Patents

Literature

55results about How to "Limit migration" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Synthetic method of transparent water-whitening resistant polyacrylate emulsion

The invention discloses a synthetic method of a transparent water-whitening resistant polyacrylate emulsion. The synthetic method is as follows: uniformly mixing an emulsifier, a soft monomer, a hard monomer and a functional monomer to obtain a monomer mixed liquor containing the emulsifier; adding deionized water in a reactor, heating to a preset temperature, adding 30wt%-50wt% of an initiator, stirring for 5min, dropping the monomer mixed liquor, dropping for 2-5h; after the monomer mixed liquor is added for 30min, dropping the rest of the initiator, dropping for 2-5h, controlling the reaction temperature to be 70-90 DEG C, keeping warm for 0.5-1 h; cooling to 60 DEG C, adding tert-butyl hydroperoxide and sodium formaldehyde sulfoxylate, continuing to react for 0.5h, cooling to 45 DEG C, and adding ammonium hydroxide for adjusting the pH value to be 6-8. According to the synthetic method, a monomer pre-emulsification step is omitted in an emulsion polymerization process, the operation is simpler, the energy consumption is reduced, the work efficiency is improved, and at the same time, the emulsion has excellent performances and a good water-whitening resistant characteristic.

Owner:SHANGHAI CHENGYING NEW MATERIALS +1

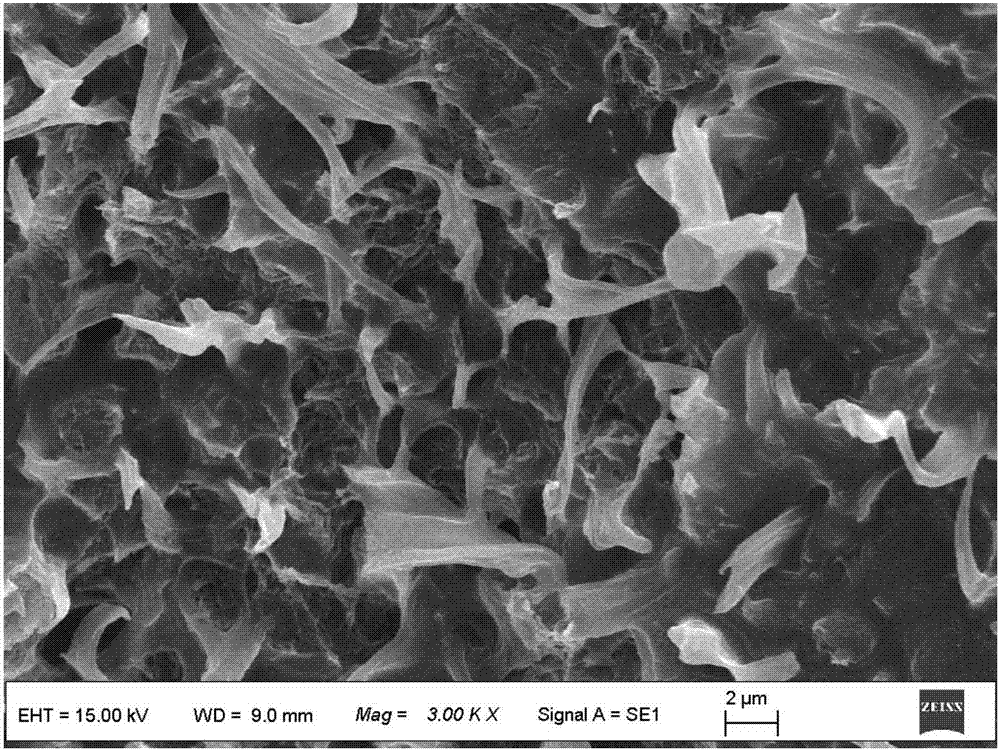

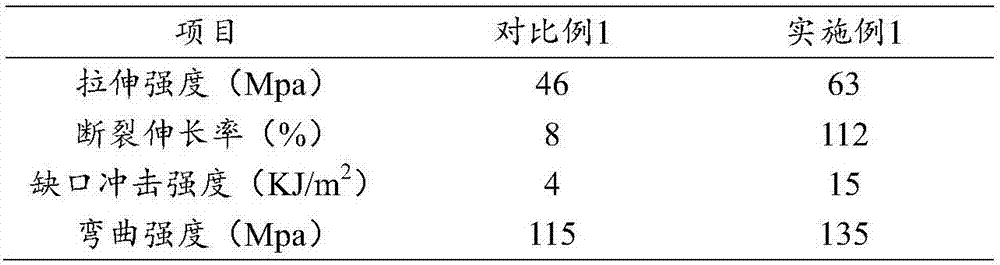

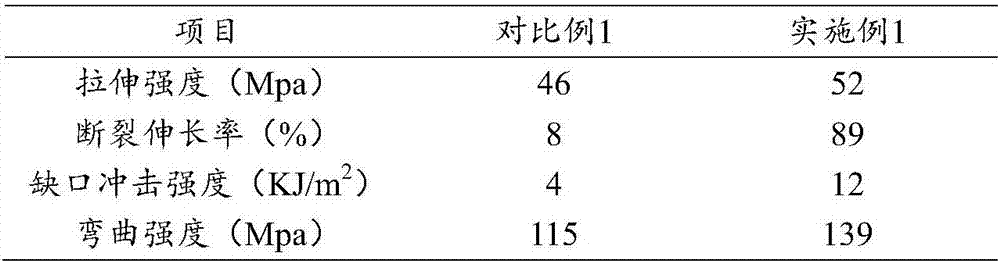

Reinforcing and toughening polylactic acid material and preparation method thereof

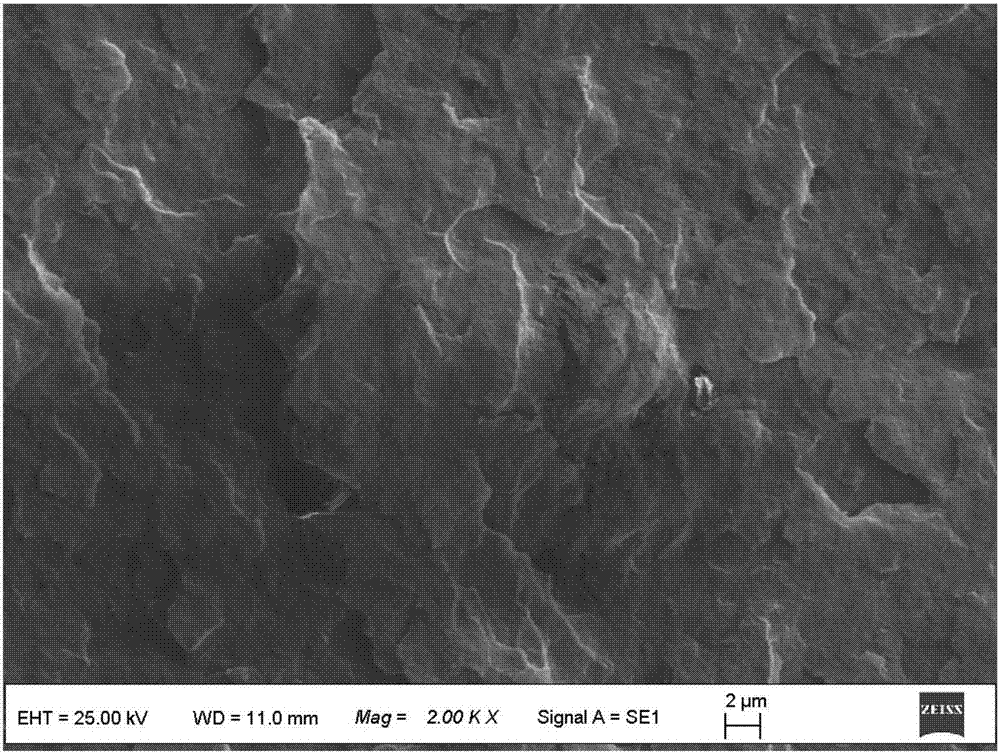

The invention provides a reinforcing and toughening polylactic acid material and a preparation method thereof, and relates to the field of polymer materials. The preparation method comprises the steps of mixing layered double hydroxides with epsilon-caprolactone and obtaining reactants, and after a ring opening polymerization, obtaining polycaprolactone modifier; conducting addition polymerization on the polycaprolactone modifier and diisocyanate, and obtaining prepolymer; making the prepolymer react with chain extender, and obtaining polyurethane modifier; melting and mixing the polyurethane modifier and polylactic acid, and obtaining the reinforcing and toughening polylactic acid material. Flexible chain segments of the polyurethane modifier improve the elasticity and flexibility of the material, rigid chain segments of the polyurethane modifier improve the strength and heat resistance of the material, and finally the overall mechanical property of the material is improved. Since the layered double hydroxides with a laminated structure are dispersed in a base material, the bending strength and stretching strength of the material are improved, and the anchoring effect of the material can avoid the modifier compatibility and migration problem which is easily generated from simple physical blending.

Owner:HUNAN UNIV OF TECH

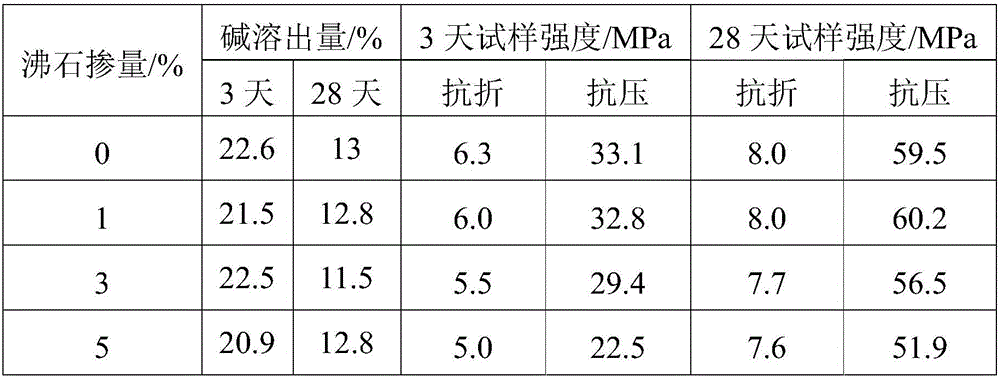

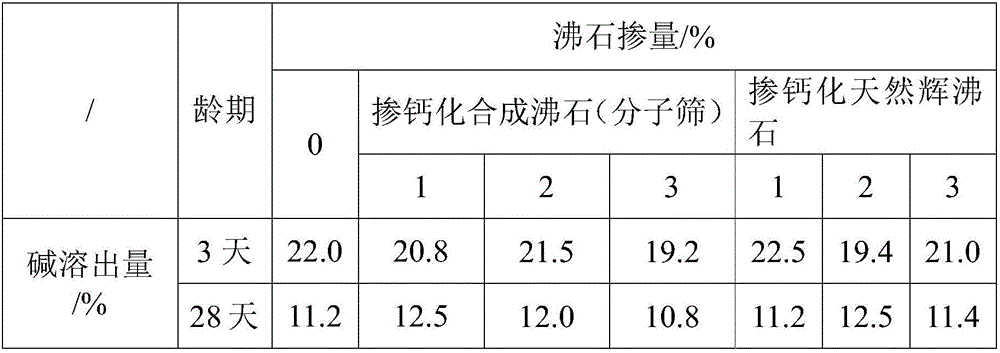

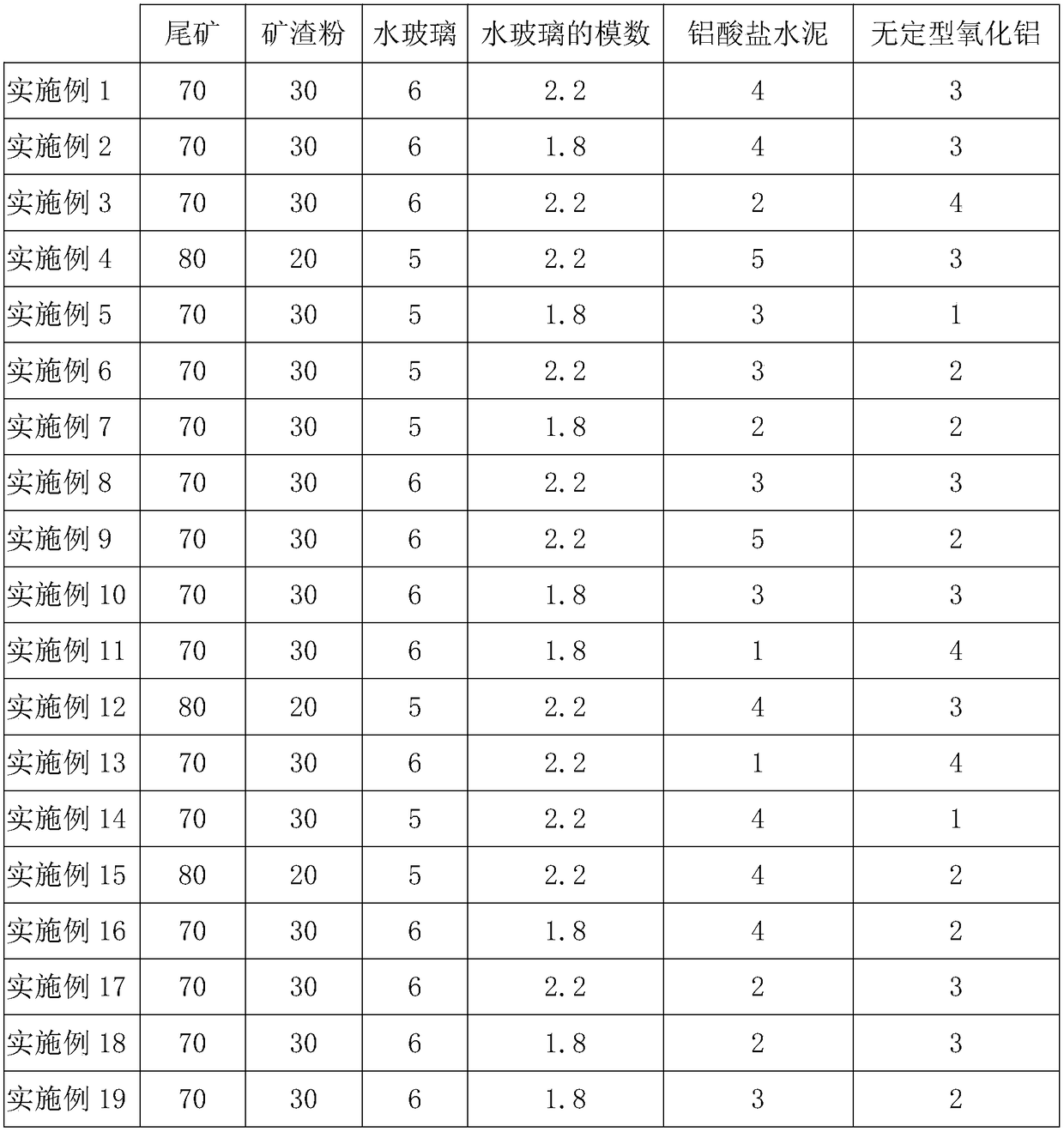

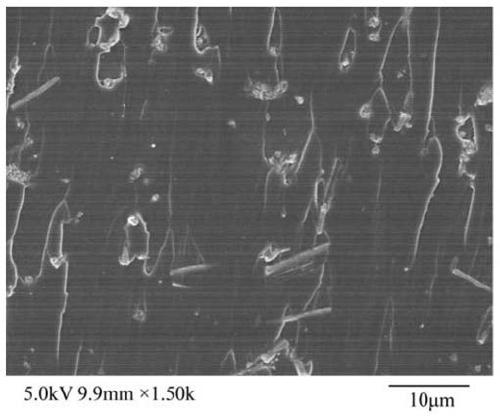

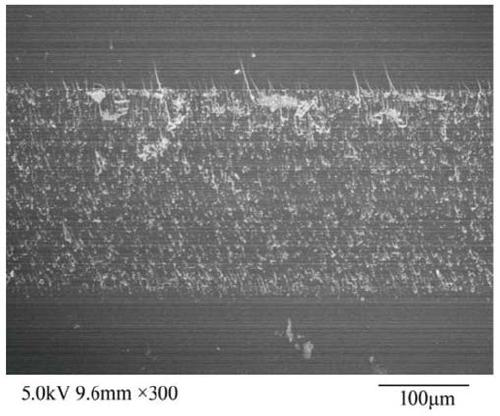

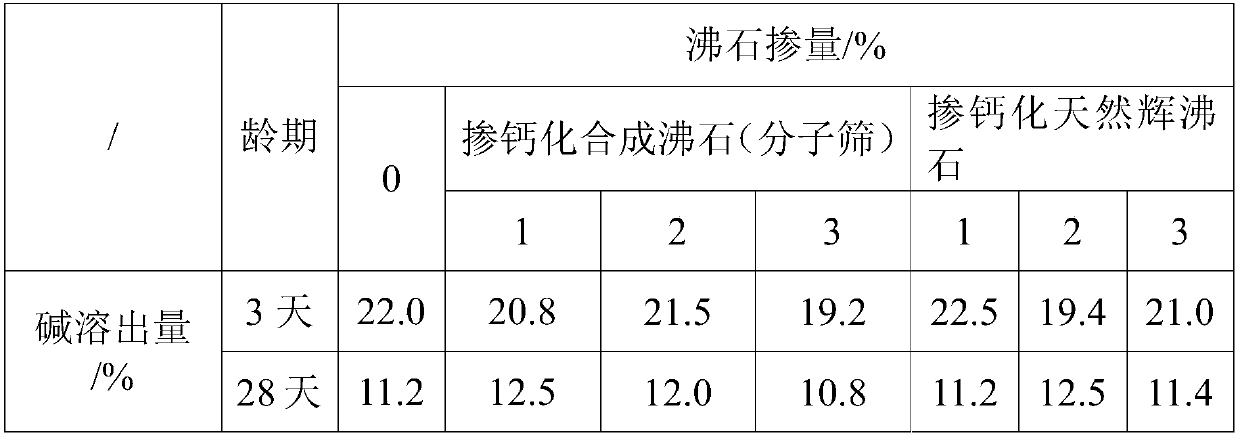

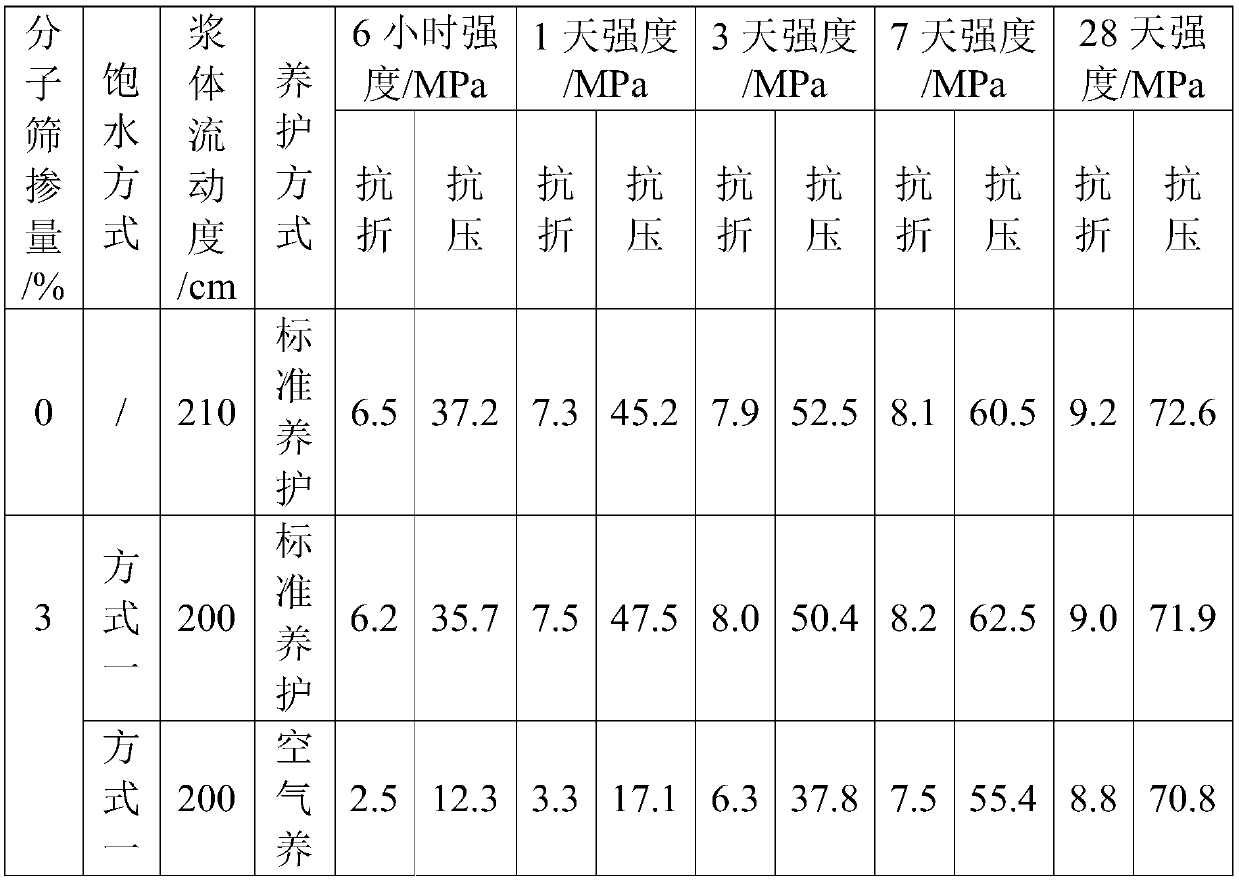

Alkali-activated cementing material and preparation method thereof

ActiveCN106746781AGuaranteed StrengthGuaranteed work performanceCement productionAlkali activatedDissolution

