Method for preparing olefin compound based on catalyst obtained by compounding carbon tubes and transition metals

A technology of transition metals and compounds, which is applied in the field of preparing olefin compounds based on carbon tubes and transition metal composite catalysts, can solve the problems of unfriendly environment, complex catalyst preparation process, high cost, etc., achieve improved stability, mild reaction conditions, The effect of super stable performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

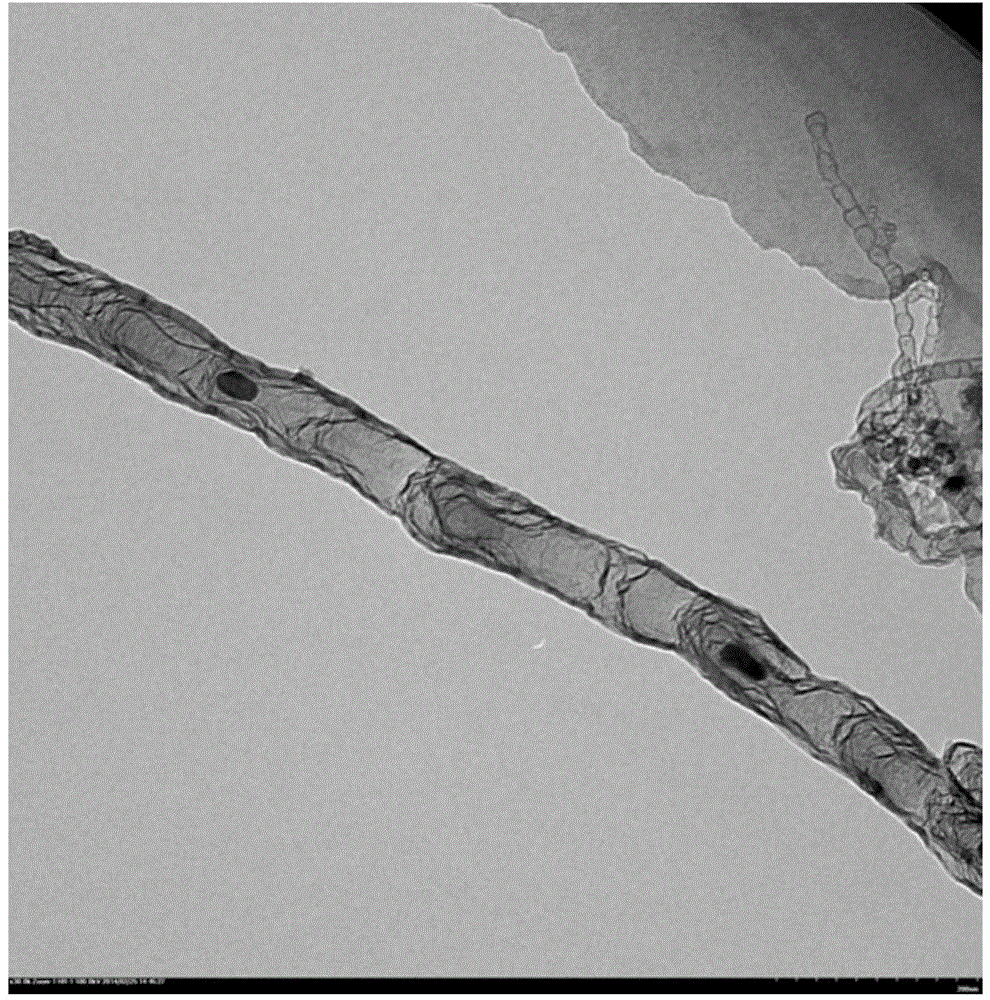

[0056] Physically mix 1g of glucosamine hydrochloride, 20g of melamine and 0.7g of nickel nitrate, and place the evenly mixed solid powder in an inert atmosphere in a crucible for calcination. Calcining at 1200°C for 0.5-1.5h, and cooling to room temperature in an inert atmosphere after the calcination procedure is finished, to obtain a composite catalyst of 20wt%-25wt% nickel / nickel oxide and 75wt%-80wt% carbon tubes. Transmission electron microscope picture as figure 1 shown.

