Water purifying equipment capable of recycling concentrated water

A kind of water purification equipment and concentrated water technology, applied in the direction of water/sewage multi-stage treatment, water/sludge/sewage treatment, chemical instruments and methods, etc., can solve the complex structure of concentrated water recovery device, unfavorable popularization and use, and production cost Problems such as rising and falling, to achieve the effect of simple structure, low production cost and saving water resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

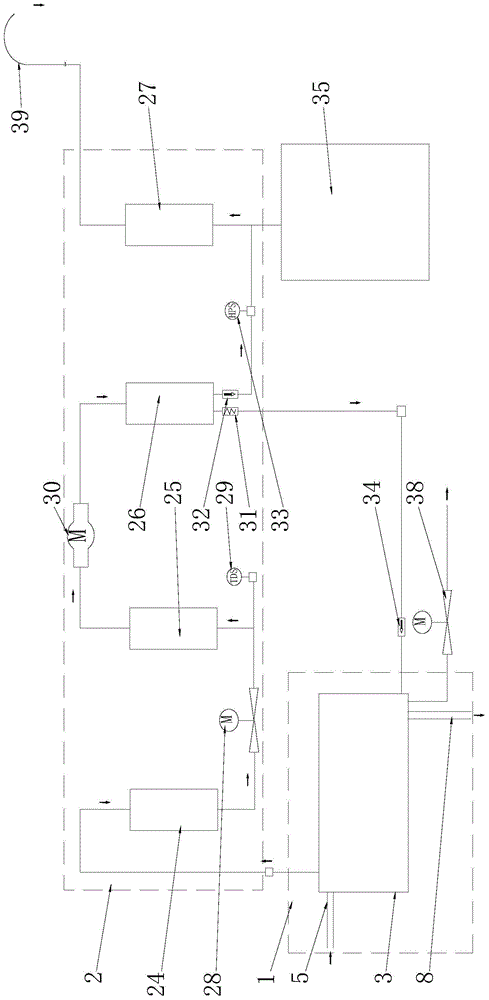

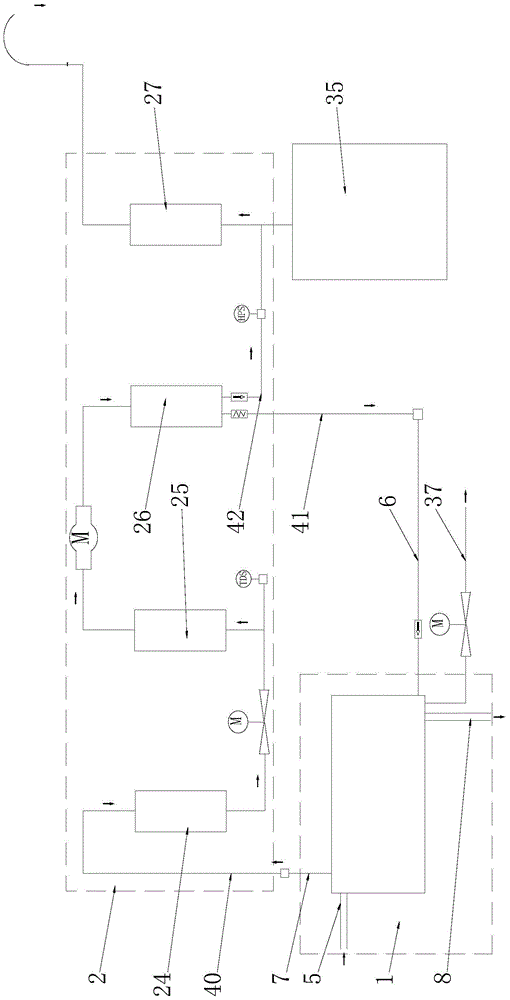

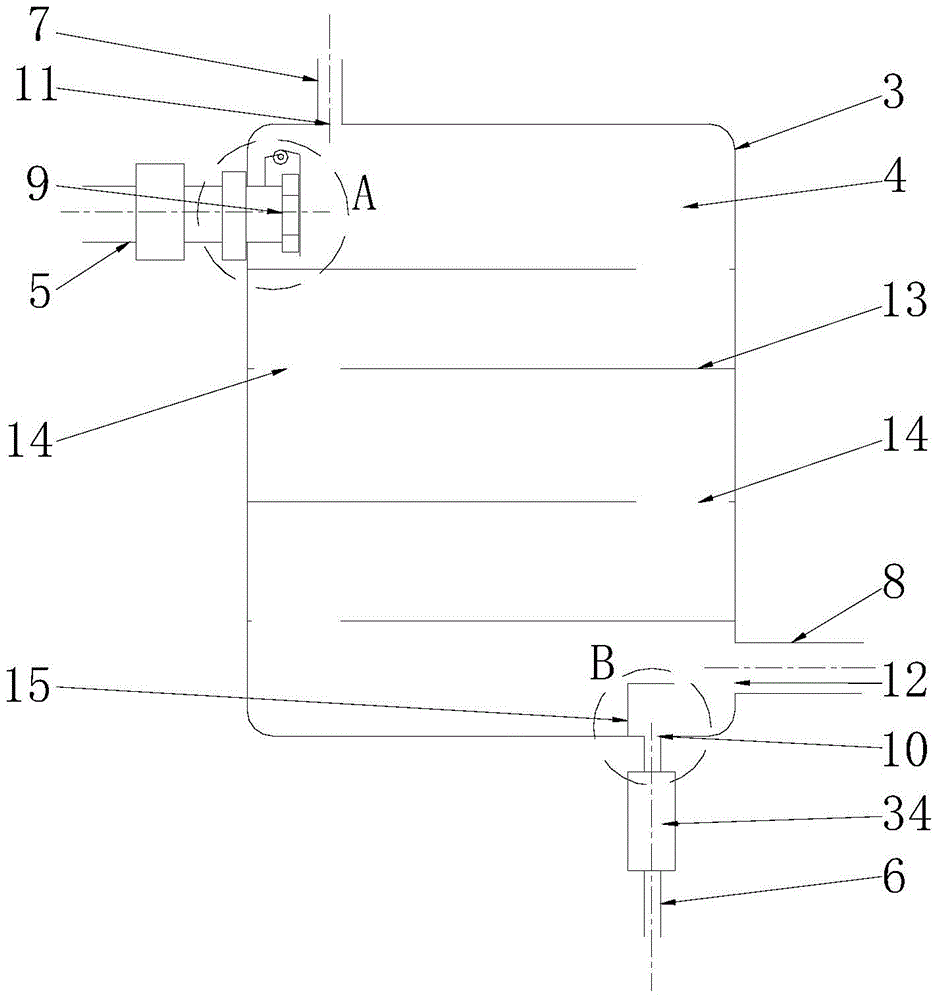

[0048] Such as figure 1 , 2 As shown, the water purification equipment is composed of a concentrated water recovery device 1 and a water purification system 2 . As shown in the figure, in this embodiment 1, the concentrated water recovery device 1 includes a box body 3 , and a sealed chamber 4 is formed in the box body 3 . The box body 3 is also connected with the raw water inlet pipe 5, the concentrated water inlet pipe 6, the raw water outlet pipe 7 and the domestic water outlet pipe 8 which communicate with the chamber 4, wherein the raw water outlet pipe 7 is located at the top of the box body 3 and is connected with the The tap water pipeline is connected; the raw water inlet pipe 5 is positioned at the side of the casing 3 and near the top of the casing 3, near the raw water outlet pipe 7, and is connected with the water purification system inlet pipe 40 of the water purification system; The water pipe 6 is located at the bottom of the box body 3 and communicates with ...

