Patents

Literature

43 results about "Reverse diffusion" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Reverse diffusion refers to a situation where the transport of particles (atoms or molecules) in a medium occurs towards regions of higher concentration gradients, opposite to that observed during diffusion. This phenomenon occurs during phase separation and is described by the Cahn–Hilliard equation. Reverse diffusion also refers to when water is forced from a region of lower concentration to high. It can occur in osmosis.

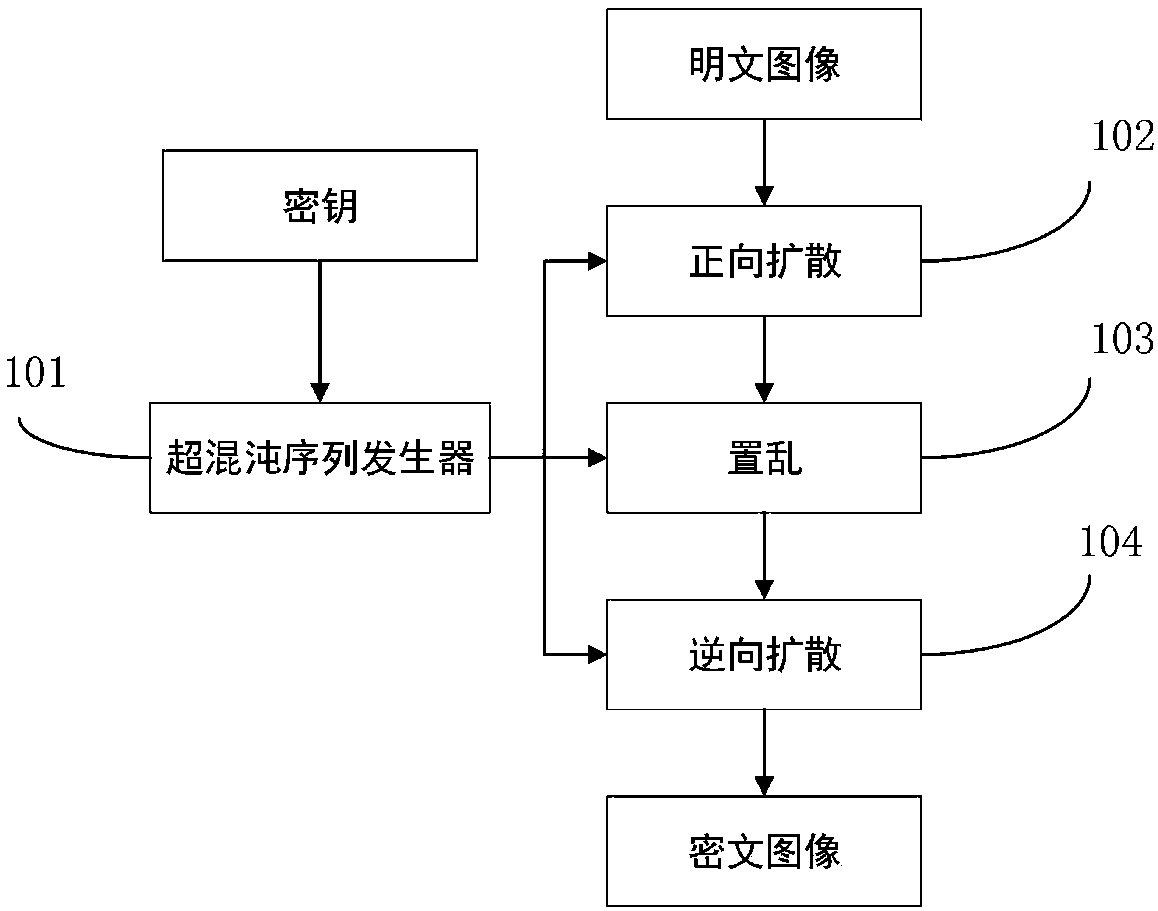

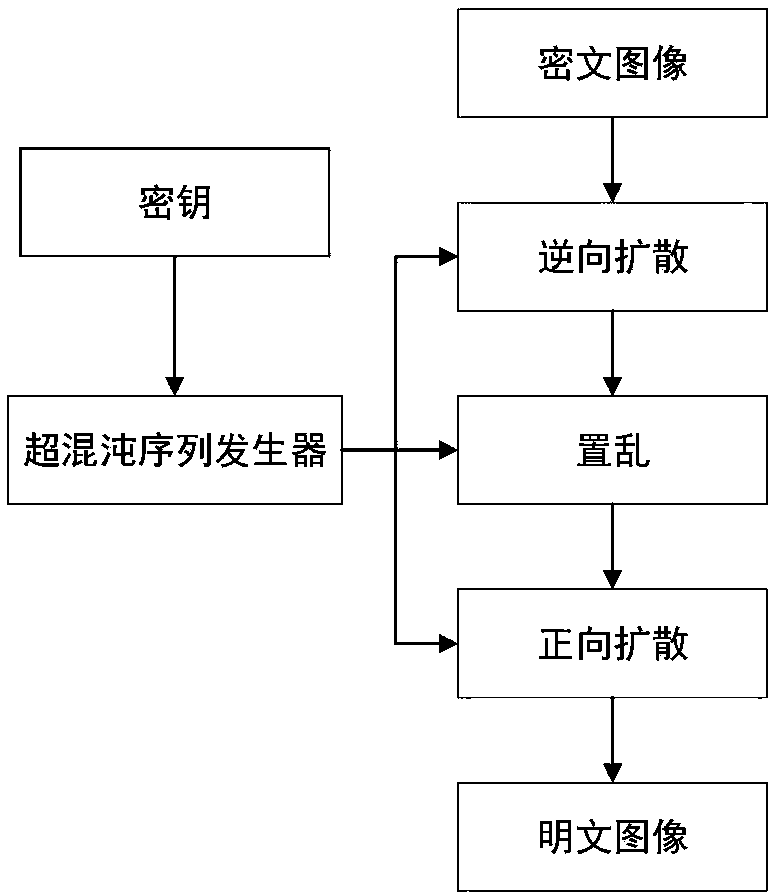

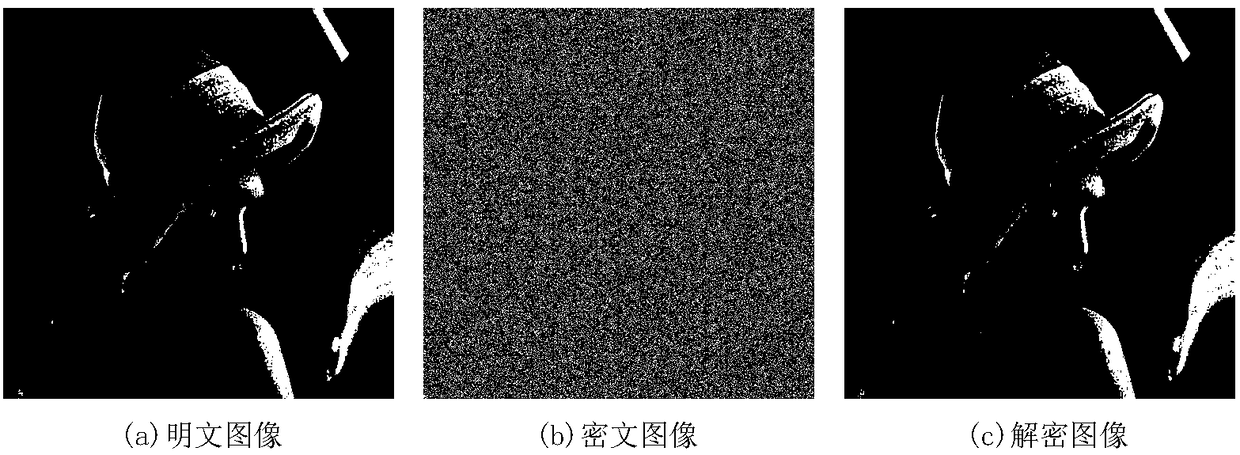

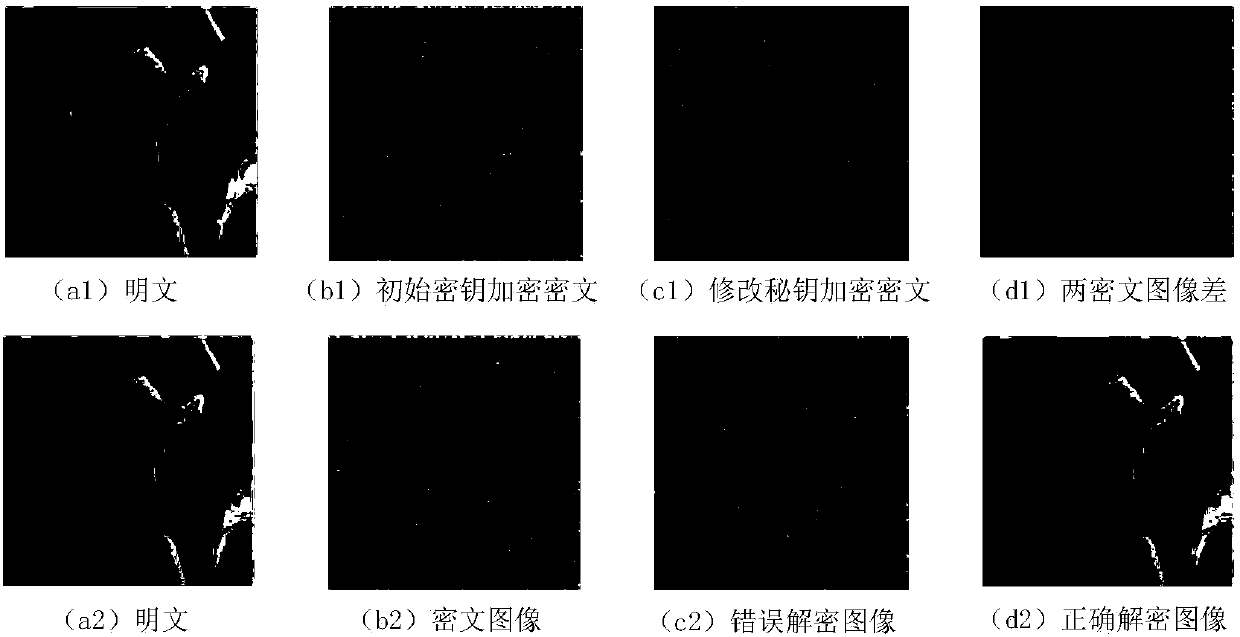

Plaintext associated image encryption algorithm based on hyperchaos Chen system

InactiveCN108234813AReduce the number of iterationsImprove the ability to resist known plaintext attacksKey distribution for secure communicationSecuring communication by chaotic signalsChosen-plaintext attackRelevant information

The invention relates to an image encryption algorithm based on a chaotic system, used for solving security problems that the image encryption algorithm is small in key space and poor in capacity of resisting to plaintext attacks. The algorithm comprises four modules such as a hyperchaos sequence generator, a forward diffusion module, a scrambling module and a reverse diffusion module. Firstly thehyperchaos Chen system is used for generating four chaotic pseudorandom sequences, a chaotic sequence and a plaintext image are used for performing forward diffusion operation to acquire a matrix A,then computation is performed in combination with the pseudorandom sequences and information related to the plaintext image to acquire a scrambled coordinate, the coordinate scrambling is performed onthe matrix A to acquire a matrix B, and at last the chaotic pseudorandom sequences and the matrix B are used for performing reverse diffusion operation to acquire a ciphertext image C. An experimentsimulation result expresses that the algorithm can improve the defect that the image encryption algorithm is small in key space, effectively resist to statistical attacks, differential attacks, and chosen-plaintext attacks, and achieve good encryption effect.

Owner:CHONGQING UNIV OF POSTS & TELECOMM

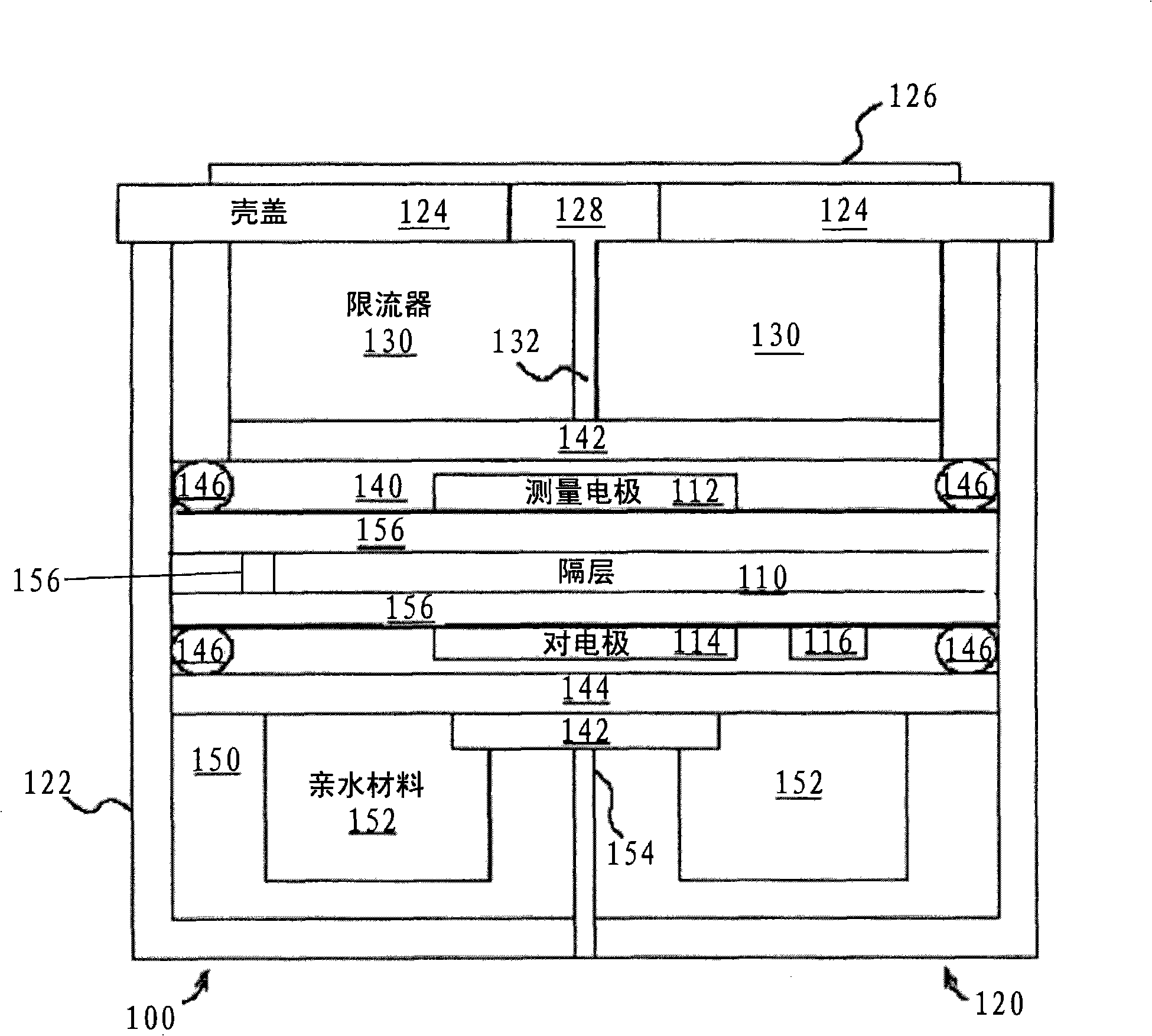

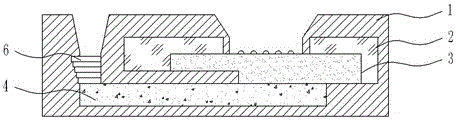

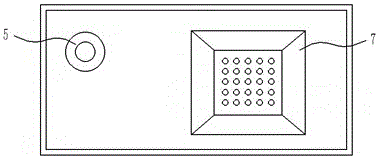

Gas sensor

ActiveCN101275923APrevent reverse diffusionMaterial analysis by electric/magnetic meansInterference resistanceElectrical conductor

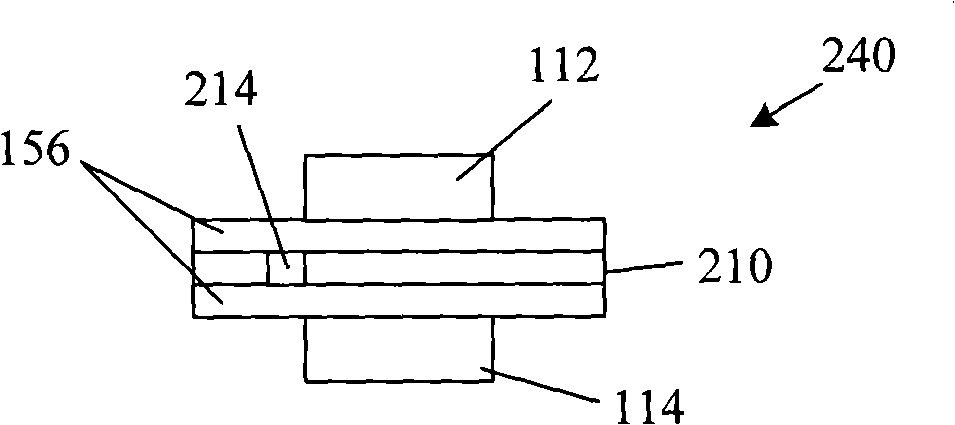

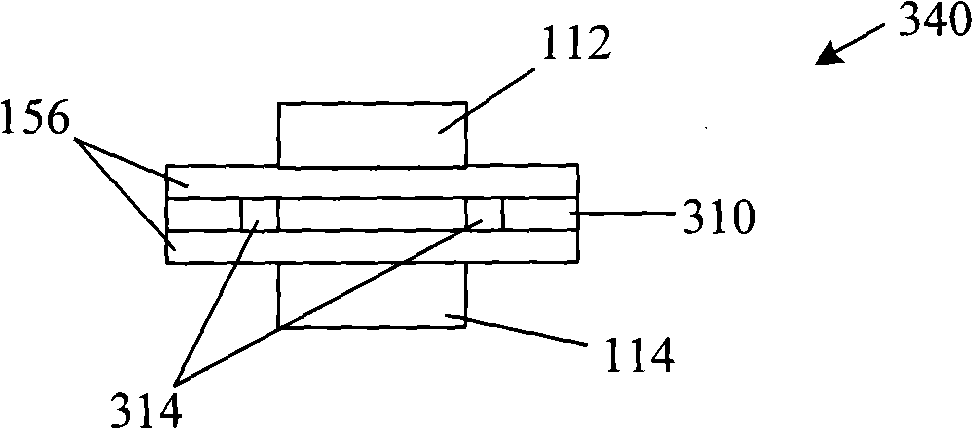

The present invention provides an oxygen sensor which comprises the following components: an electrolyte interlayer (110) which is provided with at least one through hole; a measuring electrode (112) which is arranged at one side of the electrolyte interlayer; and a counter electrode (114) which is arranged at the other side of the electrolyte interlayer. The dimension of at least one through hole satisfies the following relationship: A<liquid phase> / l<interlayer> <6.5*10<3>(A<entry> / l<entry>), wherein A<liquid phase> is the total sectional area of at least one through hole, l<interlayer> is the thickness of the through hole, A<entry> is the sectional area of the air inlet hole, and A<entry> is the length of the air inlet hole. The through hole can comprise a hydrophilic liquid-absorptionmaterial. The position is departed from the electric field formed by the measuring electrode and the counter electrode. The electrolyte interlayer can also be a hydrophilic micropore array formwork. In the oxygen sensor of the invention, the electrolyte interlayer structure which is provided with at least one through hole not only can be taken as an ion conductor for communicating the measuring electrode with the counter electrode but also can prevent the reverse diffusion of the oxygen. At the same time, the prepared oxygen sensor not only has excellent interference resistance but also has the advantage small volume.

