Patents

Literature

33 results about "Electrodialysis reversal" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

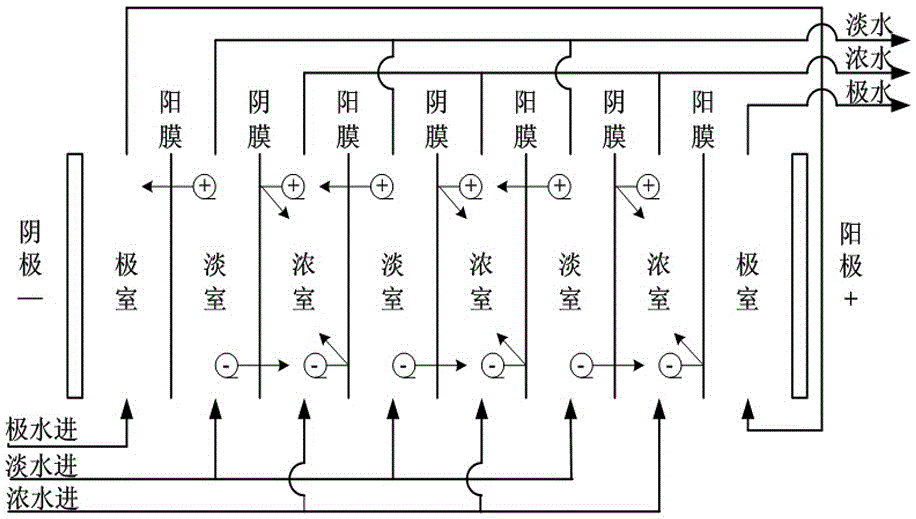

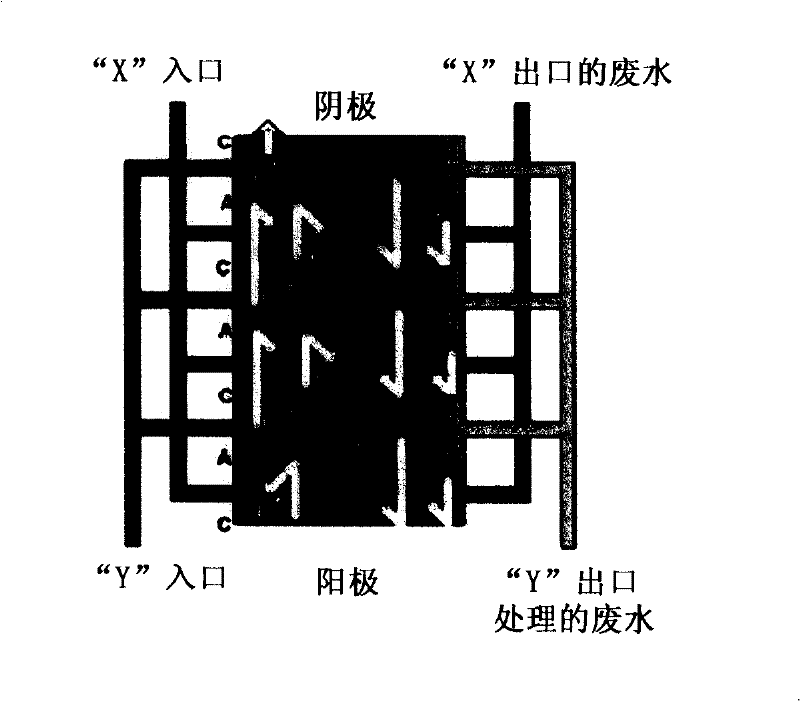

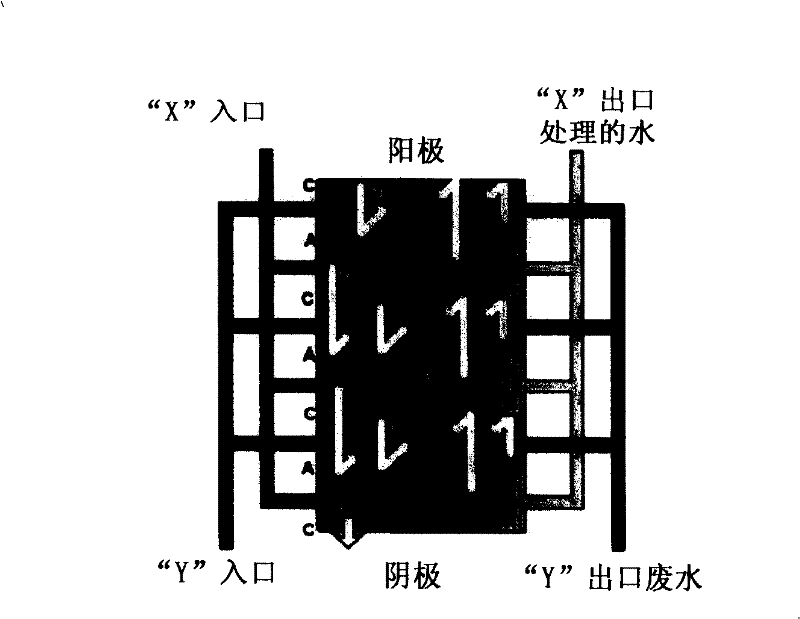

Electrodialysis reversal (EDR) is an electrodialysis reversal water desalination membrane process that has been commercially used since the early 1960s. An electric current migrates dissolved salt ions, including fluorides, nitrates and sulfates, through an electrodialysis stack consisting of alternating layers of cationic and anionic ion exchange membranes. Periodically, the direction of ion flow is reversed by reversing the polarity of the applied electric current.

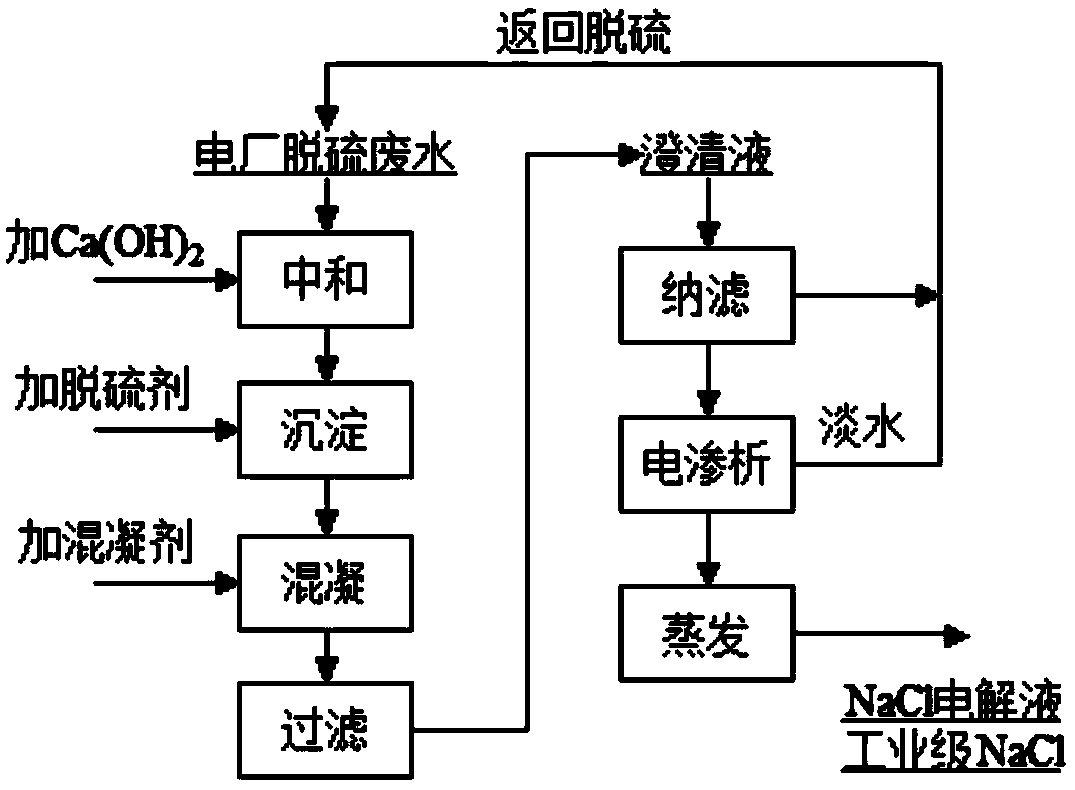

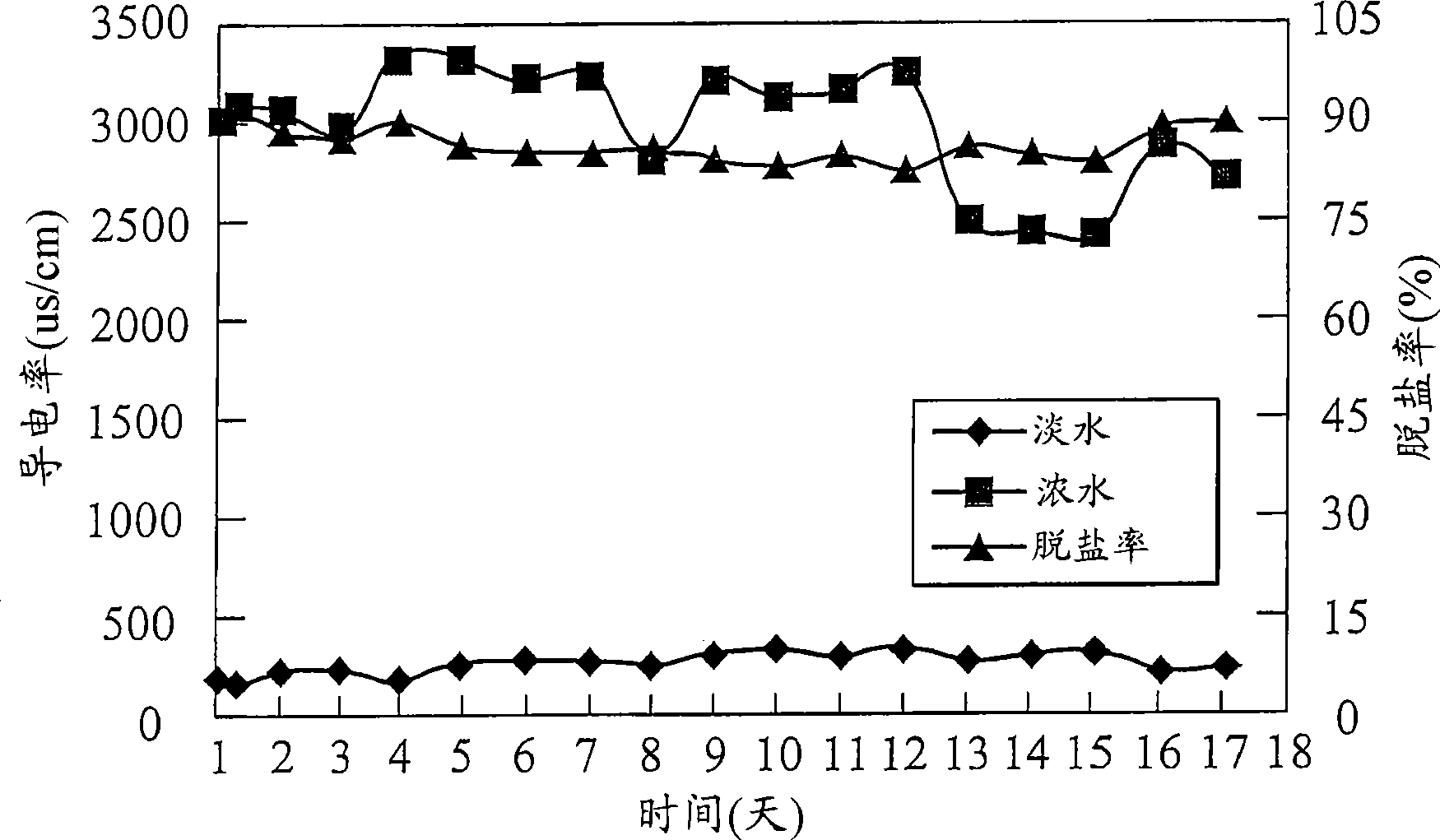

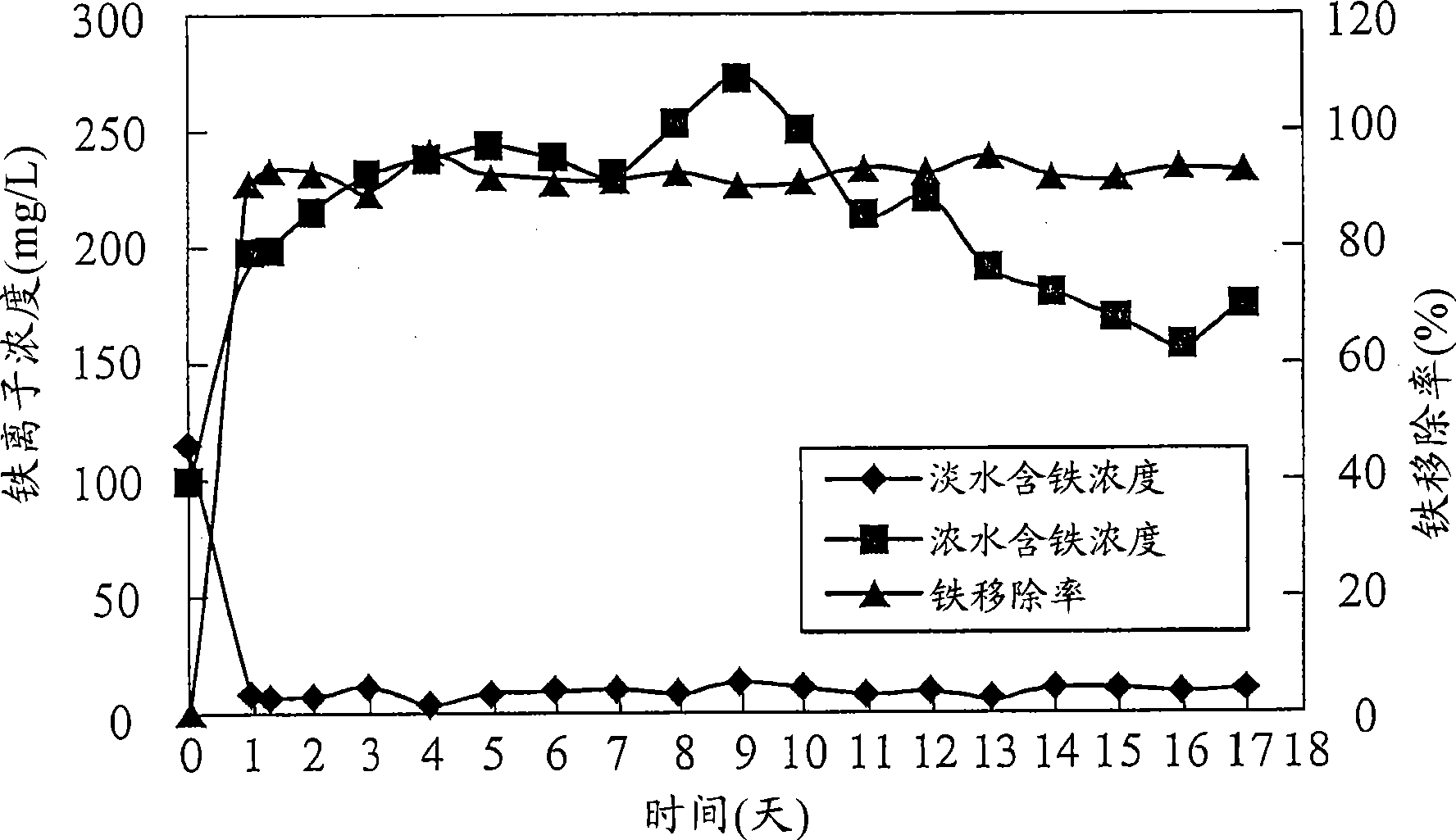

Method for carrying out desalination and zero-discharge processing of power plant desulphurization wastewater by adopting electrodialysis technology

ActiveCN104355473AMeet water requirementsImprove running stabilityGeneral water supply conservationDispersed particle separationChemical oxygen demandResource utilization

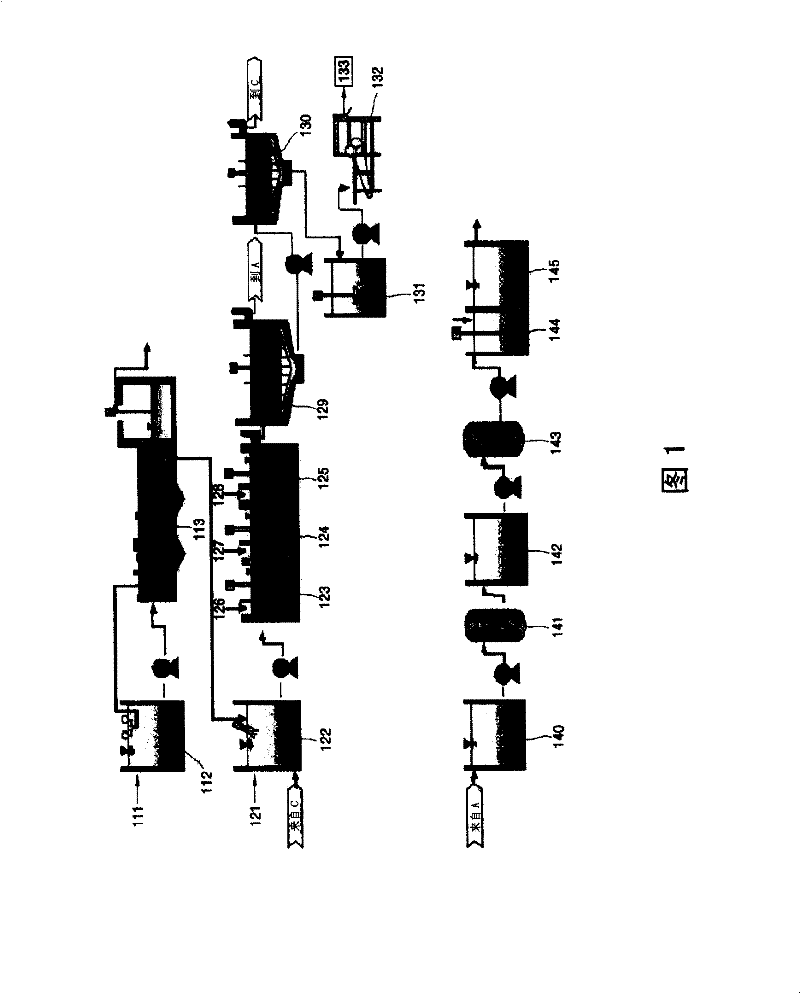

The invention relates to a method for carrying out desalination and zero-discharge processing of power plant desulphurization wastewater by adopting an electrodialysis technology. The method comprises the following steps: neutralizing, precipitating, coagulating and filtering the power plant desulphurization wastewater and removing CODs (Chemical Oxygen Demands), heavy metals, F-ions, gypsum, silicon dioxide, hydroxide of iron and aluminum and other insoluble particles in waste water; separating C1-ions and other monovalent ions in clear liquid from SO3<2->, SO4<2-> and other divalent ions through nanofiltration; desalinating and concentrating water produced by the nanofiltration by adopting a multistage countercurrent reverse electrodialysis method. The method has the advantages that the concentration of the Cl-ions in nanofiltration concentrated water and electrodialysis freshwater generated by the method is lower, and the nanofiltration concentrated water and the electrodialysis freshwater can be returned for flue gas desulfurization; the content of NaCl in a small amount of electrodialysis concentrated water produced reaches above 12 percent, the bivalent ions and other impurities are removed by nanofiltration, and the electrodialysis concentrated water is further evaporated and concentrated, so that chlorine-alkali industry electrolytes and NaCl salt can be obtained. Through the method, the zero-discharge treatment and the resource utilization of the desulfurization wastewater can be realized.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

