Patents

Literature

52results about How to "The film making method is simple" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Preparation method of metal-organic framework material/polymer composite proton exchange membrane

ActiveCN105789668AStrong penetrating powerImprove performanceRegenerative fuel cellsVanadium redox batteryMetal-organic framework

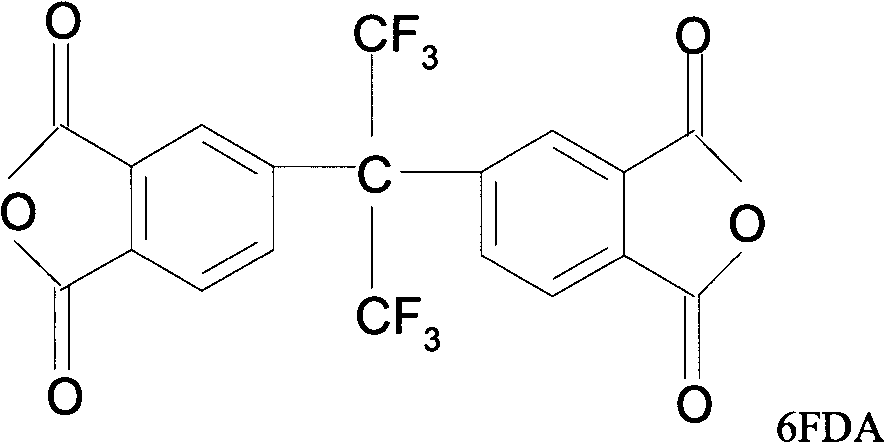

The invention relates to a preparation method of a metal-organic framework material / polymer composite proton exchange membrane. The method is characterized by comprising the following steps: dissolving a polymer matrix and a certain amount of metal-organic framework material with an organic solvent and carrying out ultrasonic dispersion to form a uniform membrane liquid; coating the flat and smooth surface of a glass plate with the obtained membrane liquid, and then removing the organic solvent to obtain a composite membrane; and carrying out vacuum drying on the composite membrane for 24 hours to prepare the composite proton exchange membrane for an all-vanadium redox flow battery. The composite proton exchange membrane is smooth in surface; the internal structure of the membrane is regular; the membrane is uniform in thickness and free of a defect; and the thickness is 10-300 microns. The composite proton exchange membrane provided by the invention has excellent vanadium ion permeation blocking ability, keeps excellent proton transfer performance, overcomes the defect of relatively high vanadium ion permeability of an existing all-vanadium redox flow battery membrane, and has the advantages of being simple in preparation process, high in proton transmittance, excellent in vanadium blocking property, excellent in oxidative resistance, easy to industrially amplify and the like.

Owner:INST OF CHEM CHINESE ACAD OF SCI

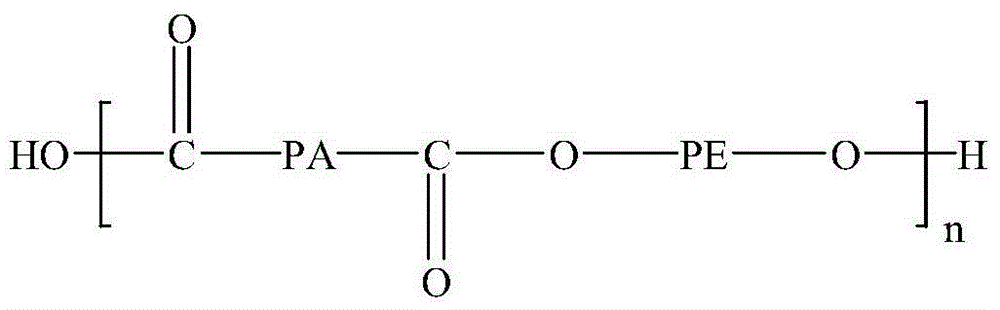

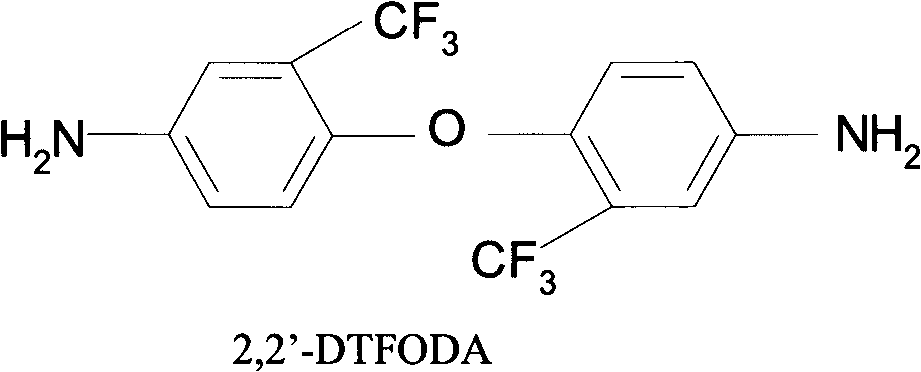

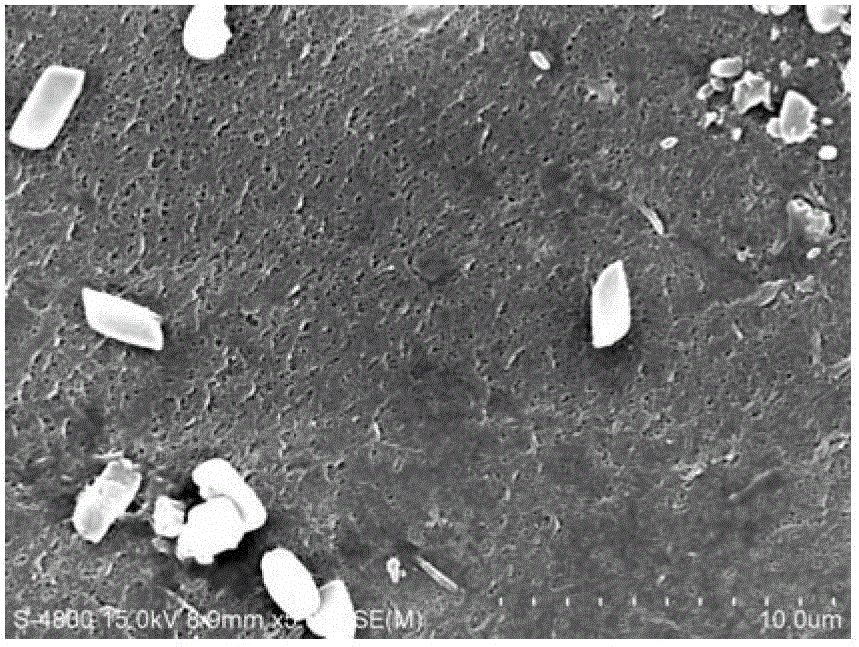

Novel charged polyamide composite nanofiltration membrane and preparation method thereof

ActiveCN103990392AInhibition of reunion behaviorGood dispersionSemi-permeable membranesSilica nanoparticlesUltrafiltration

The invention discloses a novel charged polyamide composite nanofiltration membrane and a preparation method thereof. The method comprises the following steps: grafting charged polymer onto the surface of the silicon dioxide nanoparticles by active / controllable free-radical polymerization to obtain charged-polymer-modified silicon dioxide nanoparticles; dispersing the charged-polymer-modified silicon dioxide nanoparticles and amine monomer in water to prepare a water-phase amine monomer solution; dissolving acyl chloride monomer in an organic solvent to prepare an oil-phase acyl chloride monomer solution; and immersing the polymer ultrafiltration membrane into the water-phase amine monomer solution, and immersing into the oil-phase acyl chloride monomer solution to obtain the novel polyamide composite nanofiltration membrane of which the separating layer contains the charged-polymer-modified silicon dioxide nanoparticles. The method is simple and easy to implement, has the advantages of low production cost and obvious, stable and permanent modification effect, and has favorable industrialization application prospects.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

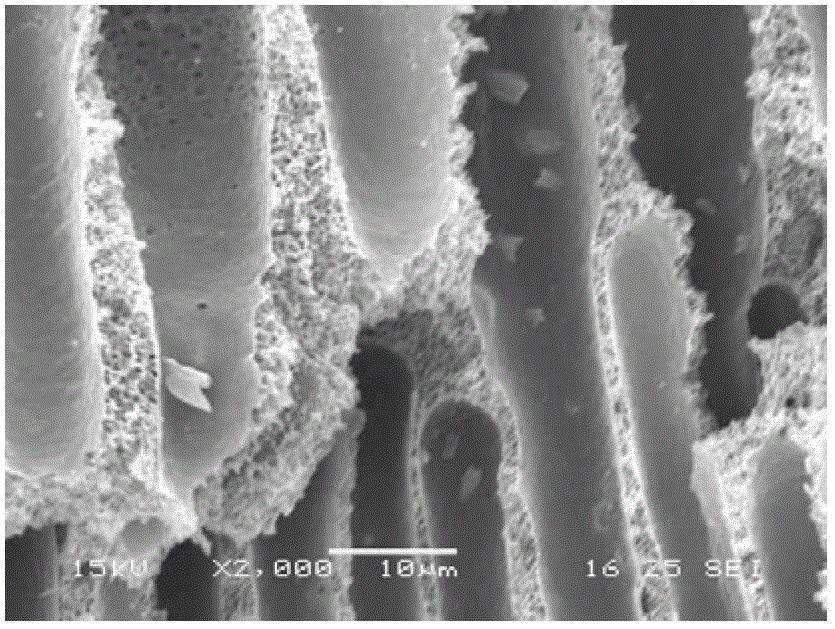

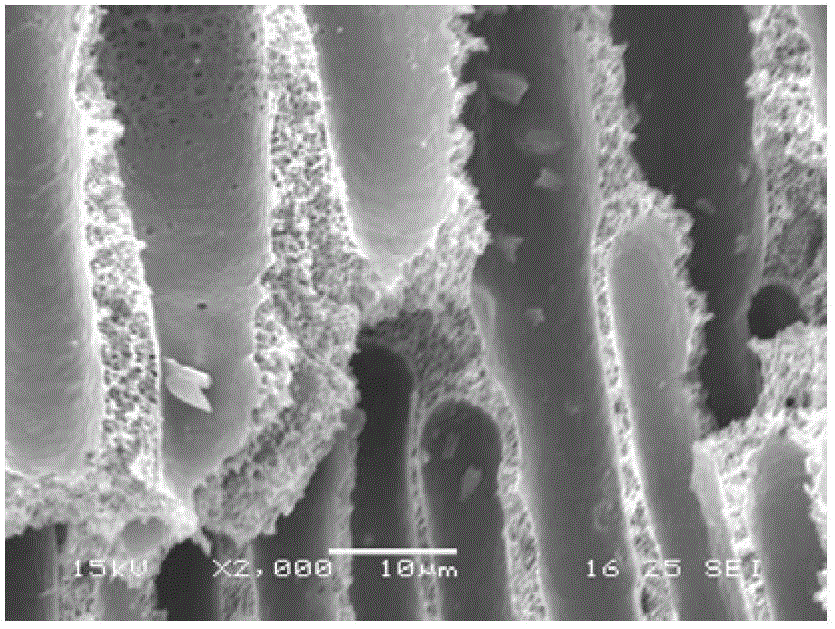

Convenient for cleaning hollow fiber membrane, preparation of the same and products produced thereby

ActiveCN101239283AIncrease temperatureImprove responsivenessSemi-permeable membranesFiberHollow fibre membrane

The present invention provides a PVDF hollow fibre intelligent film, it is easy to cleaning, the preparing method and the product. The hydrophilicity, double-sensibility of pH and temperature and the inoxidability and the strength of the PVDF of the tricomponent polymer of the PVDF-acrylic acid-NIPA are combined, the hollow fiber film not only has the inoxidability and the strength of the PVDF, but also has the hydrophilicity, double-sensibility of pH and temperature of the tricomponent polymer of the PVDF-acrylic acid-NIPA, used for municipal sewage and industrial waste treatment and the deep treatment, and easy to clean.