Owner:RAE SYST SHANGHAI

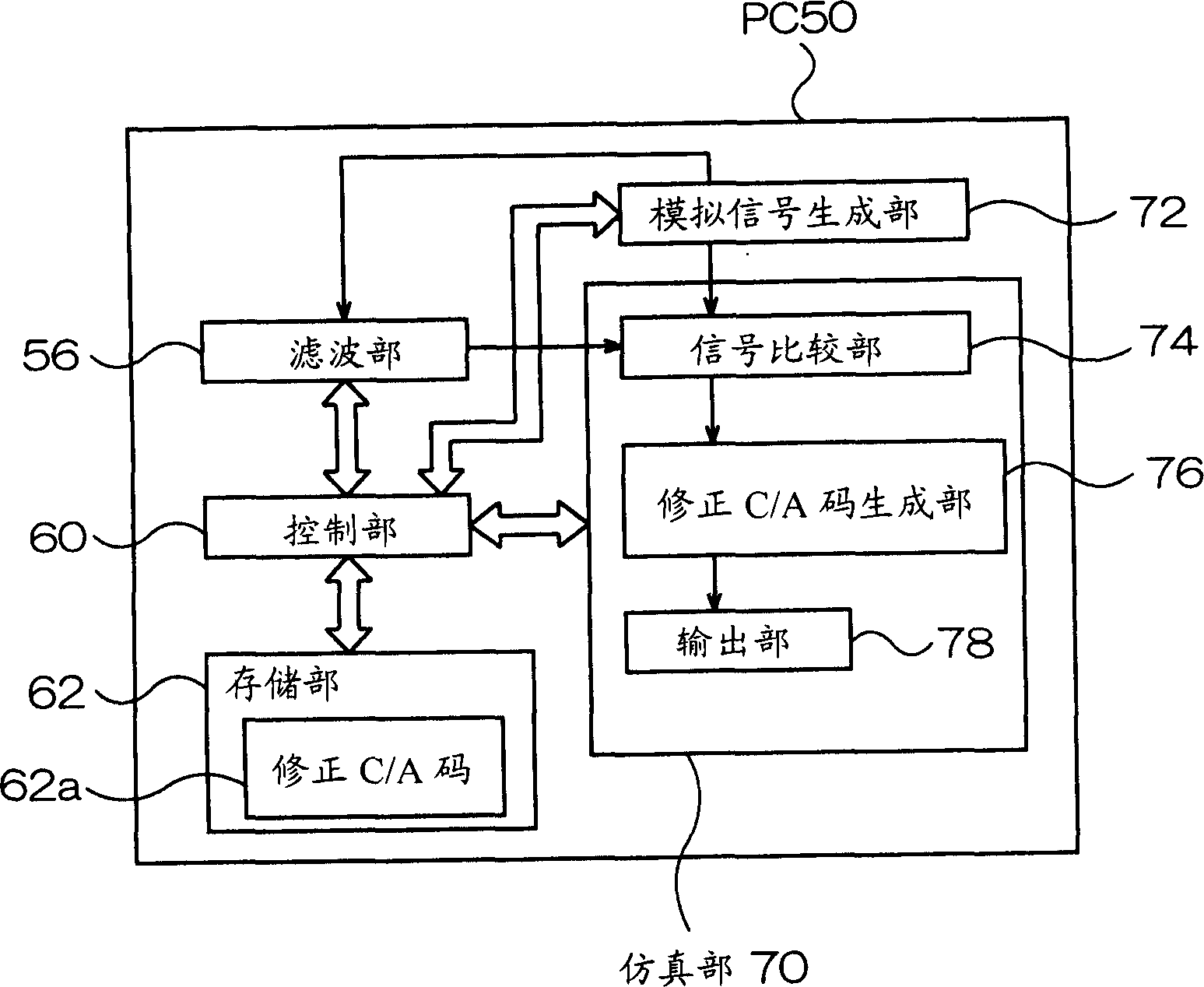

CDMA communication system and channel estimating method used in the same

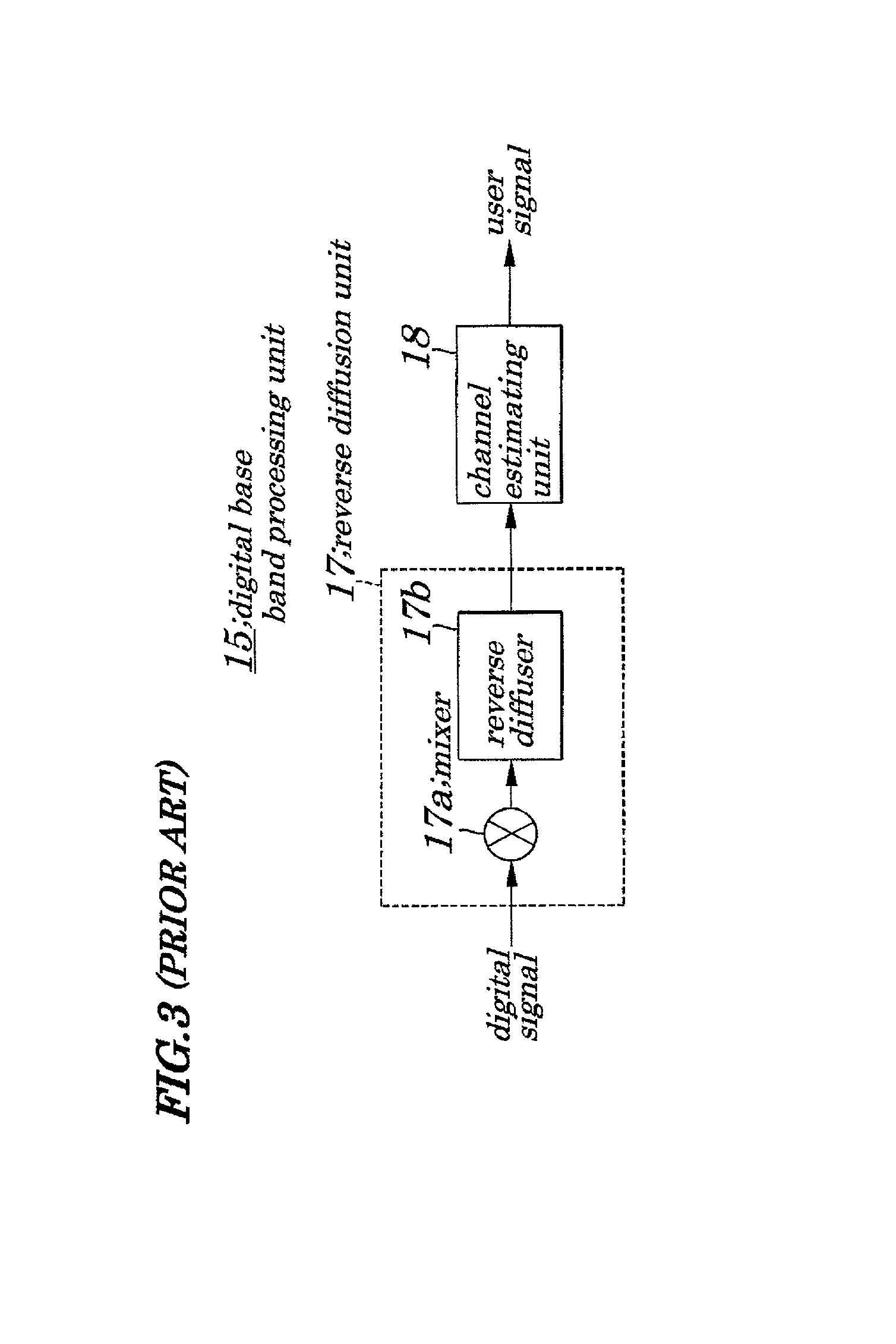

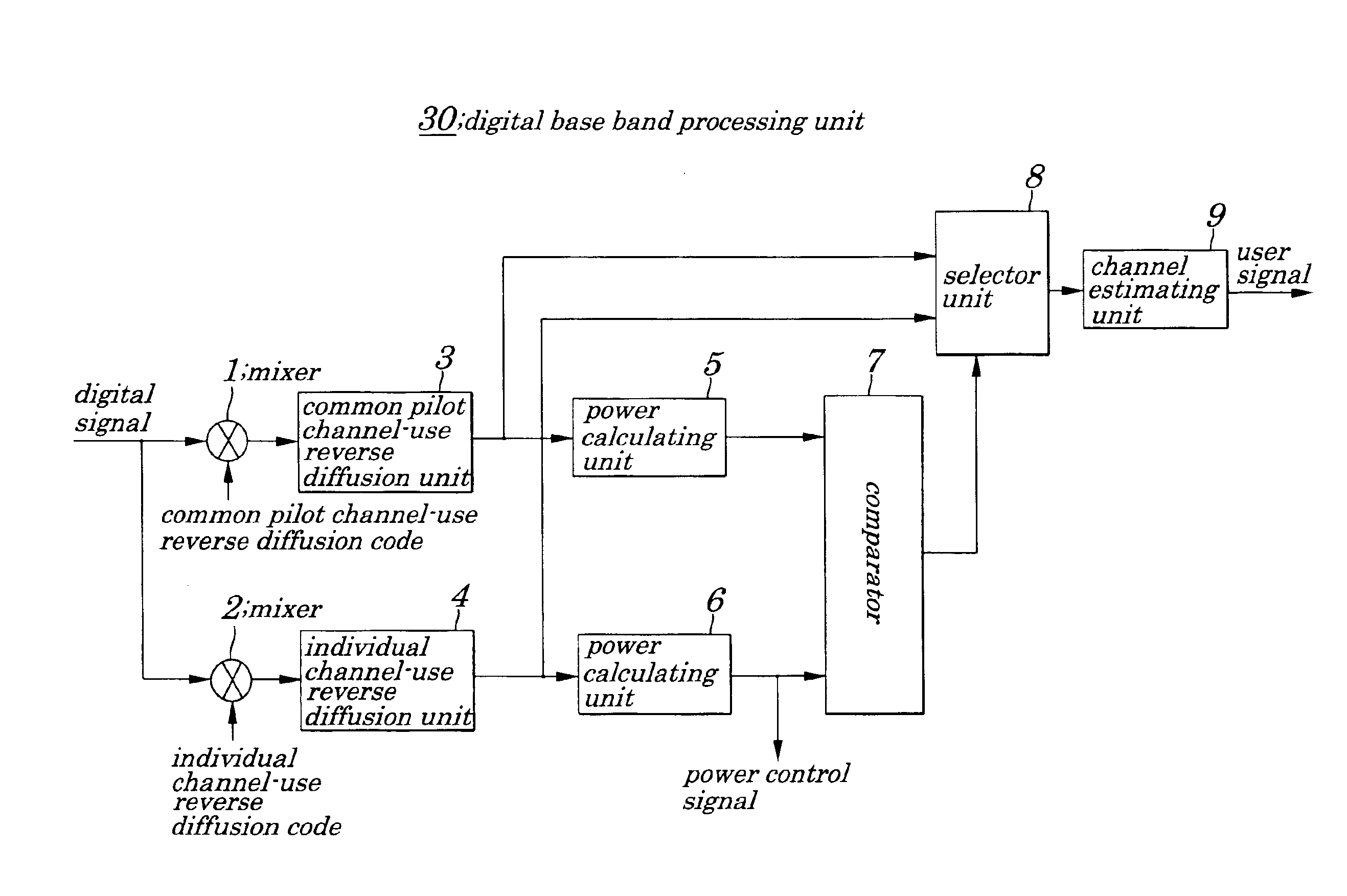

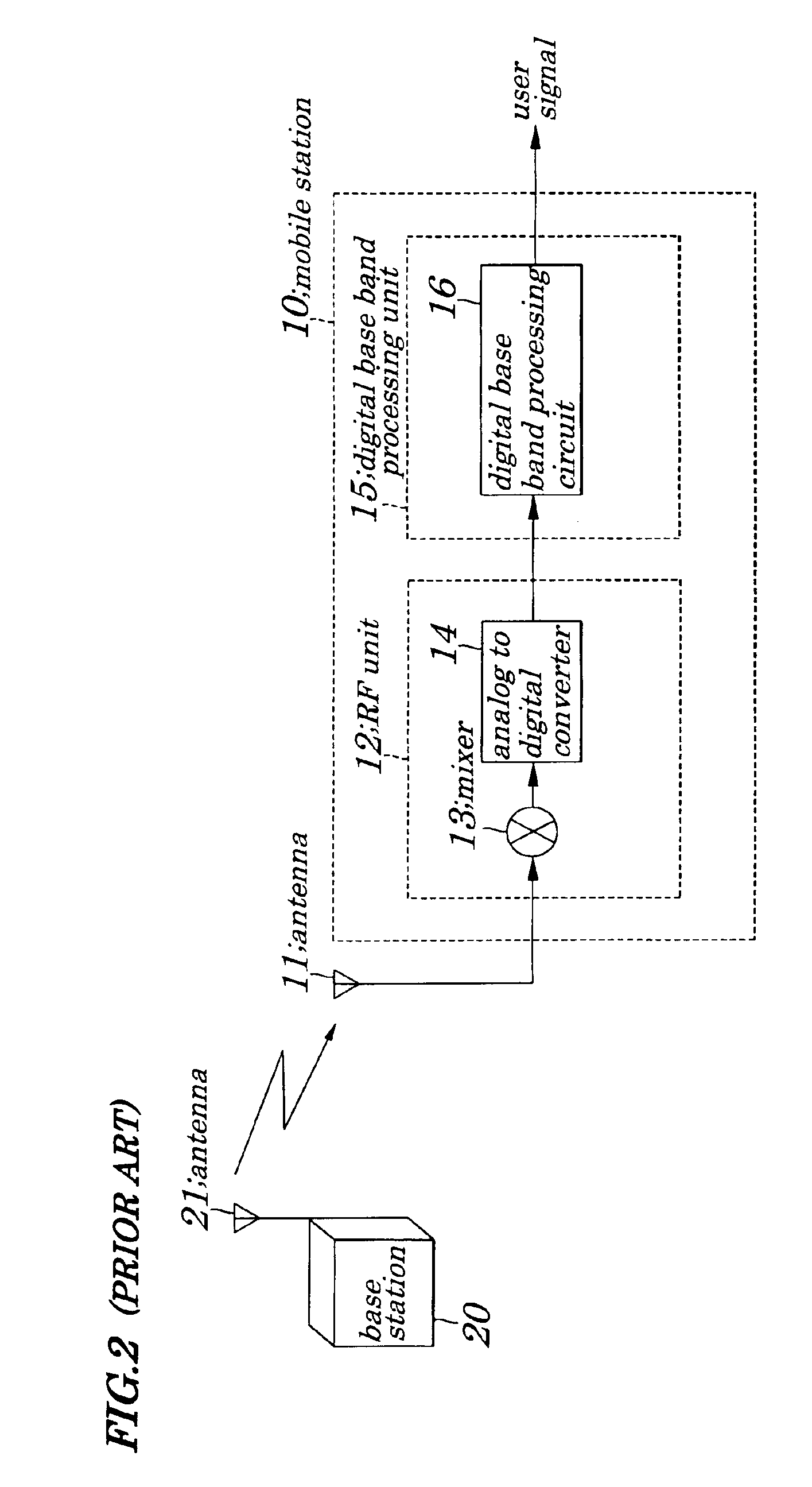

InactiveUS20010043642A1Total current dropPower managementModulated-carrier systemsChannel dataCommon pilot channel

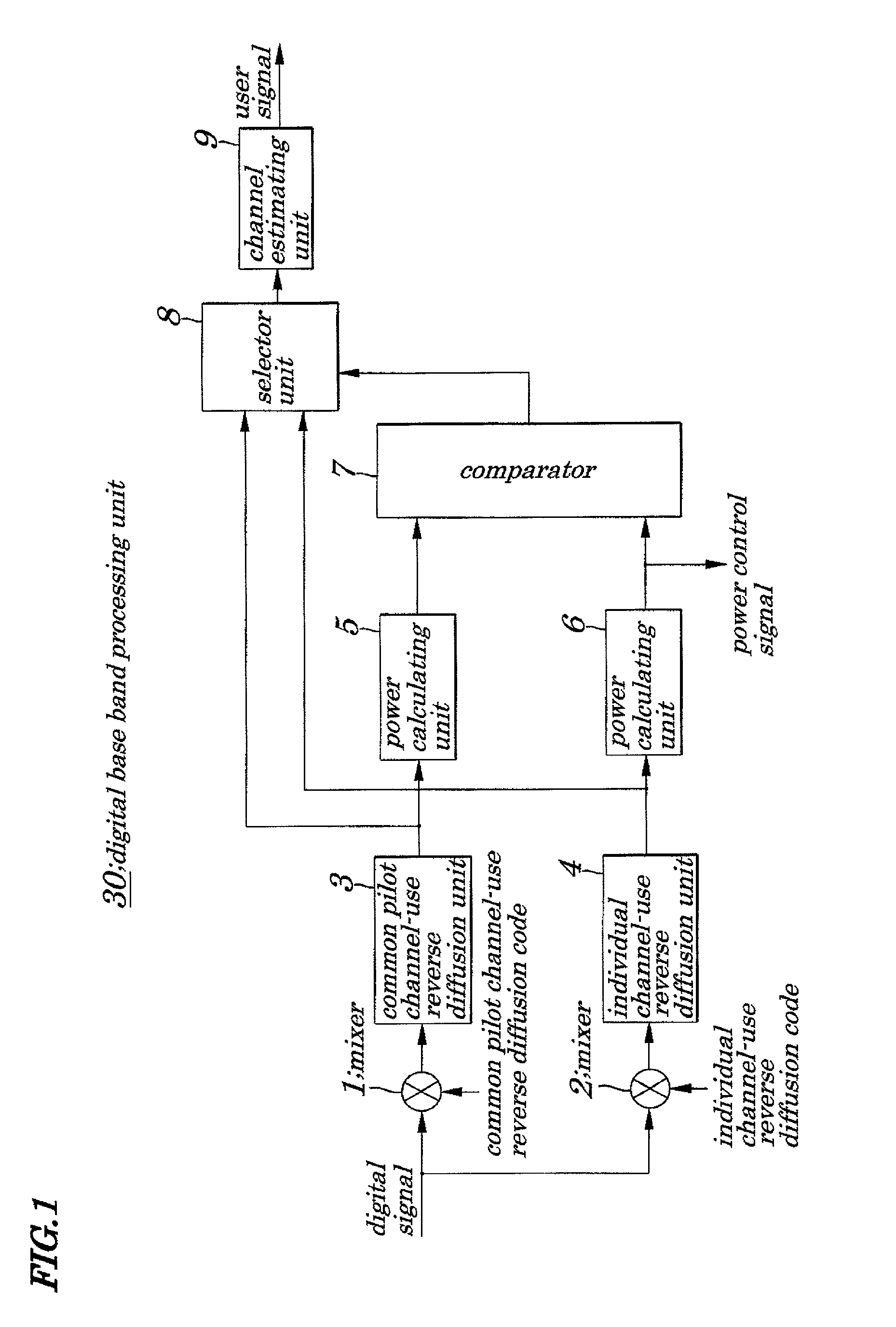

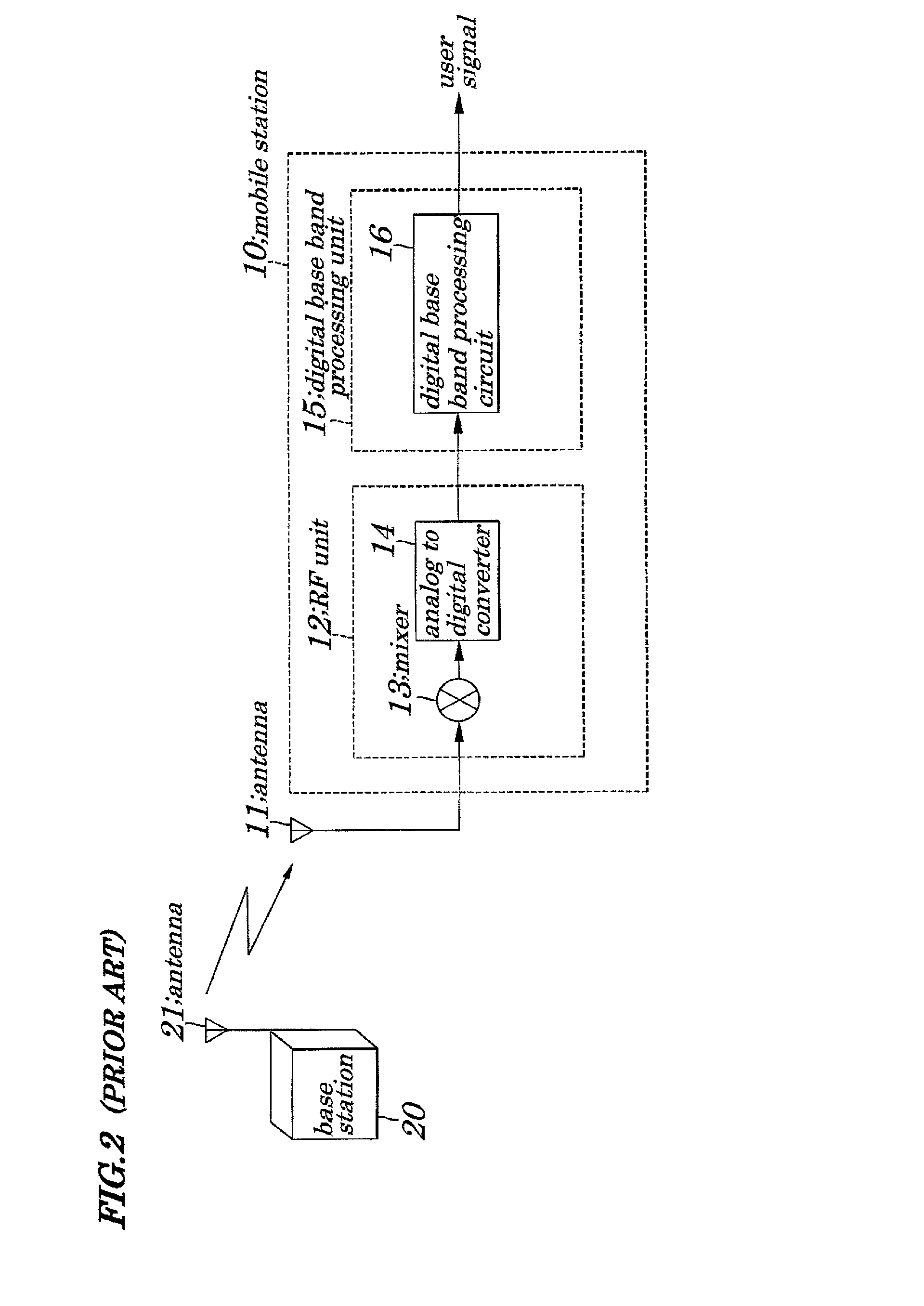

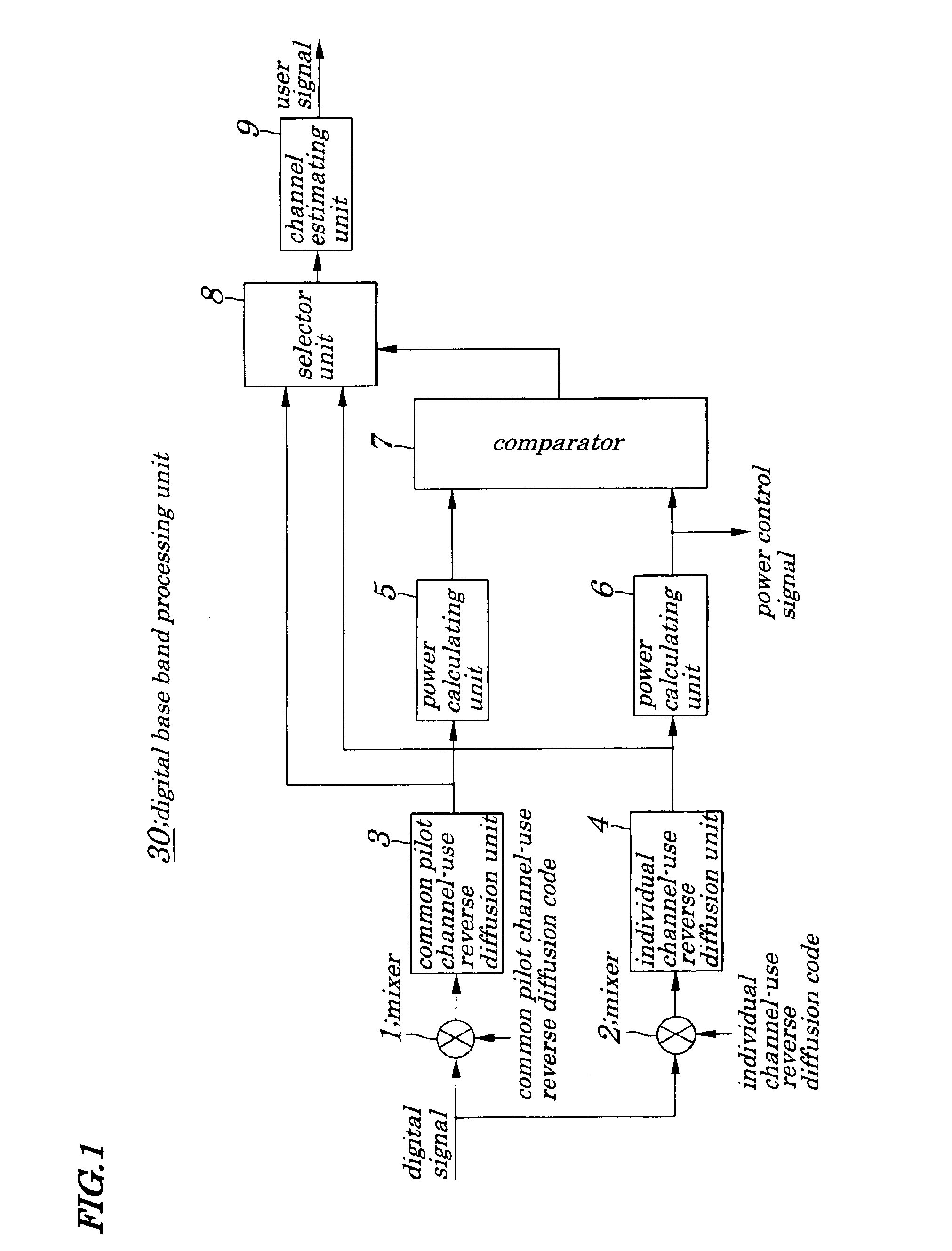

A common pilot channel-use reverse diffusion unit generates common pilot data using a received digital signal and a common pilot channel-use reverse diffusion code, while an individual channel-use reverse diffusion unit generates individual channel data using the received digital signal and an individual channel-use reverse diffusion code. Power calculating unit converts respective output data items of the common pilot channel-use reverse diffusion unit and the individual channel-use reverse diffusion unit into power values, a larger one of which is then determined by a comparator. A selector unit selects the data item having thus determined larger power value of those output data items of those reverse diffusion units. A channel estimating unit estimates the channel using data symbols of the data item thus selected by the selector unit.

Owner:NEC CORP

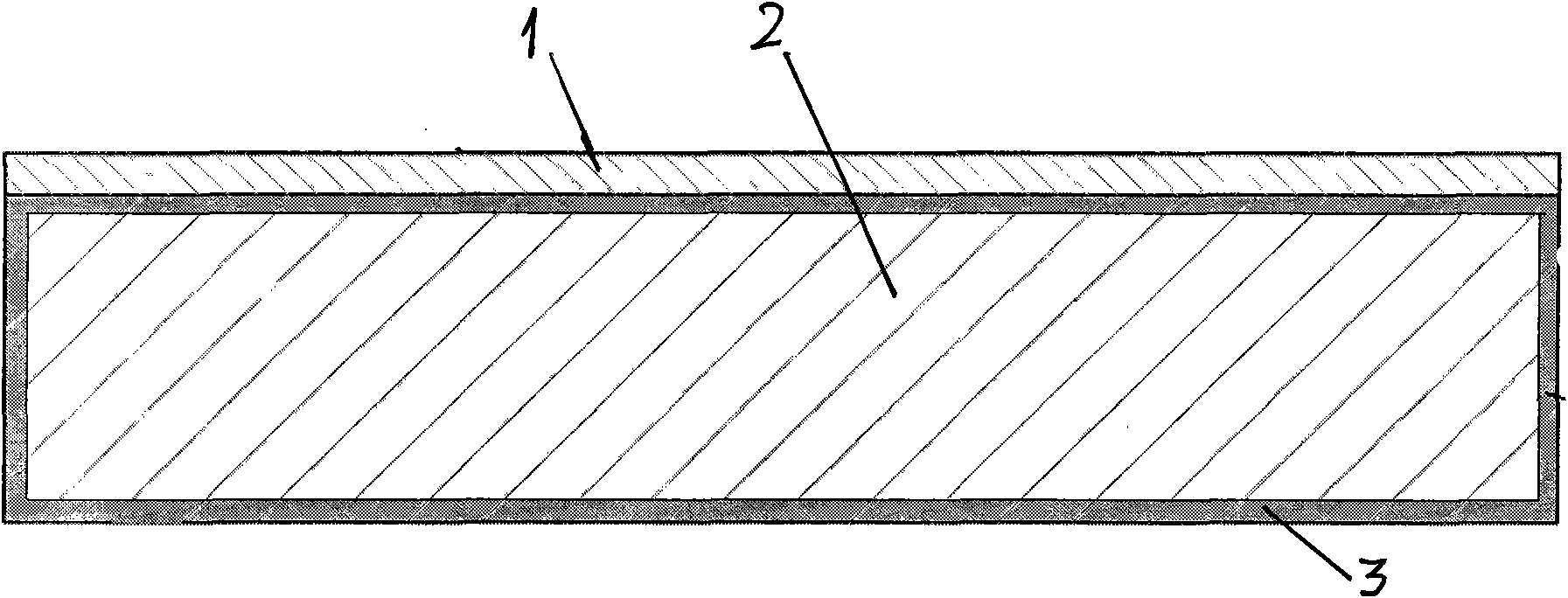

Etching method of solar battery silicon chip edges and reverse diffusion layer

InactiveCN101587922AEfficient removalReduce peripheral defectsFinal product manufactureSemiconductor devicesElectricityChemical solution

The invention discloses an etching method of solar battery silicon chip edges and reverse diffusion layer, the processing steps are: depositing barrier layer mask of one side of diffused solar battery silicon chip; then putting the solar battery silicon chip into etching solution to etch away non-deposited barrier layer mask side of the solar battery silicon ship and lateral side diffusion layer, and then taking out and washing with deionized water; putting the solar battery silicon chip into chemical solution to remove barrier layer mask and then taking out to wash with deionized water. The invention provided method can remove diffusion layer silicon of edge and reverse, and reduce leakage of electricity effectively and finally affect bettery performance, because the barrier layer etching slow or even non-etching in etching solution and area without barrier layer has a fast etching speed. The invention provided method can reduce defects and cracks of silicon chips periphery, reduce fragmentation ratio in following process, and can control surface morphology of two sides at the same time.

Owner:CHINA SUNERGY CO LTD

CDMA communication system and channel estimating method used in the same

InactiveUS6937642B2Same characteristicsTotal current dropPower managementModulated-carrier systemsChannel dataEngineering

A common pilot channel-use reverse diffusion unit generates common pilot data using a received digital signal and a common pilot channel-use reverse diffusion code, while an individual channel-use reverse diffusion unit generates individual channel data using the received digital signal and an individual channel-use reverse diffusion code. Power calculating unit converts respective output data items of the common pilot channel-use reverse diffusion unit and the individual channel-use reverse diffusion unit into power values, a larger one of which is then determined by a comparator. A selector unit selects the data item having thus determined larger power value of those output data items of those reverse diffusion units. A channel estimating unit estimates the channel using data symbols of the data item thus selected by the selector unit.

Owner:NEC CORP

Method for encrypting bit-level synchronous promiscuous diffusion images and pixel-level annular diffusion images

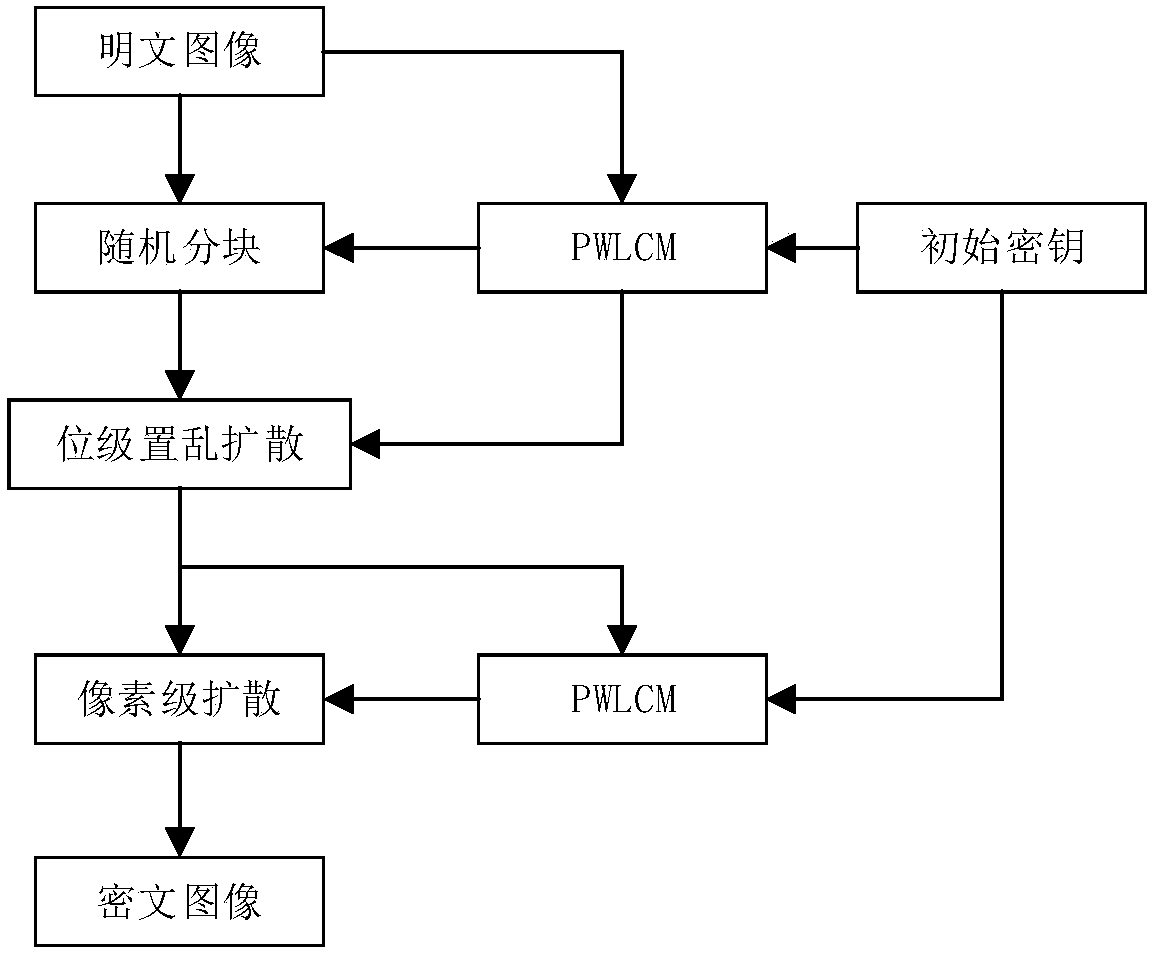

InactiveCN108319859ASmall amount of calculationEnhanced defense against differential attacksDigital data protectionSecuring communication by chaotic signalsComputer hardwareDiffusion methods

The invention provides a method for encrypting bit-level synchronous promiscuous diffusion images and pixel-level annular diffusion digital images. According to the method, bit-level encryption and pixel-level encryption are carried out on an image by utilizing a chaos sequence generated by piecewise linear chaotic map, so that ideal encryption effect can be obtained through one round of encryption. In the bit-level encryption stage, random blocking is carried out on the image by utilizing the chaos sequence to destroy the correlation of adjacent pixels, a low four-bit plane, a previous ciphertext pixel and a key stream are combined, synchronous promiscuous diffusion encryption is carried out on a high four-bit plane with a high information amount, overall scrambling is carried out on thelow four-bit plane with an extremely low information amount through cyclic shift, and inter-block diffusion is realized through parameter transfer. In the pixel-level encryption stage, a transverse sequential diffusion and longitudinal reversed diffusion combined annular diffusion method is adopted, so that phenomena such as plaintext sensitivity non-uniformity and break points caused by diffusionof each pixel along one direction are avoided.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

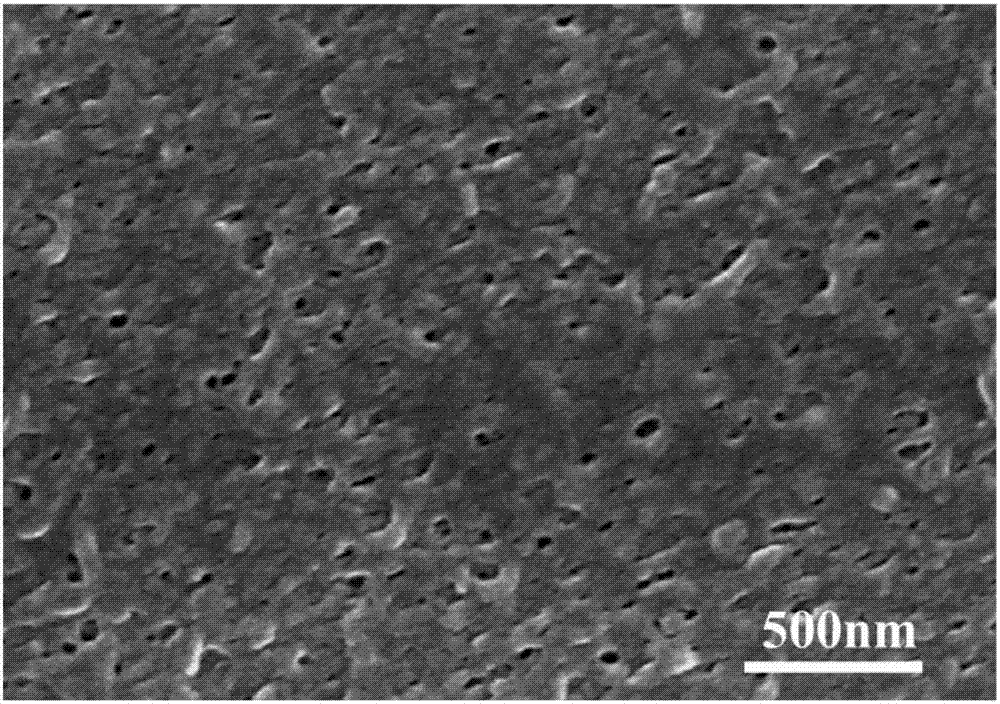

High-performance Janus forward osmosis membrane and preparation method thereof

ActiveCN109276998AIncrease water fluxThe film making method is simpleSemi-permeable membranesMembranesMembrane matrixInorganic nanoparticles

The invention discloses a high-performance Janus forward osmosis membrane, comprising a first surface of a super-hydrophilic polymer microporous membrane, a polymer membrane matrix intermediate layerand a second surface away from the first surface and coated with a super-hydrophobic inorganic nanoparticle coating, wherein the water droplet infiltration time of the first surface of the super-hydrophilic polymer microporous membrane is less than two seconds, and the second surface coated with the super-hydrophobic inorganic nanoparticle coating has a water droplet contact angle of greater than150 degrees. The Janus forward osmosis membrane has the advantage of high water flux and low-salt reverse diffusion flux.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

