Porous membrane with nanometer aperture and preparation method thereof

A porous membrane, pore size technology, applied in electrical components, circuits, battery pack components, etc., can solve the problems of adverse effects on the consistency of membrane product quality, difficulty in large-scale mass production, environmental pollution, etc., and achieve easy industrial scale production. , Strong electrochemical corrosion resistance, and the effect of improving ion conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

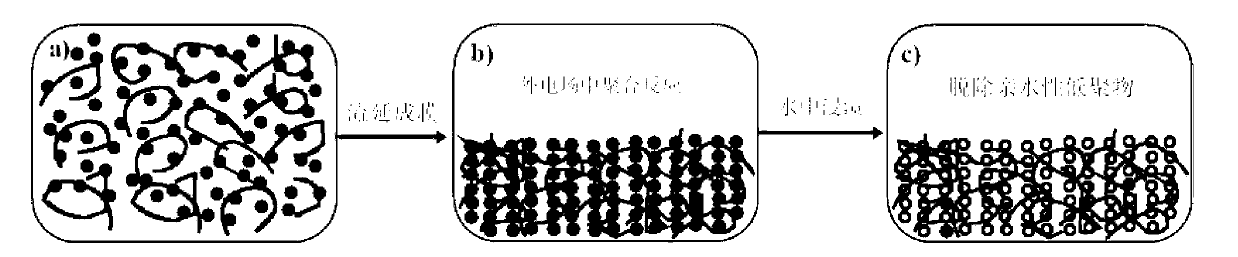

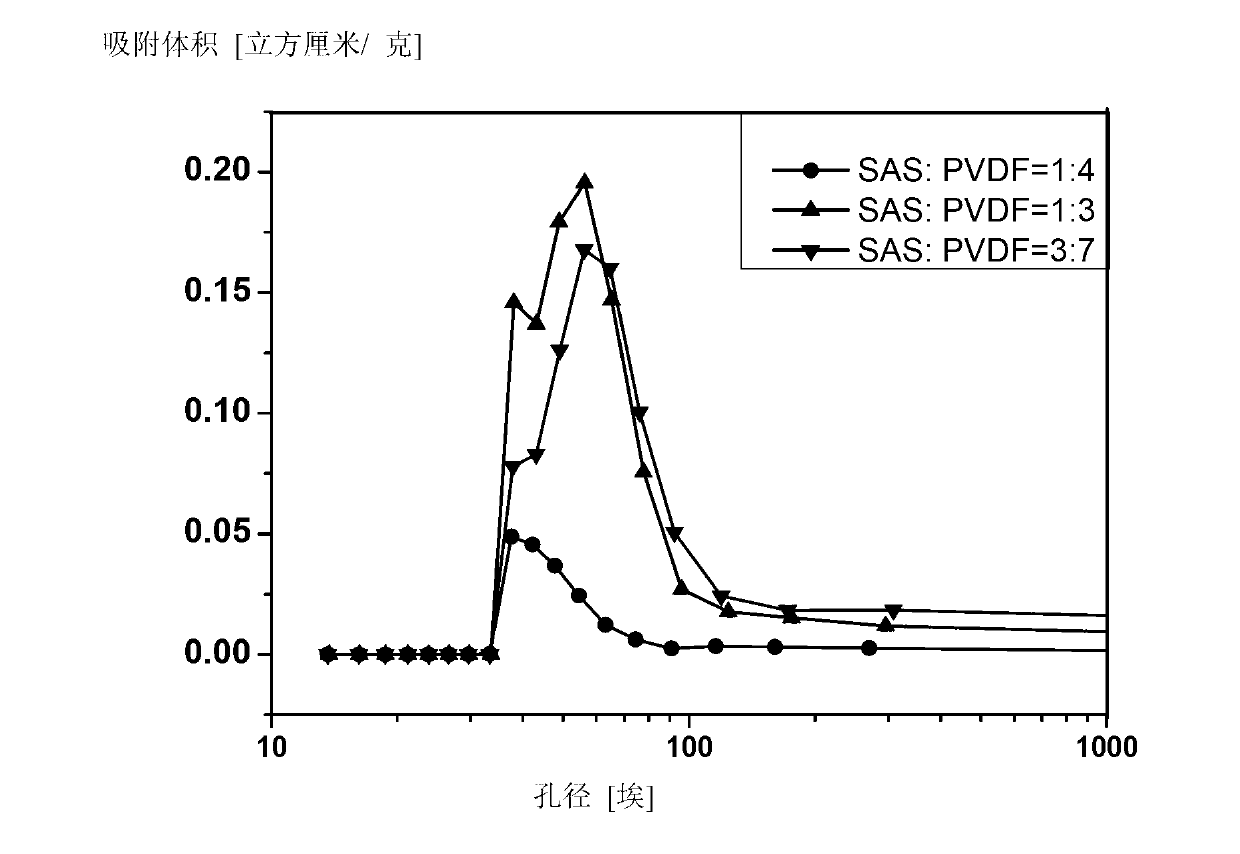

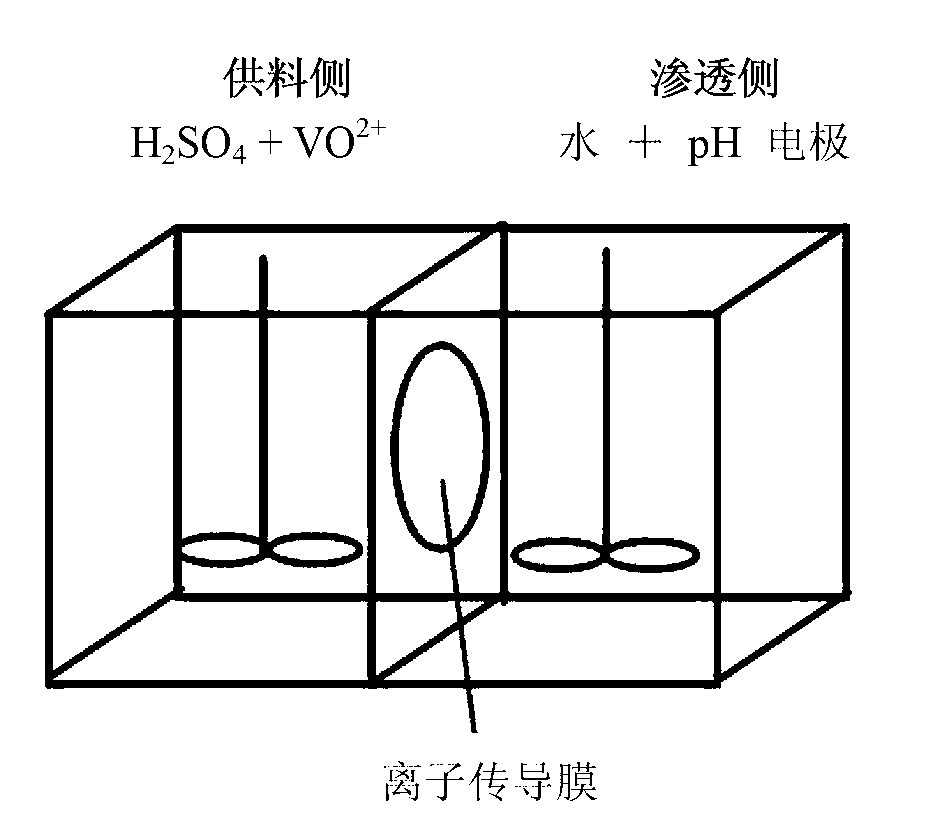

[0029] Example 1: Preparation of Nanopore Porous Membrane and Its Performance Test

[0030] Put 7.5 grams of polyvinylidene fluoride and 2.5 grams of sodium allyl sulfonate into a conical flask, add 60 ml of dimethyl sulfoxide (the mass ratio of polyvinylidene fluoride to dimethyl sulfoxide is 1:9 ) to obtain the casting solution. Place in a water bath at 80°C and stir for 2 hours until uniform. Thereafter, the film-casting solution was placed in a vacuum drying oven to remove air bubbles, and after standing still for 3 hours, the film was scraped on a glass plate to obtain a film with a thickness of 100 microns. The film was placed in an oven at 80° C. for 12 hours at a constant temperature to induce allyl sulfonate to form a low-molecular polymer while removing the solvent. Thereafter, the sodium allyl sulfonate low molecular weight polymer was removed by immersion in deionized water. This process was carried out three times to obtain a porous membrane with a membrane thic...

Embodiment 2

[0036] Embodiment 2: Preparation of nano-aperture porous membrane and its performance test under the condition of applying an external electric field

[0037] Put 7.5 grams of commercially available polyvinylidene fluoride and 2.5 grams of sodium allyl sulfonate into a conical flask, add 60 milliliters of dimethyl sulfoxide (the mass ratio of polyvinylidene fluoride to dimethyl sulfoxide is 1 : 9) Obtain a casting solution. Place in a water bath at 80°C and stir for 2 hours until uniform. Thereafter, the casting solution was placed in a vacuum drying oven to remove air bubbles, and after standing still for 3 hours, the film was scraped on a glass plate to obtain a film with a thickness of 220 microns. The film was placed between electrodes made of copper sheets at a distance of 1.2 mm from the electrode to the film surface. When other conditions are exactly the same, the film prepared without external electric field is used as a blank sample for comparison. The applied elec...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com