Owner:BEIJING ORIGINWATER TECH CO LTD

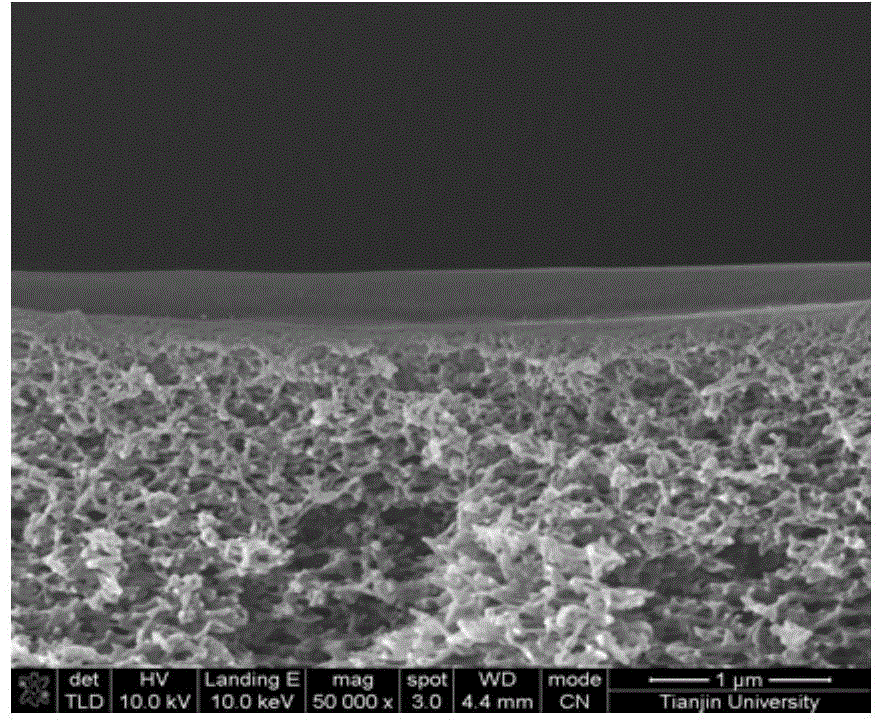

High-performance Janus forward osmosis membrane and preparation method thereof

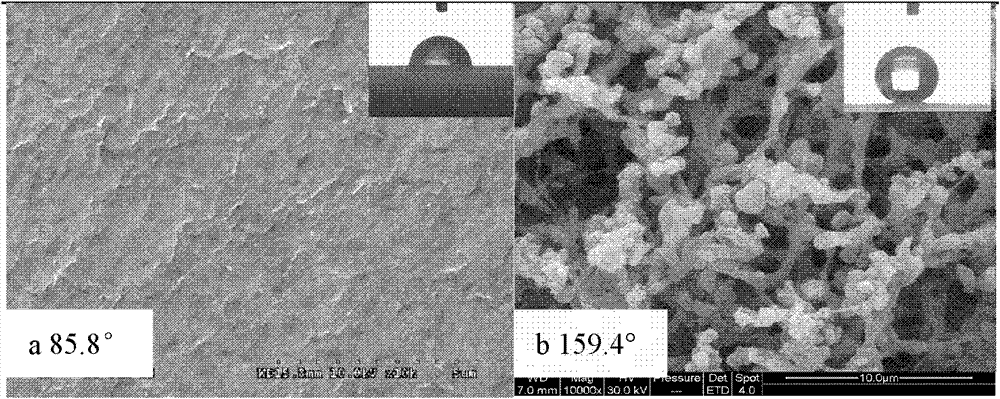

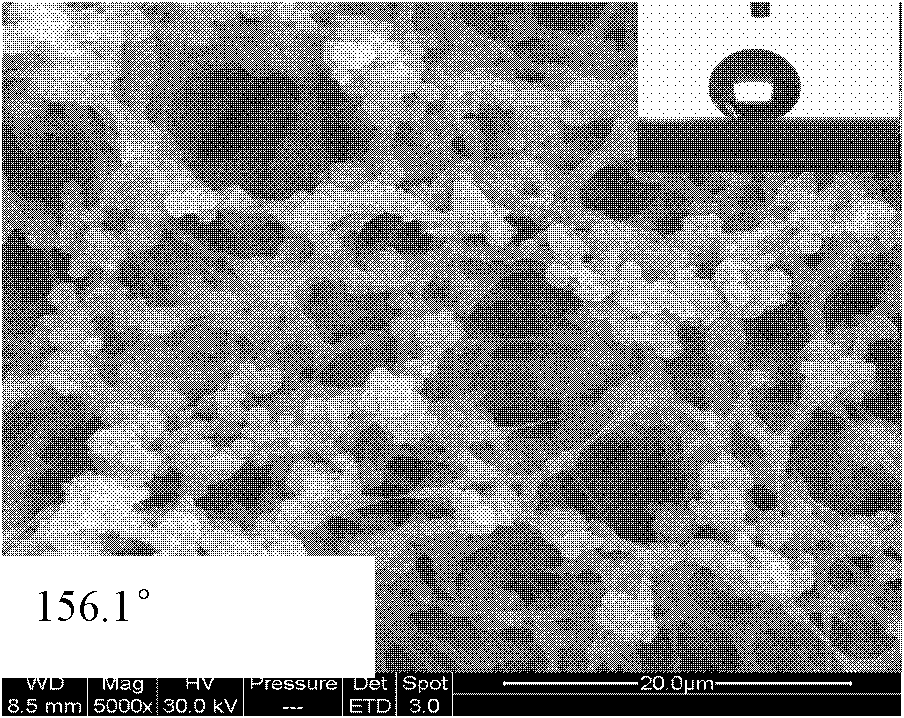

ActiveCN109276998AIncrease water fluxThe film making method is simpleSemi-permeable membranesMembranesMembrane matrixInorganic nanoparticles

The invention discloses a high-performance Janus forward osmosis membrane, comprising a first surface of a super-hydrophilic polymer microporous membrane, a polymer membrane matrix intermediate layerand a second surface away from the first surface and coated with a super-hydrophobic inorganic nanoparticle coating, wherein the water droplet infiltration time of the first surface of the super-hydrophilic polymer microporous membrane is less than two seconds, and the second surface coated with the super-hydrophobic inorganic nanoparticle coating has a water droplet contact angle of greater than150 degrees. The Janus forward osmosis membrane has the advantage of high water flux and low-salt reverse diffusion flux.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

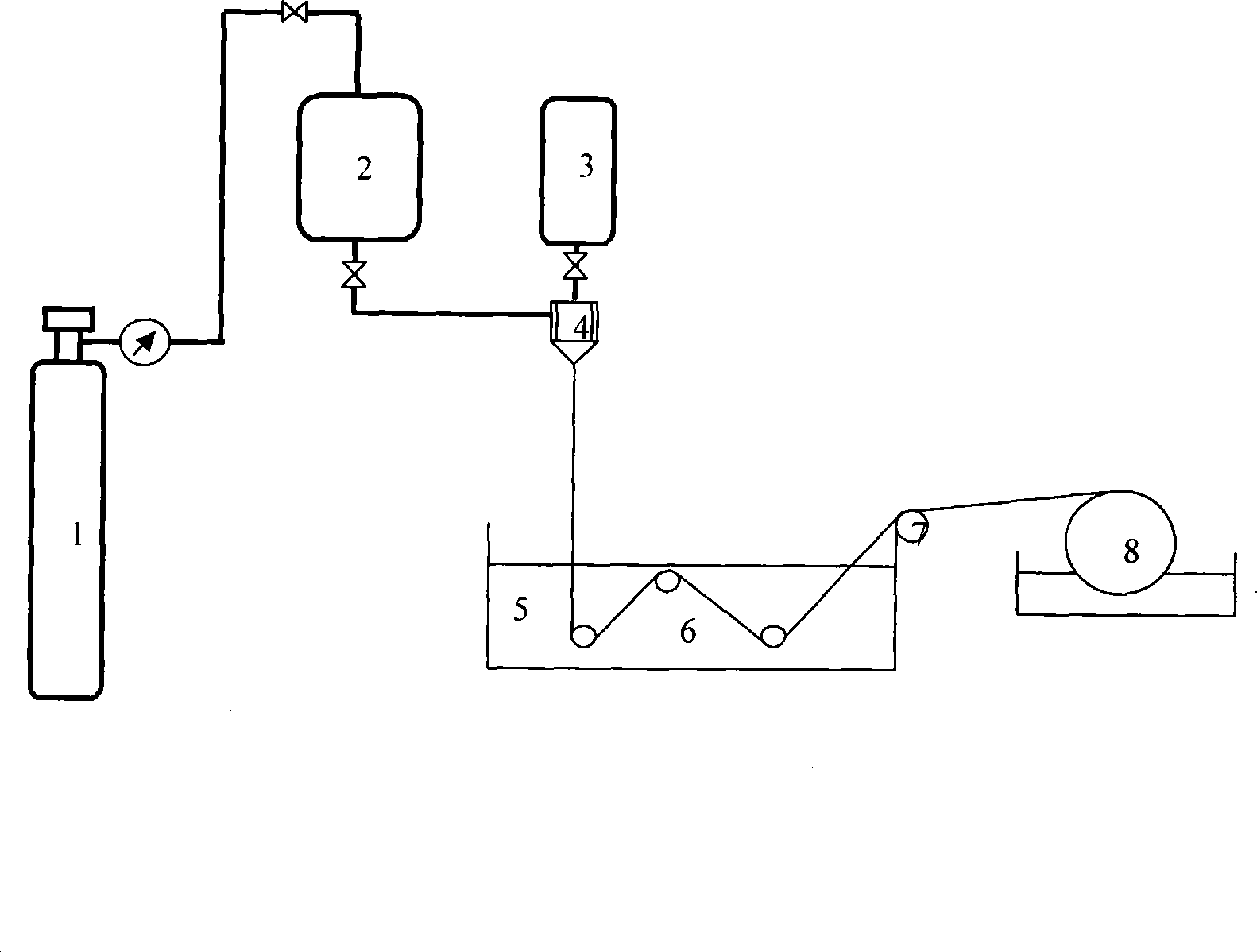

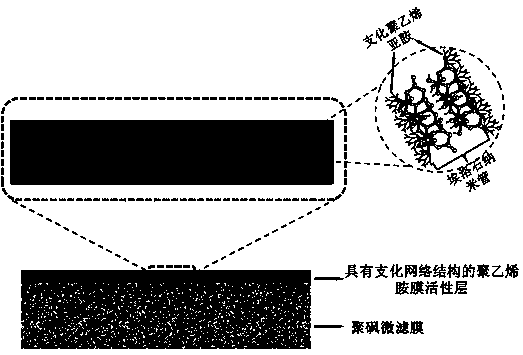

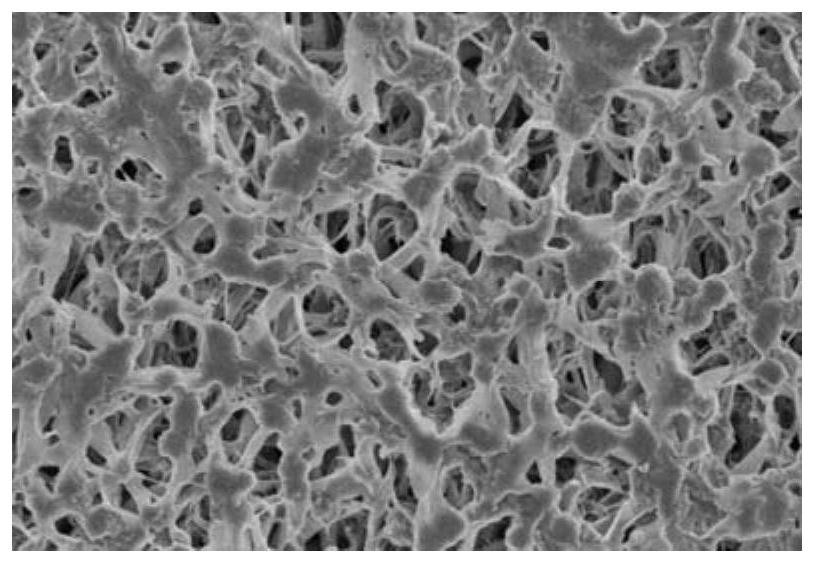

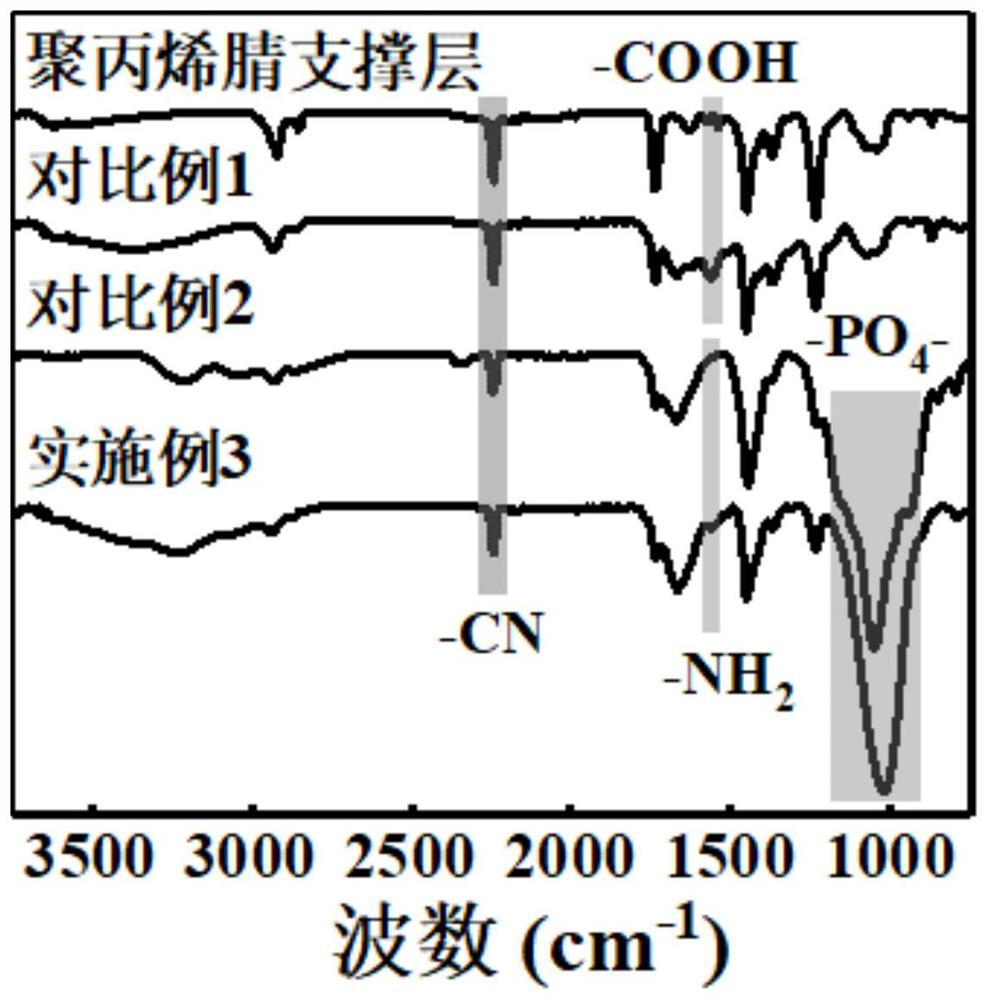

Polyvinylamine film with branched network structure as well as preparation method and application of film

ActiveCN108816063AReduce crystallizationEvenly dispersedMembranesSemi-permeable membranesNetwork structureNanotube

The invention discloses a polyvinylamine film with a branched network structure as well as a preparation method and an application of the film. The film consists of a polyethyleneimine modified indianite tube composite and a polyvinylamine substrate in the mass ratio being (0.1-5.0):100. Firstly, polyethyleneimine with a branched network structure is supported on indianite nanotubes with an electrostatic self-assembling technology, then, the polyethyleneimine modified indianite nanotubes and polyvinylamine are blended, a membrane casting solution is obtained and applied to the surface of a microporous filter membrane, and the functional polyvinylamine film with the branched network structure is prepared and has the thickness of 1-100 mu m. By means of the polyethyleneimine modified indianite nanotubes, crystallization of polyvinylamine molecular chains can be reduced, the polyethyleneimine modified indianite nanotubes with the branched network structure are uniformly dispersed in the polyvinylamine film, and a rapid delivery channel is provided for CO2.