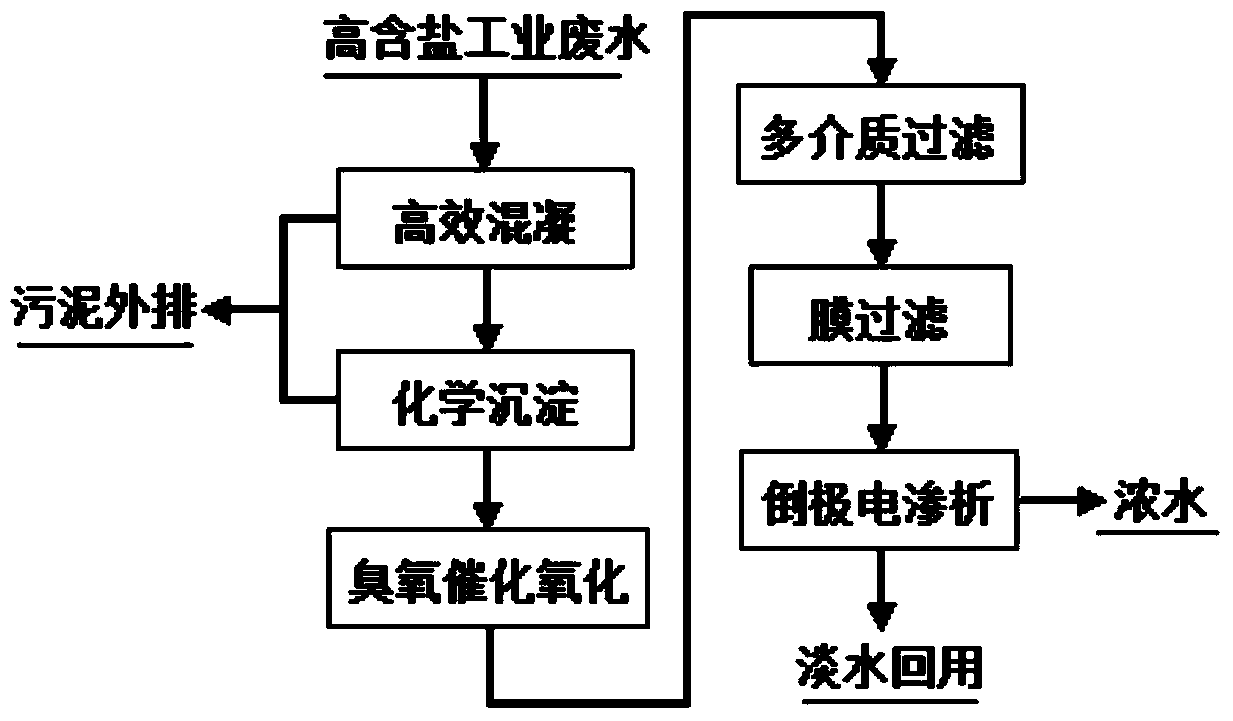

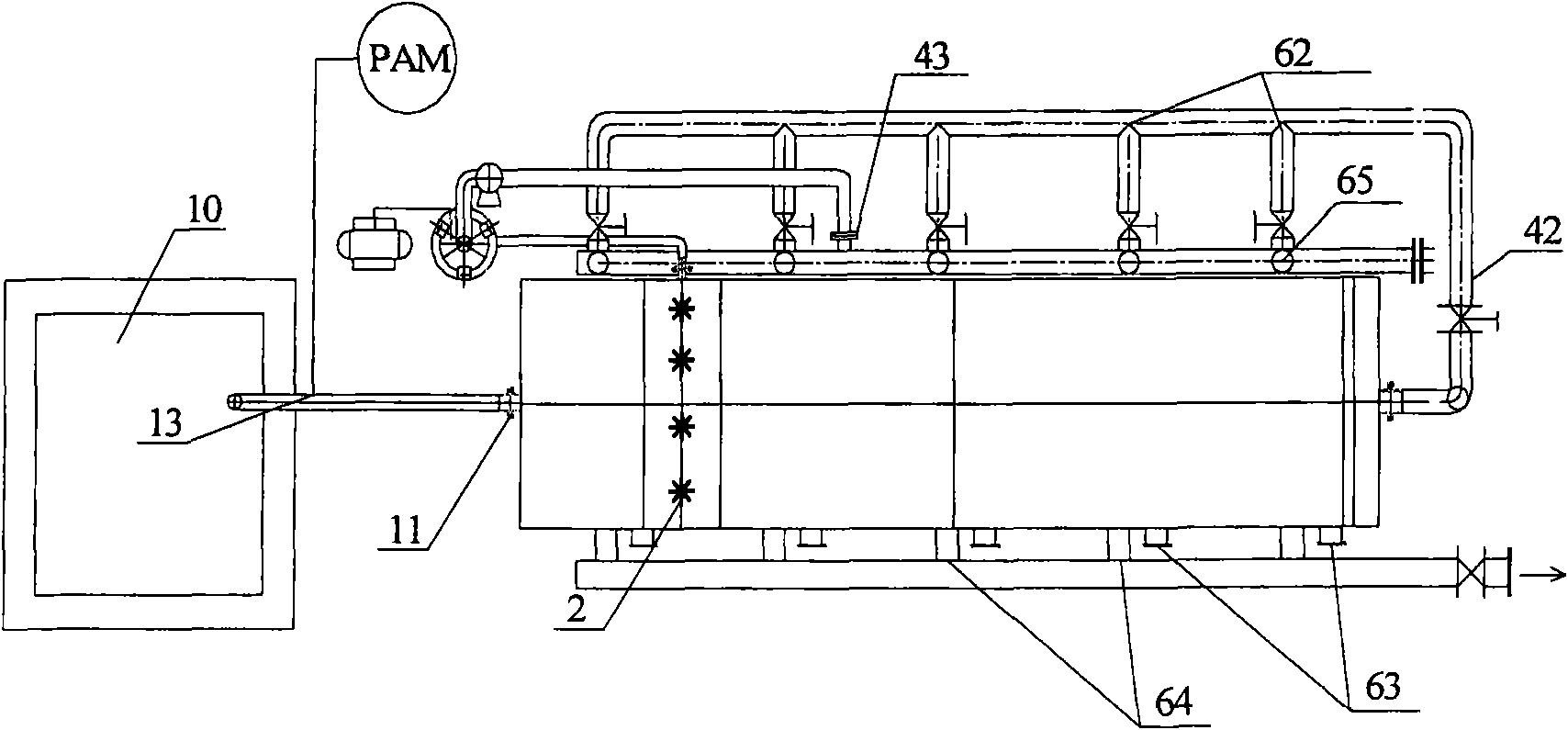

Method for deeply treating, desalting and recycling industrial wastewater with high salt content

ActiveCN104016530AImprove catalytic oxidation efficiencyGood removal effectMultistage water/sewage treatmentSuspended particlesFiltration

The invention relates to the field of industrial wastewater treatment processes and provides a method for deeply treating, desalting and recycling industrial wastewater with high salt content. The method comprises the following steps: 1) carrying out efficient coagulation treatment on the industrial wastewater with high salt content to obtain supernatant; 2) carrying out chemical precipitation on the supernatant obtained in the step 1) to remove high valence ions with valence higher than bivalence in the wastewater; 3) carrying out catalytic ozonation treatment on the supernatant subjected to chemical precipitation in the step 2); 4) carrying out multi-media filtration, precise filtration and membrane filtration treatment on the wastewater subjected to catalytic ozonation in the step 3) in sequence; and 5) carrying out electrodialysis reversal treatment on the effluent obtained after membrane filtration in the step 4). By adopting the method, organic matters, bacteria, colloids, suspended particles, Ca<2+>, Mg<2+> and high valence ions, other soluble inorganic salts and the like in the industrial wastewater with high salt content are removed by utilizing the coupling and synergistic effects of different unit technologies, thus achieving deep treatment, desalting and recycling of the industrial wastewater with high salt content.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

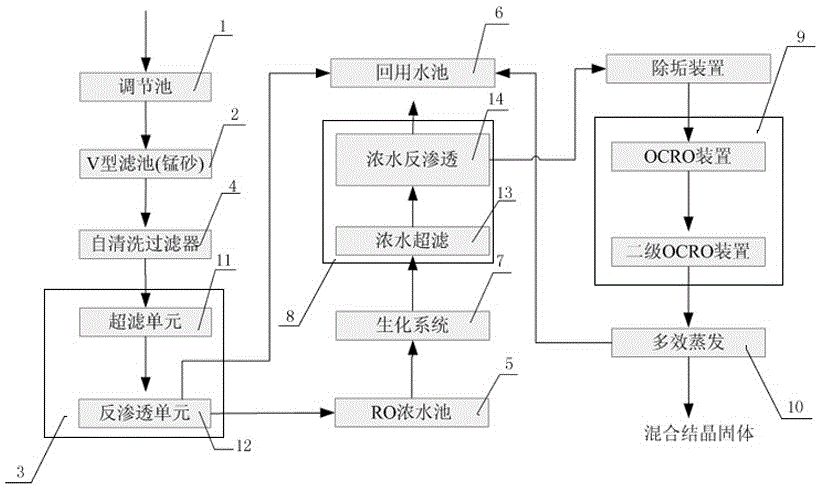

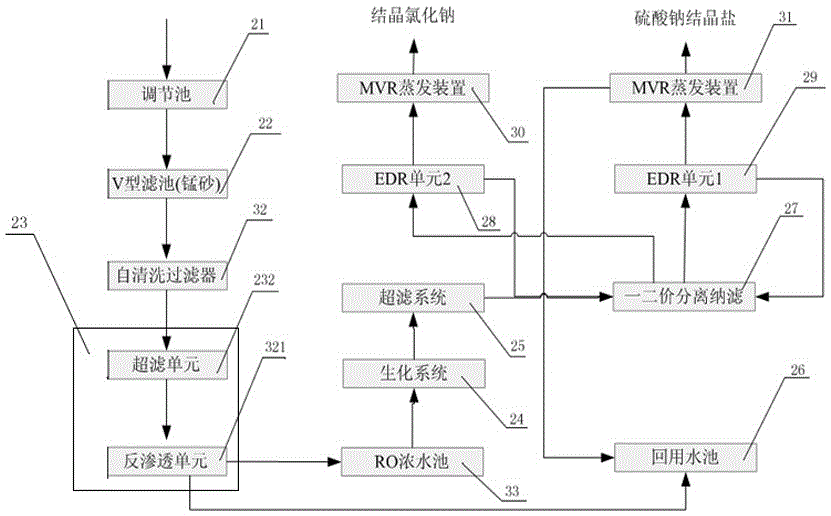

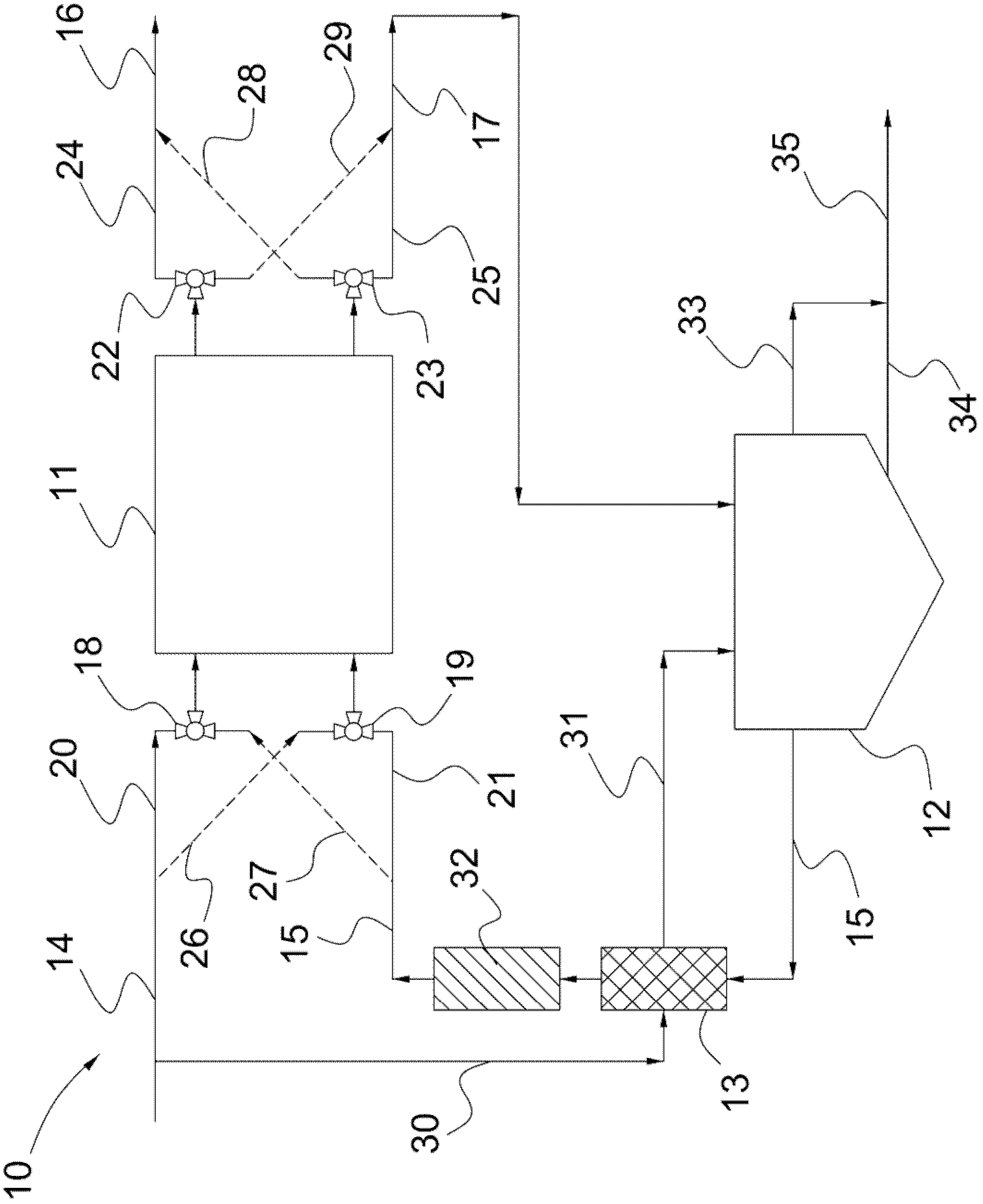

Wastewater zero-emission industrial sewage treatment system and treatment method

InactiveCN105000755AAchieve solid waste reductionTurn waste into treasureGeneral water supply conservationMultistage water/sewage treatmentUltrafiltrationFiltration

The invention discloses a wastewater zero-emission industrial sewage treatment system and a wastewater zero-emission industrial sewage treatment method. The system comprises an adjustment tank used for gathering sewage. A pretreatment system mainly composed of a V-shaped filtering tank is connected after the adjustment tank. A first ultrafiltration + reverse osmosis system is connected after the pretreatment system. After a reverse osmosis unit of the first ultrafiltration + reverse osmosis system, a way of reverse osmosis concentrated water enters a biochemical treatment unit directly or indirectly connected with the concentrated water. After the biochemical treatment unit, outlet water is connected into a second ultrafiltration unit. After the first reverse osmosis unit, another way of diluted water is connected into a recycling water tank or is communicated with a recycling diluted water outlet pipe of the recycling water tank. Diluted liquid after a first frequent electrodialysis reversal system and a second frequent electrodialysis reversal system is returned to a water inlet of a monovalent-divalent separation nano-filtration device.