The invention discloses an alkali-activated cementing material and a preparation method thereof, belonging to the building field. The preparation method comprises the following steps: (1) weighing raw materials, wherein the raw materials include powder, an aqueous solution of a liquid activator and calcium-containing zeolite, the powder is prepared by mixing calcined bauxite tailings and slag powder in a mass ratio of (7-8):(3-2), the mass of the aqueous solution of the liquid activator is 4-5% of the mass of the powder based on the mass of Na2O, and the mass of the calcium-containing zeolite is 1-5% of the mass of the powder; and (2) mixing the raw materials to obtain the alkali-activated cementing material, wherein the mass ratio of the water to solid raw materials in the raw materials is 0.4-0.5. In the invention, the cementing material prepared by the method has the advantage of low alkali dissolution.

Owner:CHINA BUILDING MATERIALS ACAD

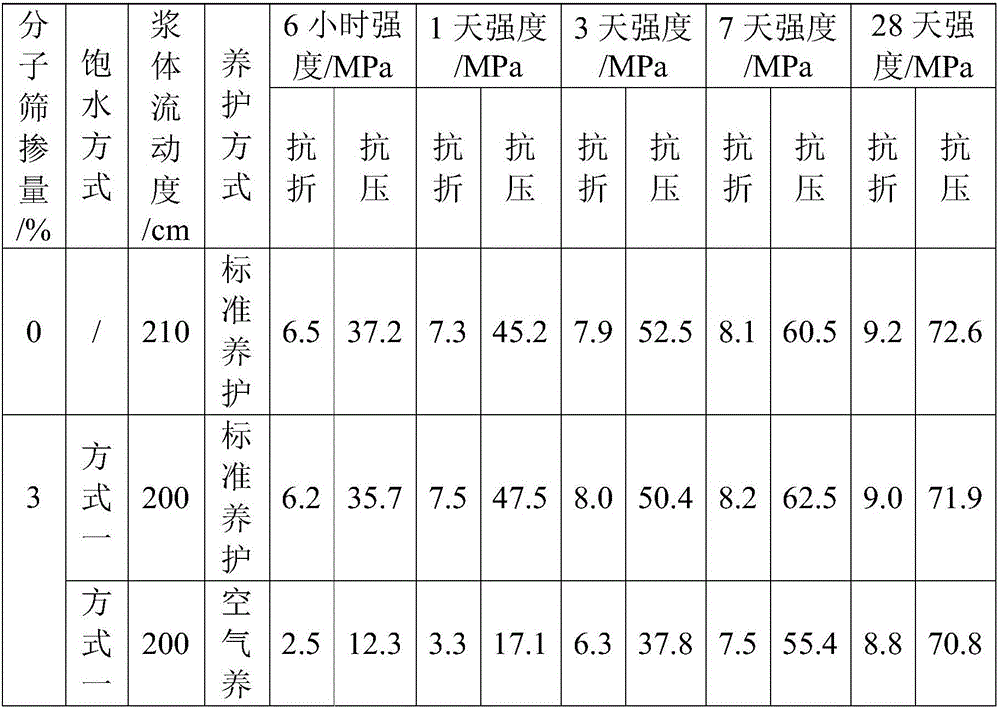

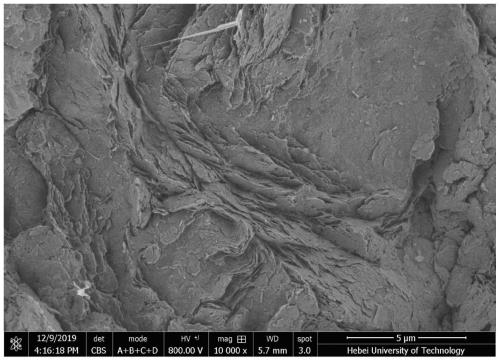

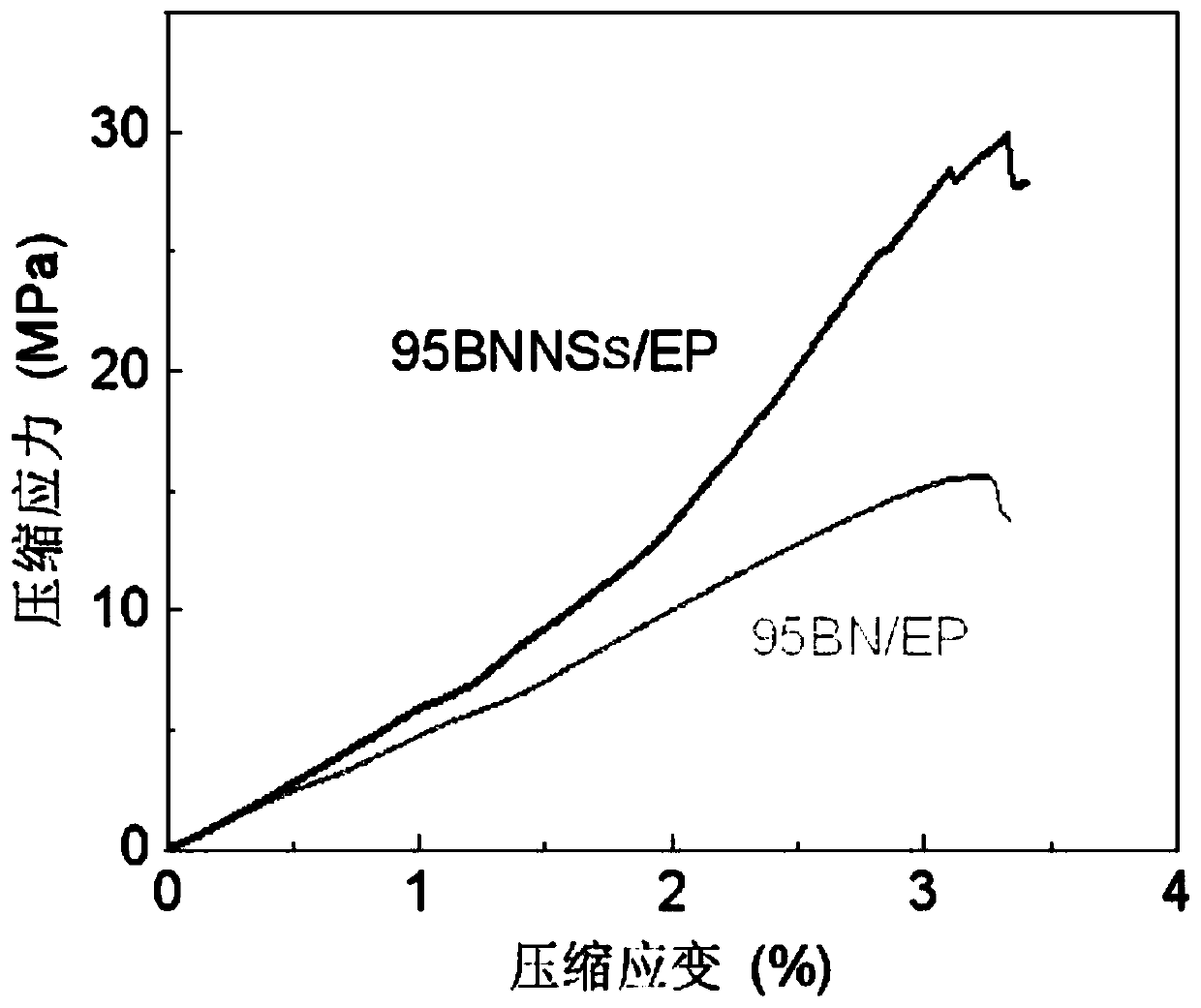

Preparation method of hexagonal boron nitride/polymer blocky composite material with high filling amount

ActiveCN111423699AStrong dense connection structureHigh compressive strengthCompression moldingPolymer science

The invention relates to a preparation method of a hexagonal boron nitride / polymer blocky composite material with high filling amount, wherein the method comprises the steps: step 1, adding hexagonalboron nitride and a polymer matrix into a mortar, grinding uniformly, and mixing to obtain a hexagonal boron nitride-polymer matrix mixture, wherein the polymer matrix is in a liquid state at normal temperature and normal pressure, and can be cured under the condition of changing temperature and / or pressure; step 2, putting the mixture obtained in the step 1 into a ball milling tank, and carryingout uniform ball milling to obtain a mixture obtained by further mixing and uniformly carrying out a reaction on hexagonal boron nitride and the polymer matrix; step 3, putting the mixture obtained inthe step 2 into a mold, and carrying out compression molding to obtain a blocky molded prototype of the polymer composite material; and step 4, polymerizing and curing the blocky forming prototype ofthe polymer composite material obtained in the step 3 to obtain the blocky material of the hexagonal boron nitride / polymer composite material with high filling amount. The composite material has ultrahigh mechanical properties and huge thermal management application potential.

Owner:HEBEI UNIV OF TECH

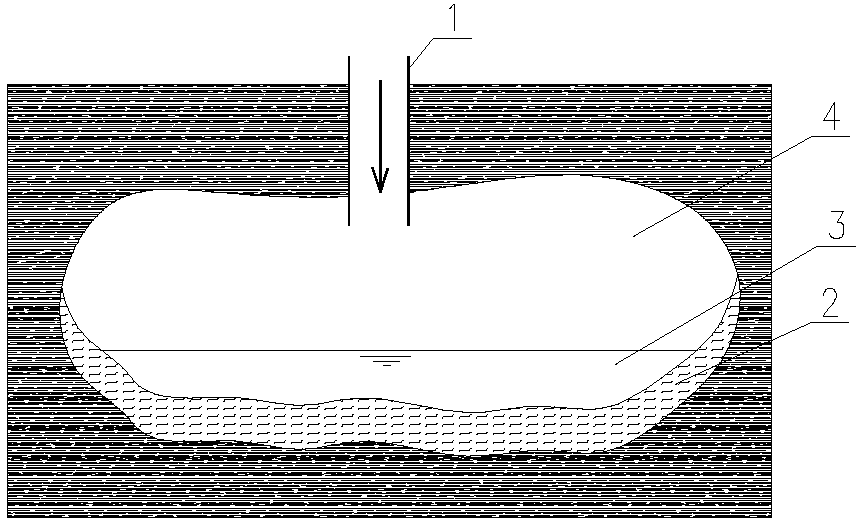

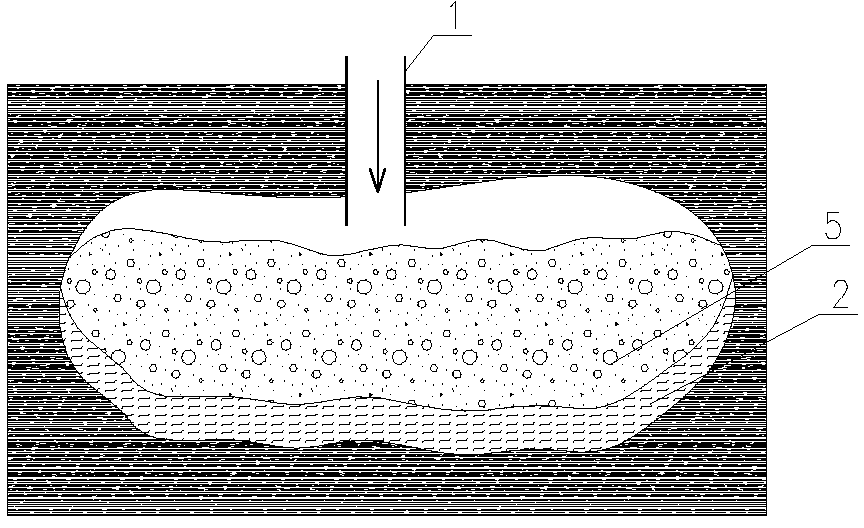

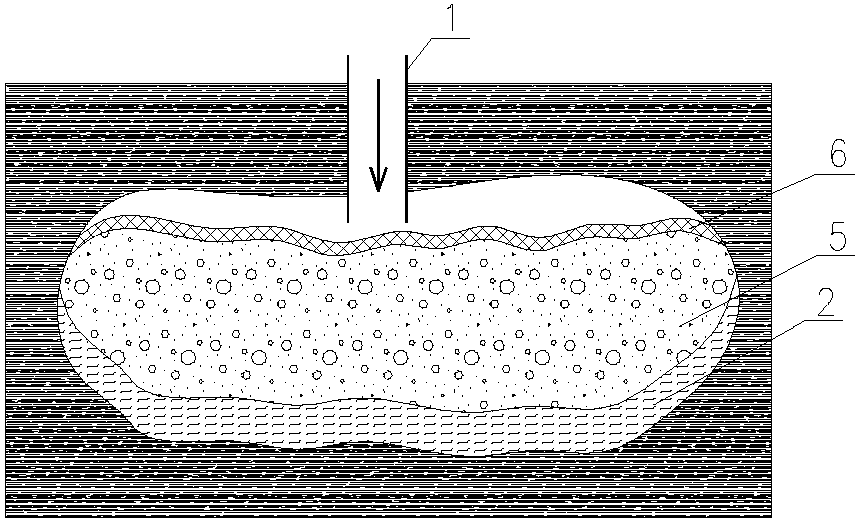

Method for controlling diffusion and migration of underground gasification residual pollutants

ActiveCN103244178APrevent evictionImprove interception abilityConstructionsCoal gasificationWater sourceStructure of the Earth

The invention relates to a method for controlling diffusion and migration of underground gasification residual pollutants. The method for controlling the diffusion and the migration of underground gasification residual pollutants comprises steps of building a bottom impervious layer, building a middle supporting layer and building a top waterproof layer. The method for controlling the diffusion and the migration of the underground gasification residual pollutants has the advantages of being simple in structure and convenient to construct; controlling the migration of the pollutants due to the facts that the impervious layer is a bentonite impervious layer and strong in pollutant retaining in gasified waste water and the bentonite are inorganic minerals, cheap and easy to obtain and good in pollutant retaining and absorption capability; and preventing clean water source from entering into an underground gasification waste water area through the top water proof layer, isolating the clean water source from the underground gasification waste water area and preventing surface water permeating into the underground gasification waste water area through a rock stratum and contacting with gasification waste water to be polluted.

Owner:CHINA UNIV OF MINING & TECH (BEIJING)

Alkali-activated cementing material and preparation method thereof

InactiveCN106431025AOptimize the amount of additionGuaranteed StrengthCement productionAlkali activatedAqueous solution

The invention discloses an alkali-activated cementing material and a preparation method thereof, and belongs to the field of buildings. The method comprises the following steps: (1), weighing raw materials, wherein the raw materials include powder, water solution of a liquid activator and an aluminum-containing addition agent, the powder is formed by roasted bauxite separation tailing and slag powder which are mixed according to the mass ratio of (7 to 8):(3 to 2), the mass of the water solution of the liquid activator is 4 to 5% that of powder according to the mass of Na2O, the mass of the aluminum-containing addition agent is calculated according to the mass of the Na2O, the aluminum-contained addition agent is weighed, and a molar ratio between the Na2O and Al2O3 is (0.9 to 1.3):1; (2), evenly mixing the powder and the aluminum-containing addition agent to obtain a solid raw material, and evenly mixing the solid raw material with the water solution of the liquid activator to obtain the alkali-activated cementing material, wherein a mass ratio between water in the raw materials and the solid raw materials is 0.4 to 0.5. The method has the advantage of being low in alkali dissolution quantity.