Owner:TAIYUAN UNIV OF TECH

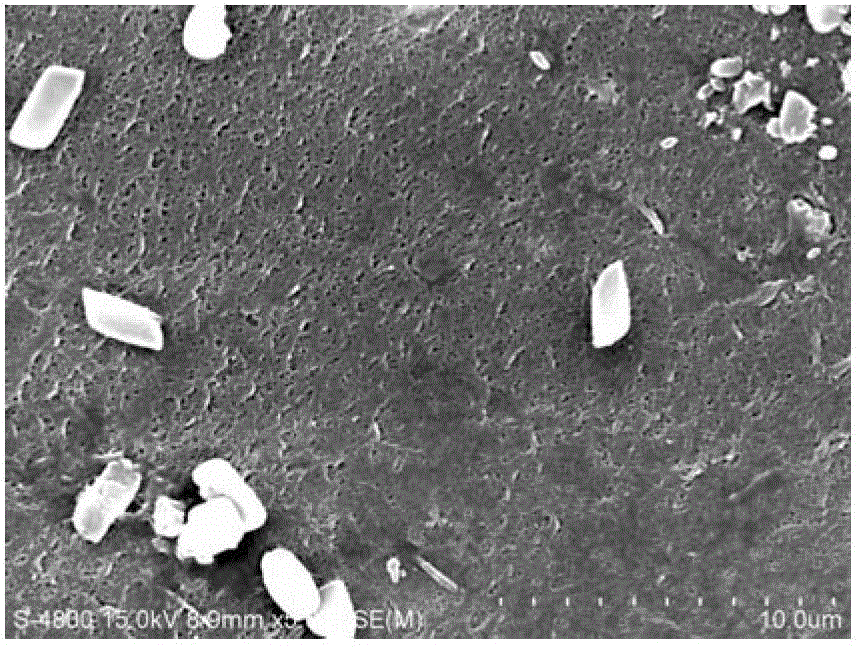

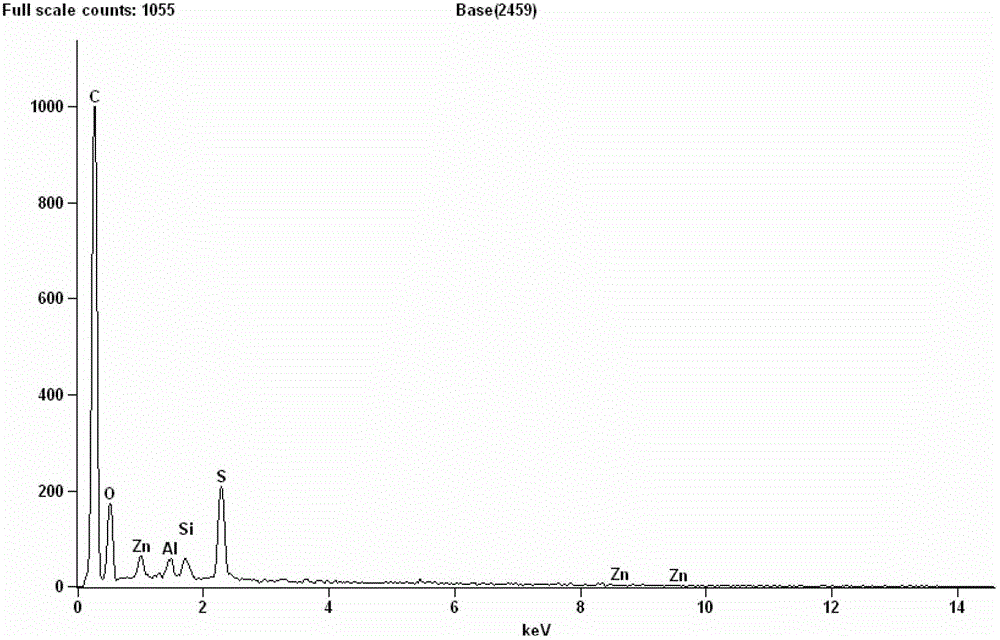

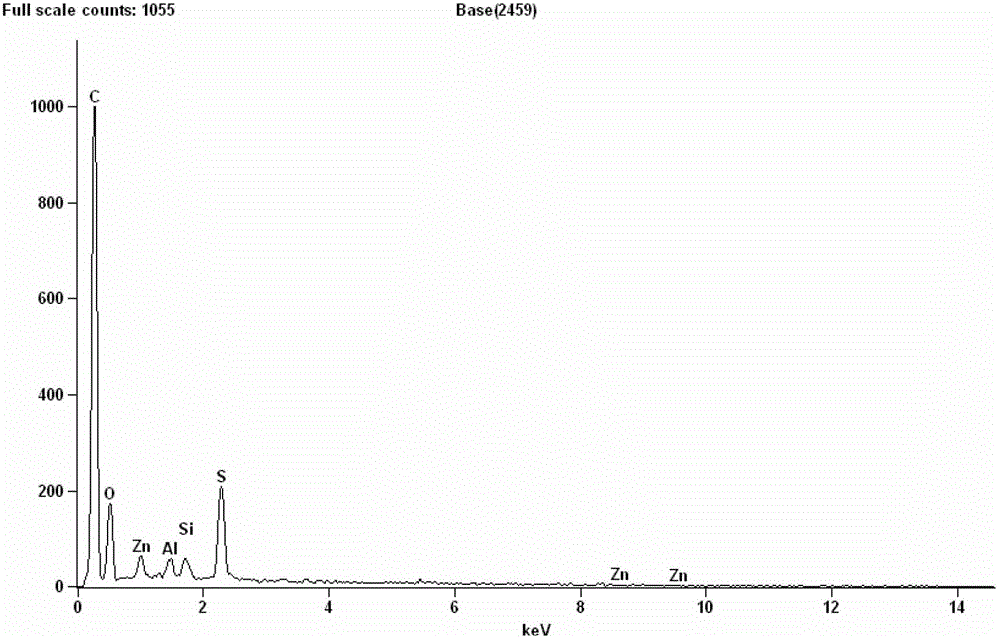

Composite flat-sheet polysulfone membrane doped with active carbon and nanometer zinc oxide and preparation method thereof

InactiveCN102974236AImprove hydrophilicityIncrease water fluxSemi-permeable membranesPolymer scienceMeth-

The invention discloses a composite flat-sheet polysulfone membrane doped with active carbon and nanometer zinc oxide and a preparation method. The preparation steps are as follows: mixing nanometer zinc oxide, active carbon particles, polysulfone and 1-methyl-2-pyrrolidone in a mass ratio of (0.5-1) to 5 to 20 to 100; ultrasonically oscillating and dispersing the components; stirring the mixture until the components are completely dissolved, de-foamed and membrane-pushed; standing the pushed membrane in the air for 15-20 seconds, then soaking the membrane to a water coagulating bath for 20 minutes, putting the soaked membrane to deionized water to soak for 3 days and then taking out the soaked membrane. The composite flat-sheet polysulfone membrane provided by the invention can improve anti-pollution and adsorption performances of the membrane, and further can carry out photocatalysis under ultraviolet irradiation to effectively remove degradation-resistant pollutants in the water.

Owner:HOHAI UNIV

Polyvinylidene fluoride/palladium nanoparticle hybrid hollow fiber membrane and preparation method thereof

InactiveCN103861477AImproved hydrophilicity and anti-fouling propertiesThe film making method is simpleSemi-permeable membranesOrganic-compounds/hydrides/coordination-complexes catalystsPolyvinylidene fluorideChemistry

The invention relates to a polyvinylidene fluoride / palladium nanoparticle hybrid hollow fiber membrane and a preparation method thereof. With combination of hydrophilicity of a polymer gel, high catalytic activity of palladium nanoparticles, and corrosion resistance and good film-forming property of polyvinylidene fluoride, the hybrid hollow fiber membrane with good anti-pollution ability, high catalytic activity and good separation property is prepared. The hollow fiber membrane can be used for catalyzing a reduction reaction of nitro in amino nitrobenzene, nitrophenol, nitrobenzene, methyl nitrobenzene, dimethyl nitrobenzene, cyano nitrobenzene, chloronitrobenzene, vinyl nitrobenzene, nitrocyclohexane and other molecules to transform nitro into amino. At the same time, the hollow fiber membrane also can be used for separation of different-size substances in a liquid mixture.

Owner:TIANJIN POLYTECHNIC UNIV

Preparation method of novel super-hydrophilic oleophobic film

InactiveCN113018910AImprove hydrophilicityImprove hydraulic stabilityFatty/oily/floating substances removal devicesLiquid separationHydrophilic monomerCellulose

The invention relates to a preparation method of a novel super-hydrophilic oleophobic membrane, which comprises the following steps: directly dissolving cellulose by using N-methylmorpholine-N-oxide monohydrate (NMMO.H2O) as a solvent to prepare a coating solution, and coating the surface of a porous material with the coating solution. The preparation method comprises the following steps: oxidizing ortho-hydroxyl of cellulose into an aldehyde group by using an oxidizing agent, carrying out chemical crosslinking on the cellulose on the surface of a porous material by using a crosslinking agent to improve the stability of the cellulose, and further grafting a hydrophilic monomer on the surface of a cellulose membrane to prepare the super-hydrophilic oleophobic membrane. The preparation process is simple and environment-friendly, the oil-water separation efficiency is high, the anti-pollution capacity is high, and the good industrial application value is achieved.

Owner:CNOOC ENERGY SAVING & ENVIRONMENTAL PROTECTION SERVICES +1

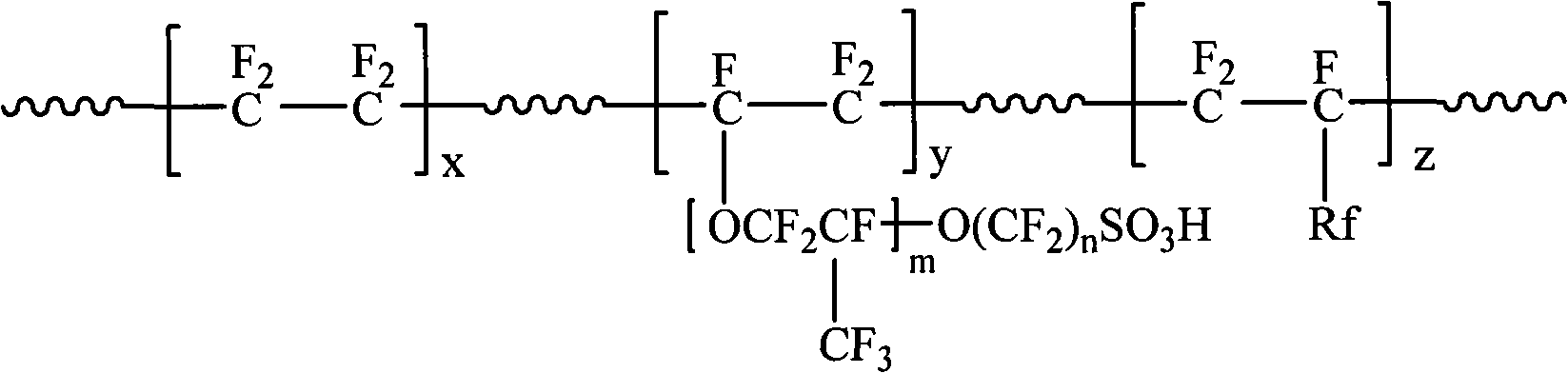

Porous membrane with nanometer aperture and preparation method thereof

InactiveCN102983301AHigh ion conductivityStrong resistance to electrochemical corrosionCell component detailsDouble bondElectrochemistry

