High-water-yield treatment method and device for boiler feed water

A treatment device and boiler feed water technology, which is applied in the field of water treatment, can solve the problems of low utilization rate of raw water and achieve the effects of improving the utilization rate of raw water, lowering infrastructure costs, and reducing renovation costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

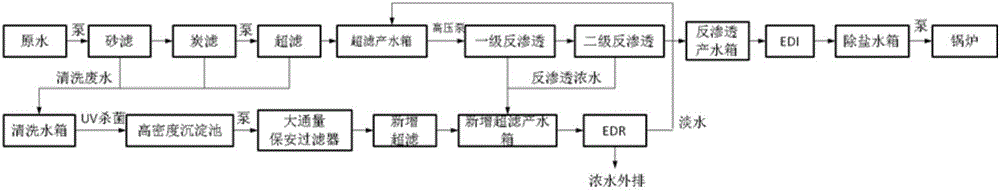

[0020] Such as figure 1 As shown, a high water production rate boiler feed water treatment method related to this embodiment specifically includes the following steps:

[0021] (1) Transport the cleaning wastewater from the sand filter, carbon filter and ultrafiltration system in the boiler water treatment device of the membrane method power plant to the cleaning water tank. When the cleaning wastewater flows through the pipeline between the high-density sedimentation tanks from the cleaning water tank, Under the action of the ultraviolet sterilizing device in the pipeline, the algae and other organisms in the cleaning wastewater are removed;

[0022] (2) The wastewater after ultraviolet sterilizing treatment is passed through a high-density sedimentation tank to remove suspended solids such as sand and sand in the wastewater cleaned by sand filtration and carbon filtration, and flocs in the wastewater cleaned by the ultrafiltration system;

[0023] (3) The wastewater treated...

Embodiment 2

[0029] Taking reverse osmosis concentrated water, filter backwash water, and ultrafiltration cleaning water produced by a thermal power plant to prepare boiler water as research objects, according to figure 1 The shown process carries out the process of recovering reverse osmosis concentrated water, filter backwash water, and ultrafiltration tank cleaning water. Adopting the technical route of high-efficiency filtration-ultrafiltration-EDR, the EDR electric drive membrane desalination system adopts the form of two sets of membrane stacks connected in parallel, and each set of membrane stacks is composed of three sets of electric membranes connected in series to improve the desalination rate. Before entering the EDR, the conductivity of the mixed water is 2900μS / cm. After being treated by the EDR system, the conductivity of the product water drops to 500μS / cm, which meets the water quality requirements of reverse osmosis. After the deep desalination treatment of the reverse osm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com