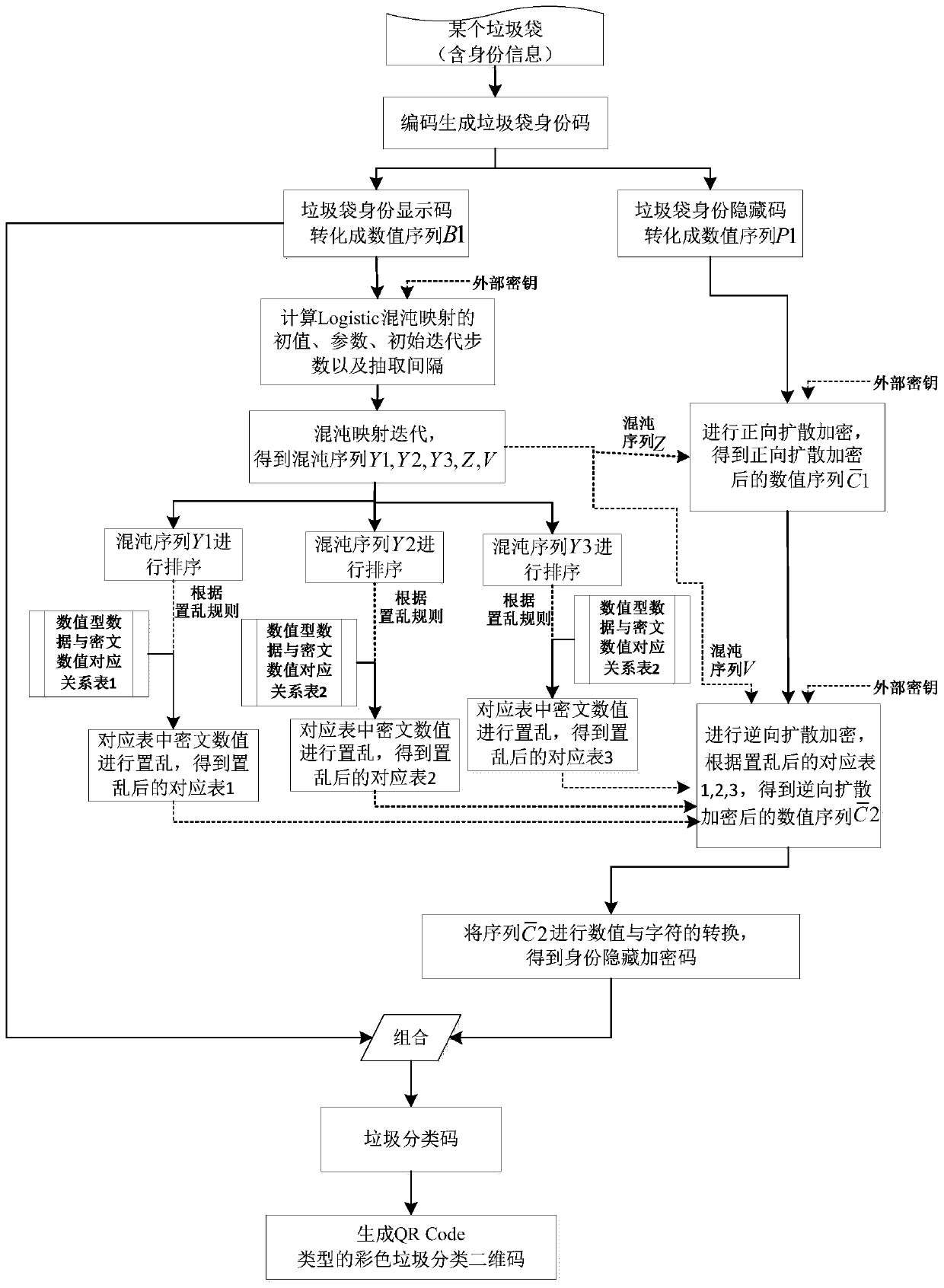

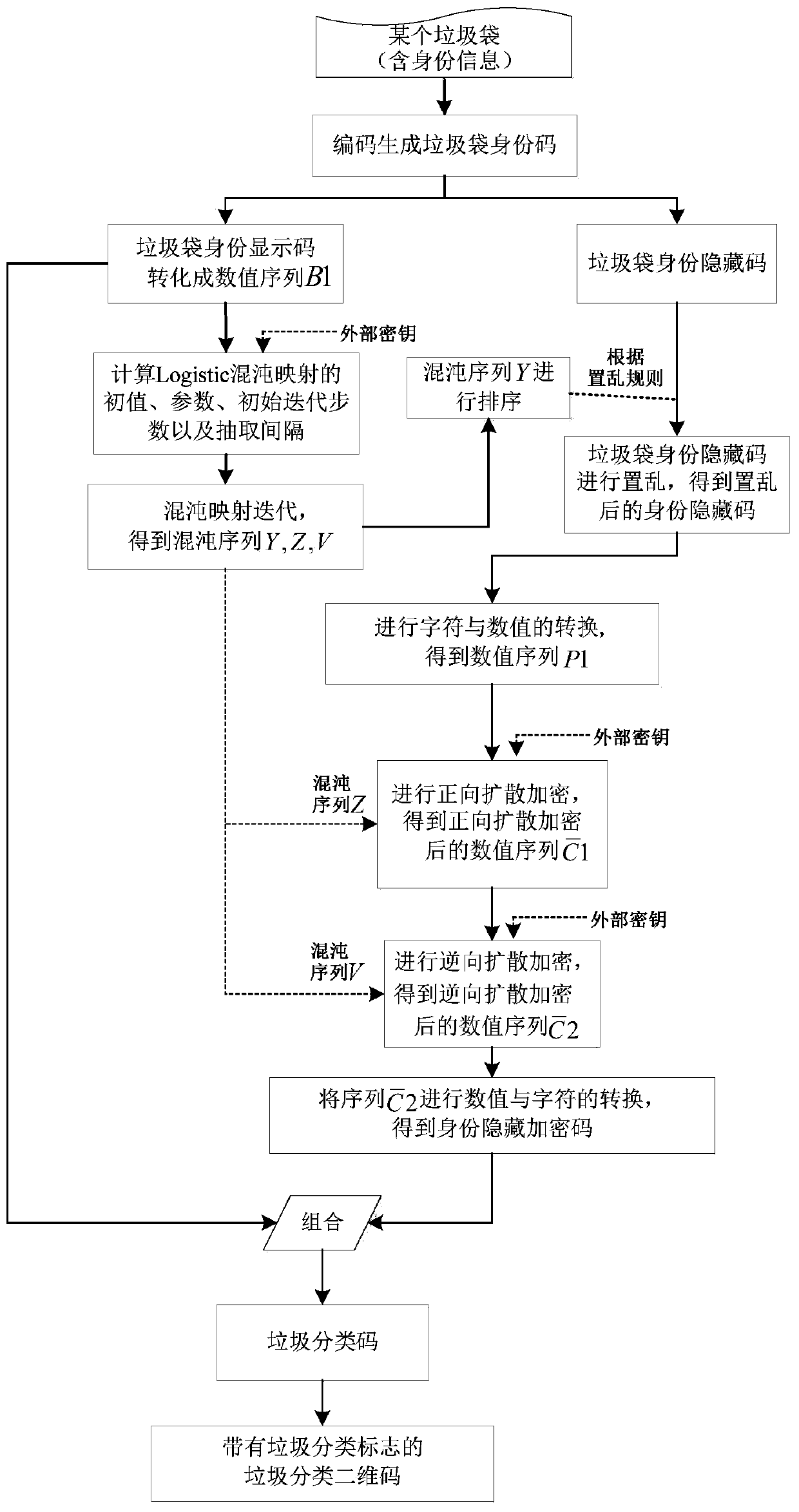

Method for generating color garbage classification two-dimensional code

ActiveCN110033066AImprove securityUniqueness guaranteedDigital data protectionSecuring communication by chaotic signalsDiffusionCiphertext

The invention discloses a method for generating a color garbage classification two-dimensional code. The method comprises the steps of coding the garbage bag identity information to generate a uniquegarbage bag identity code; extracting an identity display code and an identity hiding code, and respectively converting the identity display code and the identity hiding code into the numerical data;respectively calculating to obtain an initial value, parameters, an initial iteration step number and an extraction interval of the chaotic system, and performing iteration on the Logistic chaotic mapping to generate a chaotic sequence; respectively scrambling the ciphertext numerical values in the three custom numerical value type data and ciphertext numerical value corresponding relation tables;and meanwhile, carrying out the corresponding forward diffusion encryption and reverse diffusion encryption on different numerical values of the identity hidden code conversion data, generating an identity hidden encryption code according to the scrambled corresponding relation table, and then generating a garbage classification code through combination, so that the color garbage classification two-dimensional code is obtained. The method for generating the color garbage classification two-dimensional code provided by the invention is simple and feasible, has very strong safety and is not easy to crack, and the generated color garbage classification two-dimensional code is convenient for guiding garbage classification, can effectively protect the privacy of the user in garbage bag identity hidden information, and has the uniqueness and safety.

Owner:IANGSU COLLEGE OF ENG & TECH

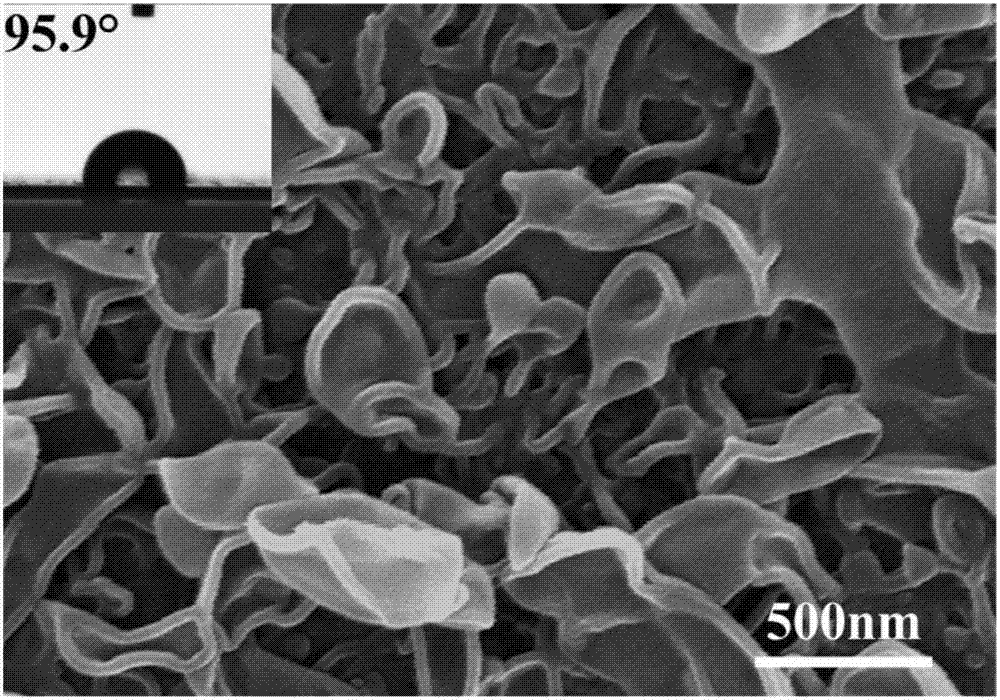

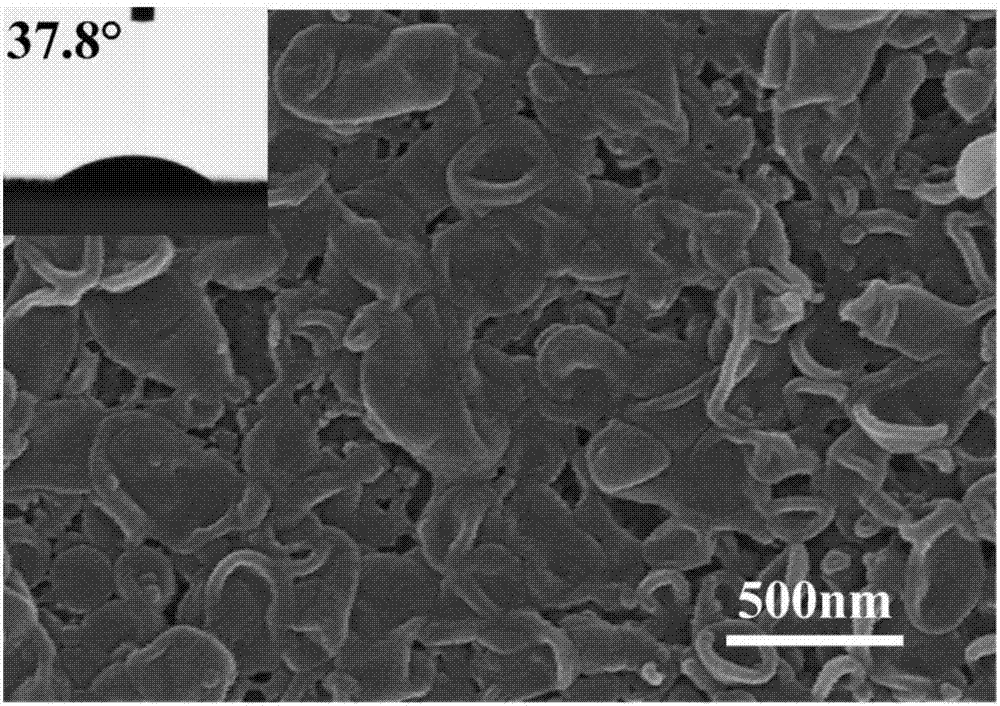

Preparation method of nanometer composite forward osmosis membrane with organic silane grafted multi-wall carbon nanometer tubes embedded into polyamide separation layer

InactiveCN107398188AImprove compatibilityImprove hydrophilicitySemi-permeable membranesWater/sewage treatment bu osmosis/dialysisFilling materialsPolyamide

The invention discloses a preparation method of a nanometer composite forward osmosis membrane with organic silane grafted multi-wall carbon nanometer tubes embedded into a polyamide separation layer. The carbon nanometer tube is added into concentrated acid to obtain the carbon nanometer tubes with carboxyls on the surface; thionyl chloride is used for acyl chlorization on the carbon nanometer tubes; further, reaction is performed with organic silane containing amino groups or sulfydryls; the organic silane is grafted onto the carbon nanometer tubes; macromolecular membrane materials are prepared into a porous organic filtering membrane; a thin separation layer is polymerized on the surface interface of a support layer of the porous organic filtering membrane; the organic silane grafted carbon nanometer tubes are used as nanometer filling materials to be added into an oil phase; the organic silane grafted carbon nanometer tubes are embedded into a separation layer to obtain a target product. The method provided by the invention has the advantages that the water flux of the product is greatly improved; the reverse diffusion quantity of a draw solution solute is reduced; in addition, good anti-pollution capability is shown; the membrane belongs to a novel forward osmosis membrane with a wide application potential.

Owner:ZHEJIANG UNIV OF TECH

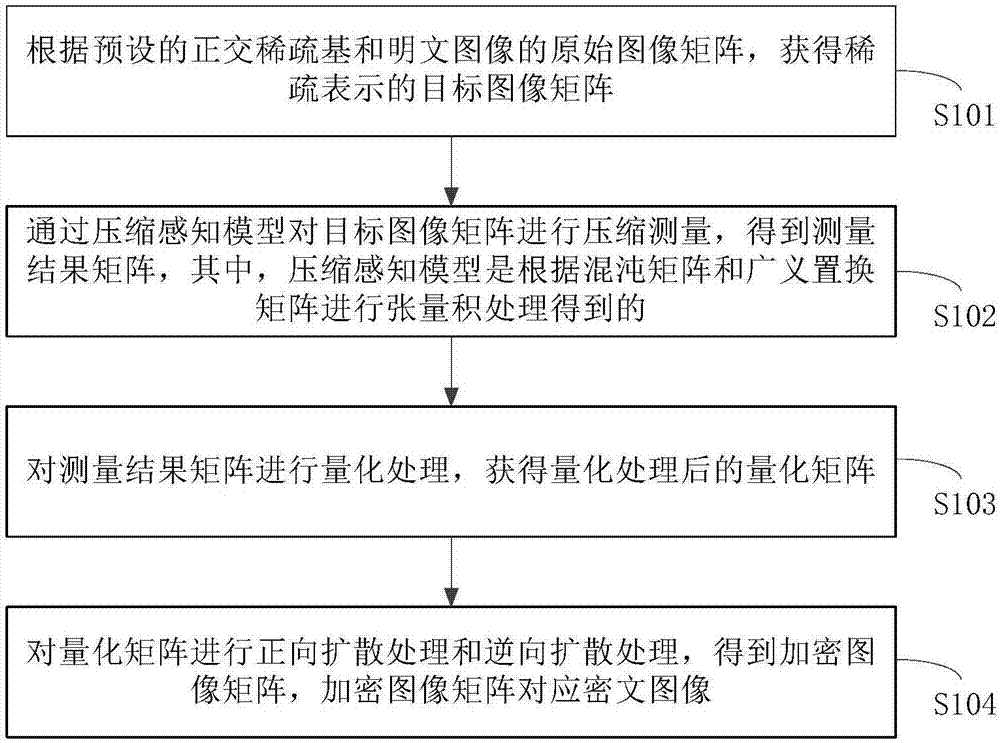

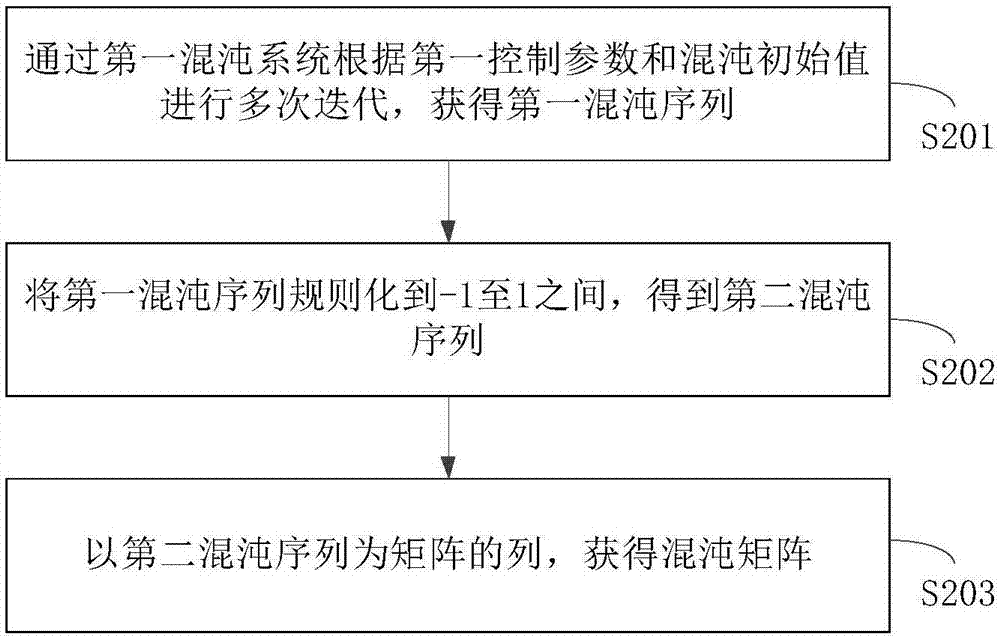

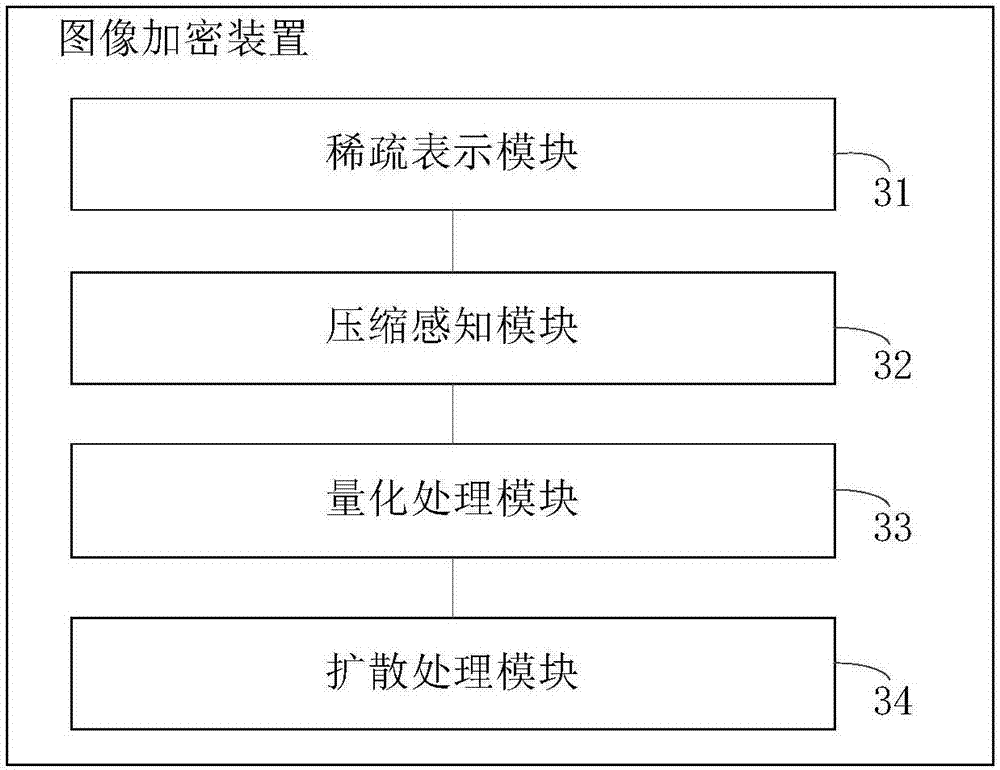

Image encryption method and apparatus

ActiveCN107888370AAchieve dimensionality reductionReduce computational complexityData stream serial/continuous modificationSecuring communication by chaotic signalsDiffusionChaotic systems

The invention provides an image encryption method and apparatus. According to the method, by adopting a target image matrix of sparse representation according to a preset orthogonal sparse base and anoriginal image matrix of a plaintext image, the computational complexity is reduced. A measurement result matrix is obtained by performing compression measurement on the target image matrix through acompressed sensing model, wherein the compressed sensing model is obtained by performing tensor product processing according to a chaotic matrix and a generalized permutation matrix; and the compressed sensing model is obtained by performing the tensor product processing by matrixes generated by two chaotic systems separately, so the compressed sensing model has interrelation that is small enough, and thus the possibility of successful restoration is improved. Quantitative processing is performed on the measurement result matrix to obtain a quantitative matrix subjected to the quantitative processing; and forward diffusion processing and reverse diffusion processing are performed on the quantitative matrix to obtain an encrypted image matrix, the encrypted image matrix corresponds to a ciphertext image, and the forward diffusion processing and the reverse diffusion processing can ensure more uniform image energy distribution and further improve the system security and the image encryption performance.

Owner:BEIJING UNIV OF POSTS & TELECOMM

Double annealing process for reducing back diffusion of impurity in polysilicon ingot

InactiveCN103361737ASmall sizeMitigate backdiffusionPolycrystalline material growthAfter-treatment detailsRoom temperatureIngot

The invention belongs to the field of polysilicon purification, and particularly relates to a double annealing process for reducing back diffusion of impurities in a polysilicon ingot. The secondary annealing process includes the steps of (1) first annealing after crystal growth in polysilicon ingot process; (2) cooling the polysilicon ingot to room temperature; (3) dividing the polysilicon ingot to obtain a square ingot; (4) placing the square ingot into an annealing oven for second annealing, and then cooling the square ingot to room temperature; and (5) polishing the square ingot. The double annealing process has the advantages that: (1) leftover materials with high content of impurities has been removed during dividing, thus reverse diffusion can be reduced in later annealing and yield is improved; (2) the size of a silicon block is relatively small, so the internal temperature distribution in the annealing step is uniform and the annealing effect can be improved; and (3) production cycle is reduced, production efficiency is improved, and production cost is reduced by 5%.

Owner:QINGDAO XINSHIJI SOLAR ENERGY TECH CO LTD

Garbage classification code generation method

ActiveCN109933755ASimple methodImprove securityKey distribution for secure communicationRecord carriers used with machinesProgramming languageChaotic systems

The invention discloses a garbage classification code generation method. The method comprises the following steps: encoding garbage bag identity information to generate a unique garbage bag identity code; extracting an identity display code and an identity hidden code, and converting the identity display code into numerical data; carrying out calculation to obtain an initial value, parameters, aninitial iteration step number and an iteration interval step number of a chaotic system, and carrying out iteration to generate a chaotic sequence; scrambling the identity hidden codes in the garbageidentity codes by utilizing a position change rule before and after chaotic signal sorting; performing conversion between characters and numerical values; obtaining a corresponding numeric sequence; performing corresponding forward diffusion encryption and reverse diffusion encryption according to different numerical values in the numeric sequence to complete conversion of the numerical values andcharacters, thereby generating an identity hidden encryption code, and further combining and generating the garbage classification code, and obtaining the garbage classification two-dimensional codewith the garbage classification mark at the same time. The garbage classification code generation method provided by the invention is simple and feasible, has very high safety and is not easy to crack, the generated garbage classification code is convenient for guiding garbage classification, the privacy of a user in garbage bag identity hidden information can be effectively protected, and the garbage classification code has uniqueness and safety.

Owner:IANGSU COLLEGE OF ENG & TECH

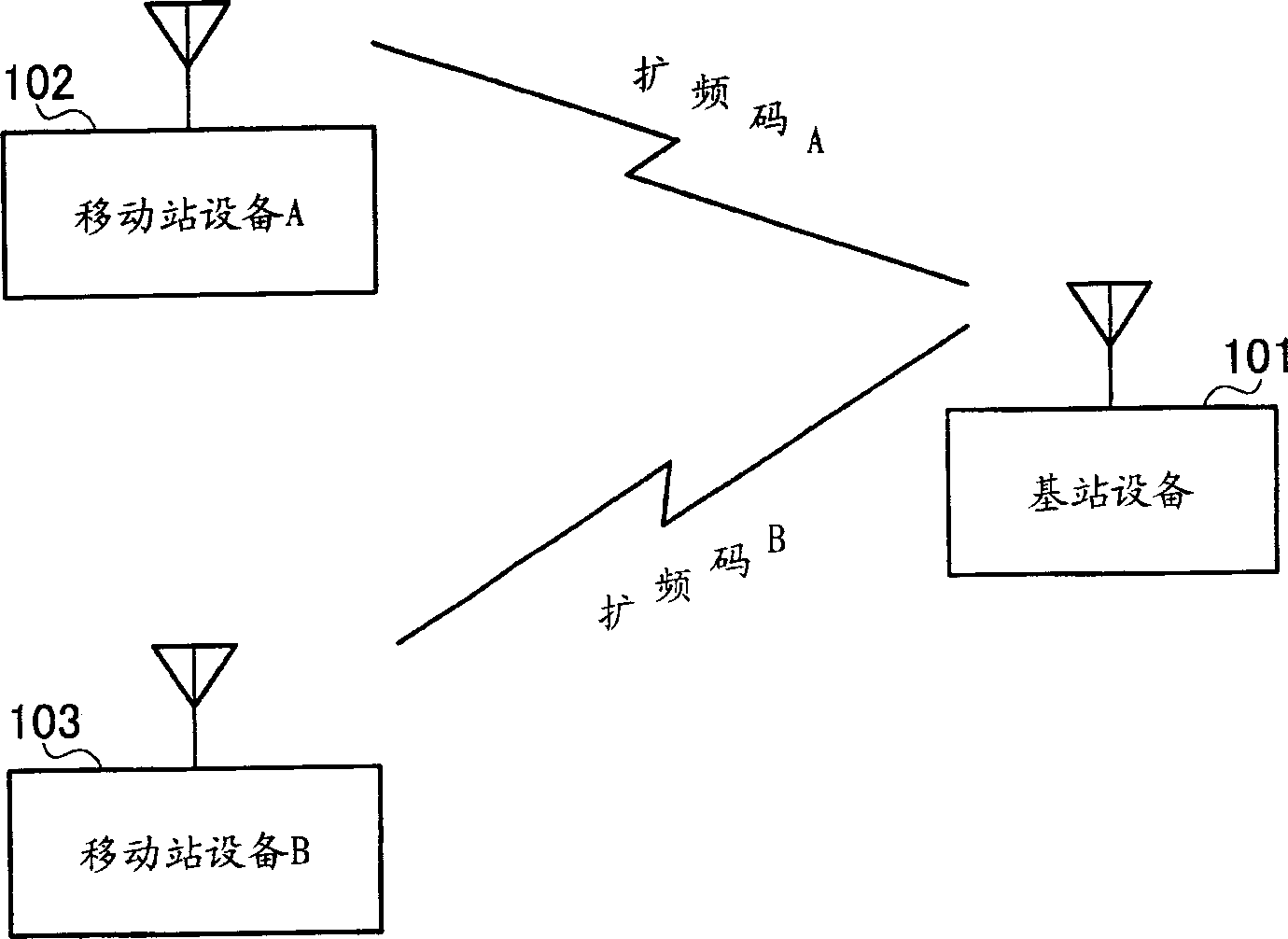

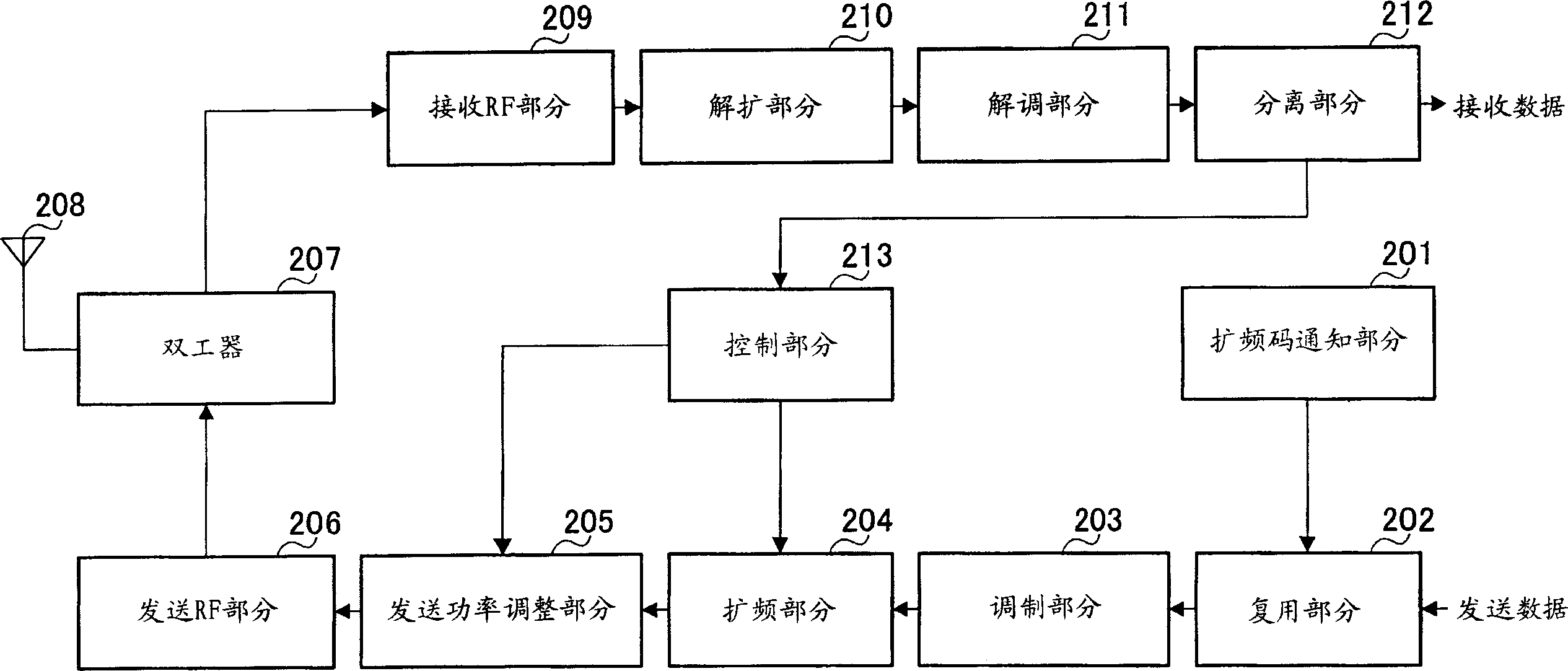

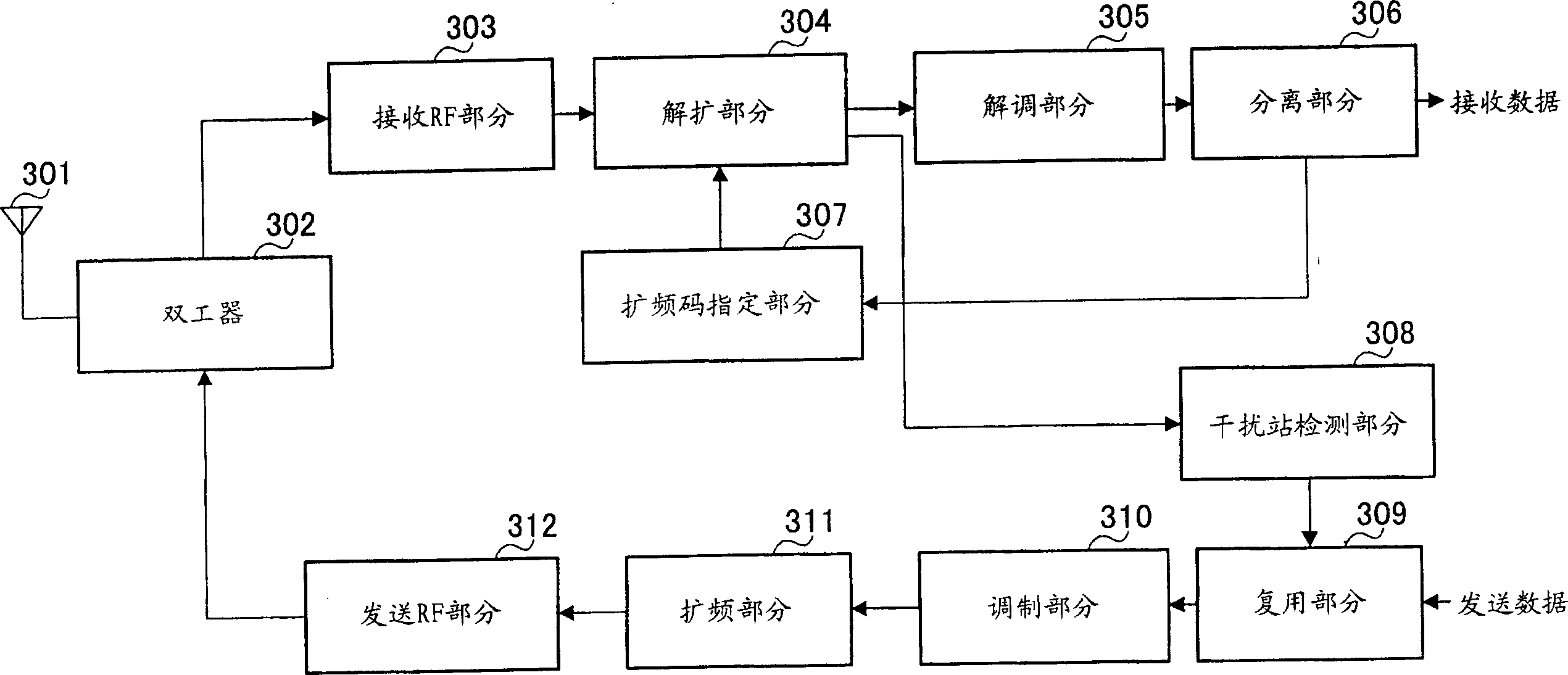

Base station device, mobile station device and transmission power control method

InactiveCN1493120AReduce the amount of noisePower managementEnergy efficient ICTBase station identity codeEngineering