Owner:浙江沐源环境工程有限公司

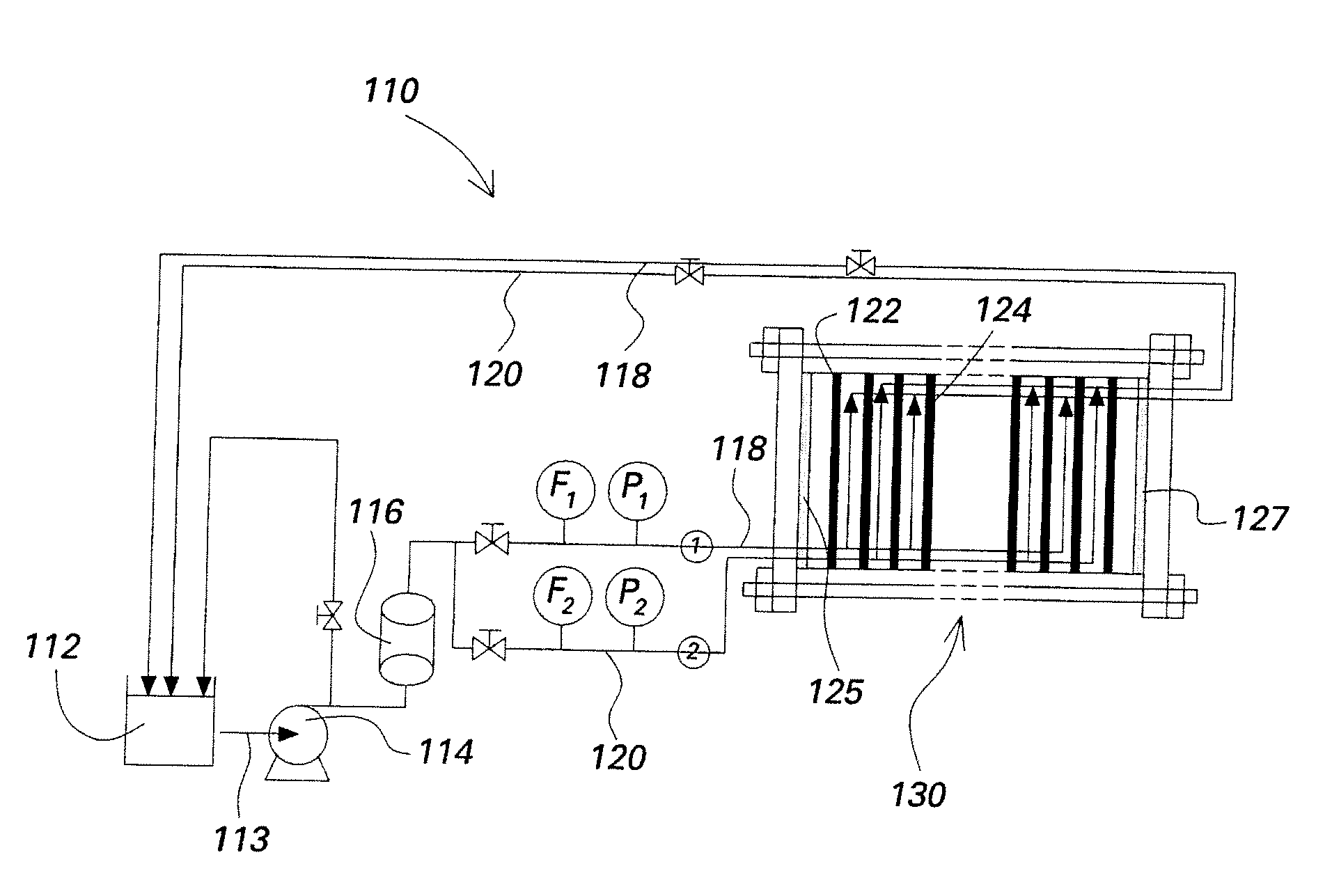

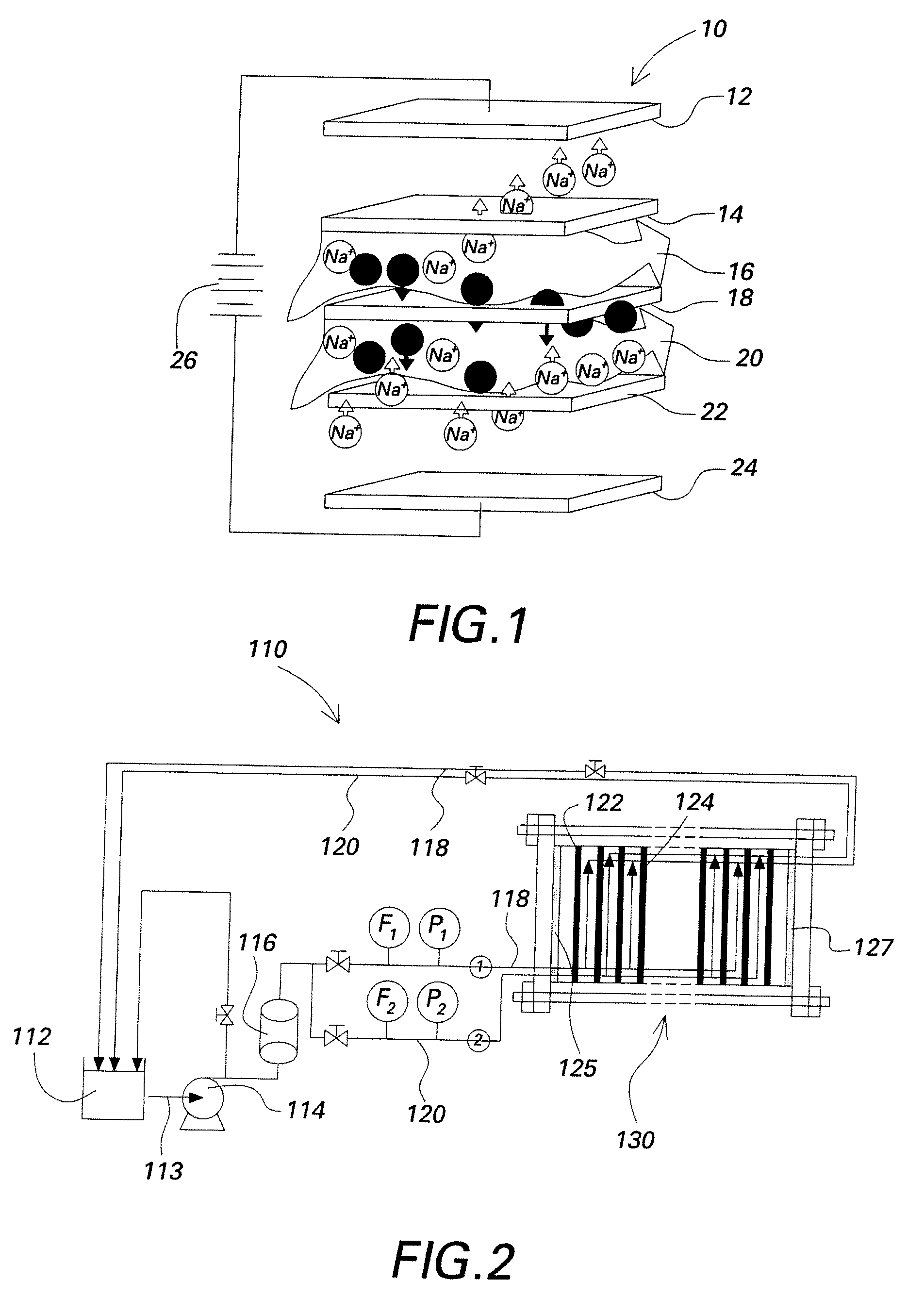

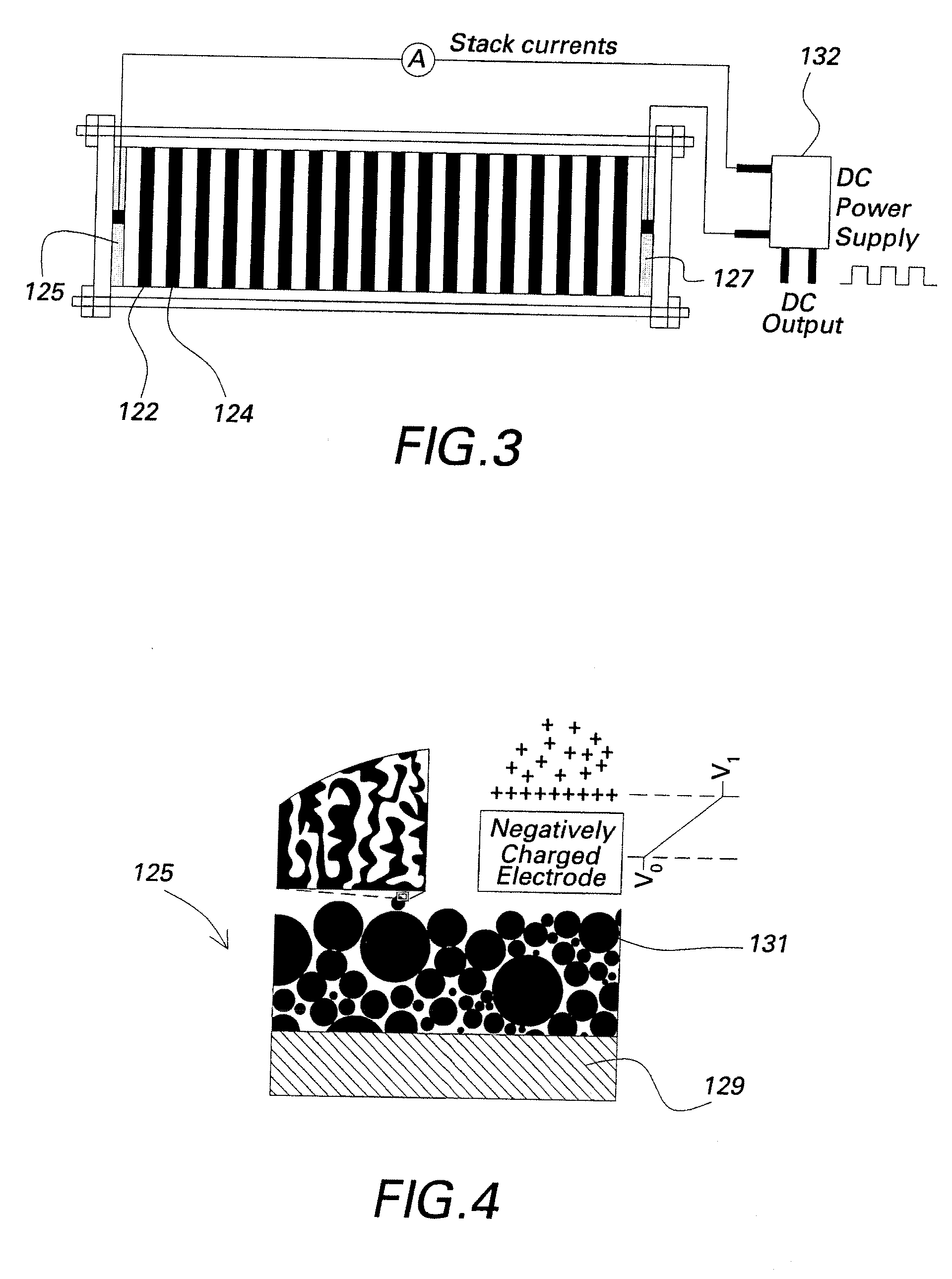

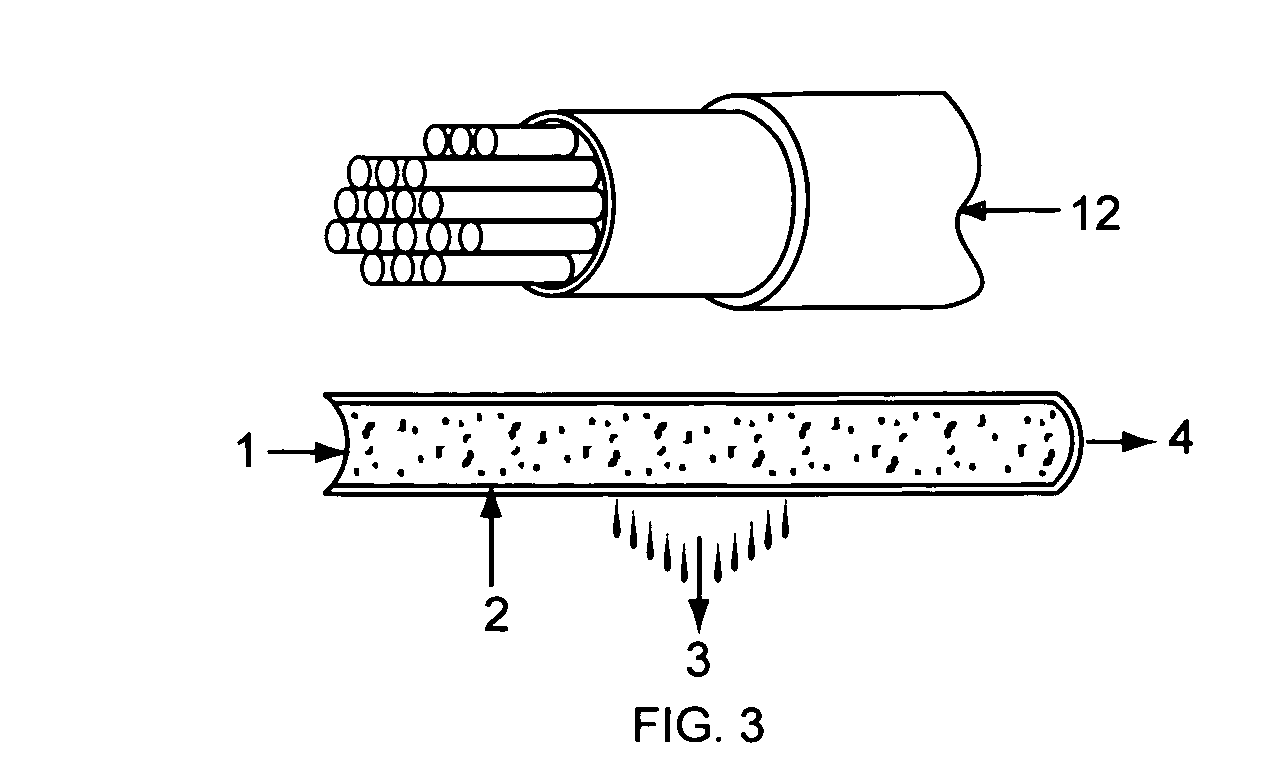

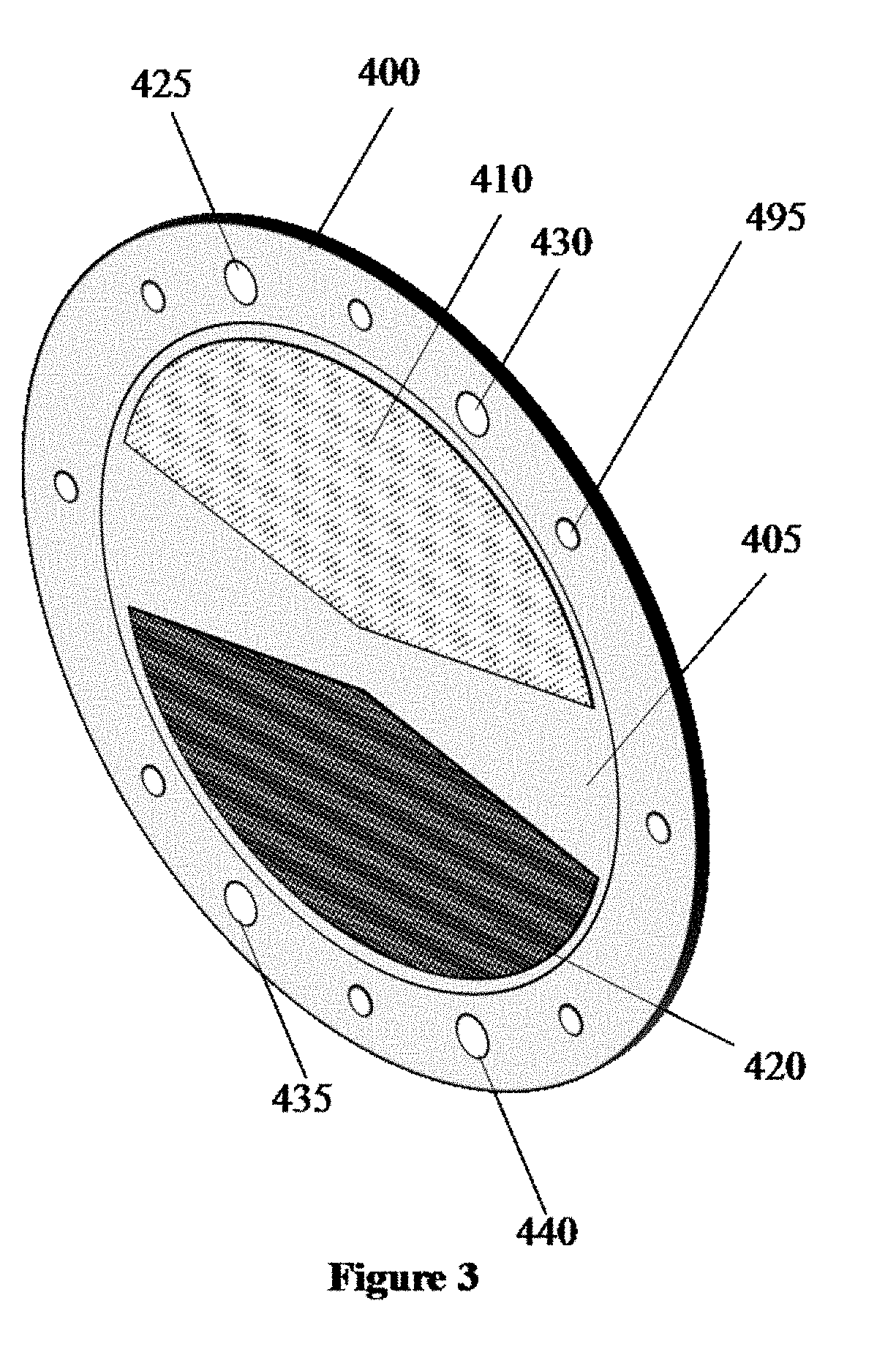

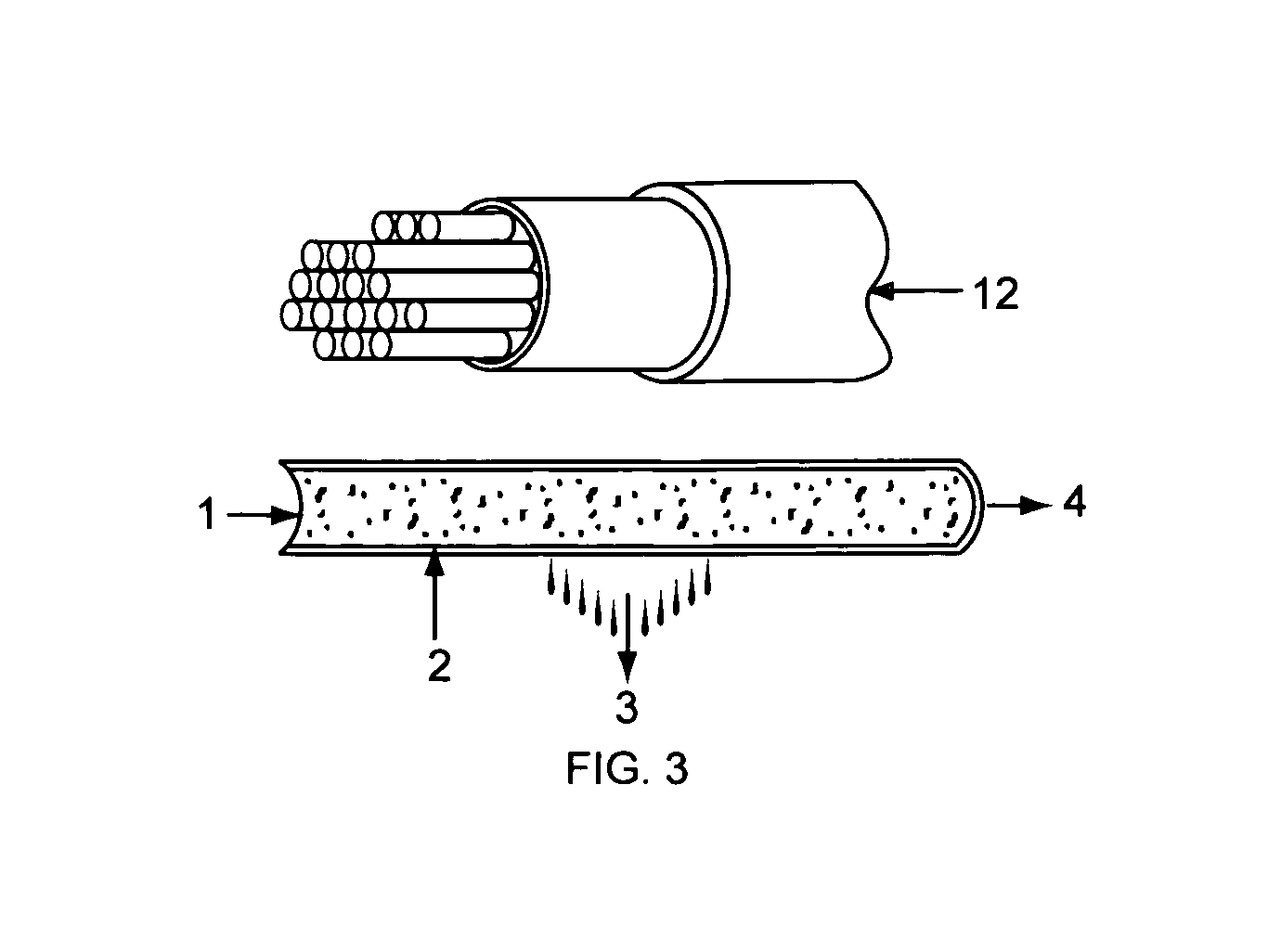

Non-faraday based systems, devices and methods for removing ionic species from liquid

A non-Faraday ionic species removal process and system is described. The system includes a power supply, a pump for transporting a liquid through the system, and a plurality of porous electrodes. The electrodes , each include an electrically conductive porous portion. The electrodes may also include a substrate contiguous with the porous portion. The porous electrode can be utilized in electrodialysis and electrodialysis reversal systems. A method for forming a porous electrode is described.

Owner:GENERAL ELECTRIC CO

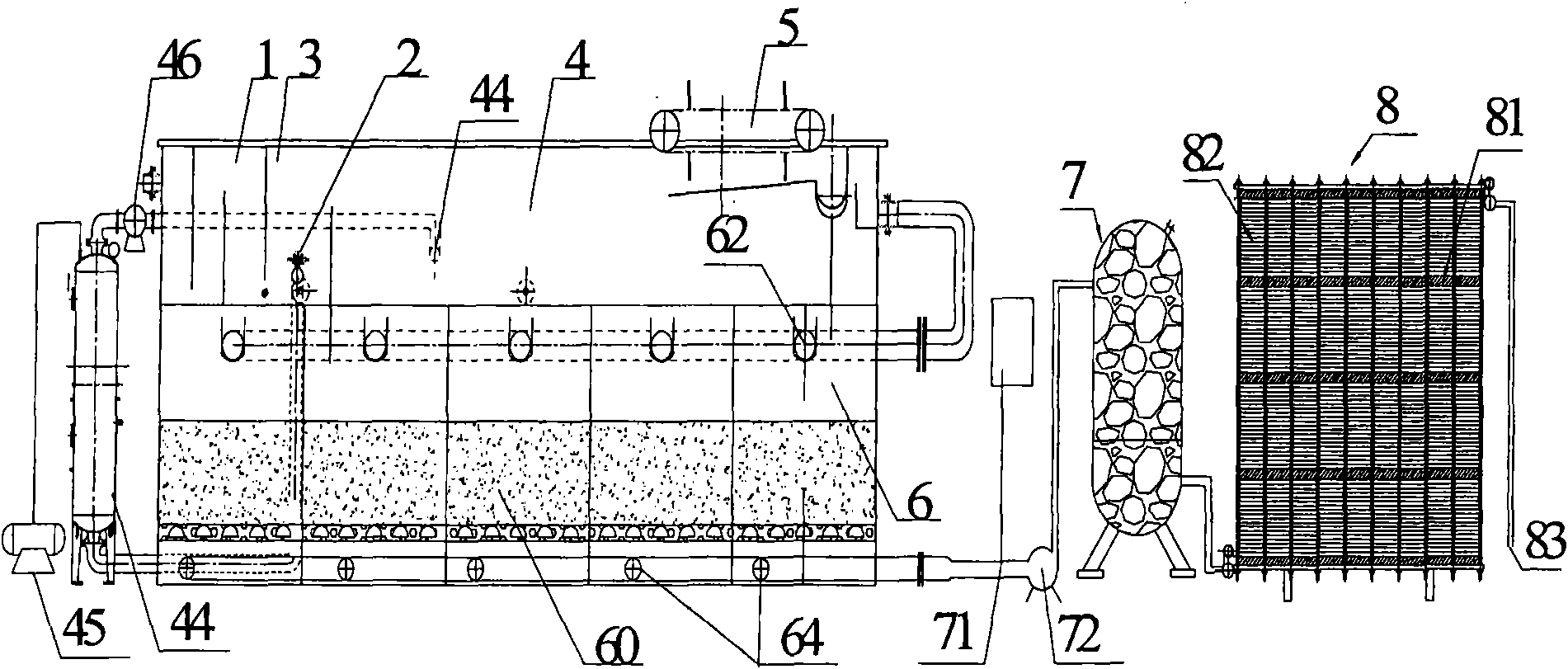

Method for treating and recycling circulating wastewater

ActiveCN101870530AHigh hardnessAchieving processing powerGeneral water supply conservationDispersed particle separationWater qualityWater production

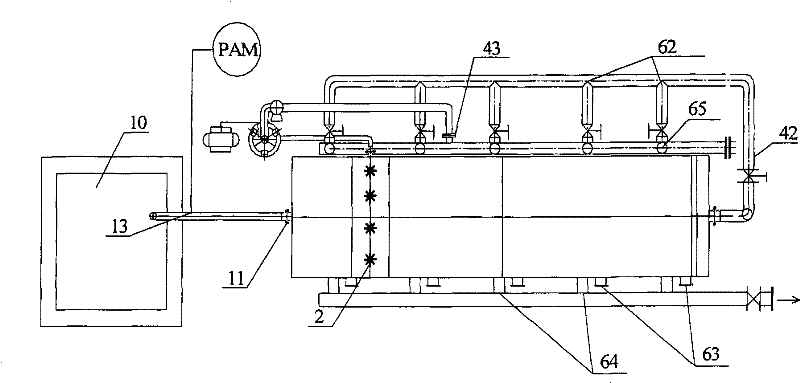

The invention provides a method for treating and recycling industrial circulating wastewater, which comprises the following steps of: adding a polyacrylamide flocculant into the circulating wastewater to perform flocculation reaction, wherein 4 to 8mg of flocculant is added into every 1L of sewage and the flocculation reaction time is controlled to be at least 5 minutes; allowing the sewage after the flocculation reaction to enter a high-efficiency floatation tank, controlling the air floatation time to be at least 10 minutes, allowing the air floatation water to discharge into a filter tank, and discharging the water after filtering; adding an acid into the filtered discharged water to regulate the alkalinity of the water body, adding a scale inhibitor and delivering the water to a cartridge filter; and delivering the filtered effluent from the cartridge filter to an electrodialysis reversal system to perform desalination, wherein the effluent treated by the electrodialysis reversal system is used as make-up water for circulating water. The method can more effectively realize continuous treatment of the sewage and water production without using nanofiltration and reverse osmosis technology; the treated sewage keeps a certain amount of ions; and the effluent meets the requirements of the water quality of reused water of a circulating water system.

Owner:北京新金应利科技发展有限公司

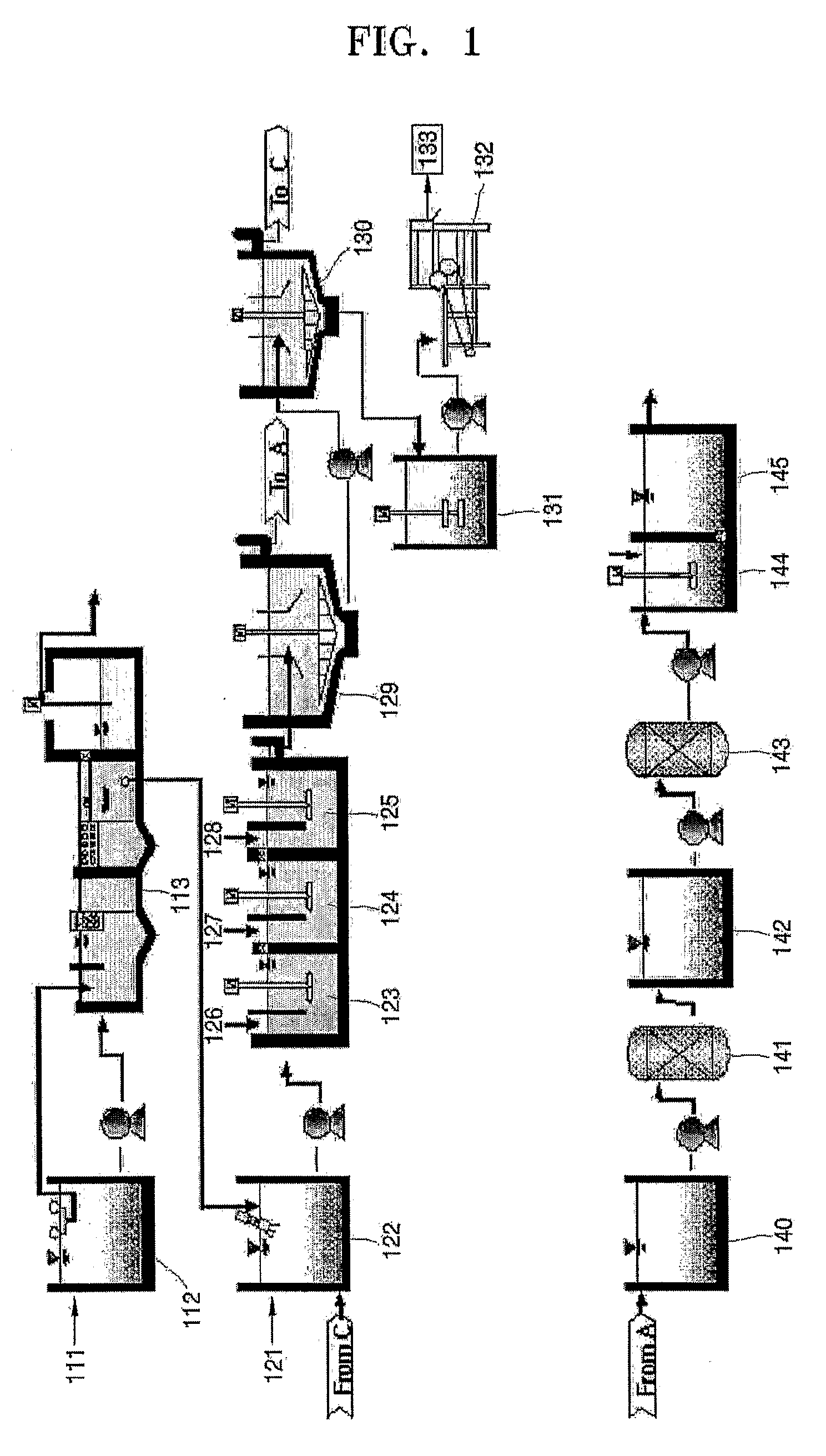

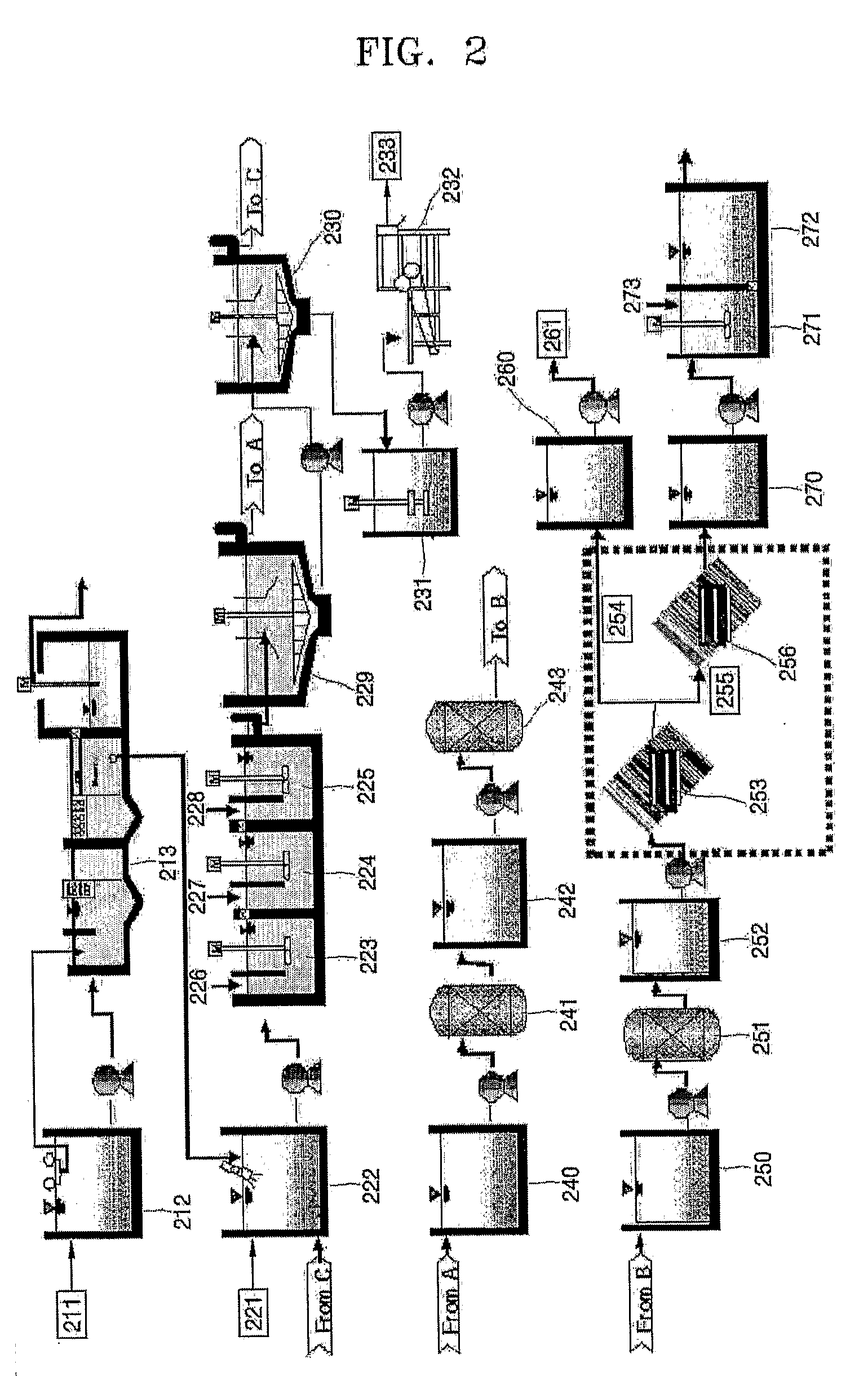

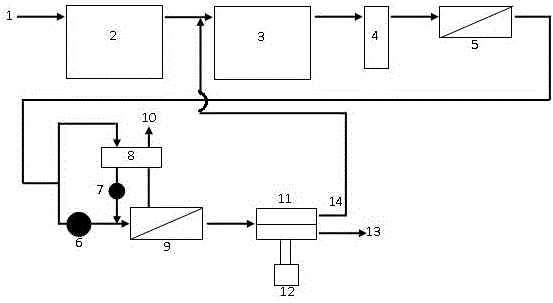

Electrodialysis reversal and electrochemical wastewater treatment method of compound containing nitrogen