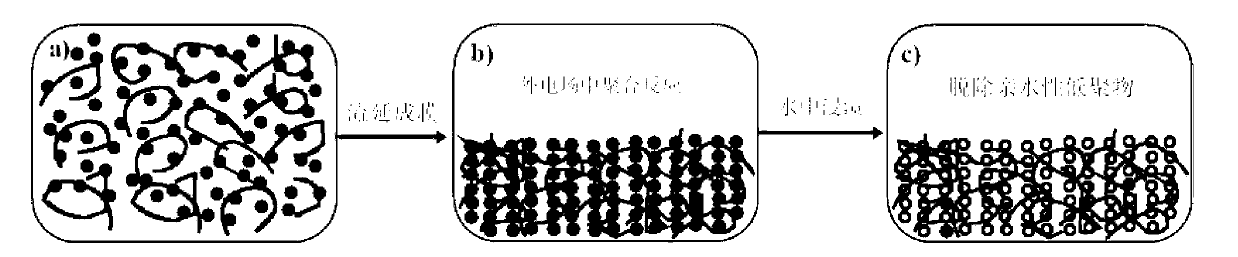

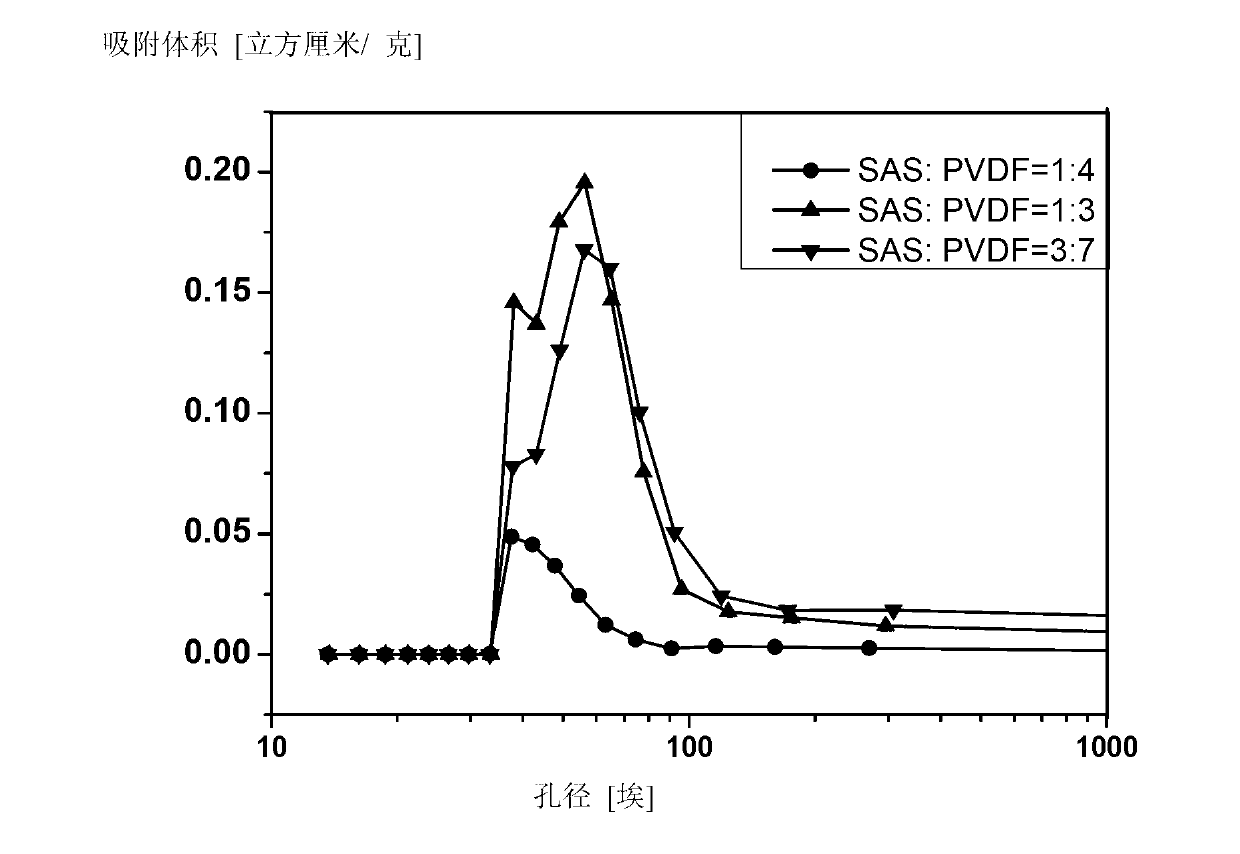

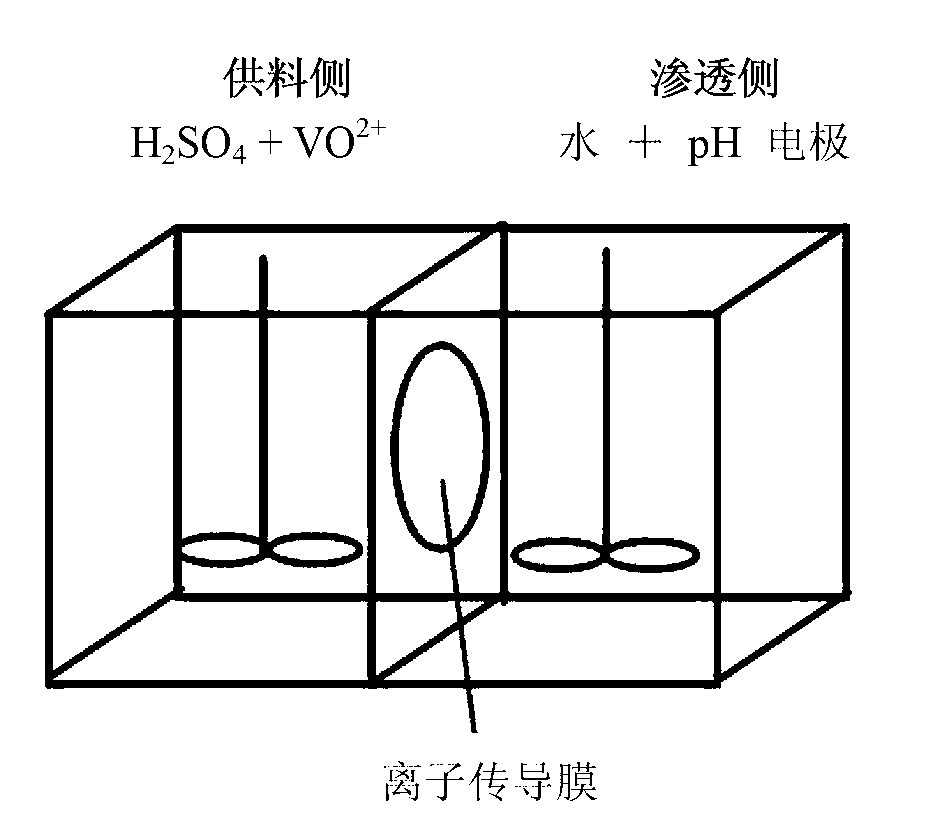

The invention discloses a porous membrane with nanometer aperture and a preparation method thereof. The preparation method comprises the following steps of: (1) dissolving a polymerization monomer containing hydrophilic radical groups and double bonds and polyvinylidene fluoride in an organic solvent, so as to obtain a casting film solution; (2) carrying out curtain coating on the casting film solution by using a casting film method to form a thin film; (3) carrying out polymerization reaction on the polymerization monomer inside the thin film to generate low-molecule polymers, so that the organic solvent inside the thin film is evaporated and removed; and further arranging the thin film in an outer electric field, so that the polymerization monomer is subjected to the polymerization reaction under the effect of the outer electric filed; and (4) placing the thin film processed in the step (3) for impregnation in a water solution, and removing all the low-molecule polymers, so as to obtain the porous membrane with the nanometer aperture. The porous membrane with the nanometer aperture is suitably used as a membrane in an electric chemical device, and further can be used in a separation process and a matter conversion process under the driving of the electric field. With the adoption of the preparation method provided by the invention, the complicated processes of normally using a sulfonating agent in the conventional preparation ion conduction film, executing a plurality of preparation steps and the like can be avoided. The preparation method is simple, and the industrial amplification production can be easily realized.

Owner:TSINGHUA UNIV

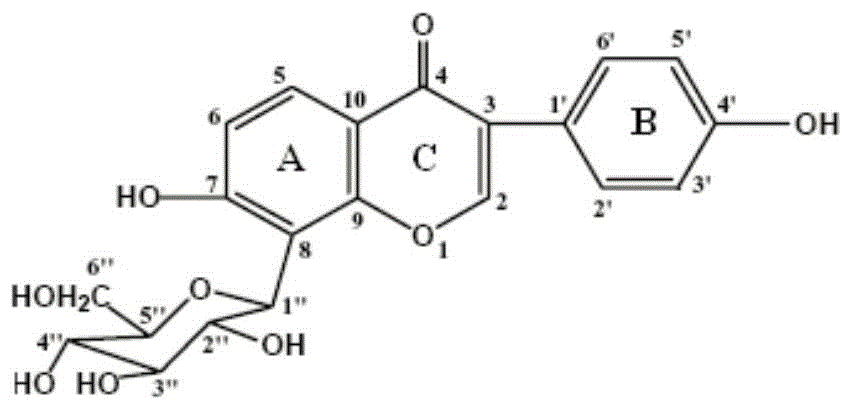

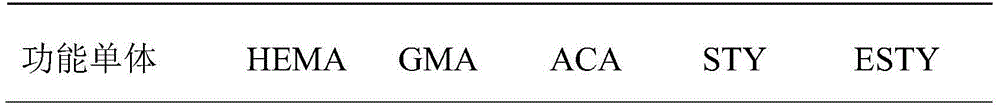

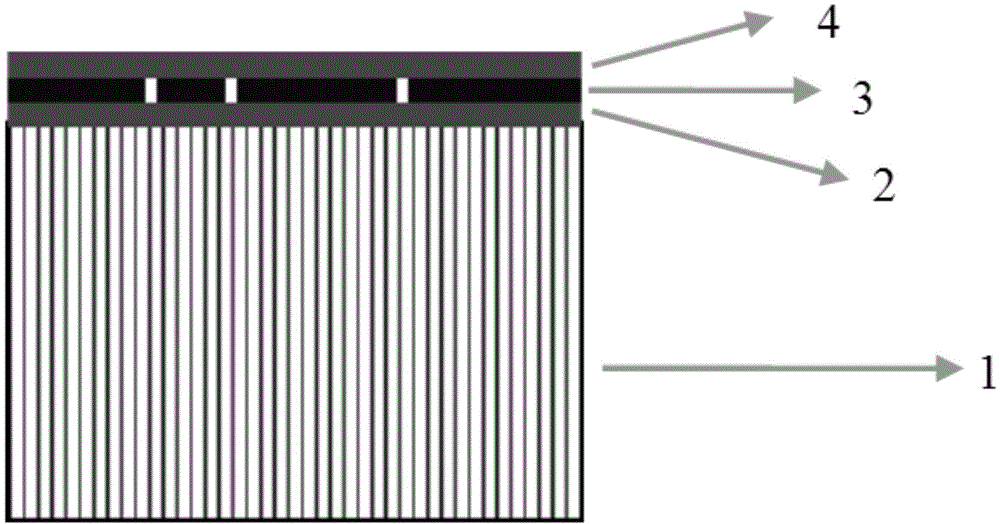

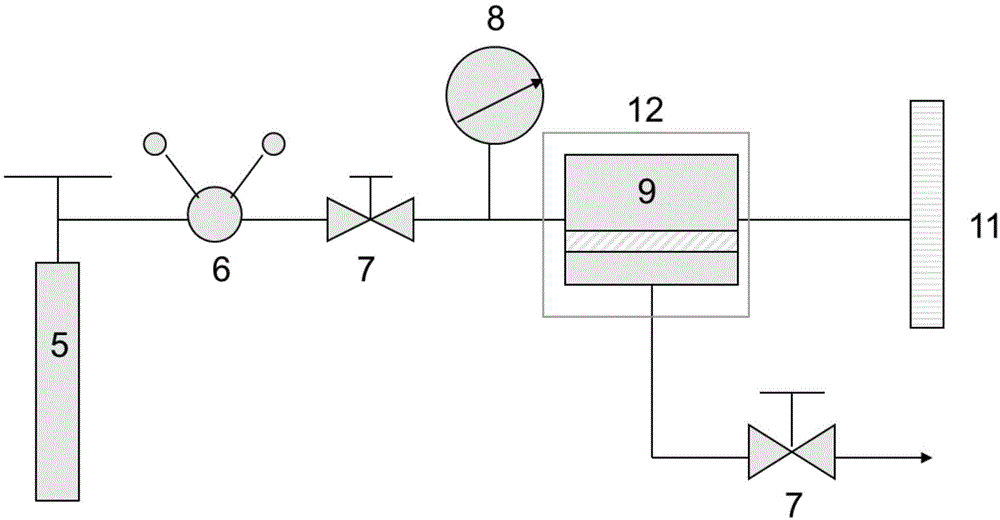

A functional monomer screening method for a molecularly imprinted membrane and a preparing method

ActiveCN105440211AGood forecastShorten the timeSemi-permeable membranesOther chemical processesFunctional monomerInteraction energy

The invention relates to the technical field of membrane separation and particularly relates to a functional monomer screening method for a molecularly imprinted membrane and a preparing method. By adopting a molecular dynamics simulation technique, building a molecular model, calculating parameters, and researching the relation between interaction energy [delta]E between a selected model molecule and functional monomers and spatial conformation, a functional monomer used for synthesis of molecularly imprinted polymer is determined, thus directing designing and preparation of the molecularly imprinted membrane. The molecularly imprinted membrane is prepared by adopting a polymer micropore filtration membrane as a supporting membrane, adopting puerarin as the model molecule and initiating surface modification polymerization through ultraviolet light. The prepared molecularly imprinted membrane has an excellent puerarin molecule recognition performance, is advantaged by saved time and investment and high prediction capability, and is good in separation selectivity.