Owner:CHINA BUILDING MATERIALS ACAD

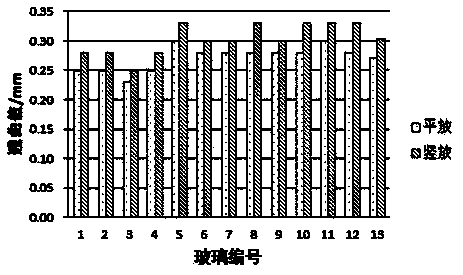

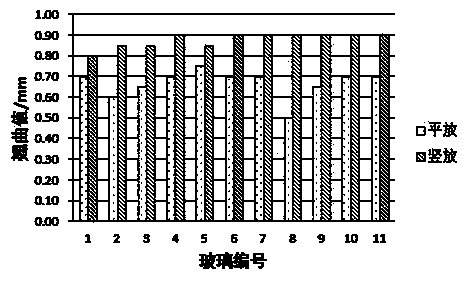

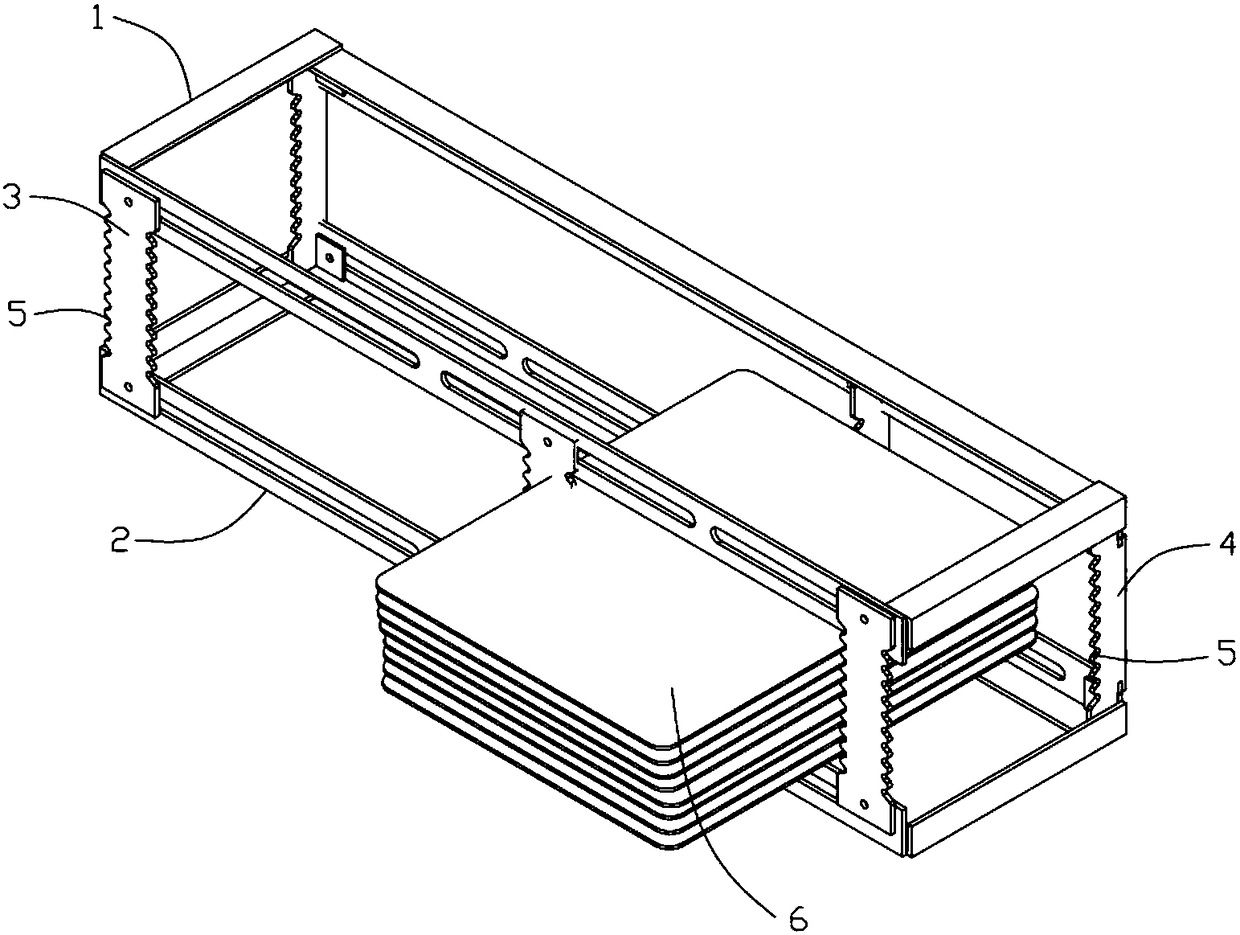

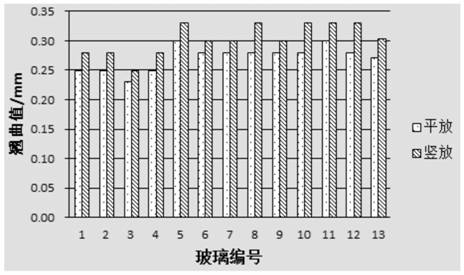

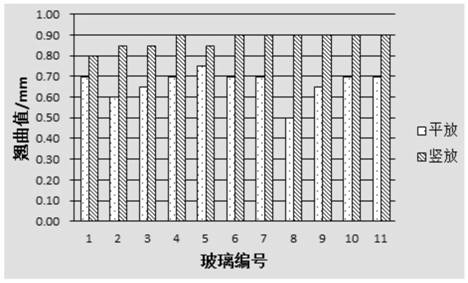

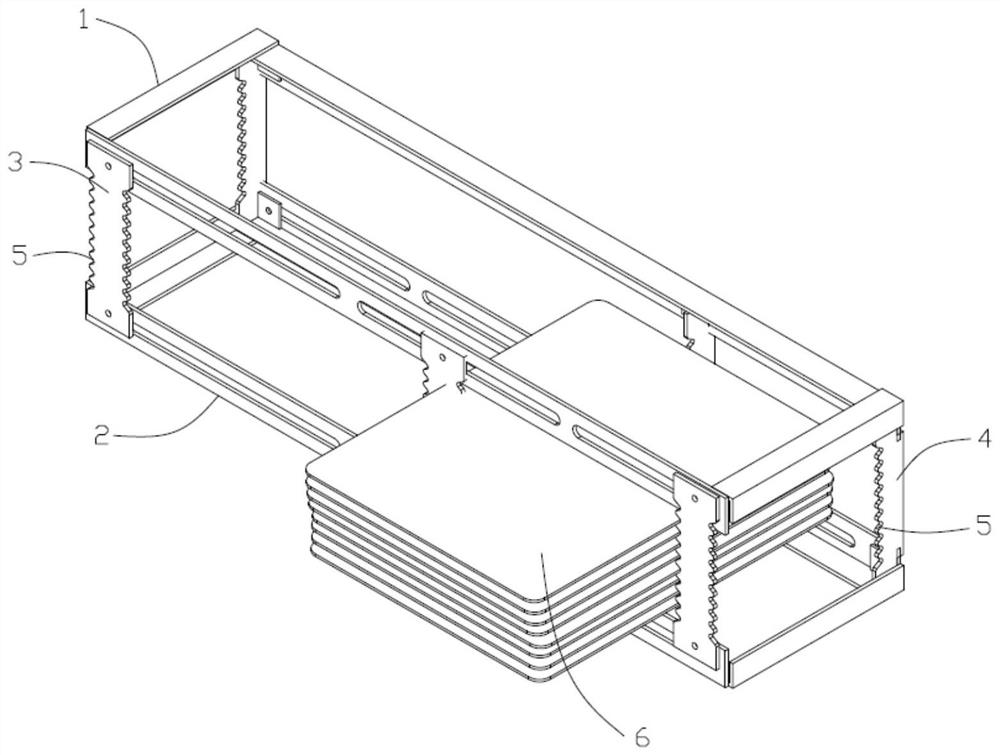

Method for reducing warping in chemical strengthening of glass and jig for strengthening

The invention relates to the technical field of manufacturing of float glass and discloses a method for reducing warping in chemical strengthening of glass and a jig for strengthening. According to the method for reducing warping in chemical strengthening of the glass, before chemical strengthening of the glass, the glass is flat placed, a tin surface of the glass faces downwards, and in the process of chemical strengthening of the glass, the temperature of ion exchange is set to be 380-450 DEG C. The jig for strengthening is applied to the method for reducing warping in chemical strengtheningof the glass and used for bearing the glass and making the glass flat placed. According to the method for reducing warping in chemical strengthening of the glass and the jig for strengthening, the value of warping generated by the float glass in the chemical strengthening process can be effectively reduced, and the qualification rate of the glass is increased.

Owner:河北视窗玻璃有限公司 +1

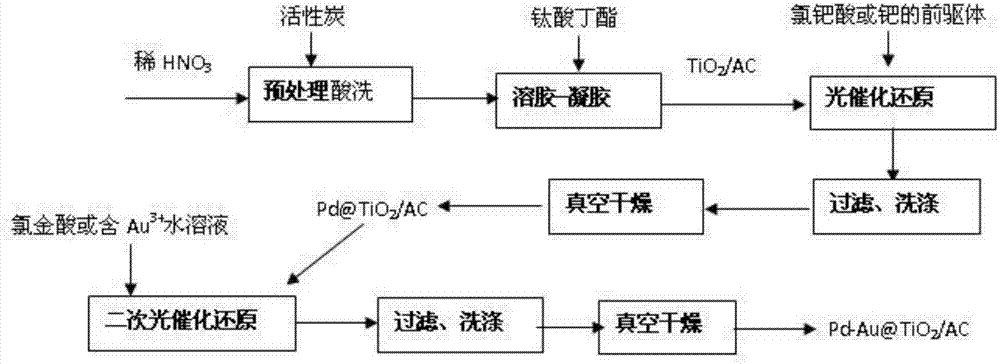

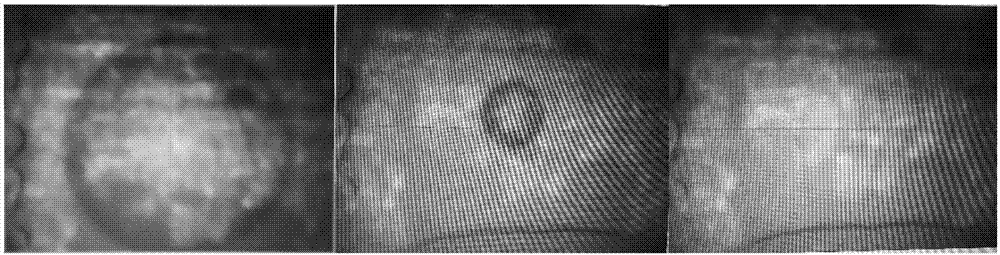

Metal catalyst, preparation method and application

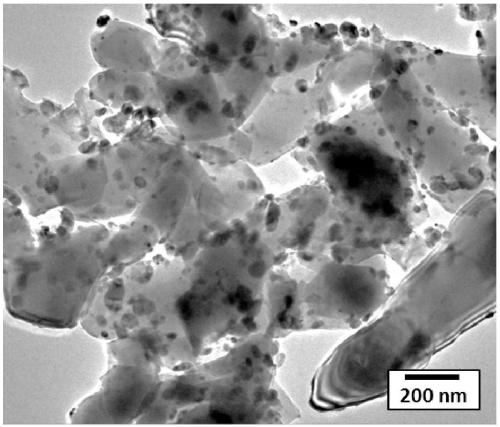

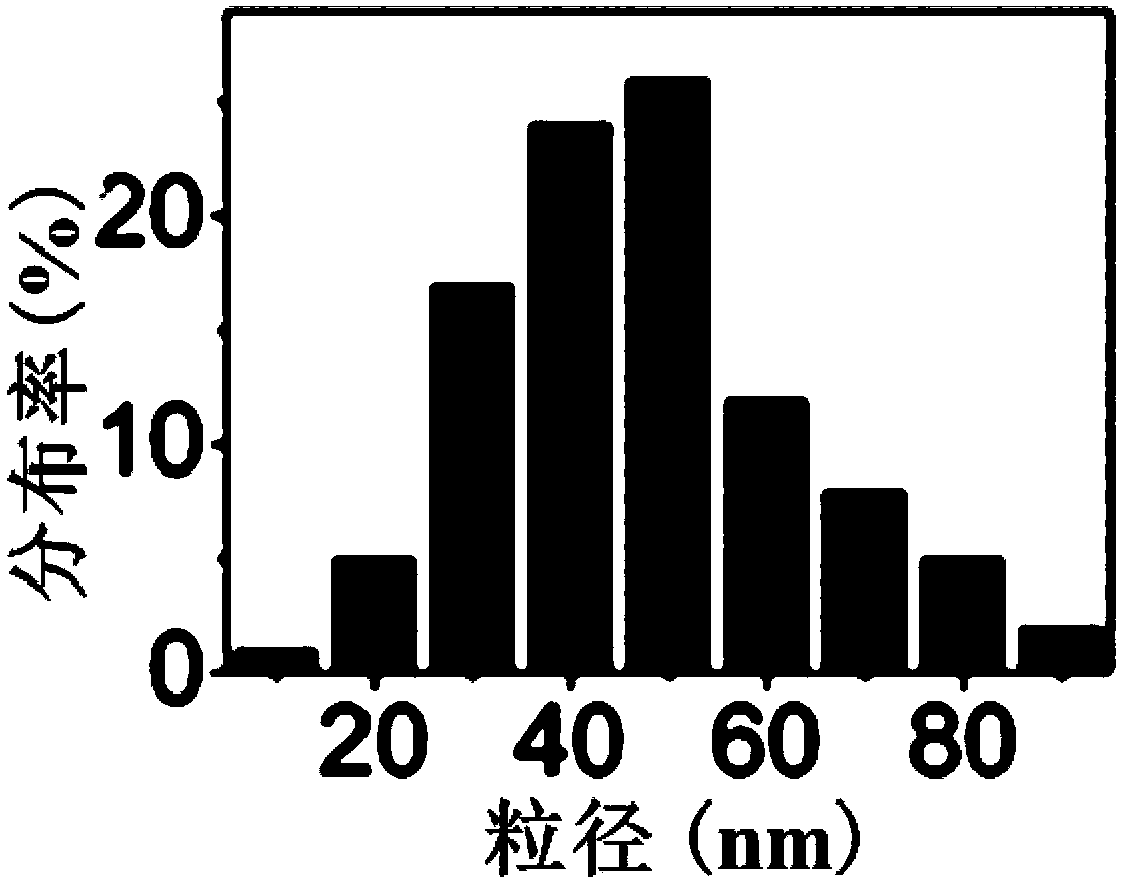

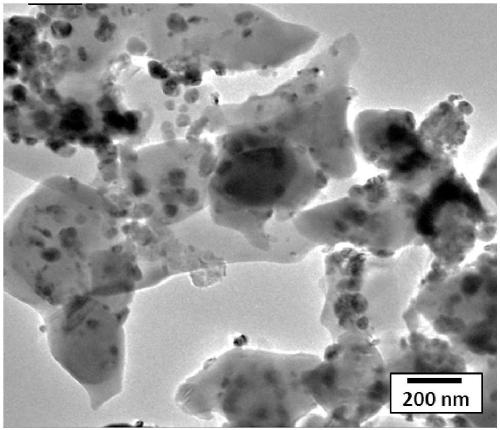

ActiveCN103691434AThe load rate is close to or even fullyAvoid reunionOrganic compound preparationCarbonyl compound preparationCyclohexanoneActive component

The invention relates to a metal catalyst which comprises: 1) a nano TiO2 modified porous material as a composite carrier, and 2) a nano particle of at least one out of Pd and other transition metals as an active component, wherein the active component and TiO2 in the composite carrier have strong metal-carrier interaction to form a Pd@TiO2 structure or a Pd-M@TiO2 structure, thereby forming the Pd-M@TiO2 / porous carrier catalyst, and M is at least one out of the transition metals except Pd. The invention further relates to a preparation method of the catalyst, and an application of the catalyst in preparing cyclohexanone through selective phenol hydrogenation.

Owner:XIANGTAN UNIV

Inkjet printing ink and method for preparing metal oxide film from inkjet printing ink

ActiveCN107955459ALimit migrationInhibitory loop effectDuplicating/marking methodsInksEngineeringSolvent

The invention belongs to the field of printing electronics and discloses inkjet printing ink and a method for preparing a metal oxide film from the inkjet printing ink. The inkjet printing ink is prepared from a glycol solvent, 0.3-5wt.% polyacrylamide and 0.1-0.6M zirconium oxychloride octahydrate. The method comprises the following steps: pre-treating a substrate, then setting the temperature ofa base plate of an inkjet printer to be 25-30 DEG C, the voltage of a nozzle to be 30-40V, the temperature of the nozzle to be 55-65 DEG C and the ink droplet interval to be 30-45mu m, and performinginkjet printing on the substrate; after the printing is completed, raising the temperature of the base plate to 40-60 DEG C, and performing standing for 10-15min; and after a liquid membrane completely gels, performing heating treatment at the temperature of 250-500 DEG C so as to obtain a zirconium oxide film. The added water-soluble polymer polyacrylamide containing polar groups has chelation on metal ions, enables the system to quickly gel after temperature rise, limits solute-solvent migration and inhibits the coffee-ring stain effect.

Owner:SOUTH CHINA UNIV OF TECH

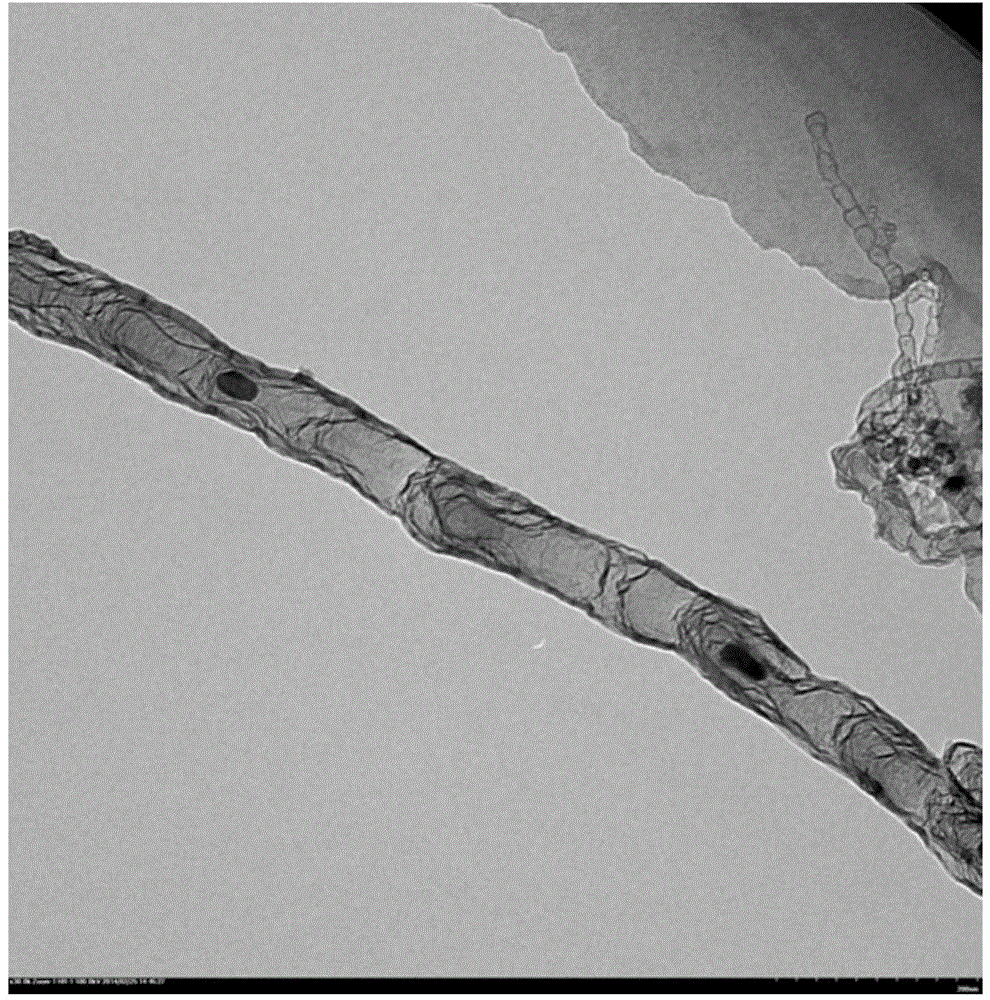

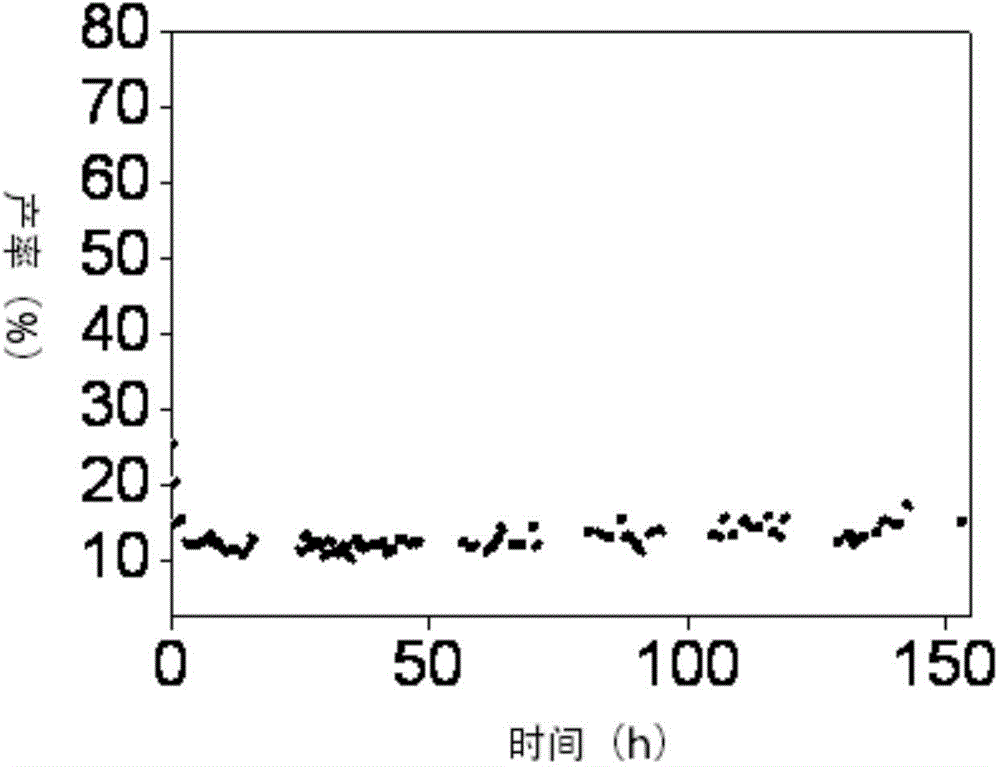

Method for preparing olefin compound based on catalyst obtained by compounding carbon tubes and transition metals

ActiveCN104549293AImprove conversion rateImprove stabilityHydrocarbonsMetal/metal-oxides/metal-hydroxide catalystsDehydrogenationBiological activation

The invention discloses a method for preparing an olefin compound based on a catalyst obtained by compounding carbon tubes and transition metals. The method comprises the following steps: preheating and vaporizing an alkane compound, mixing the compound with carrier gas, and carrying out a dehydrogenation reaction in a reactor under the action of a catalyst; and collecting the olefin compound after condensation, wherein the catalyst contains 5-30wt% of transition metals / transition metal oxides and 70-95wt% of carbon tubes. The method is used for preparing aliphatic olefin compounds and aromatic olefin compounds, the catalyst compounded based on the carbon tubes and transition metal elements / transition metal oxides is stable to water, air and heat, the catalytic activity is invariable after the continuous experiment of over 150 hours, continuous operation can be realized, activation is not needed, and the catalyst is economic and convenient. According to the method disclosed by the invention, when the catalyst is applied to ethylbenzene gaseous phase direct dehydrogenation so as to prepare styrene, the conversion rate of the alkane compound is not less than10 percent, and the selectivity of the olefin compound can be more than or equal to 97 percent.