InactiveUS20090127194A1Improve performanceEfficient removalWater treatment parameter controlWater contaminantsWater useEnvironmental regulation

Provided is a wastewater treatment method using an electrodialysis reversal (EDR)-electrochemical wastewater treatment (EWT) combined process, the method including: separating inflow wastewater which contains nitrogen compounds into product water and concentrated water using an EDR facility; and decomposing the concentrated water into target materials to be eliminated from the wastewater in an EWT facility. Provided is a wastewater treatment method for decomposing inflow water containing a nitrogen-containing compound into target materials to be eliminated using an EWT facility alone. According to the wastewater treatment method, product water which is flowed out from an EDR facility can be reused as raw water, and the method guarantees reliability and stability by simultaneously processing recalcitrant COD and T-N in the concentrated water. The wastewater treatment method efficiently removes recalcitrant COD and T-N, which are derived from ethanolamine (ETA), in wastewater produced in a power plant and an industrial facility using ETA as a pH-adjusting agent. EDR-EWT process can be easily combined with a common wastewater treatment and can efficiently and stably treat wastewater containing recalcitrant COD and T-N. Therefore, the method can actively satisfy the strengthening environmental regulation criteria.

Owner:KEPCO ENGINEERING & CONSTRUCTION COMPANY INC

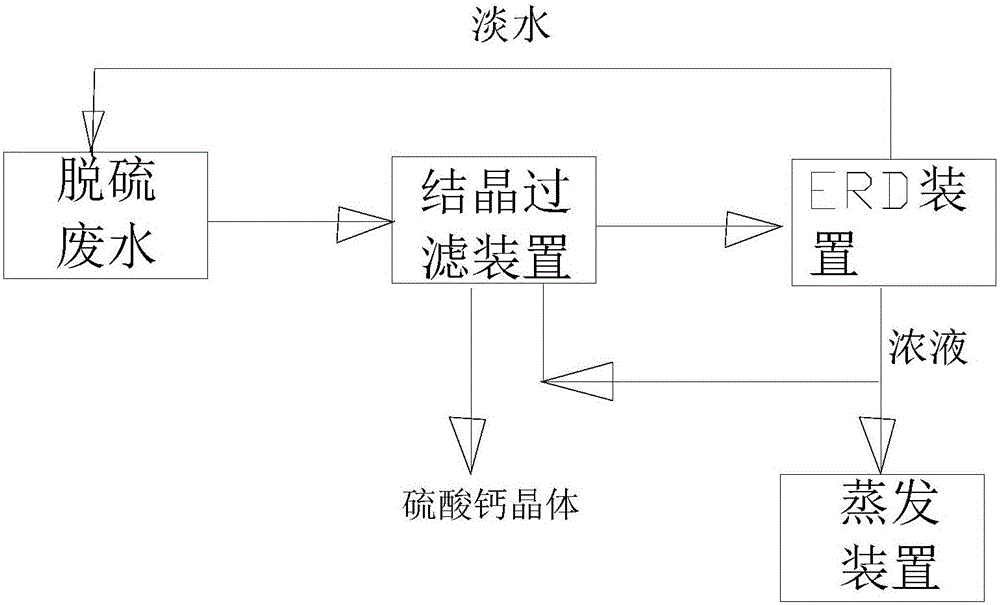

Softening-free concentration device for desulfurization wastewater from power plant

PendingCN106477800ASimple structureEasy to operateCalcium/strontium/barium sulfatesWaste water treatment from gaseous effluentsEvaporationWastewater

The invention discloses equipment in the technical field of water treatment, and particularly relates to a softening-free concentration device for desulfurization wastewater from a power plant. The softening-free concentration device comprises a crystallization and filter device, a high-frequency magnetic field generator and an EDR (electrodialysis reversal) device. A produced water outlet of the crystallization and filter device is connected with an inlet of the EDR device, a strong liquor outlet of the EDR device is divided into two branches, the two branches are respectively connected with the crystallization and filter device and an evaporation device, a fresh water outlet is connected with a desulfurization system of the power plant, the EDR device comprises EDR membrane assemblies, and the EDR membrane assemblies are arranged in high-frequency magnetic fields of the high-frequency magnetic field generator. The softening-free concentration device has the advantages that the softening-free concentration device is simple in equipment structure and convenient to operate; the softening-free concentration device is low in energy consumption and high in efficiency in integral implementation procedures, and the like.

Owner:HANGZHOU WATER TREATMENT TECH DEV CENT

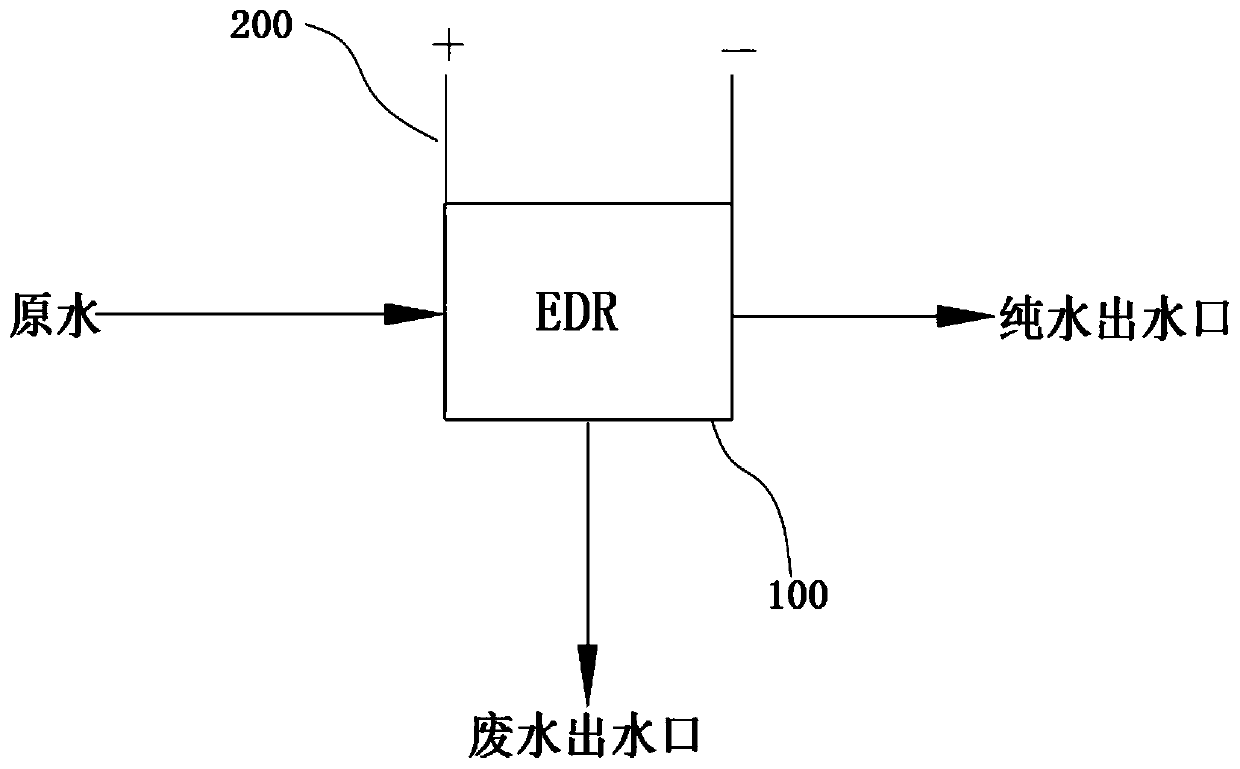

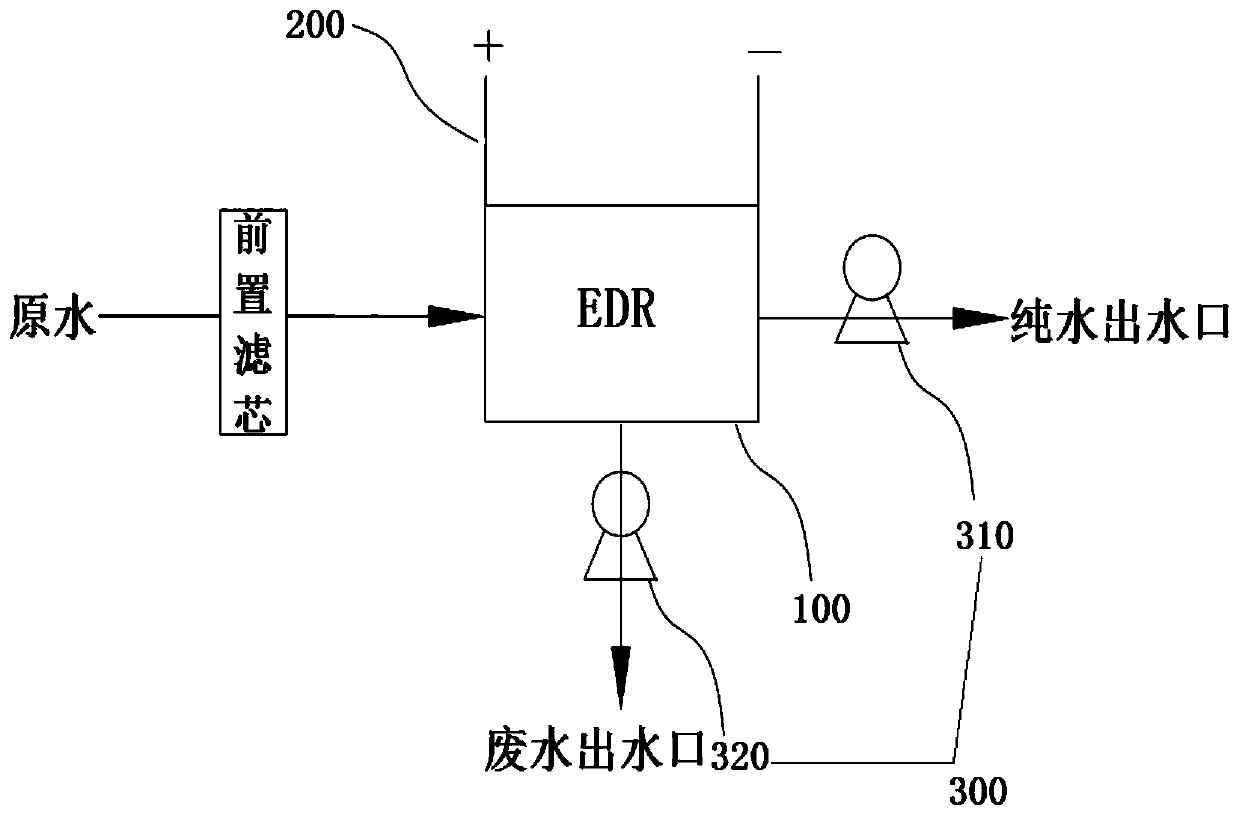

EDR electrodialysis water purification system and method, and water purifier

PendingCN110526352AReal-time monitoring of desalination effectImprove effluent qualityGeneral water supply conservationDispersed particle separationElectricityPower flow

The invention discloses a water purifier. A water purification system is provided with an electrodialysis reversal (EDR) unit and a current monitoring unit for monitoring a current in the EDR unit. Under an operation condition, applied voltage of the EDR unit is adjusted, so that the current, monitored by the current monitoring unit, in the EDR unit meets a target current range, and then output water of the EDR unit meets the water quality requirement according to judgment; and under a shutdown working condition, voltage is started regularly, so that the current, monitored by the current monitoring unit, in the EDR unit meets a target current range. According to the EDR electrodialysis water purification system, whether the current in the system meets the target current range is determined; the desalination effect of water in the EDR unit is monitored in real time; stability of outgoing water quality can be kept after the system stands for a long time; and meanwhile, a self-suction mechanism is additionally arranged to suck water in the EDR unit, so that the pressure borne by the EDR unit is kept within the maximum range borne by the EDR unit, and stability of the purification performance of the water purification system is improved.

Owner:GUANGDONG LIZI TECH CO LTD

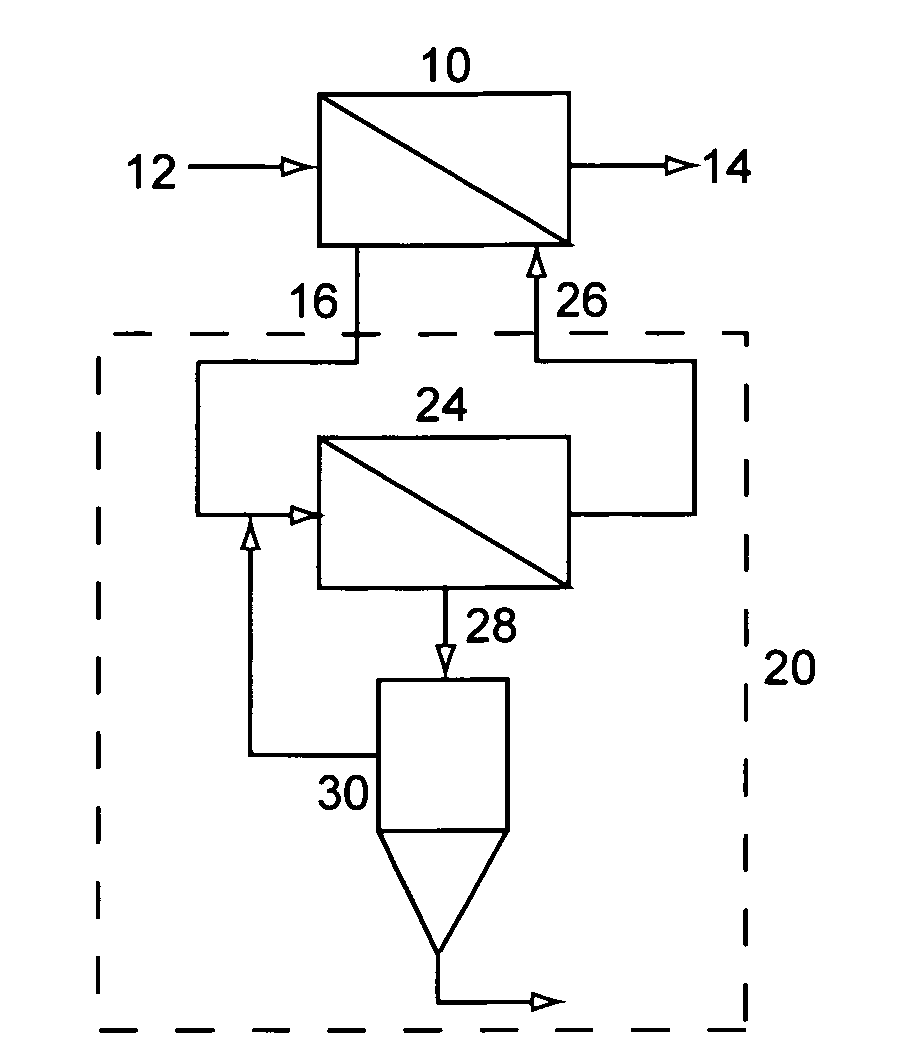

Brine treatment scaling control system and method

ActiveUS20130206689A1Reduce salinityMembranesSeawater treatmentElectrodialysis reversalTotal recovery

The present invention may be used in systems and methods for brine treatment scaling control in a water treatment system. A concentrated brine stream influent may be treated in an electrodialysis-reversal process to produce a concentrated brine stream effluent and a lower salinity diluent water, which may be potable water effluent. The concentrated brine stream effluent may be processed in a brine treatment scaling control system that may have a mixing vessel and a membrane filter with the mixing vessel seeded with calcium sulfate. A lowered salinity brine stream effluent may be produced for return to the electrodialysis-reversal process to allow operation at greater overall recovery and an elevated concentrated brine stream may be produced.

Owner:CAROLLO ENGINEERS

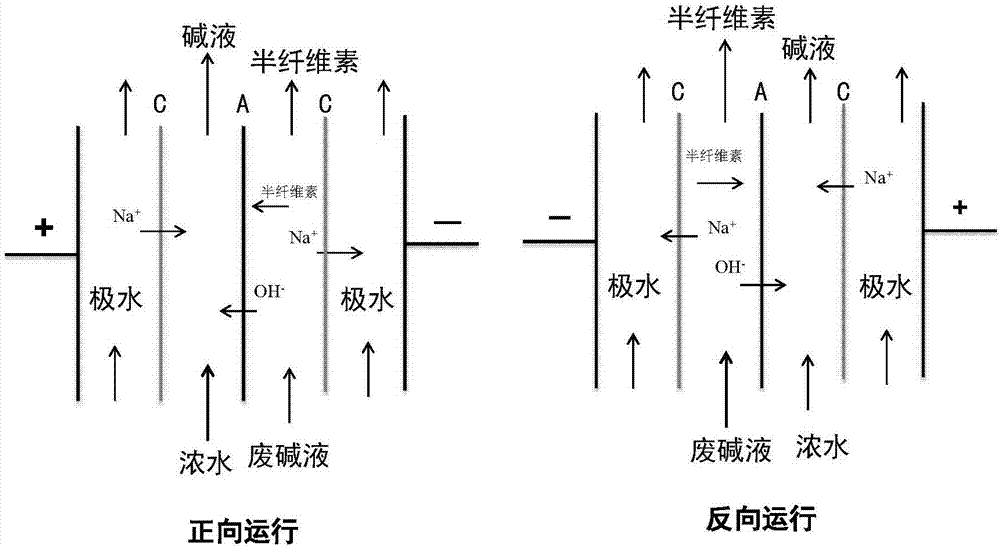

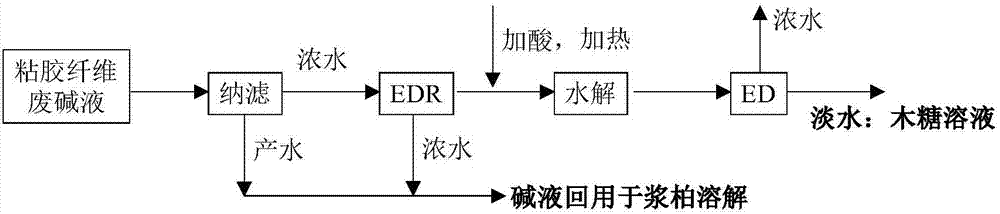

Resource utilization method of waste alkali liquid of viscose

InactiveCN107572697AHigh recovery rateSolve the problem of pollutionMultistage water/sewage treatmentNature of treatment waterHydrolysateResource utilization

The invention provides a resource utilization method of waste alkali liquid of viscose. The method mainly comprises the steps of high recovery of alkali liquid, high recovery of hemicelluloses and preparation of xylose. The method concretely comprises the following steps: recovering part of alkali in the waste alkali liquid of the viscose by adopting a nanofiltration process, and then recovering the rest alkali in the waste alkali liquid by adopting an electrodialysis reversal (EDR) process; then, hydrolyzing the dealkalized waste alkali liquid under the acidic condition, and then carrying outdeacidifying treatment and desalting treatment on hydrolysate by adopting an ED process so as to obtain a xylose solution. The resource utilization method has the actual advantages that 1, the methodis reasonable in combination and adopts nanofiltration and EDR so as to realize segmented efficient recovery of hemicellulose and alkali; after the EDR technique is adopted, the problems absorption and pollution of the hemicelluloses to a membrane are effectively solved in a long-term running process, so that a high alkali liquid recovery rate is realized; the ED technique is used for carrying out the deacidifying treatment and the desalting treatment on the hemicellulose hydrolysate, so that a high hemicellulose hydrolysate xylose recovery rate is realized; 2, the recovered alkali liquid canbe used for a viscose fiber pulp dissolution process; the separated hemicellulose can be used as a new raw material of the xylose.

