Method for carrying out desalination and zero-discharge processing of power plant desulphurization wastewater by adopting electrodialysis technology

A desulfurization wastewater and electrodialysis technology, which is applied in the direction of gaseous effluent wastewater treatment, water/sewage multi-stage treatment, water/sludge/sewage treatment, etc., can solve equipment corrosion, soil salinization, increase in water body salt concentration, etc. problems, to achieve the effects of improving operational stability, realizing resource utilization and zero-discharge treatment, and reducing fresh water consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Example 1 Simulation of Power Plant Desulfurization Wastewater Electrodialysis Treatment

[0029] Electrodialysis technology was used to treat simulated power plant flue gas desulfurization wastewater, and the effects of different initial Cl- ions in concentrated water and fresh water on desalination rate, energy consumption and membrane stack voltage were investigated. Studies have shown that when the initial concentration of Cl- in fresh water is 1000, 5000, 10000 and 20000 mg / L, and the concentration of concentrated water is controlled at 20000 mg / L, the content of Cl- ions in fresh water after 150 minutes under constant pressure conditions can be reduced. However, when the concentration of Cl- ions in concentrated water is high, the removal rate of Cl- ions decreases, which is speculated to be caused by the reverse diffusion of Cl- ions in concentrated water; the current efficiency at different initial concentrations of fresh water They all show that the pre-desalin...

Embodiment 2

[0030] Example 2 Electrodialysis Desalination of Power Plant Flue Gas Desulfurization Wastewater

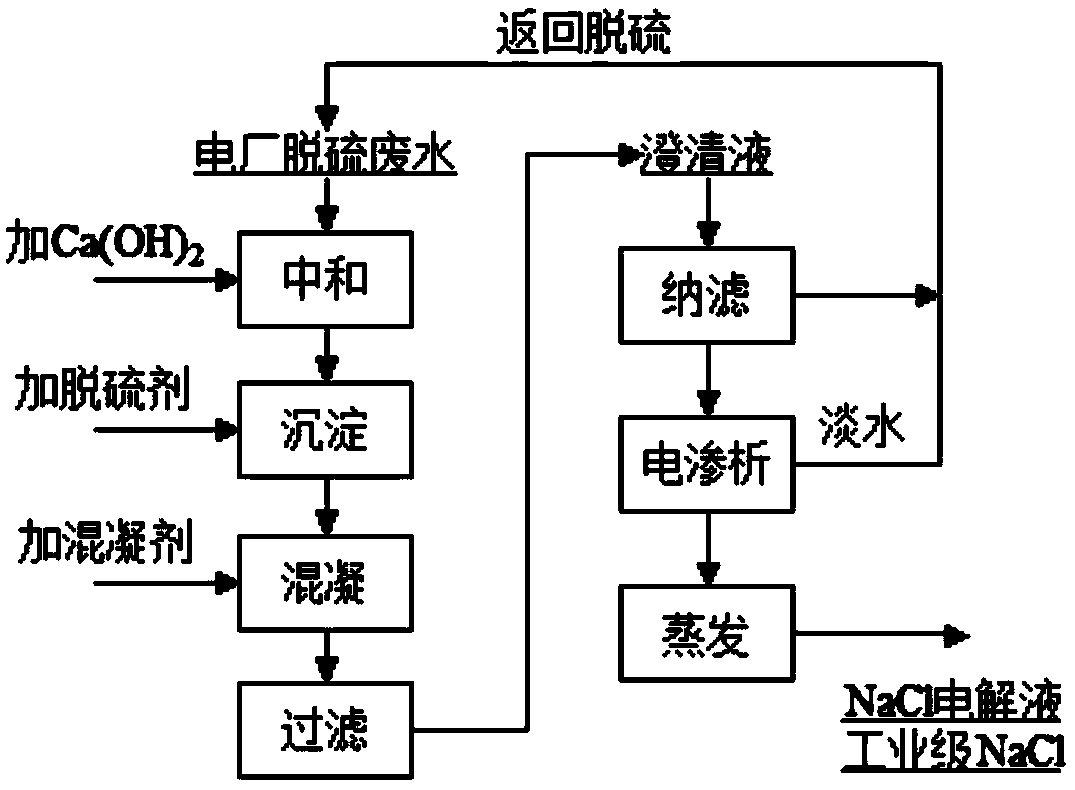

[0031] Such as figure 1 As shown, the flue gas desulfurization wastewater of power plants is pretreated by neutralization, precipitation, coagulation, filtration, etc., that is, by adding Ca(OH) 2 , desulfurizer and coagulant, etc., to remove COD, heavy metals, F-ions, and insoluble particles such as gypsum, silicon dioxide, iron and aluminum hydroxides in wastewater, and the obtained clarified liquid can meet the needs of subsequent membrane systems. Water requirements; desulfurization wastewater is pretreated and then treated by nanofiltration to obtain a large amount of Cl - ionized nanofiltration product water and removal of Cl - Ionic nanofiltration concentrated water; containing a lot of Cl - The ionized nanofiltration fresh water is further treated by multi-stage countercurrent reverse electrode electrodialysis technology to obtain fresh water with a Cl- ion concentrati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com