System for preparing demineralized water by recycling reverse osmosis concentrated water

A technology of reverse osmosis concentrated water and reverse osmosis equipment, applied in the field of water treatment, can solve the problems of low recycling rate, waste and pollution of reverse osmosis concentrated water, and achieve high recycling rate of concentrated water, easy operation and good economic benefits Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

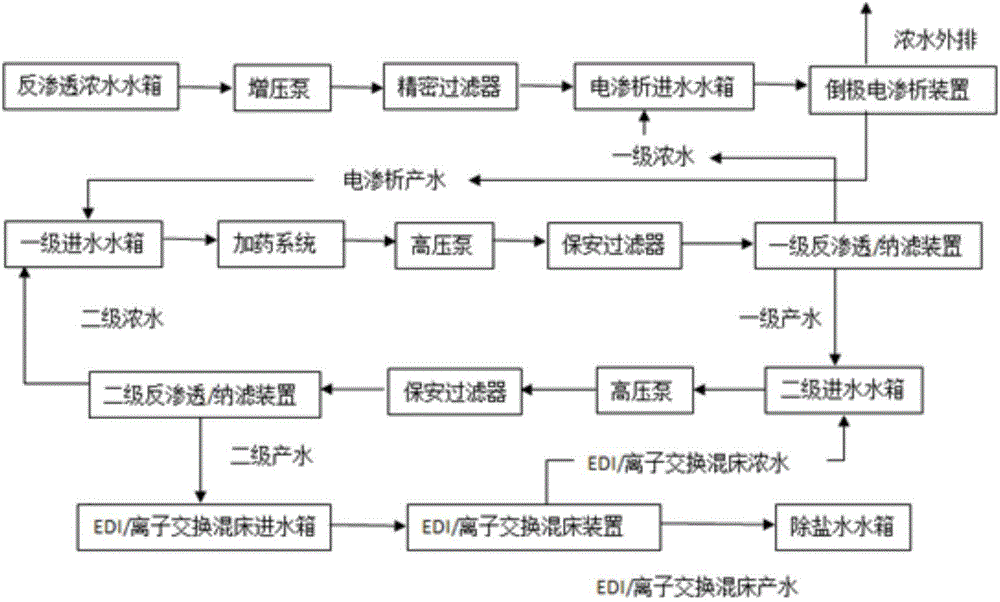

[0017] Taking the reverse osmosis concentrated water produced by boiler water preparation in a thermal power plant as the research object, according to figure 1 The process shown is to recover reverse osmosis concentrated water to prepare demineralized water. The technical route of reverse osmosis electrodialysis-two-stage reverse osmosis-EDI is adopted. The conductivity of reverse osmosis concentrated water is about 3700μS / cm. After the desalination treatment of the electrodialysis device, the conductivity of the electrodialysis product water drops to about 1000μS / cm, which meets the water quality requirements of reverse osmosis. After the desalination treatment of the electrodialysis product water, the conductivity drops to about 5μS / cm, after the deep desalination treatment of the reverse osmosis water by the EDI device, the conductivity of the produced desalted water is reduced to about 0.2μS / cm, which meets the requirements of boiler water. Using this process, the company...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com