A diffusion code reporting unit reports diffusion codes corresponding to communicating mobile station devices to respective mobile station devices, a separation unit separates, from a received signal, information indicating an interference station detected from reverse-diffusion results in respective mobile station devices, and a control unit reduces the transmission power of a signal to the interference station.

Owner:PANASONIC INTELLECTUAL PROPERTY CORP OF AMERICA

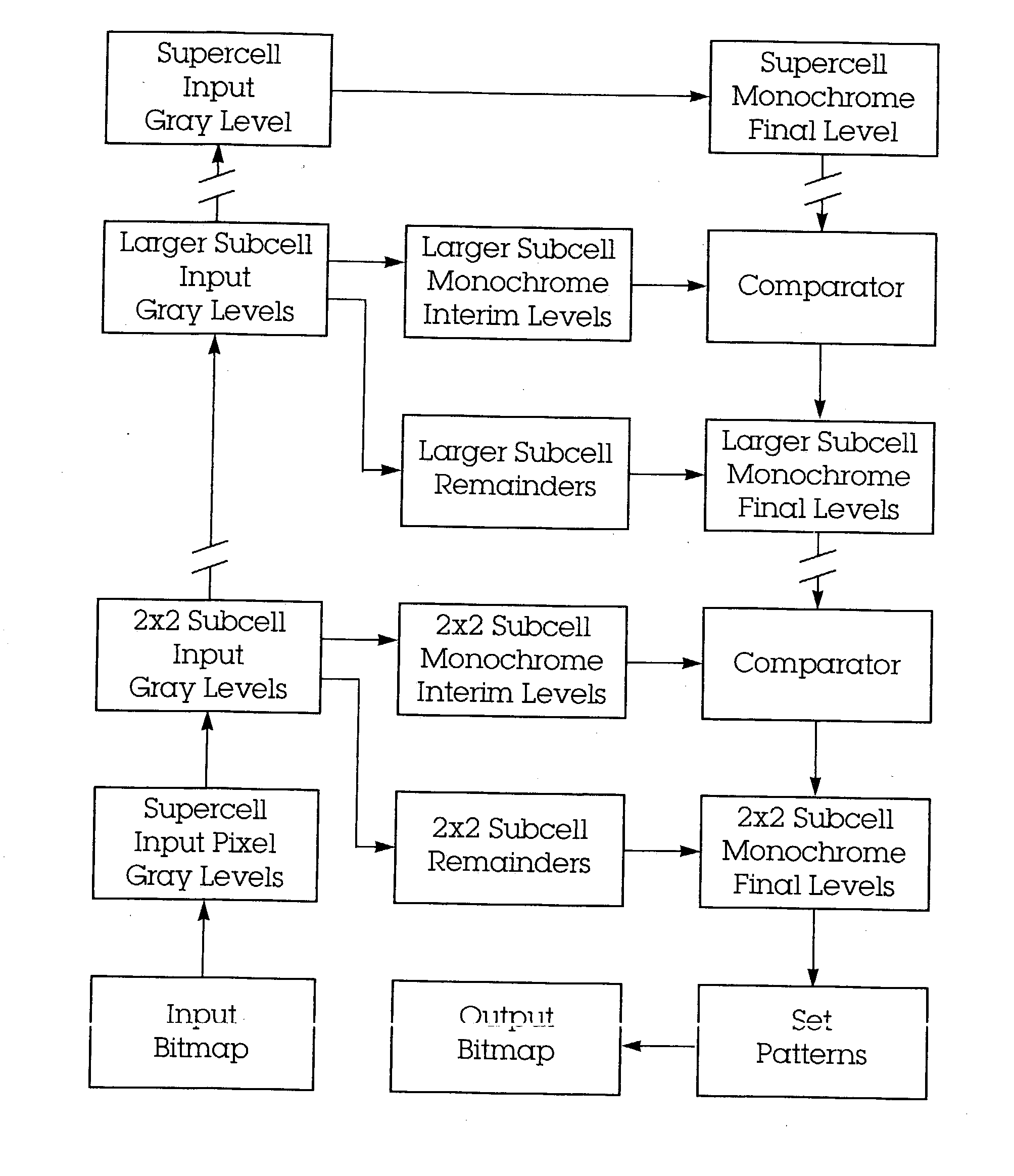

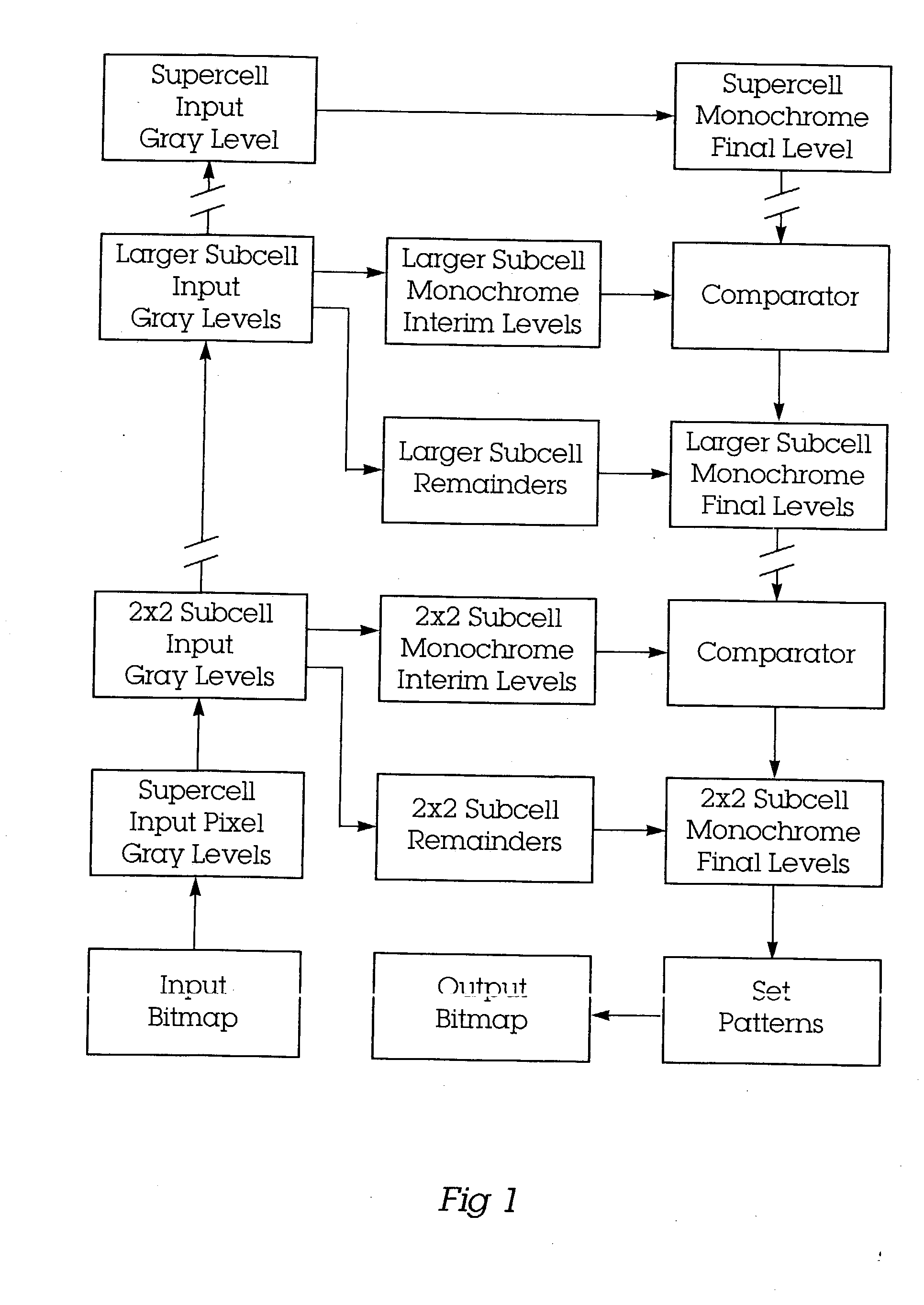

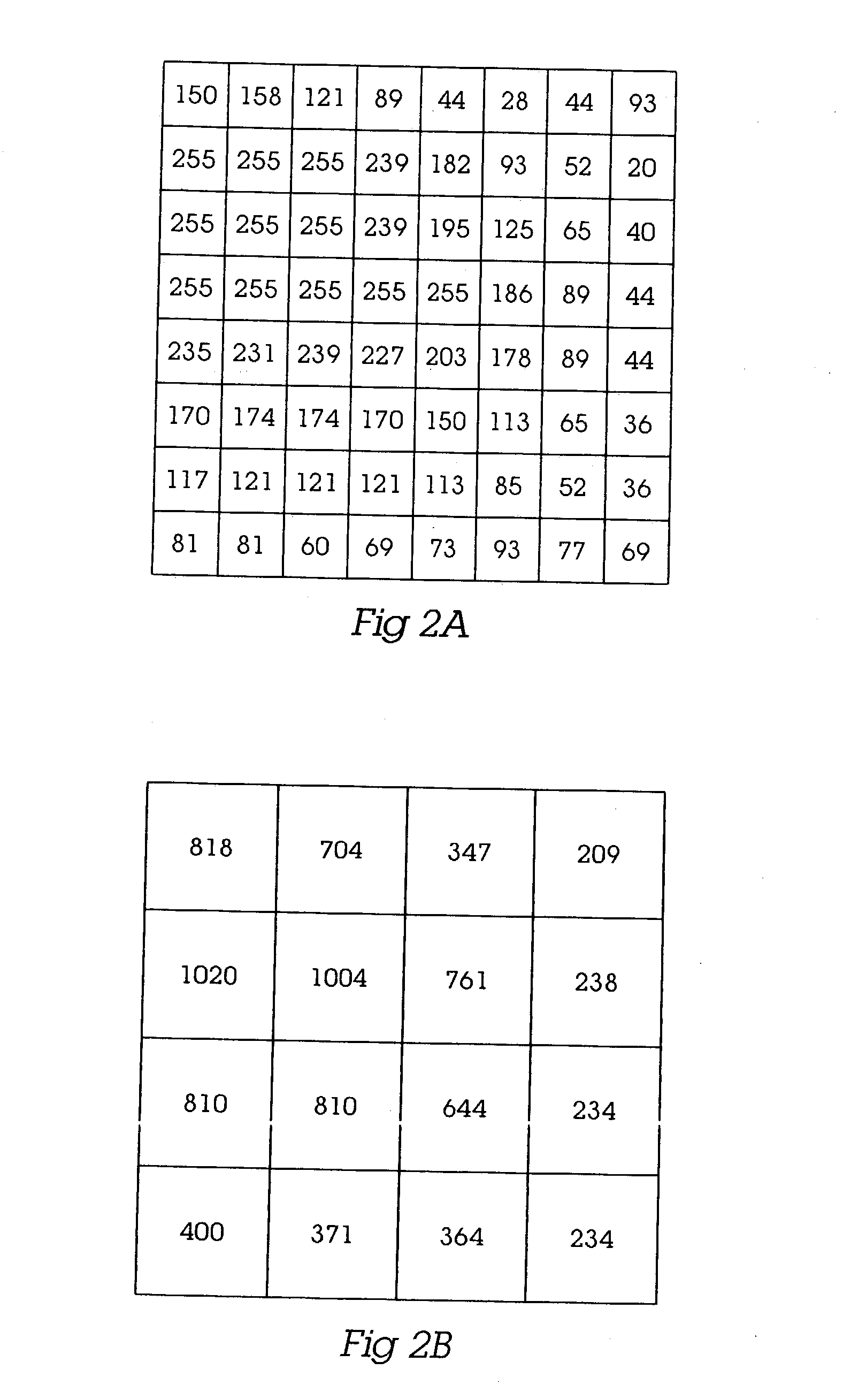

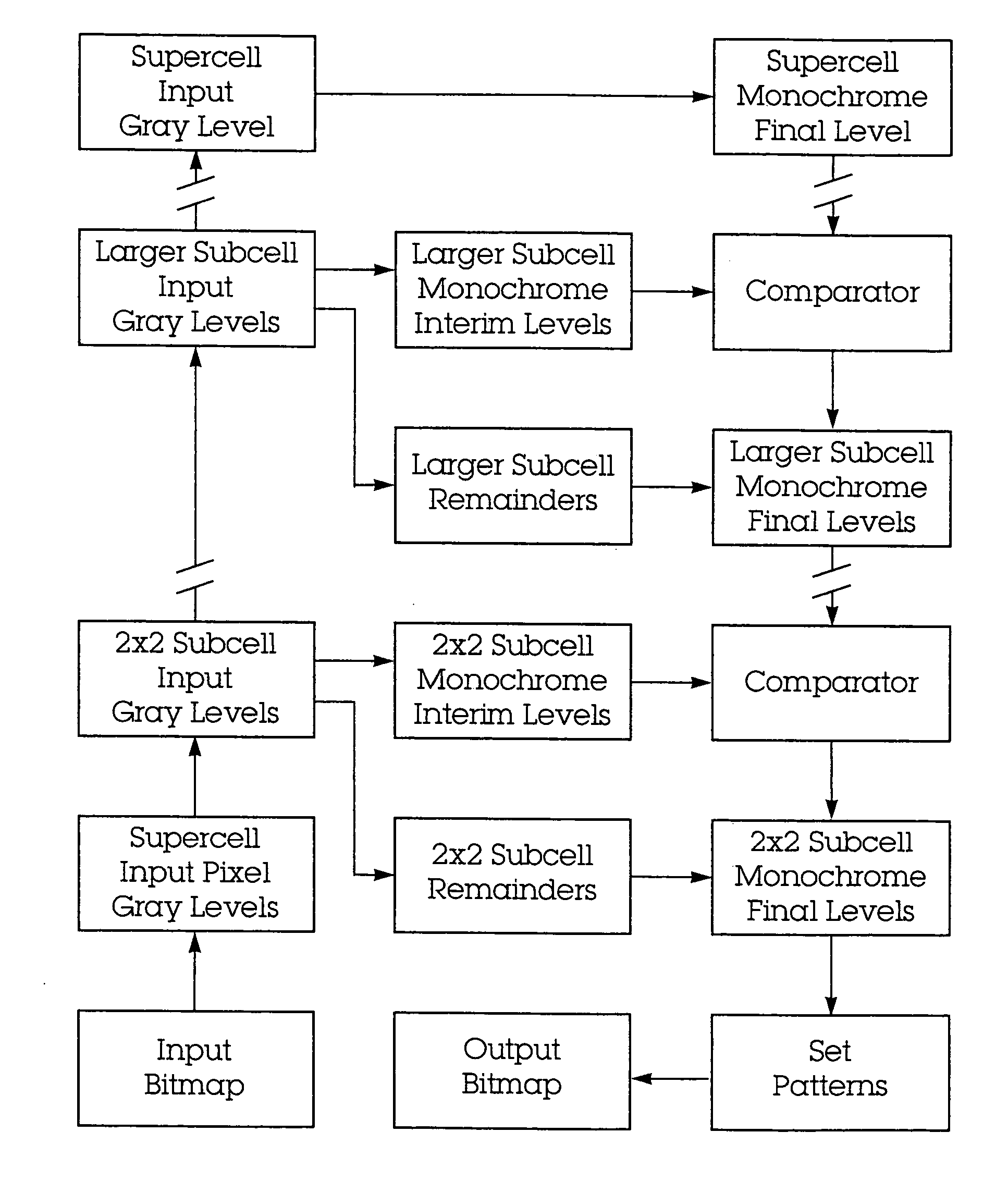

Reverse diffusion digital halftone quantization

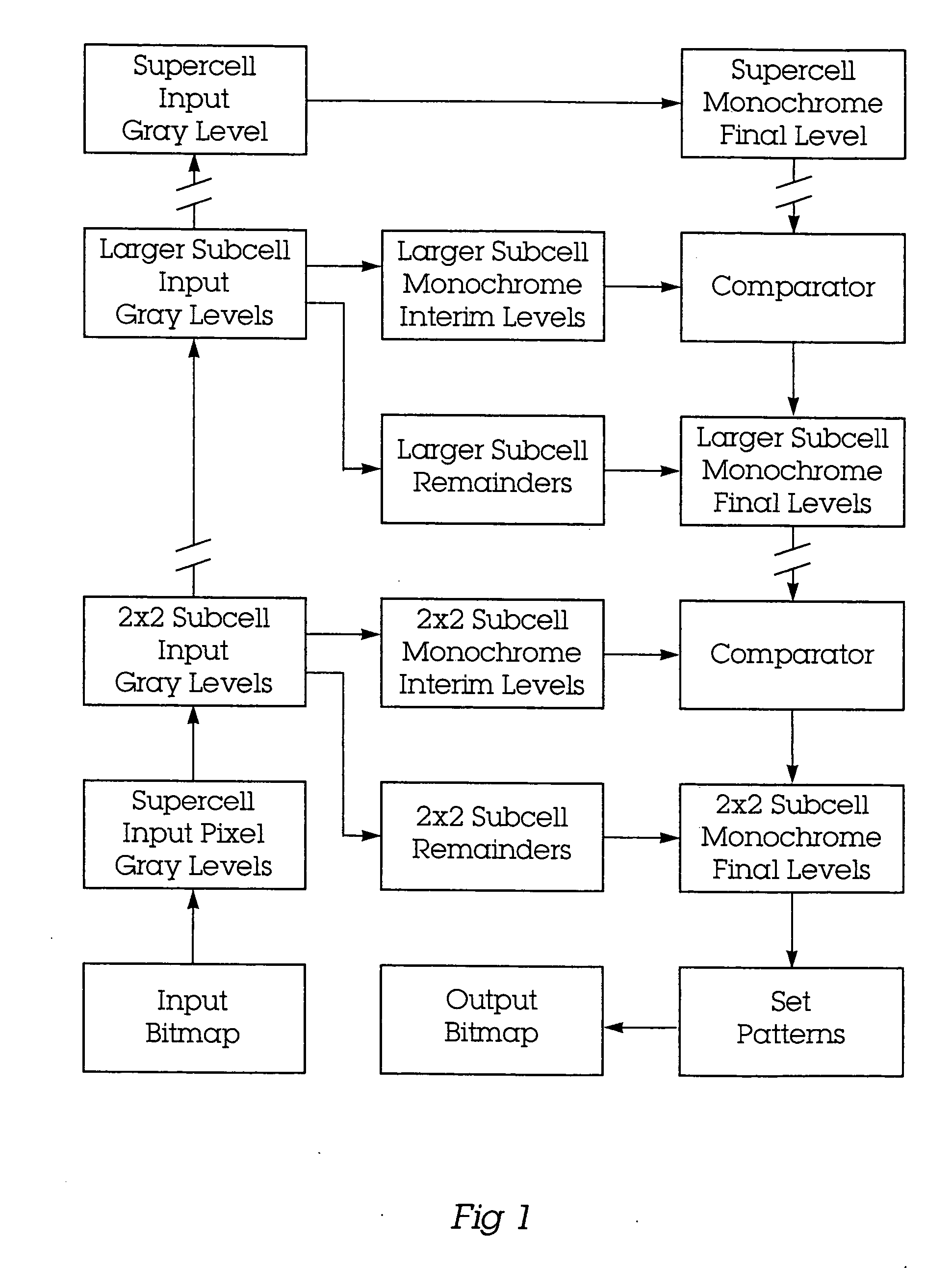

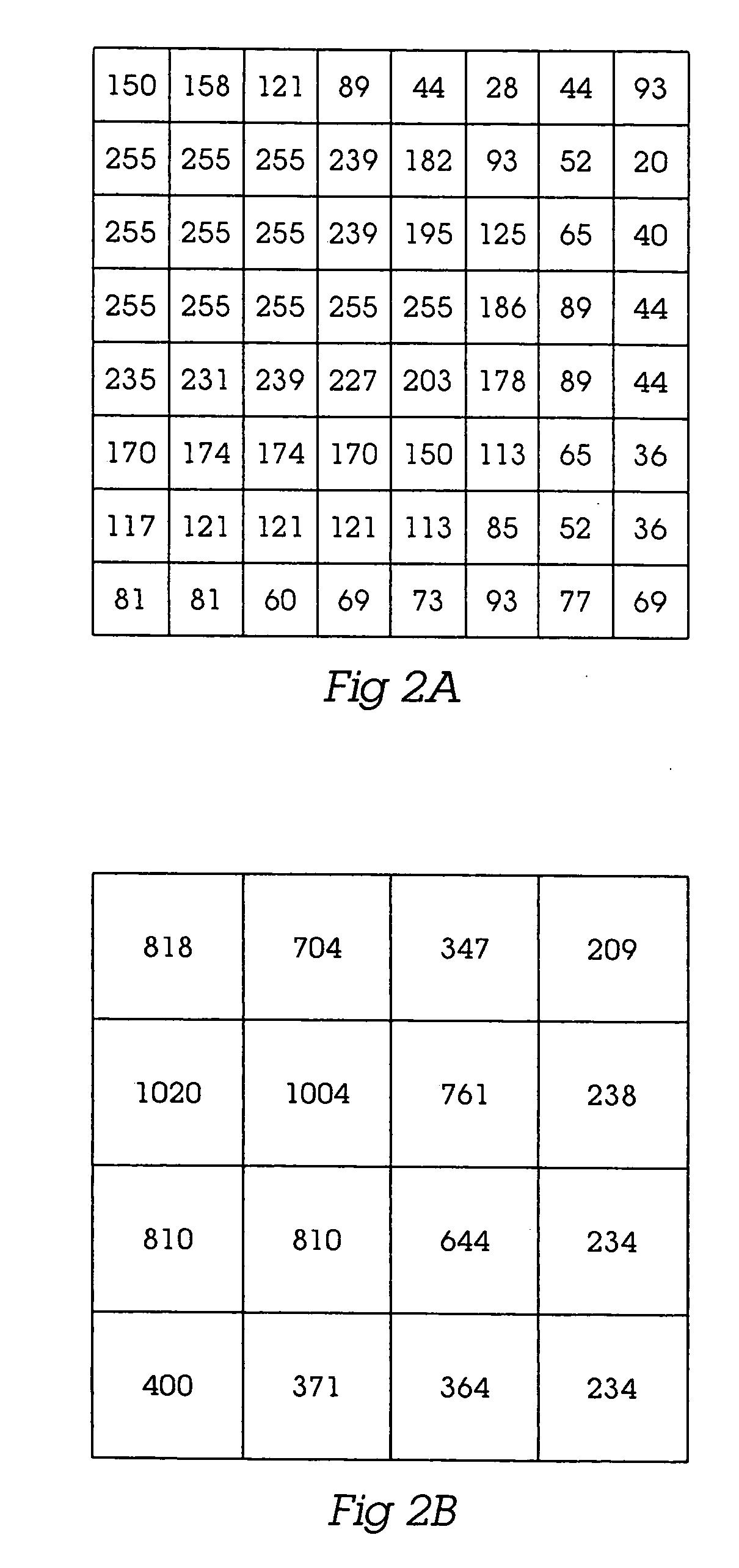

An improved digital halftoning method that uses an input image's global gray levels to determine the local gray levels of a monochrome output image. Input multi-bit pixels grouped into two-pixel-by-two-pixel local subcells are variously aggregated into one or more larger supercells. The size of said supercell(s) is related to and limited by the size of the global input bitmap. A final monochrome gray level is derived from said supercell(s) and distributed within contained subcells. Subcell gray levels are expressed as interim whole monochrome pixels and gray level remainders. A comparison is made of the final supercell and the summed interim subcell monochrome gray levels. An ordering of the remainders is used for assignment of additional monochrome pixels, if necessary, to yield final subcell monochrome gray levels. Gray level rounding errors thus are quantized by reverse diffusion until a monochrome gray level for each of the global image's two-pixel-by-two-pixel local subcells is derived.

Owner:XYLON LLC

Rapid freezing method of polycrystalline silicon

InactiveCN103539126AFreeze fastIncrease stressSilicon compoundsWater coolingDirectional solidification

The invention relates to a reverse freezing method of polycrystalline silicon, and belongs to the field of polycrystalline silicon production. The rapid freezing method of polycrystalline silicon comprises the steps of preparing materials, smelting and freezing. The freezing method comprises the following steps of: directionally freezing silicon liquid in a polycrystalline silicon reverse freezing device until the volume of remained silicon liquid is 1-25% of the initial volume; and contacting a water cooling copper plate at 0-500 DEG C with the remained silicon liquid until the remained silicon liquid is frozen. By adopting the rapid freezing method of polycrystalline silicon, strong condensate depression is formed after the water cooling copper plate enters the upper surface of silicon liquid, so that silicon liquid can be frozen rapidly and large stress is formed to break easily, reverse diffusion of impurities is inhibited and post processing is facilitated.