Owner:CHINA PETROLEUM & CHEM CORP +1

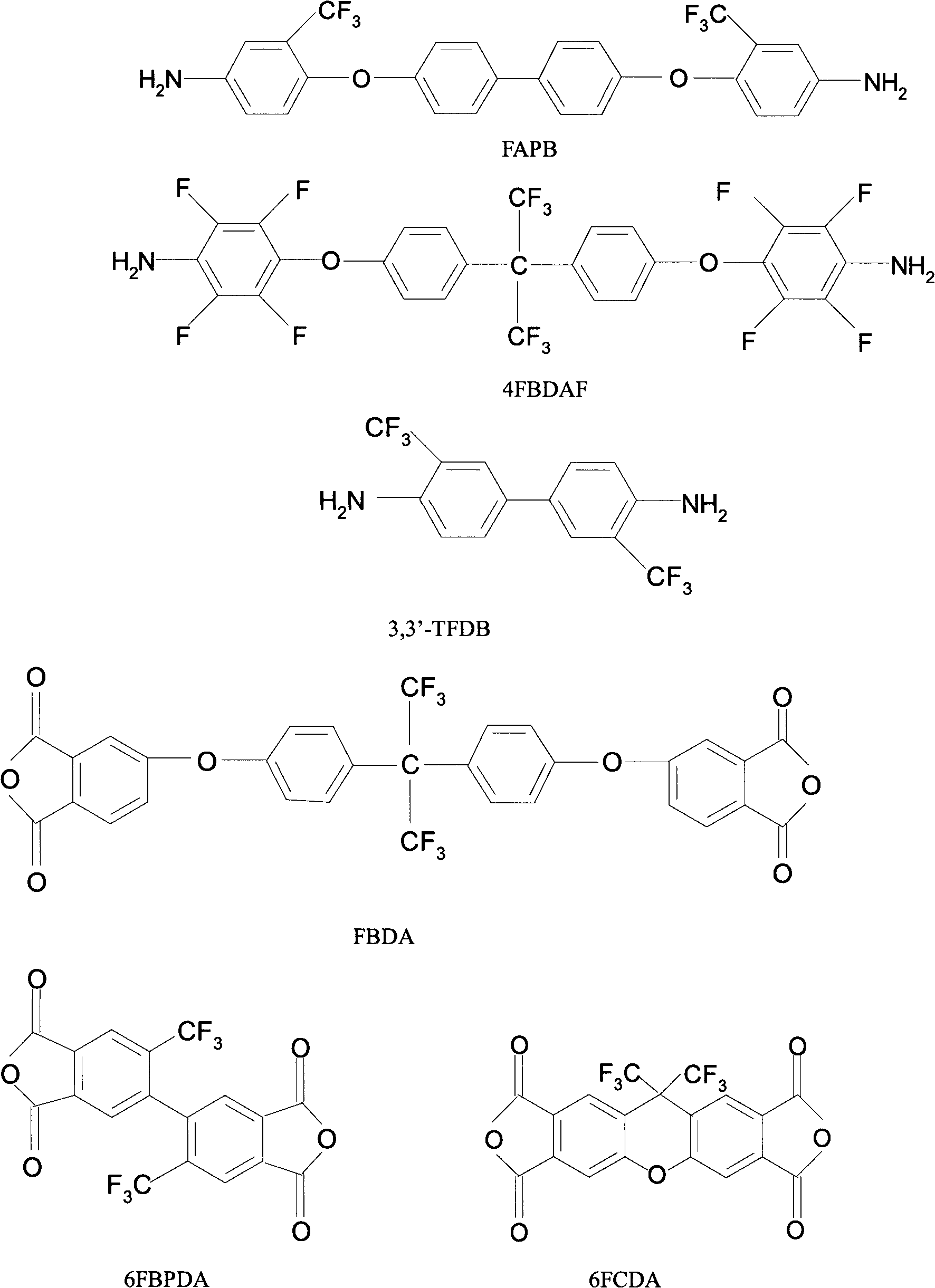

Multilayer gas separation composite membrane and preparation method thereof

InactiveCN104971628AHigh permeation fluxInhibition of porositySemi-permeable membranesDispersed particle separationChemical physicsGlycerol

The invention aims to improve the gas separation performance of a membrane material by means of blending modification to the membrane material and particularly provides a multilayer gas separation composite membrane having an ultrathin separation layer and a preparation method thereof. The membrane is mainly used for separating acidic gases, such as CO2 and the like. In the invention, the multilayer gas separation composite membrane is prepared with a block polymer Pebax and glycerol triacetate as the main material of a separation layer. The preparation method is simple and is easy to achieve large-scale production.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Novel polyvinyl alcohol nanofiltration membrane preparation method

ActiveCN106914156AImprove wettabilityUniform and firm attachmentSemi-permeable membranesCross-linkPolymer science

The invention discloses a novel polyvinyl alcohol nanofiltration membrane and a preparation method thereof. The method comprises the following steps: 1) mixing and dissolving ethylene glycol monomethyl ether and deionized water according to mass ratio of 1: 1 to prepare a solvent, respectively adding terephthalaldehyde and sodium dodecanesulphonate in the above solvent to prepare a mixing solution, heating the above mixing solution to the temperature of 60-65 DEG C, and stirring and dissolving the material to obtain a cross-linking agent solution; 2) dissolving the polyvinyl alcohol in deionized water to prepare an aqueous solution with mass fraction of 0.05-0.1%, heating the above aqueous solution to the temperature of 90-100 DEG C and stirring the material for 1.5 hours to prepare a polyvinyl alcohol aqueous solution; and 3) pouring the prepared cross-linking agent on a polysulfone base membrane, standing the material for 5 min and removing the superfluous solvent, placing the material in a baking oven at the temperature of 28 DEG C and drying the material; pouring the prepared polyvinyl alcohol aqueous solution on the surface of the membrane, and transferring the material into the baking oven and drying the material at the temperature of 60-90 DEG C for forming the membrane. The prepared polyvinyl alcohol nanofiltration membrane has high penetration selectivity and pollution-resistant performance, the method is easy to carry out, and a used modifier is easily available.

Owner:ZHEJIANG UNIV OF TECH

Method for producing diaphragm of super capacitor

ActiveCN102629519AEasy and quick passStrong resistance to electrochemical corrosionElectrolytic capacitorsPorosityEngineering

A method for producing a diaphragm of a super capacitor belongs to the technical field of ion channel membranes. The method is characterized in that dimethylacetamide is used for dissolving soluble polyimide and hybrid materials having ion channels; the tape casting method is used for forming a film on a smooth solid surface; and the film is heated, so that the hybrid materials are subjected to a sol-gel reaction to form iron transmission channels, and the hybrid materials and the polyimide form the diaphragm of the super capacitor. The novel diaphragm, which has good ion transmission performance and small resistance, of the supper capacitor can be obtained through the method, and the defect of high porosity of present diaphragms is eliminated. The method has the advantages of being simple in producing process and easy to magnify.

Owner:INST OF CHEM CHINESE ACAD OF SCI

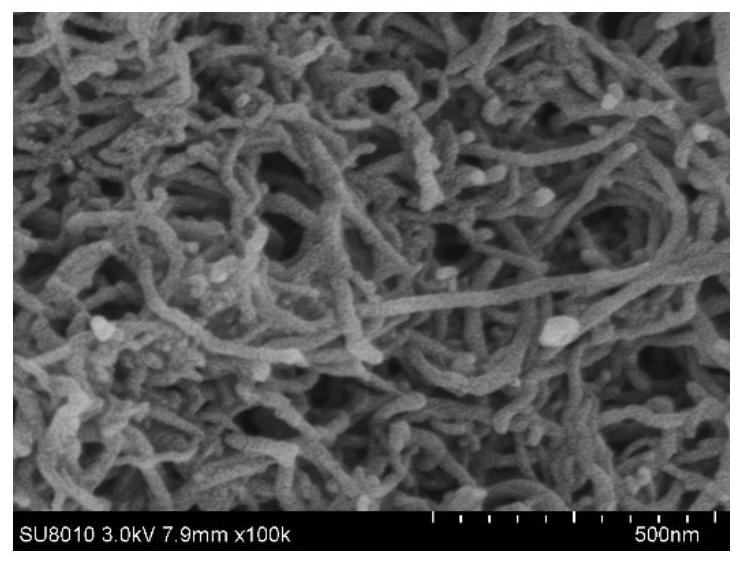

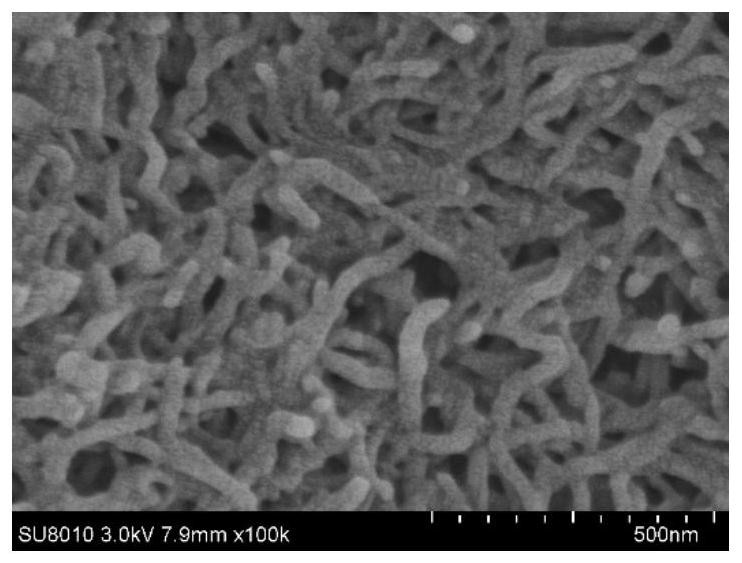

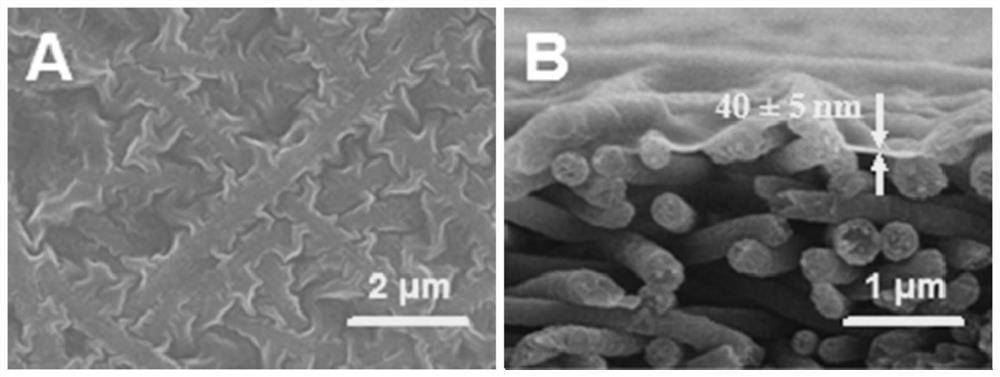

High-flux super-hydrophilic/underwater super-oleophobic Janus membrane modification method

PendingCN113144903AImprove hydrophilic abilitySmall fluxMembranesDistillationHydrophilizationPolymer science

The invention relates to a high-flux super-hydrophilic / underwater super-oleophobic Janus membrane modification method, which is characterized in that a dopamine and polyethyleneimine co-deposition technology is adopted to coat a hydrophilic carbon nanotube on the surface of one side of a hydrophobic membrane, and a stable hydrophilic carbon nanotube coating is synthesized, so that one side of the membrane keeps the original characteristics, and the other side of the membrane has excellent super-hydrophilic / underwater super-oleophobic characteristics; the membrane flux is increased, and the oil pollution resistance of the membrane is improved; a synthesis method comprises the following steps: coating the surface of the membrane with a carbon nano tube ethanol solution in a negative pressure vacuum manner, and then stably fixing the coated carbon nano tube in a dopamine and polyethyleneimine codeposition manner, so that the obtained modified Janus membrane has the pore diameter of 0.2-0.25 [mu]m, the water contact angle of 9 degrees and the oil contact angle of 180 degrees, and the membrane has extremely high hydrophilicity and super-oleophobic characteristics. The method is simple and efficient, and the prepared super-hydrophilic / underwater super-oleophobic janus membrane is high in flux and resistant to oil pollution.

Owner:BEIJING FORESTRY UNIVERSITY +1

Corn bran based degradable antibacterial film and preparation method thereof

The invention relates to a corn bran based degradable antibacterial film and a preparation method thereof which is prepared from the following components by mass volume ratio: 4-9 percent of corn bran powder, 12-16 percent of sodium hydroxide, 3-5 percent of konjak gum, 1.0-1.6 percent of chitosan, 7.0-9.0 percent of acetic acid, 2-4 percent of arabic gum, 4-5 percent of allyl isothiocyanate and 10-15 percent of deionized water, wherein the corn bran powder selects 270-mesh corn bran powder. The corn bran based degradable antibacterial film has the thickness being 60-140 microns, the tensile strength being 35.9-46.7MP, the elongation at break being 21.6-30 percent and the folding endurance being 20-26 times. According to the corn bran based degradable antibacterial film, corn bran powder fine particles and antibacterial substances are uniformly distributed in a material, and a prepared packaging film has stronger mechanical properties and barrier property and can realize sealing with heating.