Owner:HANGZHOU BLUETEC ENVIRONMENTAL TECH +1

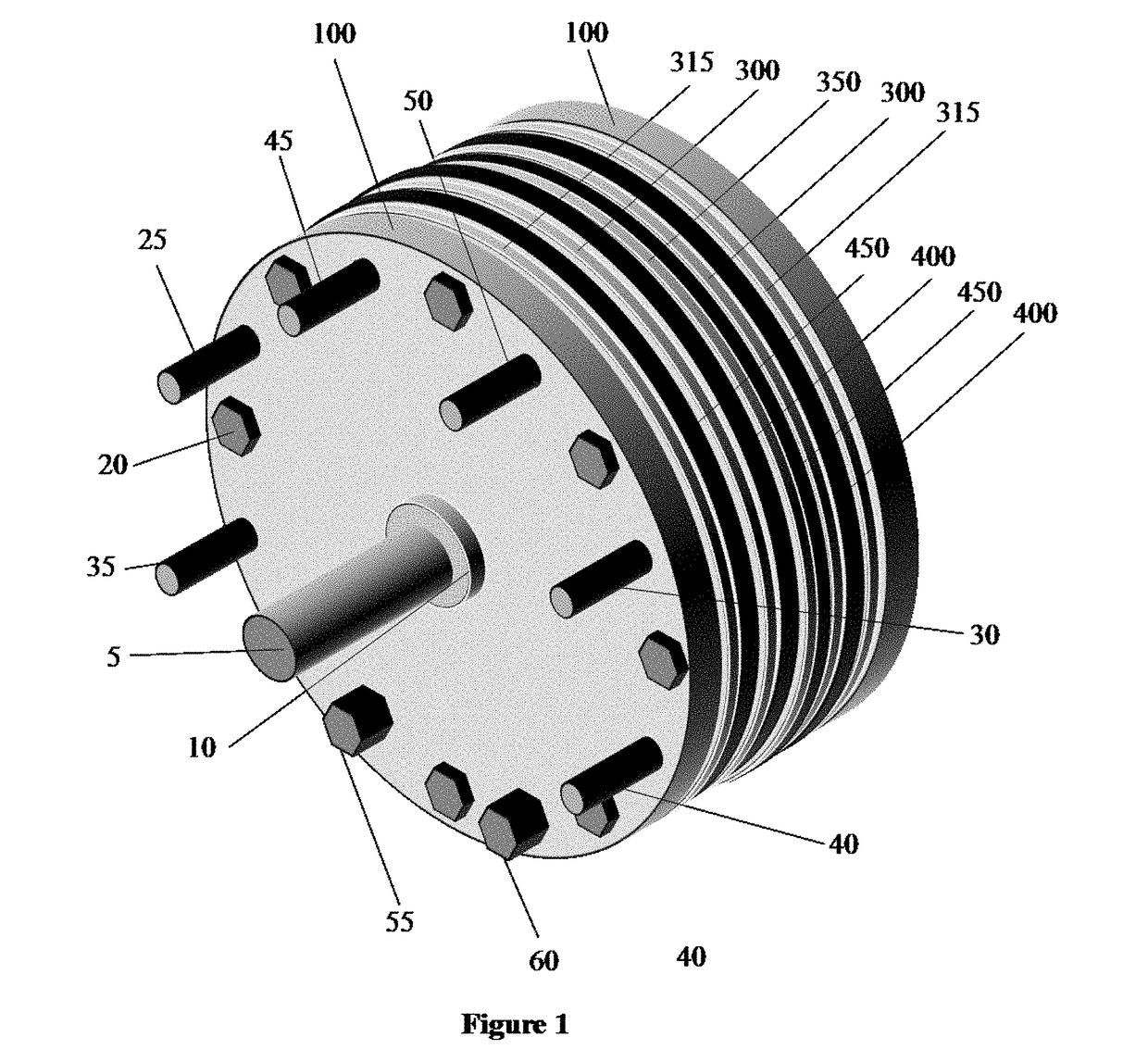

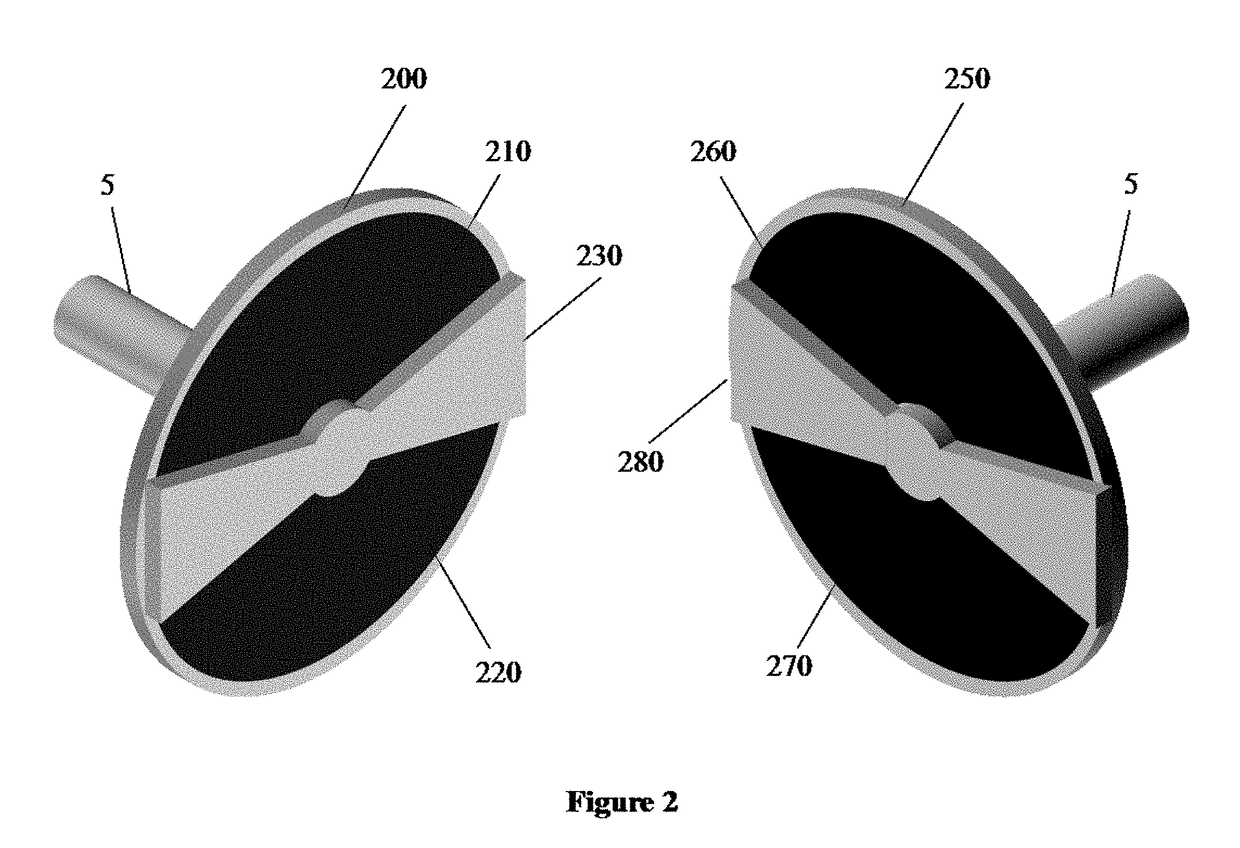

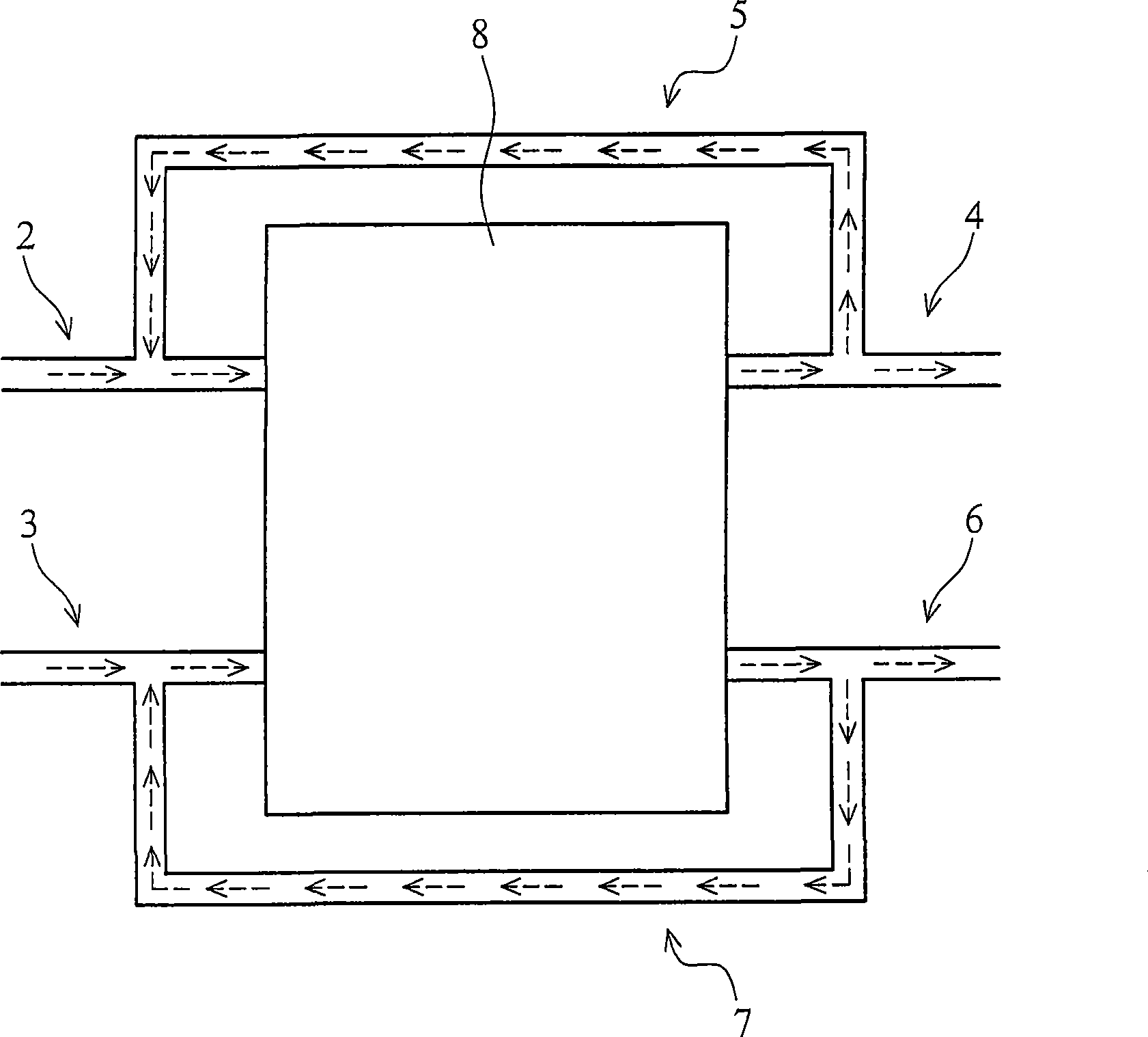

Capacitive Electro Dialysis Reversal

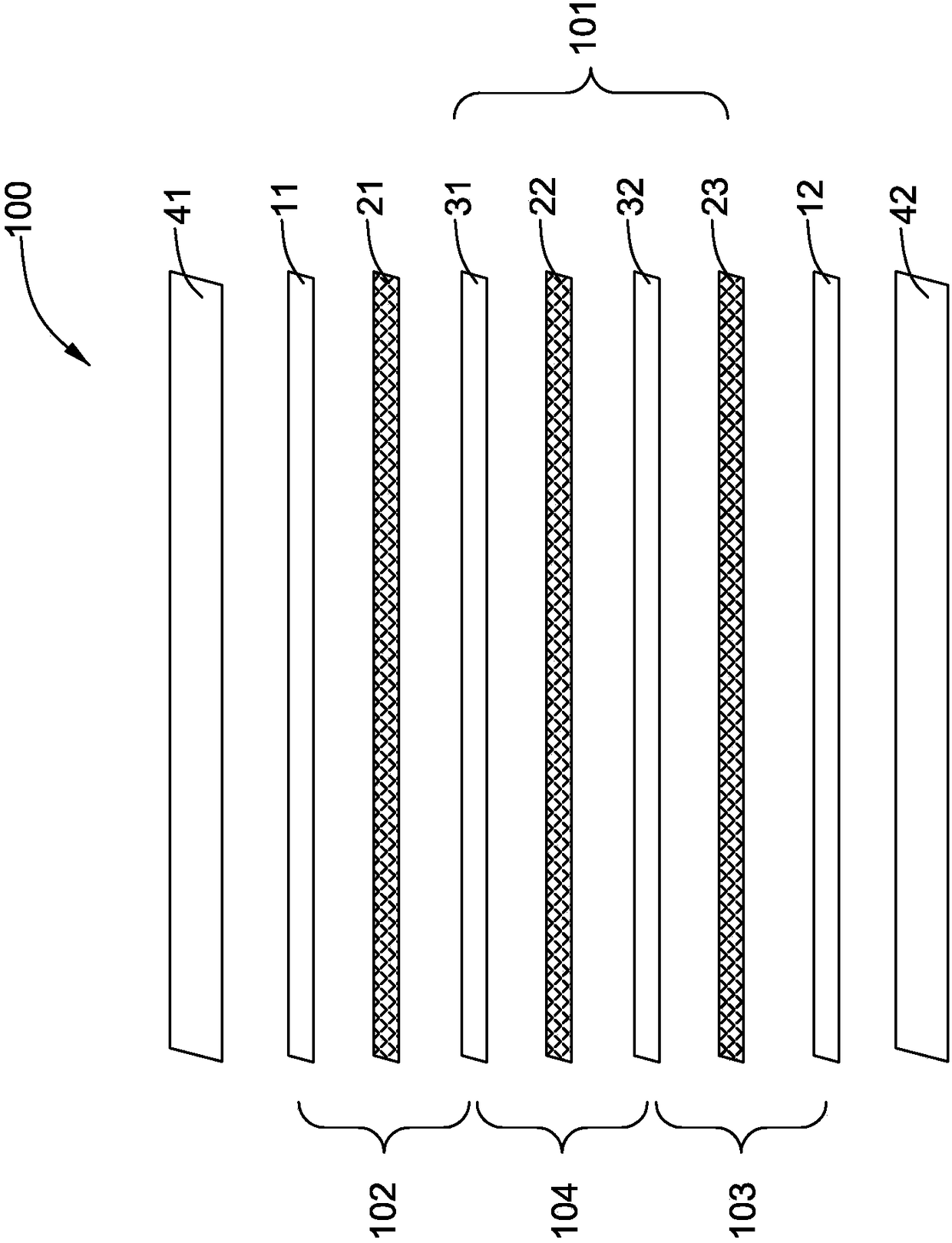

InactiveUS20190015784A1Less exchangeMembranesGeneral water supply conservationElectrodialysis reversalPhysics

This Capacitive Electro Dialysis Reversal (CEDR) invention desalinates and concentrates saline water. The CEDR unit employs two identical parallel oppositely oriented modified Electro Dialysis Reversal EDR constructions that have shared dilute and concentrated saline water channels. The four electrodes of the two identical oppositely oriented parallel EDR like constructions are replaced with four supercapacitor electrodes. Each EDR like construction consists of a stack of ion exchange membranes and spacers plus the supercapacitor electrodes but one cation exchange membrane is trimmed from each of the two stacks of EDR like ion exchange membranes. During a cycle of operation, the supercapacitor electrodes discharge and then charge causing ions to be pulled out of the shared dilute saline water channels and placed in the shared concentrated saline water channels except at the ends where the ions flow in and out of the supercapacitor electrodes. The two adjacent supercapacitor electrodes on either end are exchanged between the two-modified parallel EDR like constructions at the end of each cycle of operation. This process of supercapacitor discharging and charging and then exchanging places operates continuously. A benefit of this CEDR invention is that no gasses are formed at the supercapacitor electrodes like EDR does using conducting electrodes but a similar performance to that of EDR is maintained. A feature of this CEDR invention is that almost all the energy delivered to it is used in desalination and saline water concentration while energy losses at the supercapacitor electrodes located at the ends of the CEDR unit are very small and negligible.

Owner:CANTRELL BEN HARRISON

Recovery processing method for acid wastewater

InactiveCN101468837ASimple stepsLow costGeneral water supply conservationDispersed particle separationWastewaterElectrodialysis reversal

The invention provides a method for recovering and treating acidic wastewater. The method for recovering and treating acidic wastewater comprises: introducing acidic wastewater (pH less than 7) containing metal ions to an electrodialysis reversal device and carrying out the steps of desalination and metal ion removal at the same time; and leading out the acidic recovered producing water. As the method for recovering and treating acidic wastewater can directly introduce the acidic waste water containing the metal ions into the electrodialysis reversal device without carrying out steps of pH value adjustment and settlement in advance, the steps of the recovery and treatment method are simplified and the cost is reduced at the same time.

Owner:IND TECH RES INST

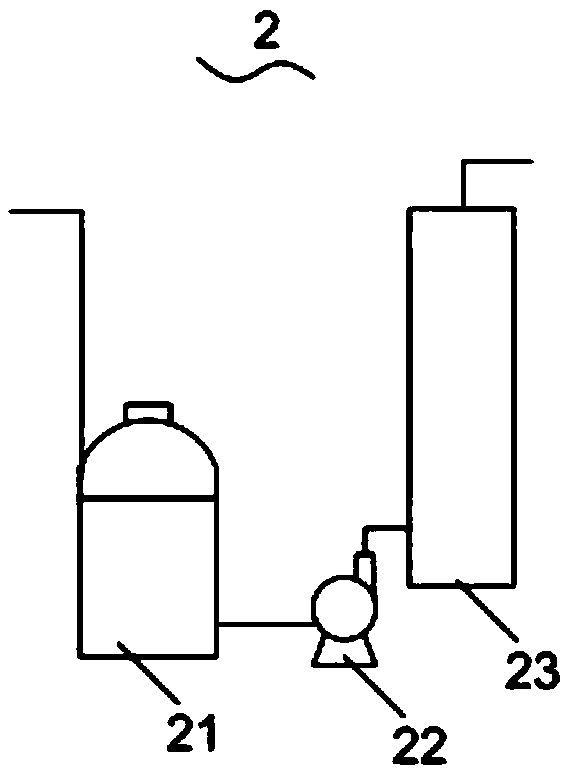

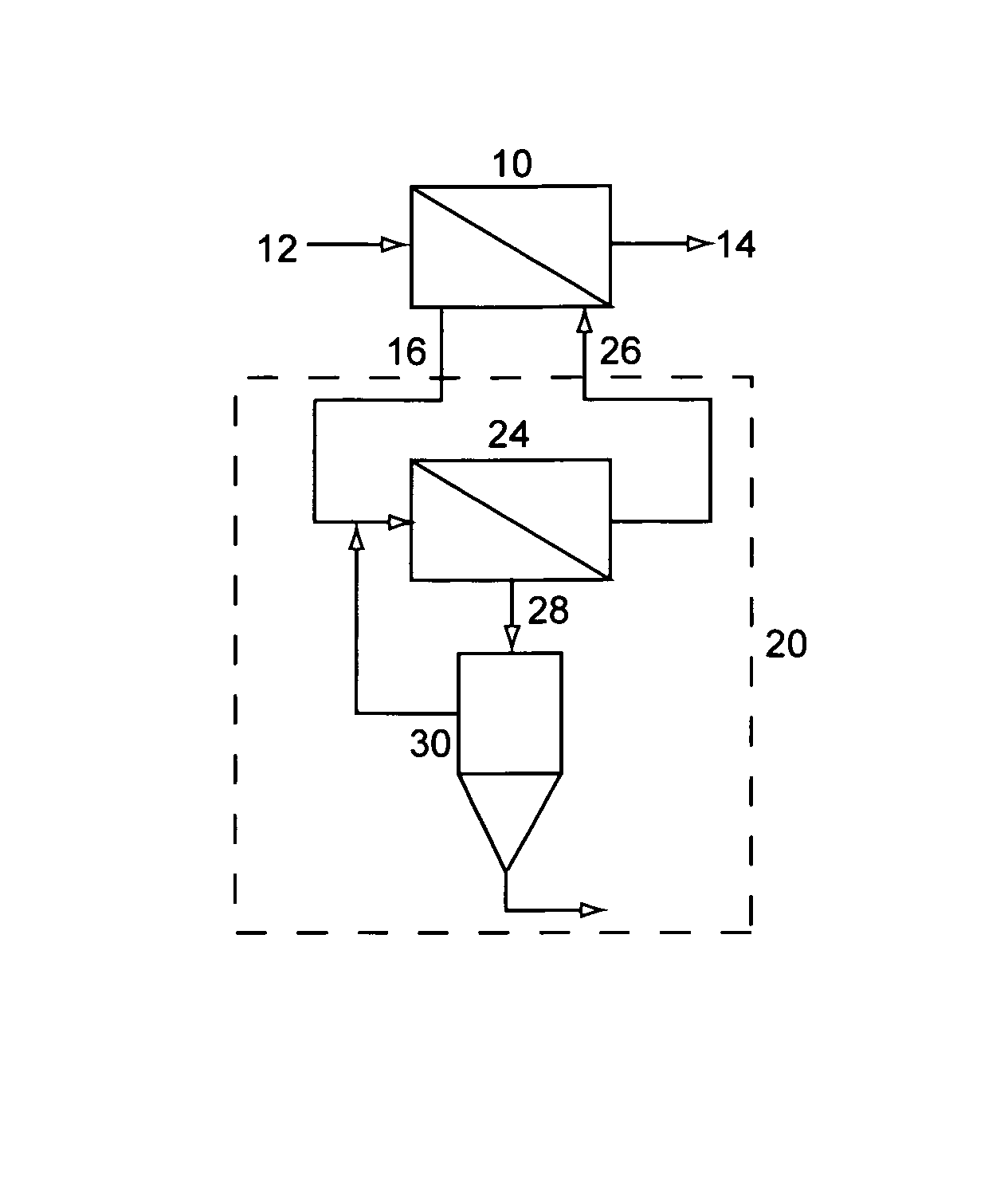

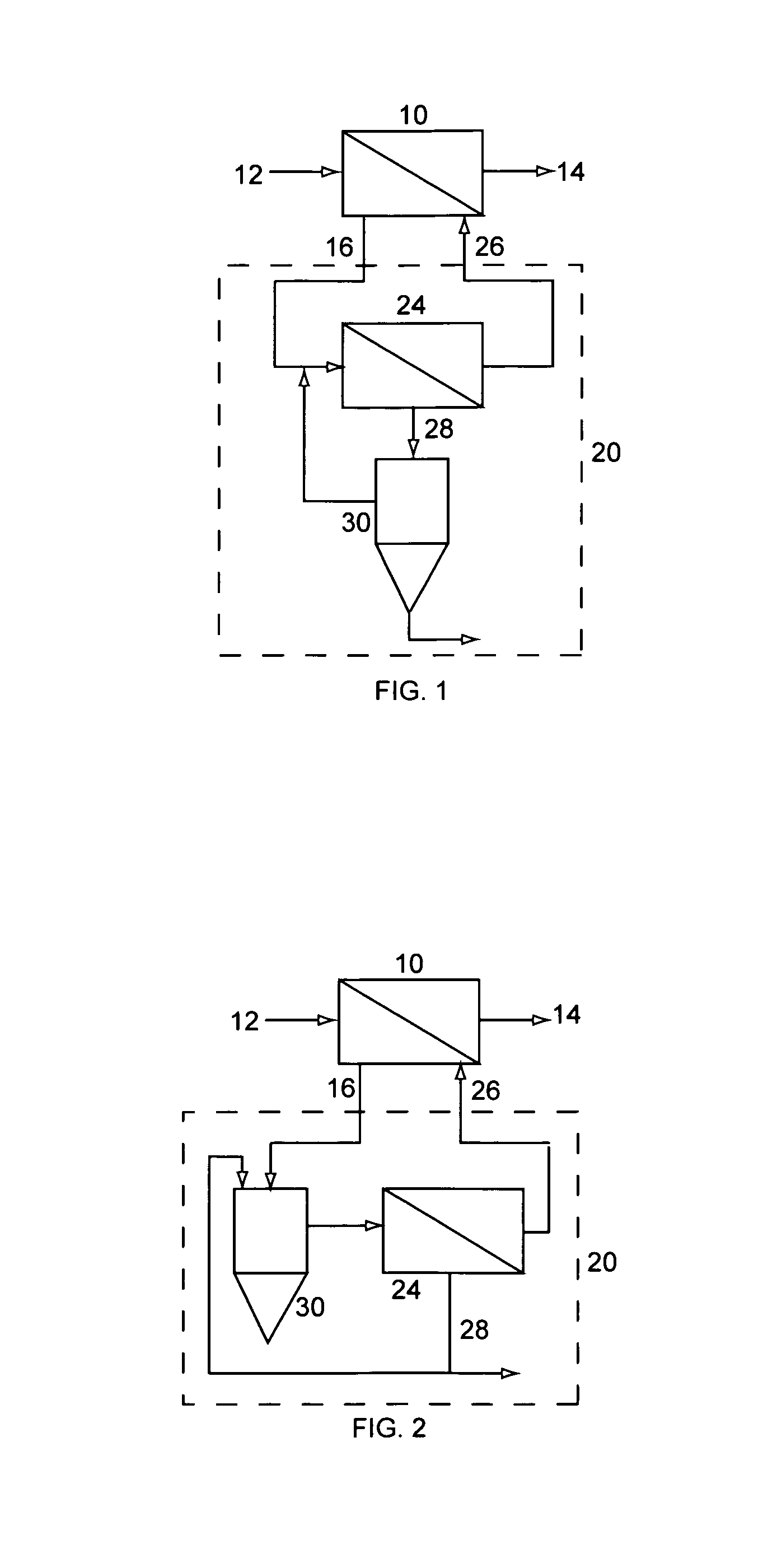

Desalination system and desalination method

InactiveCN103130363AGeneral water supply conservationSpecific water treatment objectivesOperation modeElectrodialysis reversal