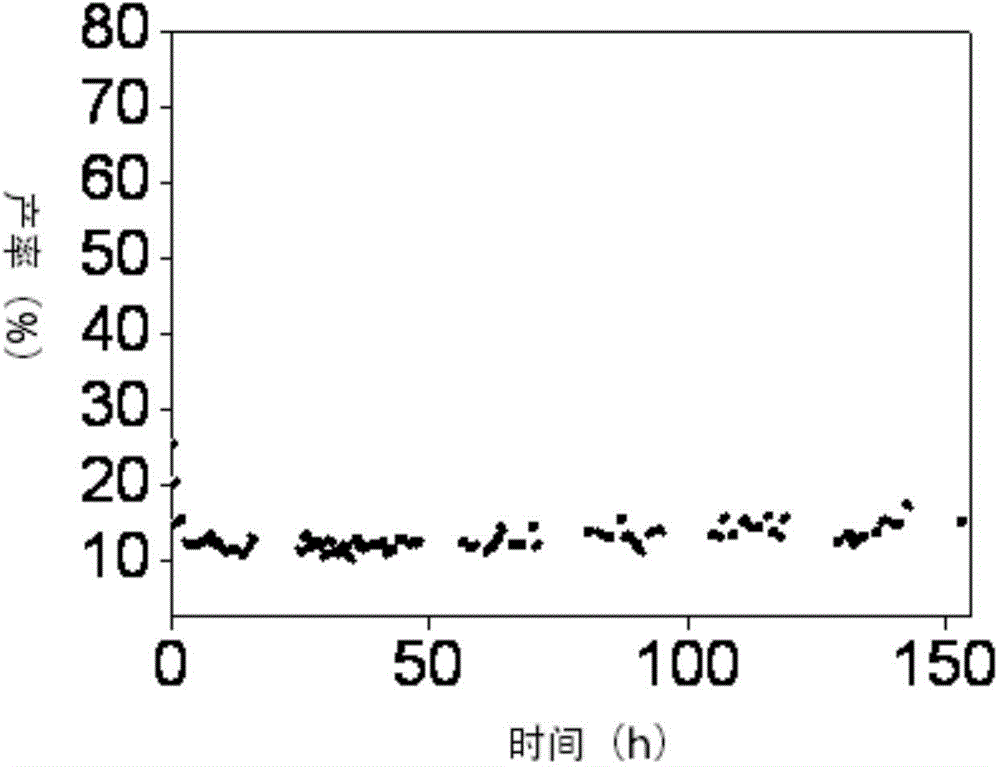

[0057] The obtained 0.08g catalyst is mixed with 6g quartz sand and packed into a quartz tube reactor with an inner diameter of 5mm. The volume fraction of ethylbenzene in argon is 5%, and the mass space velocity of ethylbenzene is 1.0h -1 , the flow rate is 10mL / min, the reaction temperature is 450°C, and the pressure is normal pressure. After the reaction is stable, it is detected by gas chromatography equipped with a capillary column and a hydrogen flame detector. At the reaction temperature, the...

Embodiment 2

[0059] Physically mix 1g of glucosamine hydrochloride, 20g of melamine and 0.7g of nickel nitrate, and place the evenly mixed solid powder in an inert atmosphere in a crucible for calcination. Calcining at 1200°C for 0.5-1.5h, and cooling to room temperature in an inert atmosphere after the calcination procedure is over, to obtain a composite catalyst of 20wt%-25wt% nickel / nickel oxide and 75wt%-80wt% carbon tubes.

[0060] The obtained 0.08g catalyst is mixed with 6g quartz sand and packed into a quartz tube reactor with an inner diameter of 5mm. The volume fraction of ethylbenzene in argon is 1.0%, and the mass space velocity of ethylbenzene is 1.2h -1 , the flow rate is 10mL / min, the reaction temperature is 500°C, and the pressure is normal pressure. After the reaction is stable, it is detected by gas chromatography equipped with a capillary column and a hydrogen flame detector. At the reaction temperature, the conversion rate of ethylbenzene is 10%, the selectivity of styr...

Embodiment 3

[0062] Physically mix 1g of glucosamine hydrochloride, 20g of melamine and 0.7g of nickel nitrate, and place the uniformly mixed solid powder in an inert atmosphere in a crucible for calcination. After calcination for 1 hour, after the calcination procedure is completed, cool down to room temperature in an inert atmosphere to obtain a composite catalyst of 25wt% nickel / nickel oxide and 75wt% carbon tubes.

[0063] The obtained 0.08g catalyst is mixed with 6g quartz sand and packed into a quartz tube reactor with an inner diameter of 5mm. The volume fraction of ethylbenzene in argon is 1.0%-5.0%, and the flow rate is 10mL / min. The mass space velocity is 1.8h -1 , the reaction temperature is 550°C, and the pressure is normal pressure. After the reaction is stable, it is detected by a gas chromatograph equipped with a capillary column and a hydrogen flame detector. At this reaction temperature, the conversion rate of ethylbenzene is 10-20%, the selectivity of styrene is 97-98%, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com