Owner:HEILONGJIANG BAYI AGRICULTURAL UNIVERSITY

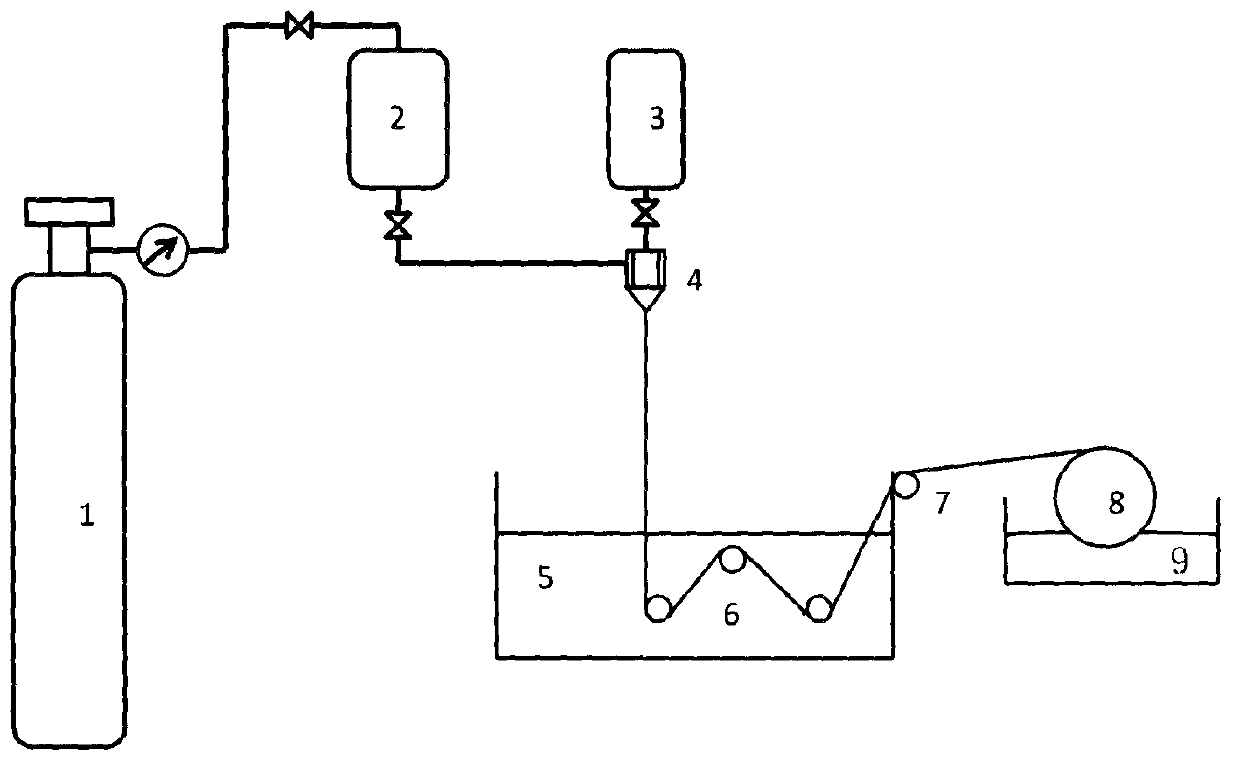

Preparation of proton conduction membrane

ActiveCN101475699BImprove conductivityStrong resistance to electrochemical corrosionCell component detailsProtonNetwork structure

The invention relates to a preparation method for a proton-conducting membrane, and belongs to the technical field of ion exchange membranes. The preparation method is characterized in that dimethyl sulfoxide is adopted to dissolve polyvinylidene fluoride and sodium allylsulfonate monomer containing proton conducting functional group; a flow casting method is adopted to form a membrane on a smooth solid surface through flow casting; the sodium allylsulfonate monomer is initiated to carry out polyreaction; and the products of the polyreaction and polyvinylidene fluoride molecular chain are formed into the proton-conducting membrane of macromolecular interpenetrating network structure. The preparation method can obtain an ion exchange membrane material with ideal proton conductibility, and overcomes the disadvantage that the prior melting mould pressing process cannot prepare homogeneous phase ion exchange membranes; moreover, the preparation method has the advantages of simple technological process, easy industrial scaling up and the like.

Owner:TSINGHUA UNIV

Preparation process of reinforced hybrid organic-inorganic film

InactiveCN100463712CThe film making method is simpleEliminate requirementsSemi-permeable membranesHollow fibrePolymer science

The present invention is preparation process of reinforced hybrid organic-inorganic film and belongs to the field of organic-inorganic separating film preparing technology. During the preparation of the reinforced hybrid organic-inorganic film, inorganic precursor is added directly into filming liquid of organic polymer to obtain the mixture film casting liquid comprising organic polymer 10-20 wt%, additive 0-10 wt%, solvent 55-80 wt% and inorganic precursor 0-24 wt%; the film casting liquid is then cured at 25-75 deg.c for 1-2 days before flow casting or spinning; the flow cast or extruded filming liquid is pre-evaporated in the air for 0-120 s before curing in solidification bath in pH 0.4-4 or pH 10-13; and the cured film is further soaked in the solidification bath for 5-25 min and soaked in pure water for 1-2 days. The reinforced hybrid organic-inorganic film has simplified preparation process and high mechanical strength.

Owner:BEIJING UNIV OF TECH

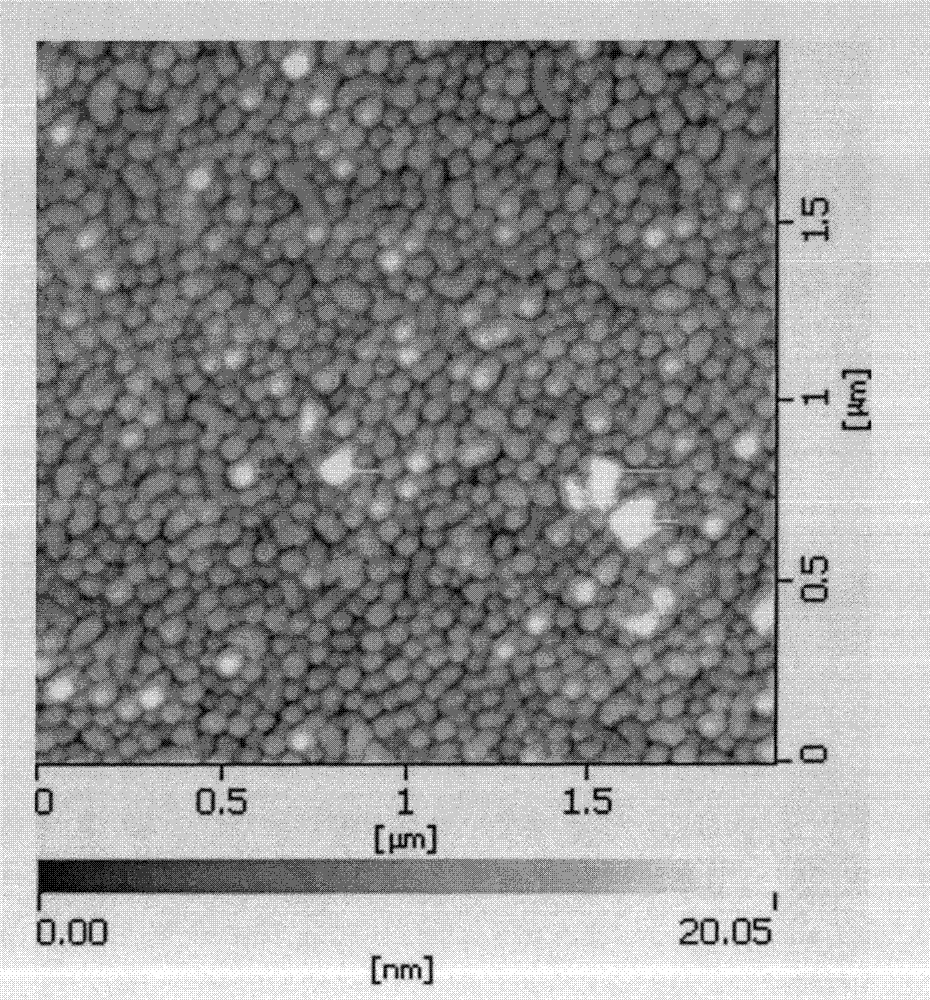

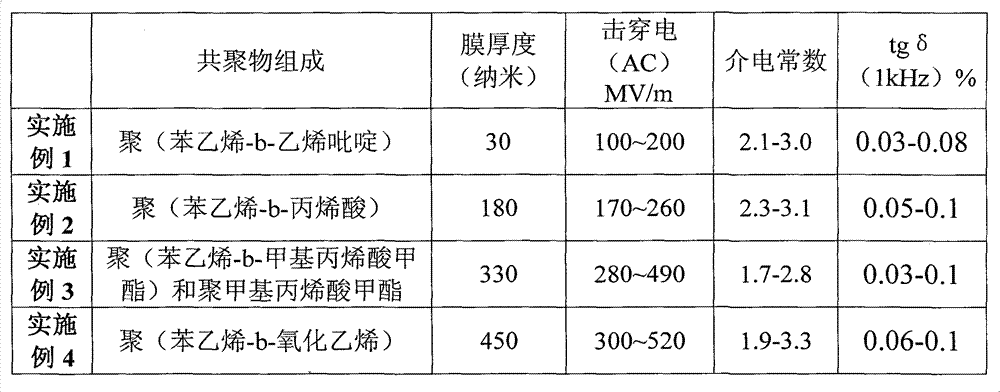

Preparation method of capacitor ultrathin film

ActiveCN102930982AHigh strengthOptimal Control StructureElectrolytic capacitorsFixed capacitor dielectricPolymer scienceSpinning

The invention discloses a preparation method of a capacitor ultrathin film. The preparation method of the capacitor ultrathin film is characterized by comprising the steps of: dissolving a segmented copolymer containing polystyrene segments by utilizing solvents such as toluene; and coating on a smooth electrode surface in a spinning mode by utilizing a spin coating method to form a film, wherein the surface of the film is even and compact, the internal structure of the film is put in order, the film thickness is uniform and has no defect, and is 10-500nanometers. According to the preparation method of the film, the polymer film with the nano-level thickness is obtained, the defect that the film of the existing film capacitor is high in thickness is overcome, and the preparation method has the advantages of simple preparation process, nano-level film thickness, easiness in industrial amplification, high accuracy, high stability and the like.

Owner:INST OF CHEM CHINESE ACAD OF SCI

Preparation method of metal organic framework material/polymer composite proton exchange membrane

ActiveCN105789668BStrong penetrating powerImprove performanceRegenerative fuel cellsVanadium redox batteryMetal-organic framework

Owner:INST OF CHEM CHINESE ACAD OF SCI

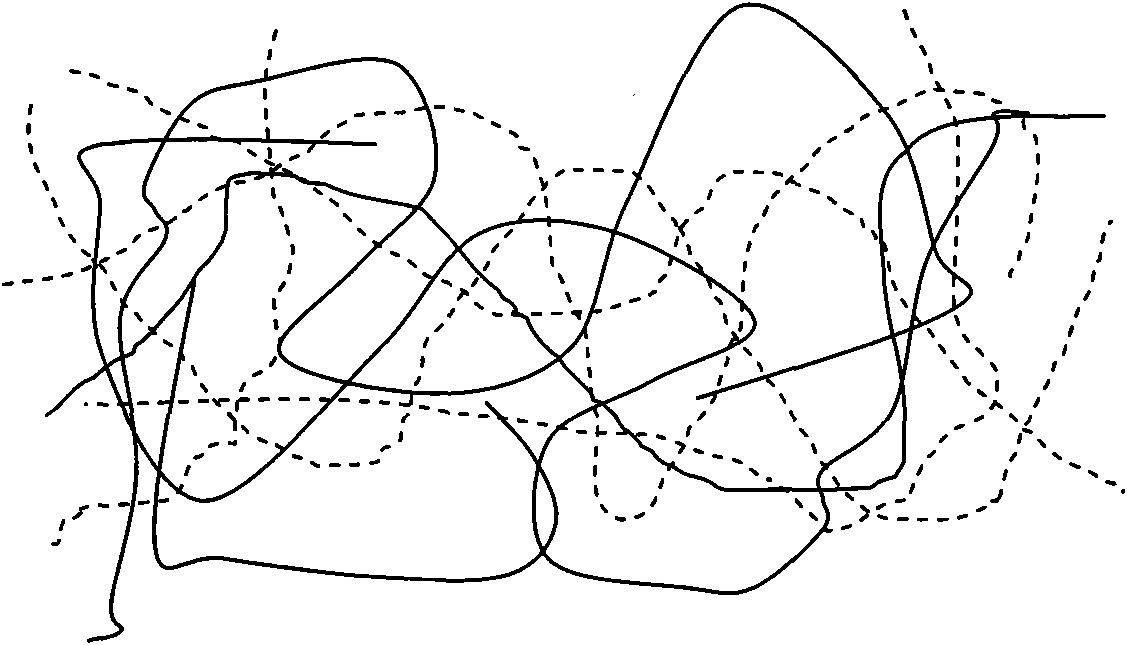

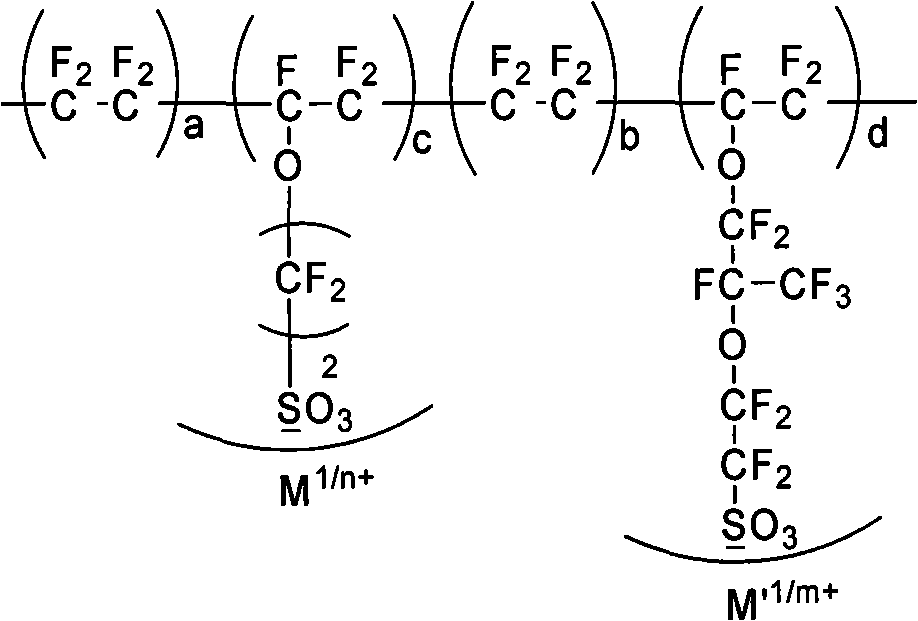

Ion exchange membrane of interpenetrating network structure and preparation method thereof

ActiveCN101794888AImprove conductivityStrong resistance to electrochemical corrosionCell electrodesOrganic solventHydrogen

The invention relates to an ion exchange membrane of interpenetrating network structure and a preparation method thereof. The preparation method is characterized by dissolving a hydrogen type perfluorosulfonic acid ion exchange resin and a salt type perfluorosulfonic acid ion exchange resin with a polar organic solvent; casting the solution on the smooth solid surface; and then forming the membrane under heating condition, wherein the molecular chains of the hydrogen type perfluorosulfonic acid ion exchange resin and the salt type perfluorosulfonic acid ion exchange resin form the macromolecular ion exchange membrane of interpenetrating network structure. The ion exchange membrane with good mechanical performance can be obtained by the method, thus overcoming the defect that the homogeneous crosslinked ion exchange membranes can not be prepared in the existing fusing and molding processes, and the method has the advantages of simple technological process, easy industrial scale-up, etc.