The invention relates to a desalination system and a desalination method. The desalination system comprises an electrodialysis reversal device, a sediment unit and a back-washing filtering device, wherein the electrodialysis reversal device is capable of receiving first fluid, carrying out desalination treatment on the first fluid, and receiving second fluid to move away ions removed from the first fluid. The sediment unit is communicated with the fluid of the electrodialysis reversal device and is used for providing the second fluid and enabling the second fluid to circulate between the sediment unit and the electrodialysis reversal device. The back-washing filtering device is arranged between the electrodialysis reversal device and the sediment unit, is communicated with the fluids, and is used for filtering the second fluid under a normal operation mode.

Owner:GENERAL ELECTRIC CO

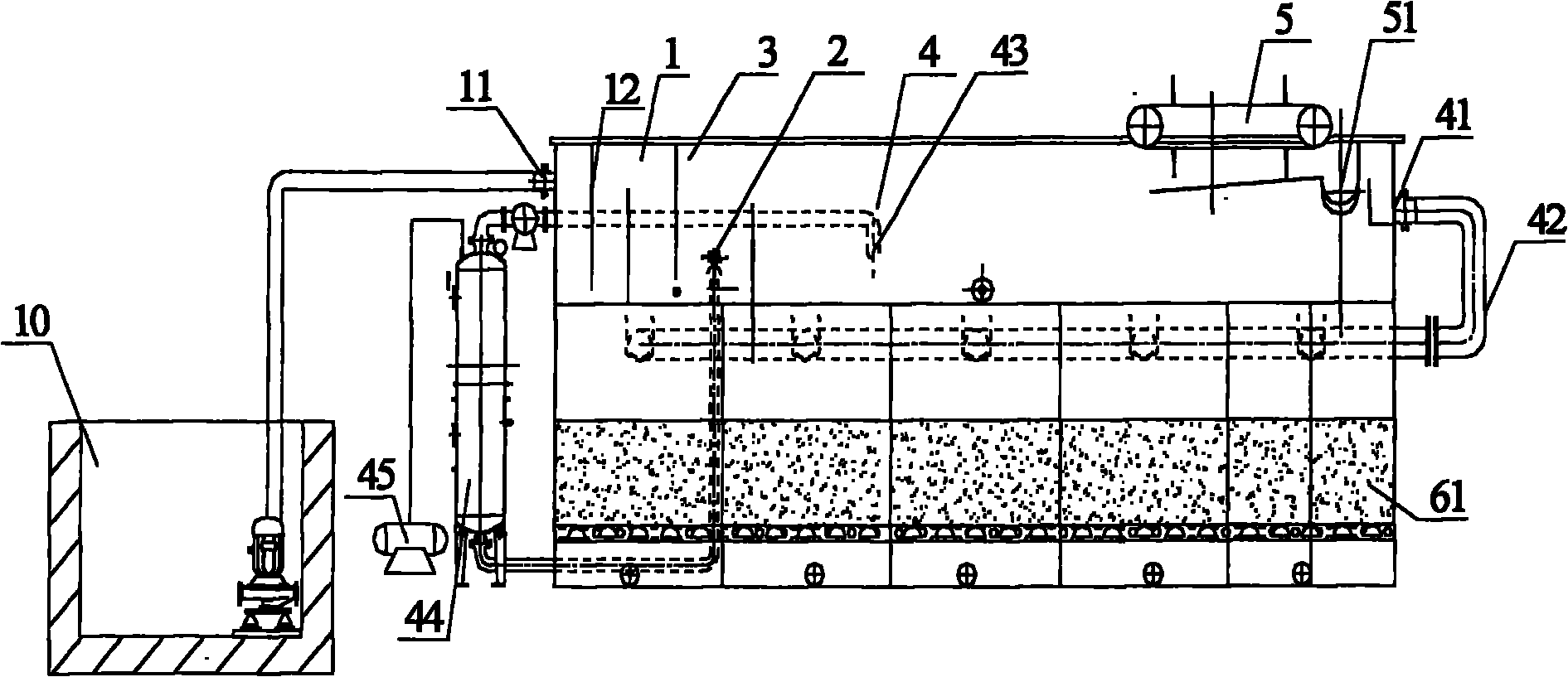

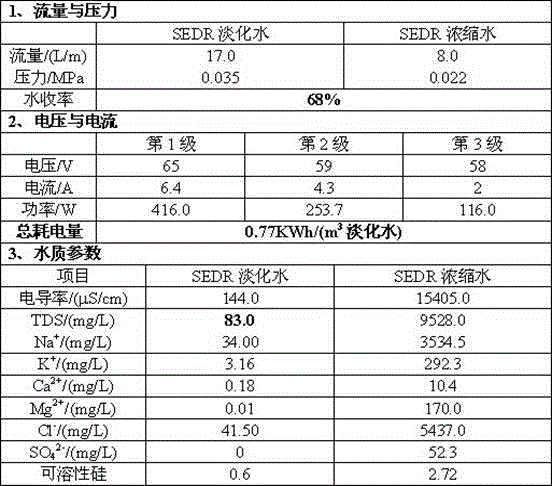

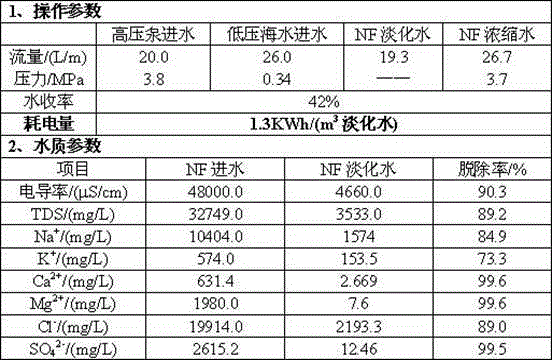

Seawater desalination method for integrated membrane process

ActiveCN104909503AImprove conductivitySlow down the electrode reactionSeawater treatmentMultistage water/sewage treatmentUltrafiltrationHigh energy

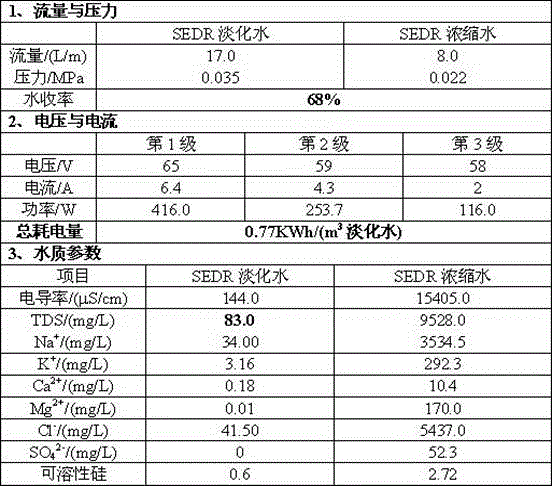

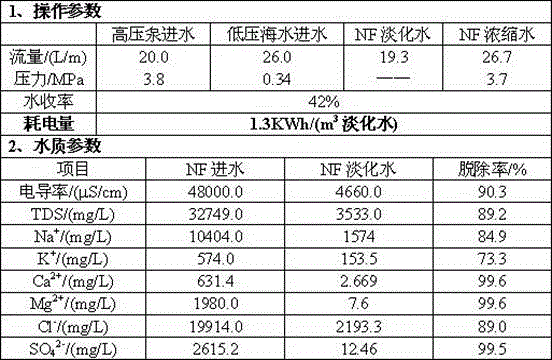

The invention provides a seawater desalination method for an integrated membrane process and belongs to a water desalination technology. Aiming at the defects of high investment, high pressure, high energy consumption and the like in an existing membrane-method seawater desalination process, 'nanofiltration / electrodialysis reversal' is taken as a core desalination process, wherein during nanofiltration, a high-desalination nanofiltration membrane with desalination ratio of 90% is adopted; during electrodialysis reversal, a thin-type electrode chamber is filled with a multistage multi-section energy-saving electroosmosis device provided with mixed-bed ion exchange resin. Seawater raw water is sequentially pretreated by virtue of a coagulative precipitation tank, a settling tank, a sand filter and an ultrafiltration membrane, and then is subjected to graded desaltination sequentially by virtue of a nanofiltration desalination device with an energy recovery device, and an energy-saving frequent electrodialysis reversal device; nanofiltration and energy-saving electrodialysis are respectively performed at low operation pressures which do not exceed 3.8MPa and 0.4MPa; the salt content of water produced by the system is 80-250mg / L, the total desalinization ratio can be mechanically regulated within a range of 99-99.75%, the body power consumption of per ton of water does not exceed 2.15KWh / m<3>, the investment and energy consumption of the whole seawater desalination process are obviously reduced, and the process operation is relatively safe and stable.

Owner:天津中领水系统技术有限公司

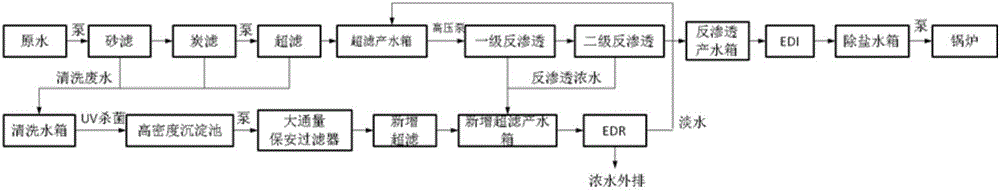

High-water-yield treatment method and device for boiler feed water

PendingCN106746057AImprove raw water utilizationSimple structureWater/sewage treatment by irradiationGeneral water supply conservationWater requirementElectrodialysis reversal

The invention discloses a high-water-yield treatment method for boiler feed water. The high-water-yield treatment method comprises the following steps of (1), conveying all washing wastewater of sand filtering, carbon filtering and ultrafiltration systems into a washing water tank, and removing organisms of an alga and the like in the washing wastewater under the action of an ultraviolet sterilization device in a pipeline; (2), afterwards, making the washing wastewater pass through a high-density sedimentation pool; (3), afterwards, making the washing wastewater pass through a high-flux security filter and enter a newly added ultrafiltration system again for treatment; (4), making concentrated water produced by the primary reverse osmosis and the secondary reverse osmosis in a membrane-method power-plant boiler water treating device enter a newly added ultrafiltration water producing box and mixed with the wastewater treated through the newly added ultrafiltration system in the step (3), making mixed wastewater enter an electrodialysis reversal device, decreasing the salt content of the wastewater to make the wastewater meet the inlet water requirement of a reverse osmosis device, making outlet water of an electrodialysis reversal desalination chamber enter the ultrafiltration water producing box to carry out cyclic treatment, and outwards discharging outlet water of an electrodialysis reversal condensation chamber. The utilization rate of raw water is improved in a process; the device is simple in structure; the capital expenditure is low.

Owner:QINGDAO NORTH ENERGY & ENVIRONMENT

Treatment device and method for recycling reclaimed water in effluent from secondary sedimentation tank

PendingCN109437455AReduce foulingReduce bacterial growthWater treatment parameter controlWater contaminantsSulfate radicalsUltrafiltration

The invention belongs to the technical field of wastewater treatment and specifically relates to a treatment device and method for recycling reclaimed water in effluent from a secondary sedimentationtank. According to the invention, EDR (Electrodialysis Reversal) is adopted for desalinizing the effluent from the secondary sedimentation tank generated during the process of paper making; the removal rate of sulfate radicals and chloride ions in water can reach 90% or above; the recycling rate of water can reach 75% or above; EDR, ultrafiltration and other technologies are adopted for greatly improving the processing capacity for water of the secondary sedimentation tank; the equipment is simply operated and easily used; the energy consumption is lower; in addition, no more infrastructures need be established; and meanwhile, the EDR technology only has a migrating function for salts in water and cannot migrate COD substances, so that the advanced oxidation treatment process for concentrated water can be avoided, and therefore, the subsequent evaporation treatment can be conveniently performed, and the production cost can be greatly saved; the treated fresh water can be recycled, so that the discharge of papermaking wastewater can be greatly reduced, and meanwhile, the use ratio of water resource is increased; not only is the clean and environment-friendly treatment realized, butalso the original treatment process is greatly simplified and the overall wastewater treatment cost is lowered.

Owner:HANGZHOU BLUETEC ENVIRONMENTAL TECH

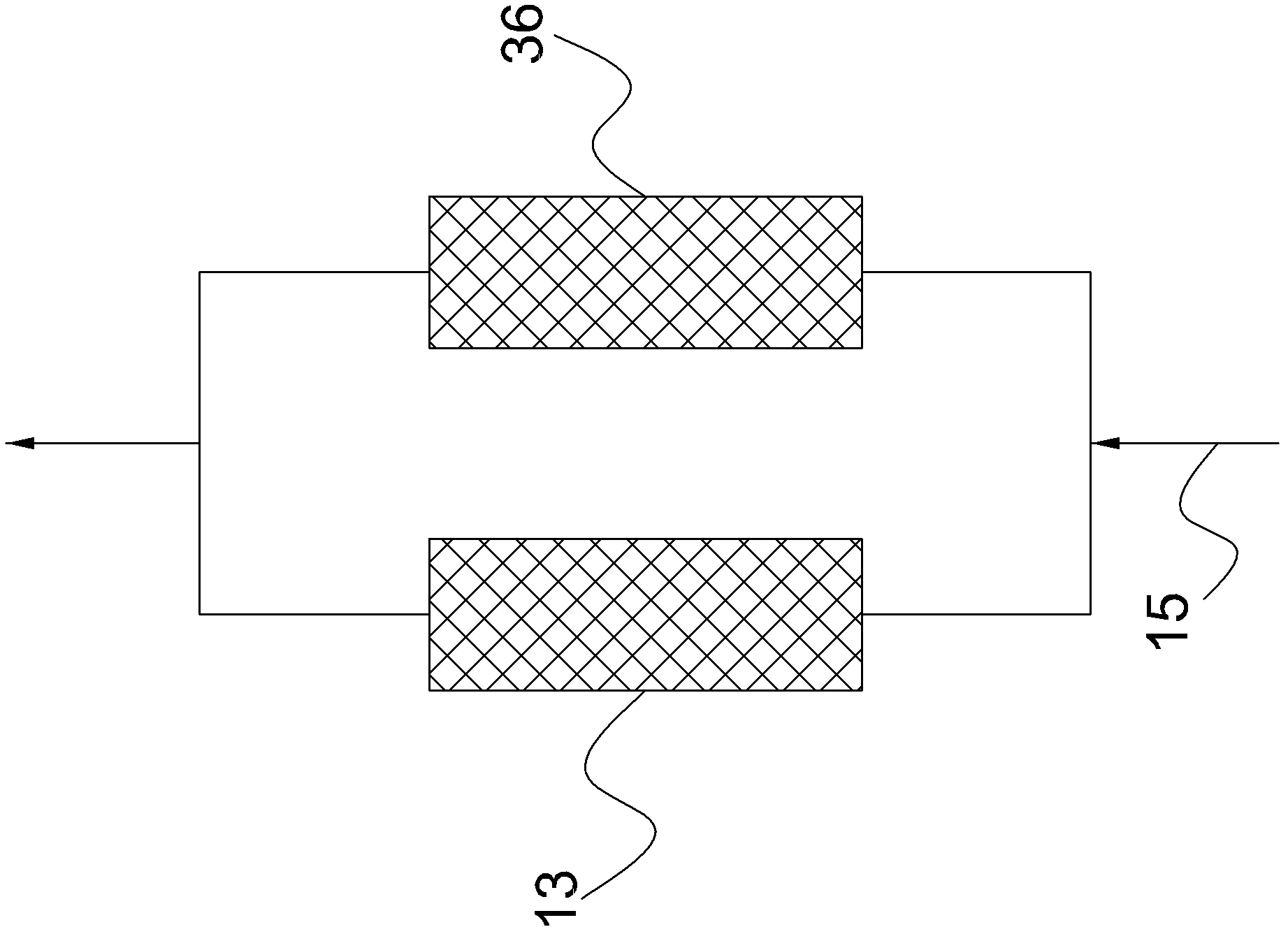

Ionic conductive separator plate, production method thereof, and electrodialysis reversal device

The invention discloses an ionic conductive separator plate applied to an electrodialysis reversal device. The ionic conductive separator plate comprises a plastic net and a polymer coating layer applied to the plastic net. The polymer coating layer contains a charged group, the form of the polymer coating layer has interconnected ion clusters, and interconnected ion clusters allow ions to be macroscopically continuously transported through the surface of the plastic net. The invention also discloses the electrodialysis reversal device using the ionic conductive separator plate, and a production method of the ionic conductive separator plate.

