Switching water production method of double outlet pure water machine with concentrated drain water recovery device

A pure water machine and recovery device technology, applied in chemical instruments and methods, water/sewage multi-stage treatment, water/sludge/sewage treatment, etc., can solve the quality problems of water purification faucets and affect the popularization and use of water purifiers Users are not used to such problems, to avoid troublesome installation, high utilization rate, wide application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

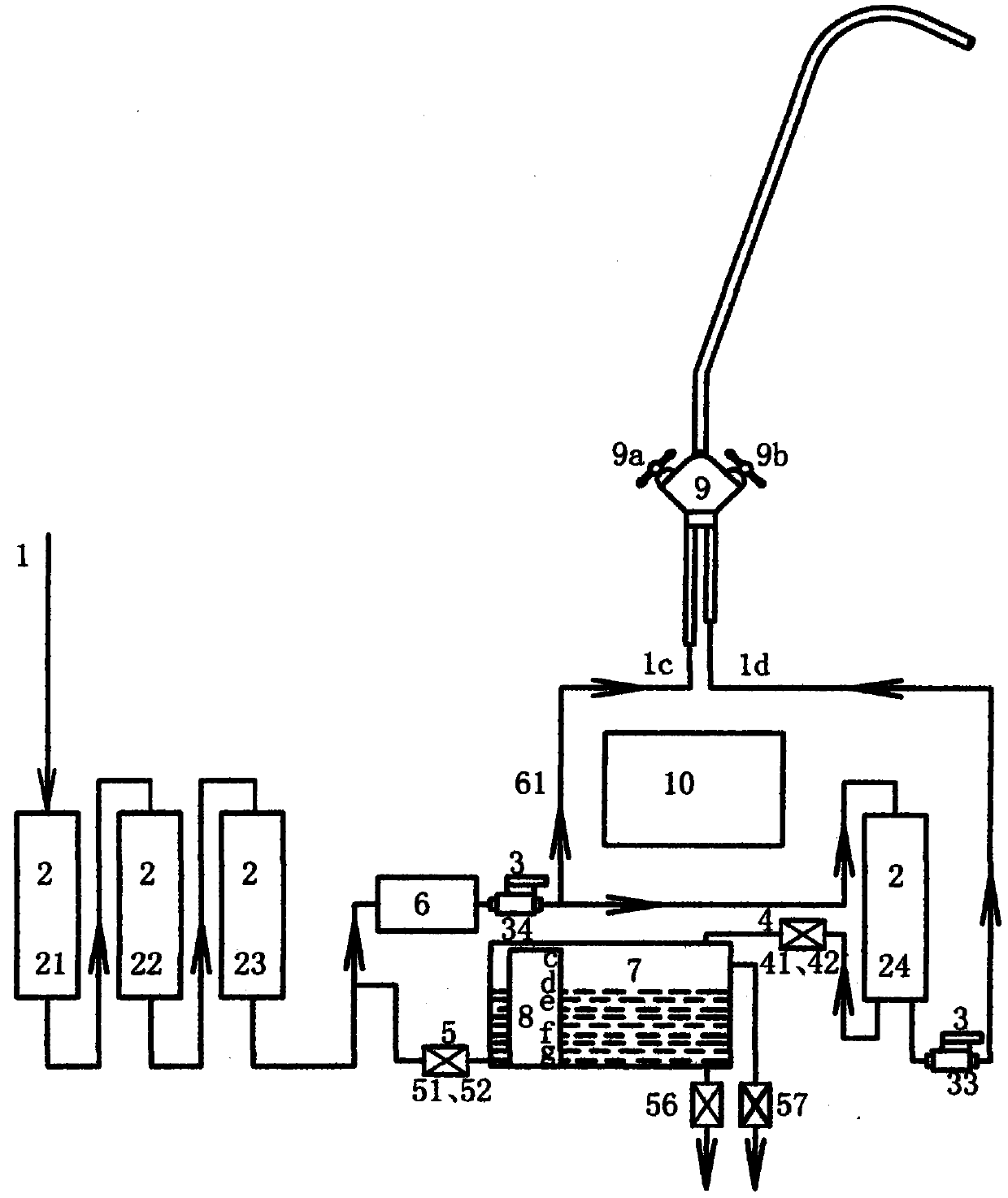

[0046] Example 1. attached figure 1In the filter channel 1, the pre-filter gallbladder 21, 22, 23 and the fine filter gallbladder device 24 provided with the inlet, outlet and concentrated water outlet are connected in series in sequence, and the water outlet of the pre-filter gallbladder 23 is connected with the fine gallbladder device. The booster pump 6 is connected in series between the 24 water inlets; the concentrated water outlet of the fine gallbladder filter device 24 is connected to the concentrated water storage device 7 with a return water port through the flow control device 4 provided, and the return water port passes through the return water control device 5 The water return line of the backwater line communicates with the water inlet line of the booster pump 6, and the connection of the backwater line is specifically arranged in the pipeline between the pre-filter gallbladder and the booster pump. The backwater control device 5 is an electric backwater control...

