Palladium carbon catalyst as well as preparation method and application thereof

A palladium-carbon catalyst and a catalyst technology are applied in the preparation of carbon-based compounds, chemical instruments and methods, preparation of organic compounds, etc., to achieve the effects of good stability, easy particle size, and omitting operation techniques

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

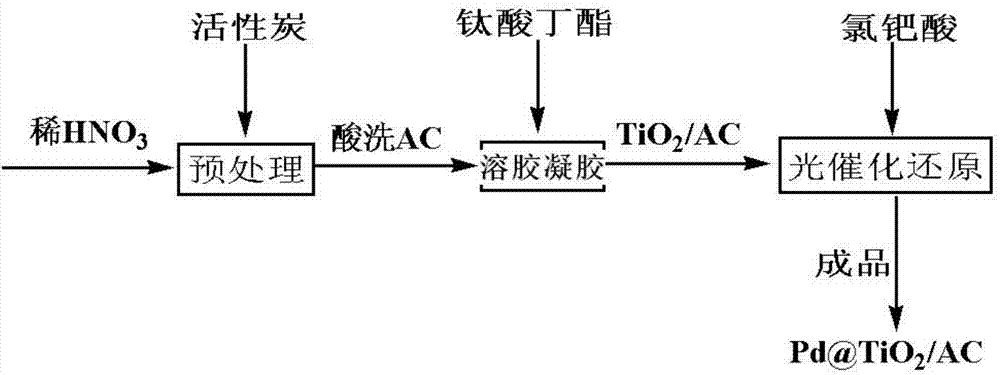

Method used

Image

Examples

Embodiment 1

[0065] 1) Activated carbon pretreatment: put the coconut shell activated carbon that has been washed and boiled 2 to 3 times in a nitric acid solution with a mass fraction of 10.94%, heat and reflux in a water bath at ~60°C for 4 hours, filter with deionized water, and wash to pH It is neutral, and dried at 110°C for 12 hours to obtain oxidized modified activated carbon;