Owner:ZHEJIANG UNIV

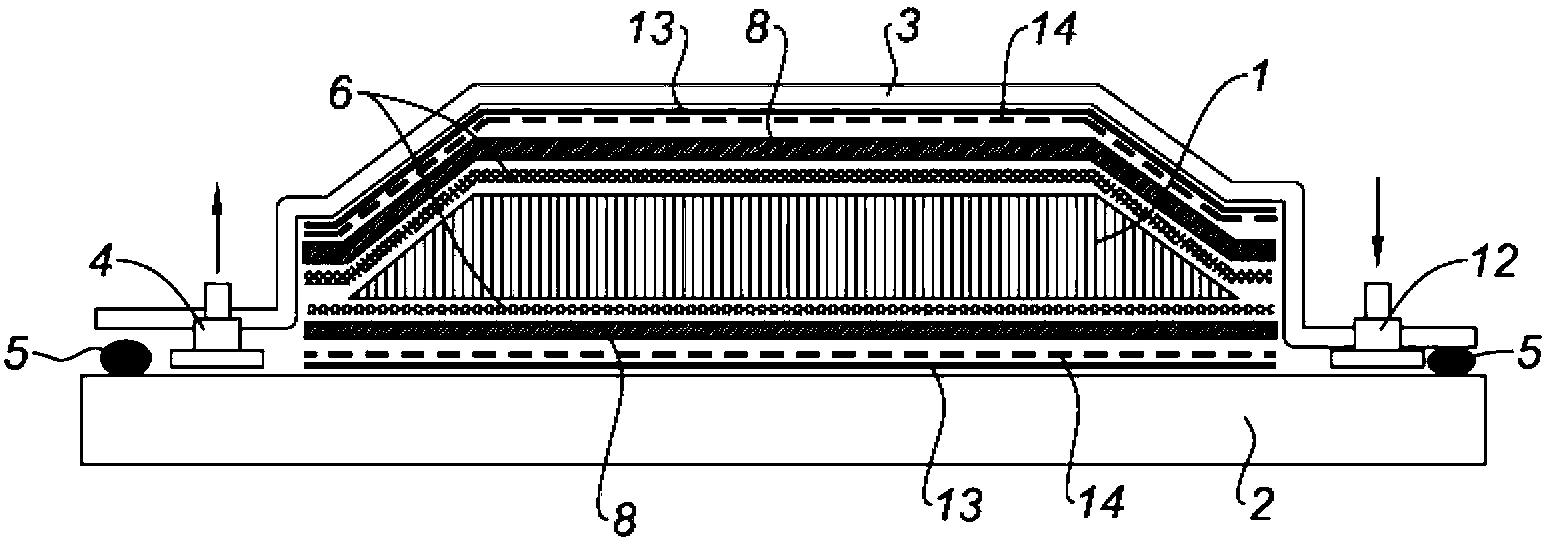

Process for manufacturing a part made of a composite having a hollow core

InactiveCN102917863AUniform penetrationAvoid formingHollow wall articlesAdhesivesPolymer scienceHollow form

The present invention relates to a process for manufacturing a part made of a composite having a hollow core (1) comprising the following steps: - applying at least one adhesive layer (6) to an open surface of the hollow core, said process being characterized in that the adhesive layer is a polymerizable blocking adhesive layer having, after polymerization, sealing properties with respect to a resin, and capable of preventing the diffusion of a resin into the hollow core; - and polymerizing the blocking adhesive layer so as to seal the hollow core.

Owner:洛林航空工程公司 +3

Microtreatment and microstructure of carbide containing iron-based alloy

Processes and apparatuses for micro-treating iron-based alloys to transform and / or shape them and the resulting materials obtained by treating low, medium, and high carbon steel and other iron-based alloys to form at least a mixed microstructure that may contain martensite, bainite and un-dissolved carbides, and may also contain complex steel microstructures including portions of bainite, coalesced bainite, acicular ferrite, retained austenite and / or martensite along with combinations thereof by micro-treating said iron based alloy.

Owner:加里 M 科拉

Regeneration method for deactivated transition metal catalyst

InactiveCN109647436AAchieve regenerationSolve the problem of sintering permanent deactivationHydrocarbon from carbon oxidesCatalyst regeneration/reactivationOxygenCarbon deposition

The invention provides a regeneration method for a deactivated transition metal catalyst. The method includes the steps of (1) roasting the deactivated catalyst in an oxygen-containing gas; (2) carrying out purging with a protective gas to replace the oxygen-containing gas; (3) introducing a reducing gas for a reduction reaction to obtain a regenerated catalyst. By adopting the high-temperature solid-phase reaction and controlled reduction strategies, carbon deposition can be eliminated to realize regeneration of the catalyst deactivated by carbon deposition, and meanwhile agglomerated metal nanoparticles can be dispersed again to realize regeneration of the catalyst deactivated by metal sintering. The method is easy and convenient to implement and high in regeneration efficiency, the catalyst can be repeatedly regenerated, the carbon deposition and sintering resistance of the regenerated catalyst is improved, and the service life of the regenerated catalyst is prolonged.

Owner:LANGFANG INST OF PROCESS ENG CAS +1

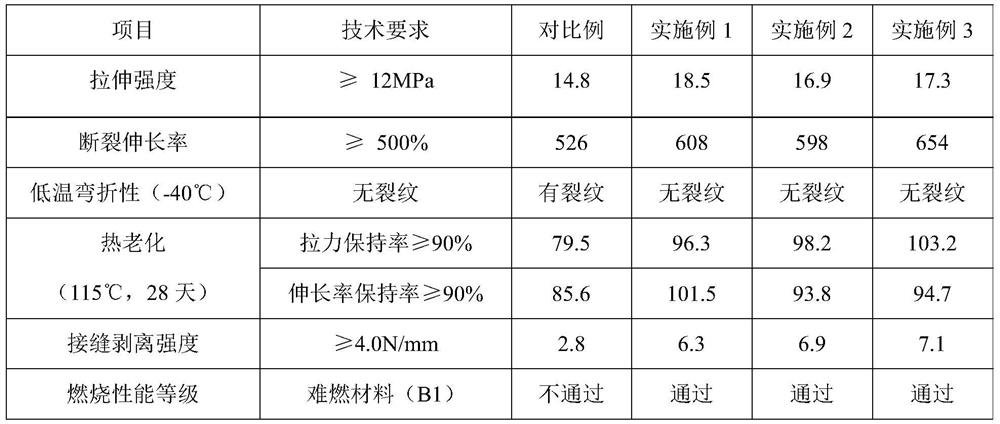

Polyolefin elastomer waterproof roll and preparation method thereof

PendingCN112694680AImprove performanceImprove aging resistanceRoof covering using flexible materialsElastomerPolymer science

The invention discloses a polyolefin elastomer waterproof roll and a preparation method thereof. The polyolefin elastomer waterproof roll comprises the following components: polyolefin resin and a supported auxiliary agent, wherein the polyolefin resin comprises rubber, polypropylene, a polyolefin elastomer, an initiator and an assistant cross-linking agent; the supported auxiliary agent comprises a carrier and an auxiliary agent, and the auxiliary agent comprises at least one of an antioxidant, an anti-ultraviolet agent, a flame retardant and a pigment. The polyolefin elastomer waterproof roll provided by the invention is stable in performance, has excellent aging resistance, weather resistance, cracking resistance and weldability, is particularly suitable for waterproofing of various roofs, and has a wide market prospect.

Owner:广州大禹防漏技术开发有限公司

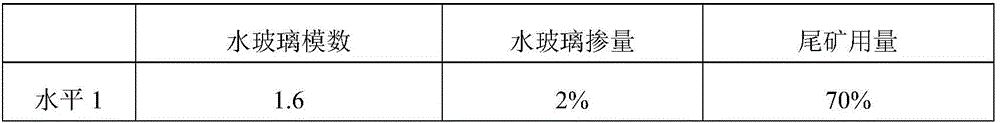

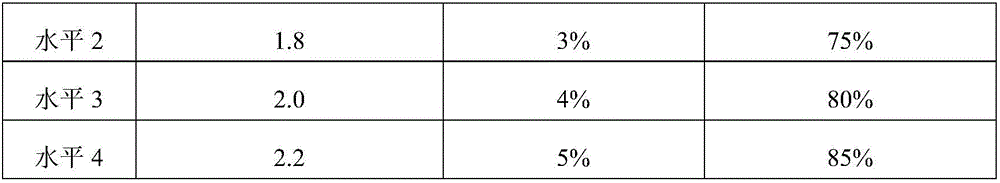

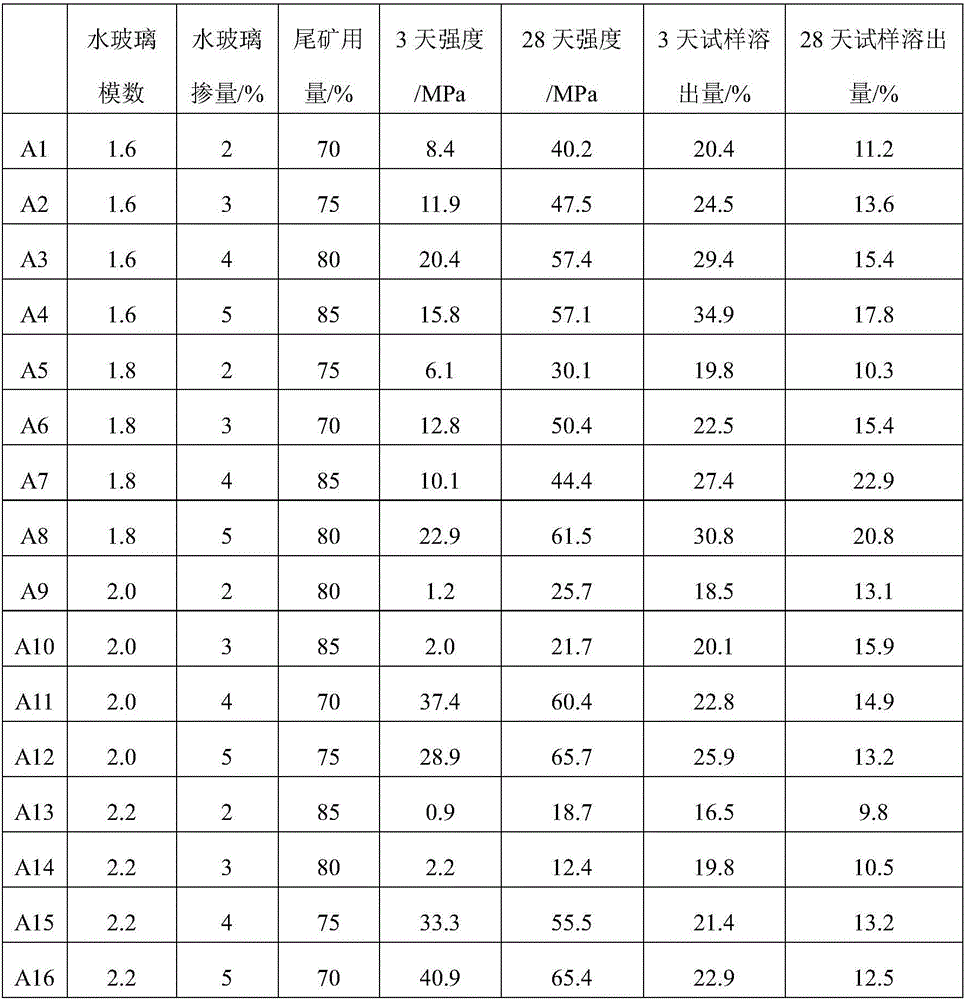

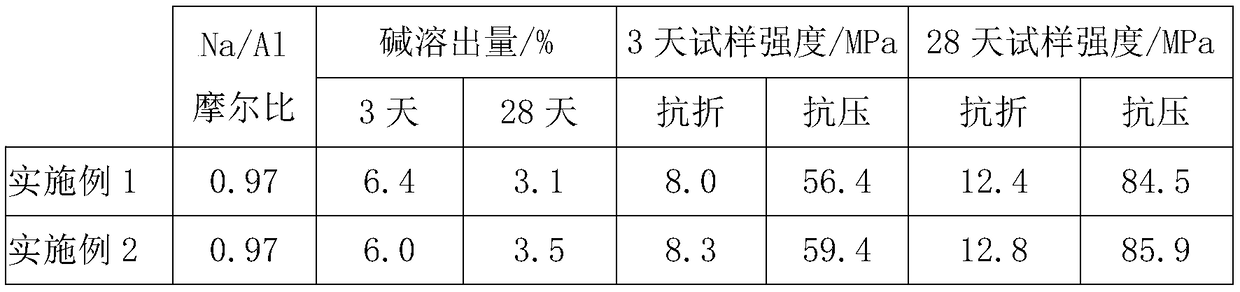

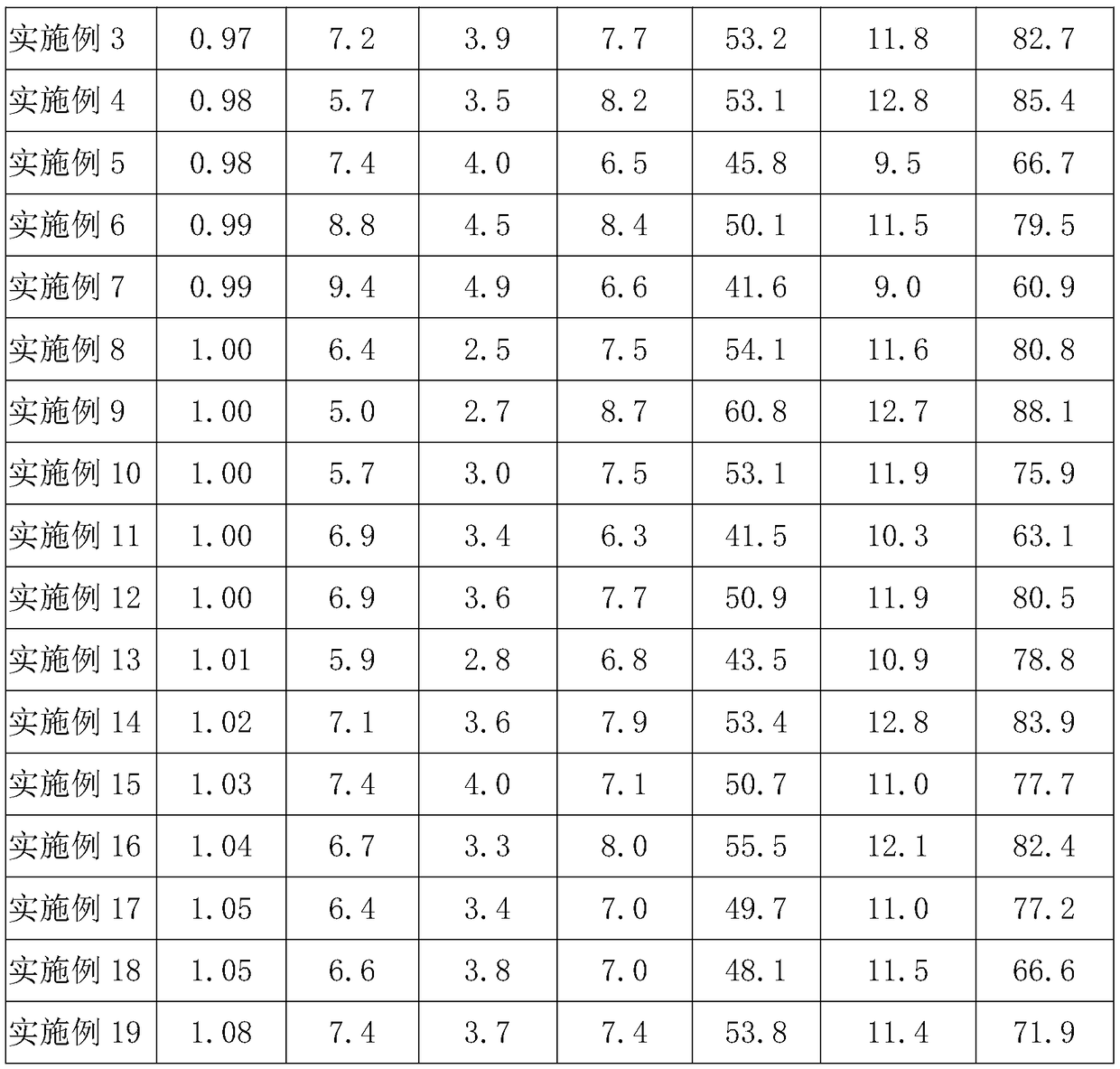

Normal-temperature-maintenance alkali-activated cementing material with low alkali dissolution quantity and preparation method thereof

ActiveCN109437614APhysical performance improvements and enhancementsPromote polymerizationCement productionAluminateAlkali activated

The invention provides a normal-temperature-maintenance alkali-activated cementing material with low alkali dissolution quantity and a preparation method thereof. The alkali-activated cementing material is prepared from the components in parts by mass: 100 parts of cementing powder, 5 to 6 parts of sodium silicate (with the modulus of 1.8 to 2.2 according to Na2O contained in the sodium silicate),1 to 5 parts of aluminate cement, and 1 to 4 parts of amorphous alumina, wherein the amorphous alumina and the aluminate cement are used as an aluminum-containing additive together; the mass parts ofthe aluminum-containing additive is 4 to 8 parts. The alkali-activated cementing material is prepared from the raw materials: Na2O and Al2O3 with the molar ratio of 0.97 to 1.08. According to the cementing material, through adding the high-activity aluminum-containing additive, the alkali dissolution quantity is less than or equal to 4 percent; meanwhile, during the preparation process, a bettercombination property can be achieved through normal-temperature maintenance.

