Coal mining area wastewater treatment recycling system

A technology for sewage treatment and mining areas, applied in the field of water treatment, can solve the problems of sewage treatment and reuse, and achieve the effect of reducing facility construction, saving water resources and protecting the environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

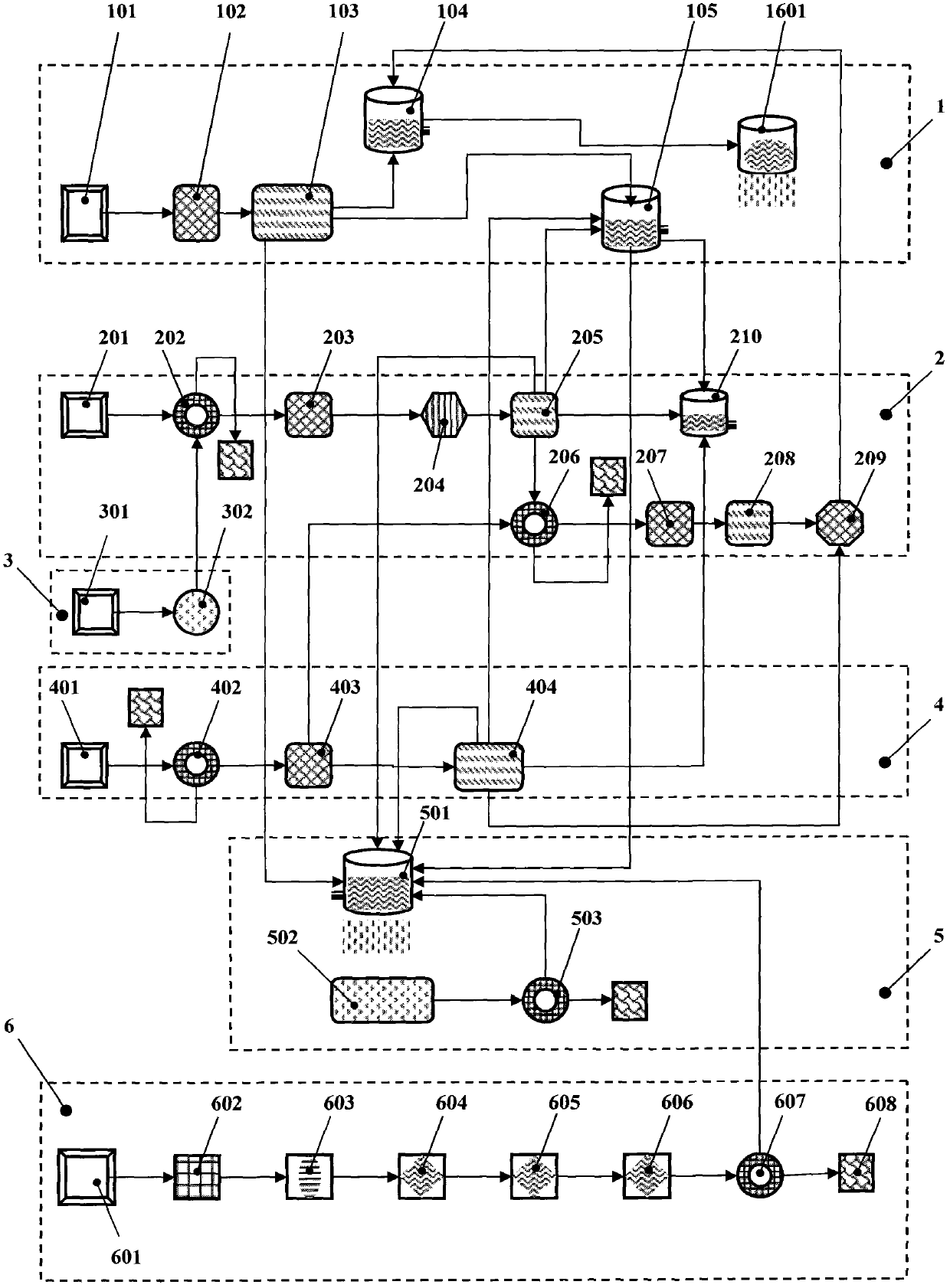

[0069] exist figure 1 A sewage treatment and reuse system in a coal mine is shown, including a clean mine water reuse subsystem 1, a high salinity mine water treatment and reuse subsystem 2, an acidic mine water reuse subsystem 3, and a mine containing suspended matter Water reuse subsystem 4, coal washing wastewater reuse subsystem 5 and domestic sewage treatment and reuse subsystem 6,

[0070] The clean mine water reuse subsystem 1 includes a gushing water interception device 101, a filter tank 102, a disinfection device 103, a domestic water storage device 104, a municipal water storage device 105,

[0071] The gushing water interception device 101 is arranged on the mining face, and the outlet of the gushing water interception device 101 is connected with the water inlet of the filter tank 102 with a drainage pipe, and the outlet of the filter tank 102 is connected with the water inlet of the disinfection device 103. Connect with the drainage pipe, and communicate with th...

