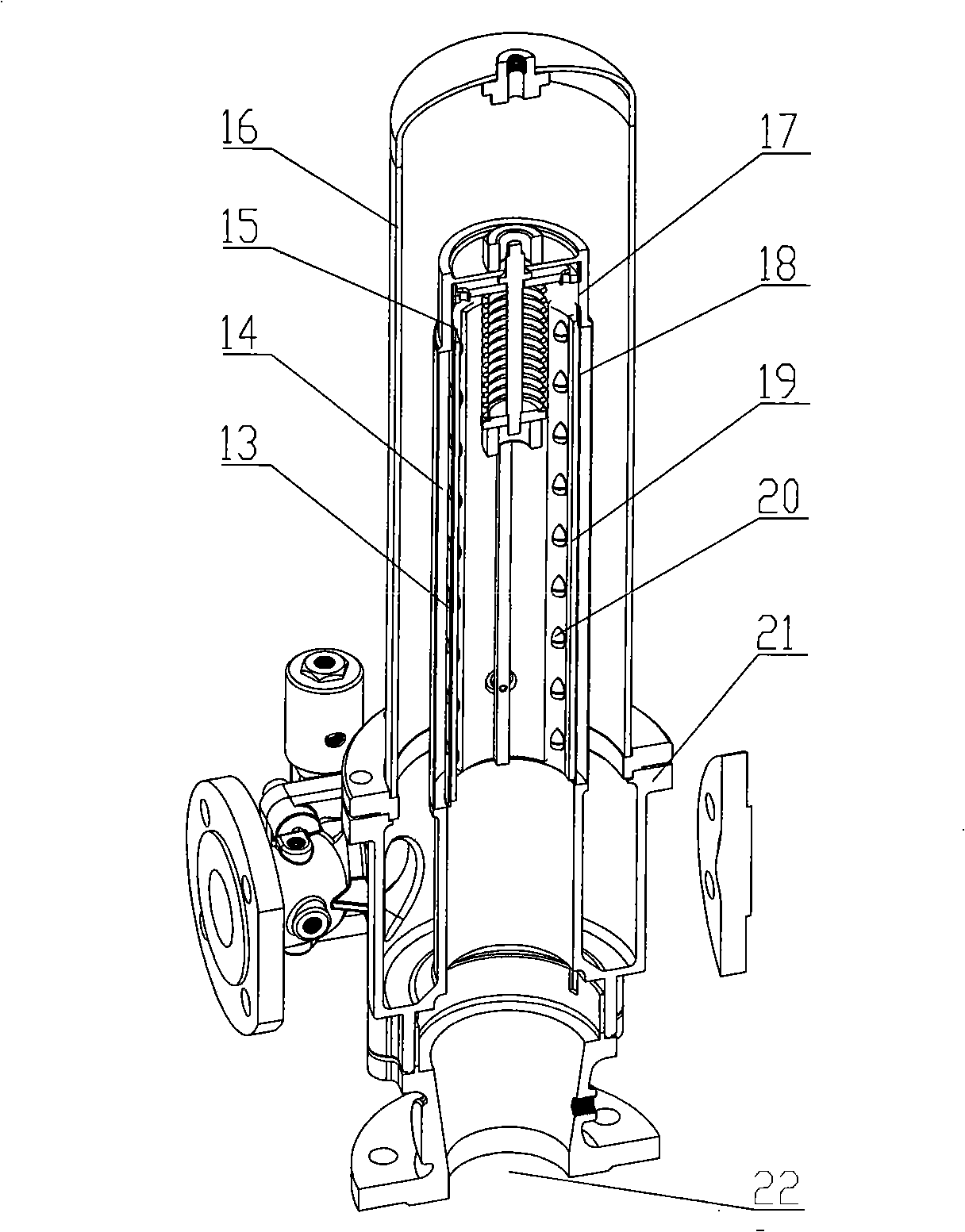

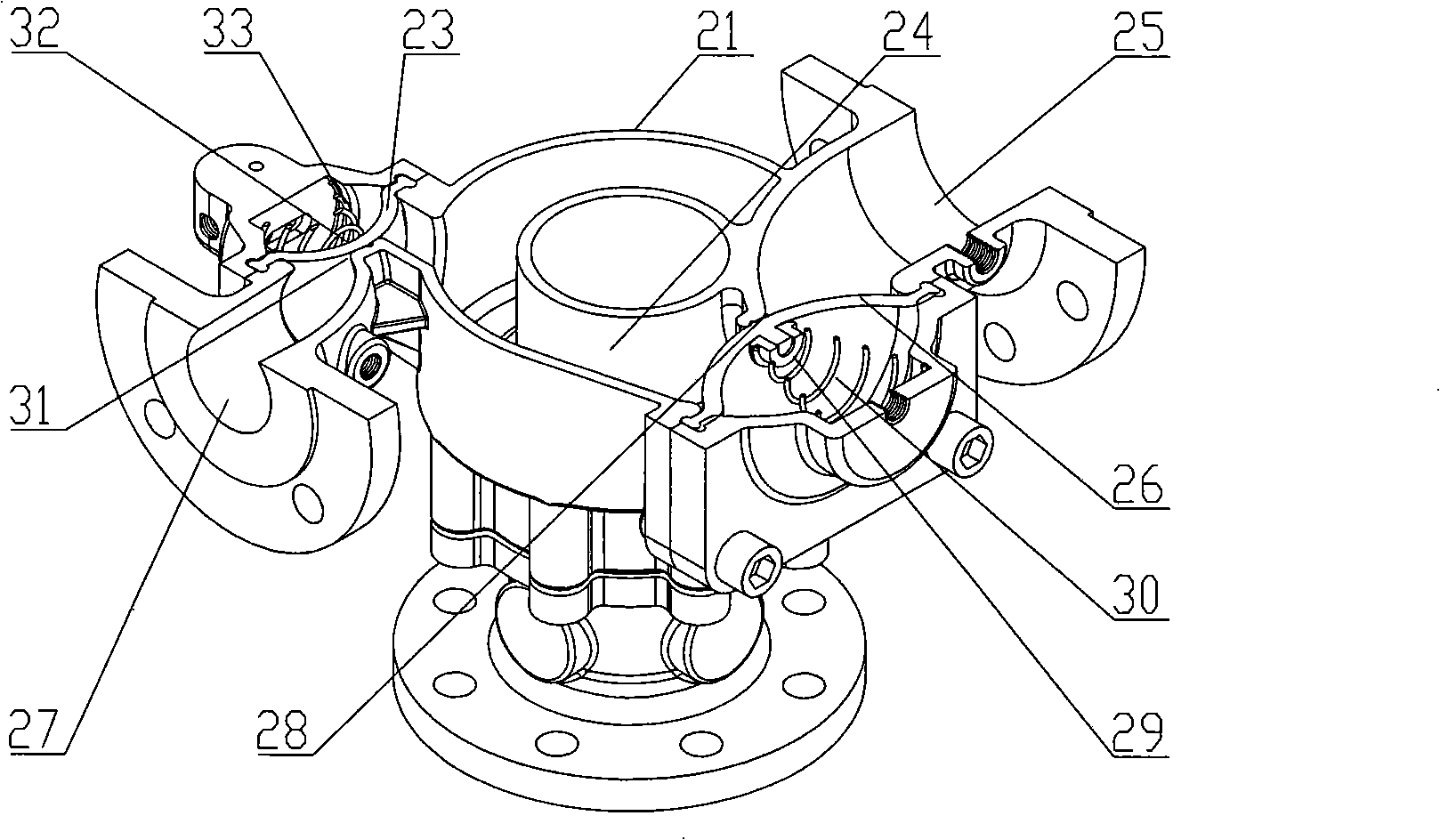

[0032] Such as Figure 1-5 Shown, filter structure of the present invention is as follows:

[0033] The filter is composed of an inlet pipeline 3, a filter unit group 2, a sewage pipeline 5, an outlet pipeline 9 and the like. Inlet pipeline 3 communicates with the inlet of each filter unit of filter unit group 2, and outlet pipeline 9 communicates with the outlet of each filter unit of filter unit group 2; The valve body at the bottom of the filter unit 4 is equipped with a solenoid valve 6 that controls the opening and closing of the valve body; there is a filter inlet 1 at one end of the inlet pipeline 3, and between the inlet pipeline 3 and each filter unit of the filter unit group 2 There is an inlet shut-off valve 10, and the inlet pipeline 3 is connected to each filter unit through the inlet shut-off valve 10; a bypass shut-off valve 11 is provided at the lower part of the inlet pipeline 3, and the lower part of the bypass shut-off valve 11 is connected to the outlet pi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com