Owner:CHINA BUILDING MATERIALS ACAD

Three-layer structural resin-based composite material and application thereof

ActiveCN109776832AHigh energy storage densityHigh dielectric constantSynthetic resin layered productsEpoxyElectrical conductor

The invention discloses a three-layer structure resin matrix composite material and application thereof. An oriented carbon nanotube bundle / epoxy resin composite material (referred to as a layer B) isprepared by a microwave curing method, and a barium titanate nanofiber / epoxy resin composite material (referred to as a layer E) is prepared by a scratch coating-thermocuring method; the B-E-B three-layer structural composite material is formed by a layer-by-layer curing technology. Compared with a conductor / insulation layer / polymer layer type structural composite material in the prior art, the three-layer structure composite material provided by the invention has high dielectric constant (being greater than 1000, @100 Hz), low dielectric loss and high energy storage density, and the preparation process is controllable and feasible, short in production period, and suitable for large-scale application.

Owner:SUZHOU UNIV

Alkali activated gelling material and preparation method thereof

ActiveCN106746781BGuaranteed StrengthGuaranteed work performanceCement productionAlkali activatedDissolution

Owner:CHINA BUILDING MATERIALS ACAD

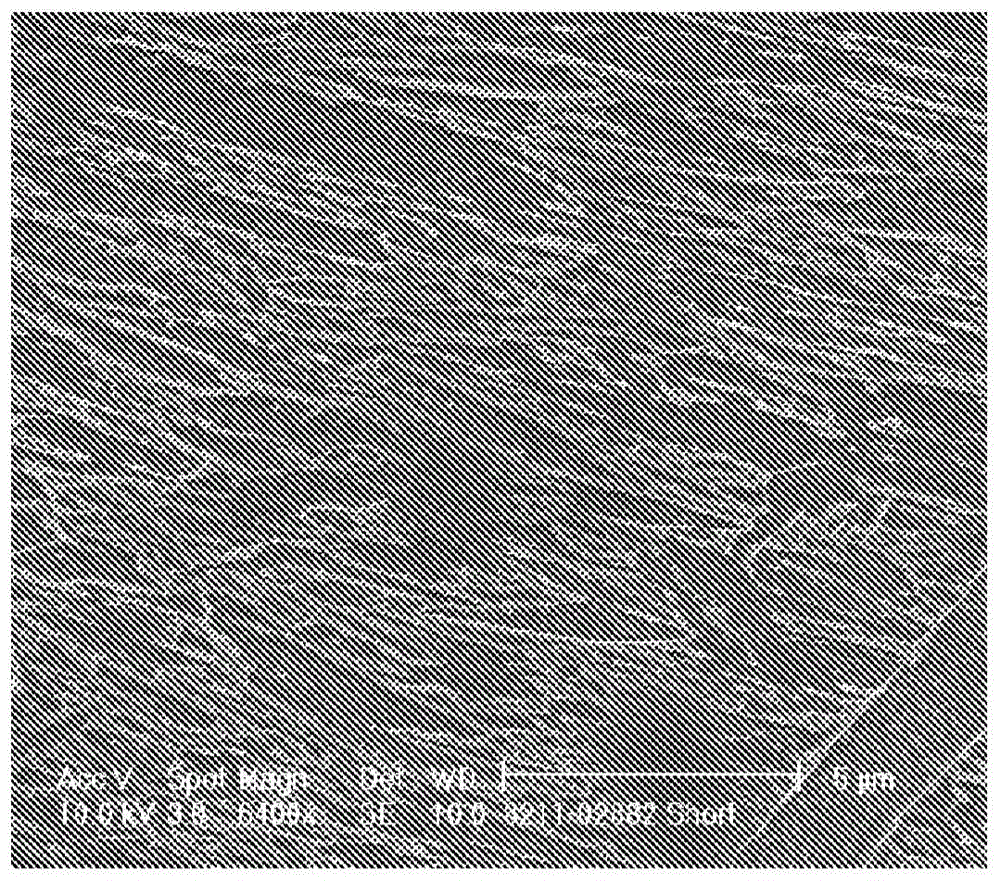

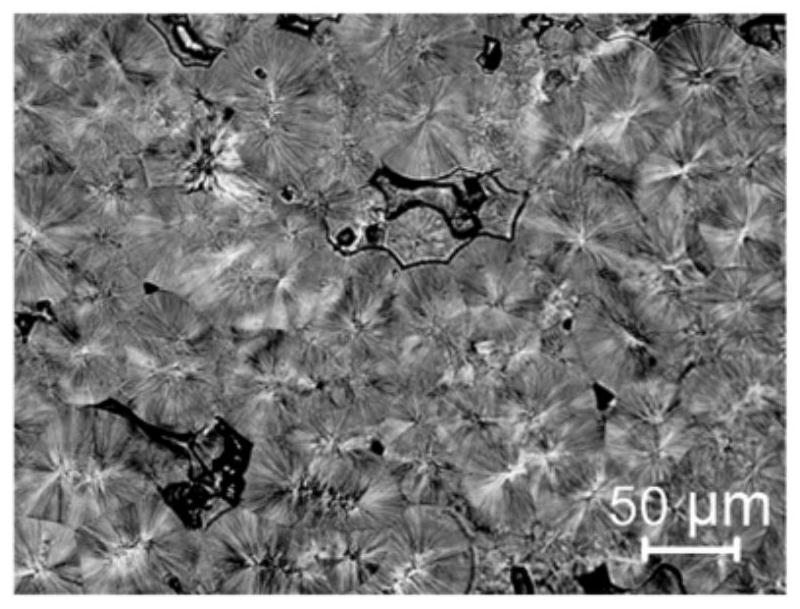

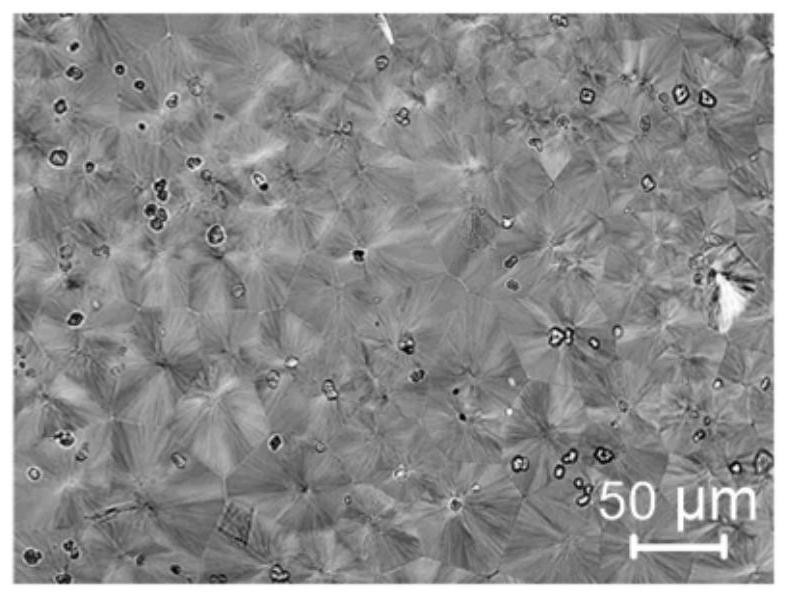

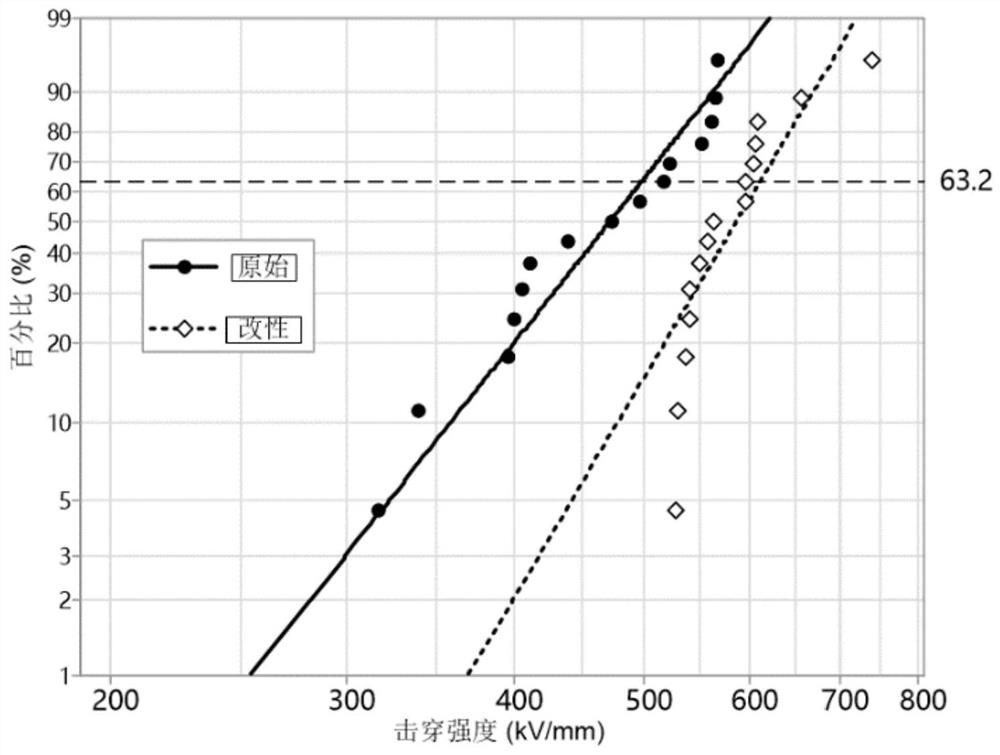

Polypropylene film insulation characteristic improving method based on crystal morphology regulation and control

ActiveCN112873670AIncrease crystallinity and densityImprove microstructureFlat articlesCrystal morphologyThin membrane

A polypropylene film insulation characteristic improving method based on crystal morphology regulation and control comprises the following steps that polypropylene master batch is fully mixed with a nucleating agent by using a double-roller machine to obtain a mixture with the nucleating agent content of 0-0.05% in percentage by mass; the mixture is melted by adopting a press vulcanizer; hot-pressing shaping is conducted on the molten mixture, specifically, the temperature of the press vulcanizer is slowly reduced from 185 DEG C-195 DEG C to 100 DEG C-140 DEG C; and after hot-pressing shaping is completed, a polypropylene / nucleating agent composite film is taken out, and the film is naturally cooled to 25 DEG C in air to obtain the modified polypropylene film. According to the polypropylene film insulation characteristic improving method based on crystal morphology regulation and control, the crystallization process of the polypropylene film can be regulated and controlled, the crystallinity and density of the micron-sized polypropylene film are increased, the microscopic crystal region of the polypropylene film is perfected by improving the microstructure and optimizing the microstructure, carrier migration is limited, the insulation performance of the film is improved, the insulation failure fault is avoided, and reliability of a direct-current transmission system is improved.

Owner:TIANJIN UNIV +1

Toughened modified polylactic acid material and preparation method thereof

The invention provides a toughened modified polylactic acid material and a preparation method thereof and relates to the field of polymer materials. The preparation method comprises mixing a layered double hydroxide and epsilon-caprolactone to obtain a reactant, carrying out a ring-opening polymerization reaction process to obtain a modified layered double hydroxide, melting the modified layered double hydroxide and polylactic acid, and preparing the toughened modified polylactic acid material through an isocyanate as a chain extender. The toughened modified polylactic acid material has good impact resistance and toughness, improves overall mechanical properties, and prevents low molecular weight plasticization (or toughening) modifier migration easily caused by simple physical blending. Through use of the strong polar -NHCOO- group, polylactic acid toughness, aging resistance and wear resistance are further improved. The toughened modified polylactic acid material can be used as a degradable material for individual use and can also be used as a modified polylactic acid master batch for mixing with pure polylactic acid.

Owner:HUNAN UNIV OF TECH

Anti-aging yoghurt containing modified starch and preparation method thereof

The present invention discloses anti-aging yoghurt containing modified starch and a preparation method thereof. The anti-aging yoghurt containing the modified starch comprises the following raw materials in parts by weight: 40-100 parts of bovine colostrum, 10-30 parts of fish collagen peptide powder, 1-5 parts of a thickener, 2-6 parts of concentrated fruit juice, 0.5-1.5 parts of tea polyphenol nanoparticles, 0.1-1 part of a sweetener and 0.1-1 part of probiotics. The thickener is composed of sodium alginate and modified starch according to a mass ratio of 1:(4-6). The anti-aging yoghurt containing the modified starch is rich in nutrients, delicate in mouthfeel, smooth and refreshing, has effects of regulating balance of human body intestinal micro-ecology, improving intestinal functions, lowering blood lipids and lowering blood pressure, enhancing human body immunity and delaying aging, and is simple and easy to implement in the preparation method, strong in operability, low in cost and suitable for factory production applications.