Embodiment 2

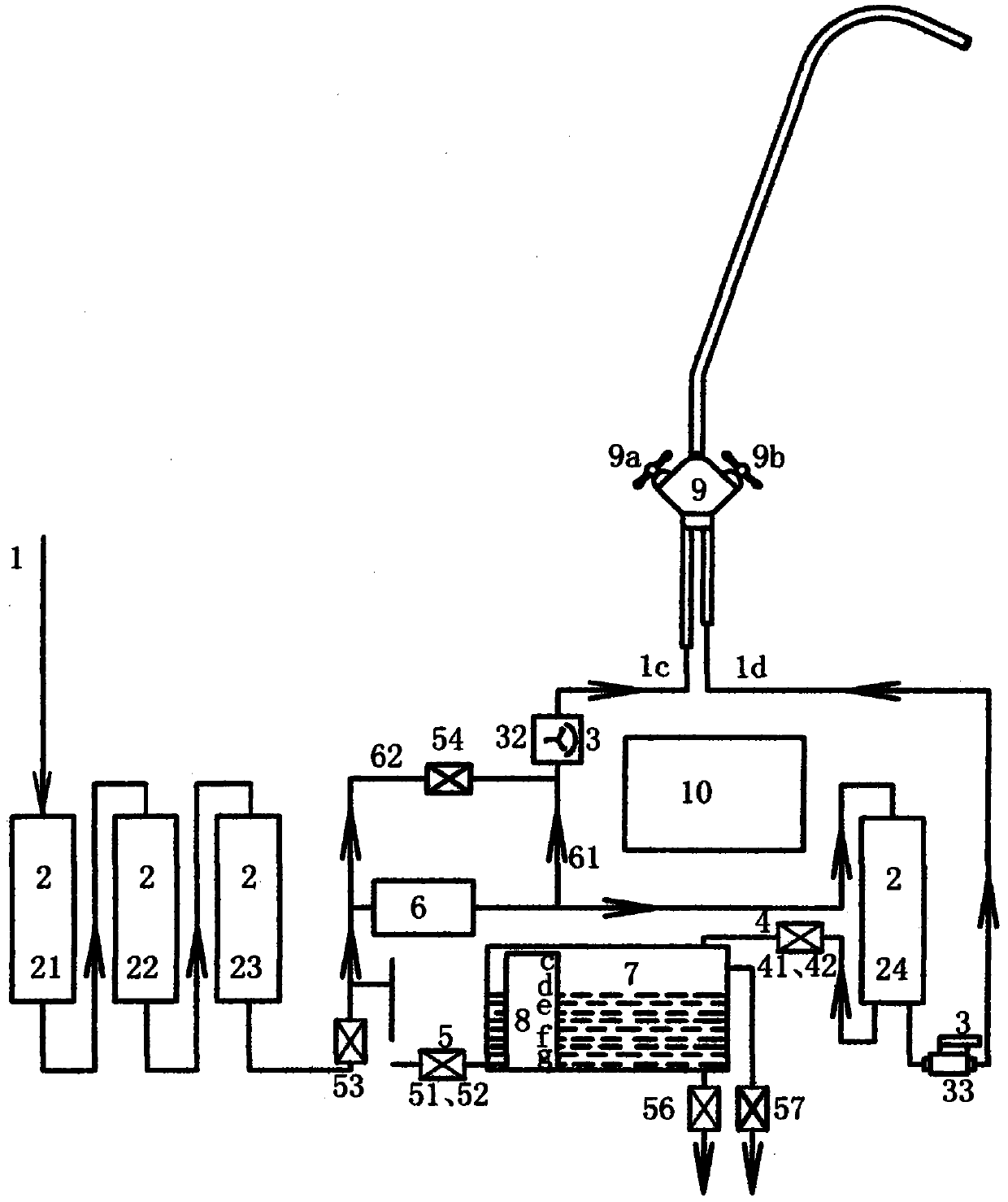

[0052] Example 2. attached Figure 4 In the filter channel 1, each pre-filter gallbladder and the fine gallbladder device 24 provided with the inlet, outlet and concentrated water outlet are connected in series in sequence, and the water outlet of the pre-filter gallbladder and the water inlet of the fine gallbladder device are connected in series. Connect the booster pump 6; the concentrated water outlet of the fine filter gallbladder device 24 communicates with the concentrated water storage device 7 with the return water port through the flow control device 4 provided, and the return water port communicates with the return water pipeline with the return water control device 5 to increase The water inlet pipeline of the pressure pump 6; the return water control device 5 is a return water electric control valve 52. The double-outlet non-pressure faucet is equipped with the water purification valve 9c that simultaneously controls the connection and disconnection of the water ...