Embodiment 2

[0062] The difference between this embodiment 2 and embodiment 1 is that, as Figure 9 As shown, in this embodiment 2, the bottom of the chamber 4 of the concentrated water recovery device 1 is not provided with a stopper 15, and the bottom of the box body 3 is connected with a concentrated water inlet pipe 6 and a domestic water outlet pipe 8 through a three-way joint. . Although the three-way joint is an external part, the concentrated water inlet pipe 6 and the domestic water outlet pipe 8 are still in communication with the chamber 4. The inside of the three-way joint can be regarded as an extension of the chamber 4, and the concentrated water inlet pipe 6 is still visible. In order to be connected to the bottom of the casing 3 , the domestic water outlet pipe 8 is connected near the bottom of the casing 3 . The working principle of the entire concentrated water recovery device is the same as that of the concentrated water recovery device in Embodiment 1.

Embodiment 3

[0064] The difference between this embodiment 3 and embodiment 1 is that, as Figure 10 As shown, in this embodiment 3, the bottom of the chamber 4 of the concentrated water recovery device 1 is not provided with a stopper 15, and the most downstream of the raw water inlet pipe 5 along the water flow direction is not provided with a backstop device, and the entire concentrated water recovery The working principle of the device is still the same as that of the concentrated water recovery device in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com