Owner:GUANGXI GAOYUAN STARCH

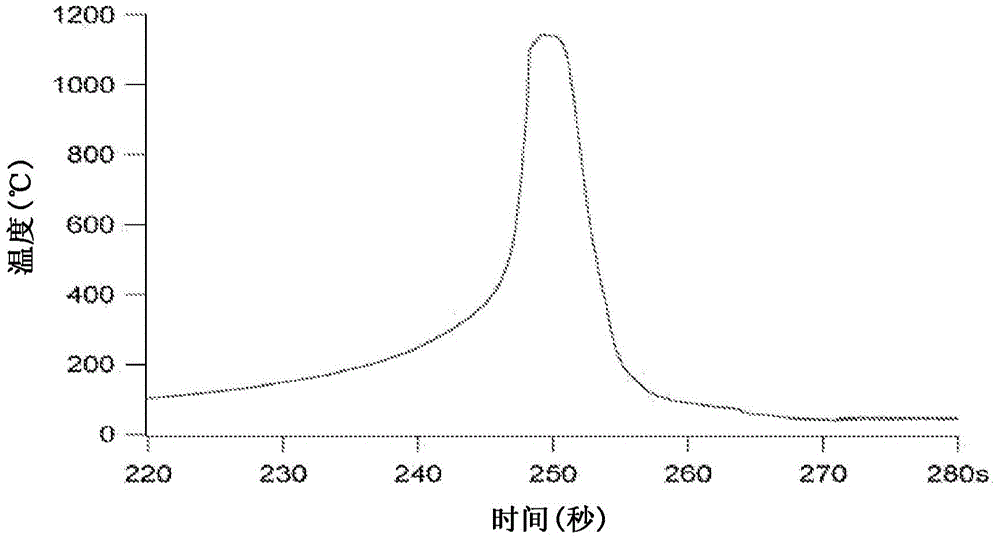

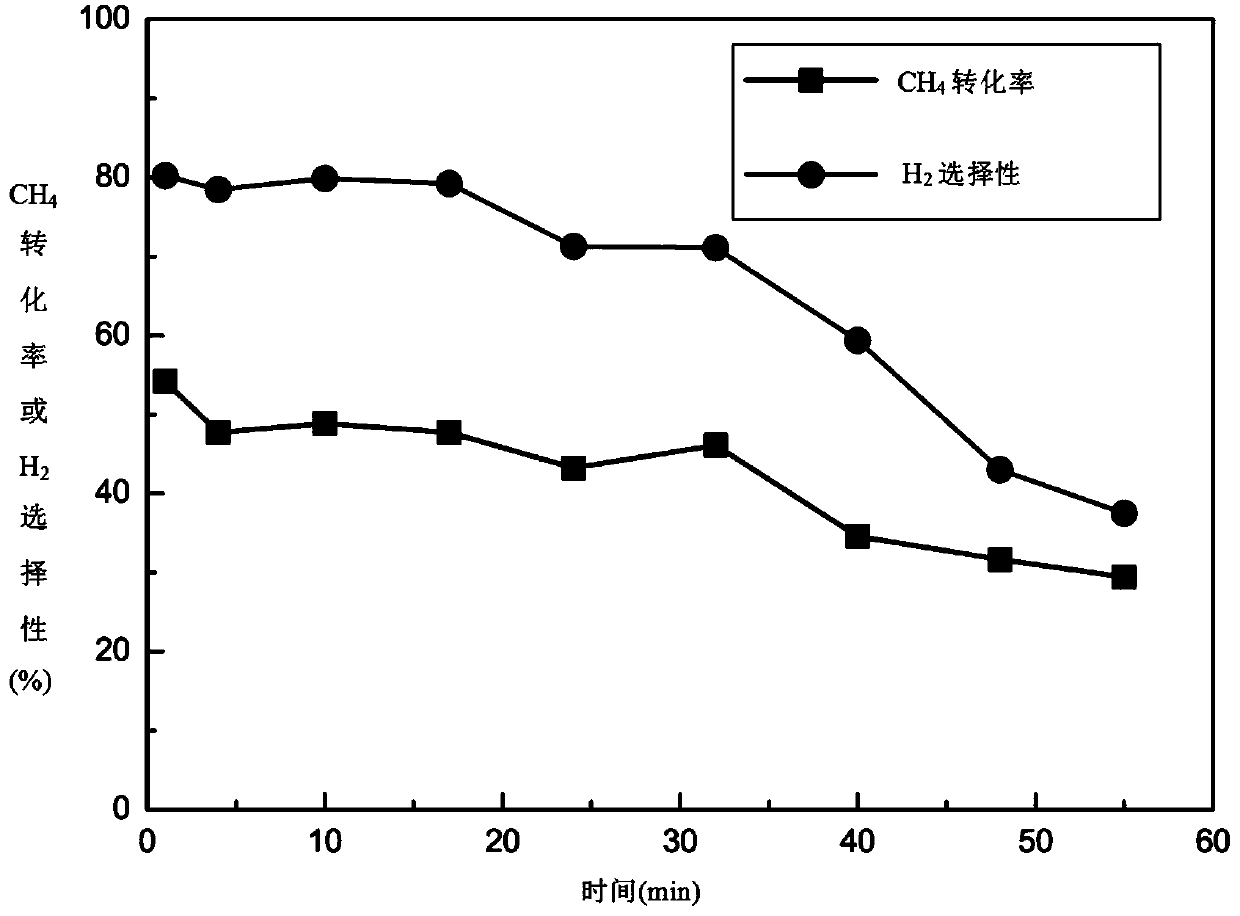

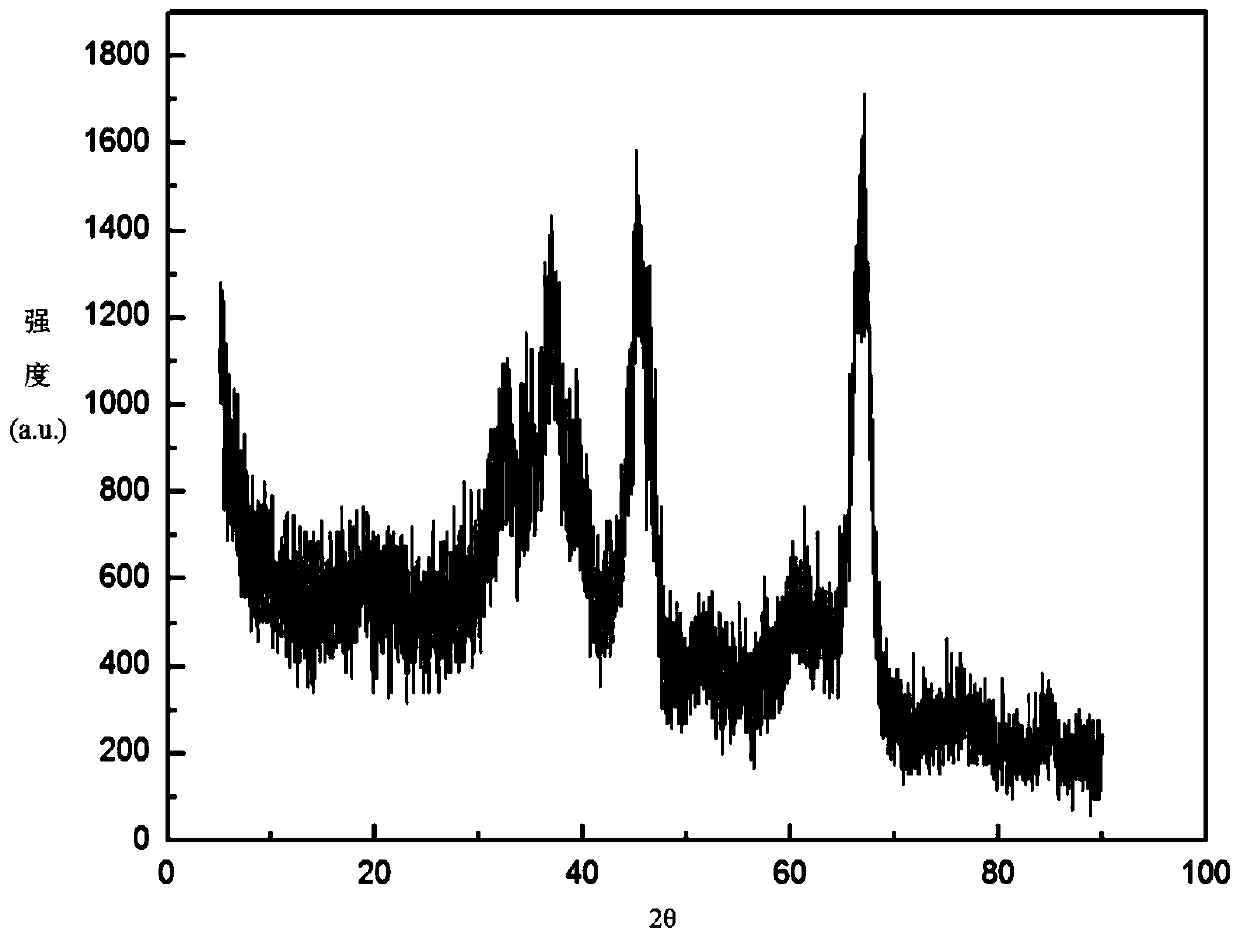

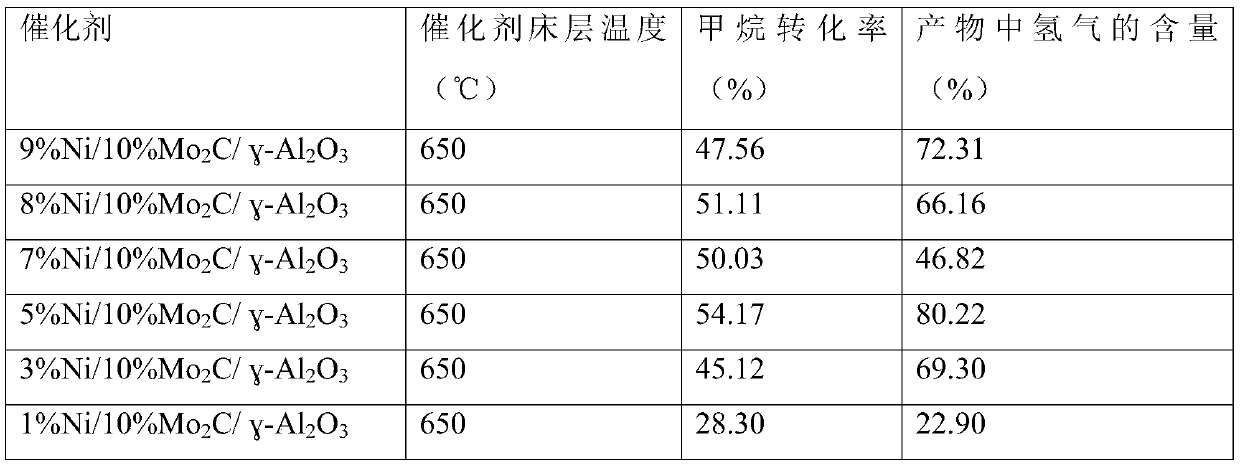

Method for directly producing hydrogen by catalyzing methane conversion through microwaves

ActiveCN110980639AReduce manufacturing costGood dispersionHydrogenCatalyst activation/preparationPtru catalystPhysical chemistry

The intention provides a method for directly producing hydrogen by catalyzing methane conversion through microwaves, and the method comprises the following steps of: directly catalyzing methane conversion to generate hydrogen under the action of microwaves by using a composite nano-structure catalyst which is Ni / Mo2C / gamma-Al2O3; the preparation method of the composite nano-structure catalyst comprises the following steps: firstly, loading Mo2C on gamma-Al2O3 by adopting an impregnation method to obtain a composite carrier with one or more layers of Mo2C films flatly laid on the gamma-Al2O3, and then loading an active component Ni on Mo2C / gamma-Al2O3 by adopting a urea precipitation method to obtain the composite nano-structure catalyst. The catalyst can be prepared. The problem of poor activity of the nickel-based supported catalyst under the existing microwave condition is solved. The problems that an existing microwave catalyst is poor in carbon deposition resistance, prone to inactivation, poor in stability and the like are solved to a certain extent.

Owner:XIANGTAN UNIV

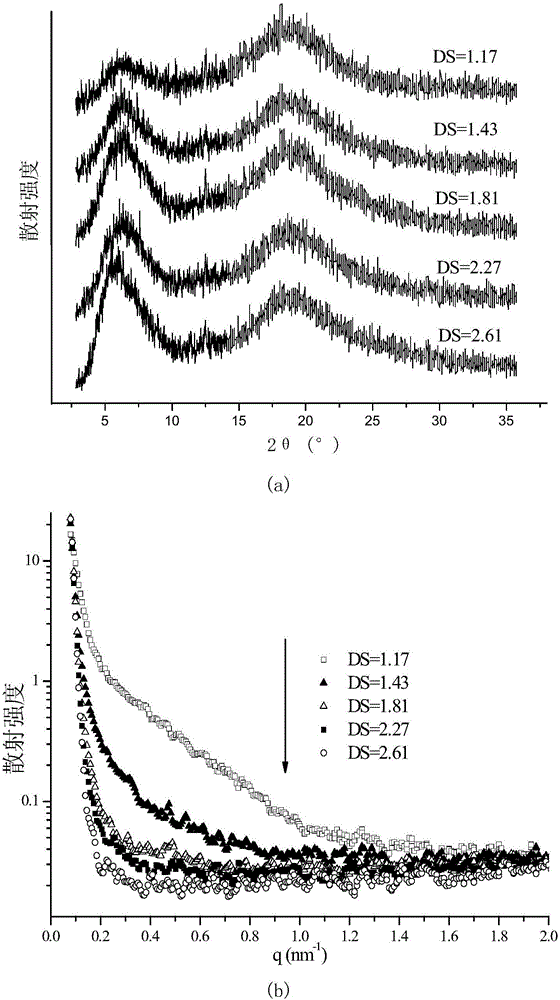

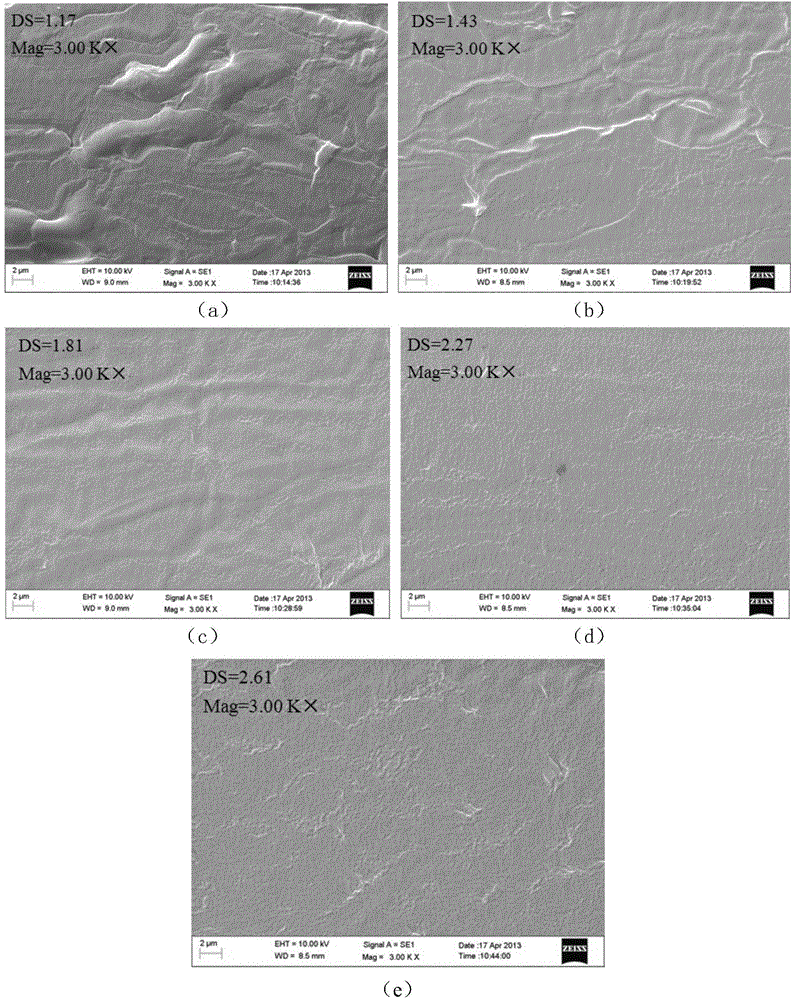

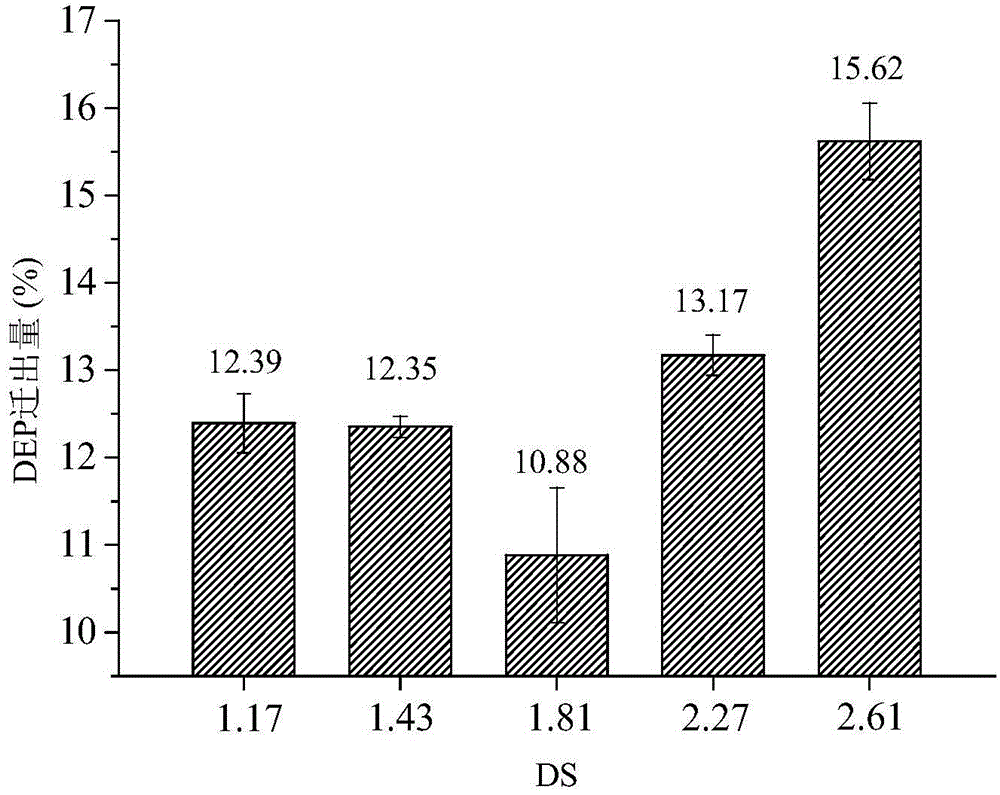

Method for inhibiting migration of plasticizer in esterified starch film and esterified starch film

The invention discloses a method for inhibiting migration of a plasticizer in an esterified starch film and an esterified starch film. The method comprises the following steps: (1) adding starch milk with a certain moisture content into a high-temperature high-pressure reaction kettle, controlling the pH of the system, adding acetic anhydride or propionic anhydride, stirring and reacting for 0.5-4.0 hours at a temperature of 80-100 DEG C, then, adding water to precipitate, filtering and drying to obtain esterified starch; (3) dissolving the esterified starch in acetone to prepare a 40% solution, adding a 20-30% plasticizer, spraying on a polytetrafluoroethylene plate though a fluidized bed at a temperature of 50-55 DEG C with a spraying rate of 1.0-2.8mL / min and atomizing pressure of 0.5-1.5MPa to form a semitransparent film, thereby obtaining the esterified starch film. The method disclosed by the invention can be used for reasonably controlling an aggregation state structure inside the esterified starch film, so that the good in effect in inhibiting the migration of the plasticizer is achieved, the operability is strong and the applied range is wide.

Owner:SOUTH CHINA UNIV OF TECH +1

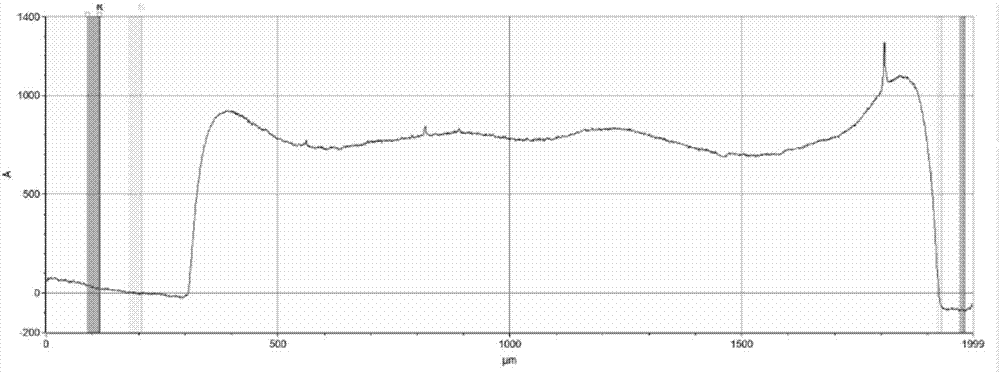

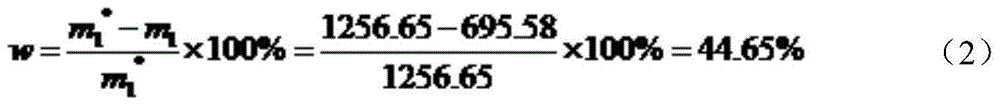

Method for measuring heat conductivity of heat insulation material under different water contents

ActiveCN105044149AGuaranteed uniformityLimit migrationMaterial heat developmentOhmic conductivityWater content

The invention discloses a method for measuring the heat conductivity of a heat insulation material under different water contents. The method includes the steps that two identical samples are taken and dried to be absolute dry, one sample serves as a calibration sample, and the other sample serves as a sample to be measured; the sample to be measured is subjected to water absorption treatment to have a needed water content w; the heat conductivity of the calibration sample is measured through a steady state method under the mean temperature T, and a test result is recorded as lambda2; a non-steady state method is calibrated through the calibration sample and the test result lambda2 under the mean temperature T; the sample, obtained after water absorption treatment, to be measured is tested through the calibrated non-steady state method under the mean temperature T, the heat conductivity lambda (w, T) of the sample to be measured under the water content w and the mean temperature T is obtained, and measurement is completed. By means of the method for measuring the heat conductivity of the heat insulation material under the different water contents, water can be effectively restrained from migrating in the samples or dispersing outwards, and therefore it is guaranteed that the water content in the samples is uniform in measurement. The method has the advantages of being simple, high in accuracy and the like.