Owner:DALIAN UNIV OF TECH

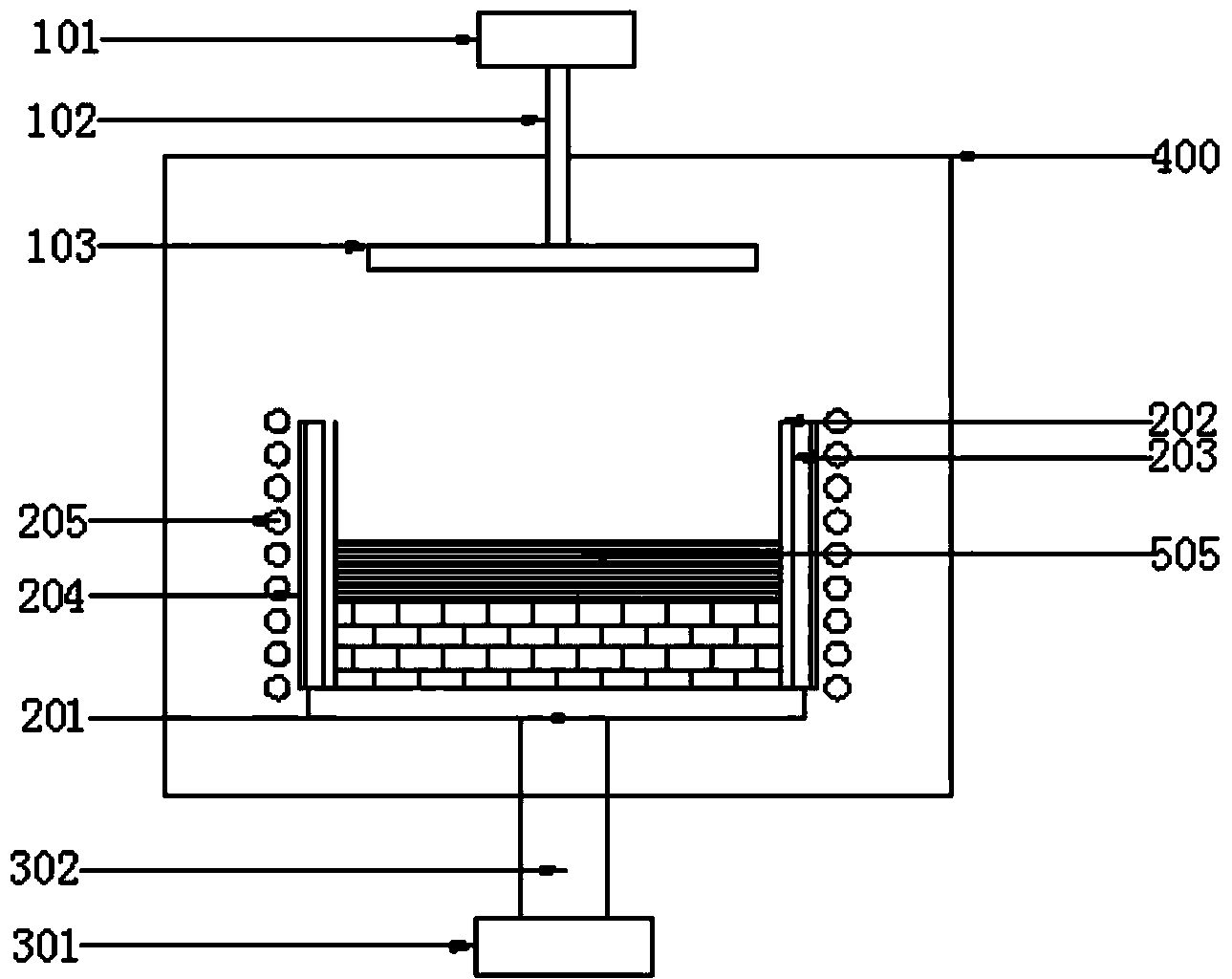

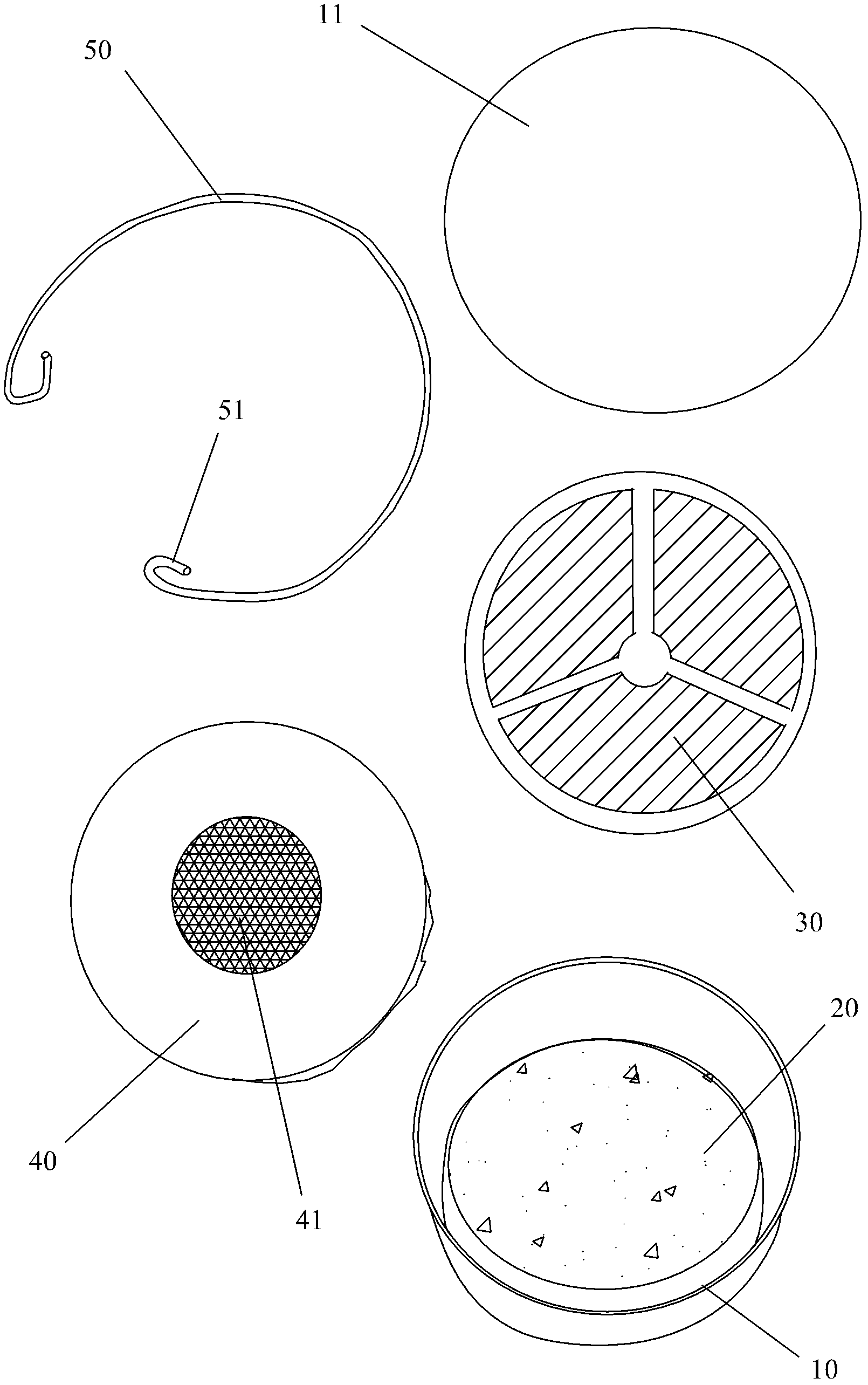

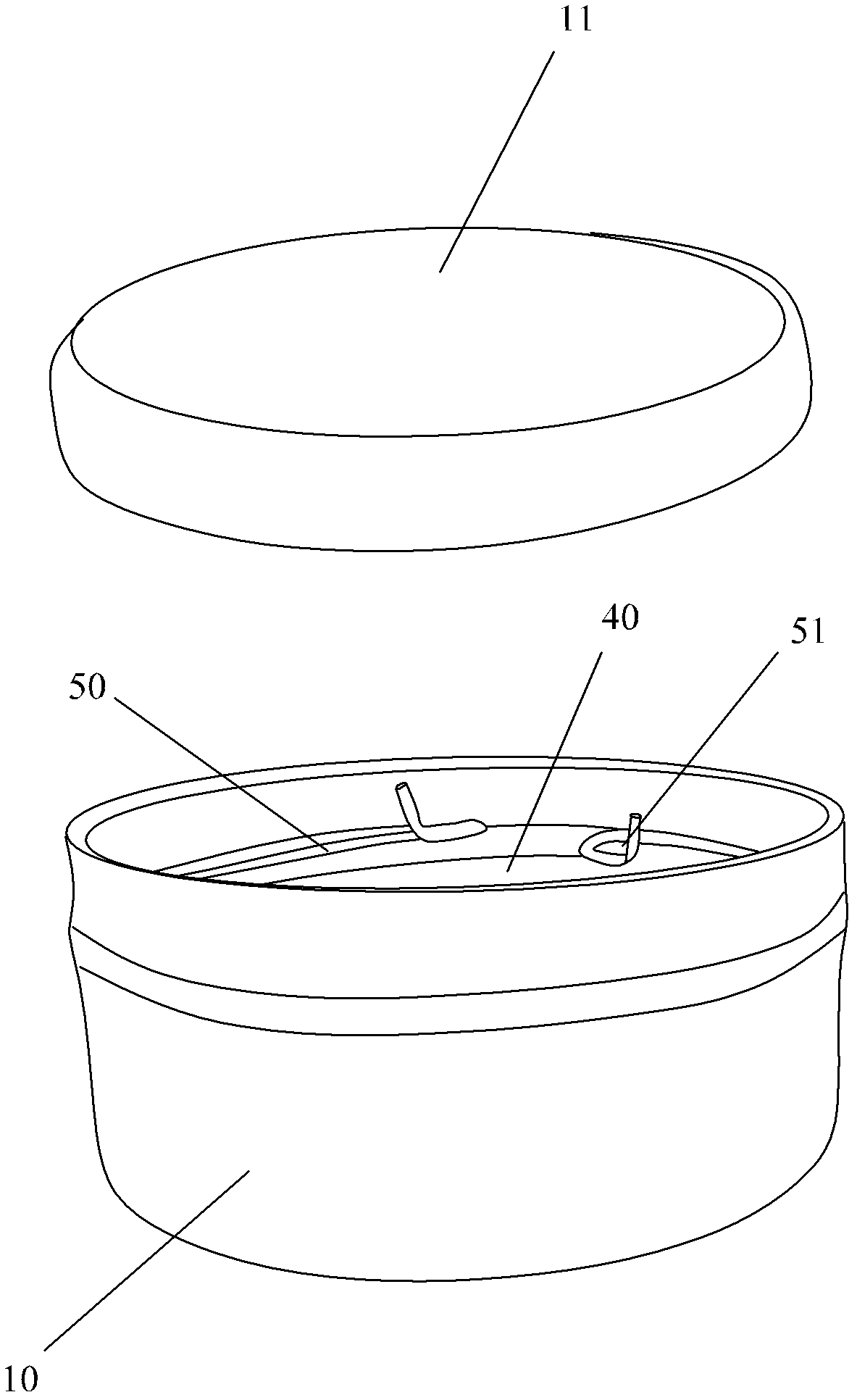

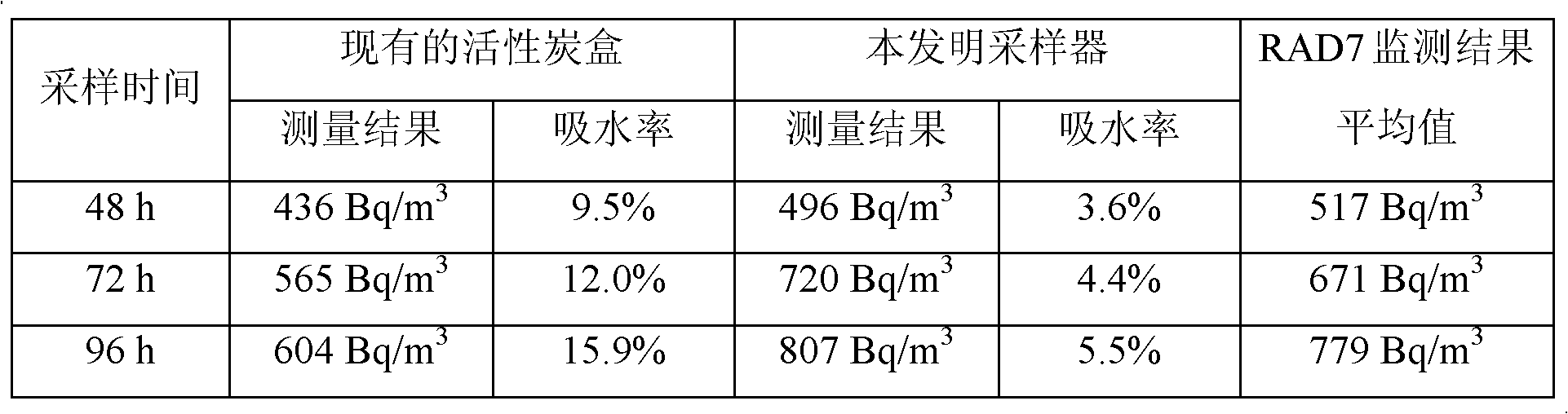

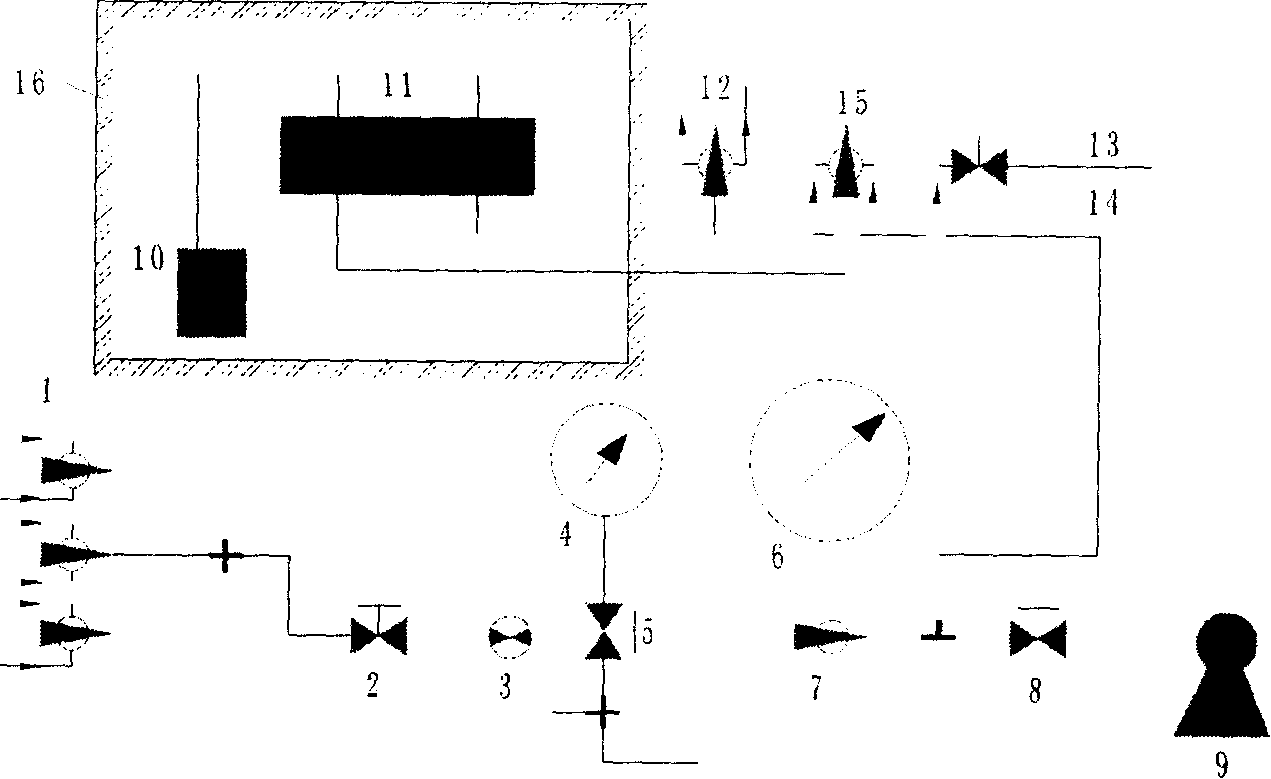

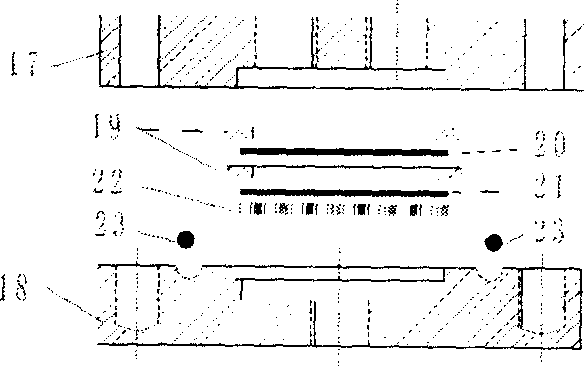

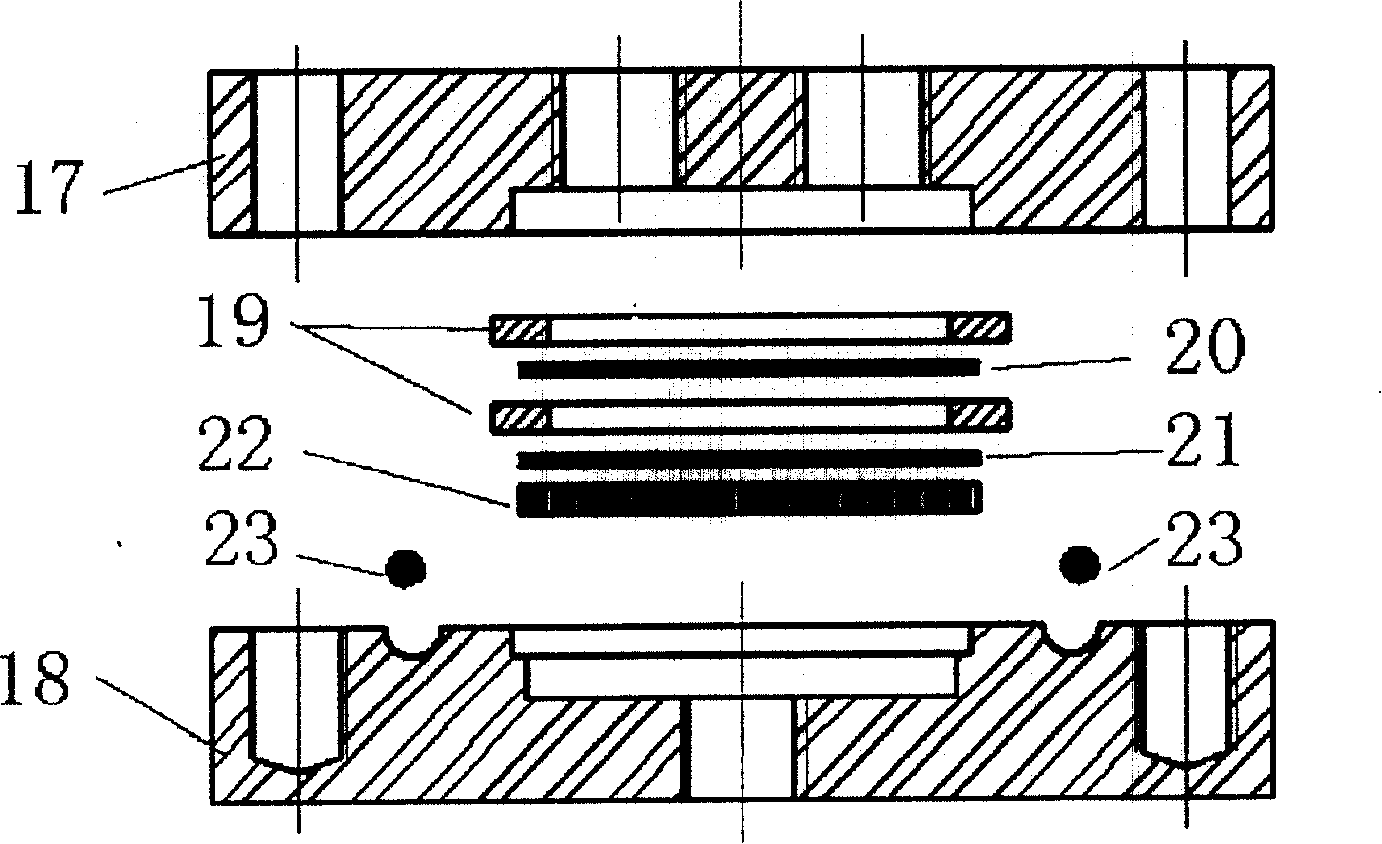

Active carbon box sampler with diffusion barrier

ActiveCN102607897ATransmittance has little effectControl water absorptionWithdrawing sample devicesActivated carbonDiffusion barrier

The invention discloses an active carbon box sampler with a diffusion barrier, which comprises a circular aluminum cover with a cover, the diffusion barrier, a stainless steel pressing sheet, a stainless steel net, a location snap ring and active carbon, wherein the active carbon is arranged in the aluminum box, the stainless steel net is placed on the active carbon, and the stainless steel pressing sheet provided with the diffusion barrier is placed on the stainless steel net and is located by the location snap ring and then sealed by the cover. In the invention, the sampling efficiency is increased through selecting the active carbon with high radon adsorption efficiency, the influence of water in the air to a detection result is reduced through additionally arranging the diffusion barrier and changing the structure of the sample, and reverse diffusion of radon is reduced; and the concentration of the radon in a room is detected by using the sampler disclosed by the invention, thus the reliability of the detection result is improved. The sampler is suitable for massively detecting the radon in the room for a current construction project, and has the advantages of stable detection result, simplicity in operation, saving of a great quantity of manpower works, and the like.

Owner:GUANGZHOU TESTING CENTRE OF CONSTRUCTION QUALITY AND SAFETY CO LTD +1

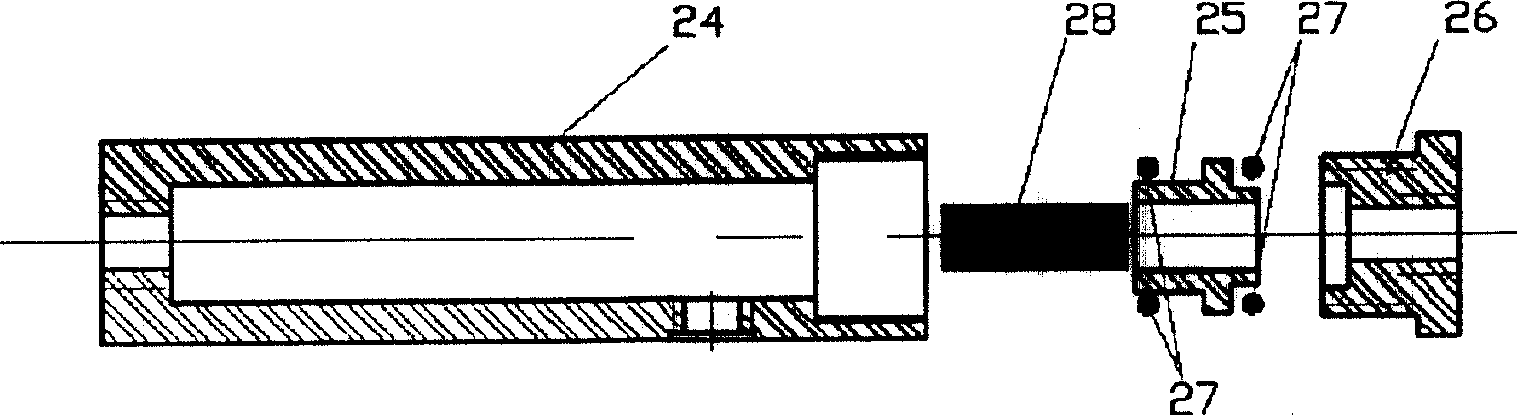

Method of improving gas separation film penetration instrument

InactiveCN1830524AGuaranteed accuracyEasy to operateDispersed particle separationProduct gasImproved method

A method for improving the osmosis apparatus with gas separating membrane features that when a constant-pressure volume-varying method is used to measure the gas osmosis of membrane, a vacuumizing method is used at up-stream of membrane pool for exhausting the gas from pipeline and membrane and a capillary soap membrane flowmeter isolated from air is used at the down-stream for measuring the osmotic speed of gas, so effectively preventing the reverse diffusion of gas.

