Metal catalyst, preparation method and application

A metal catalyst and catalyst technology, applied in the direction of metal/metal oxide/metal hydroxide catalyst, carbon-based compound preparation, chemical instruments and methods, etc., to achieve the effects of easy operation and control, easy particle size, and mild preparation conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

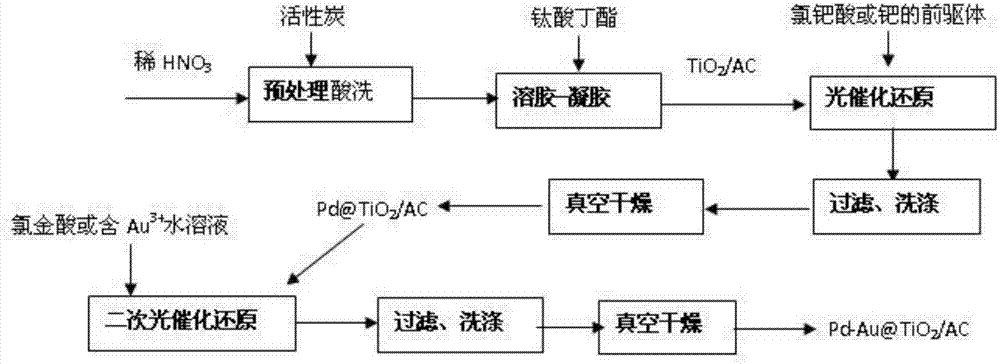

Method used

Image

Examples

Embodiment 1

[0057] 1) Activated carbon pretreatment: put the coconut shell activated carbon that has been washed and boiled 2 to 3 times in a nitric acid solution with a mass fraction of 10.94%, heat and reflux in a water bath at ~60°C for 4 hours, filter with deionized water, and wash to pH It is neutral, and dried at 110°C for 12 hours to obtain oxidized modified activated carbon;

[0058] 2) TiO loaded by sol-gel method 2 : Configure solution A and solution B, under the condition of magnetic stirring, slowly add B to solution A drop by drop to form mixed solution C sol, disperse 12.03g of modified activated carbon obtained in step 1) into solution C, add concentrated HNO 3 (66-68% by mass) to adjust the pH to 3, stir for 5-10 minutes, and then ultrasonically oscillate for 10 minutes to make the sol enter the AC channel, stop stirring and let stand to form a gel, dry at 80°C for 12h, and calcinate at 500°C for 2h to obtain TiO 2 Composite carrier material TiO with a loading of 9.95% ...

Embodiment 2

[0062] TiO by sol-gel method 2 Loaded on the modified activated carbon to obtain the composite carrier TiO 2 / AC. Then use the method of photocatalytic reduction to load metal palladium onto the composite carrier TiO 2 / AC, after subsequent filtration, washing, and drying processes, PdTiO 2 / AC.

[0063] The specific implementation process is the same as in Example 1, except that HNO 3 The concentration is 11.13% by mass, the composite carrier TiO 2 TiO in / AC 2 The content is 9.89% by mass, the catalyst PdTiO 2 The content of palladium in / AC was 0.5% by mass.

[0064] 4) Photocatalytic reduction of loaded Au: take the PdTiO prepared in step 3) 2 / AC Catalyst TiO 2 / AC composite carrier material 5.316g, stirring and dispersing in 300ml ultrapure water, adding 10ml of methanol, stirring in the dark for 10min, then adding 2.21ml of the prepared chloroauric acid solution, the content of chloroauric acid is 20g / L, and the content of chloroauric acid is 37 Mass% concentr...

Embodiment 3

[0066] With embodiment 1, different is that composite carrier TiO 2 TiO in / AC 2 The mass content is 15%, the catalyst PdTiO 2 The mass content of Pd in / AC is 0.916%.

[0067] 4) Photocatalytic reduction of loaded Au: take the PdTiO prepared in step 3) 2 / AC Catalyst TiO 2 / AC composite carrier material 5.316g, stirred and dispersed in 300ml ultrapure water, added 10ml of methanol, stirred in the dark for 10min, then added 1.21ml of prepared chloroauric acid solution, the content of chloroauric acid was 20g / L, with 37% Adjust the pH to 3-5 with concentrated hydrochloric acid, stir rapidly in the dark for 1h, then place under 15w ultraviolet light for 5h, filter and wash until the filtrate is neutral, and dry at 90°C for 12h to obtain Au-PdTiO 2 / AC catalyst, the mass fraction of palladium is 0.916%, and the mass fraction of Au is 0.5%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com