Owner:NANJING FIBERGLASS RES & DESIGN INST CO LTD

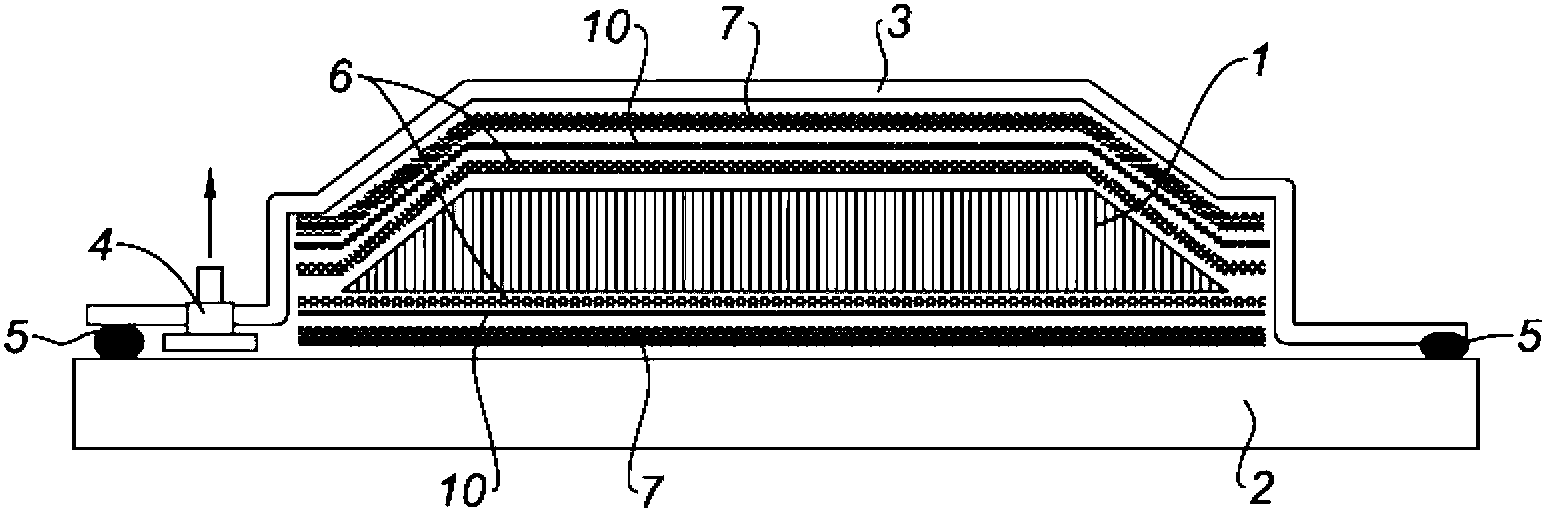

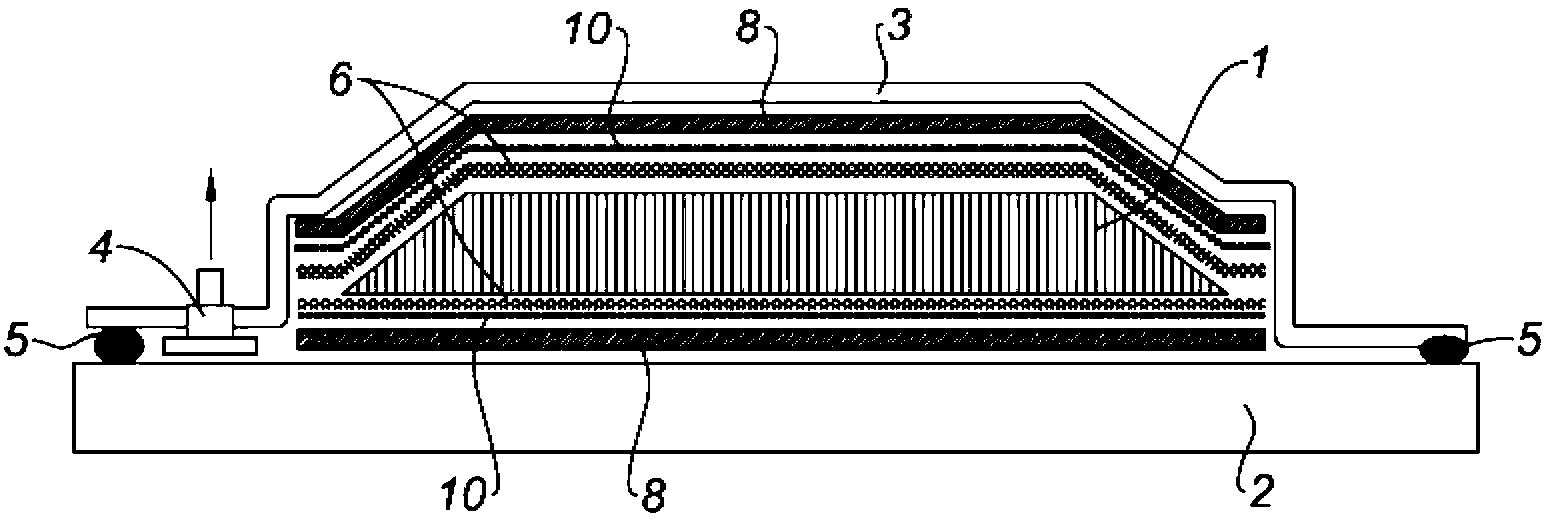

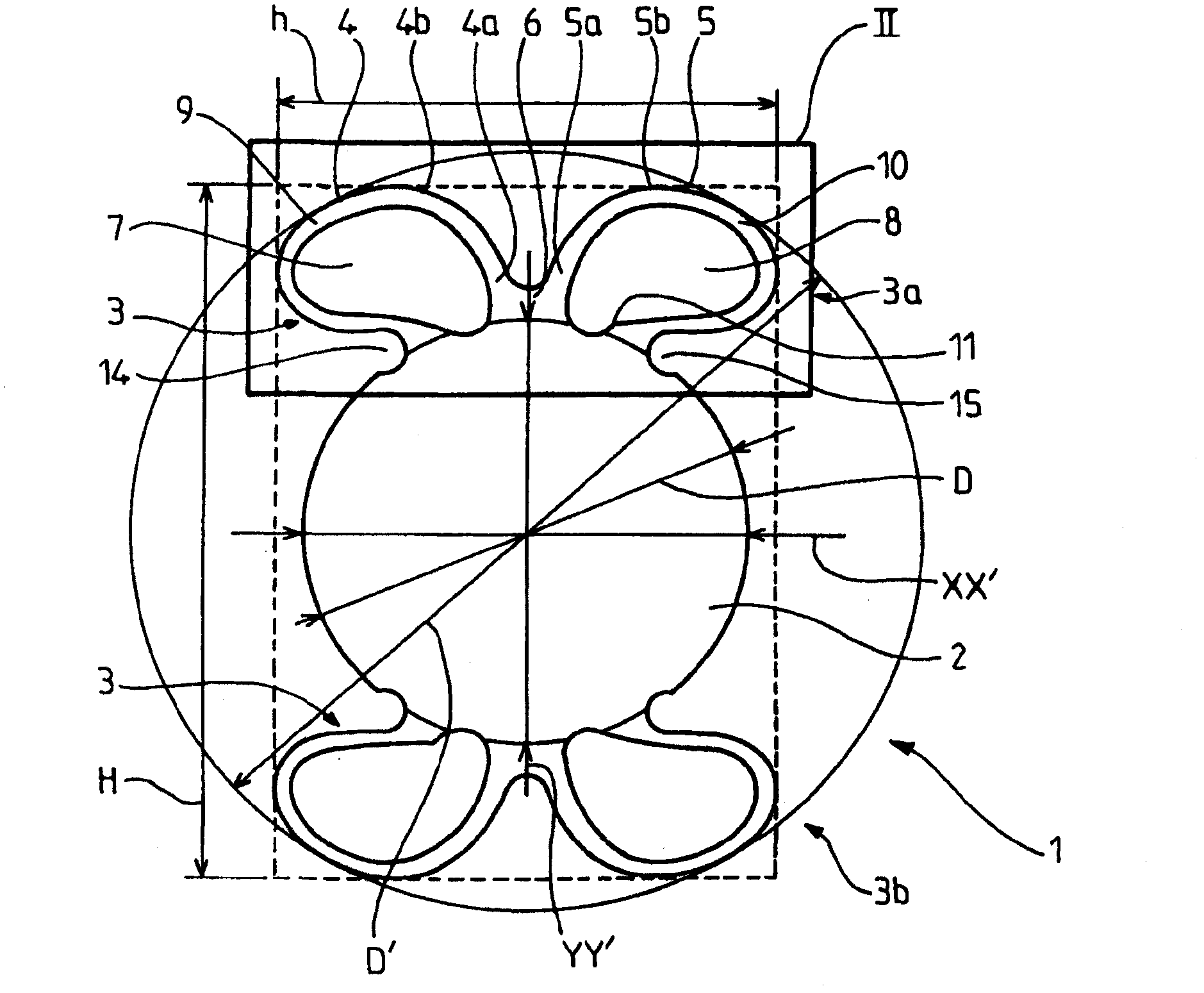

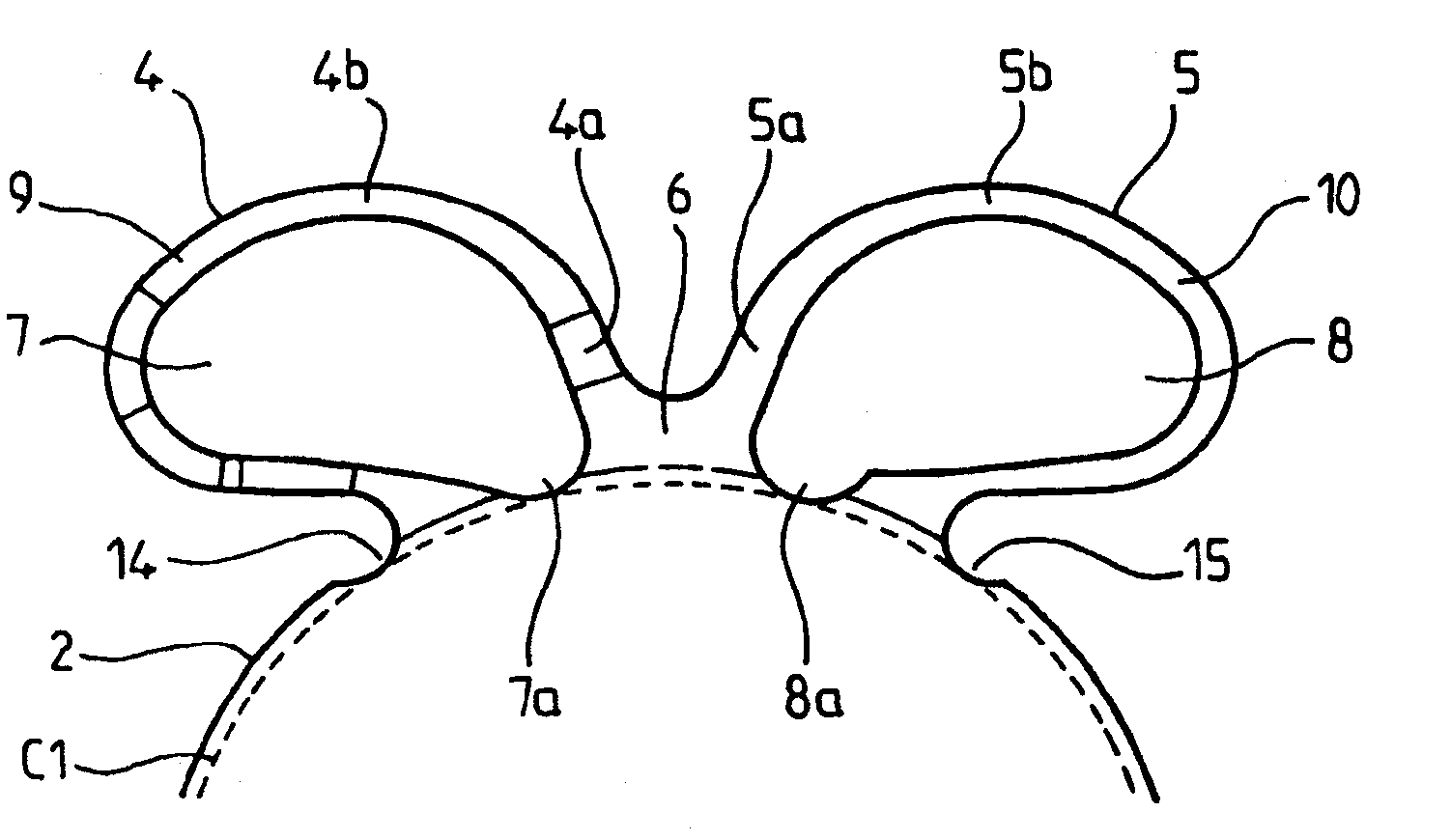

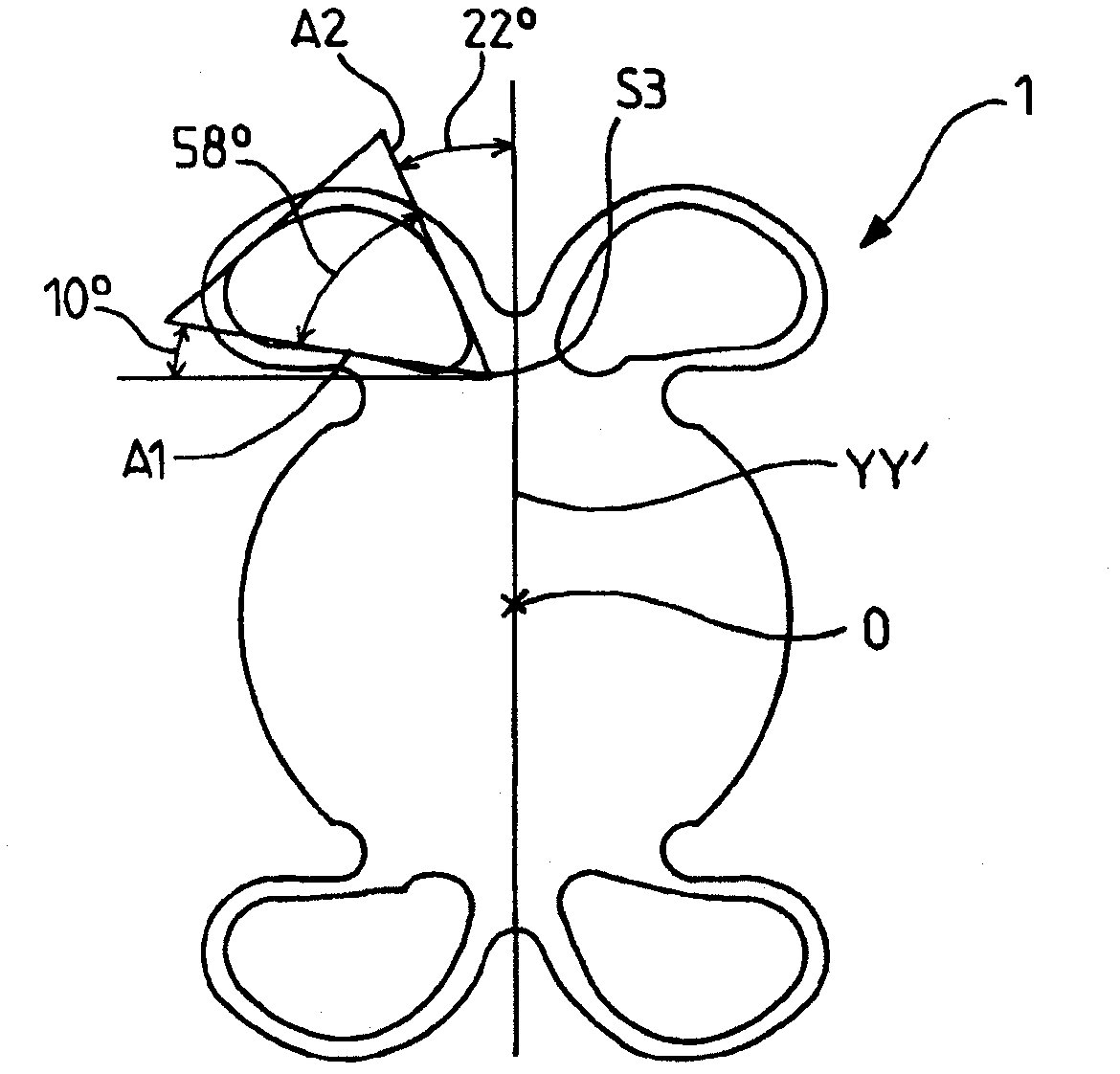

Intraocular lens

Intraocular lens (1, 101) with an optic part (2) and a haptic part (3, 103), characterized in that it comprises, at each transition between said optic part (2) and said haptic part (3, 103), two notches (7a, 8a, 14, 15, 122, 123), said two notches (7a, 8a, 14, 15, 122, 123) being arranged respectively on either side of said transition, each notch (7a, 8a, 14, 15, 122, 123) extending along the edge of said haptic part (3, 103) and impinging on the periphery of said optic part (2).

Owner:麦迪康特医药有限责任公司

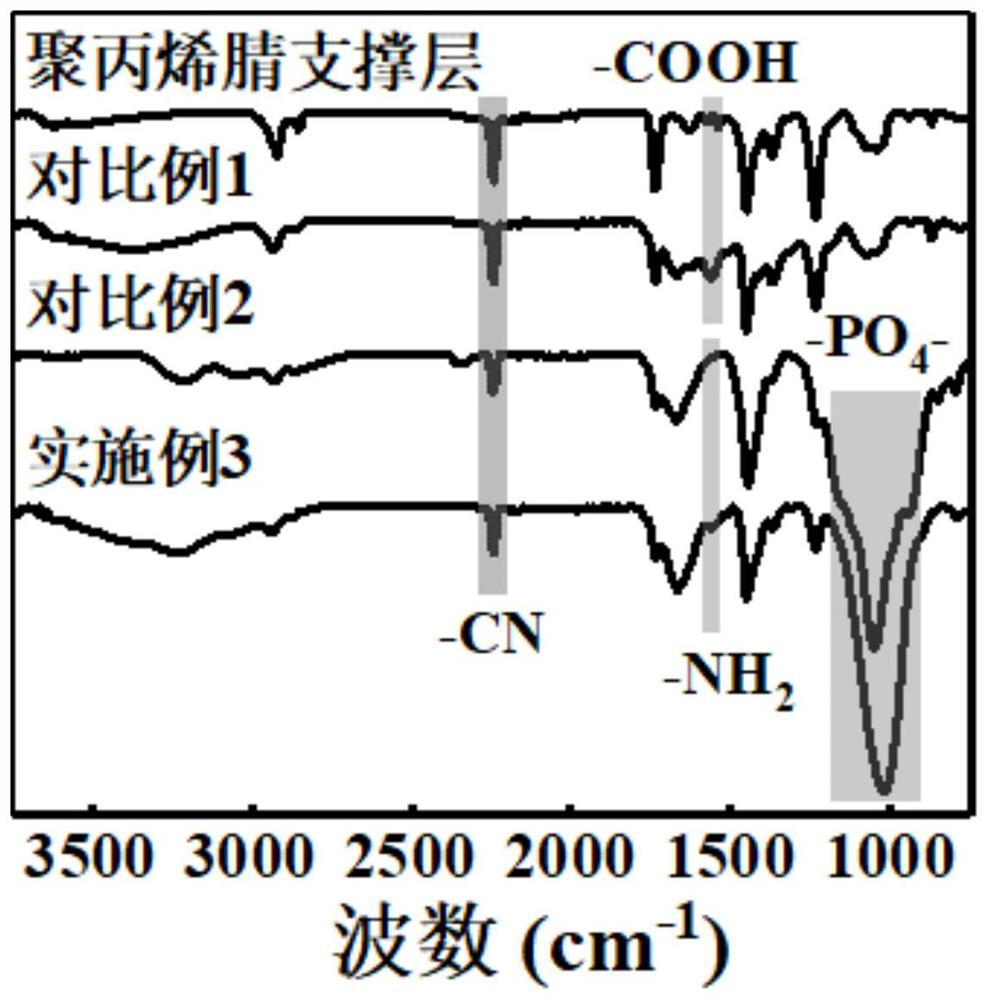

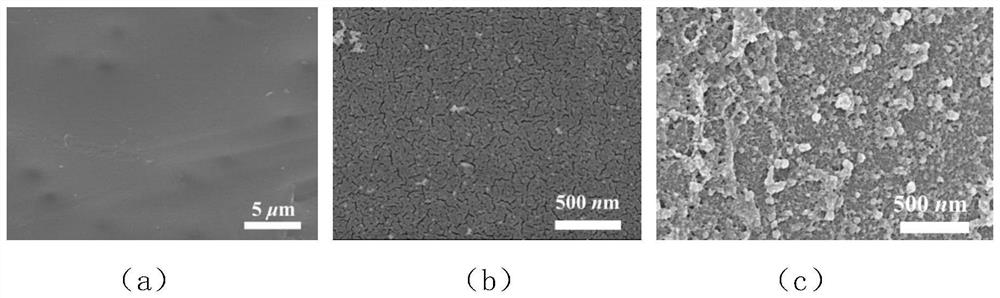

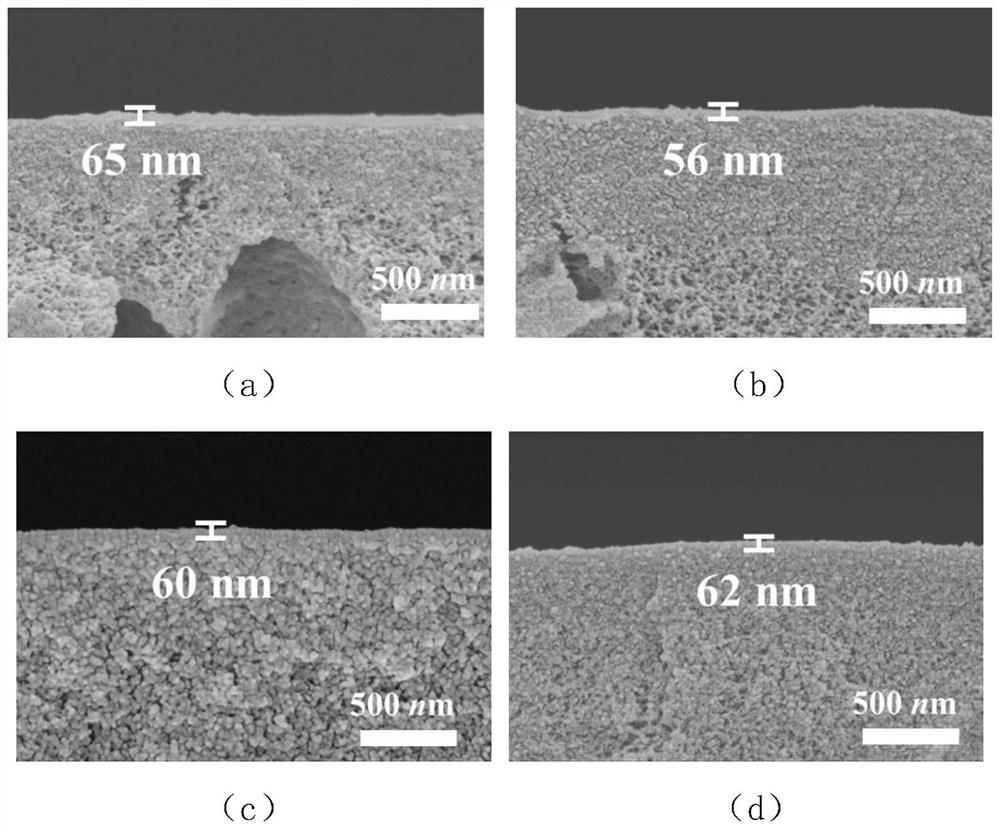

Metal ion-organic acid complex in-situ cross-linked composite membrane and preparation and application thereof

ActiveCN114797494AEasy to separateNarrow pore size distributionGeneral water supply conservationReverse osmosisOrganic acidPolymer science

The invention relates to a metal ion-organic acid complex in-situ cross-linked composite membrane as well as preparation and application thereof, and belongs to the field of membrane separation. The preparation method comprises the following steps: anchoring a crosslinking component on the surface of the polymer supporting layer in advance in the form of a metal ion-organic acid complex to form the crosslinking layer, and then carrying out in-situ crosslinking on the polymer on the surface of the crosslinking layer to prepare the polymer selection layer, thereby obtaining the polymer composite membrane. The polymer composite membrane is prepared by preferentially anchoring the crosslinking layer to crosslink the polymer in situ, so that the formation of a thin and compact polymer selection layer is facilitated, and the mass transfer resistance is reduced. When the prepared polymer composite membrane is applied to dehydration of an organic solvent (ethanol), compared with a polymer composite membrane prepared by a traditional cross-linking method, the separation performance is obviously improved.