Owner:DALIAN UNIV OF TECH

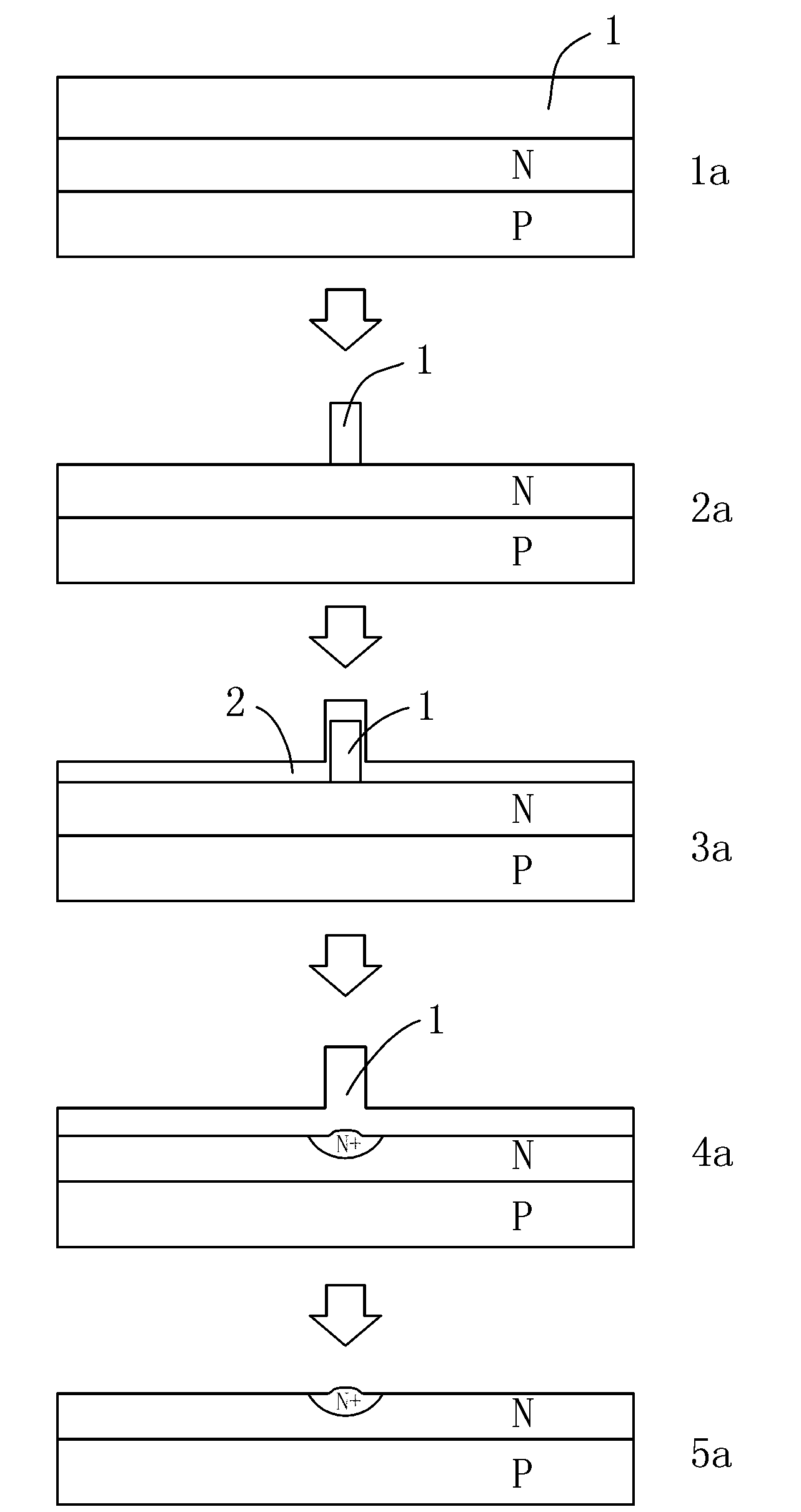

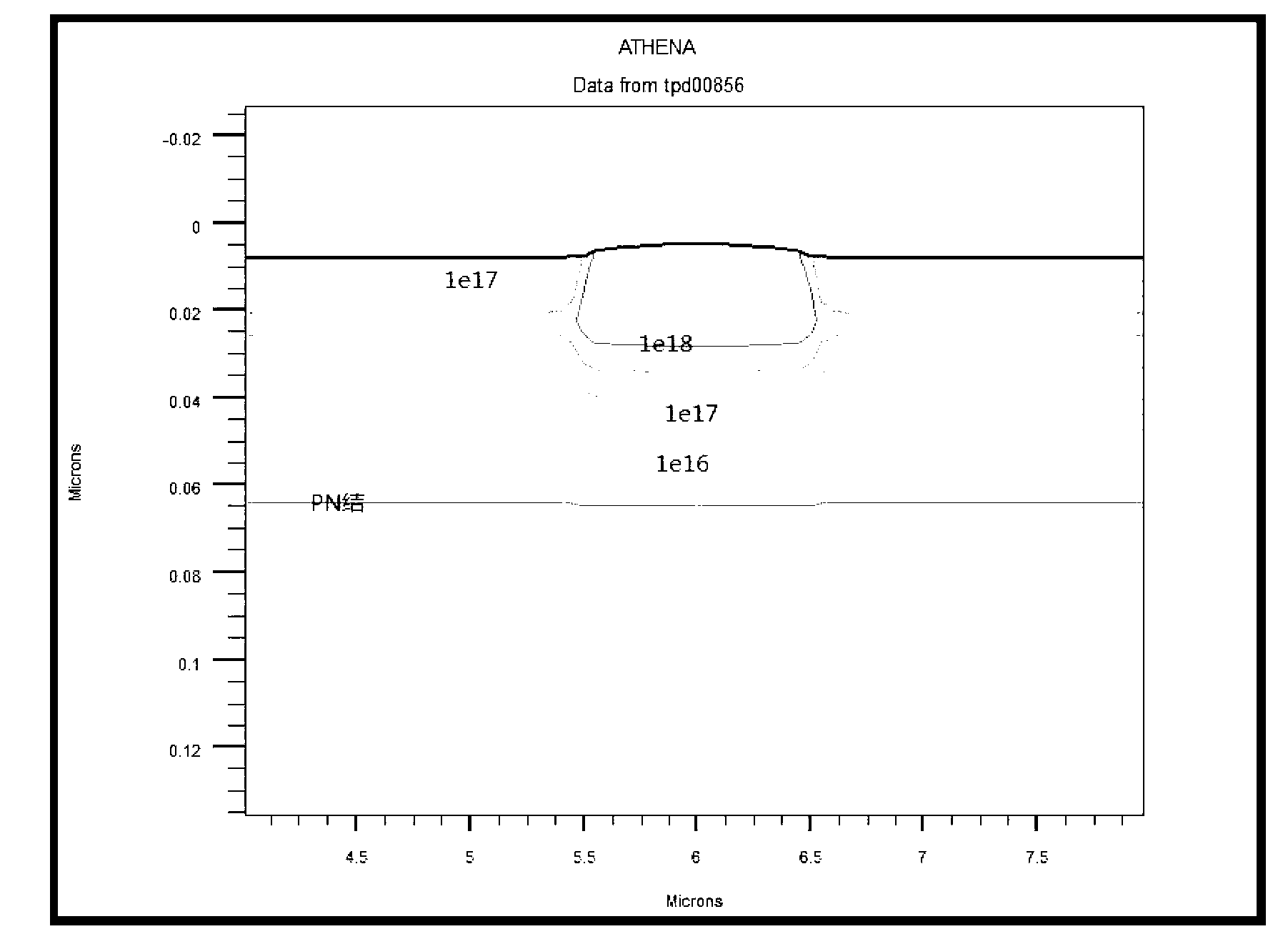

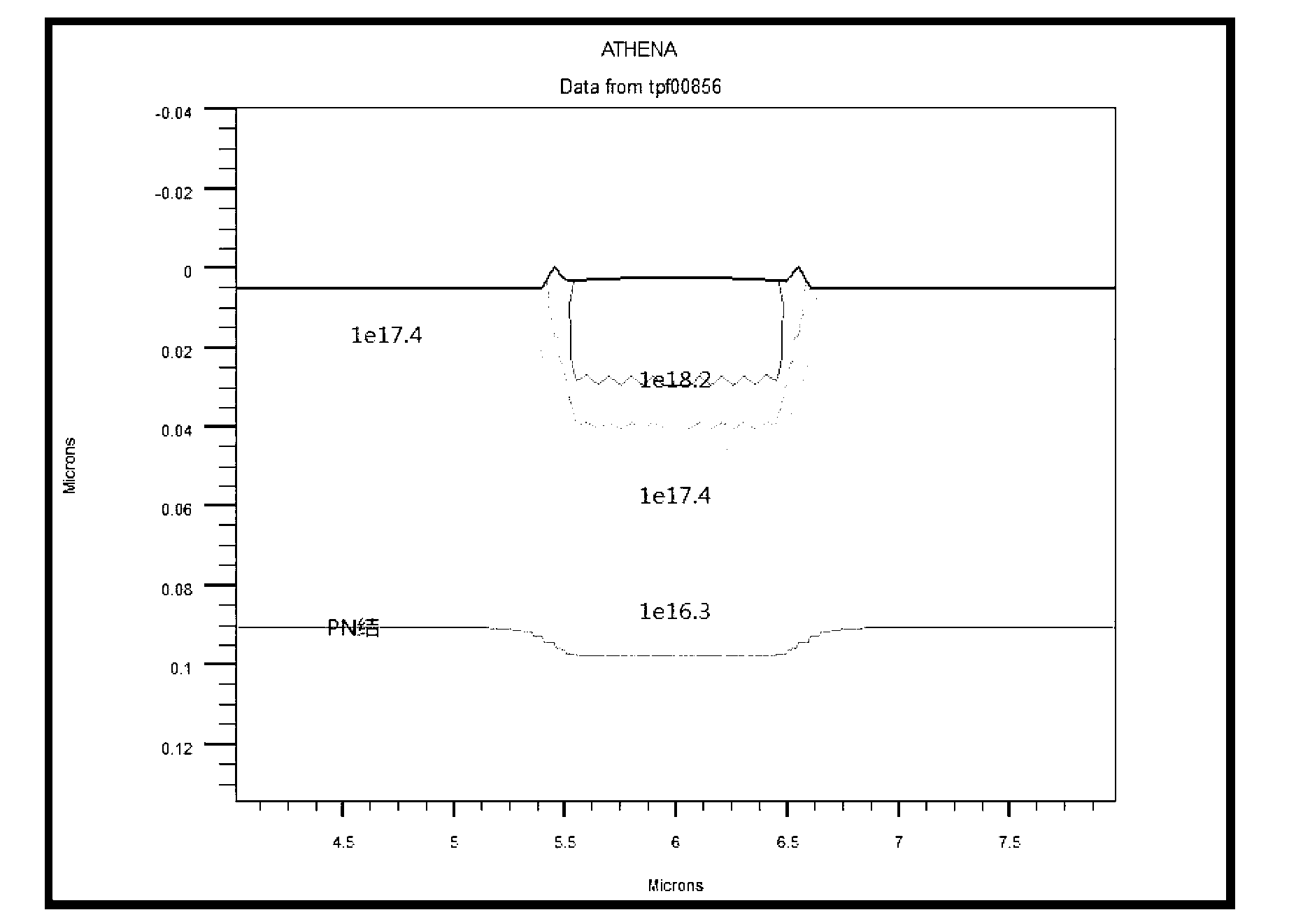

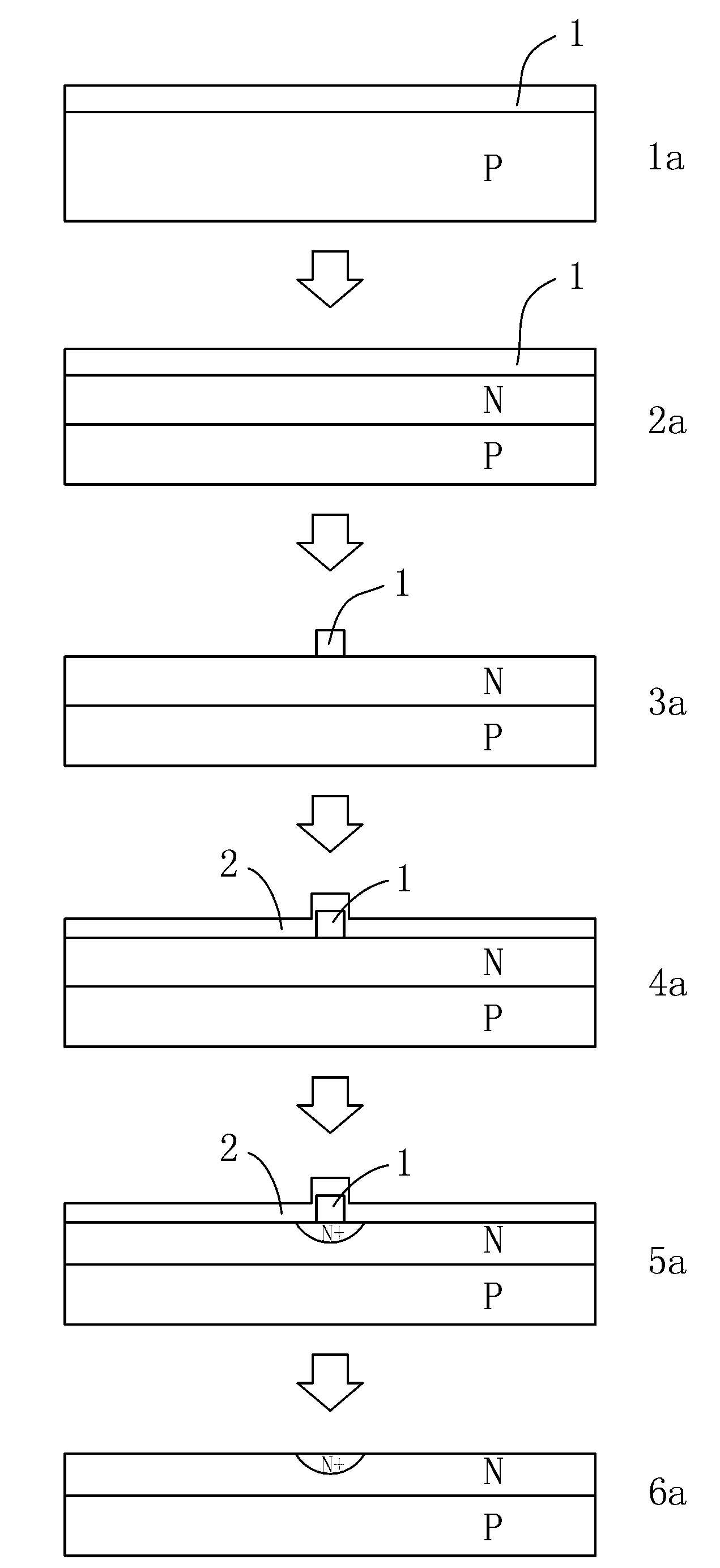

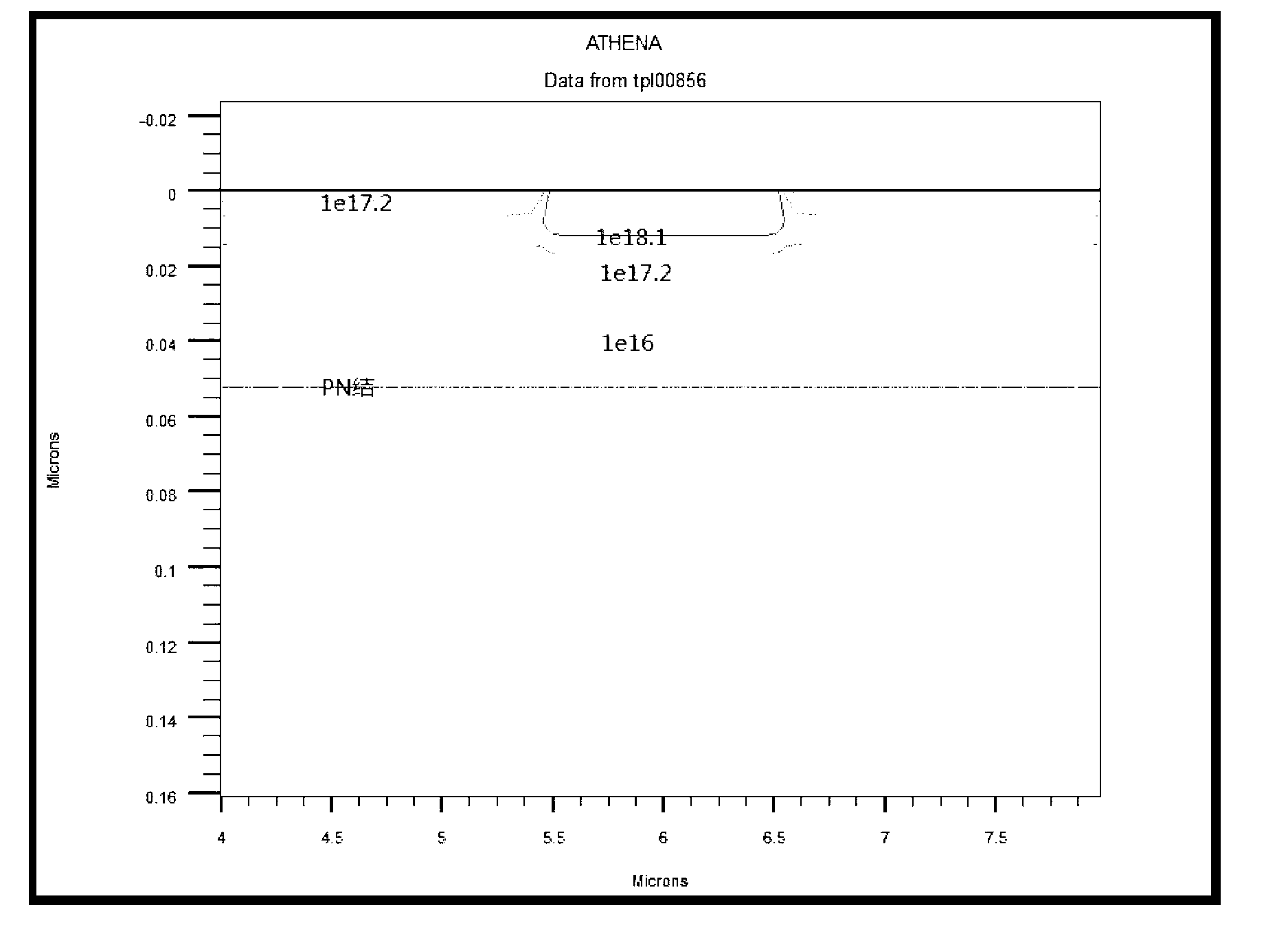

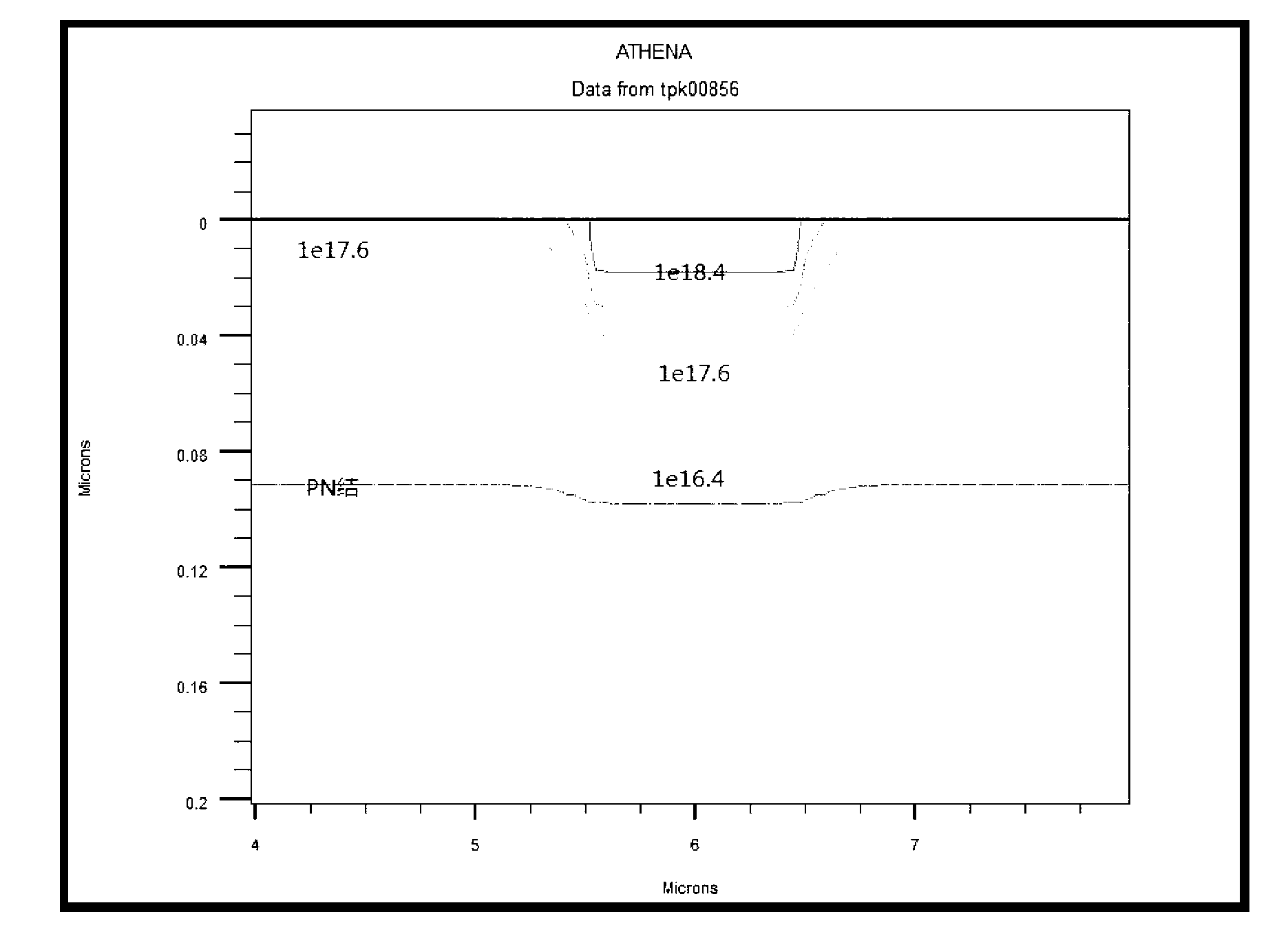

Selective doping method for solar cell based on reverse diffusion

InactiveCN103165758AReduce doping concentrationWill not polluteFinal product manufactureSemiconductor/solid-state device manufacturingAmorphous siliconOxygen

The invention relates to a selective doping method for a solar cell based on reverse diffusion. The method includes the steps: diffusing a silicon slice in an aerobic environment at a high temperature to form a PN junction and oxidizing the upper surface of the silicon slice; removing an oxidation layer outside a top electrode area of the silicon slice; depositing an intrinsic amorphous silicon layer on the upper surface of the silicon slice; diffusing the silicon slice in a wet-oxygen environment at a high temperature, reversely diffusing doping elements in a non-top electrode area into the amorphous silicon layer, diffusing doping elements in an oxidation layer of the top electrode area to the top electrode area and oxidizing the amorphous silicon layer and the non-top electrode area of the surface of the silicon slice to form an oxidation layer; and removing the oxidation layer on the surface of the silicon slice to selectively dope the solar cell based on reverse diffusion. By means of reverse diffusion, impurities in the non-top electrode area are absorbed by amorphous silicon, the doping concentration of the non-top electrode area is reduced, the top electrode area is secondarily doped, the doping concentration difference between the top electrode area and the non-top electrode area is further increased, and selective doping effects are improved.

Owner:NANTONG UNIVERSITY

Selective doping method for solar cell

InactiveCN103165760AReduce doping concentrationIncrease currentFinal product manufactureSemiconductor/solid-state device manufacturingAmorphous siliconOxygen

The invention relates to a selective doping method for a solar cell. The selective doping method includes the steps: depositing phosphorus silicon glass on the upper surface of a silicon slice; diffusing the deposited silicon slice at a high temperature and diffusing phosphorus into the silicon slice to form a PN junction; removing the phosphorus silicon glass outside a top electrode area of the upper surface of the silicon slice; depositing an intrinsic amorphous silicon layer on the upper surface of the silicon slice; diffusing the silicon slice in an oxygen-free environment at a high temperature, diffusing phosphorus not in the top electrode area of the silicon slice into the amorphous silicon layer and further diffusing phosphorus in the phosphorus silicon glass in the top electrode area to the top electrode area; and removing the amorphous silicon layer and the phosphorus silicon glass on the surface of the silicon slice to selectively dope the solar cell by reverse diffusion. By means of reverse diffusion, impurities in a non-top electrode area are absorbed by amorphous silicon, the doping concentration of the non-top electrode area is reduced, the top electrode area is secondarily doped, the doping concentration difference between the top electrode area and the non-top electrode area is further increased, and selective doping effects are improved.

Owner:NANTONG UNIVERSITY

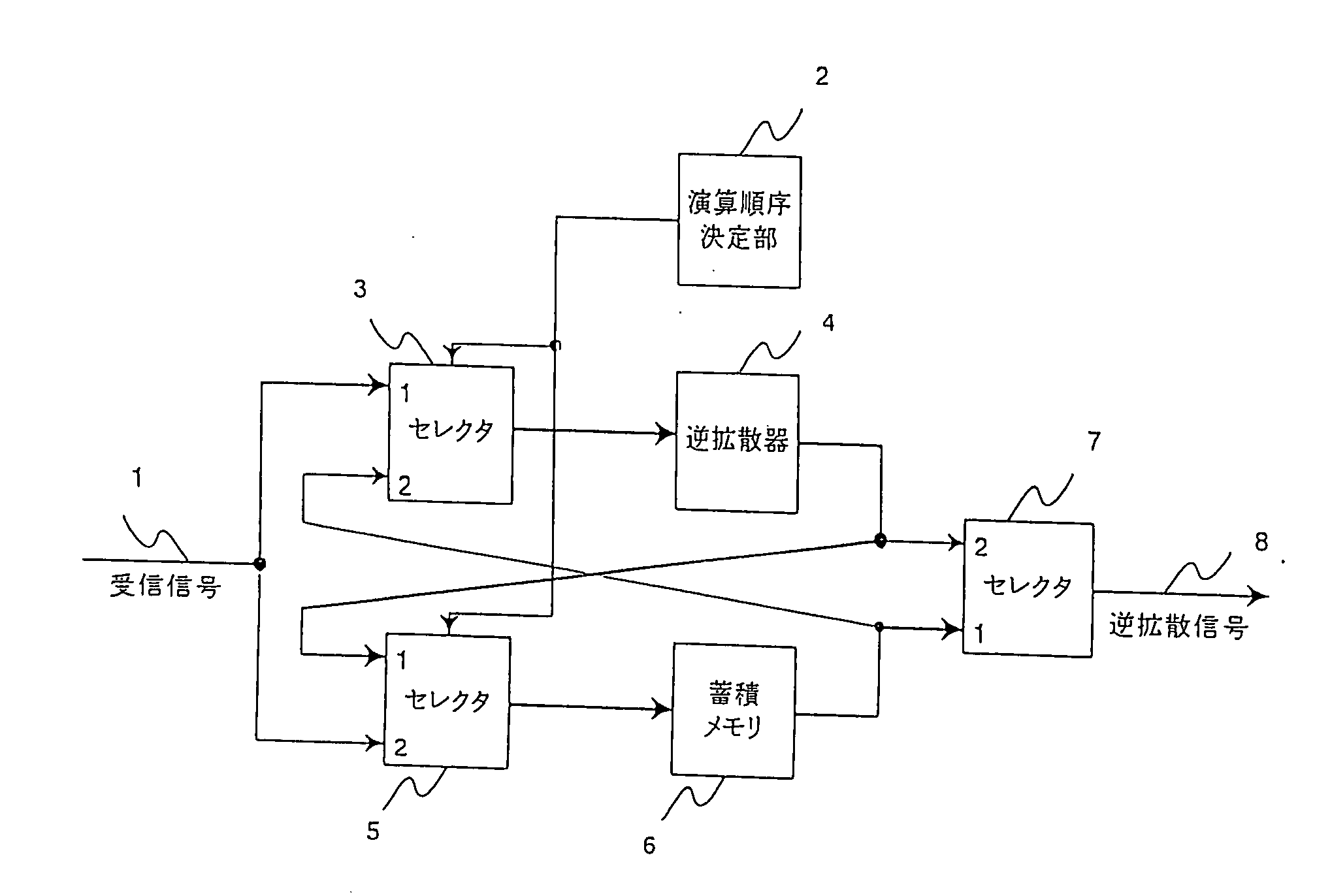

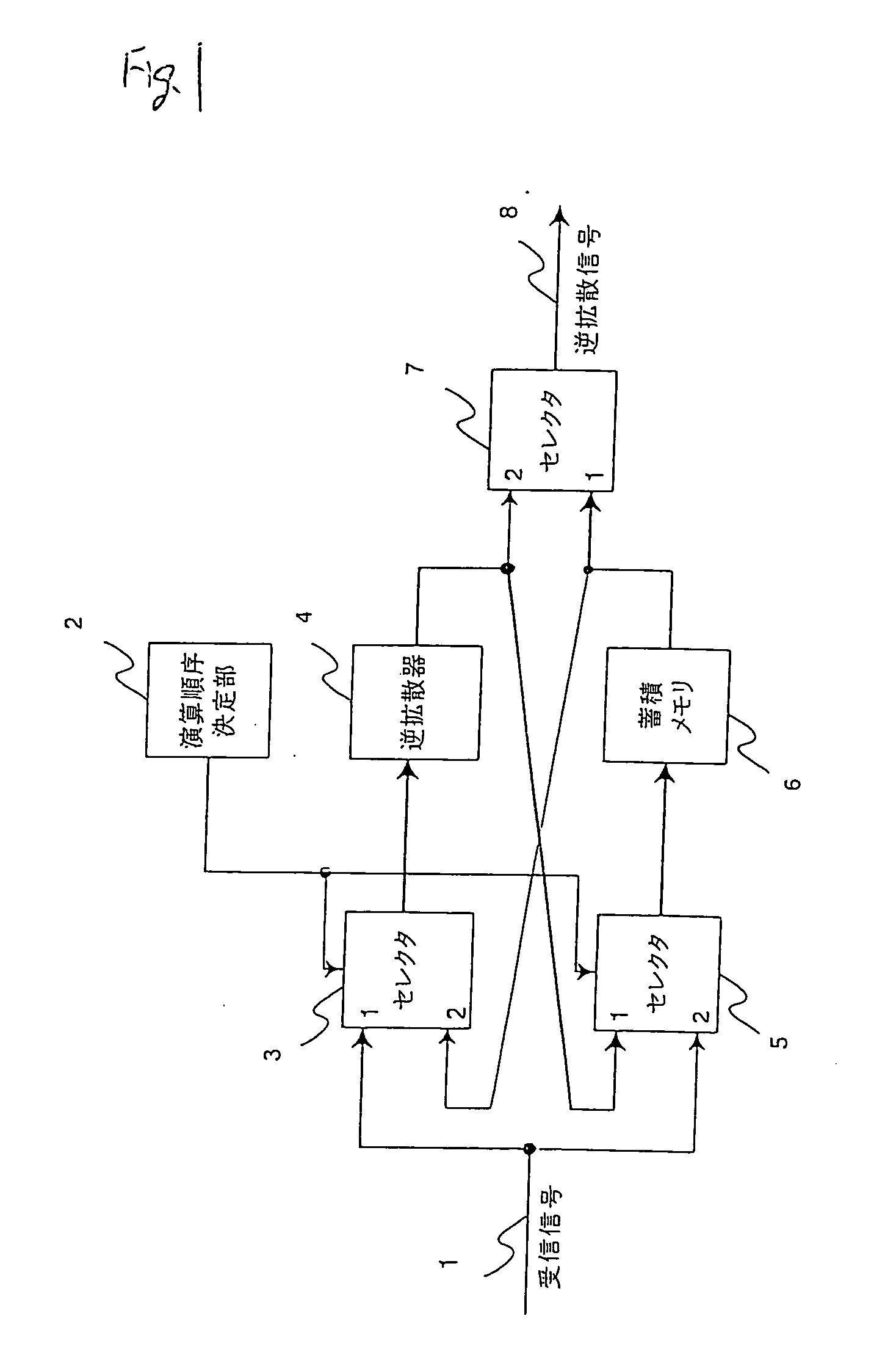

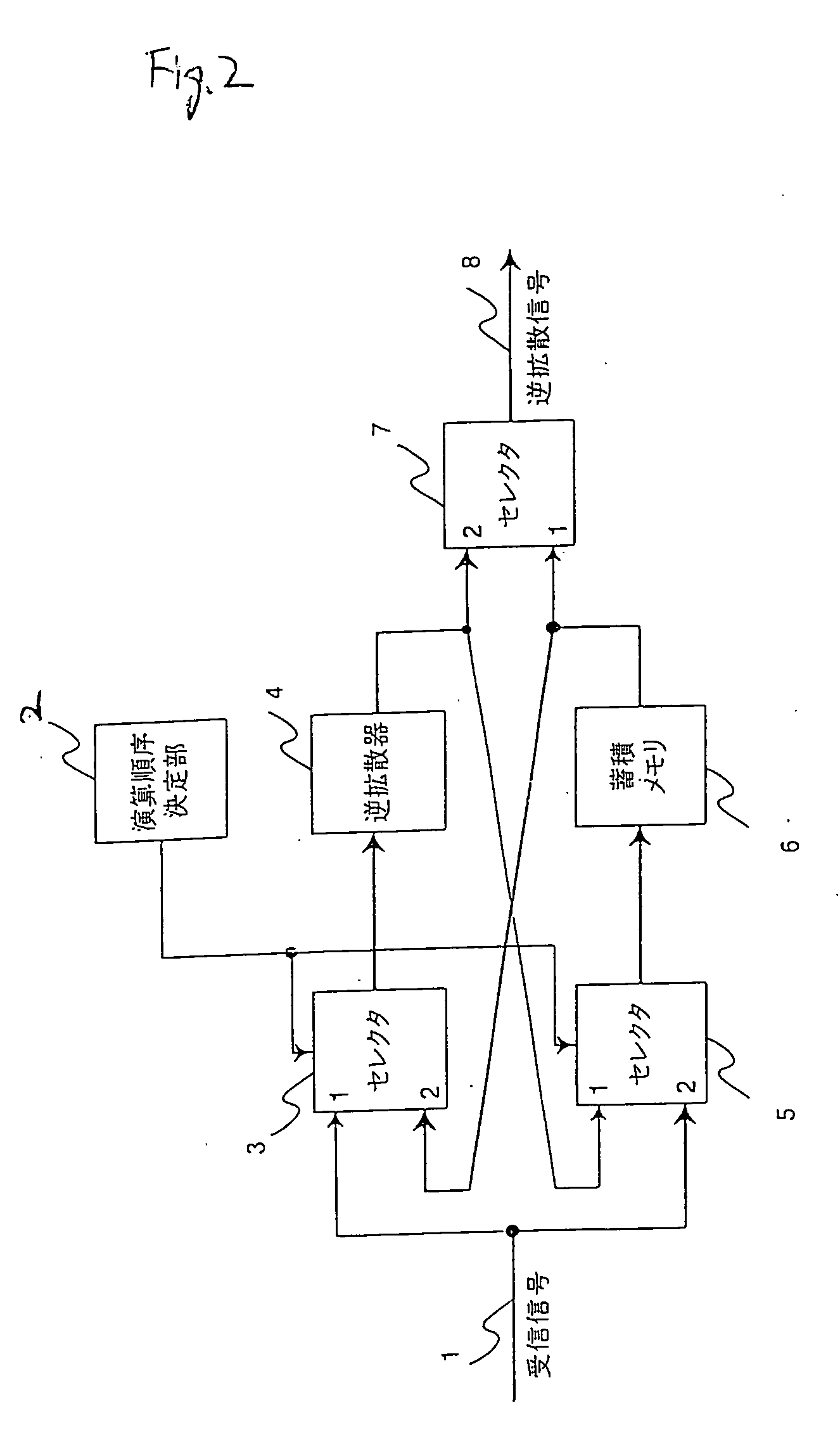

Receiver

It is an object of the invention to switch the storage of receive data which have not been diffused reversely or the storage of symbol data subjected to the reverse diffusion depending on various factors when receiving a large number of channels at the same time, thereby reducing storage memories to increase a degree of freedom of a processing timing in the reverse diffusion processing. There are provided a calculation order determining portion (2), selectors (3, 5, 7), a reverse diffusing portion (4) and a storage memory (6). When the receive data of a multichannel are to be received, the inputs of the selectors (3, 5) are switched to a 2 side by the calculation order determining portion (2) to store, in the storage memory (6), the receive data which have not been diffused reversely in place of the symbol data subjected to the reverse diffusion. Consequently, it is possible to reduce the storage memory (6) and to increase the degree of freedom of the processing timing in the reverse diffusion processing.

