Novel polyvinyl alcohol nanofiltration membrane preparation method

A technology of polyvinyl alcohol and nanofiltration membranes, applied in chemical instruments and methods, membrane technology, semipermeable membrane separation, etc., can solve the problems of water permeability reduction and achieve improved wettability, increased strength, high permeability selectivity and Effect of Pollution Resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0012] Mix ethylene glycol methyl ether and pure water in a mass ratio of 1:1 to form a solvent, use it as a solvent to add terephthalaldehyde and sodium dodecylsulfonate with mass fractions of 0.1% and 0.15% respectively, heat and stir Dissolve to make a crosslinking agent solution; dissolve polyvinyl alcohol in deionized water with a mass fraction of 0.05%, heat and stir at 60°C for 1.5 hours to make an aqueous solution. Pour the crosslinking agent solution on the polysulfone bottom film, let it stand for five minutes to pour off the excess solvent, put it in an oven at 28°C until the solvent is dried; then pour polyvinyl alcohol aqueous solution on the surface of the film, and dry it at 70°C 10 minutes to form a film.

[0013] Tested under the pressure of 0.8MPa, the permeation flux of the membrane is 142.5L / m 2 .h, for Na 2 SO 4 The rejection rates of xylenol orange and semi-xylenol orange were 74.7% and 94%, respectively.

Embodiment 2

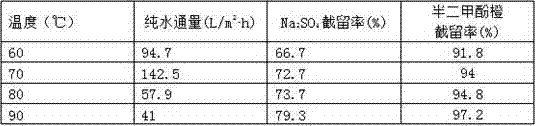

[0015] Change the mass fraction of terephthalaldehyde in the crosslinking agent solution, other steps are the same as in Example 1, prepare a composite film and test, and the results are as follows:

[0016] .

Embodiment 3

[0018] Change the mass fraction of sodium dodecylsulfonate in the crosslinking agent solution, the mass fraction of PVA is 0.1%, and the other steps are the same as in Example 1, and the composite membrane is prepared and tested, and the results are as follows:

[0019] .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com