Owner:HUAZHONG UNIV OF SCI & TECH

Viscosity modifier for controlling bleeding of concrete by utilization of high-molecular-weight polycarboxylic acid and application thereof

The invention discloses a viscosity modifier for controlling bleeding of concrete by the utilization of high-molecular-weight polycarboxylic acid. The viscosity modifier is mainly formed by compounding high-molecular-weight polycarboxylic acid and common-molecular-weight polycarboxylic acid. The molecular weight of the high-molecular-weight polycarboxylic acid is 600-2000 thousand, and the molecular weight of the common-molecular-weight polycarboxylic acid is 200-700 thousand. In the viscosity modifier, solid content of the common-molecular-weight polycarboxylic acid is 6-20%, and the high-molecular-weight polycarboxylic acid accounts for 1-20%. The viscosity modifier can be effectively applied to manufacturing of concrete of C50 and above (including C50, C55, C60, C70 and C80) and the above premixed concrete. By directly compounding of 1-20% high-molecular-weight polycarboxylic acid and common-molecular-weight polycarboxylic acid and without influencing water-reducing rate and antisag property, viscosity of the premixed concrete is effectively enhanced, and bleeding and segregation are controlled. In addition, the problem of compatibility between traditional VMA and a polycarboxylate superplasticizer is fundamentally solved.

Owner:WUXI KINGSTON NEW MATERIAL TECH CO LTD

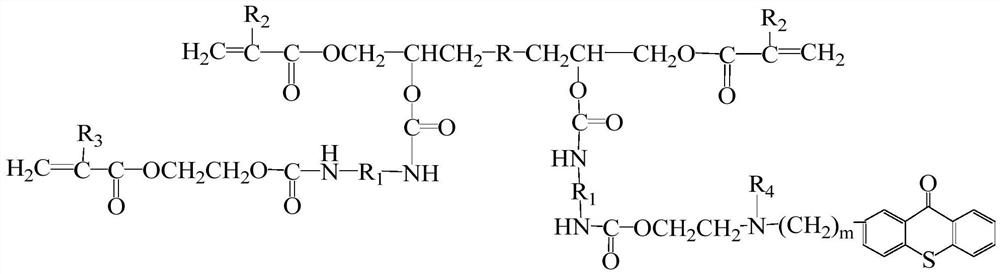

Amine-containing thioxanthone polyurethane modified epoxy acrylate LED light-cured resin

InactiveCN113754859AStrong adhesionImprove water resistanceInksPolyurea/polyurethane coatingsEnergy migrationPolymer science

The invention relates to an amine-containing thioxanthone polyurethane modified epoxy acrylate LED light-cured resin and a preparation method thereof. The LED resin contains three active groups and one amine-containing thioxanthone photo-initiation group; the LED light-cured resin has the following characteristics: 1) energy migration and intermolecular reaction in a polymer chain are easier, and the resin has high self-initiation activity under UV-LED light; 2) the distance between a photoactive group and a main chain is shortened, and the photosensitivity is improved; 3) the system compatibility is excellent; and 4) a tertiary amine co-initiator does not need to be added, the photocuring efficiency is high, and the defects caused by a bimolecular photoinitiation system are overcome. The LED resin prepared by the method has excellent adhesive force, water resistance, aging resistance, chemical resistance and coating odor removal property, also has high wear resistance, high fullness, high tensile strength and excellent flexibility, and is widely applied to UV floor coating, UV wood coating, UV alloy coating, UV circuit board ink, UV plastic coating and the like.

Owner:明光科迪新材料有限公司

High-water-white-resistance acrylic acid water-in-water emulsion and preparation method thereof

The invention belongs to the technical field of coatings and particularly relates to a high-water-white-resistance acrylic acid water-in-water emulsion and a preparation method thereof. The high-water-white-resistance acrylic acid water-in-water emulsion is prepared from the following substances in parts by weight: 50-80 parts of an acrylate emulsion, 50-70 parts of a silicone acrylate emulsion, 5-12 parts of cellulose, 10-40 parts of an inorganic filler, 5-18 parts of pigments, 5-12 parts of organic silicate ester, 5-12 parts of a silane coupling agent, 1-3 parts of an emulsifying agent, 3-8 parts of an initiator and 50-100 parts of water. By utilizing a reactive emulsifying agent, most emulsifying agent molecules can be bonded to a molecular chain through polymerization reaction, so that a micromolecular existence form of the emulsifying agent is reduced, the desorption, migration and aggregation of the emulsifying agent are avoided, and therefore, the water white resistance of an emulsion coating film is improved.

Owner:GUANGDONG VALSPAR CHEM IND

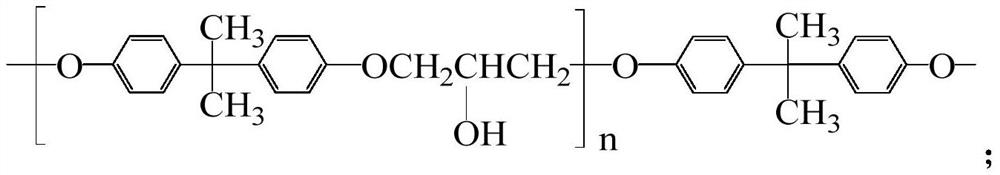

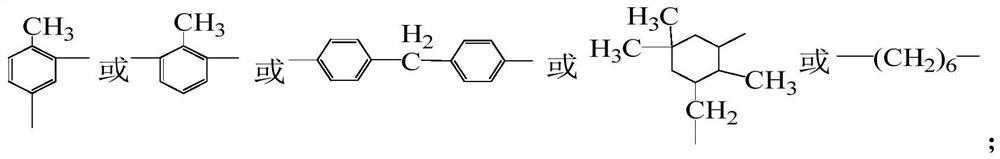

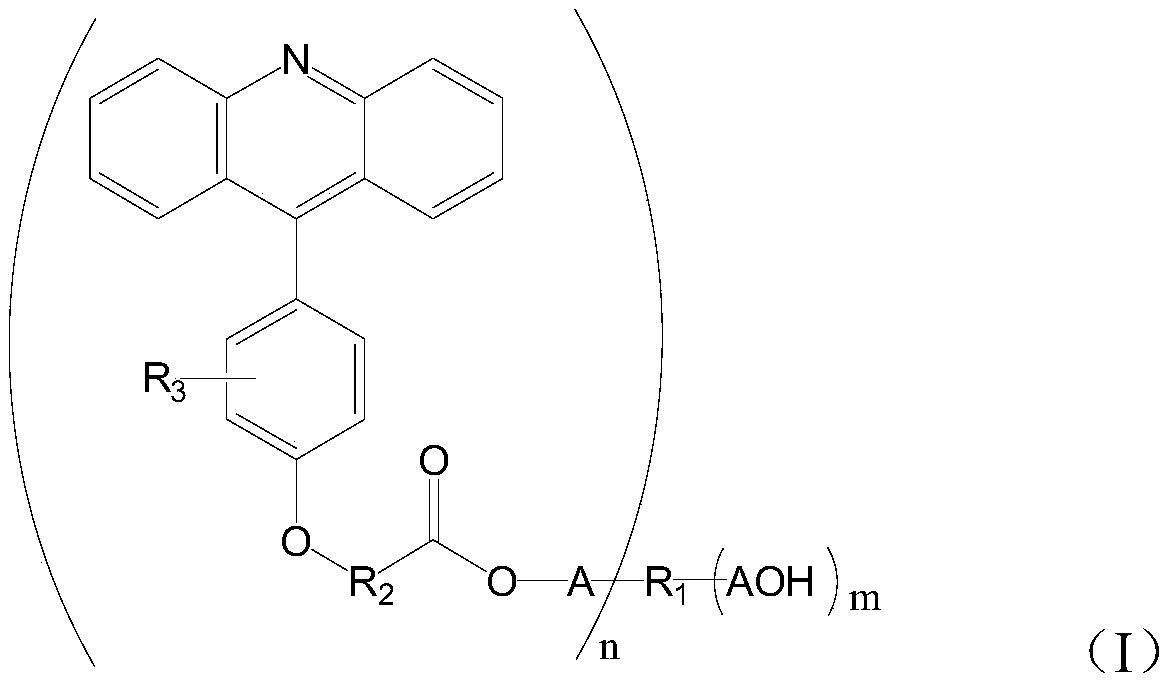

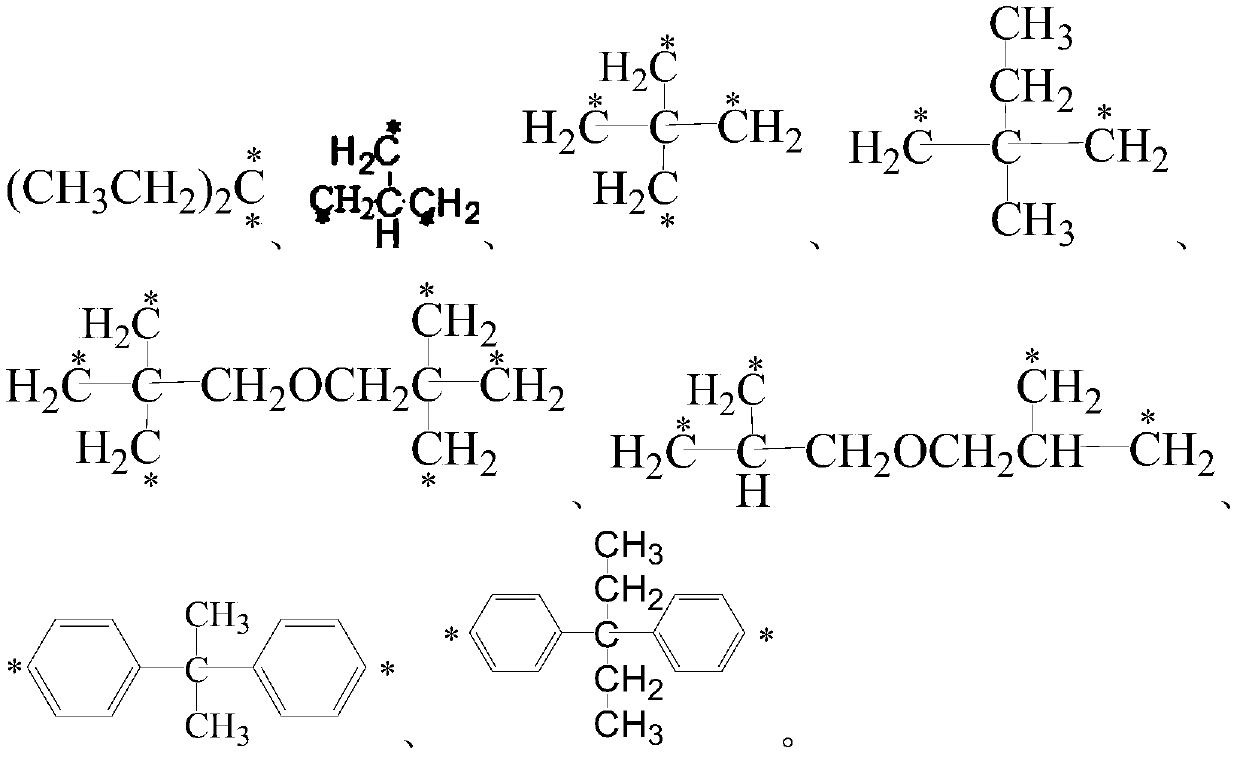

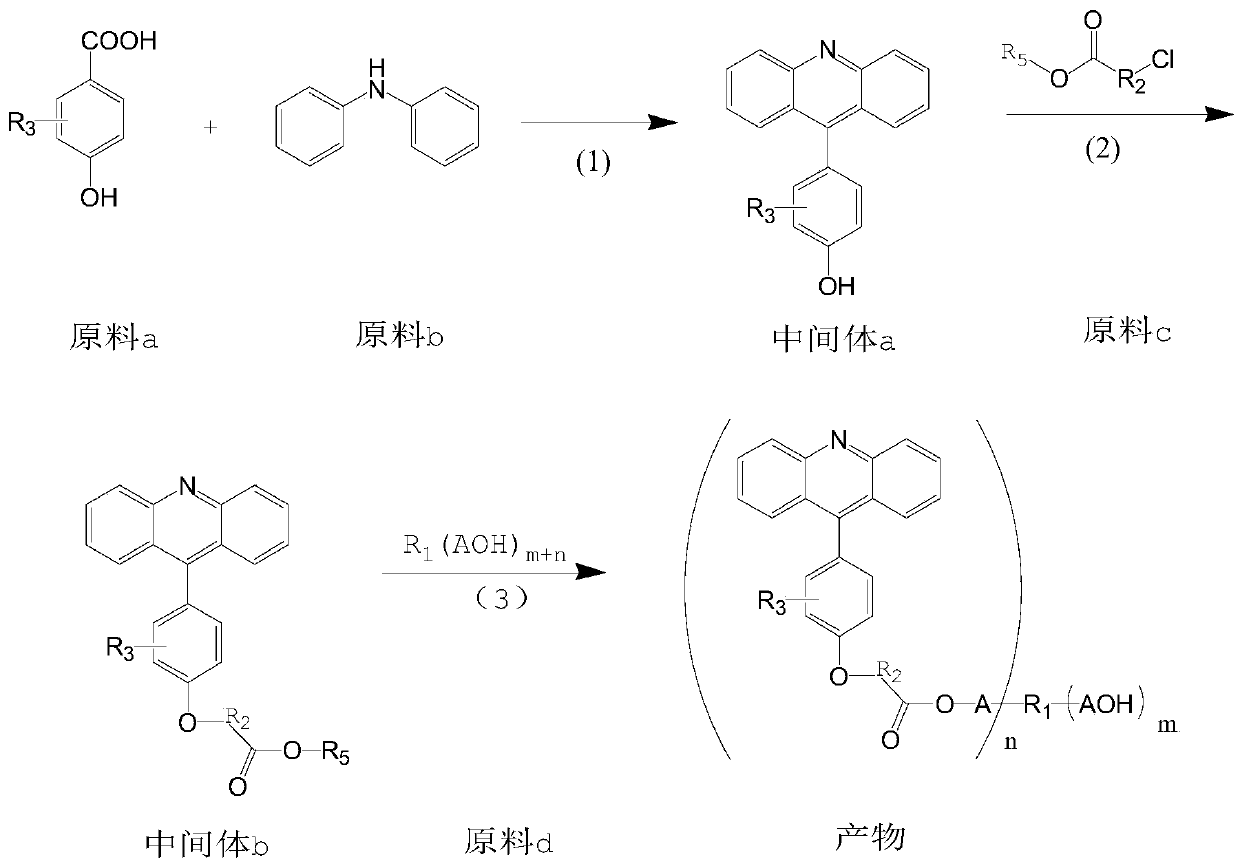

A kind of 9-phenylacridine macromolecular photosensitizer and its preparation method and application

ActiveCN107765510BGood water solubilityGood lifting effectOrganic chemistryPhotosensitive materials for photomechanical apparatusAcridinePhotosens

Disclosed are a 9-phenylacridine macromolecule photosensitizer, and a preparing method and use thereof. The 9-phenylacridine macromolecule photosensitizer comprises at least one of the compounds having a structure as shown in formula (I), in which R1 is a linear or branched C1-C60 alkyl group with a valency of m + n, wherein a -CH2- thereof may be optionally substituted by oxygen, sulphur or 1,4-phenylene; each A independently represents -[(CHR4)x-O]y-, wherein each R4 independently represents hydrogen, a methyl group, or an ethyl group, x is an integer of 1-10, and y is an integer of 1-20; R2 represents a linear or branched C1-C20 alkylene group, wherein a -CH2- thereof may be optionally substituted by oxygen, sulphur or a phenylene; R3 represents hydrogen or a substituent group; m represents an integer of 0-20, and n represents an integer of 1-20. When used in a photocuring system, the photosensitizer has good compatibility and good photosensitivity improving effect, and a film prepared therefrom has excellent resolution, adhesion, and high solubility in water.

Owner:CHANGZHOU TRONLY NEW ELECTRONICS MATERIALS +1

Method for reducing warpage in glass chemical strengthening and fixture for strengthening

The invention relates to the technical field of manufacture of float glass, and discloses a method for reducing warpage during chemical strengthening of glass and a fixture for strengthening. A method for reducing warpage during chemical strengthening of glass. Before chemical strengthening of glass, the glass is laid flat with the tin side of the glass facing down. During the process of chemical strengthening of glass, ion-exchanged The temperature is set at 380‑450°C. The strengthening jig is used in the above-mentioned method for reducing warpage during chemical strengthening of glass, and is used to support the glass and make the glass lie flat. The method for reducing warpage during chemical strengthening of glass and the fixture for strengthening according to the invention can effectively reduce the warpage value of float glass during chemical strengthening and improve the pass rate of glass.

Owner:河北视窗玻璃有限公司 +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com