Metal ion-organic acid complex in-situ cross-linked composite membrane and preparation and application thereof

A metal ion and in-situ cross-linking technology, applied in the field of composite membranes, can solve problems such as the difficulty in preparing thin polymer composite membranes, achieve good universality, overcome high concentration, and reduce mass transfer resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0033] The invention provides a metal ion-organic acid complex-assisted in-situ cross-linked polymer composite membrane and a preparation method and application thereof, which mainly include the following steps:

[0034] (1) Anchoring the cross-linked layer on the surface of the polymer support layer

[0035]Place the polymer support layer in 0.5-3.0M NaOH solution for alkali treatment for 15-60 minutes, then soak in deionized water to remove the adsorbed alkali solution; then soak the alkali-treated polymer support layer in the metal ion solution Take it out after 3-30 minutes, wash off the residual solution on the surface of the support layer with deionized water; then take it out after soaking in an organic acid solution for 3-30 minutes, and wash off the residual solution on the surface of the support layer with deionized water. Repeat the above steps until the surface has enough cross-linking reaction sites, and after drying, a polymer support layer with a cross-linked la...

Embodiment 1

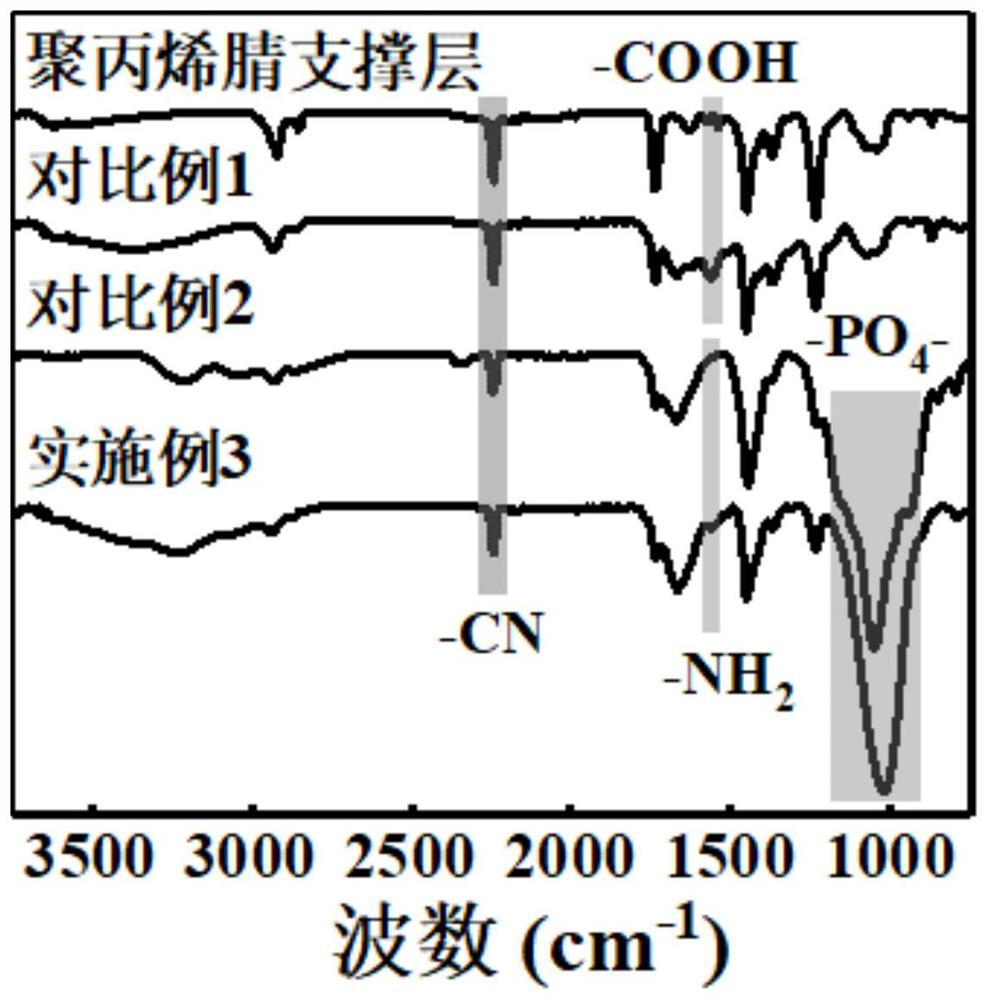

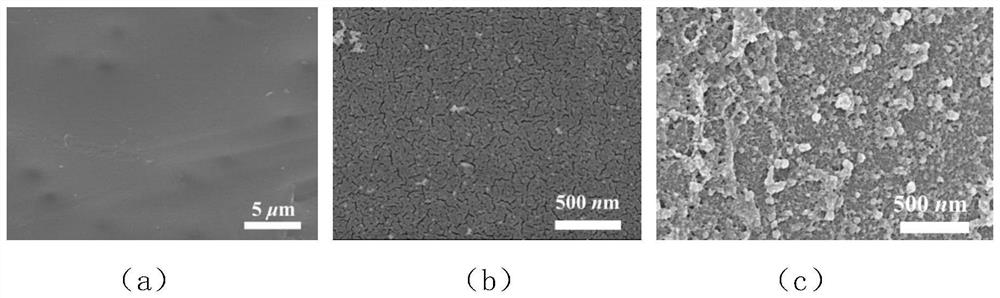

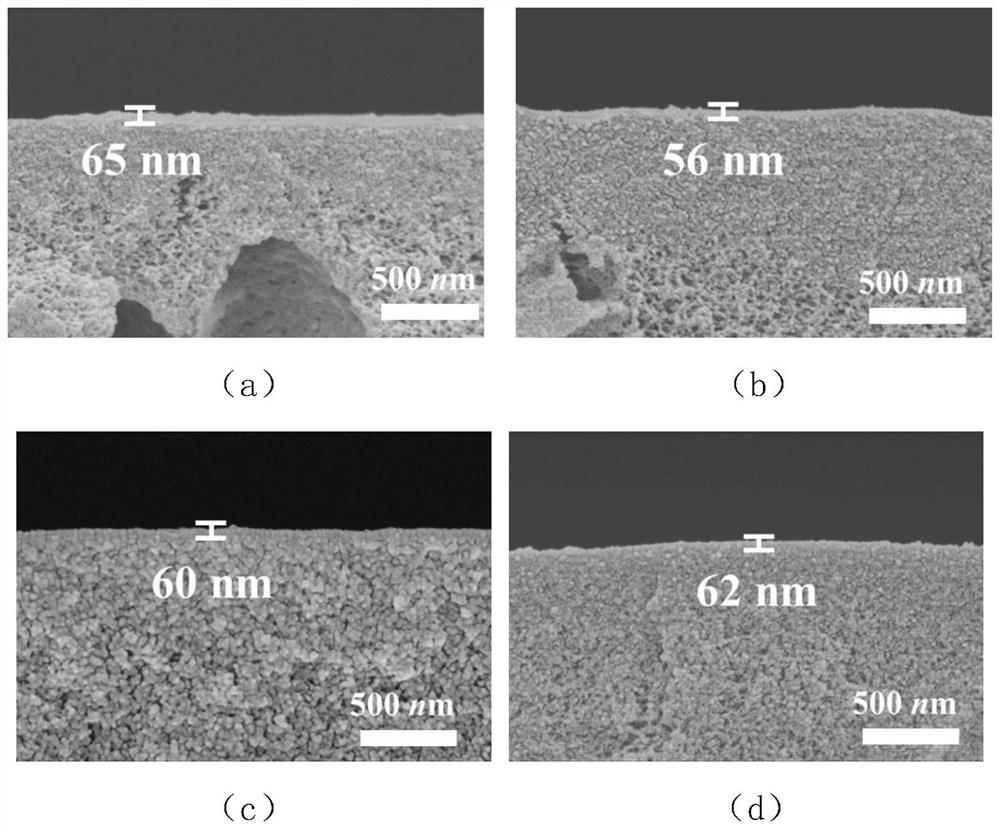

[0053] Example 1 is an in-situ cross-linked chitosan composite membrane, and the support layer of the composite membrane is a polyacrylonitrile hollow fiber membrane. The preparation process of the composite membrane includes the following steps:

[0054] (1) The polyacrylonitrile hollow fiber membrane was alkali-treated at 50° C. for 30 minutes.

[0055] (2) Soak the alkali-treated polyacrylonitrile support layer in FeCl 3 In the solution for 5 minutes, the residual solution on the surface of the support layer was washed with deionized water; then, it was soaked in a phytic acid solution for 5 minutes, and the residual solution on the surface of the support layer was washed with deionized water.

[0056] (3) A chitosan / acetic acid aqueous solution with a mass fraction of 1 wt % was prepared, and the solution was fully stirred until it was completely dissolved. The two ends of the support layer prepared in step (2) are blocked with epoxy resin quick-drying adhesive, soaked i...

Embodiment 2

[0058] The experimental operation is the same as that of Example 1, the difference is that after completing step (2), it continues to soak in FeCl 3 solution once.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com