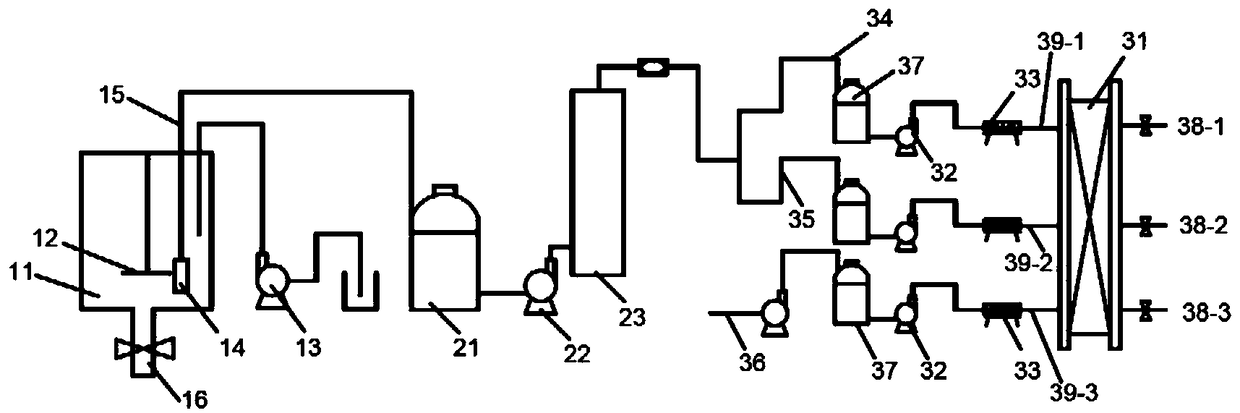

Treatment device and method for recycling reclaimed water in effluent from secondary sedimentation tank

A technology of treatment equipment and secondary sedimentation tank, which is applied in water/sewage treatment equipment, water/sewage treatment, water/sewage multi-stage treatment, etc. It can solve the problems of large water output, unstable water quality, and waste of resources in secondary sedimentation tanks. , to achieve the effect of reducing wastewater treatment costs, reducing internal scaling of equipment, and saving production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

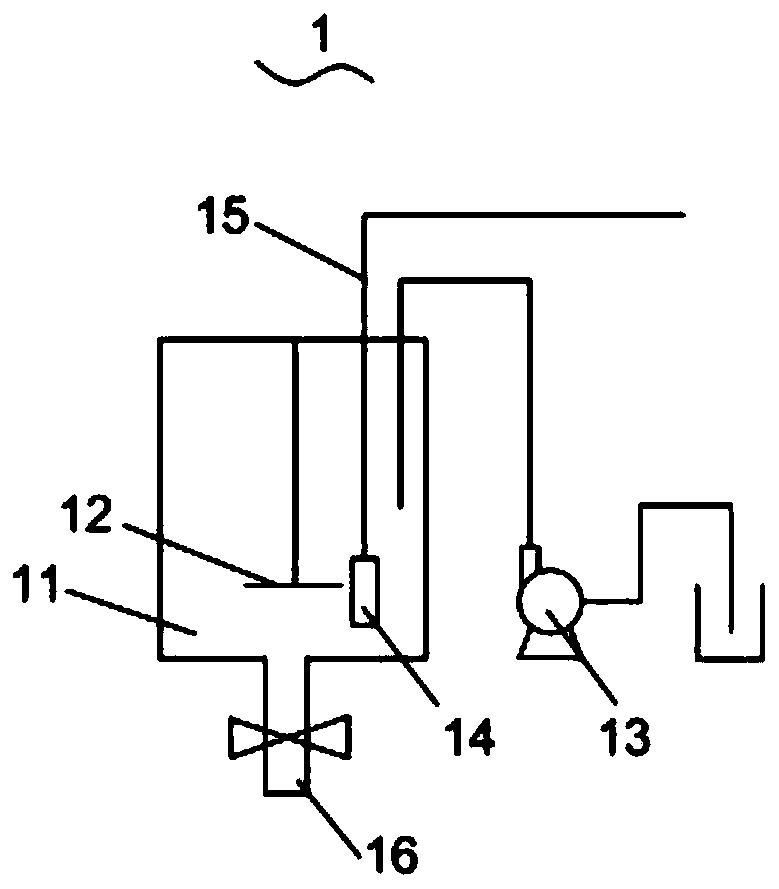

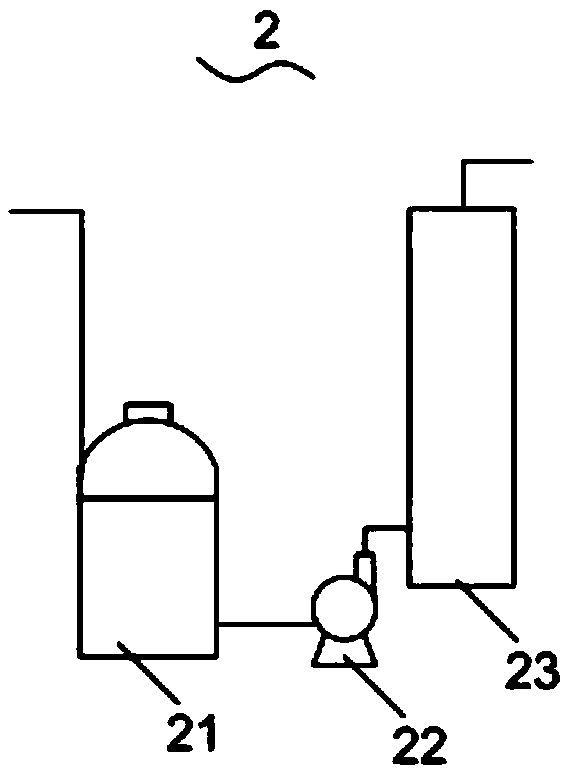

Method used

Image

Examples

Embodiment 1

[0056] The chloride ion content in the untreated secondary sedimentation pool water is 375mg / L, the sulfate ion content is 272mg / L, and the conductivity is 2000us / cm.

[0057] The method for advanced treatment of secondary sedimentation tank water comprises the following steps:

[0058] S1. Add NaOH solution with a mass fraction of 30% to the water in the secondary settling tank to soften the wastewater. The consumption of lye agent is 0.8L / t. After the softening treatment, the content of calcium and magnesium ions in the wastewater is 40mg / L. After the precipitation is complete, separate the supernatant liquid, add mass fraction of 20% hydrochloric acid to the supernatant, the consumption of hydrochloric acid agent is 0.5L / t, and the pH is adjusted to 6. Then add EDTA to the material as a scale inhibitor, and the concentration of EDTA in the material is 0.1mg / L.

[0059] S2. Pass the supernatant liquid treated in step S1 through an ultrafiltration system. The molecular weigh...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com