Owner:SHANDONG DONGYUE POLYMER MATERIAL

Method for preparing high-density polyethylene/ethylene-vinyl acetate blended hydrophobic microporous membranes

InactiveCN107617343AImprove throughputHigh mechanical strengthSemi-permeable membranesPorosityLow-density polyethylene

The invention discloses a method for preparing high-density polyethylene / ethylene-vinyl acetate blended hydrophobic microporous membranes. The method is characterized in that the high-density polyethylene / ethylene-vinyl acetate blended hydrophobic microporous membranes comprise, by weight, 10-50 parts of high-density polyethylene, 1-30 parts of ethylene-vinyl acetate, 50-80 parts of diluents and 0-4 parts of nucleating agents. The method for preparing the high-density polyethylene / ethylene-vinyl acetate blended hydrophobic microporous membranes which are blended membranes is a thermally induced phase separation method. The method has the advantages that obvious modification effects can be realized for the blended membranes under the condition that the excellent chemical properties and thehigh strength of the high-density polyethylene are not changed; the mechanical performance of the membranes which are products can be greatly enhanced, and the membranes are excellent in flexibility,high in breaking elongation and long in service life; the ethylene-vinyl acetate is added, accordingly, the membrane pore sizes are narrow and uniform in distribution, the pore sizes and the porosityare easy to control, the pore sizes range from 0.1 micrometer to 1 micrometer, and the porosity is higher than 62%; the heat conductivity coefficients of the membranes which are the products can be lowered, the method can be applied to membrane distillation procedures, accordingly, the temperature difference of two sides of each membrane and the vapor pressure difference can be increased, heat loss can be reduced, and the heat efficiency can be improved.

Owner:TIANJIN UNIV OF SCI & TECH

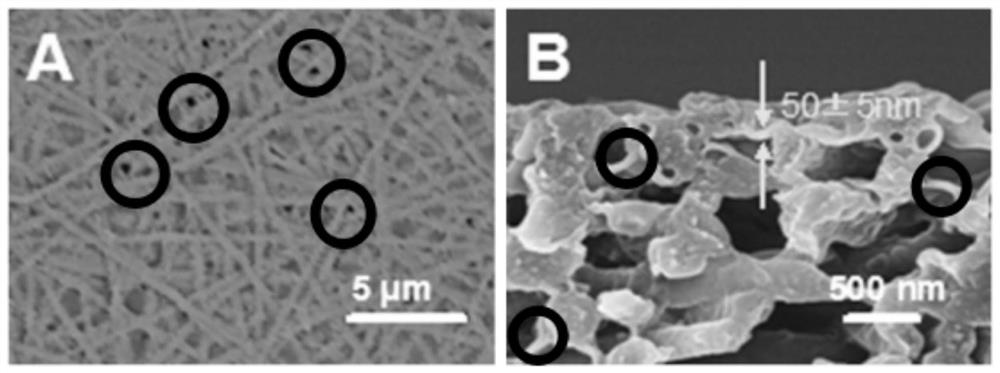

A method for preparing nanofiber-based composite nanofiltration membranes by low-temperature reverse interfacial polymerization

InactiveCN110124517BReduce evaporation rateSolve surface defectsSeawater treatmentWater/sewage treatment bu osmosis/dialysisPolymer scienceElectrospinning

The invention discloses a method for preparing a nanofiber-based composite nanofiltration membrane by low-temperature reverse interface polymerization, which is characterized in that it comprises: electrospinning a polymer solution to obtain a nanofiber non-woven fabric, which is obtained after cold pressing The nanofiber porous base membrane; the surface of the nanofiber porous base membrane is infiltrated with a low-temperature oil phase monomer solution; then the water phase monomer solution is added for reverse interfacial polymerization reaction; the nanofiber base composite nanofiltration membrane is obtained after heat treatment. The invention reduces the volatilization rate of the oil phase under low temperature conditions by controlling the temperature of the oil phase solution, provides a complete and uniform reaction interface for the reverse interface polymerization, and overcomes the skin layer inherent in the reverse interface polymerization caused by the rapid volatilization of the oil phase Defects and infiltration problems, the thickness, uniformity and density of the functional barrier layer are optimized by controlling the temperature of the oil phase solution and the polymerization parameters of the reverse interface, thereby enhancing the nanofiltration performance of the composite membrane.

Owner:DONGHUA UNIV

Method for preparing charged nanofiltration membrane by chloromethylated polysulfone

ActiveCN106914155AGood anti-pollutionHigh selectivityMembranesSemi-permeable membranesUltrafiltrationNanofiltration

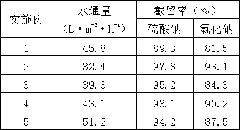

The invention discloses a method for preparing a charged nanofiltration membrane by chloromethylated polysulfone. According to the invention, chloromethylated polysulfone is placed in a trimethylamine solution to obtain a positively charged polysulfone material, then the material is subjected to magnetic stirring for 24 h, the positively charged polysulfone material is placed in ethylene glycol monomethyl ether to prepare a casting solution, the casting solution is used for coating the surface of a polysulfone ultrafiltration base membrane, and the base membrane is dried in a temperature scope of 30-40 DEG C to prepare the nanofiltration membrane; under pressure of 1.2 MPa, the nanofiltration membrane has retention rate and flux on sodium chloride and magnesium chloride being 69.3% / 52.6 L.m<-2>.h<-1> and 76.8% / 40.6 L.m<-2>.h<-1>. The film forming material contains a positively charged group, the retention rate of a positively charged dye by the membrane can reach 95% and above, the charged nanofiltration membrane can be used for separating the salt and the positively charged dye, the nanofiltration membrane has the hydrophilic group, and has good anti-pollution performance.

Owner:ZHEJIANG UNIV OF TECH

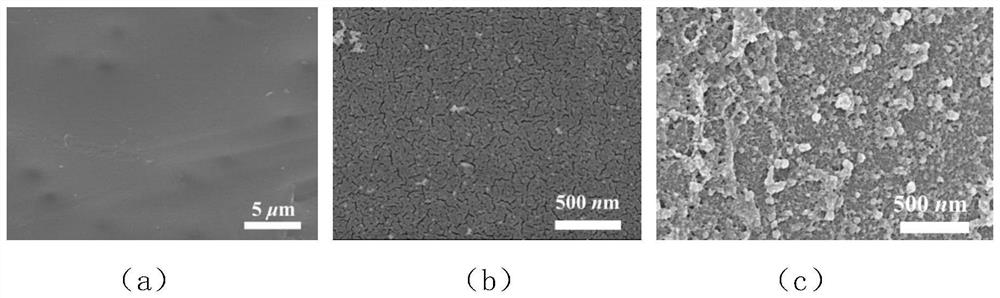

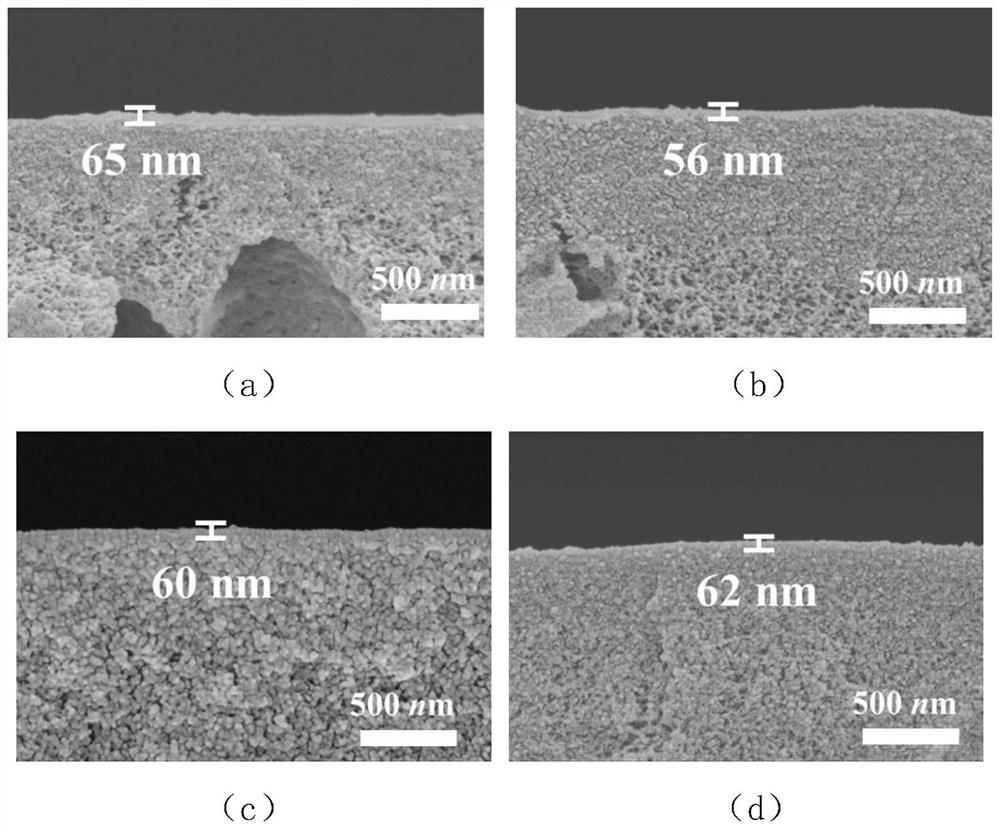

Metal ion-organic acid complex in-situ cross-linked composite membrane and preparation and application thereof

ActiveCN114797494AEasy to separateNarrow pore size distributionGeneral water supply conservationReverse osmosisOrganic acidPolymer science

The invention relates to a metal ion-organic acid complex in-situ cross-linked composite membrane as well as preparation and application thereof, and belongs to the field of membrane separation. The preparation method comprises the following steps: anchoring a crosslinking component on the surface of the polymer supporting layer in advance in the form of a metal ion-organic acid complex to form the crosslinking layer, and then carrying out in-situ crosslinking on the polymer on the surface of the crosslinking layer to prepare the polymer selection layer, thereby obtaining the polymer composite membrane. The polymer composite membrane is prepared by preferentially anchoring the crosslinking layer to crosslink the polymer in situ, so that the formation of a thin and compact polymer selection layer is facilitated, and the mass transfer resistance is reduced. When the prepared polymer composite membrane is applied to dehydration of an organic solvent (ethanol), compared with a polymer composite membrane prepared by a traditional cross-linking method, the separation performance is obviously improved.