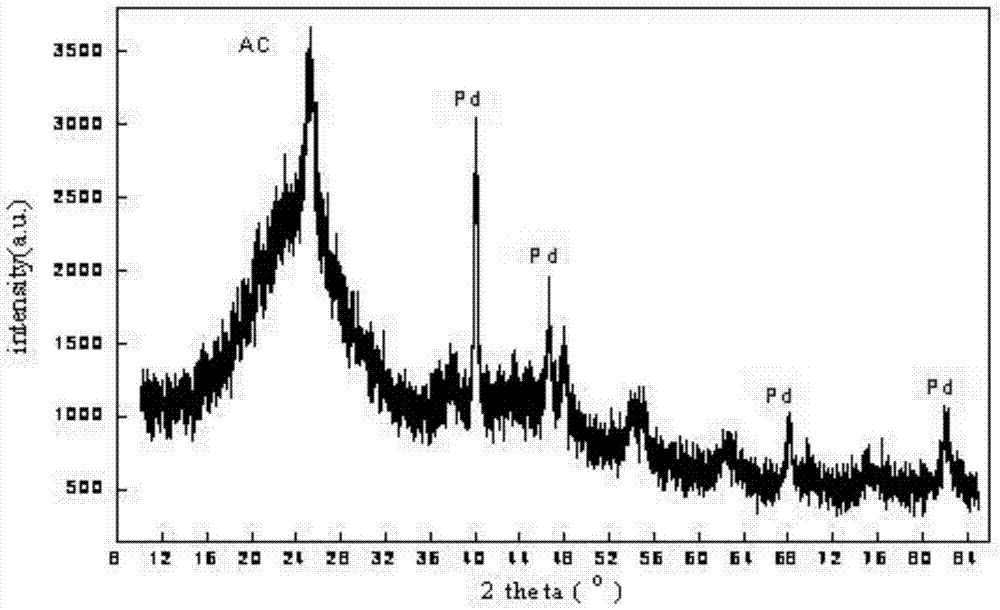

[0066] 2) TiO loaded by sol-gel method 2 : Configure solution A and solution B, under the condition of magnetic stirring, slowly add B to solution A drop by drop to form mixed solution C sol, disperse 12.03g of modified activated carbon obtained in step 1) into solution C, add concentrated HNO 3(66-68% by mass) to adjust the pH to 3, stir for 5-10 minutes, and then ultrasonically oscillate for 10 minutes to make the sol enter the AC channel, stop stirring and let stand to form a gel, dry at 80°C for 12h, and calcinate at 500°C for 2h to obtain TiO 2 Composite carrier material TiO with a loading of 9.95% 2...

Embodiment 2

[0070] TiO by sol-gel method 2 Loaded on the modified activated carbon to obtain the composite carrier TiO 2 / AC. Then use the method of photocatalytic reduction to load metal palladium onto the composite carrier TiO 2 / AC, after subsequent filtration, washing, and drying processes, PdTiO 2 / AC.

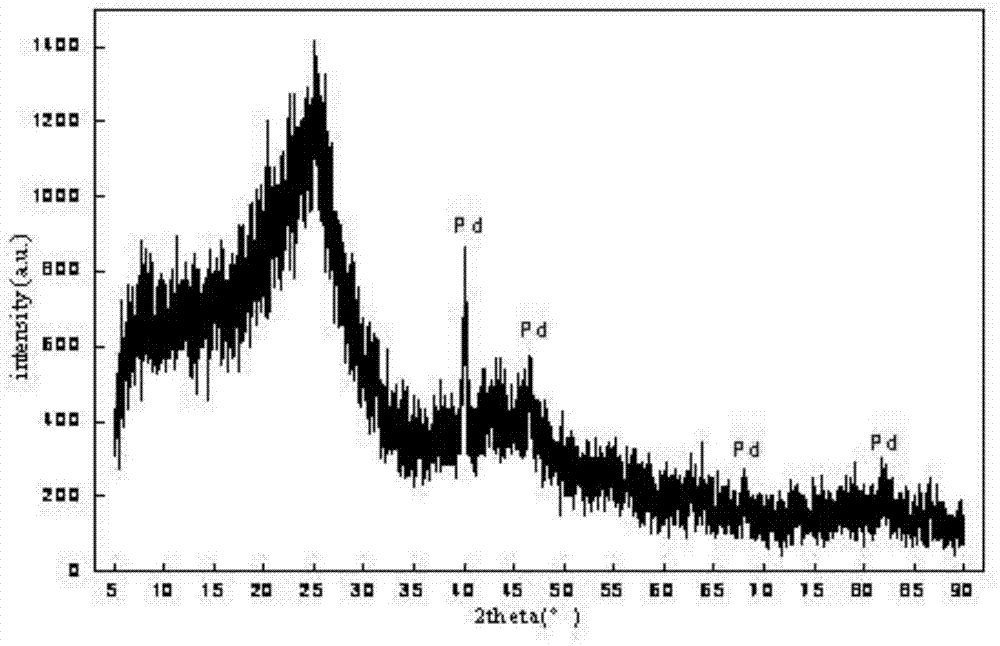

[0071] The specific implementation process is the same as in Example 1, except that HNO 3 The concentration is 11.13%, the composite carrier TiO 2 TiO in / AC 2 The mass content is 9.89%, the catalyst PdTiO 2 The mass content of palladium in / AC is 0.5%.

[0072] The XRD figure of the catalyst that present embodiment obtains is as follows figure 2 said, by figure 2 It can be seen that the single crystal peak of Pa is very obvious, and it can be seen that the catalyst is loaded with single crystal Pa crystal particles.

Embodiment 3

[0074] With embodiment 1, different is that composite carrier TiO 2 TiO in / AC 2 The mass content is 15%, the catalyst PdTiO 2 The Pd content in / AC was 0.5% by mass.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com