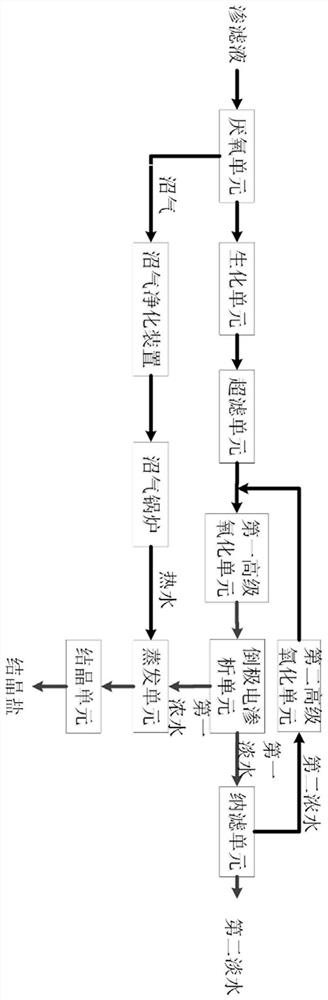

Leachate treatment method and leachate treatment system

A treatment method and a treatment system technology, applied in the field of liquid purification, can solve problems such as the difficulty of achieving full treatment and zero discharge, and achieve the effects of avoiding organic matter problems, stable operation, and improved operation stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0066] The process of the present invention is used to treat the leachate of a waste incineration plant. The water quality is as follows: COD is 30000~50000 mg / L, TDS is 10000~12000 mg / L, NH 3 -N is 1000~2000 mg / L.

[0067] The anaerobic unit adopts the form of UASB, and the COD of the effluent after the leachate is treated by the anaerobic unit is 5000~7000 mg / L. The biogas generated by the anaerobic unit is purified and then sent to the biogas boiler to generate hot water at 90 °C. The evaporation unit is used as a heat source for the evaporation unit; the anaerobic effluent enters the biochemical unit, and the biochemical unit adopts the A / O form. The molecular weight cut-off of the ultrafiltration membrane is 1000 Da. After being treated by the biochemical unit and filtered by the ultrafiltration membrane, the COD of the ultrafiltration effluent is 500 mg / L, NH 3 -N is 10~30 mg / L; ultrafiltration effluent is sent to the first advanced oxidation treatment unit, the first a...

Embodiment 2

[0073] The process of the present invention is used to treat the leachate of a waste incineration plant. The water quality is as follows: COD is 30000~50000 mg / L, TDS is 10000~12000 mg / L, NH 3 -N is 1000~2000 mg / L.

[0074] The anaerobic unit adopts the IC form, and the COD of the effluent after the leachate is treated by the anaerobic unit is 4000~6000 mg / L. The biogas generated by the anaerobic unit is purified and then sent to the biogas boiler to generate hot water at 75°C. The evaporation unit is used as a heat source for the evaporation unit; the anaerobic effluent enters the biochemical unit, and the biochemical unit adopts a short-range nitrification and denitrification process. The molecular weight cut-off of the ultrafiltration membrane is 20,000 Da. 800 mg / L, NH 3 -N is 20~30 mg / L; ultrafiltration effluent is sent to the first advanced oxidation treatment unit, the first advanced oxidation treatment unit adopts ozone / hydrogen peroxide oxidation device, H 2 o 2 wi...

Embodiment 3

[0077] The process of the present invention is used to treat the leachate of a waste incineration plant. The water quality is as follows: COD is 30000~50000 mg / L, TDS is 10000~12000 mg / L, NH 3 -N is 1000~2000 mg / L.

[0078] The anaerobic unit adopts the form of IOC, and the COD of the effluent after the leachate is treated by the anaerobic unit is 3000~5000 mg / L. The biogas generated by the anaerobic unit is purified and then sent to the biogas boiler to generate hot water at 50 °C. The evaporation unit is used as a heat source for the evaporation unit; the anaerobic effluent enters the biochemical unit, and the biochemical unit adopts anaerobic ammonium oxidation. The molecular weight cut-off of the ultrafiltration membrane is 50,000 Da. 1000 mg / L, NH 3 -N is 20~40 mg / L; the ultrafiltration effluent is sent to the first advanced oxidation treatment unit, the first advanced oxidation treatment unit adopts an electron beam device, the irradiation dose rate is 10~20kGy, and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com