Embodiment 3

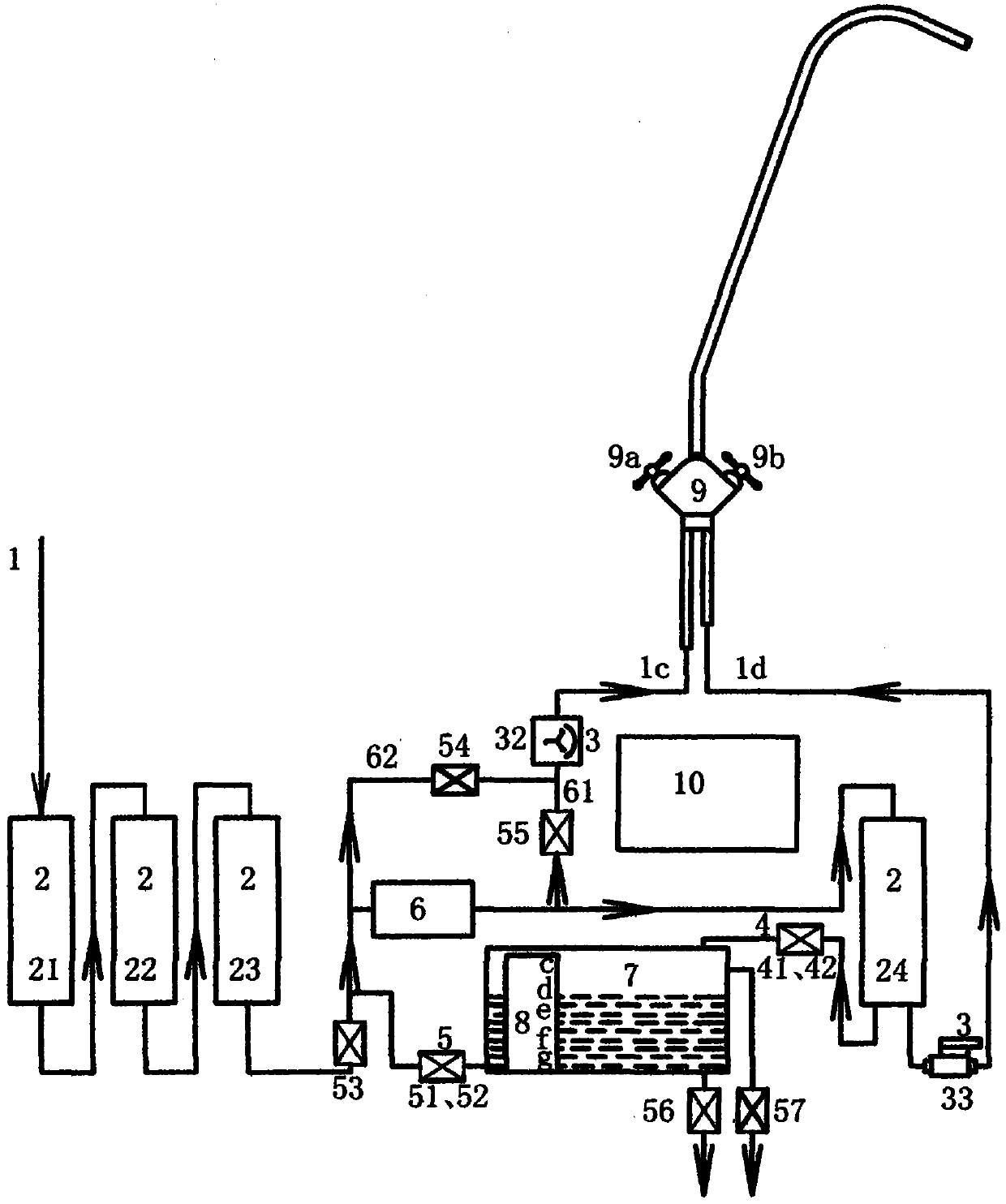

[0056] Example 3. In the filtering channel, a pre-filter gallbladder and a fine gallbladder device with inlet, outlet and concentrated water outlet are connected in series in sequence, and a booster pump is connected in series between the water outlet of the pre-filter gallbladder and the water inlet of the fine gallbladder device; The concentrated water outlet of the fine gallbladder filter device is connected to the concentrated water storage device with the water return port through the set flow control device, and the water return port is connected to the water inlet pipe of the booster pump 6 through the return water pipeline with the water return control device; The water control device 5 is either a return water check valve 51 or a return water electric control valve 52; the water outlet of the fine gallbladder filter device 24 is connected to the pure water interface 1d of the double outlet faucet. The process of starting or closing the water purification valve and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com