Embodiment 2

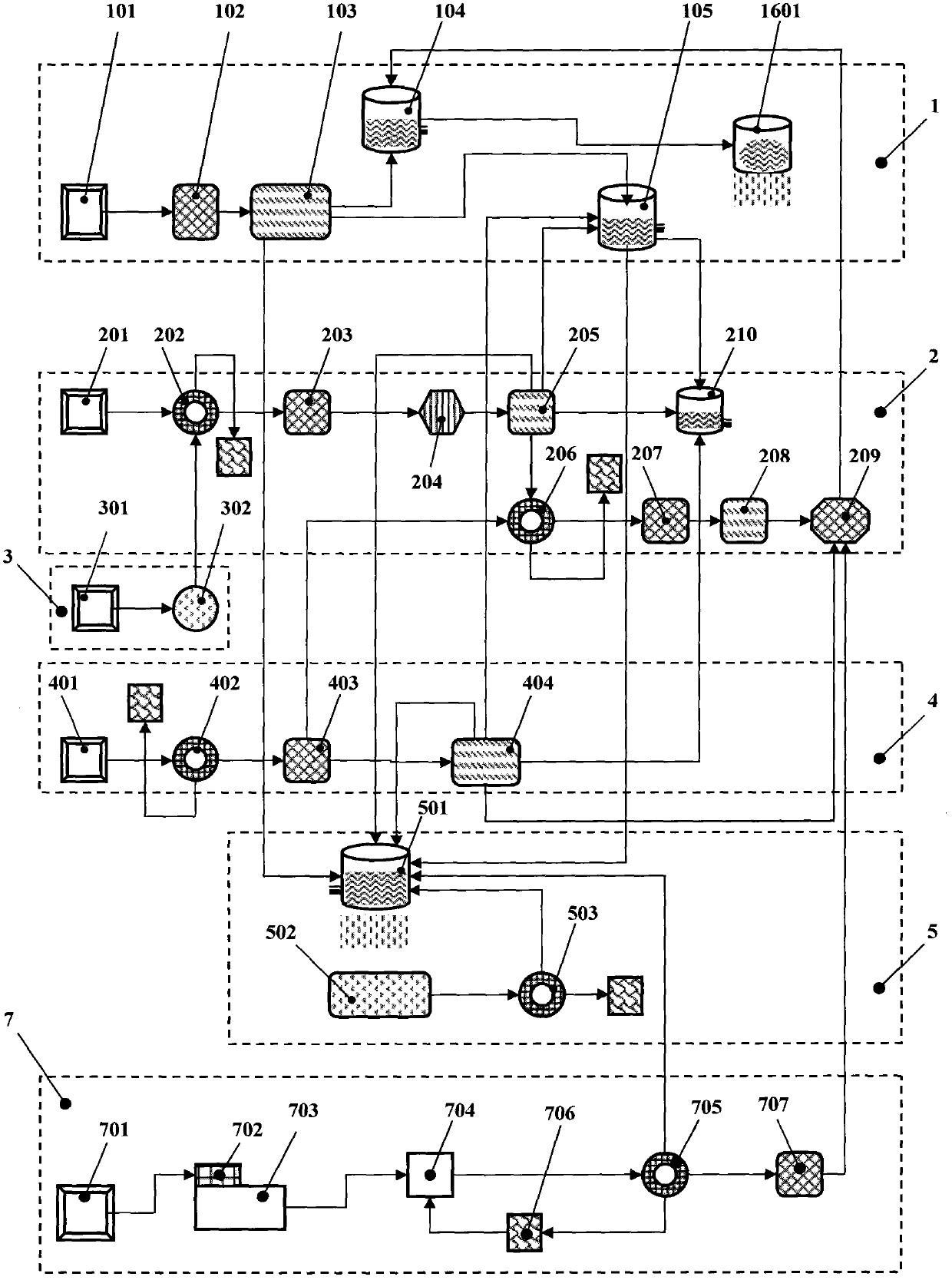

[0121] exist figure 2 A sewage treatment and reuse system in a coal mine is shown, including a clean mine water reuse subsystem 1, a high salinity mine water treatment and reuse subsystem 2, an acidic mine water reuse subsystem 3, and a mine containing suspended matter Water reuse subsystem 4, coal washing wastewater reuse subsystem 5 and domestic sewage treatment and reuse subsystem 7,

[0122] The clean mine water reuse subsystem 1 includes a gushing water interception device 101, a filter tank 102, a disinfection device 103, a domestic water storage device 104, a municipal water storage device 105,

[0123] The gushing water interception device 101 is arranged on the mining face, and the outlet of the gushing water interception device 101 is connected with the water inlet of the filter tank 102 with a drainage pipe, and the outlet of the filter tank 102 is connected with the water inlet of the disinfection device 103. Connect with the drainage pipe, and communicate with t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com