Owner:BL TECH INC

Electrodialysis control method and device and water purifier

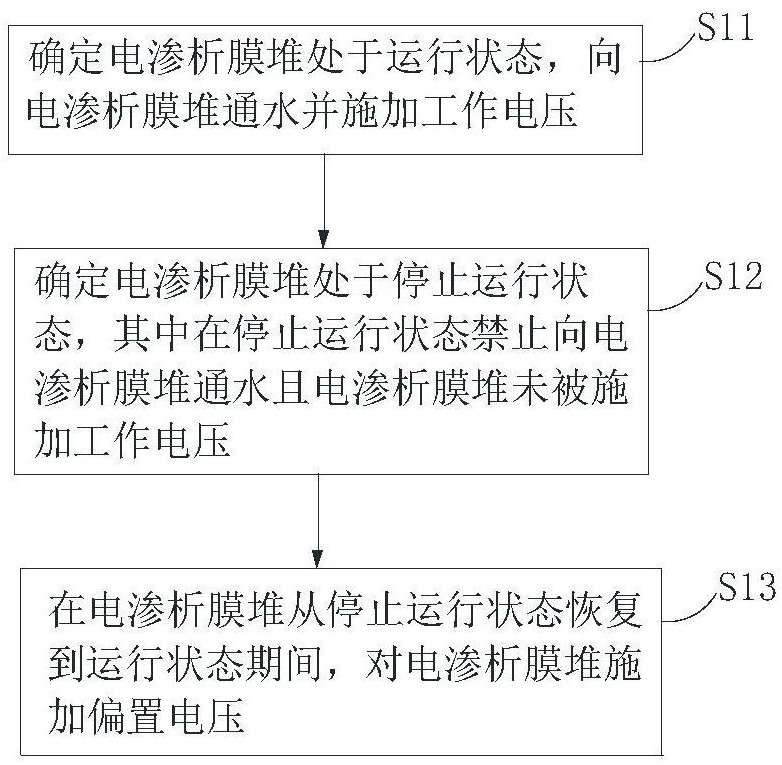

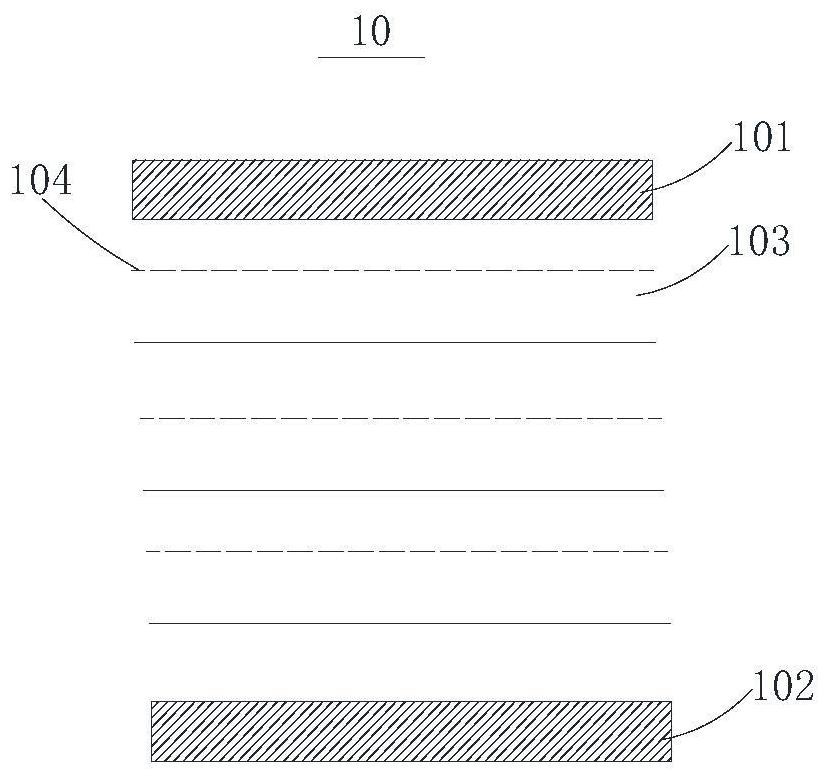

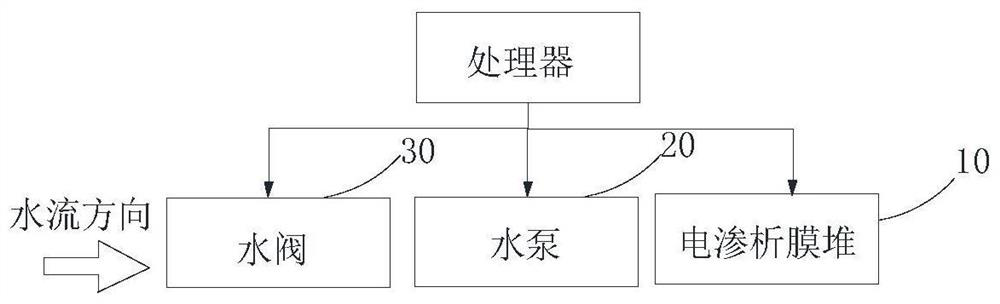

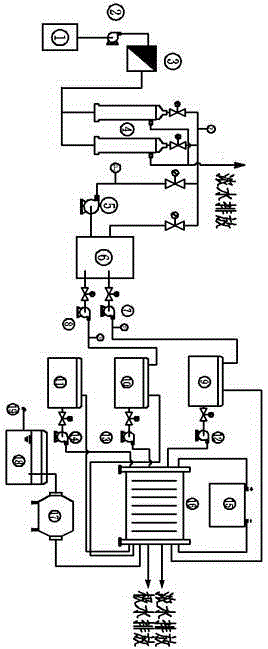

ActiveCN112645414AMeet drinking water health requirementsSolve the first glass of water problemWater treatment parameter controlDispersed particle separationProcess engineeringEnvironmental engineering

The embodiment of the invention provides an electrodialysis control method which is applied to water purification equipment. The water purification equipment comprises a frequent electrodialysis reversal membrane stack. The control method comprises the following steps: determining that the frequent electrodialysis reversal membrane stack is in a stop running state, wherein in an operation stopping state, water is forbidden to flow into the frequent electrodialysis reversal membrane stack, and no working voltage is applied to the frequent electrodialysis reversal membrane stack; and applying bias voltage to the frequent electrodialysis reversal membrane stack during the period that the frequent electrodialysis reversal membrane stack is recovered from the operation stopping state to an operation state. The bias voltage is applied to the frequent electrodialysis reversal membrane stack when the frequent electrodialysis reversal membrane stack is recovered from the operation stopping state to the operation state, so that residual water under the action of permeation is ionized before being discharged, the problem of first cup of water in the industry is solved, the drinking water health requirement of a user is met, and in addition, the problem of deposition and scaling can be solved by adopting frequent electrodialysis reversal.

Owner:FOSHAN SHUNDE MIDEA WATER DISPENSER MFG

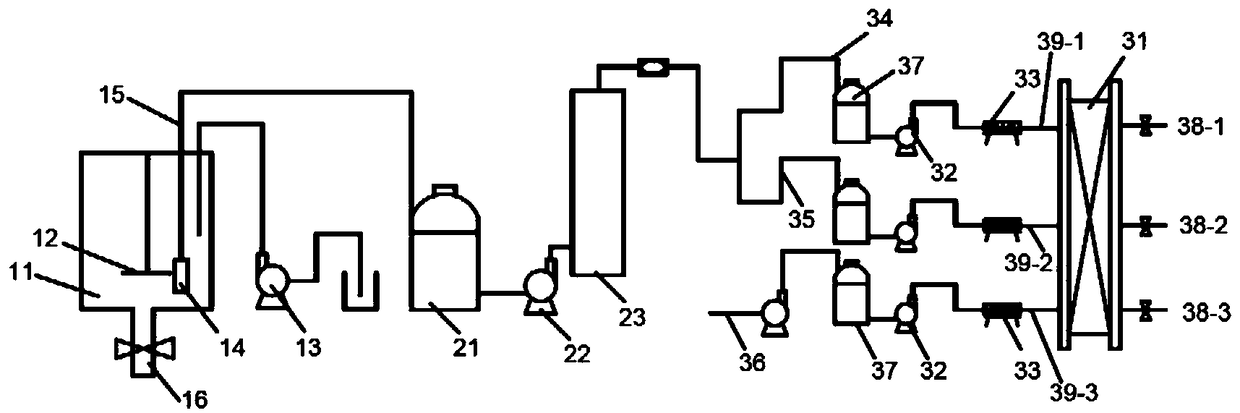

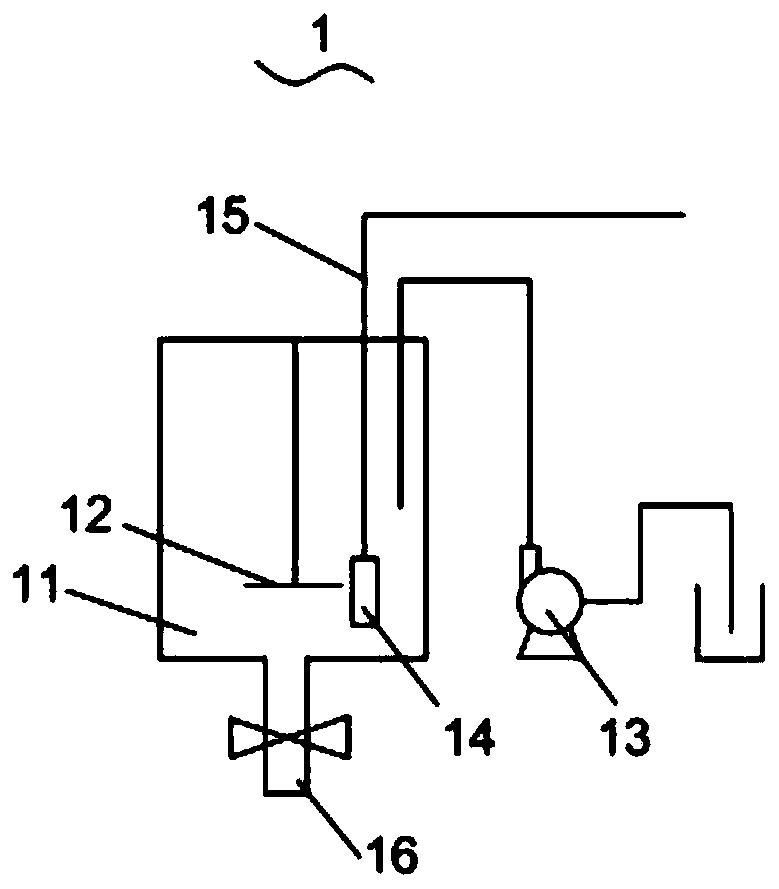

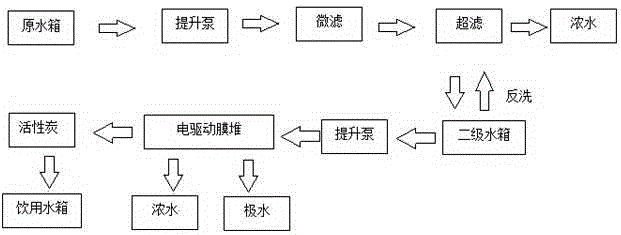

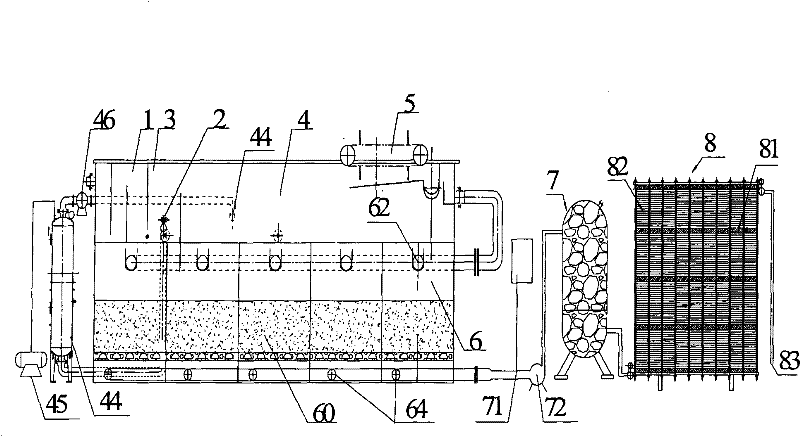

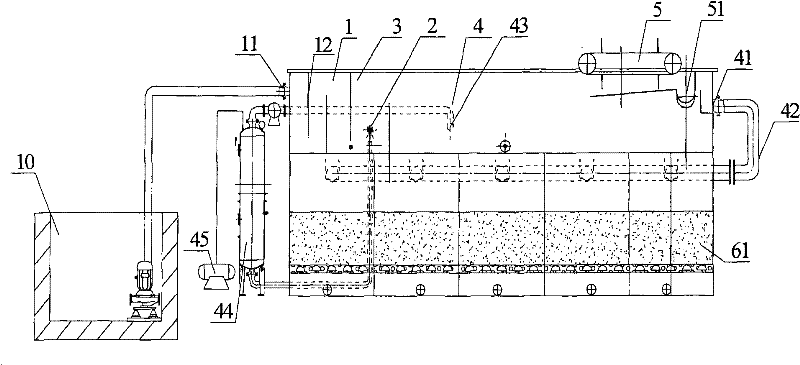

Multi-membrane-method sea water desalination integrated device

InactiveCN105174545AIncrease water fluxHigh breaking strengthSeawater treatmentMultistage water/sewage treatmentWater desalinationWater quality

The invention provides a multi-membrane-method sea water desalination integrated device. According to the multi-membrane-method sea water desalination integrated device, a novel multi-membrane-method sea water desalination integrated technology is created by coupling microfiltration, ultrafiltration, frequent electrodialysis reversal and active carbon optimizing, and aims at solving the problems of membrane pollution and the like in the sea water desalination process; an ultrafiltration membrane with high pollution resistance is adopted for a pre-treatment system, and the ultrafiltration membrane and an electric-driving homogeneous membrane form a double-membrane system, so that the system is more stable in running, the service life of the system is prolonged, and it is guaranteed that the quality of yielded water meets a tap water standard; the sea water desalination integrated technology is a novel sea water desalination technology.

Owner:江苏省科建成套设备有限公司

Leachate treatment method and leachate treatment system

PendingCN113800720AHigh removal rateRealize full processingWater contaminantsTreatment involving filtrationOsmolyteElectrodialysis reversal

The invention provides a leachate treatment method and system.The leachate treatment method comprises the following steps: 1, performing a biodegradation reaction on penetrating fluid through anaerobic microorganisms, and removing a part of organic matter in the penetrating fluid; 2, carrying out biological denitrification on the penetrating fluid through the anaerobic microorganism bacteria to remove part of nitrogen in the penetrating fluid; 3, filtering the penetrating fluid; 4, further degrading organic matters in the penetrating fluid through first advanced oxidation treatment; 5, treating the penetrating fluid through electrodialysis reversal to obtain first fresh water and first concentrated water; 6, evaporating and crystallizing the first concentrated water to obtain inorganic salt; 7, filtering the first fresh water to obtain second fresh water and second concentrated water, and discharging the second fresh water as produced water; 8, further degrading organic matters in the second concentrated water through second advanced oxidation treatment; and step 9, repeating the step 3 to the step 8 on the second concentrated water treated in the step 8. According to the invention, the whole amount of the penetrating fluid can be treated, and zero emission is realized.

Owner:EVERBRIGHT ENVIRONMENTAL TECH RES INST NANJING CO LTD +3

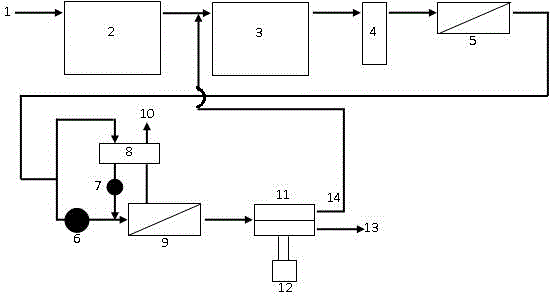

Concentrated discharge water re-concentrating apparatus

The invention relates to a concentrated discharge water re-concentrating apparatus, which at least comprises: a concentrated water collecting box, a high density pool pretreatment unit CP, a gas floating filtering pool unit DAF, a two-stage filtering membrane unit MC and a frequent electrodialysis reversal unit EDR, wherein the concentrated water collecting box for collecting concentrated discharge water is connected to the high density pool pretreatment unit CP, the concentrated discharge water collected by the concentrated water collecting box is conveyed to the high density pool pretreatment unit CP, the high density pool pretreatment unit CP for pre-treating the concentrated discharge water is connected to the gas floating filtering pool unit DAF, the gas floating filtering pool unit DAF is connected to a first-stage filtering membrane unit MC1, and the first-stage filtering membrane unit is connected to a second-stage filtering membrane unit MC2.