Owner:SOCIONEXT INC

Card type protein chip and application thereof

ActiveCN106198964AConform to simultaneous qualitativeMeets requirementsMaterial analysisPorous mediumMissed diagnosis

The invention relates to the field of biological detection, and discloses a card type protein chip and an application thereof. A protein detecting method of inverse diffusion flow guide chromatography is designed from bottom to top and based on the vertical direction, samples to be detected and reaction reagents are diffused and subjected to chromatography in porous media and finally uniformly reach reaction films to perform immune reaction, precision becoming poor and missed diagnosis probabilities caused by non-uniform reaction are reduced, the reasonably designed card type protein chip can flexibly select treating and sample adding modes of markers, additives and substrates, a functional pad is designed, extension detecting types of filter pads, marker pads and auxiliary reaction pads are increased, detection agents can be added through a result interpretation window, and a reaction system can be adjusted and can avoid interference between different reactants and reach an optimal state.

Owner:厦门信德科创生物科技有限公司

Method for reverse diffusion

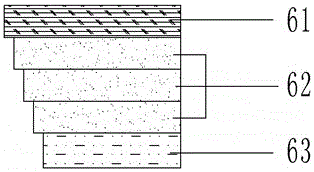

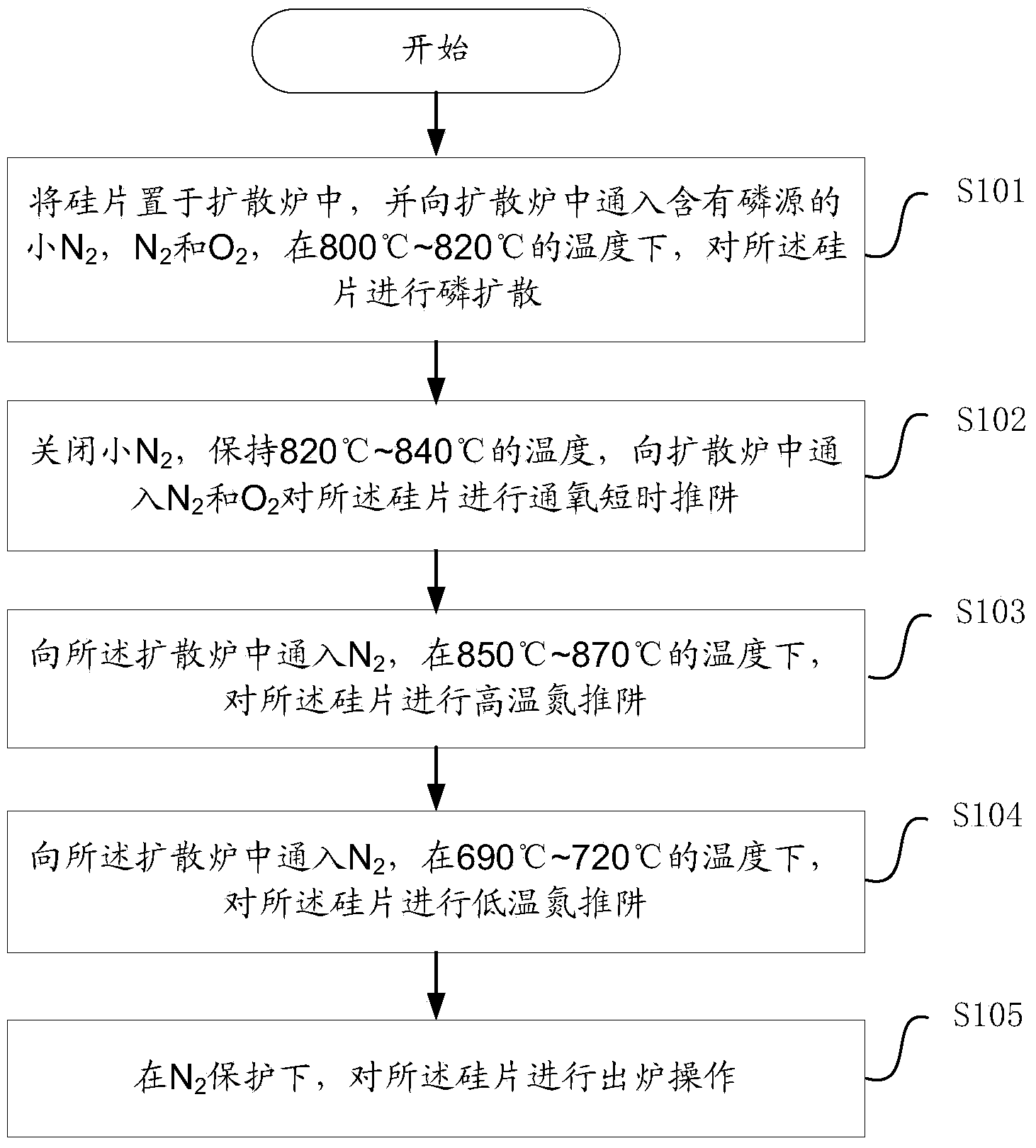

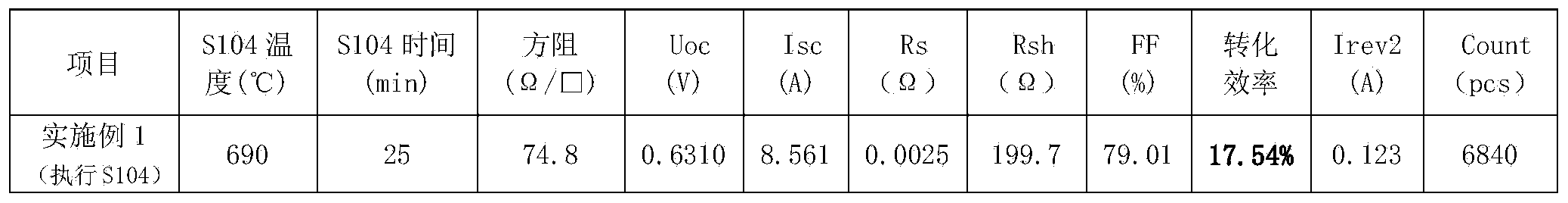

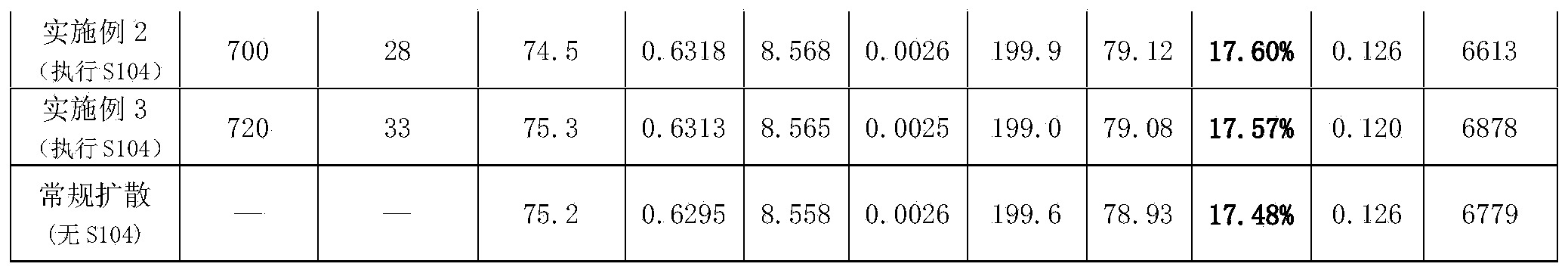

ActiveCN103715299AReduced concentration of surface impuritiesImprove photoelectric conversion efficiencyFinal product manufactureSemiconductor/solid-state device manufacturingDiffusion methodsNitrogen

The invention discloses a method for reverse diffusion. The method comprises the following steps: placing a silicon wafer to a diffusion furnace, inletting small N2 containing a phosphorus source, N2 and O2 to the diffusion furnace, and carrying out phosphorus diffusion on the silicon wafer under the temperature ranging from 800 DEC to 820 DEC; closing the small N2, keeping the temperature to be 820-840 DEC, inletting N2 and O2 to the diffusion furnace, and carrying out oxygen-inletting short-time drive-in on the silicon wafer; inletting N2 to the diffusion furnace and carrying out high-temperature nitrogen drive-in on the silicon wafer under the temperature of 850-870 DEC; inletting N2 to the diffusion furnace and carrying out reverse diffusion on the silicon wafer under the temperature of 690-720 DEC; and under the protection of the N2, taking the silicon wafer out of the furnace. With the diffusion method provided in the invention, and under the condition of the same doping amount, phosphorus atoms are allowed to have relatively-low doping density on the surface of the silicon wafer, thereby reducing surface recombination and improving an open-circuit voltage and photoelectric conversion efficiency of a solar cell.

Owner:CHINT NEW ENERGY TECH (HAINING) CO LTD

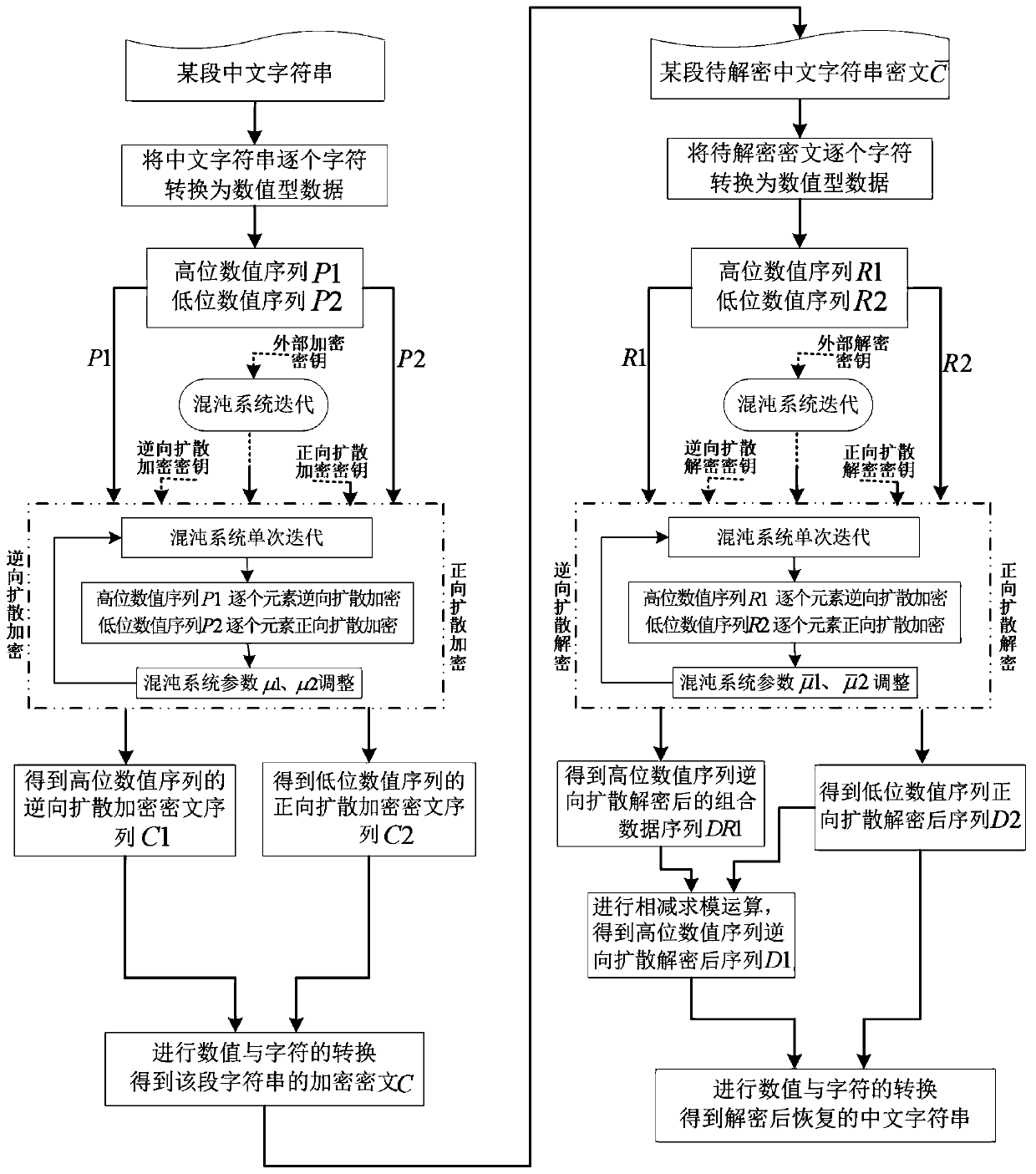

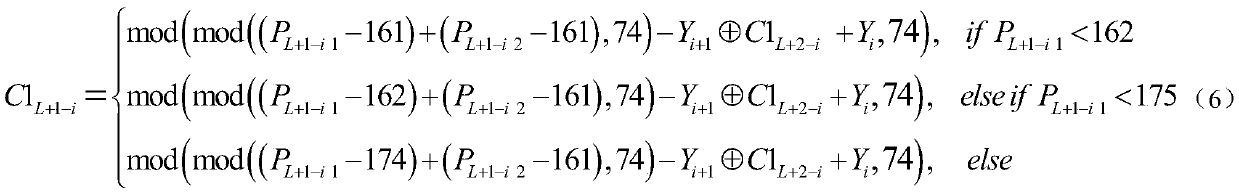

Chinese character string encryption and decryption method

ActiveCN110287713AEnsure safetyGuaranteed feasibilityDigital data protectionComputer hardwareChosen-plaintext attack

The invention discloses a Chinese character string encryption and decryption method. The method comprises the following steps of converting a certain section of Chinese character string into the high-order and low-order numerical sequences; then obtaining a reverse diffusion encrypted ciphertext sequence of the high-order numerical sequence and a forward diffusion encrypted ciphertext sequence of the low-order numerical sequence through the loop operation of the single iteration of a chaotic system, the reverse diffusion encryption of the elements of the high-order numerical sequence one by one, the forward diffusion encryption of the elements of the low-order numerical sequence one by one and the parameter adjustment series operation of the chaotic system; and finally, carrying out numerical value and character conversion on the reverse diffusion encrypted ciphertext sequence and the forward diffusion encrypted ciphertext sequence to obtain an encrypted ciphertext of the section of Chinese character string, and decrypting the ciphertext through a similar method to restore the original Chinese character string. According to the method, the Chinese character string is encrypted and decrypted by utilizing the password characteristic of the chaotic signal, so that the known / selected plaintext attack resistance and the ciphertext-only attack resistance are good, and the encryption and decryption safety of the Chinese character string is ensured.

Owner:NANTONG UNIVERSITY

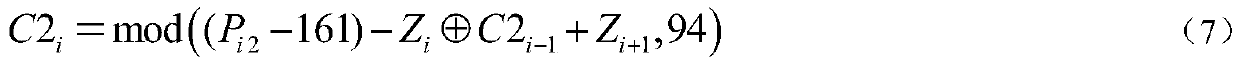

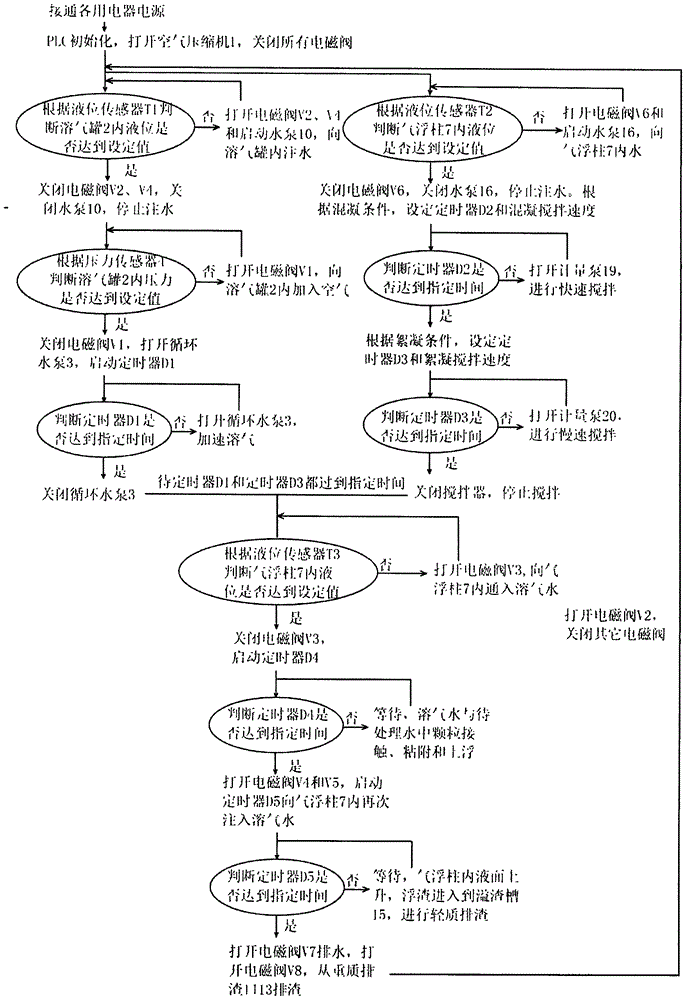

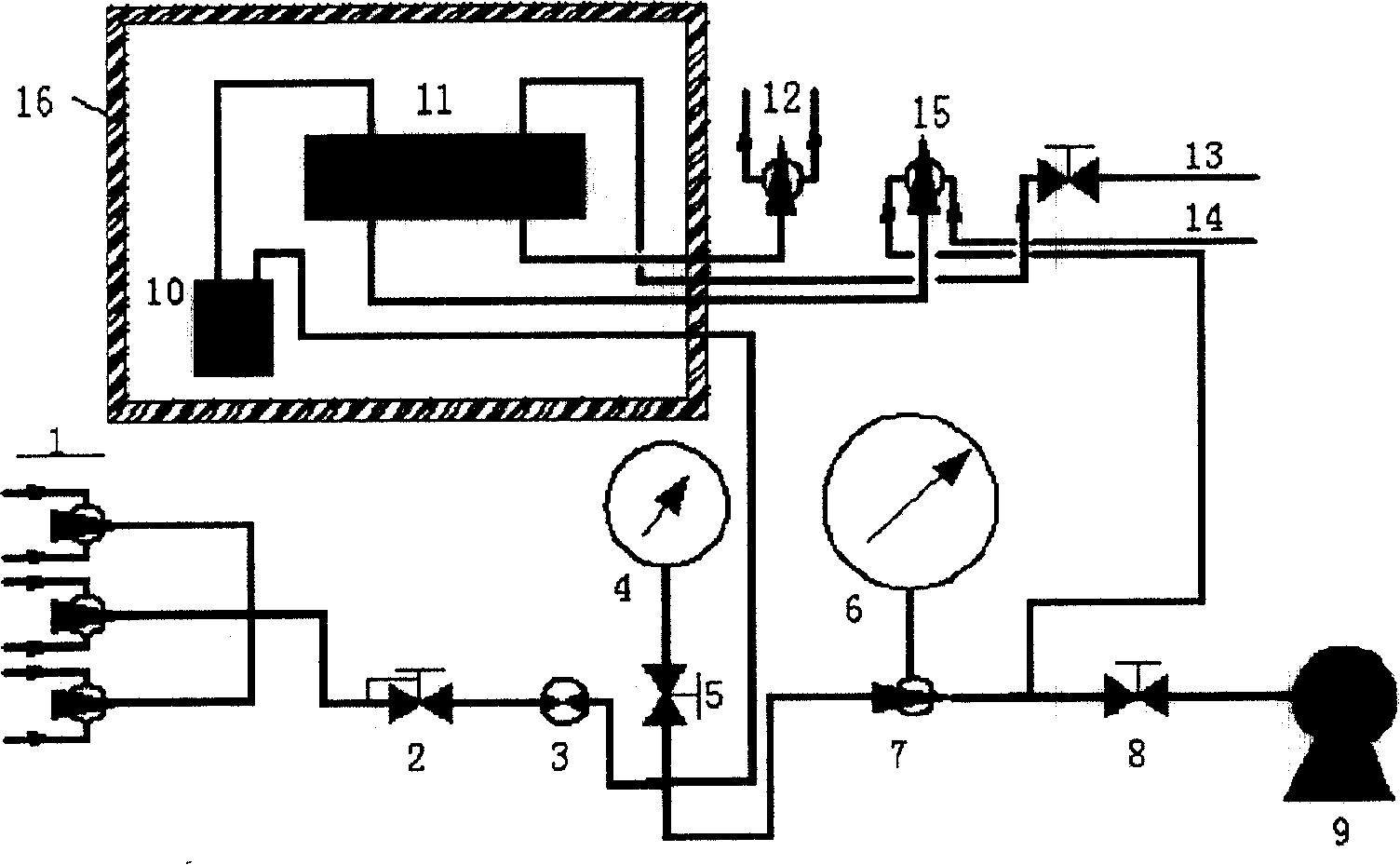

Intermittent air flotation water-purifying device

ActiveCN106517401AFacilitates reverse diffusion mixingIncrease contact timeWater treatment parameter controlWater/sewage treatment by flocculation/precipitationAutomatic controlSolenoid valve

The invention provides an intermittent air flotation water-purifying device used for treating suspended materials in water. The intermittent air flotation water-purifying device is composed of an air compressor, an air-dissolving tank, a circulating water pump, a pressure sensor, a nozzle, an air releaser, an air floating column, a stirrer, a stirring paddle, a water pump, a liquid level sensor, a solenoid valve, a metering pump, a coagulant tank, a flocculating agent tank and an automatic control device. The stirring and the air floatation are integrated, so that the floor space of the device is reduced; the weak rotational flow formed in the air floating column can promote the reverse diffusion mixing of the air-dissolving water and to-be-treated water, so that the contact time of air bubbles and grains is prolonged, and the treating efficiency is increased; and the intermittent air flotation water-purifying device has the characteristics of high adaptability, compact structure, easiness in maintenance, excellent treatment effect, and the like.

Owner:TIANJIN UNIV OF SCI & TECH

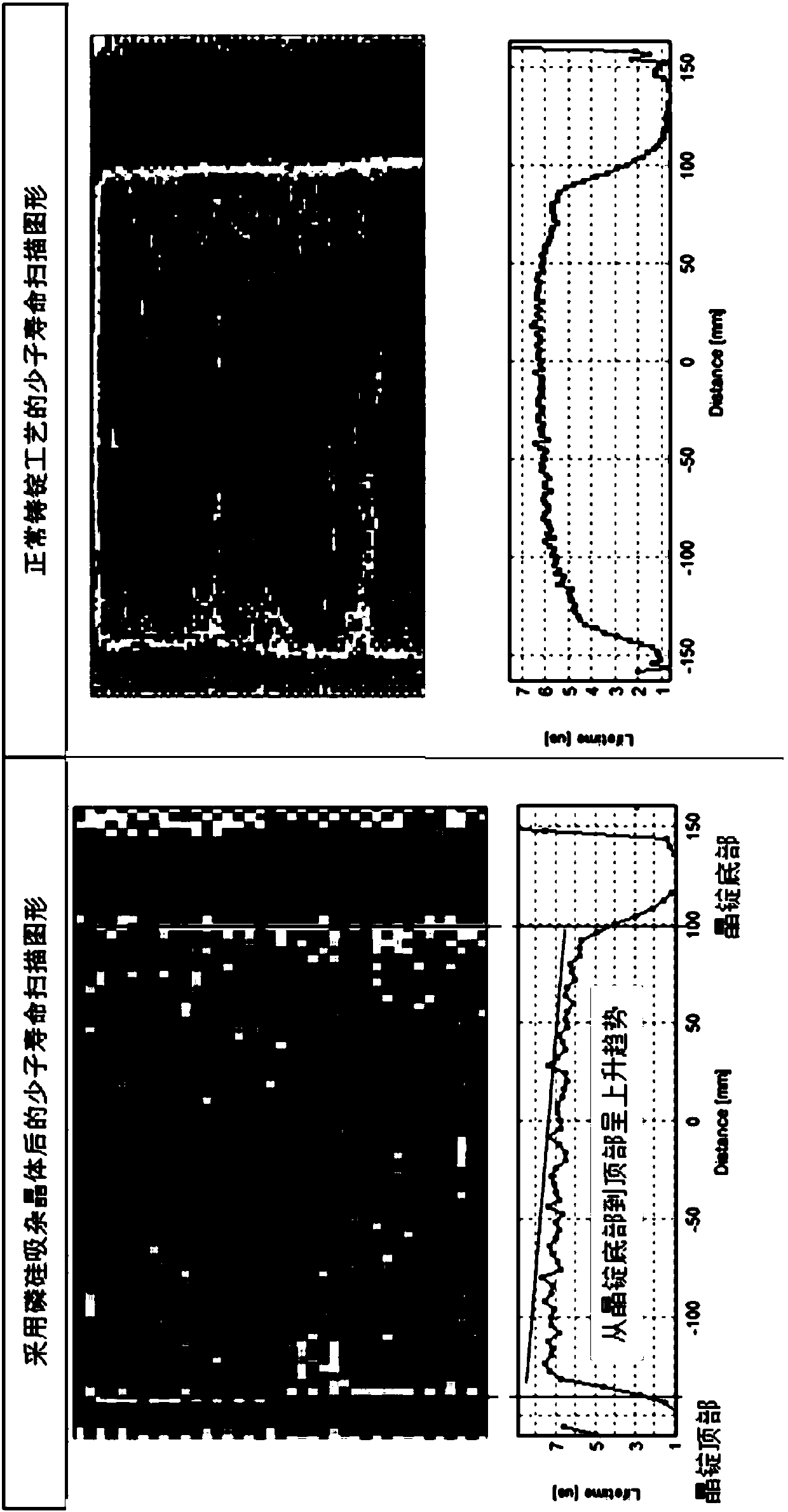

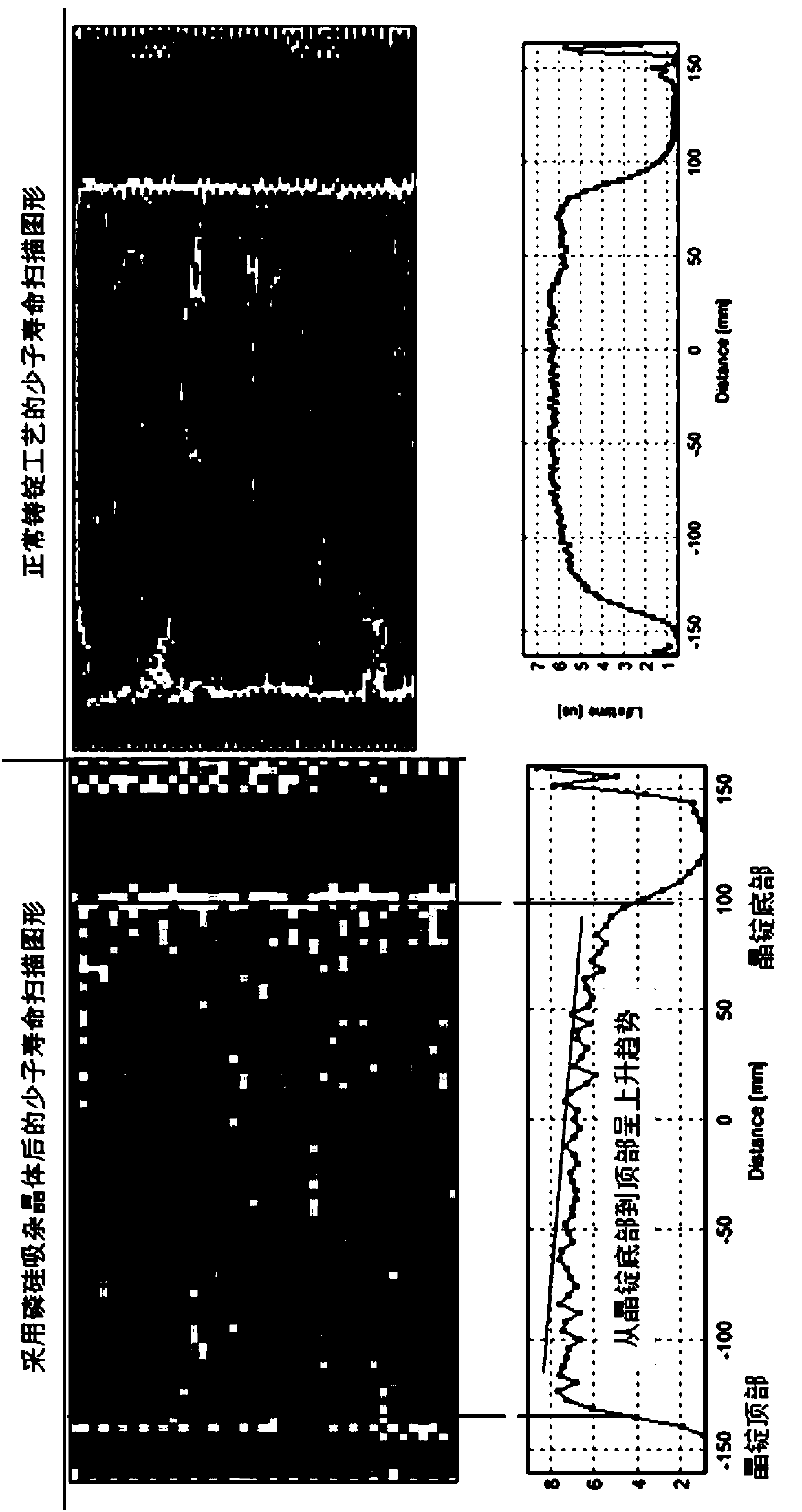

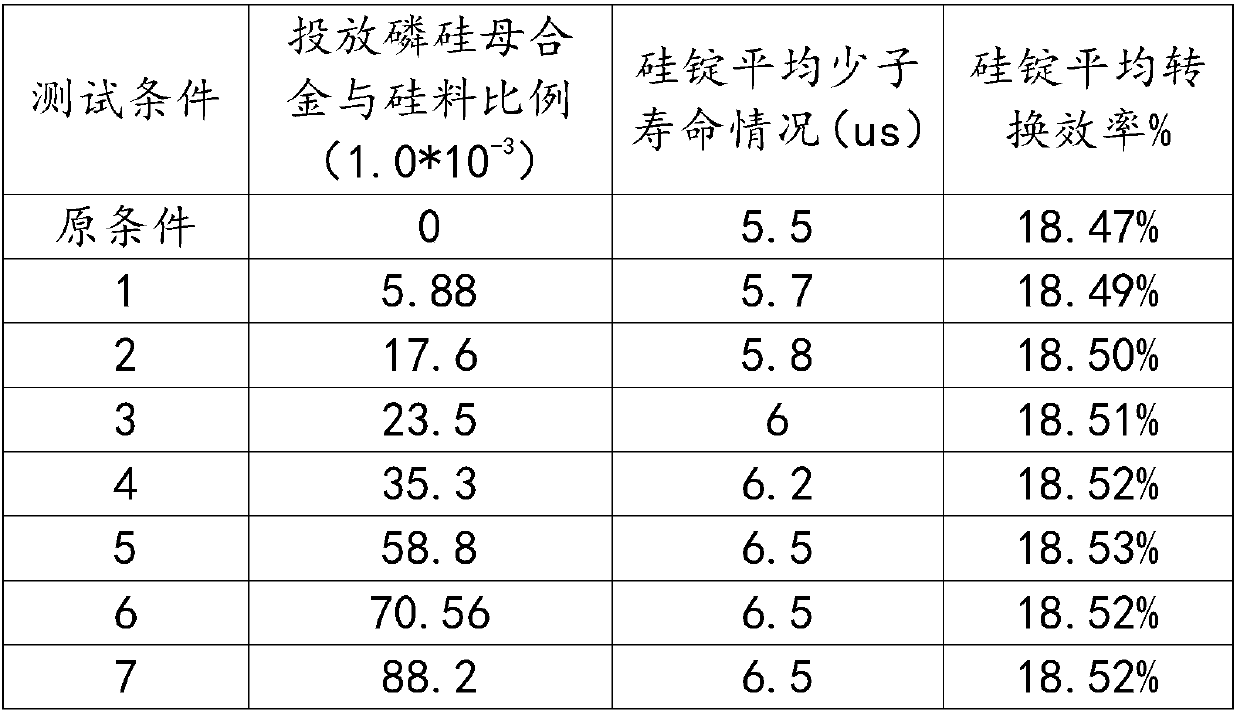

Method for increasing minority carrier lifetime of top of silicon ingot by gettering

InactiveCN107587192AImprove life expectancyReduce solid phase diffusionPolycrystalline material growthDiffusion/dopingHigh concentrationMetal impurities

The invention discloses a method for increasing the minority carrier lifetime of the top of a silicon ingot by gettering. The ingot is cast by utilizing a polycrystal semi-fusion technology, and argonis used as a protection gas in the whole ingot casting process. At the growth last period of the ingot crystal growth, namely when the height of a residual silicon liquid is 5-10 mm, gettering crystals are added into the residual silicon liquid, the gettering crystals are completely melted and are uniformly mixed with the silicon liquid, and then the ingot grows again. The minority carrier lifetime of the top of the silicon ingot is improved by 0.5-1.0 microsecond through the use of a gettering principle of high-concentration phosphorus doping diffusion, and in particular, the solid concentration is increased in a region of heavy phosphorus diffusion due to the influence of Fermi level. Meanwhile extremely serious dislocation is formed by heavy phosphorus doping in the region, and gathering and gettering are performed on metal impurities at the top of the ingot at the dislocation grain boundary. At the same time, rapid growth is completed, low-temperature annealing is carried out, andsolid-phase reverse diffusion in the annealing process is reduced, and finally the minority carrier lifetime of the silicon ingot is improved, so that the targeted high-lifetime silicon ingot is obtained.

