Ceramic diaphragm taking aerogel as powder body, and applications of ceramic diaphragm in lithium ion battery

A ceramic diaphragm and airgel technology, which is applied in secondary batteries, battery pack components, circuits, etc., can solve problems affecting the performance of ceramic diaphragms, poor uniformity, powder drop, etc., and achieve excellent thermal stability and low cost , the effect of low thermal conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

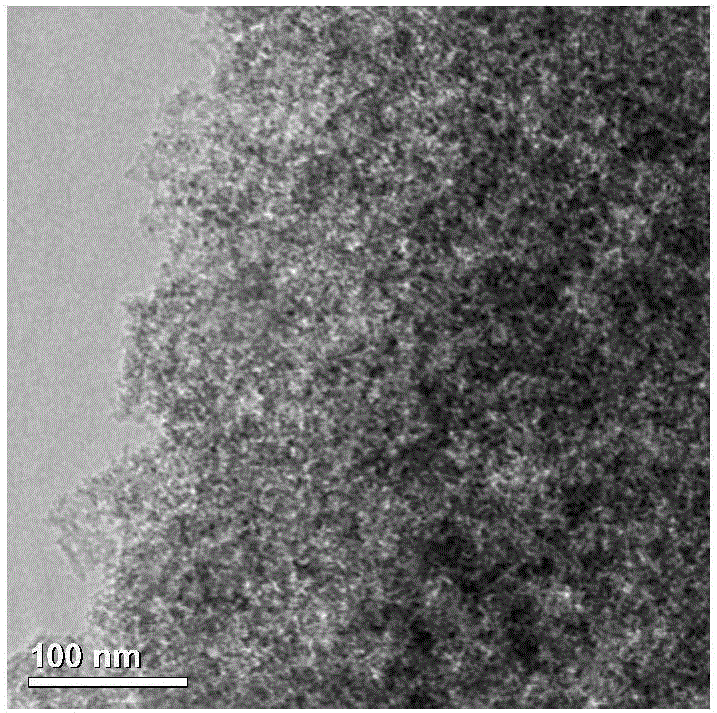

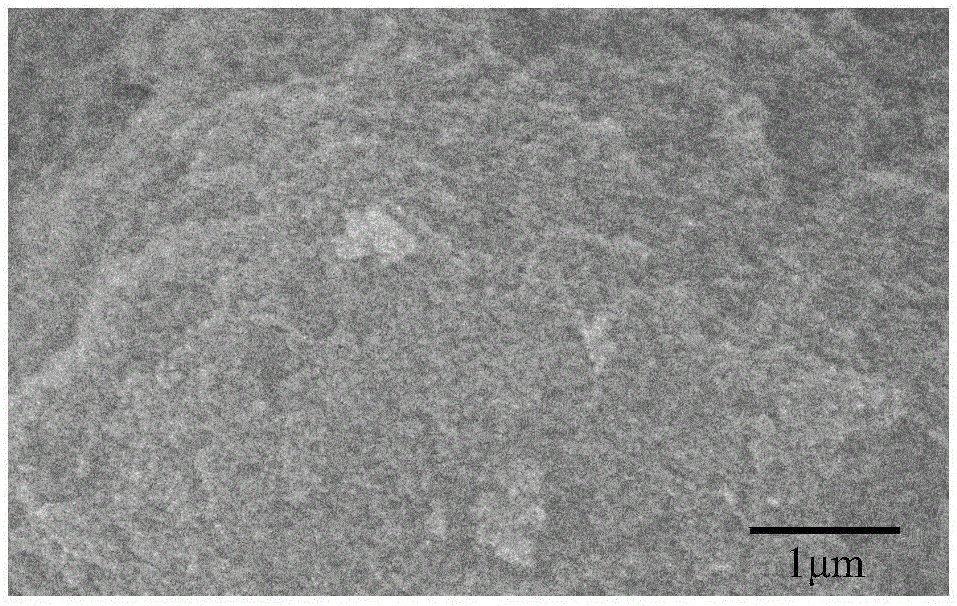

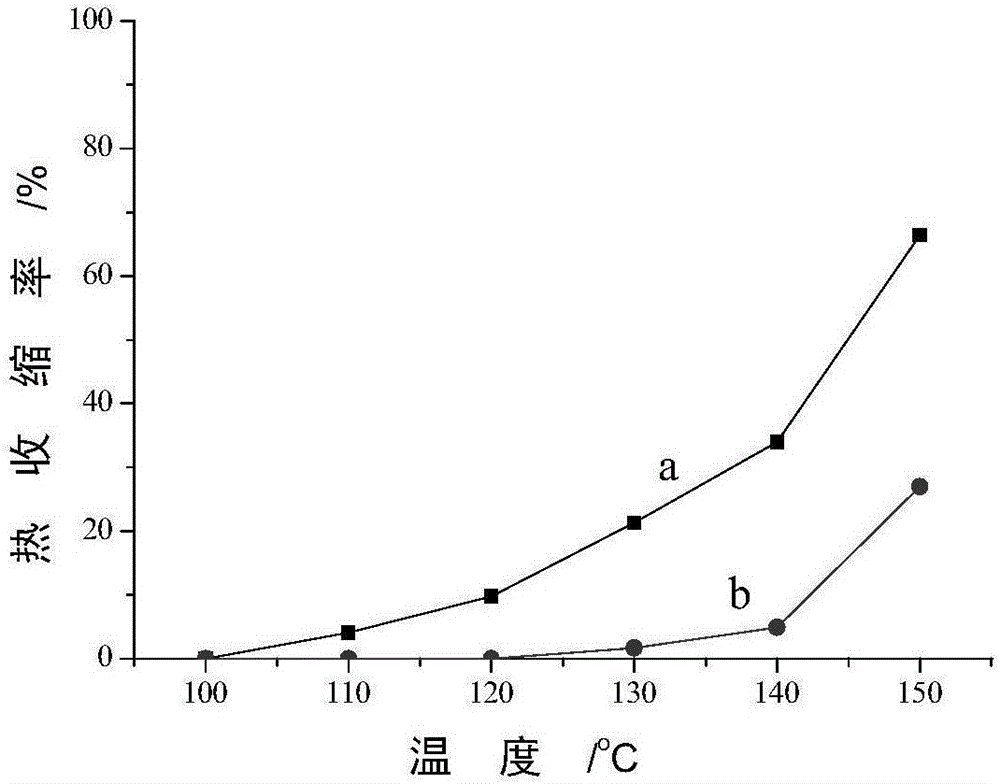

[0035] Add 8ml tetraethyl orthosilicate and 10.5ml absolute ethanol in the round bottom flask, adjust the pH value of the system to 2 with concentrated hydrochloric acid after mixing, then add 5ml of distilled water (distilled water The molar ratio is about 1:5:8), stirred and refluxed at 60°C for 90 minutes to fully hydrolyze the tetraethyl orthosilicate, and then adjust the pH to 8 with 1mol / L ammonia solution to accelerate the hydrolysis of the tetraethyl orthosilicate Polycondensation reaction occurs to obtain SiO 2 alcohol gel. The obtained alcohol gel was soaked in absolute ethanol at 60°C and ethanol solution of ethyl orthosilicate at 70°C (the volume ratio of ethyl orthosilicate to ethanol was 1:5) for 24h and 48h respectively. SiO can be obtained by drying at a constant temperature of 70°C for 72 hours 2 Airgel products. The resulting SiO 2 Airgel is a milky white translucent uniform block. figure 1 Transmission electron micrographs of the obtained airgel. The s...

Embodiment 2

[0038] Titanium dioxide airgel prepared by supercritical carbon dioxide method is used as powder, and polyvinylidene fluoride is used as binder to disperse in N-methylpyrrolidone. Double-sided coating is carried out on the polypropylene diaphragm at a speed of 2m / min, and a ceramic diaphragm is obtained after drying.

Embodiment 3

[0040] The silica airgel prepared by supercritical carbon dioxide method is used as powder, and polyvinylidene fluoride is used as binder to disperse in dimethylformamide. After dispersing for 5 hours under mechanical stirring conditions, it is coated on GTB780 Double-sided coating is carried out on the vinylidene fluoride-hexafluoropropylene copolymer film at a speed of 2m / min on the machine, and a ceramic diaphragm is obtained after drying.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com