Process for refining super filter and secondary reverse osmosis high purity water

A two-stage reverse osmosis and high-purity water technology, applied in the direction of osmosis/dialysis water/sewage treatment, etc., can solve the problems of high operating costs, complicated operation, and bulky volume, and achieve improved raw water utilization, extended service life, and reduced device volume Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

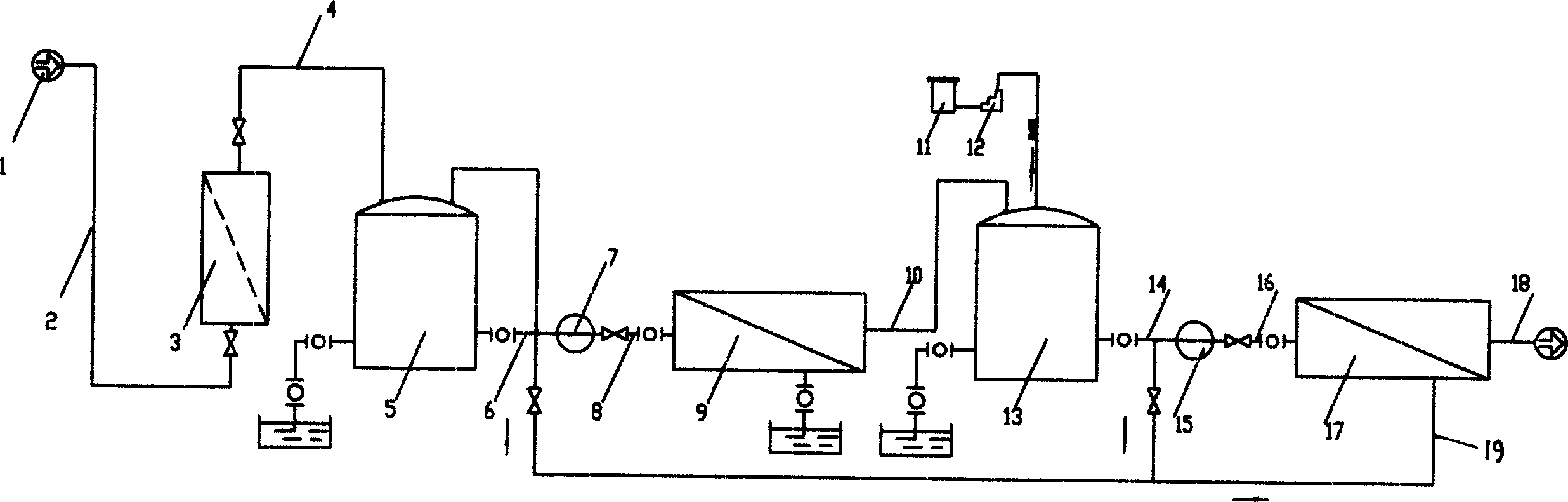

[0008] The present invention will be further described below with reference to the accompanying drawings.

[0009] Raw water (city tap water) 1 is sent to ultrafilter 3 through pipeline 2, and the ultrafiltered water filtered by the ultrafilter is sent to ultrafiltered water storage tank 5 through pipeline 4, and the inlet of first-level high-pressure pump 7 is stored with ultrafiltered water. The tank outlet pipe 6 is connected, and the outlet is connected with the inlet pipe 8 of the first-stage reverse osmosis device 9. The produced water treated by the first-stage reverse osmosis device 9 is sent to the intermediate water tank 13 through the pipeline 10, and at the same time, it passes through the lye metering pump. 12. Add the NaOH solution in the lye tank 11 into the intermediate water tank 13 in a certain proportion, the inlet of the secondary high pressure pump 15 is connected with the outlet pipe 14 of the intermediate water tank, and the outlet is connected with the w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com