Owner:宁夏申和新材料科技有限公司

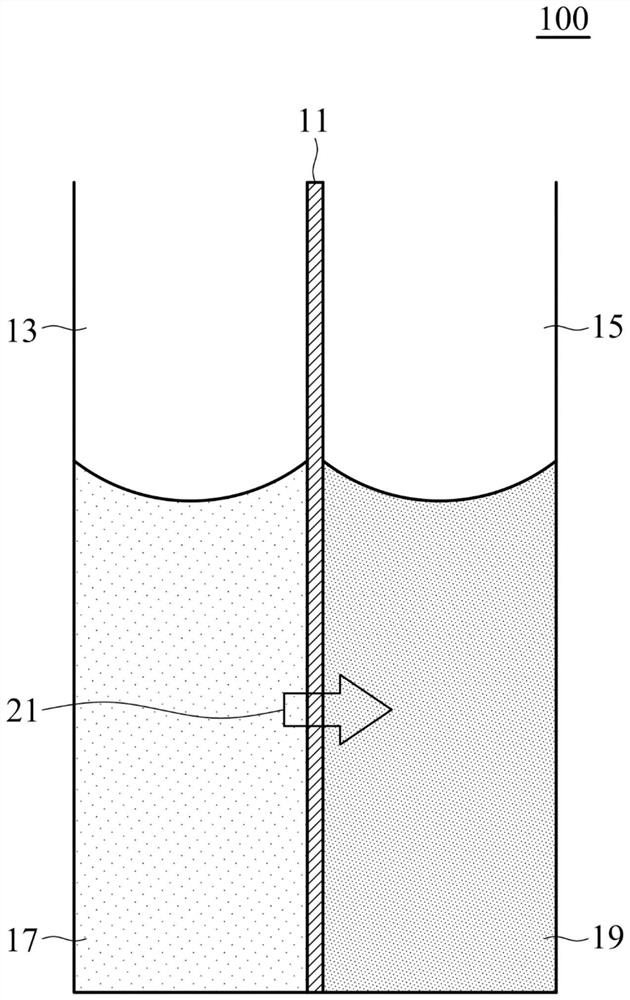

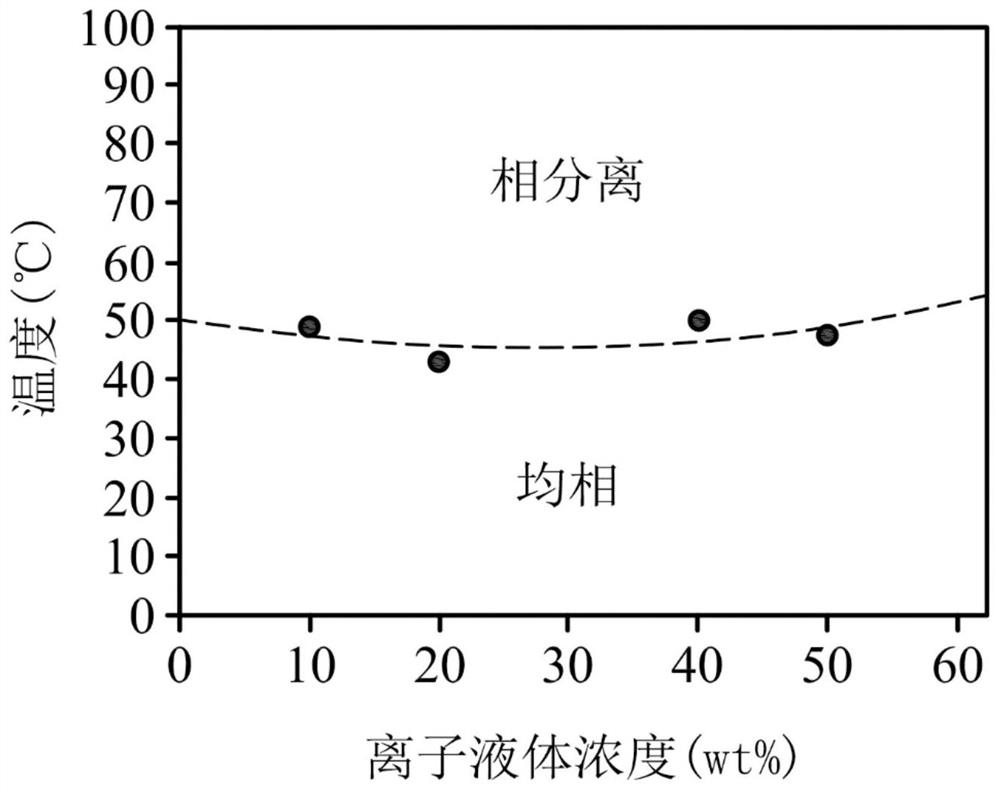

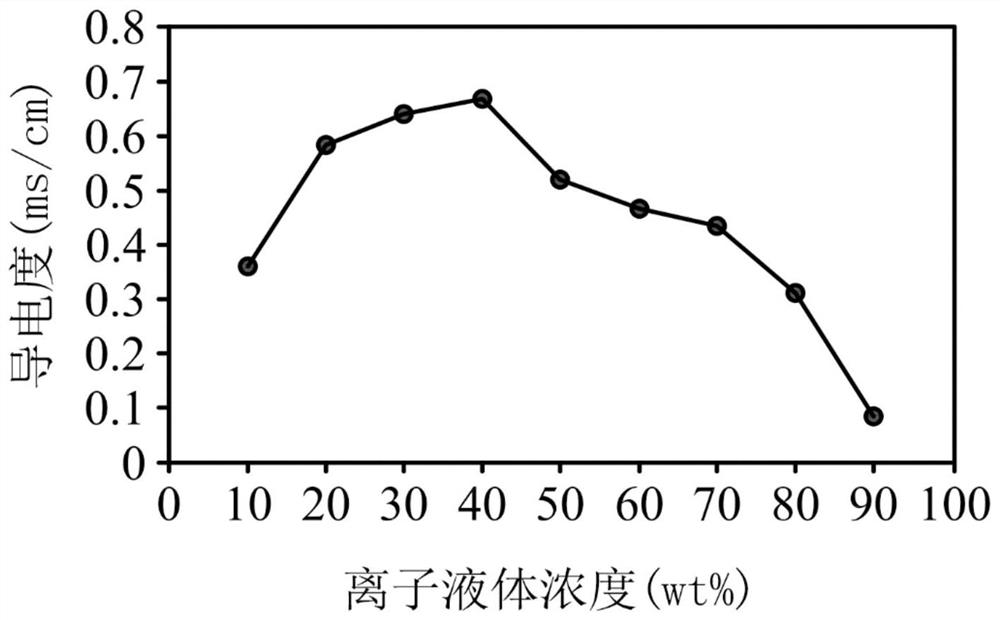

Ionic liquid and forward osmosis process using same

ActiveCN113121371ALow backdiffusionBackdiffusion reductionSemi-permeable membranesGeneral water supply conservationHigh fluxPhysical chemistry

The present disclosure provides an ionic liquid. The ionic liquid has a structure as shown in a formula (I): ABn, wherein n is 1 or 2; m is 0 or an integer among 1 to 7; R1 and R2 are independently methyl or ethyl; k is an integer from 3 to 8; i is independently 1, 2 or 3; and j is 5, 6, or 7. The ionic liquid has the advantages of high molecular weight, high hydrophilicity, biocompatibility, low biotoxicity, low preparation cost, high environmental friendliness and the like. The invention also provides a forward osmosis process using the ionic liquid. The forward osmosis procedure is to desalinate a brine in a forward osmosis (FO) mode with an extract containing an ionic liquid. The forward osmosis procedure has the advantages of high flux, low energy consumption, low film blocking rate, low solute reverse diffusion and the like.

Owner:IND TECH RES INST

Reverse diffusion digital halftone quantization

An improved digital halftoning method that uses an input image's global gray levels to determine the local gray levels of a monochrome output image. Input multi-bit pixels grouped into two-pixel-by-two-pixel local subcells are variously aggregated into one or more larger supercells. The size of said supercell(s) is related to and limited by the size of the global input bitmap. A final monochrome gray level is derived from said supercell(s) and distributed within contained subcells. Subcell gray levels are expressed as interim whole monochrome pixels and gray level remainders. A comparison is made of the final supercell and the summed interim subcell monochrome gray levels. An ordering of the remainders is used for assignment of additional monochrome pixels, if necessary, to yield final subcell monochrome gray levels. Gray level rounding errors thus are quantized by reverse diffusion until a monochrome gray level for each of the global image's two-pixel-by-two-pixel local subcells is derived.

Owner:XYLON LLC

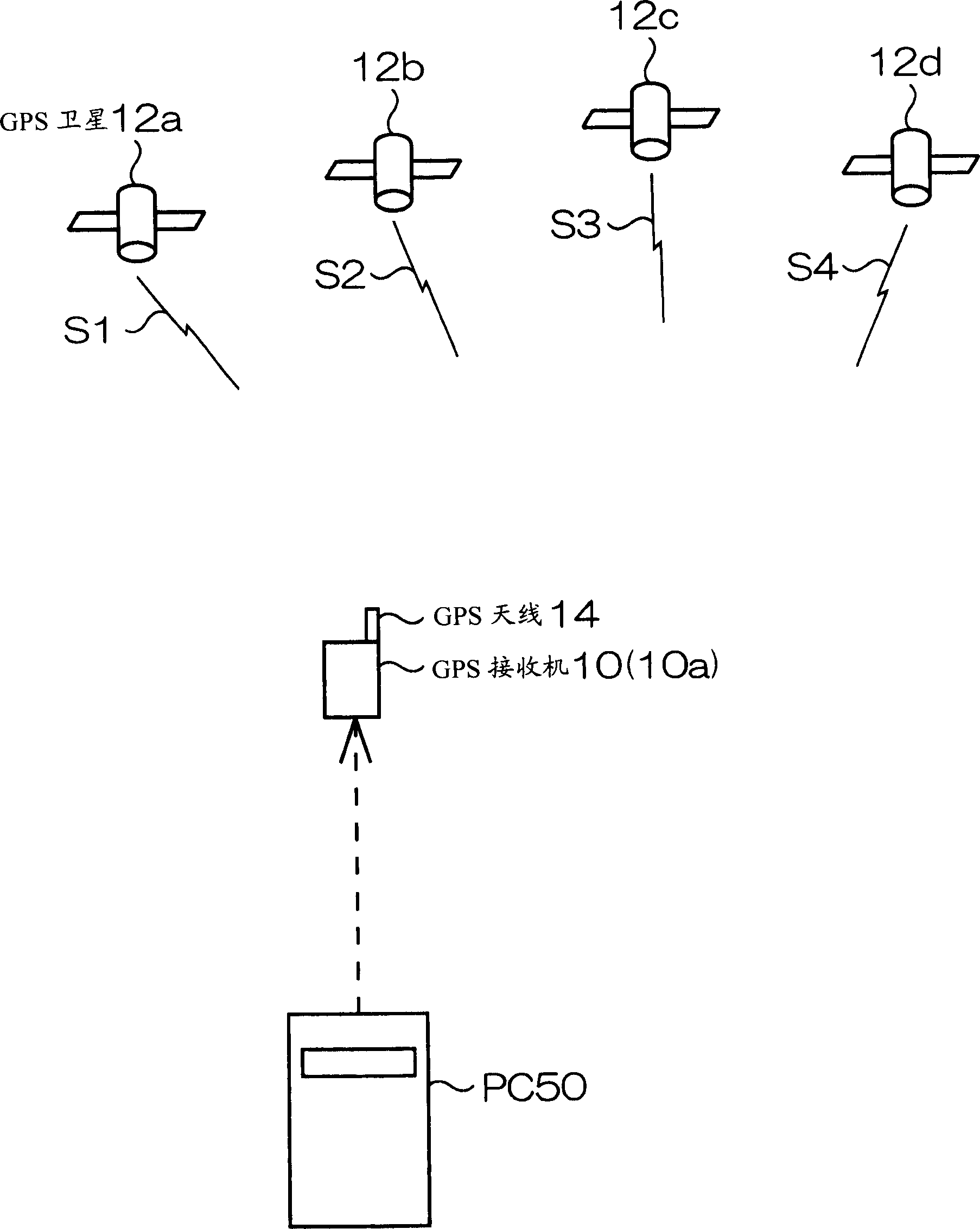

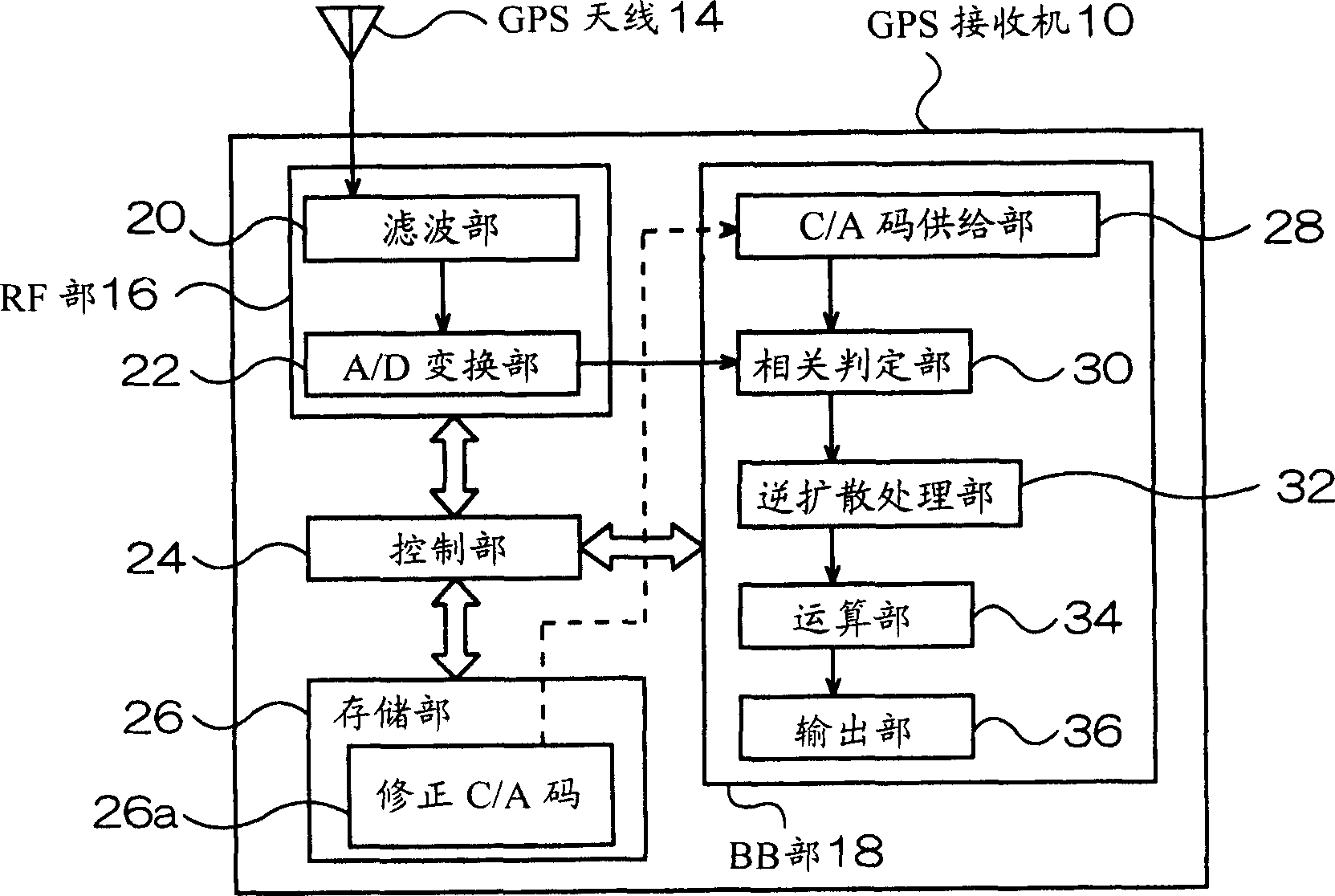

Receiver, apparatus for generating despread code, and method of generating despread code

The invention discloses a receiving device, a device for generating a modified despreading code and a method for generating the modified despreading code generated by predicting the deformation of the transmitted spreading code in a receiver circuit to perform despreading processing. Wherein, the receiving device (10) includes: a signal receiving device, used to receive the transmitted signal, and obtain the received signal; a filter device, used to remove high-frequency components from the received signal; A / D conversion device, used to convert the filter device The output signal is to generate a digital signal; the inverse diffusion processing device is used to multiply the digital signal and the inverse diffusion symbol to perform inverse diffusion processing; and the inverse diffusion symbol supply device is used to generate the modified inverse diffusion symbol generated based on the deformed diffusion symbol Despread codes are supplied to the despread processing device, wherein the spread codes correspond to the positions where the PSK-modulated signal based on the spread codes included in the received signal is significantly deformed, that is, the positions where the diffuse codes are deformed.

Owner:SEIKO EPSON CORP

Method of improving gas separation film penetration instrument

InactiveCN100398182CGuaranteed accuracyEasy to operateDispersed particle separationProduct gasImproved method

A method for improving the osmosis apparatus with gas separating membrane features that when a constant-pressure volume-varying method is used to measure the gas osmosis of membrane, a vacuumizing method is used at up-stream of membrane pool for exhausting the gas from pipeline and membrane and a capillary soap membrane flowmeter isolated from air is used at the down-stream for measuring the osmotic speed of gas, so effectively preventing the reverse diffusion of gas.

Owner:DALIAN UNIV OF TECH

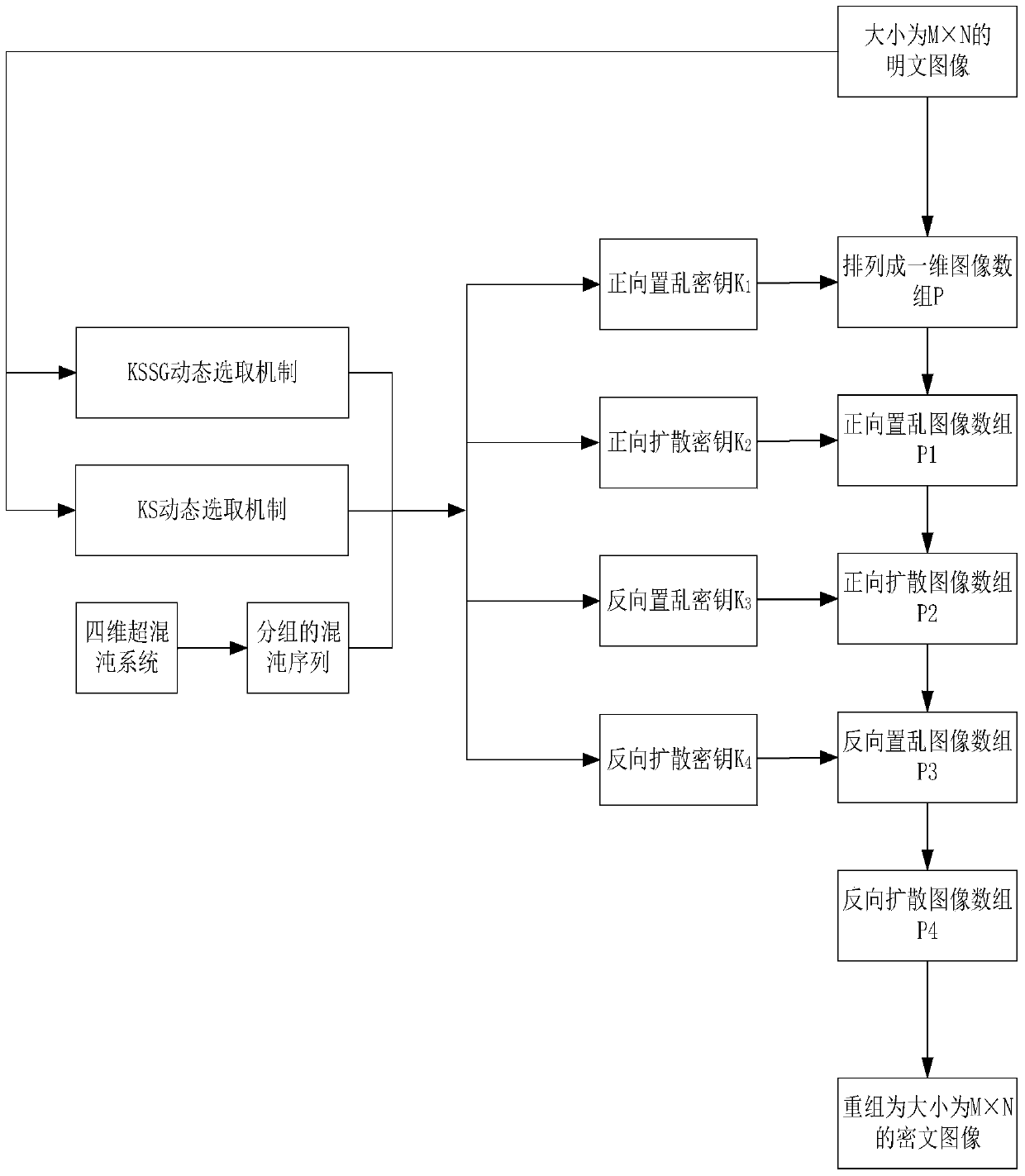

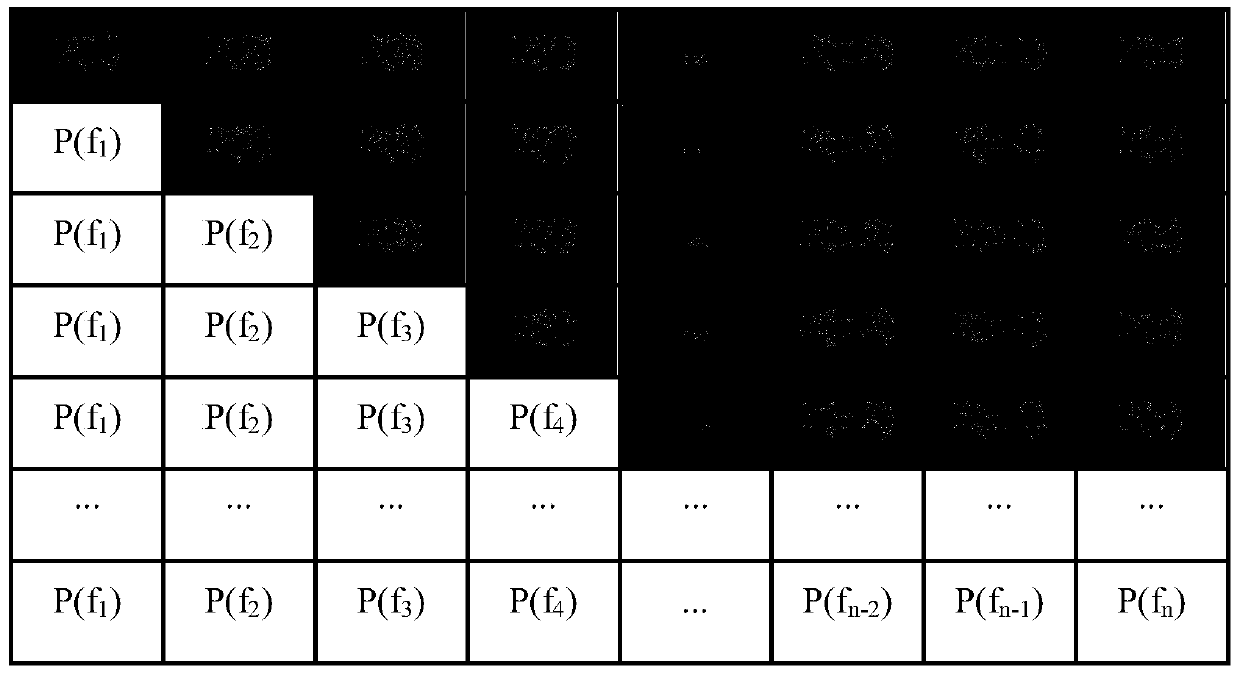

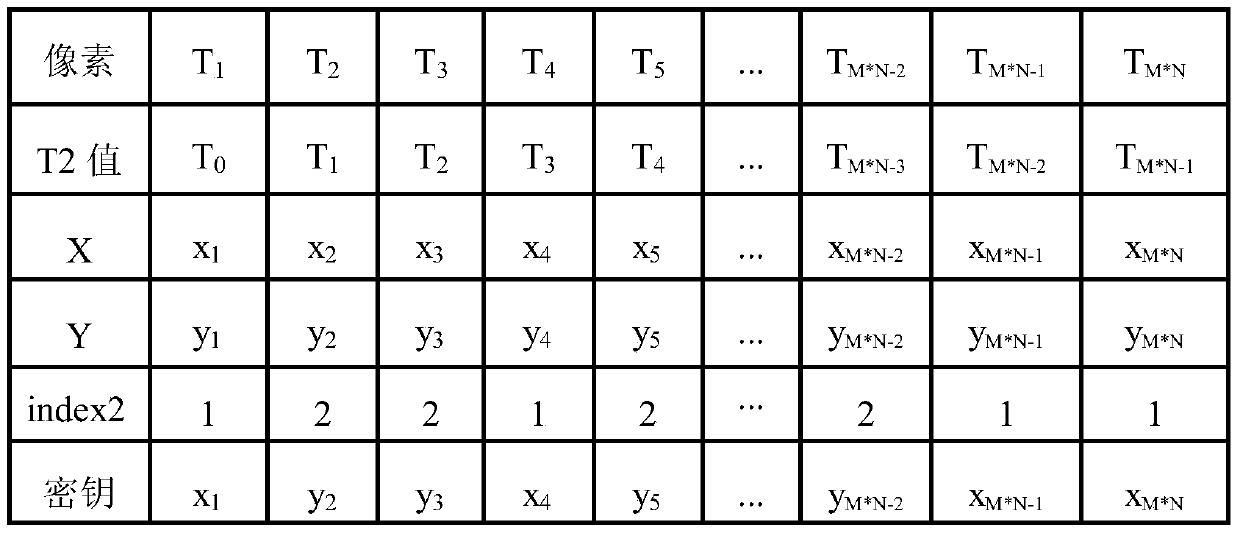

Image Encryption Method Based on Dynamic Key Selection of Hyperchaotic System

The invention relates to an image encryption method based on hyperchaotic system key dynamic selection, which mainly includes the following steps: arranging the original plaintext images into an image array P, and then using the hyperchaotic system to generate chaotic sequences and grouping them; combining the plaintext-dependent KSSG and KS dynamic selection mechanism to generate forward scrambling key K1, and perform forward scrambling on P to obtain P1; combine KSSG and KS mechanism to generate forward diffusion key K2, and perform forward diffusion on P1 to obtain P2; combine KSSG and KS The dynamic selection mechanism generates reverse scrambling key K3, reverse scrambles P2 to obtain P3; uses KSSG and KS dynamic selection mechanism to generate reverse diffusion key K4, performs reverse diffusion on P3 to obtain P4, and reorganizes P4 That is, the final ciphertext image is obtained. The above method increases the key space, makes the security, the encryption effect and the key sensitivity higher, the anti-attack ability is stronger, and it is easier to realize by hardware.

Owner:HENAN UNIVERSITY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com