Owner:德阳市尚风装饰设计有限公司

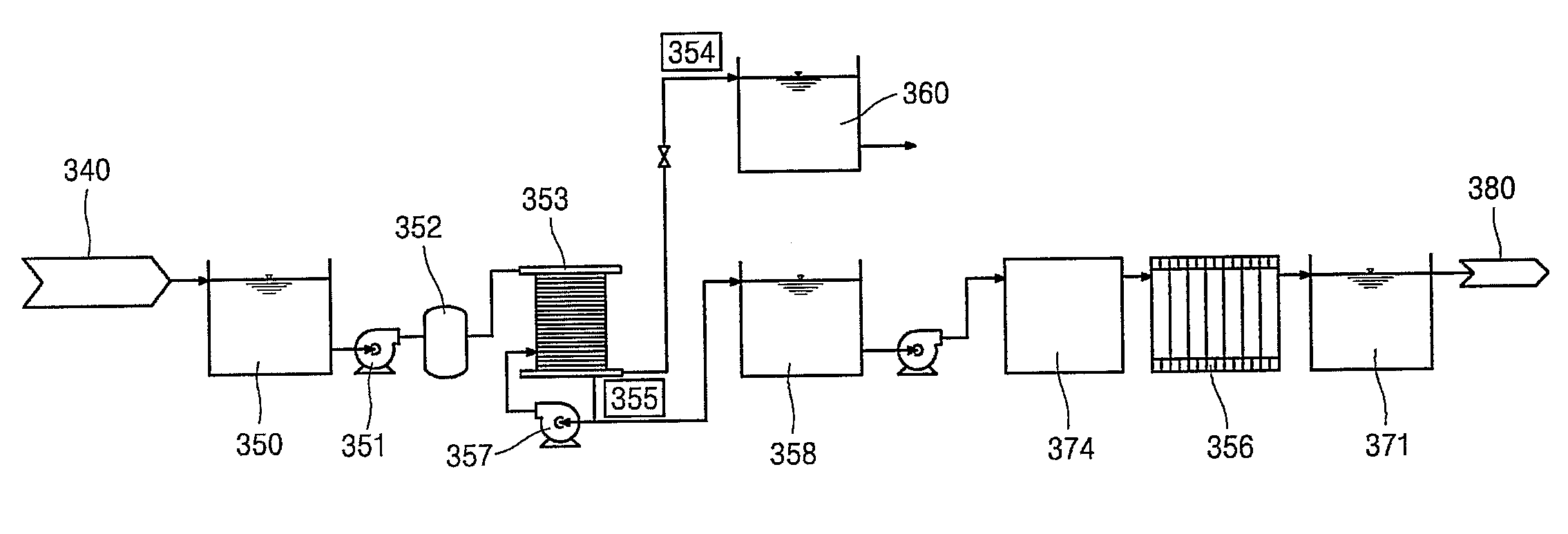

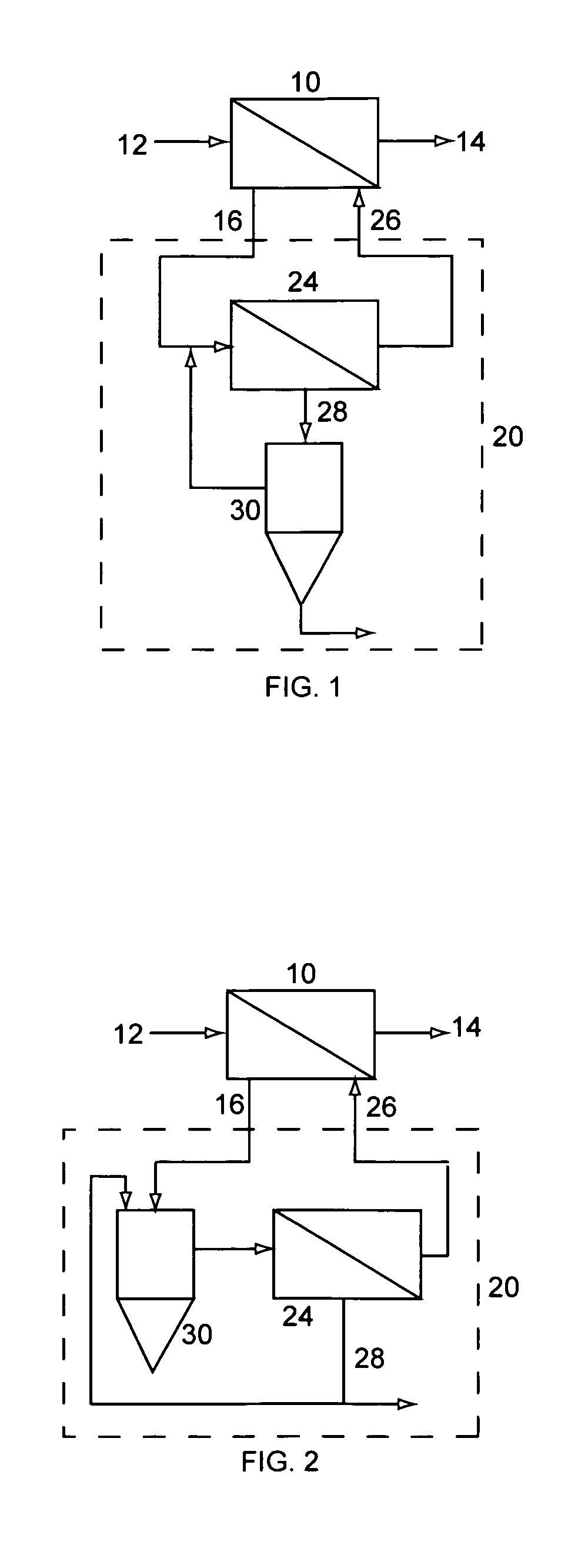

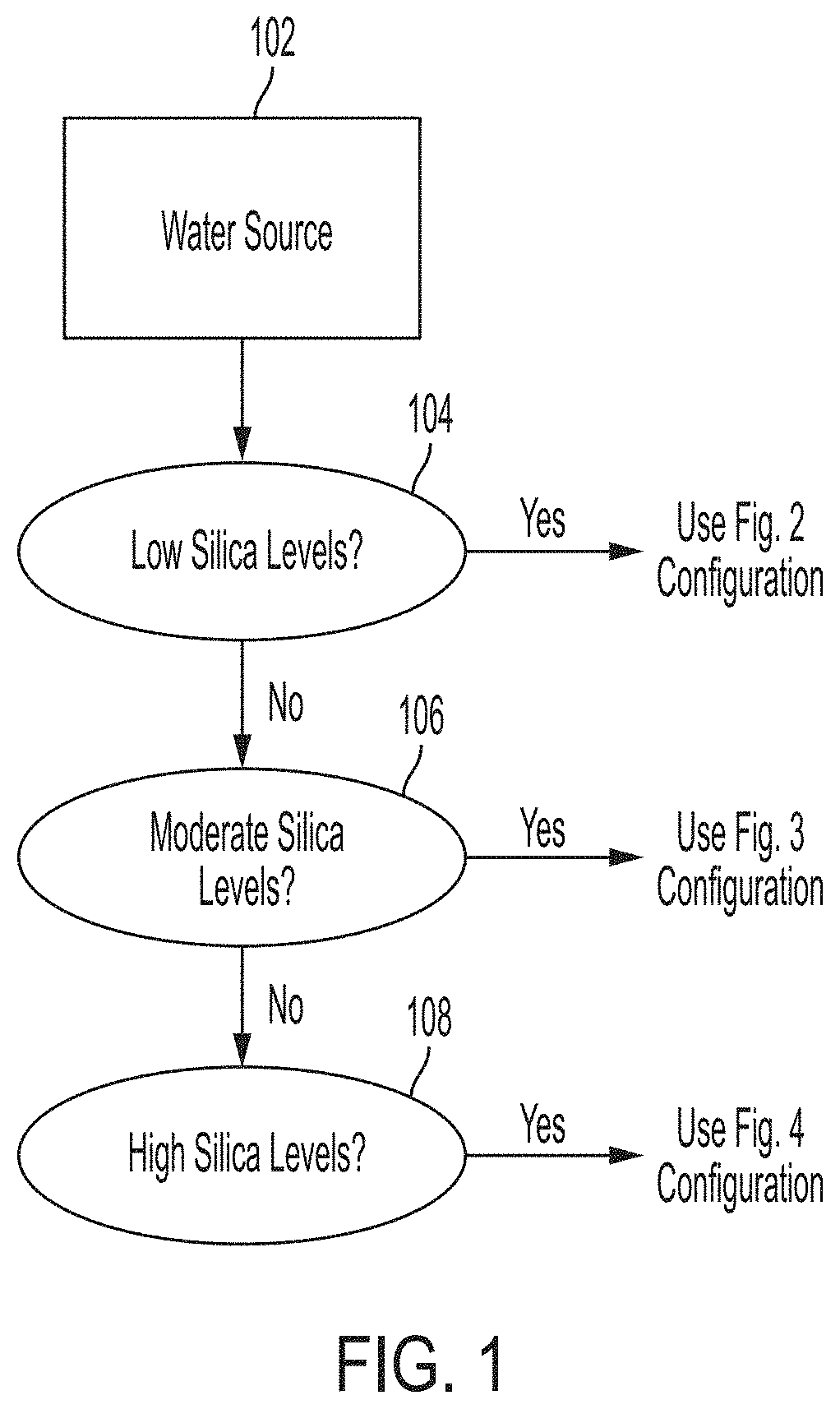

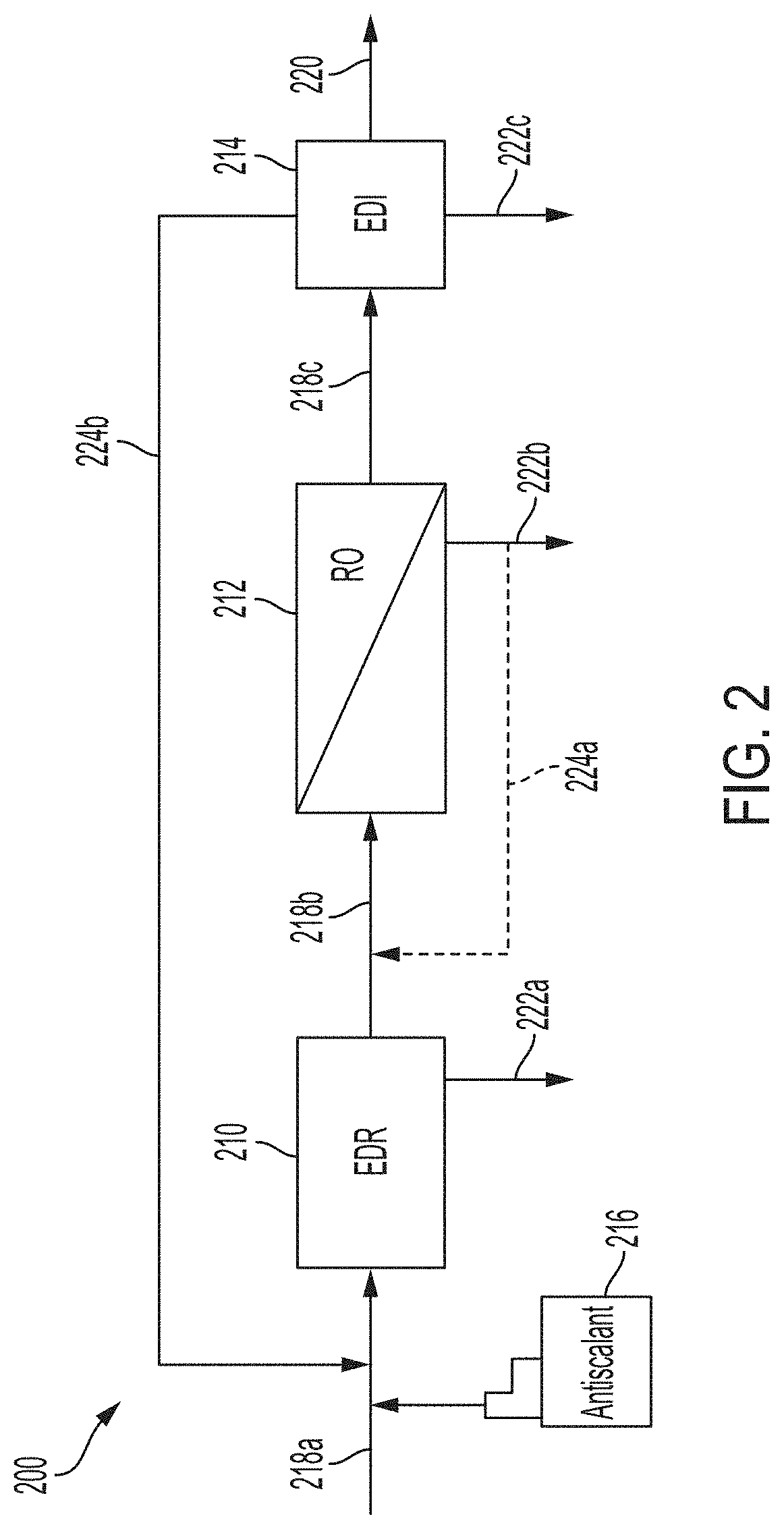

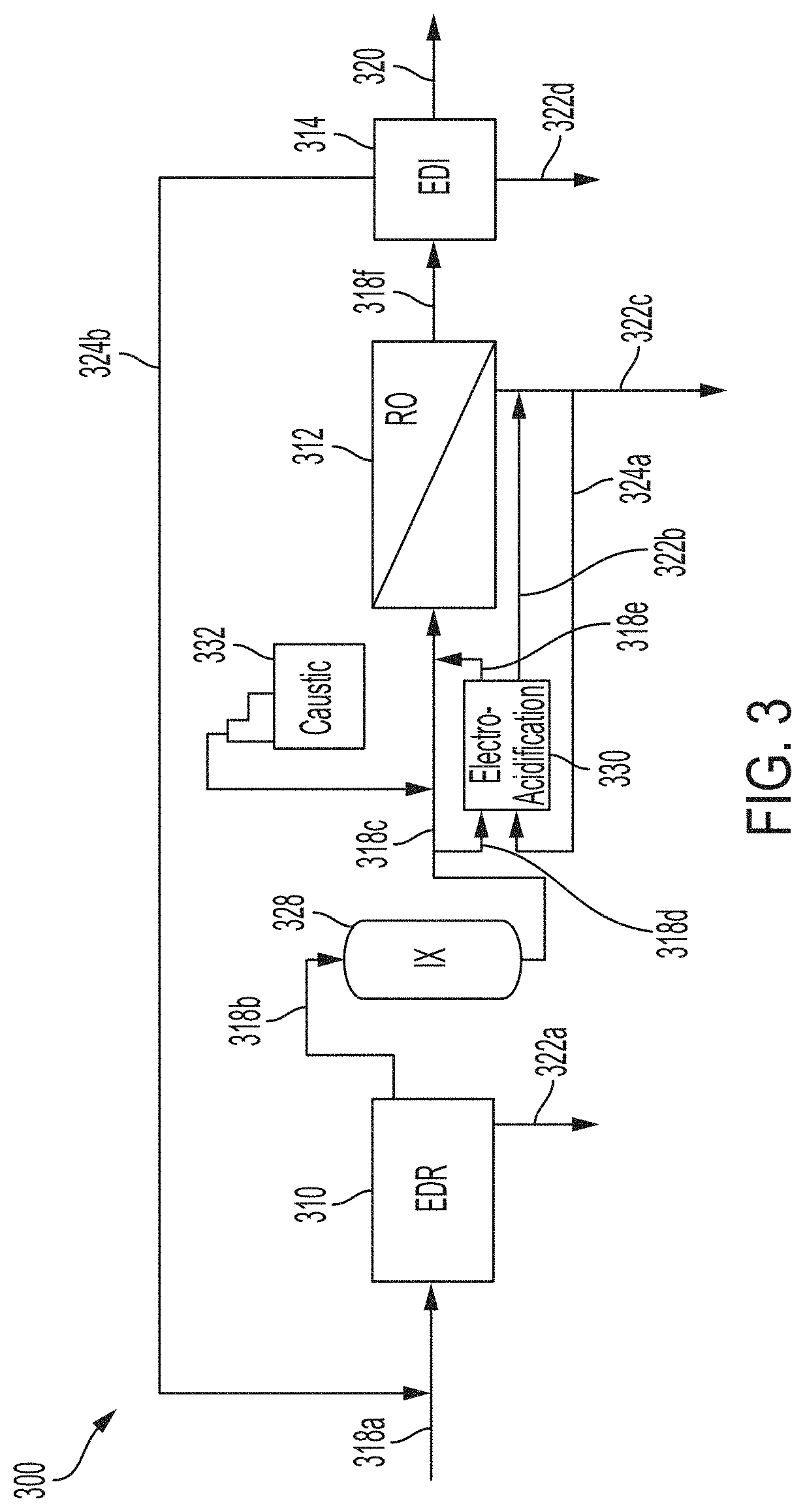

Hybrid electrochemical and membrane-based processes for treating water with high silica concentrations

ActiveUS20210094846A1Low level of consumptionPrecious timeMembranesSeawater treatmentEnvironmental chemistryElectrodialysis reversal

Provided are hybrid electrochemical and membrane-based systems for removing silica from water stream to achieve ultra-pure water. The silica concentration of a feed water stream may dictate the most effective and economical variation of disclosed hybrid processes to use. For example, for a feed water stream having a silica concentration of 1-30 ppm, a hybrid system for treating the feed water includes an electrodialysis reversal unit, the electrodialysis reversal unit comprising an inlet stream and a product outlet stream; a reverse osmosis unit, the reverse osmosis unit comprising an inlet stream and a product outlet stream, wherein the inlet stream of the reverse osmosis unit comprises the product outlet stream of the electrodialysis reversal unit; and an electrodeionization unit, the electrodeionization unit comprising an inlet stream and a product outlet stream, wherein the inlet stream of the electrodeionization unit comprises the product outlet stream of the reverse osmosis unit.

Owner:MIS IP HLDG LLC

Electrodialysis reversal and electrochemical wastewater treatment method of compound containing nitrogen

Owner:KEPCO ENG & CONSTR CO INC

Brine treatment scaling control system and method

The present invention may be used in systems and methods for brine treatment scaling control in a water treatment system. A concentrated brine stream influent may be treated in an electrodialysis-reversal process to produce a concentrated brine stream effluent and a lower salinity diluent water, which may be potable water effluent. The concentrated brine stream effluent may be processed in a brine treatment scaling control system that may have a mixing vessel and a membrane filter with the mixing vessel seeded with calcium sulfate. A lowered salinity brine stream effluent may be produced for return to the electrodialysis-reversal process to allow operation at greater overall recovery and an elevated concentrated brine stream may be produced.

Owner:CAROLLO ENGINEERS

A method for seawater desalination with integrated membrane process

ActiveCN104909503BReduce turbidityReduce chromaSeawater treatmentMultistage water/sewage treatmentUltrafiltrationHigh energy

The invention provides a seawater desalination method for an integrated membrane process and belongs to a water desalination technology. Aiming at the defects of high investment, high pressure, high energy consumption and the like in an existing membrane-method seawater desalination process, 'nanofiltration / electrodialysis reversal' is taken as a core desalination process, wherein during nanofiltration, a high-desalination nanofiltration membrane with desalination ratio of 90% is adopted; during electrodialysis reversal, a thin-type electrode chamber is filled with a multistage multi-section energy-saving electroosmosis device provided with mixed-bed ion exchange resin. Seawater raw water is sequentially pretreated by virtue of a coagulative precipitation tank, a settling tank, a sand filter and an ultrafiltration membrane, and then is subjected to graded desaltination sequentially by virtue of a nanofiltration desalination device with an energy recovery device, and an energy-saving frequent electrodialysis reversal device; nanofiltration and energy-saving electrodialysis are respectively performed at low operation pressures which do not exceed 3.8MPa and 0.4MPa; the salt content of water produced by the system is 80-250mg / L, the total desalinization ratio can be mechanically regulated within a range of 99-99.75%, the body power consumption of per ton of water does not exceed 2.15KWh / m<3>, the investment and energy consumption of the whole seawater desalination process are obviously reduced, and the process operation is relatively safe and stable.

Owner:天津中领水系统技术有限公司

Method for treating and recycling circulating wastewater

ActiveCN101870530BEliminate the concerns of easy pollutionHigh operating costsGeneral water supply conservationDispersed particle separationWater qualityReverse osmosis

The invention provides a method for treating and recycling industrial circulating wastewater, which comprises the following steps of: adding a polyacrylamide flocculant into the circulating wastewater to perform flocculation reaction, wherein 4 to 8mg of flocculant is added into every 1L of sewage and the flocculation reaction time is controlled to be at least 5 minutes; allowing the sewage afterthe flocculation reaction to enter a high-efficiency floatation tank, controlling the air floatation time to be at least 10 minutes, allowing the air floatation water to discharge into a filter tank,and discharging the water after filtering; adding an acid into the filtered discharged water to regulate the alkalinity of the water body, adding a scale inhibitor and delivering the water to a cartridge filter; and delivering the filtered effluent from the cartridge filter to an electrodialysis reversal system to perform desalination, wherein the effluent treated by the electrodialysis reversal system is used as make-up water for circulating water. The method can more effectively realize continuous treatment of the sewage and water production without using nanofiltration and reverse osmosis technology; the treated sewage keeps a certain amount of ions; and the effluent meets the requirements of the water quality of reused water of a circulating water system.

Owner:北京新金应利科技发展有限公司

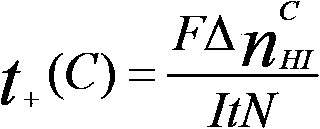

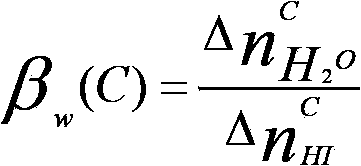

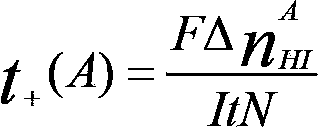

Evaluation method for condensation effect of hydrogen iodide in iodine-containing hydriodic acid by using electrolysis-electrodialysis device

ActiveCN102854082BReduce evaluation errorThe process is simple and fastWeighing by absorbing componentElectricityElectrolysis

Owner:TSINGHUA UNIV

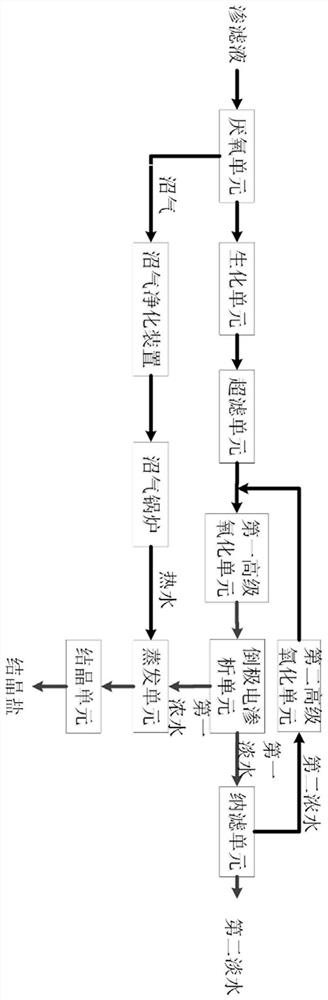

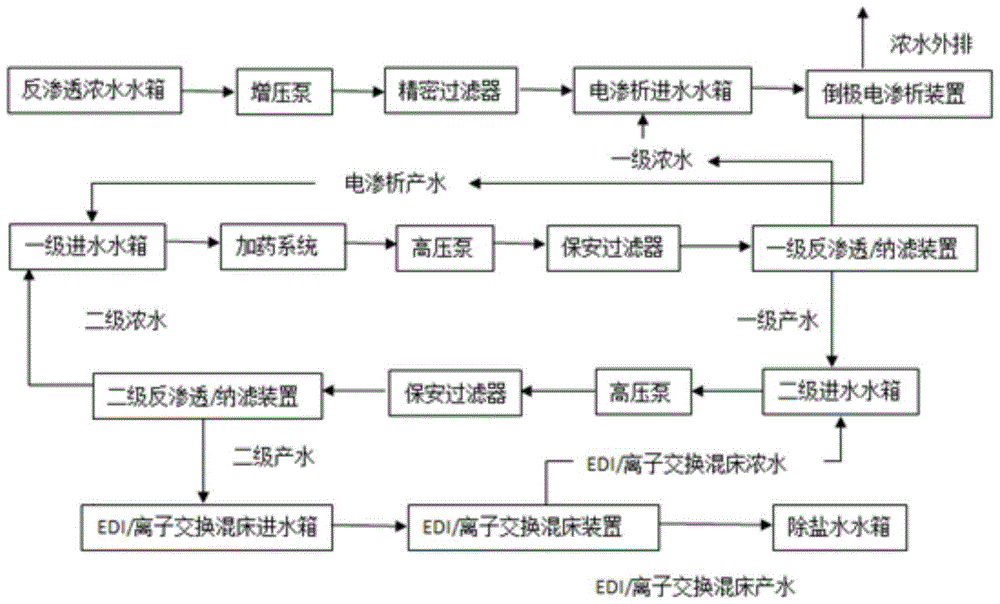

A system for recovering reverse osmosis concentrated water to produce desalted water

ActiveCN104529021BIncrease added valueImprove recycling ratesGeneral water supply conservationMultistage water/sewage treatmentWater desalinationIon exchange

The invention discloses a system for preparing demineralized water by recycling reverse osmosis concentrated water and belongs to the technical field of water treatment. The system comprises a reverse osmosis concentrated water tank, a booster pump, an ultrafilter, an electrodialysis water inlet tank, an electrodialysis reversal device, a primary water inlet tank, a dosing system, a primary high-pressure pump, a primary security filter, a primary reverse osmosis device or nanofiltration device, a secondary water inlet tank, a secondary high-pressure pump, a secondary security filter, a secondary reverse osmosis device or nanofiltration device, an EDI or ion exchange mixed bed water inlet tank, an EDI device or ion exchange mixed bed device, and a demineralized water tank. The system has the advantages of being simple in structure, easy to operate, high in concentrated water recycling rate, low in operating cost, long in service life, high in economic efficiency and the like. The system can be matched with water treatment equipment such as a sea water desalination device and a boiler water device, and is efficient, easy to use, capable of being used for a long time and high in reliability and innovativeness.

Owner:海丝节水科技(天津)有限公司

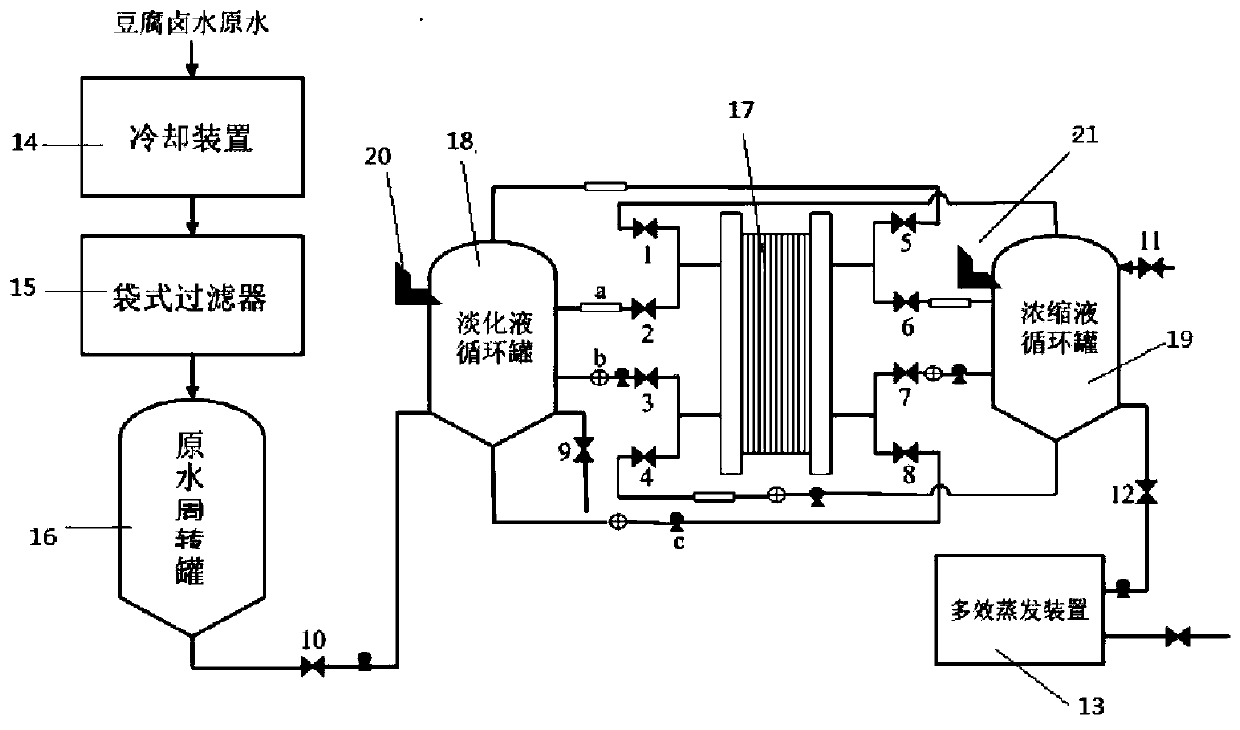

Method and device for treating tofu brine by adopting frequent electrodialysis reversal technology

InactiveCN110236082AReduce processingHigh content of active nutrientsFood scienceHigh resistanceAlloy

The invention belongs to the technical field of water treatment and relates to a method and device for treating tofu brine by adopting a frequent electrodialysis reversal technology. The frequent electrodialysis reversal technology is adopted, and a fluorine-containing alloy ion exchange membrane with high polymerization cross-linking degree and high resistance to organic pollution is utilized to realize the separation of active nutrients and bittern in medium brine. The method comprises the steps of raw water pretreatment, electrodialysis and bittern concentration; the frequent electrodialysis reversal technology is adopted for treating and removing the brine of insoluble components according to desalted fluid discharge standards that the magnesium ion concentration is reduced to 100 mg / L and the chloride ion concentration is reduced to 235 mg / L. According to a concentrated liquid discharge standard that the concentration of the brine in a concentrated liquid circulation tank reaches 12%, the desalted brine and the low-concentration bittern are separately obtained; the low-concentration bittern is dewatered and concentrated to the bittern adding process concentration. At the same time, the dedicated treating device is also provided. According to the method for treating the tofu brine by adopting the frequent electrodialysis reversal technology, the technology is simple and easy to control, and zero discharge of sewage is realized while recycling of available resources is realized. The method and the device are suitable for the bean product processing industry.

Owner:QINGDAO UNIV OF SCI & TECH

Desalination reuse apparatus of water treatment apparatus

InactiveCN109912091AGeneral water supply conservationMultistage water/sewage treatmentUltrafiltrationEvaporation

The invention relates to a desalination reuse apparatus. The desalination reuse apparatus of the water treatment apparatus comprises: a concentrated water collection box, an agent feeding unit, an efficient precipitation pool, a sand filtering unit, an ultra-filtration unit, a plastic security filter, a two-stage reverse osmosis unit, a frequent electrodialysis reversal unit, an evaporation crystallization unit and a water producing unit, wherein the concentrated water collection box for collecting sewage is connected to the efficient precipitation pool, the efficient precipitation pool is connected to the sand filtering unit, the sand filtering unit is connected to the ultra-filtration unit, the ultra-filtration unit is connected to the plastic security filter, the plastic security filteris connected to the two-stage reverse osmosis unit, the two-stage reverse osmosis unit is respectively connected to the frequent electrodialysis reversal unit and the water producing unit, and the frequent electrodialysis reversal unit is respectively connected to the evaporation crystallization unit and the water producing unit.

Owner:德阳市尚风装饰设计有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com