Owner:HUAZHONG UNIV OF SCI & TECH

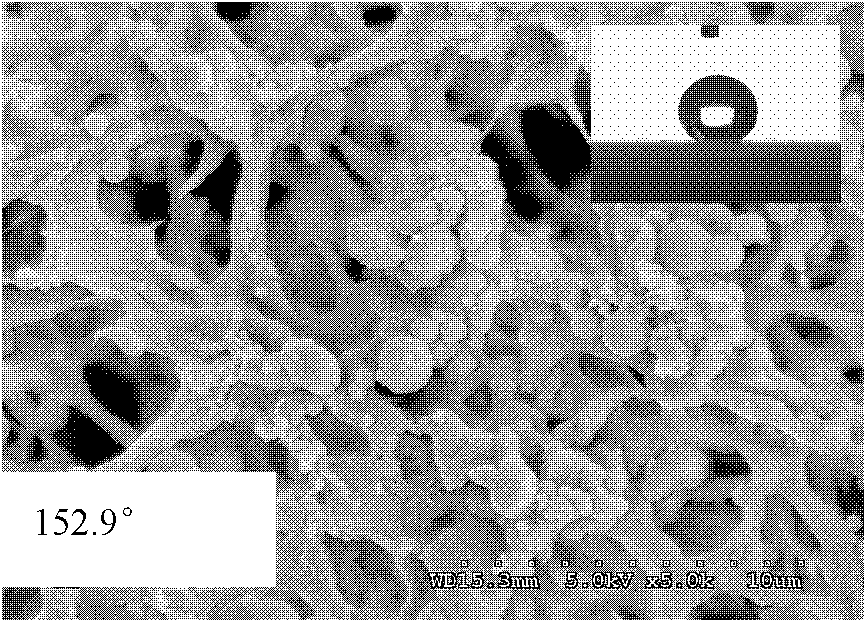

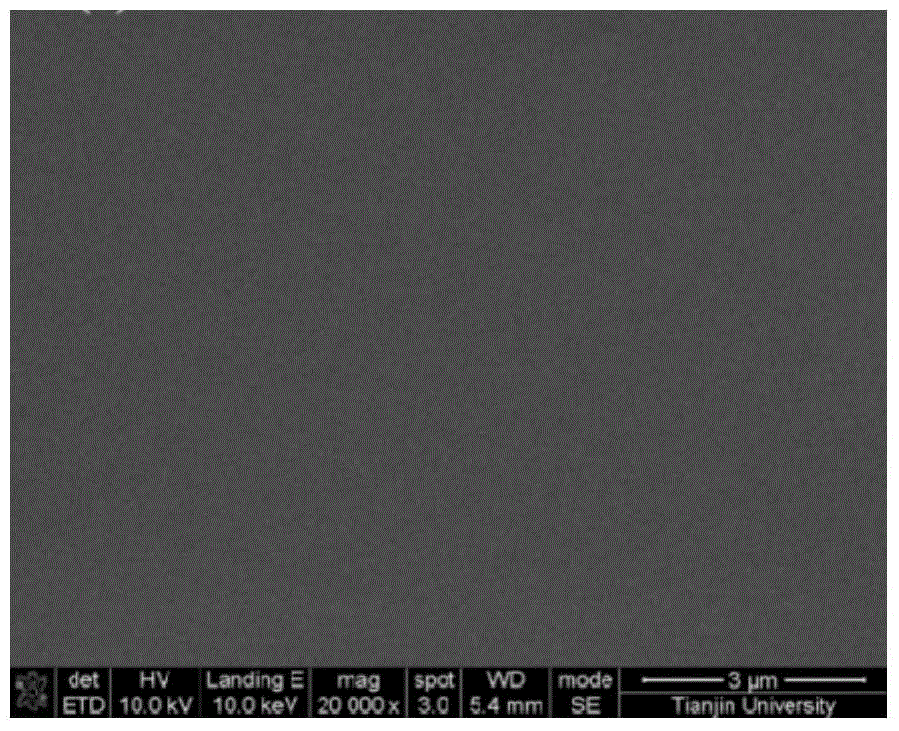

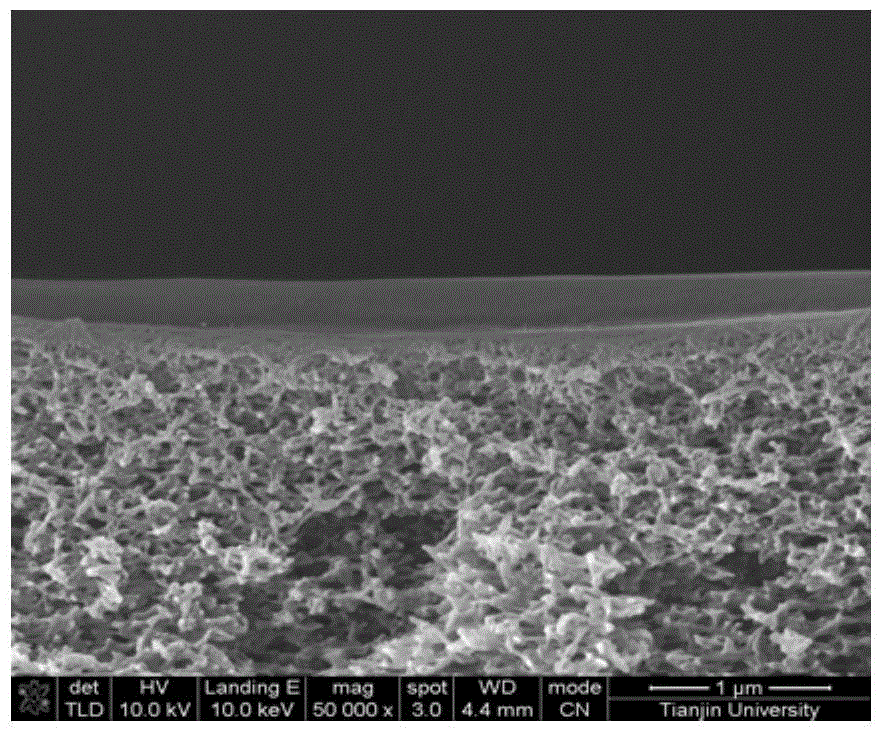

Super hydrophobic modification method for polyvinylidene fluoride hydrophobic membranes

InactiveCN102179188BImprove throughputHigh desalination rateSemi-permeable membranesComposite filmGlass sheet

The invention discloses a super hydrophobic modification method for polyvinylidene fluoride hydrophobic membranes and belongs to the technical field of membrane separation. The method comprises: preparing membrane casting solution by using polyvinylidene fluoride (PVDF), N,N-dimethylacetamide (DMAC) serving as a solvent and non-solvent low-molecular-weight alcohol and aging the membrane casting solution to form upper membrane solution; preparing membrane casting solution by using PVDF, DMAC, LiCl or / and polyvinyl pyrrolidone (PVP), and aging the membrane casting solution to form lower membrane solution, wherein the PVDF content in the lower membrane solution is higher than that in the upper membrane solution; scraping the lower membrane solution and the upper membrane solution on a glass plate in turn, and placing the glass plate in air at 50 to 75 DEG C and at a water relative humidity of 80 to 100 percent to obtain a primary ecological membrane; and immersing in running water for stripping the membrane and drying to obtain a polyvinylidene fluoride composite film of which the surface is super hydrophobic. In the invention, the method is simple, the process flow is short, the cost is low, and the prepared membrane has high flux and high salt rejection rate.

Owner:BEIJING UNIV OF TECH

Carbon dioxide separating membrane having both primary amine and carbonate and preparation method thereof

ActiveCN104857867ARealize synergistic coupling effectImprove efficiencySemi-permeable membranesDispersed particle separationUltrafiltrationPermeation

The invention relates to a carbon dioxide separating membrane having both primary amine and carbonate and a preparation method thereof; the method comprises the steps of preparing the polymer blends of poly (vinyl amine-diallyl dimethyl ammonium carbonate) copolymer and polyvinyl amine or poly diallyl dimethyl ammonium carbonate; taking polysulfone ultrafiltration membrane as a supporting body, dissolving the polymer blends into deionized water, and defoaming to obtain coating solution after stirring; under the condition of a certain temperature and relative humidity, carrying out drying treatment for a period of time to obtain the CO2 separating membrane having both the primary amine and the carbonate. The carbon dioxide separating membrane having both the primary amine and the carbonate realizes the synergic coupling effect between different function carriers: not only is the efficiency of the function carriers strengthened, but also the defects of various function carriers are avoided when the carriers are used alone. The carbon dioxide separating membrane having both the primary amine and the carbonate has excellent CO2 permeation selection performance: with regard to the mixed gas of CO2 / N2, under the condition that the feed pressure force is 0.11-2.00 MPa, the permeation rate of the CO2 is (137-1842)*10-6, and the CO2 / N2 separation factors are 23-160.

Owner:TIANJIN UNIV

Composite flat-sheet polysulfone membrane doped with active carbon and nanometer zinc oxide and preparation method thereof

InactiveCN102974236BImprove hydrophilicityLoose structureSemi-permeable membranesPolymer scienceMeth-

The invention discloses a composite flat-sheet polysulfone membrane doped with active carbon and nanometer zinc oxide and a preparation method. The preparation steps are as follows: mixing nanometer zinc oxide, active carbon particles, polysulfone and 1-methyl-2-pyrrolidone in a mass ratio of (0.5-1) to 5 to 20 to 100; ultrasonically oscillating and dispersing the components; stirring the mixture until the components are completely dissolved, de-foamed and membrane-pushed; standing the pushed membrane in the air for 15-20 seconds, then soaking the membrane to a water coagulating bath for 20 minutes, putting the soaked membrane to deionized water to soak for 3 days and then taking out the soaked membrane. The composite flat-sheet polysulfone membrane provided by the invention can improve anti-pollution and adsorption performances of the membrane, and further can carry out photocatalysis under ultraviolet irradiation to effectively remove degradation-resistant pollutants in the water.

Owner:HOHAI UNIV

Co with both primary amine and carbonate groups 2 Separation membrane and its preparation method

ActiveCN104857867BRealize synergistic coupling effectImprove efficiencySemi-permeable membranesDispersed particle separationUltrafiltrationAmmonium carbonate

The invention relates to a carbon dioxide separation membrane with primary amino groups and carbonate groups and a preparation method thereof; preparation of poly(vinylamine-diallyl dimethyl ammonium carbonate) copolymer and polyvinylamine or polydiallyl A blend of dimethyl ammonium carbonate; with polysulfone ultrafiltration membrane as a support, the blend is dissolved in deionized water, stirred and defoamed to obtain a coating solution; dried for a period of time under certain temperature and relative humidity conditions to obtain A CO2 separation membrane with both primary amine groups and carbonate groups. The invention realizes the synergistic coupling effect between different functional carriers: not only the efficiency of the functional carriers is enhanced, but also the disadvantages of various functional carriers when used alone are avoided. Excellent CO2 permeation selectivity performance: For CO2 / N2 mixed gas, under the feed gas pressure of 0.11-2.00MPa, the CO2 permeation rate is (137-1842)×10-6, and the CO2 / N2 separation factor is 23-160 .

Owner:TIANJIN UNIV

A kind of method for preparing positively charged nanofiltration membrane by chloromethylated polysulfone

ActiveCN106914155BGood anti-pollutionHigh selectivitySemi-permeable membranesMembranesUltrafiltrationNanofiltration

The invention discloses a method for preparing a charged nanofiltration membrane by chloromethylated polysulfone. According to the invention, chloromethylated polysulfone is placed in a trimethylamine solution to obtain a positively charged polysulfone material, then the material is subjected to magnetic stirring for 24 h, the positively charged polysulfone material is placed in ethylene glycol monomethyl ether to prepare a casting solution, the casting solution is used for coating the surface of a polysulfone ultrafiltration base membrane, and the base membrane is dried in a temperature scope of 30-40 DEG C to prepare the nanofiltration membrane; under pressure of 1.2 MPa, the nanofiltration membrane has retention rate and flux on sodium chloride and magnesium chloride being 69.3% / 52.6 L.m<-2>.h<-1> and 76.8% / 40.6 L.m<-2>.h<-1>. The film forming material contains a positively charged group, the retention rate of a positively charged dye by the membrane can reach 95% and above, the charged nanofiltration membrane can be used for separating the salt and the positively charged dye, the nanofiltration membrane has the hydrophilic group, and has good anti-pollution performance.

Owner:ZHEJIANG UNIV OF TECH

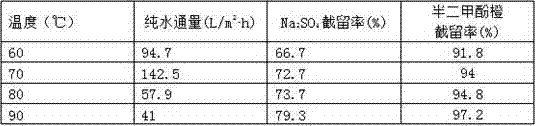

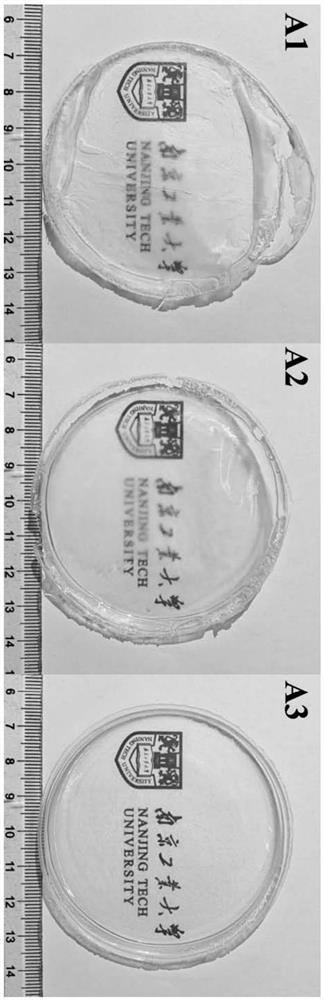

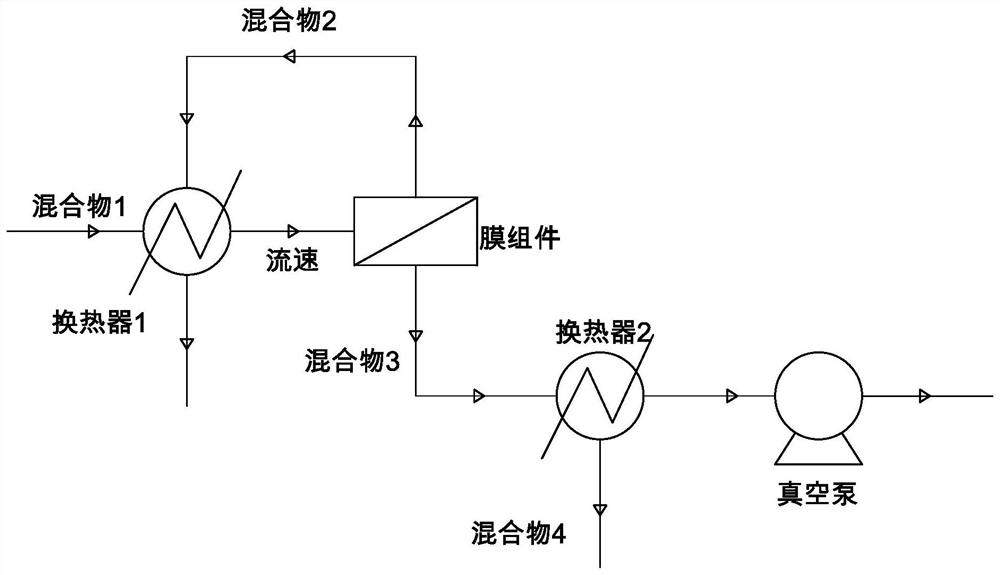

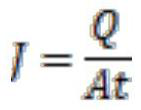

A thermoplastic pervaporation polymer film and its preparation method and application

ActiveCN113289504BGood film formingImprove film formationWater contaminantsWater/sewage treatment bu osmosis/dialysisPolymer sciencePervaporation

The invention provides a preparation method for separating phenolic organic matter / water thermoplastic pervaporation polymer membrane. Through the synergistic effect of solvent ratio, temperature and solvent volatilization rate, the curing rate of thermoplastic materials is regulated, and pervaporation polymer films with excellent film-forming properties are prepared. The pervaporation polymer membrane prepared by the method has outstanding separation performance in removing phenolic organic matter in water, and its flux and separation factor are superior to the similar separation membranes prepared by the traditional method. The method can better retain the intrinsic properties of the membrane material and maximize the performance of the separation membrane.

Owner:NANJING TECH UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com